1. Introduction

Grounding systems are essential for the safe operation of electrical installations of different voltage levels. Grounding systems primarily perform fault reduction, dissipate fault currents, limit electromagnetic interference, and afford protection from transient overvoltage [

1]. The effects of grounding system performance are quite critical to electrical safety, system stability, and equipment lifespan. However, the process of design for a grounding system depends on certain reciprocal considerations regarding the characteristics of the soil, position of the electrodes, properties of the materials being used, and acceptance of international standards like IEEE Std 80-2013 [

2] and IEC 60364-5-54 [

3]. The performance of a grounding system hinges largely on its capability to maintain both low grounding resistance and low step and touch voltage hazards. Variations in soil resistivity, moisture content, and environmental factors are major factors hampering the efficiency of an optimal grounding design [

4]. Furthermore, the selection of grounding electrodes, which can take the form of rod electrodes, grounding grids, deep-driven rods, or hybrid systems, profoundly affects the ability of a grounding system to dissipate fault currents. In this sense, medium- and high-voltage installations, such as 10 kV and 35 kV networks, could rise into hazardous conditions by the fault currents themselves, necessitating the implementation of advanced grounding methods to ensure safe dissipation of fault energy [

5].

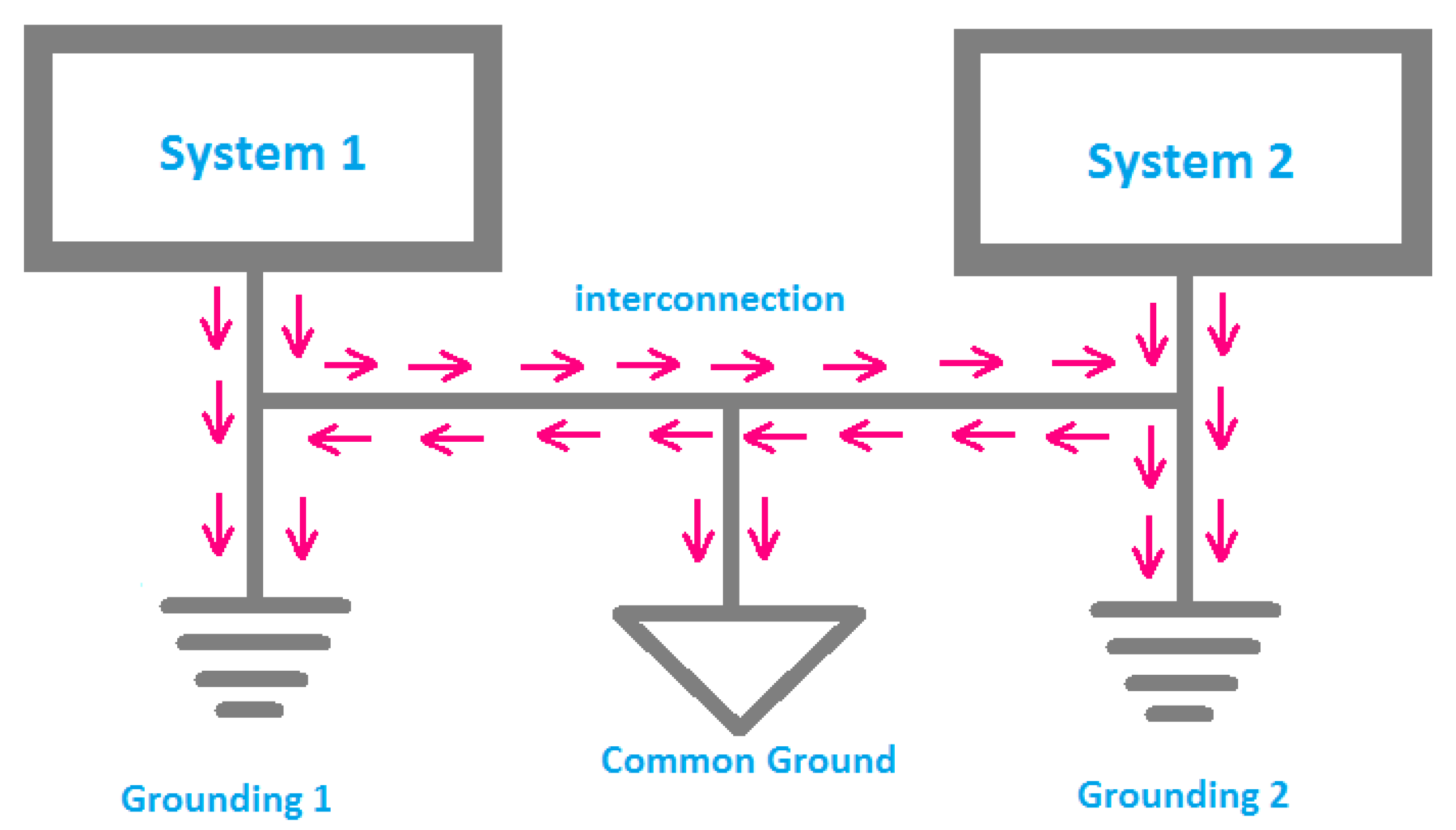

Figure 1 shows the traditional grounding system.

