Comparative In Vitro Analysis of Composite Resins Used in Clear Aligner Attachments

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Thermal Analysis and Filler Content Determination

2.3. Mechanical Testing

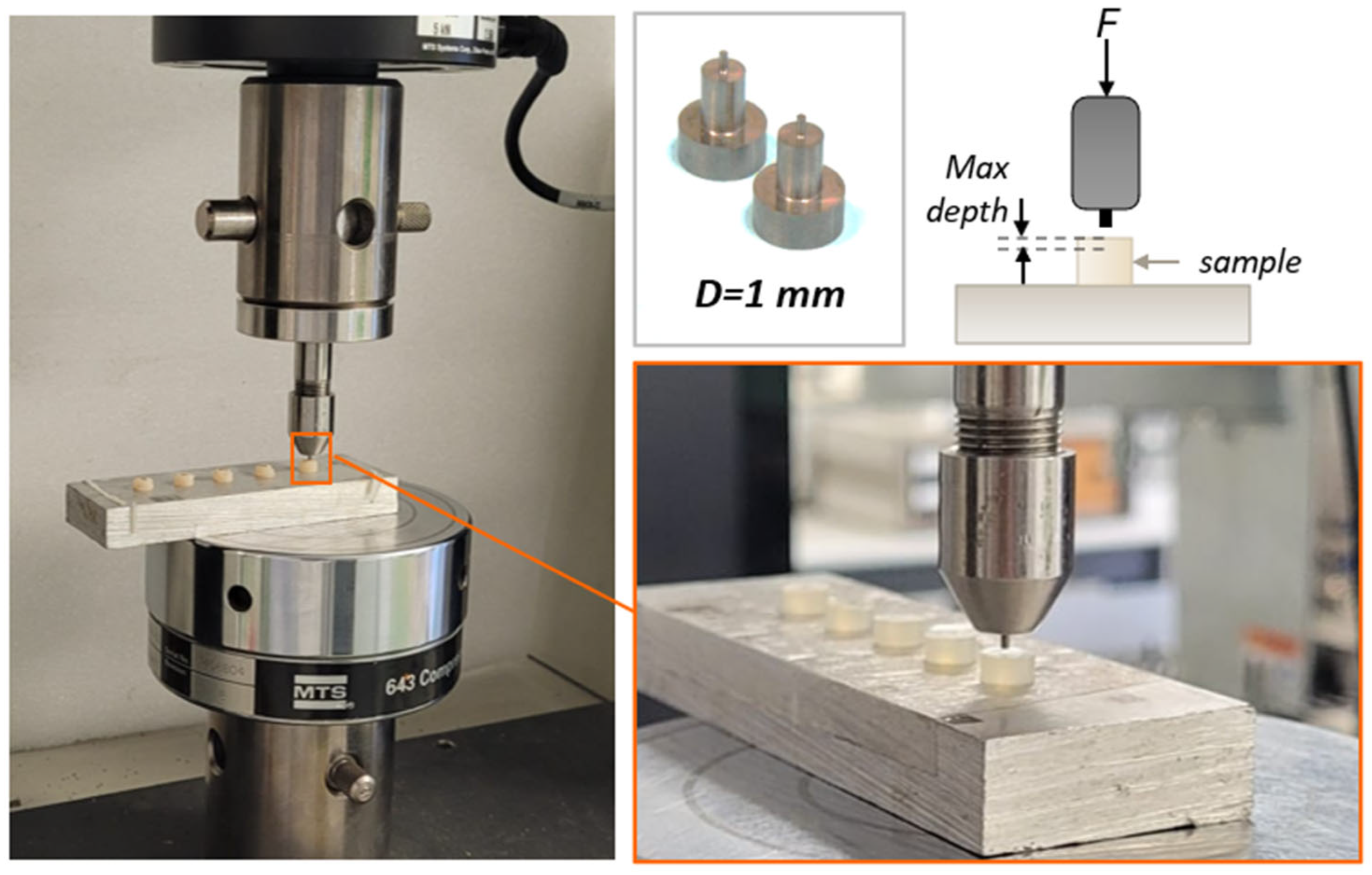

2.3.1. Indentation Testing

2.3.2. Compression Stress Relaxation

2.4. Tribological Testing and Wear Assessment

3. Results

3.1. Thermal Analysis and Combustion Testing

3.2. Mechanical Testing Results

3.2.1. Flat Indentation

3.2.2. Stress Relaxation

3.3. Tribological Results

4. Discussion

4.1. Clinical Perspective

4.2. Strength, Limitations and Future Directions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CAT | Clear Aligner Treatment |

