Scalable Chemical Vapor Deposition of Silicon Carbide Thin Films for Photonic Integrated Circuit Applications

Abstract

1. Introduction

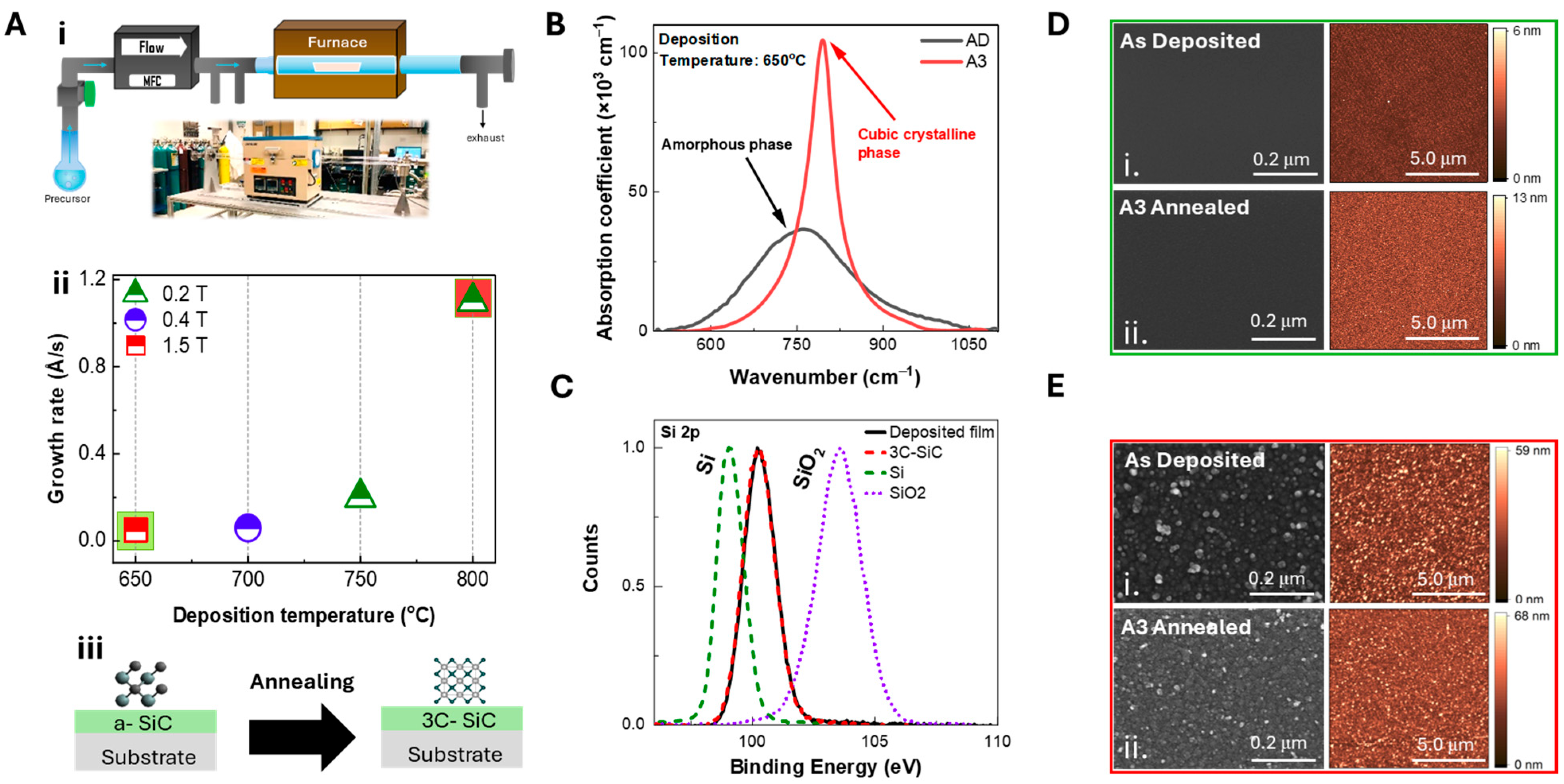

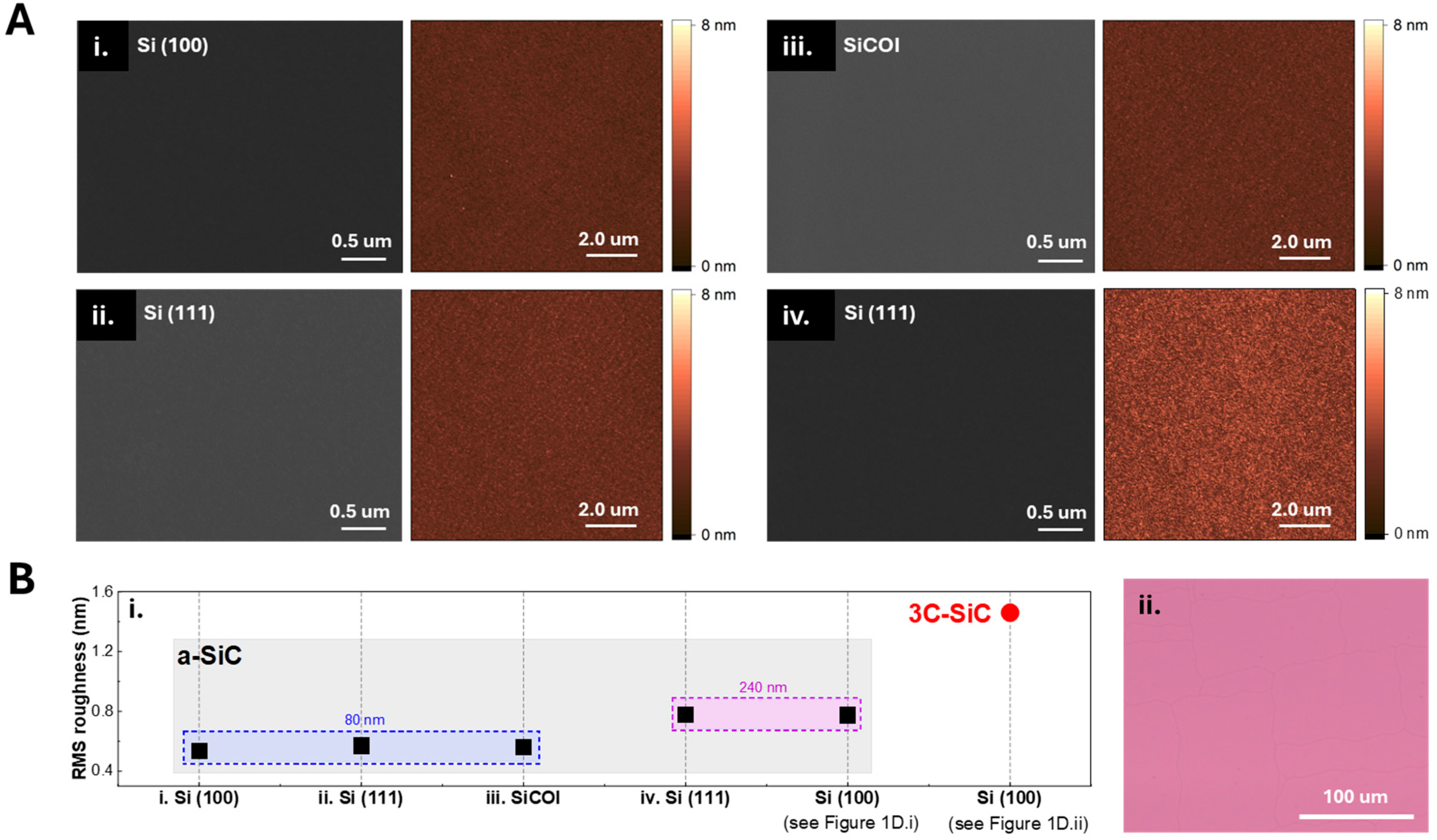

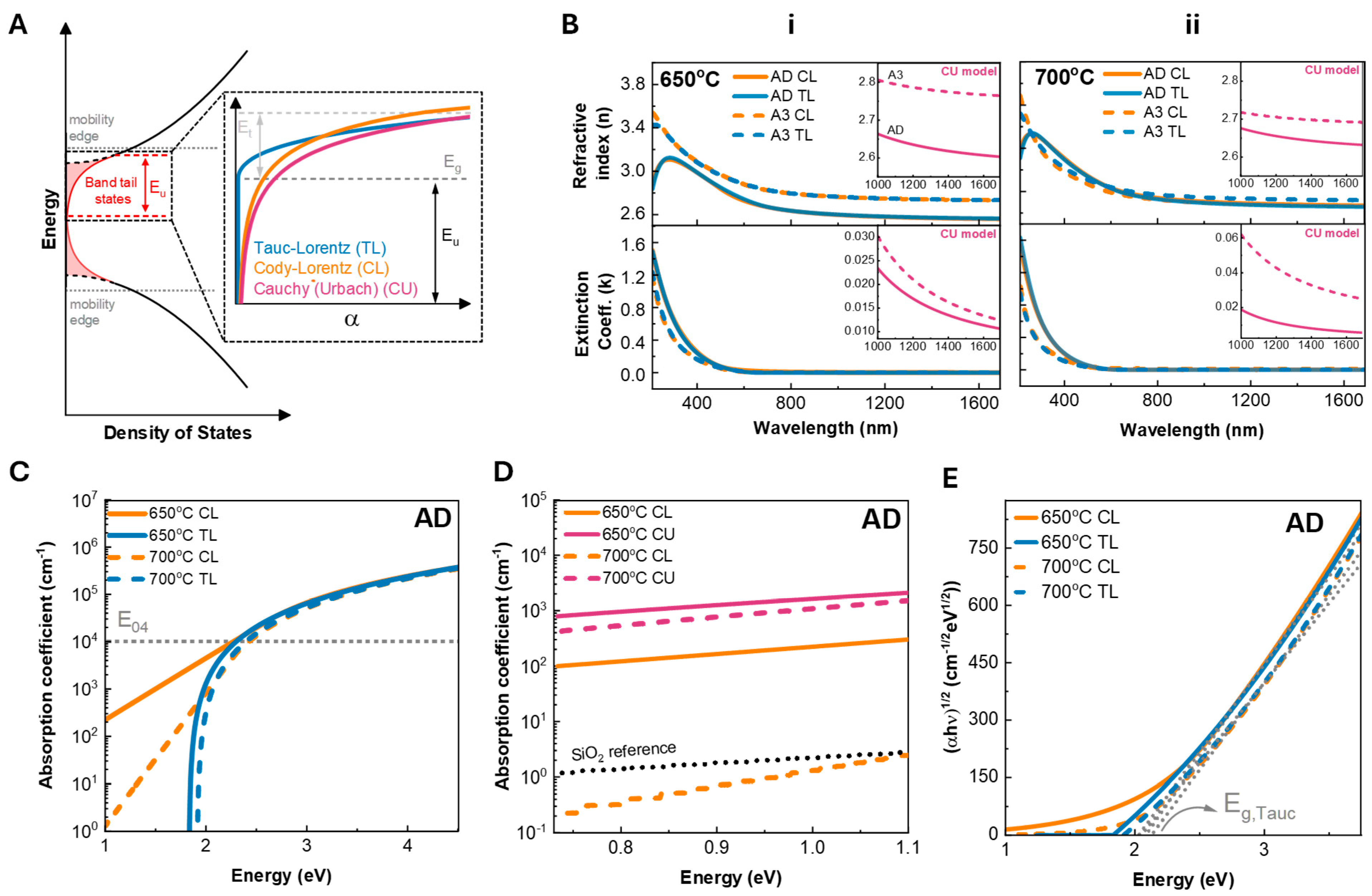

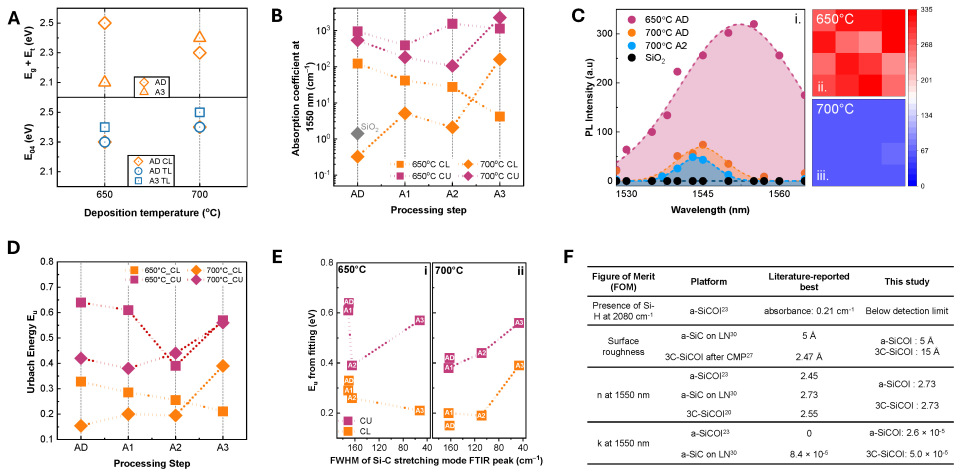

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yi, A.; Wang, C.; Zhou, L.; Zhu, Y.; Zhang, S.; You, T.; Ou, X. Silicon carbide for integrated photonics. Appl. Phys. Rev. 2022, 9, 031302. [Google Scholar] [CrossRef]

- Castelletto, S.; Peruzzo, A.; Bonato, C.; Johnson, B.C.; Radulaski, M.; Ou, H.; Wrachtrup, J. Silicon carbide photonics bridging quantum technology. ACS Photonics 2022, 9, 1434–1457. [Google Scholar] [CrossRef]