This study offers a comparative analysis of grounding systems for 400 V, 10 kV, and 35 kV electrical installations, including the range of configurations and soil conditions considered. The study employs computer simulations (finite element method—FEM), field measurements, and parametric analyses focusing on key aspects such as grounding resistance, rise in potential, step and touch voltages, and fault current dissipation efficiency [

6]. In combining computer modeling with experimental backing, this work delivers best practices for cost-effective, efficiently designed grounding systems for varied voltage requirements. Another major intention is to assess the performance of the grounding systems with respect to different soil resistivities and changing environmental conditions with regard to the effectiveness of dissipating the fault action currents and safety voltages. The study will evaluate various grounding configurations with the assistance of rod electrodes, grounding grids, deep-driven rods, and hybrid systems to determine their efficiency in optimizing grounding designs for 400 V, 10 kV, and 35 kV installations. In order to confirm that respective grounding systems fall into compliance with adherence to international standards in step and touch voltage limits for guaranteed safety and operationally highest performance of the systems, target standards taken into consideration will be IEEE Std 80-2013 and IEC 60364-5-54 [

3]. By addressing these objectives, this research aims to contribute to the development of more resilient, cost-effective, and technically optimized grounding strategies for modern electrical installations. The study not only enhances theoretical understanding but also provides practical guidelines for engineers, utility planners, and policymakers engaged in electrical grounding design.

The rest of the research is organized as follows: the principles of grounding systems in

Section 2, followed by

Section 3, Methodology, which combines FEM simulations and field measurements to assess grounding configurations across different soils.

Section 4, Grounding Configurations and Optimization Techniques, compares various systems, like rod electrodes and grids, analyzing their efficiency.

Section 5, Comparative Analysis of Grounding Performance, presents a comparison for 400 V, 10 kV, and 35 kV systems, focusing on fault current dissipation and safety voltages.

Section 6, Discussion and Recommendations, addresses environmental factors and suggests further research on advanced materials and real-time monitoring. Finally,

Section 7, Conclusion, emphasizes the need for tailored solutions and outlines areas for future research to improve safety and reliability, and suggests areas for future research to enhance safety and system reliability.

3. Methodology

The optimization of grounding systems for different voltage levels (400 V, 10 kV, and 35 kV). It involves both computational modeling and experimental field measurements. The methodology integrates numerical simulations, measurement techniques, and analysis of various parameters that influence grounding performance.

3.1. Field Measurement Techniques

Field measurements are crucial to validate the results obtained through computational modeling and provide real-world data on grounding system performance.

3.1.1. Ground Resistance Testing Using the Wenner and Schlumberger Methods

To accurately measure the ground resistance, two primary methods are used: the Wenner method and the Schlumberger method. Both methods involve injecting a current into the ground and measuring the resulting potential difference.

Wenner Method: This method uses four equally spaced electrodes placed in a straight line. A current is injected into the outer electrodes, and the voltage is measured between the inner two electrodes. The ground resistance

is calculated using

where

is the spacing between the electrodes,

is the voltage between the inner electrodes, and

is the injected current.

Schlumberger Method: In this method, the current electrodes are placed farther apart than the voltage electrodes. The resistance is calculated similarly, but the setup is more flexible for varying electrode spacings. The equation is as follows:

where

and

represent the positions of the current and voltage electrodes, respectively.

3.1.2. Step and Touch Voltage Analysis Using High-Precision Meters

Analysis of step and touch voltages is essential to assess the safety of the personnel under fault conditions [

13,

14]. Step voltage is the voltage between a person’s feet when standing on the ground, and touch voltage is the voltage between a person’s hand and the ground. Precision voltmeters and safety analyzers are employed to measure these voltages during fault simulations. The touch voltage

and step voltage

can be verified for IEEE 80-2013 compliance [

3], which recommends that these voltages should not exceed 430 V for 10 kV systems under fault conditions.

3.2. Soil Resistivity Analysis

Soil resistivity plays a significant role in the overall performance of grounding systems. Variations in soil resistivity due to seasonal changes or soil composition can significantly affect the effectiveness of a grounding system.

3.2.1. Measurement Techniques and Soil Layering Impact

Soil resistivity is measured using techniques such as the Wenner and Schlumberger methods [

15]. In addition, the impact of soil layering is analyzed by considering variations in resistivity at different depths. The total ground resistance of a system depends on the resistivity of the individual layers, as shown by the following:

where

is the resistance of the individual soil layer

,

is the number of soil layers.

3.2.2. Seasonal Variations in Soil Resistivity

Soil resistivity varies with seasonal changes, particularly with moisture content. During wet seasons, soil resistivity decreases, which may improve the grounding system’s performance. In contrast, dry conditions can significantly increase resistivity, leading to a decrease in the system’s fault current dissipation capacity. These variations are taken into account during the design and testing phases.

Seasonal resistivity

can be approximated using a temperature and moisture content-dependent formula:

where

is the resistivity of dry soil,

is the temperature,

is the moisture content, and

and

m are constants.

3.3. Evaluation Criteria

The performance of the grounding system is evaluated using several parameters that quantify the effectiveness of current dissipation, safety measures, and compliance with regulations.

