Three-Dimensional Numerical Study on Fracturing Monitoring Using Controlled-Source Electromagnetic Method with Borehole Casing

Abstract

1. Introduction

1.1. Principles of the Finite Volume Method

1.2. Metal Casings in Borehole-to-Surface Electromagnetic Imaging

2. Forward Modeling Method

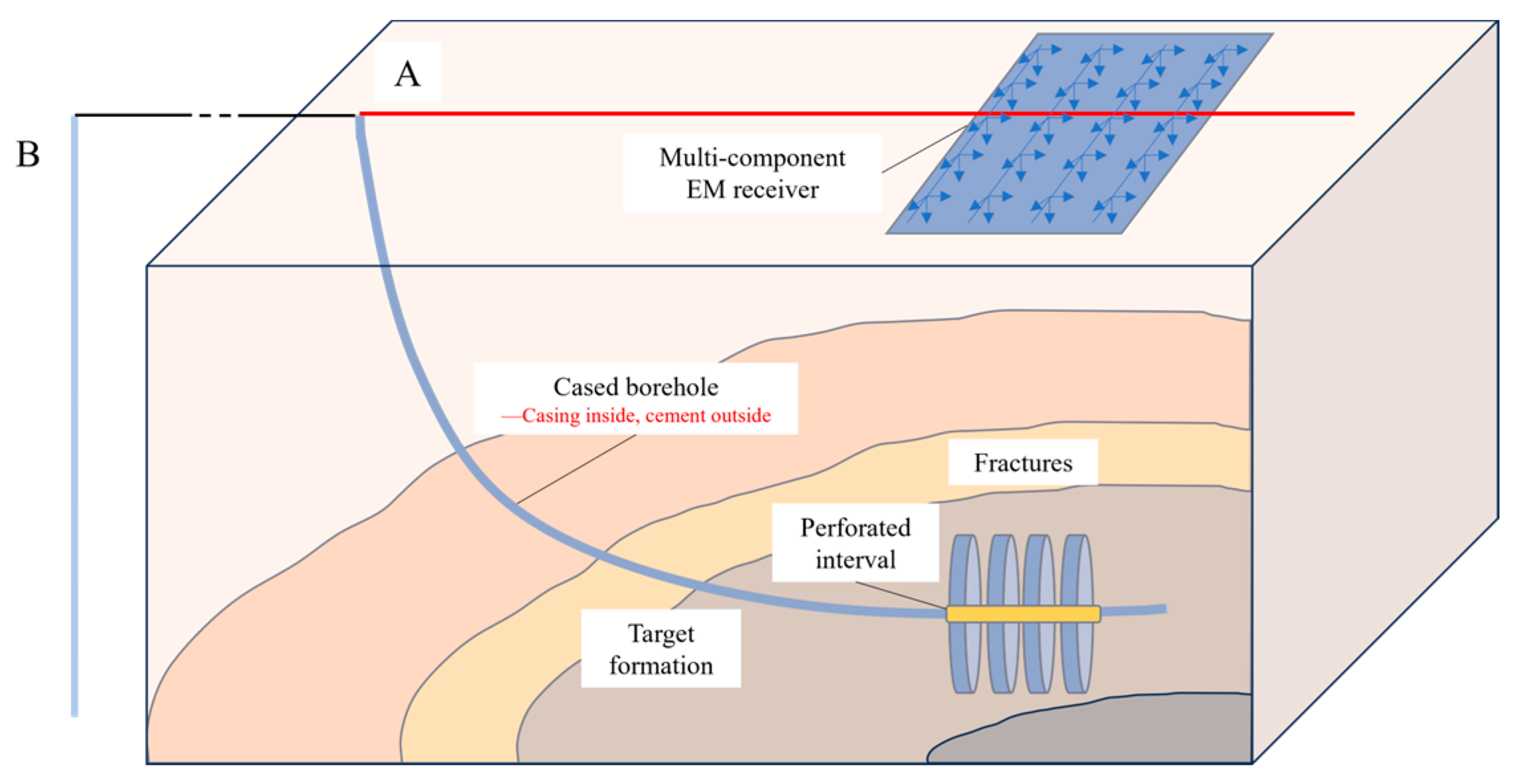

2.1. Borehole-to-Surface Electromagnetic Monitoring System

2.2. Underground Electromagnetic Field Simulation Theory

2.3. Solving the Discretization of the Target Region

2.4. Simulation of the Metal Well Casing

3. Numerical Simulation and Verification for Hydraulic Fracturing

4. Simulation of the Actual Well Casing

5. Conclusions

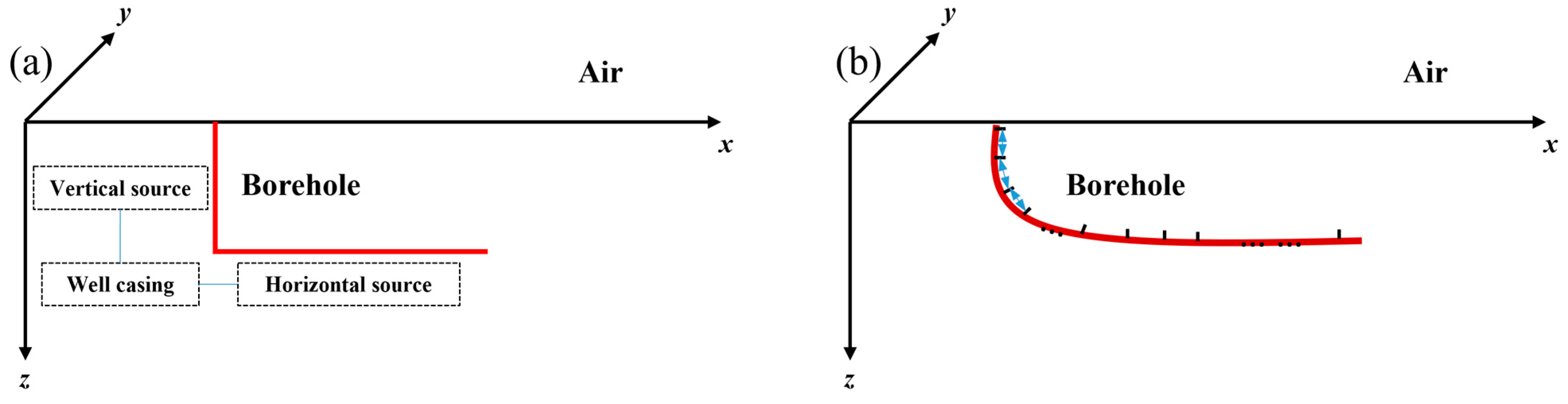

- Based on the developed frequency-domain borehole-to-surface electromagnetic 3D forward algorithm, this paper discusses the optimal method for simulating the transmitter source and conducts correctness verification of the program. A simulation method for constructing complex line sources using the borehole trajectory data of actual wells is proposed. By decomposing highly deviated wells and horizontal wells into vertical and horizontal line sources, the influence of different observation modes with varying transmitter source (B-pole) positions on surface responses is studied, proving that placing the B pole along the borehole trajectory extension direction is the optimal observation mode.

- The surface responses of line sources at a certain depth underground are studied, verifying the effectiveness of the frequency-domain borehole-to-surface electromagnetic observation system, and it is concluded that the optimal surface receiving data is the Ex and Hy components. For fracturing operations, this study verifies the effectiveness of borehole-to-surface electromagnetic method monitoring through borehole-to-surface observation modes and forward numerical simulations. In the simulation of fracturing operations in complex undulating formation models, the fracturing fracture bodies are set, proving the high observation accuracy of surface differential responses of the frequency-domain BSEM method.

- This study verifies the high sensitivity of the frequency-domain BSEM method to monitor changes during the fracturing process through forward simulation cases. By selecting surface electromagnetic field component data at appropriate monitoring frequencies, the development of fractures and fracturing effects can be understood in real time. These research results provide a scientific basis and practical guidance for the setup of borehole-to-surface electromagnetic systems in different scenarios.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mizunaga, H.; Ushijima, K. Three-Dimensional numerical modeling for the mise-a-la-masse method. Geophys. Explor. (Butsurib-Tansa) 1991, 44, 215–226. [Google Scholar]