- Ou, H.; Shi, X.; Lu, Y.; Kollmuss, M.; Steiner, J.; Tabouret, V.; Chaussende, D. Novel photonic applications of silicon carbide. Materials 2023, 16, 1014. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, Y.; Sasaki, M.; Takesue, H. Quantum information science and technology in Japan. Quantum Sci. Technol. 2019, 4, 020502. [Google Scholar] [CrossRef]

- De Leonardis, F.; Soref, R.A.; Passaro, V.M. Dispersion of nonresonant third-order nonlinearities in silicon carbide. Sci. Rep. 2017, 7, 40924. [Google Scholar] [CrossRef]

- Tabassum, N.; Kotha, M.; Kaushik, V.; Ford, B.; Dey, S.; Crawford, E.; Gallis, S. On-demand CMOS-compatible fabrication of ultrathin self-aligned SiC nanowire arrays. Nanomaterials 2018, 8, 906. [Google Scholar] [CrossRef]

- Tabassum, N.; Nikas, V.; Kaloyeros, A.E.; Kaushik, V.; Crawford, E.; Huang, M.; Gallis, S. Engineered telecom emission and controlled positioning of Er3+ enabled by SiC nanophotonic structures. Nanophotonics 2020, 9, 1425–1437. [Google Scholar] [CrossRef]

- Kaloyeros, A.E.; Gallis, S. Polarization-dependent photoluminescence properties of fab-compatible nanowire-based nanophotonic structures. Appl. Phys. Lett. 2022, 120, 231101. [Google Scholar] [CrossRef]

- Lohrmann, A.; Johnson, B.C.; McCallum, J.C.; Castelletto, S. A review on single photon sources in silicon carbide. Rep. Prog. Phys. 2017, 80, 034502. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Y.; Wang, Z.; Rasmita, A.; Yang, J.; Li, X.; Gao, W. Bright room temperature single photon source at telecom range in cubic silicon carbide. Nat. Commun. 2018, 9, 4106. [Google Scholar] [CrossRef]

- Tarasenko, S.A.; Poshakinskiy, A.V.; Simin, D.; Soltamov, V.A.; Mokhov, E.N.; Baranov, P.G.; Astakhov, G.V. Spin and optical properties of silicon vacancies in silicon carbide—A review. Phys. Status Solidi B 2018, 255, 1700258. [Google Scholar] [CrossRef]

- Castelletto, S.; Lew, C.T.; Lin, W.X.; Xu, J.S. Quantum systems in silicon carbide for sensing applications. Rep. Prog. Phys. 2023, 87, 014501. [Google Scholar] [CrossRef]

- Xu, J.S.; Li, C.F.; Guo, G.C. Silicon carbide based quantum networking. Fundam. Res. 2021, 1, 220–222. [Google Scholar] [CrossRef]

- Mahmoodi, M.; Ghazanfari, L. Fundamentals of Biomedical Applications of Biomorphic SiC; INTECH Open Access Publisher: Rijeka, Croatia, 2011. [Google Scholar]