3.3.1. Ground Resistance

Grounding resistance of a grounding device comprises three components: the resistance of the grounding body, the contact resistance between the grounding body’s surface and the soil, and the soil resistance as the current flows from the grounding body into the ground. The total ground resistance is a critical measure of the performance of the grounding system. Lower resistance enhances fault current dissipation efficiency and safety. The goal is to minimize

while ensuring the system meets all other design requirements. The efficiency of fault current dissipation is determined by the grounding system’s ability to absorb and safely direct fault currents into the earth. This efficiency is assessed by comparing the fault current dissipated by the system to the total fault current applied.

Table 3 presents the evaluation criteria for grounding system optimization.

The dissipation efficiency

can be calculated as follows:

where

is the current dissipated into the ground, and

is the total fault current.

These evaluation criteria offer a comprehensive approach to evaluating the optimization of grounding systems, from computational modeling to real-world measurements and performance criteria.

3.3.2. FEM Model Validation

To ensure the accuracy of the finite element method (FEM) simulations, a validation exercise was performed by comparing the simulated ground resistance values with those obtained from field measurements. The comparison was conducted across multiple grounding configurations using identical soil resistivity and geometric parameters. The results indicate a strong correlation between the simulated and measured values. The average absolute error observed was ±0.35 Ω, while the relative error remained below 7% for most cases. These deviations are considered acceptable within the typical range of variability expected in soil resistivity and measurement tolerances. The low error margins confirm that the FEM model accurately reflects the physical behavior of the grounding system and validates the appropriateness of the soil modeling and boundary conditions used in the simulations. This provides confidence in the use of the FEM results for optimizing design parameters and evaluating performance under various grounding scenarios.

4. Grounding Configurations and Optimization Techniques

4.1. Conventional Grounding Electrodes

Conventional earthing entails burying a copper plate or galvanized iron (GI) pipe within a pit layered alternately with salt and charcoal. This method requires regular water replenishment and periodic maintenance to ensure effective grounding. Conventional grounding electrodes include single rod electrodes and multiple rods, commonly used in electrical grounding systems [

16]. The resistance of a single vertical rod electrode can be estimated using the following equation:

where

ground resistance (Ω),

= soil resistivity (Ω·m),

= length of the rod (m),

= diameter of the rod (m). As the length of the rod

increases, the resistance

decreases, leading to a more effective grounding electrode. A larger diameter

reduces the resistance, as a wider surface area allows more current to flow into the ground. The soil resistivity

has a direct impact on the resistance, with dry or rocky soil having higher resistivity, and moist, sandy, or clay-rich soil exhibiting lower resistivity.

In many practical applications, a single rod may not provide sufficient grounding, especially in areas with high soil resistivity [

17]. To overcome this, multiple rods are used in parallel to reduce the overall grounding resistance. The resistance of the system with multiple rods depends on the number of rods nnn, their spacing, and the configuration in which they are arranged. For multiple rod configurations, the overall resistance

is reduced as given by the following:

where

denotes the number of rods and

is a spacing factor dependent on the configuration. The spacing factor

can be estimated from empirical data or specialized charts that correlate the spacing of the rods and the configuration type with the resulting resistance. The closer the rods are spaced, the more effective the grounding system will be, as the total surface area for current dissipation increases. However, if rods are placed too close to one another, their individual effectiveness may be reduced due to mutual coupling effects, which can increase the total system resistance.

For example, if the rods are placed in a linear arrangement, the resistance will decrease more slowly as the number of rods increases. However, if the rods are arranged in a triangular or rectangular grid pattern, the resistance will decrease more efficiently, especially at larger spacings.