| AC | Aligner Connect |

| CF | Connect Flow |

| DSC | Differential Scanning Calorimetry |

| 3D | Three-Dimensional |

| Tg | Glass Transition Temperature |

| C | Celsius |

| N | Newton |

| MPa | MegaPascal |

| mm | Millimeter |

| µm | Micrometer |

| Ra | Average Roughness |

| Rt | Total peak to valley height |

| PLA | Polyactic Acid |

| LED | Light-Emitting Diode |

| mW | milliWatt |

| cm | Centimeter |

| mg | Milligram |

| min | Minutes |

| kN | kiloNewton |

References

- Gazzani, F.; Bellisario, D.; Quadrini, F.; Danesi, C.; Alberti, A.; Cozza, P.; Pavoni, C. Light-curing process for clear aligners’ attachment reproduction: Comparison between two nanocomposites cured by the auxiliary of a new tool. BMC Oral Health 2022, 22, 376. [Google Scholar] [CrossRef] [PubMed]

- Gazzani, F.; Bellisario, D.; Quadrini, F.; Parrinello, F.; Pavoni, C.; Cozza, P.; Lione, R. Comparison between different composite resins used for clear aligner attachments: An in-vitro. Front. Mater. 2022, 8, 789143. [Google Scholar] [CrossRef]

- Morton, J.; Derakhshan, M.; Kaza, S.; Li, C. Design of the Invisalign System Performance. Semin. Orthod. 2017, 23, 3–11. [Google Scholar] [CrossRef]

- D’Antò, V.; Muraglie, S.; Castellano, B.; Candida, E.; Sfondrini, M.F.; Scribante, A.; Grippaudo, C. Influence of Dental Composite Viscosity in Attachment. Reproduction: An Experimental In Vitro Study. Materials 2019, 12, 4001. [Google Scholar] [CrossRef] [PubMed]

- Mantovani, E.; Castroflorio, E.; Rossini, G.; Garino, F.; Cugliari, G.; Deregibus, A.; Castroflorio, T. Scanning electron microscopy analysis of aligner fitting on anchorage attachments. J. Orofac. Orthop. 2019, 80, 79–87. [Google Scholar] [CrossRef] [PubMed]

- Weckmann, J.; Scharf, S.; Graf, I.; Schwarze j Keilig, L.; Bourauel, C.; Braumann, B. Influence of attachment bonding protocol on precision of the attachment in aligner treatments. J. Orofac. Orthop. 2020, 81, 30–40. [Google Scholar] [CrossRef] [PubMed]

- Kravitz, N.D.; Kusnoto, B.; Agran, B.; Viana, G. Influence of attachments and interproximal reduction on the accuracy of canine rotation with invisalign. A prospective clinical study. Angle Orthod. 2008, 78, 682–687. [Google Scholar] [CrossRef] [PubMed]

- Dasy, H.; Dasy, A.; Asatrian, G.; Rózsa, N.; Lee, H.F.; Kwak, J.H. Effects of variable attachment shapes and aligner material on aligner retention. Angle Orthod. 2015, 85, 934–940. [Google Scholar] [CrossRef] [PubMed]

- Kusai Baroudi, J.C.R. Flowable resin composites: A systematic review and clinical considerations. J. Clin. Diagn. Res. 2015, 9, ZE18–ZE24. [Google Scholar] [CrossRef] [PubMed]

- Barreda, G.J.; Dzierewianko, E.A.; Munoz, K.A.; Piccoli, G.I. Surface wear of resin composites used for Invisalign® attachments. Acta Odontol. Latinoam. 2017, 30, 90–95. [Google Scholar] [PubMed]

- Bowman Feinberg, K.; Souccar, N.M.; Kau, C.H.; Oster, R.A.; Lawson, N.C. Translucency, Stain Resistance, and Hardness of composites used for Invisalign Attachments. JCO 2016, 3, 170–176. [Google Scholar]

- Aminoroaya, A.; Neisiany, R.E.; Khorasani, S.N.; Panahi, P.; Das, O.; Madry, H.; Cucchiarini, M.; Ramakrishna, S. A review of dental composites: Challenges, chemistry aspects, filler influences, and future insights. Compos. B Eng. 2021, 216, 108852. [Google Scholar] [CrossRef]

- Ferracane, J.L. Resin Composite-State of the Art. Dent. Mater. 2011, 27, 29–38. [Google Scholar] [CrossRef] [PubMed]

- Bruno, G.; Gracco, A.; Barone, M.; Mutinelli, S.; De Stefani, A. Invisalign® vs. SparkTM template: Which is the most effective in the attachment bonding procedure? A randomized controlled trial. Appl. Sci. 2021, 11, 6716. [Google Scholar] [CrossRef]