- Gabriel, G.; Erill, I.; Caro, J.; Gómez, R.; Riera, D.; Villa, R.; Godignon, P. Manufacturing and full characterization of silicon carbide-based multi-sensor micro-probes for biomedical applications. Microelectron. J. 2007, 38, 406–415. [Google Scholar] [CrossRef]

- Myers, D.R. Silicon carbide resonant tuning fork for microsensing applications in high-temperature and high G-shock environments. J. Micro/Nanolithogr. MEMS MOEMS 2009, 8, 021116. [Google Scholar] [CrossRef]

- Lu, X.; Lee, J.Y.; Feng, P.X.L.; Lin, Q. High Q silicon carbide microdisk resonator. Appl. Phys. Lett. 2014, 104, 181103. [Google Scholar] [CrossRef]

- Zhao, L.X.; Yang, L.; Wu, H.W. High quality 4H-SiC homo-epitaxial wafer using the optimal C/Si ratio. J. Cryst. Growth 2020, 530, 125302. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lu, X.; Lin, Q. High-Q silicon carbide photonic-crystal cavities. Appl. Phys. Lett. 2015, 106, 041106. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Q.; Wang, J.; Poon, A.W. An integrated 3C-silicon carbide-on-insulator photonic platform for nonlinear and quantum light sources. Commun. Phys. 2024, 7, 125. [Google Scholar] [CrossRef]

- Powell, K.; Li, L.; Shams-Ansari, A.; Wang, J.; Meng, D.; Sinclair, N.; Deng, J.; Lončar, M.; Yi, X. Integrated silicon carbide electro-optic modulator. Nat. Commun. 2022, 13, 1851. [Google Scholar] [CrossRef]

- Lukin, D.M.; Dory, C.; Guidry, M.A.; Yang, K.Y.; Mishra, S.D.; Trivedi, R.; Vučković, J. 4H-silicon-carbide-on-insulator for integrated quantum and nonlinear photonics. Nat. Photonics 2020, 14, 330–334. [Google Scholar] [CrossRef]

- Xing, P.; Ma, D.; Ooi, K.J.; Choi, J.W.; Agarwal, A.M.; Tan, D. CMOS-compatible PECVD silicon carbide platform for linear and nonlinear optics. ACS Photonics 2019, 6, 1162–1167. [Google Scholar] [CrossRef]

- Lopez-Rodriguez, B.; Van Der Kolk, R.; Aggarwal, S.; Sharma, N.; Li, Z.; Van Der Plaats, D.; Zadeh, I.E. High-quality amorphous silicon carbide for hybrid photonic integration deposited at a low temperature. ACS Photonics 2023, 10, 3748–3754. [Google Scholar] [CrossRef] [PubMed]

- Pizzagalli, L.; Cicero, G.; Catellani, A. Theoretical investigations of a highly mismatched interface: SiC/Si (001). Phys. Rev. B 2003, 68, 195302. [Google Scholar] [CrossRef]

- Chen, C.; Chen, Y.; Fang, Z.; Ge, R.; Wu, J.; Chen, X. Hybrid material integration for active photonic applications. APL Photonics 2024, 9, 030901. [Google Scholar] [CrossRef]

- Fan, T.; Wu, X.; Eftekhar, A.A.; Bosi, M.; Moradinejad, H.; Woods, E.V.; Adibi, A. High-quality integrated microdisk resonators in the visible-to-near-infrared wavelength range on a 3C-silicon carbide-on-insulator platform. Opt. Lett. 2020, 45, 153–156. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.; Yi, A.; Fang, Z.; Zhou, L.; Wang, Z.; Ou, X. Soliton formation and spectral translation into visible on CMOS-compatible 4H-silicon-carbide-on-insulator platform. Light Sci. Appl. 2022, 11, 341. [Google Scholar] [CrossRef]

- DeVault, C.T.; Deckoff-Jones, S.; Liu, Y.; Hammock, I.N.; Sullivan, S.E.; Dibos, A.; High, A.A. Silicon-on-silicon carbide platform for integrated photonics. Adv. Opt. Mater. 2024, 12, 2401101. [Google Scholar] [CrossRef]