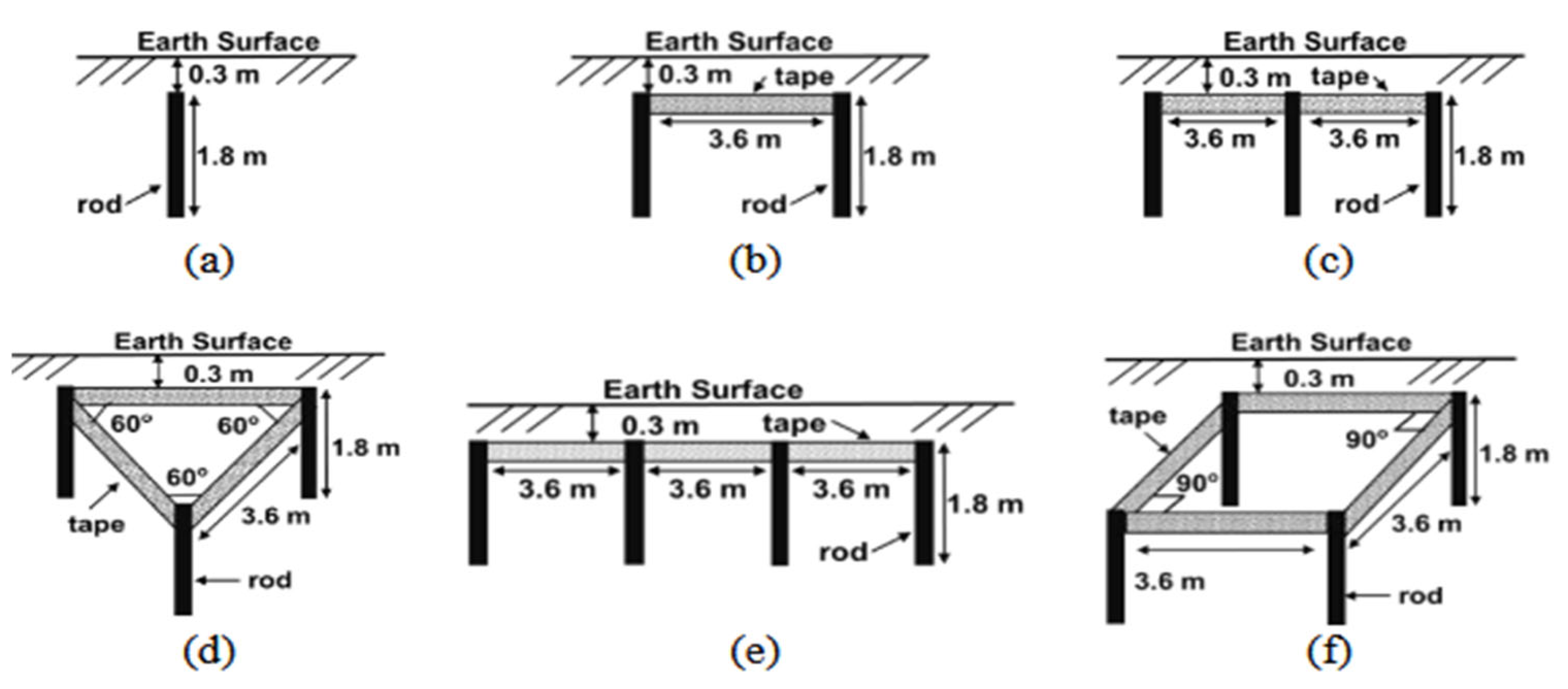

Figure 2 displays the conventional grounding system arrangements [

18].

4.2. Deep-Driven Rods and Vertical Electrodes

Deep-driven rods perform effectively in soils with high resistivity due to increased contact with lower-resistivity layers.