- Simon, M.; Keilig, L.; Schwarze, J.; Jung, B.A.; Bourauel, C. Treatment outcome and efficacy of an aligner technique—Regarding incisor torque, premolar derotation and molar distalization. BMC Oral Health 2014, 14, 68. [Google Scholar] [CrossRef] [PubMed]

- Clelland, N.L.; Pagnotto, M.P.; Kerby, R.E.; Seghi, R.R. Relative wear of flowable and highly filled composite. J. Prosthet. Dent. 2004, 93, 153–157. [Google Scholar] [CrossRef] [PubMed]

- Ocak, I.; Gorucu-Coskuner, H.; Aksu, M. Wear resistance of orthodontic attachments: A comparative analysis of different composite resins in clear aligner therapy. Clin. Oral Investig. 2025, 29, 242. [Google Scholar] [CrossRef] [PubMed]

- Bansal, G.; Gautam, R.K.; Misra, J.P.; Kishore, C.; Mishra, A.; Verma, A. Evaluation of mechanical and thermal properties of thermosetting polymer composites. In Dynamic Mechanical and Creep-Recovery Behavior of Polymer-Based Composites; Elsevier: Amsterdam, The Netherlands, 2024; pp. 53–68. [Google Scholar]

- Li, Q.; Yang, K. Surface wear of attachments in patients during clear aligner therapy: A prospective clinical study. Prog. Orthod. 2024, 25, 7. [Google Scholar] [CrossRef] [PubMed]

- Roatkanjanaporn, N.; Chavanavesh, J.; Teekavanich, C. Wear volumes of flowable and sculptable resin composite attachments and their correlation with retentive force of clear aligners: A laboratory study. BMC Oral Health 2025, 25, 483. [Google Scholar] [CrossRef] [PubMed]

- Shaalan, O.O.; Abou-Auf, E.; El Zoghby, A.F. Clinical evaluation of flowable resin composite versus conventional resin composite in carious and noncarious lesions: Systematic review and meta-analysis. J. Conserv. Dent. 2017, 20, 380–385. [Google Scholar] [CrossRef] [PubMed]

| Sample | Height (mm) | Diameter (mm) | Density (g/cm3) |

|---|---|---|---|

| AC | 2.7 ± 0.08 | 6.5 ± 0.15 | 1.50 ± 0.02 |

| CF | 3.0 ± 0.04 | 6.2 ± 0.05 | 1.30 ± 0.03 |

| Sample | Max Load (N) | Elastic Modulus (MPa) | Residual Displacement (mm) |

|---|---|---|---|

| AC | 585.9 ± 22.36 | 231.5 ± 9.1 | 0.09 ± 0.012 |

| CF | 290.2 ± 5.52 | 156 ± 10.5 | 0.11 ± 0.007 |

| Sample | Wear Surface (mm2) | Wear Volume (mm3) | Max Depth (mm) |

|---|---|---|---|

| AC | 1.82 ± 0.075 | 0.012 ± 0.0055 | 36.88 ± 3.642 |

| CF | 1.70 ± 0.159 | 0.0070 ± 0.0083 | 17.91 ± 3.387 |

| Sample | Average Roughness (Ra, µm) | Total Peak to Valley Height (Rt, µm) | ||

|---|---|---|---|---|

| Unworn Zone | Worn Zone | Unworn Zone | Worn Zone | |

| AC | 0.577 ± 0.0352 | 0.247 ± 0.03649 | 4.369 ± 0.5206 | 2.537 ± 0.6496 |

| CF | 0.337 ± 0.0703 | 0.236 ± 0.0189 | 2.862 ± 0.5488 | 2.224 ± 0.7815 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gazzani, F.; Bellisario, D.; Pavoni, C.; Santo, L.; Cozza, P.; Lione, R. Comparative In Vitro Analysis of Composite Resins Used in Clear Aligner Attachments. Appl. Sci. 2025, 15, 8698. https://doi.org/10.3390/app15158698

Gazzani F, Bellisario D, Pavoni C, Santo L, Cozza P, Lione R. Comparative In Vitro Analysis of Composite Resins Used in Clear Aligner Attachments. Applied Sciences. 2025; 15(15):8698. https://doi.org/10.3390/app15158698

Chicago/Turabian StyleGazzani, Francesca, Denise Bellisario, Chiara Pavoni, Loredana Santo, Paola Cozza, and Roberta Lione. 2025. "Comparative In Vitro Analysis of Composite Resins Used in Clear Aligner Attachments" Applied Sciences 15, no. 15: 8698. https://doi.org/10.3390/app15158698

APA StyleGazzani, F., Bellisario, D., Pavoni, C., Santo, L., Cozza, P., & Lione, R. (2025). Comparative In Vitro Analysis of Composite Resins Used in Clear Aligner Attachments. Applied Sciences, 15(15), 8698. https://doi.org/10.3390/app15158698