- Li, Z.; Sharma, N.; Lopez-Rodriguez, B.; van der Kolk, R.; Scholte, T.; Voncken, H.; Zadeh, I.E. Heterogeneous integration of amorphous silicon carbide on thin film lithium niobate. APL Photonics 2025, 10, 010101. [Google Scholar] [CrossRef]

- Shekhar, S.; Bogaerts, W.; Chrostowski, L.; Bowers, J.E.; Hochberg, M.; Soref, R.; Shastri, B.J. Road mapping the next generation of silicon photonics. Nat. Commun. 2024, 15, 751. [Google Scholar] [CrossRef]

- Jin, W.; Yang, Q.F.; Chang, L.; Shen, B.; Wang, H.; Leal, M.A.; Wu, L.; Gao, M.; Feshali, A.; Paniccia, M.; et al. Hertz-Linewidth Semiconductor Lasers Using CMOS-Ready Ultra-High-Q Microresonators. Nat. Photonics 2021, 15, 346–353. [Google Scholar] [CrossRef]

- Pfeiffer, M.H.; Liu, J.; Raja, A.S.; Morais, T.; Ghadiani, B.; Kippenberg, T.J. Ultra-Smooth Silicon Nitride Waveguides Based on the Damascene Reflow Process: Fabrication and Loss Origins. Optica 2018, 5, 884–892. [Google Scholar] [CrossRef]

- Kaloyeros, A.; Dutta, S.; Gallis, S. Engineering and polarization properties of erbium-implanted lithium niobate films for integrated quantum applications. APL Mater. 2024, 12, 111101. [Google Scholar] [CrossRef]

- Kaloyeros, A.E.; Goff, J.; Arkles, B. Defect- and H-free stoichiometric silicon carbide by thermal CVD from the single source precursor trisilacyclohexane. Electron. Mater. 2022, 3, 27–40. [Google Scholar] [CrossRef]

- Bhaviripudi, S.; Jia, X.; Dresselhaus, M.S.; Kong, J. Role of kinetic factors in chemical vapor deposition synthesis of uniform large area graphene using copper catalyst. Nano Lett. 2010, 10, 4128–4133. [Google Scholar] [CrossRef]

- Chen, W.; Xie, X.N.; Xu, H.; Wee, A.T.S.; Loh, K.P. Atomic scale oxidation of silicon nanoclusters on silicon carbide surfaces. J. Phys. Chem. B 2003, 107, 11597–11603. [Google Scholar] [CrossRef]

- Gallis, S.; Nikas, V.; Huang, M.; Eisenbraun, E.; Kaloyeros, A.E. Comparative study of the effects of thermal treatment on the optical properties of hydrogenated amorphous silicon-oxycarbide. J. Appl. Phys. 2007, 102, 024302. [Google Scholar] [CrossRef]

- Foti, G. Silicon carbide: From amorphous to crystalline material. Appl. Surf. Sci. 2001, 184, 20–26. [Google Scholar] [CrossRef]

- Ishimaru, M.; Bae, I.T.; Hirotsu, Y.; Matsumura, S.; Sickafus, K.E. Structural relaxation of amorphous silicon carbide. Phys. Rev. Lett. 2002, 89, 055502. [Google Scholar] [CrossRef]

- Calcagno, L.; Musumeci, P.; Roccaforte, F.; Bongiorno, C.; Foti, G. Crystallisation mechanism of amorphous silicon carbide. Appl. Surf. Sci. 2001, 184, 123–127. [Google Scholar] [CrossRef]

- Tolstoy, V.P.; Chernyshova, I.; Skryshevsky, V.A. Handbook of Infrared Spectroscopy of Ultrathin Films; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Abdurazik, D. Fourier Transform Infrared Spectroscopy (FTIR) Analysis of Silicon Carbide Nanowires. Master’s Thesis, Ankara Üniversitesi, Ankara, Turkey, 2016. [Google Scholar]

- Huseynov, E.M. Investigation of the agglomeration and amorphous transformation effects of neutron irradiation on the nanocrystalline silicon carbide (3C-SiC) using TEM and SEM methods. Physical B 2017, 510, 99–103. [Google Scholar] [CrossRef]

- Di, M.; Bersch, E.; Diebold, A.C.; Consiglio, S.; Clark, R.D.; Leusink, G.J.; Kaack, T. Comparison of methods to determine bandgaps of ultrathin HfO2 films using spectroscopic ellipsometry. J. Vac. Sci. Technol. A 2011, 29, 041001. [Google Scholar] [CrossRef]