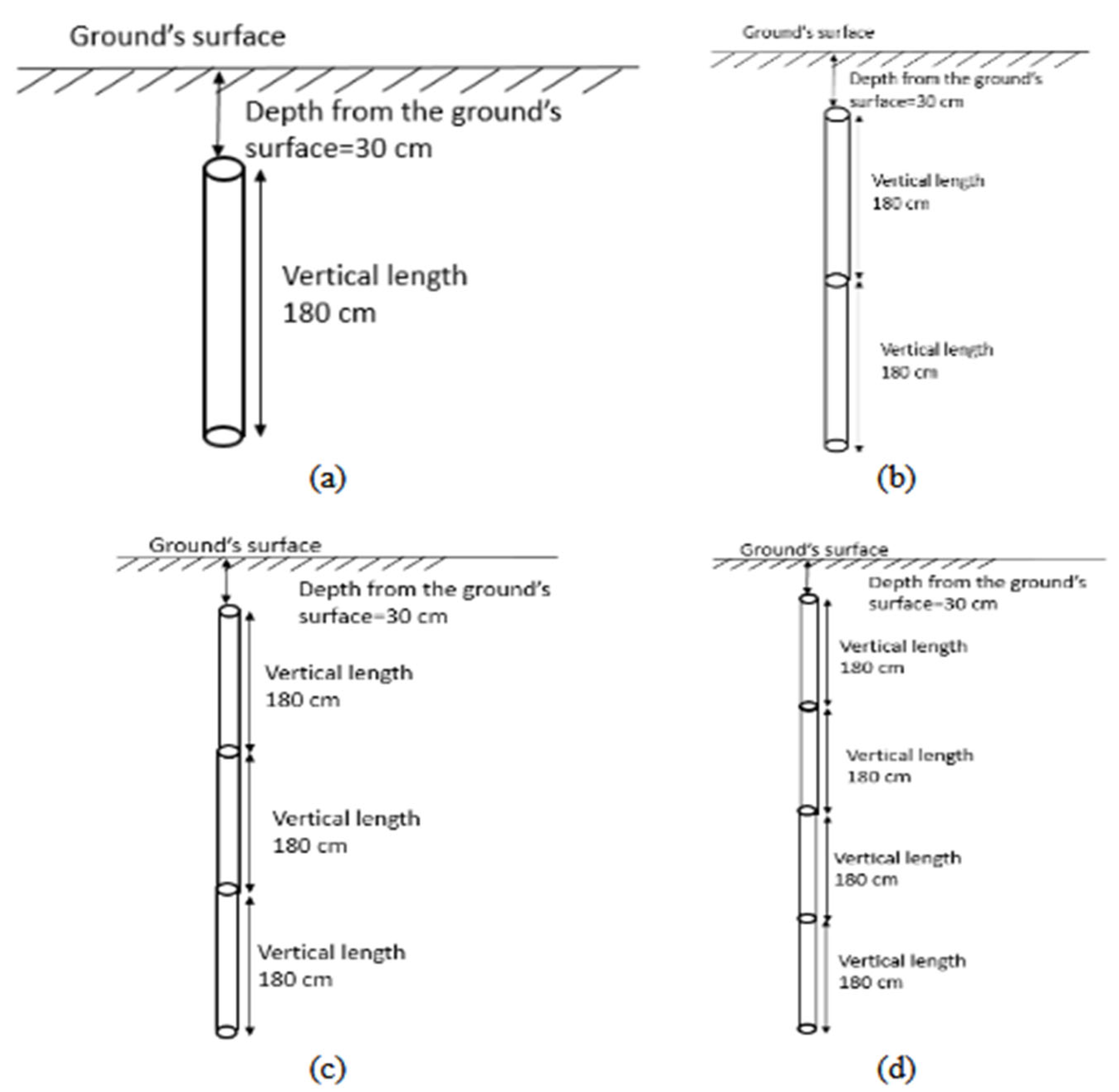

Figure 3 shows the ground electrodes used in vertical formulation [

19]. This grounding system has been employed and tested in Cyberjaya, Malaysia. The reduction in resistance with increasing depth is as follows:

Table 4 shows that as the rod length increases, the resistance decreases. In formation V1 (1.8 m rod), the resistance is highest at 35 Ω, indicating poor conductivity with the shorter rod. In formation V2 (3.6 m rod), resistance drops to 17 Ω, improving grounding efficiency. This trend continues in formation V3 (5.4 m rod) with a resistance of 15 Ω, and formation V4 (7.2 m rod) shows a further slight decrease to 13.5 Ω. While longer rods provide better grounding, the reduction in resistance diminishes as rod length increases, suggesting a point of diminishing returns. The error range was typically ±0.2 to ±0.5 Ω, depending on soil moisture at the time of testing.

4.3. Grounding Grids and Mesh Systems

Grounding grids improve fault current dissipation by providing multiple current paths. The grid resistance can be estimated as follows:

where

is a coefficient dependent on the grid layout.

For optimal design, IEEE Std 80-2013 suggests spacing electrodes based on the maximum step and touch voltage limits:

where

= step voltage (V),

= fault current (A), and

= surface area of the grid (m

2)

4.4. Use of Enhancing Materials (Bentonite, Conductive Concrete)

Enhancing materials like bentonite and conductive concrete reduces soil resistivity, improving grounding efficiency. The resistance of an electrode with an enhancement layer can be estimated using the following:

where

is the modified resistivity, and

is the thickness of the enhancement layer.

Table 5 shows the comparison of ground resistance with enhancing materials. The reduction in ground resistance was computed using the baseline resistance without enhancement material

and the resistance with material

via the following formula:

4.5. Hybrid Grounding Systems

Hybrid grounding combines vertical rods and horizontal conductors for improved performance [

20]. The combined resistance is given by the following:

where

= resistance of vertical electrodes, and

= resistance of horizontal electrodes.

Chemical electrodes can further reduce resistance by ionizing the surrounding soil, ensuring long-term stability.