- Tauc, J.; Grigorovici, R.; Vancu, A. Optical properties and electronic structure of amorphous germanium. Phys. Status Solidi B 1966, 15, 627–637. [Google Scholar] [CrossRef]

- Diebold, A.C.; Antonelli, A.; Keller, N. Perspective: Optical measurement of feature dimensions and shapes by scatterometry. APL Mater. 2018, 6, 058201. [Google Scholar] [CrossRef]

- Kalas, B.; Zolnai, Z.; Sáfrán, G.; Serényi, M.; Agocs, E.; Lohner, T.; Petrik, P. Micro-combinatorial sampling of the optical properties of hydrogenated amorphous Si1−xGex for the entire range of compositions towards a database for optoelectronics. Sci. Rep. 2020, 10, 19266. [Google Scholar] [CrossRef]

- Ferlauto, A.S.; Ferreira, G.M.; Pearce, J.M.; Wronski, C.R.; Collins, R.W.; Deng, X.; Ganguly, G. Analytical model for the optical functions of amorphous semiconductors from the near-infrared to ultraviolet: Applications in thin film photovoltaics. J. Appl. Phys. 2002, 92, 2424–2436. [Google Scholar] [CrossRef]

- Liu, H.; Li, S.; Sun, P.; Yang, X.; Liu, D.; Ji, Y.; Cui, Y. Study on characterization method of optical constants of germanium thin films from absorption to transparent region. Mater. Sci. Semicond. Process. 2018, 83, 58–62. [Google Scholar] [CrossRef]

- Pavunny, S.P.; Thomas, R.; Katiyar, R.S. Cauchy-Urbach dielectric function modeling of amorphous high-k LaGdO3 films. ECS Trans. 2012, 45, 219–229. [Google Scholar] [CrossRef]

- Andreoli, F.; Gullans, M.J.; High, A.A.; Browaeys, A.; Chang, D.E. Maximum refractive index of an atomic medium. Phys. Rev. X 2021, 11, 011026. [Google Scholar] [CrossRef]

- Kim, H.K.; Shi, F.G. Refractive index of polycrystalline submicrometer polymer thin films: Thickness dependence. J. Mater. Sci. Mater. Electron. 2001, 12, 361–364. [Google Scholar] [CrossRef]

- Luusua, H.; Gädda, T.; Salunke, J.; Han, Z.; Kekkonen, H.; Rantala, J.; Liu, G. A design approach for ultra-low-k dielectric organosiloxane polymers. In Proceedings of the 2024 IEEE International Interconnect Technology Conference (IITC), San Jose, CA, USA, 3–6 June 2024; pp. 1–3. [Google Scholar]

- Fujiwara, H. Spectroscopic Ellipsometry: Principles and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Pliskin, W.A.; Esch, R.P. Refractive index of SiO2 films grown on silicon. J. Appl. Phys. 1965, 36, 2011–2013. [Google Scholar] [CrossRef]

- Klein, J.; Kampermann, L.; Mockenhaupt, B.; Behrens, M.; Strunk, J.; Bacher, G. Limitations of the Tauc plot method. Adv. Funct. Mater. 2023, 33, 2304523. [Google Scholar] [CrossRef]

- Zanatta, A.R. Revisiting the optical bandgap of semiconductors and the proposal of a unified methodology to its determination. Sci. Rep. 2019, 9, 11225. [Google Scholar] [CrossRef] [PubMed]

- Larruquert, J.I.; Pérez-Marín, A.P.; García-Cortés, S.; Rodríguez-de Marcos, L.; Aznárez, J.A.; Méndez, J.A. Self-consistent optical constants of SiC thin films. J. Opt. Soc. Am. A 2011, 28, 2340–2345. [Google Scholar] [CrossRef]

- Vedula, R.P.; Anderson, N.L.; Strachan, A. Effect of topological disorder on structural, mechanical, and electronic properties of amorphous silicon nitride: An atomistic study. Phys. Rev. B 2012, 85, 205209. [Google Scholar] [CrossRef]