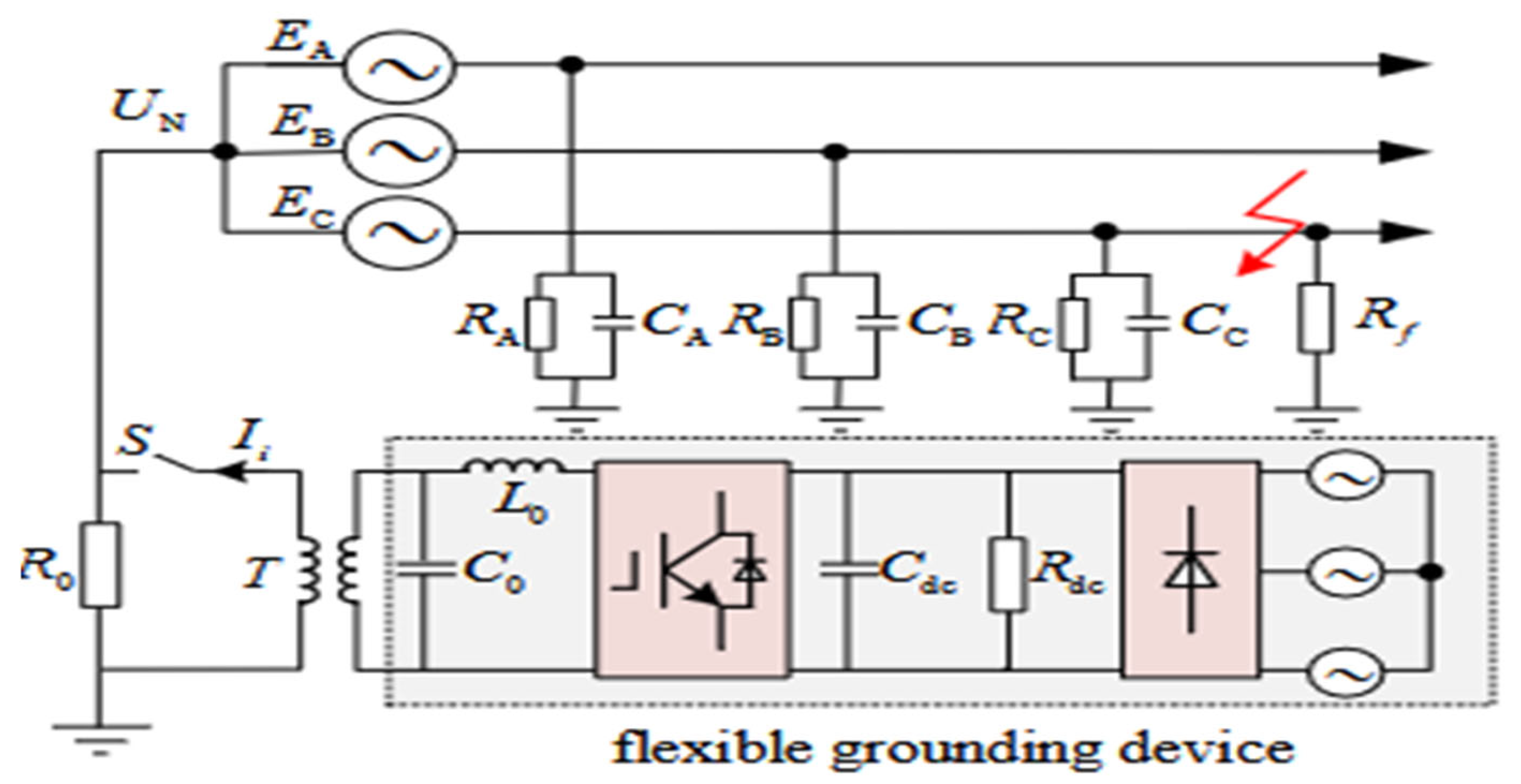

Figure 4 illustrates a hybrid grounding system layout.

4.6. Grounding Using Natural Conductors

In addition to conventional grounding methods involving rods, plates, and mesh systems, natural conductors such as metal water pipes, structural steel frameworks, and underground metallic fittings can serve as effective grounding paths. These elements, often already embedded in the infrastructure, provide an economical and practical means of achieving grounding, particularly in low-voltage or commercial installations. According to NEC Article 250.52(A) [

3] and IEC 60364-5-54 (Clause 54.3), such conductors may be recognized as grounding electrodes, provided they meet specific criteria regarding their electrical continuity, corrosion resistance, and direct contact with the soil. For example, metal water pipes must be in contact with the earth for at least 3 m and must not be coated with insulating material that would inhibit conductivity. Similarly, structural steel must be securely bonded to the grounding system using approved mechanical or welded connections.

The use of natural conductors offers several advantages, including reduced material costs, simplified installation, especially in new buildings, and potential redundancy when used alongside conventional electrodes. However, there are limitations that must be considered. These include the risk of corrosion over time, potential discontinuities due to mechanical disassembly or use of insulating joints, and challenges in verifying the integrity of buried or inaccessible connections. Consequently, natural grounding conductors are best used to supplement, rather than replace, dedicated grounding electrodes, particularly in high-fault-current environments or critical systems requiring high reliability.

Regular testing and verification are essential to ensure the ongoing effectiveness of natural conductors in grounding applications. Their performance can vary widely depending on the type of material, the size and shape of the conductor, soil characteristics, and environmental exposure. When appropriately validated and maintained, natural conductors can play a valuable role in achieving safe and cost-effective grounding for electrical installations, particularly in residential, commercial, and light industrial settings.

6. Discussion and Recommendations

6.1. Impact of Soil Resistivity Variations

Soil resistivity is a key factor influencing grounding system effectiveness. Since soil resistivity is affected by the moisture content, temperature variations, and soil composition, seasonal changes create a dramatic change in grounding system performance. For example, soil resistivity increases during dry periods, raising ground resistance, thus impairing fault current dissipation and augmenting the potential risk of equipment damage; some mitigation techniques to offset peak resistivity during dry weather include soil conditioning via chemical additives or conductive backfill installation. As we see it, these treatments work best in high-resistivity soil areas and thus make for a continuity of system reliability throughout the year. However, the effectiveness of soil treatments may be limited by unavoidable environmental factors, which may demand periodic maintenance for sustained effectiveness.

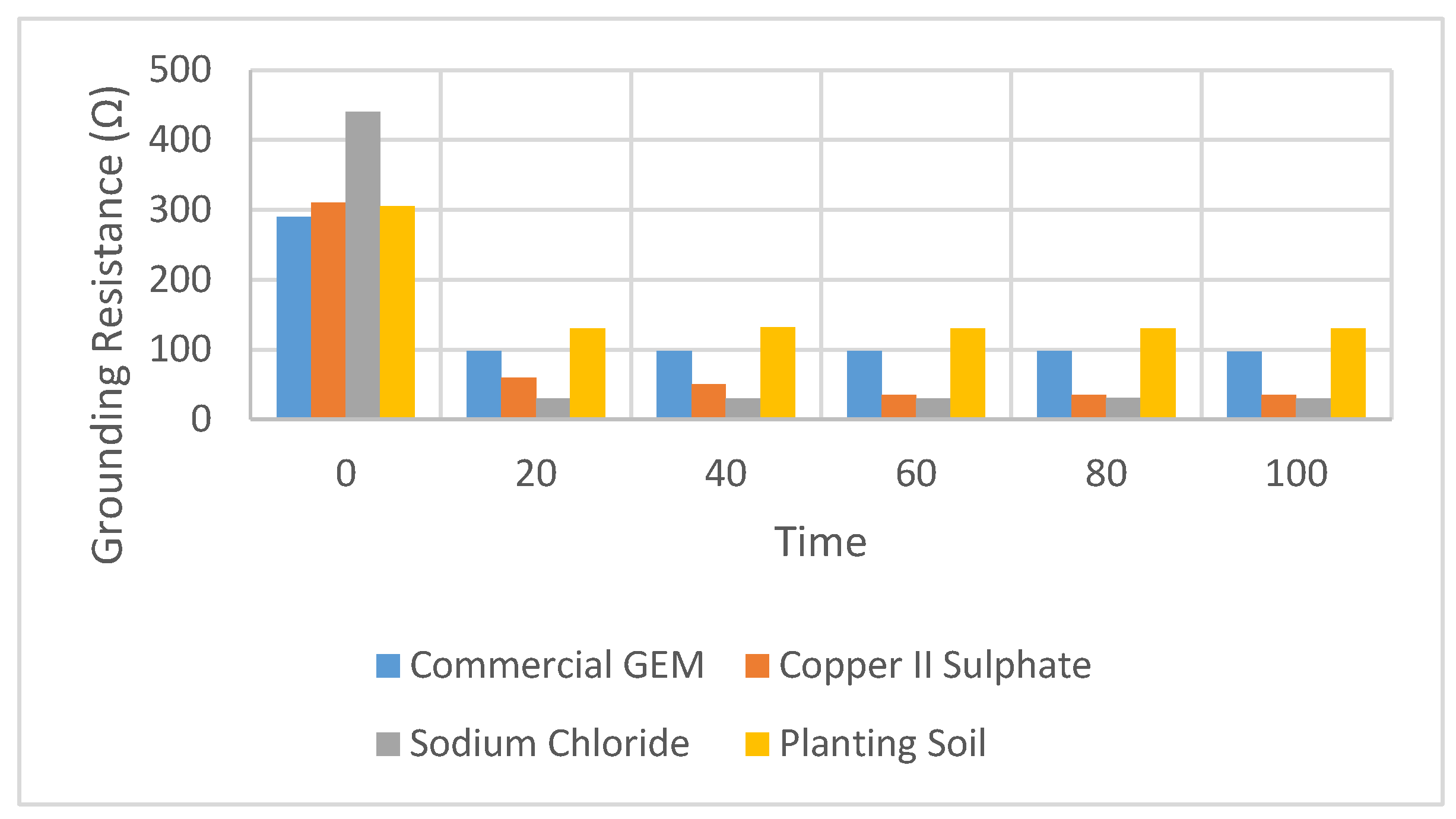

Grounding enhancement materials (GEM) such as Sodium Chloride and Copper II Sulphate provide significant reductions in earthing resistance. In

Figure 6, Sodium Chloride shows the highest reduction of 96.45%), the commercially available GEM exhibits superior stability over time. The commercial GEM maintained a consistent earthing resistance with minimal fluctuation, making it more reliable for long-term use, especially in environments where moisture retention is crucial. Fluctuation of earthing resistance is shown in

Table 14. Sodium Chloride, while effective initially, was found to dissolve in heavy rain, highlighting the need for periodic replenishment in tropical climates. Thus, for stable long-term performance, the commercial GEM is recommended.

6.2. Effectiveness of Different Electrode Materials

Electrode selection significantly impacts the performance and lifespan of grounding systems. Although the general consensus is that copper electrodes are the best due to their low resistance and high conductivity, guaranteed performance, and non-degradation, their high cost makes them uneconomical for large-scale installations. Galvanized steel electrodes, conversely, exhibit lower conductivity compared to copper. With their cost-effectiveness, adequate grounding performance is still experienced in many applications. Nevertheless, galvanized steel does corrode more easily as time progresses, particularly when buried in soils with high moisture, acid conditions, or both, hence additional reduction in longevity. Corrosion resistance and electrode lifespan are crucial factors that must be evaluated against local environmental conditions to ensure that the grounding system remains a viable prospect over time.

6.3. Safety Considerations and Compliance with Standards

Standards have to be followed through the IEEE and IEC for safety and performance. The standards state specifications with regard to ground resistance, electrode installation, and system performance that allow the proper execution of the grounding system in relation to the protective abilities of the personnel and equipment from an electrical fault. A periodic risk assessment and analysis for a fault scenario must be performed to find a justification for the potential fault conditions of a system high-fault currents or unexpected voltage surges [

29]. Their ultimate aim shall be to indicate or expose the weaknesses in a certain grounding system, and draw conclusions for improvements required in order to obtain the safety of the grounding system. They are, therefore, requisite facilities to consider for safety against electrical hazards that mainly include, but are not restricted to, electric shocks and damage to equipment, while at the same time trying to ensure adequate system performance and reliability under all kinds of fault conditions [

30].

6.4. Grounding Considerations in High-Altitude Mining Environments

Power supply security in high-altitude mining operations presents unique engineering challenges that directly affect grounding system performance. At high altitudes, lower atmospheric pressure, reduced air ionization, and dry or frozen soil conditions significantly decrease soil conductivity, resulting in higher ground resistance and elevated ground potential rise (GPR). These factors increase the risk of unsafe step and touch voltages, especially during fault or lightning events. Moreover, extreme temperature variations can accelerate corrosion in grounding conductors and compromise the long-term reliability of the system.