- Nguyen-Tran, T.; Suendo, V.; Roca i Cabarrocas, P. Optical study of disorder and defects in hydrogenated amorphous silicon carbon alloys. Appl. Phys. Lett. 2005, 87, 011903. [Google Scholar] [CrossRef]

- Fanchini, G.; Tagliaferro, A. Disorder and Urbach energy in hydrogenated amorphous carbon: A phenomenological model. Appl. Phys. Lett. 2004, 85, 730–732. [Google Scholar] [CrossRef]

| Deposition Temp.(°C) | Annealing | Model | Tauc’s Optical Gap (eV) | E04(eV) | n @ 1550 nm | k @ 1550 nm | Abs. Coeff.@ 1550 nm (cm−1) |

|---|---|---|---|---|---|---|---|

| 650 | AD | TL | 2.0 | 2.3 | 2.57 | 0 | 0 |

| CL | 2.1 | 2.3 | 2.56 | 1.5 × 10−3 | 121 | ||

| Cauchy | NA | NA | 2.56 | 11.8 × 10−3 | 957 | ||

| 700 | TL | 2.1 | 2.4 | 2.66 | 0 | 0 | |

| CL | 2.1 | 2.4 | 2.67 | 4.0 × 10−6 | 0 | ||

| Cauchy | NA | NA | 2.59 | 6.6 × 10−3 | 539 | ||

| 650 | A1 | TL | 2.1 | 2.4 | 2.65 | 0 | 0 |

| CL | 2.0 | 2.4 | 2.65 | 5.1 × 10−4 | 41 | ||

| Cauchy | NA | NA | 2.65 | 4.8 × 10−3 | 389 | ||

| 700 | TL | 2.0 | 2.3 | 2.76 | 0 | 0 | |

| CL | 2.1 | 2.3 | 2.76 | 6.3 × 10−5 | 5 | ||

| Cauchy | NA | NA | 2.66 | 2.2 × 10−3 | 182 | ||

| 650 | A2 | TL | 2.0 | 2.3 | 2.73 | 0 | 0 |

| CL | 2.0 | 2.3 | 2.73 | 3.4 × 10−4 | 27 | ||

| Cauchy | NA | NA | 2.72 | 19.1 × 10−3 | 1546 | ||

| 700 | TL | 2.0 | 2.3 | 2.73 | 0 | 0 | |

| CL | 2.1 | 2.4 | 2.73 | 2.6 × 10−5 | 2 | ||

| Cauchy | NA | NA | 2.58 | 1.3 × 10−3 | 105 | ||

| 650 | A3 | TL | 2.0 | 2.4 | 2.73 | 0 | 0 |

| CL | 2.0 | 2.4 | 2.73 | 5.0 × 10−5 | 4 | ||

| Cauchy | NA | NA | 2.72 | 14.0 × 10−3 | 1135 | ||

| 700 | TL | 2.1 | 2.5 | 2.69 | 0 | 0 | |

| CL | 2.0 | 2.4 | 2.68 | 1.9 × 10−3 | 160 | ||

| Cauchy | NA | NA | 2.64 | 28.2 × 10−3 | 2200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dutta, S.; Kaloyeros, A.; Nanaware, A.; Gallis, S. Scalable Chemical Vapor Deposition of Silicon Carbide Thin Films for Photonic Integrated Circuit Applications. Appl. Sci. 2025, 15, 8603. https://doi.org/10.3390/app15158603

Dutta S, Kaloyeros A, Nanaware A, Gallis S. Scalable Chemical Vapor Deposition of Silicon Carbide Thin Films for Photonic Integrated Circuit Applications. Applied Sciences. 2025; 15(15):8603. https://doi.org/10.3390/app15158603

Chicago/Turabian StyleDutta, Souryaya, Alex Kaloyeros, Animesh Nanaware, and Spyros Gallis. 2025. "Scalable Chemical Vapor Deposition of Silicon Carbide Thin Films for Photonic Integrated Circuit Applications" Applied Sciences 15, no. 15: 8603. https://doi.org/10.3390/app15158603

APA StyleDutta, S., Kaloyeros, A., Nanaware, A., & Gallis, S. (2025). Scalable Chemical Vapor Deposition of Silicon Carbide Thin Films for Photonic Integrated Circuit Applications. Applied Sciences, 15(15), 8603. https://doi.org/10.3390/app15158603