In such environments, conventional shallow-grounding techniques are often inadequate. Instead, deep-well electrodes, counterpoise systems, and soil conditioning compounds must be deployed to ensure adequate fault current dissipation. As highlighted in recent studies, the implementation of automated monitoring systems and remote control operations in high-altitude mines increases the reliance on stable and secure power systems, where grounding design becomes a foundational safety and reliability element [

31]. The adaptation of grounding infrastructure to meet the demands of electrified and digitized mining systems is also emphasized in regional case studies [

32].

Furthermore, grounding systems should be considered in tandem with insulation studies to offer a more comprehensive electrical safety strategy. Insulation degradation at high altitudes, combined with elevated GPR, can exacerbate insulation stress and increase the likelihood of equipment failure or personnel hazard. Therefore, integrating grounding system optimization with insulation coordination and surge protection schemes is essential for ensuring safe and reliable operations in high-altitude mining environments.

6.5. Recommendations for Optimal Grounding Strategies

Best practices for grounding design differ significantly across voltage levels; the specific needs of the installation dictate these differences. For low-voltage systems (e.g., 400 volts), normally, a simple solid grounding system or TN-C-S system is used; these systems assuredly protect in very much lower fault-risk environments. Medium- and high-voltage systems (e.g., 10 kV and above) utilize resistance grounding or multiple electrodes to cope with hefty fault currents and diminish ground potential rise (GPR), thus providing better protection and functional stability. Optimizing grounding systems in the present involves the loading of intelligent monitoring technologies-real-time resistance measure and automatic fault detection systems that bring in the smart, responsive, and high-efficiency maintenance system. Consequently, these technologies facilitate continuous monitoring and adjustment of grounding systems with minimal maintenance, which in turn boosts performance, permits lower maintenance costs, and makes them responsive. With all this, further protection can also be allotted to those grounding systems to optimize performance with due consideration to safety, reliability, and cost across different voltage levels and installation types.

6.6. Predictive Modeling of Long-Term Soil Resistivity Variations

Long-term variations in soil resistivity significantly affect the performance and reliability of grounding systems. These variations are primarily influenced by seasonal changes in temperature and moisture content, which alter the conductivity of the soil over time. To address this, a simple empirical predictive model is introduced to estimate the temporal evolution of soil resistivity, allowing for better planning and optimization of grounding system maintenance and performance forecasting. The model is expressed as follows:

where the

is the predicted soil resistivity at time

,

is the baseline soil resistivity under dry reference conditions,

is the deviation in soil temperature from the baseline,

is the deviation in soil moisture content from the baseline,

and

are soil-type-specific coefficients that quantify the sensitivity of resistivity to temperature and moisture changes, respectively. This model allows for proactive adjustment of grounding system parameters based on environmental forecasts or sensor data. For example, in tropical climates, soil resistivity may increase significantly during dry seasons due to evaporation and reduced conductivity, while during the rainy season, increased moisture levels reduce resistivity and improve grounding effectiveness. By estimating future resistivity values, system designers can determine when to implement supplementary electrodes, chemical treatments, or system recalibrations.

In future work, this model can be enhanced using real-time monitoring tools (e.g., IoT-based soil sensors) and integrated into smart grounding system architectures for continuous adaptation to environmental conditions.

7. Conclusions

This study provides a comprehensive analysis of key aspects in optimizing grounding systems for 400 V, 10 kV, and 35 kV electrical installations, dealing with grounding resistance, fault current dissipation values, and safety voltages. The results reiterated the fact that soil resistivity plays a major role in the performance of grounding systems: at high resistivity, deep-driven rods were found to function better, while grounding grids were better at dissipating fault current in substations. Further reductions in grounding resistance and performance enhancements were observed with conductive backfill materials like bentonite and conductive concrete. The work discusses various configurations of grounding electrodes, such as rod electrodes, grids, deep-driven rods, and hybrid systems, also signifying that the best grounding system is contingent upon environmental conditions and the magnitude of the fault current. The grounding systems developed, in compliance with the respective international standards, IEEE Std 80-2013 and IEC 60364-5-54, provide the necessary protection against hazards associated with step and touch voltages, ensuring personnel safety and system reliability. This study contributes practical guidance for designing cost-effective, high-efficiency grounding systems across voltage levels that meet stringent safety and operational demands. By fusing computational simulation with field data, the study offers substantial perspectives on resilient grounding system designs that ensure enhanced safety and reliability in operations.

Future research should focus on the long-term performance, particularly in areas with extreme fluctuations of seasonal soil resistivity affecting the grounding systems. Understanding the mechanisms of electrode material degradation, especially those that occur in a corrosive environment, would lead to the enhancement of grounding system durability and lifespan. At the same time, through a dynamic view of soil resistivity and grounding system performance, diverse real-time monitoring tools, like those based on IoT sensors, may support more immersive and responsive designs of grounding. Further improvements may be expected from more sophisticated computational models that simulate elaborate fault and transient conditions, combined with larger-scale field data for the improvement of grounding system design for the standards of optimal performance. Lastly, assessing the economic performance of various grounding models in large-scale installations for a deeper understanding of the cost/benefit tradeoffs of optimizing grounding systems.