- Ushijima, K.; Mizunaga, H.T.; Tanaka, T. Reservoir Monitoring by a 4-D Electrical Technique. Lead. Edge 1999, 18, 1422–1424. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Liu, D.J.; Ai, Q.H.; Qin, M.J. 3D modeling and inversion of electrical resistivity tomography using steel cased boreholes as electrodes. J. Appl. Geophys. 2014, 109, 292–300. [Google Scholar] [CrossRef]

- Tafti, T.A.; Sahimi, M.; Aminzadeh, F.; Sammis, C.G. Use of microseismicity for determining the structure of the fracture network of large-scale porous media. Phys. Rev. E 2013, 87, 032152. [Google Scholar] [CrossRef]

- Palisch, T.; Al-Tailji, W.; Bartel, L.; Cannan, C.; Zhang, J.; Czapski, M.; Lynch, K. Far-Field Proppant Detection Using Electromagnetic Methods: Latest Field Results. SPE Prod. Oper. 2018, 33, 557–568. [Google Scholar] [CrossRef]

- Ry, R.V.; Septyana, T.; Widiyantoro, S.; Nugraha, A.; Ardjuna, A. Borehole microseismic imaging of hydraulic fracturing: A pilot study on a coal bed methane reservoir in Indonesia. J. Eng. Technol. Sci. 2019, 51, 251–271. [Google Scholar] [CrossRef]

- Hu, Y.; Yang, D.; Li, Y.; Wang, Z.; Lu, Y. 3-D Numerical Study on Controlled Source Electromagnetic Monitoring of Hydraulic Fracturing Fluid with the Effect of Steel-Cased Wells. IEEE Trans. Geosci. Remote Sens. 2022, 60, 1–10. [Google Scholar] [CrossRef]

- Alfano, L. Geoelectric prospecting with underground electrodes. Geophys. Prospect. 1961, 10, 290–303. [Google Scholar] [CrossRef]

- Snyder, D.D.; Merkel, R.M. Analytic models for the interpretation of electrical surveys using buried current electrodes. Geophysics 1973, 38, 513–529. [Google Scholar] [CrossRef]

- Merkel, R.H. Resistivity analysis for plane-layer half-space models with buried current sources. Geophys. Prospect. 1971, 19, 626–639. [Google Scholar] [CrossRef]

- Kaufman, A.A. The electrical field in a borehole with a casing. Geophysics 1990, 55, 29–38. [Google Scholar] [CrossRef]

- Kaufman, A.A.; Wightman, E.W. A transmission-line model for electrical logging through casing. Geophysics 1993, 58, 1739. [Google Scholar] [CrossRef]

- Schenkel, C.J.; Morrison, H.F. Electrical resistivity measurement through metal casing. Geophysics 1994, 59, 1072–1082. [Google Scholar] [CrossRef]

- Wilt, M.; Alumbaugh, D. Oil field reservoir characterization and monitoring using electromagnetic geophysical techniques. J. Pet. Sci. Eng. 2003, 39, 85–97. [Google Scholar] [CrossRef]

- Tsourlos, P.; Ogilvy, R.; Papazachos, C.; Meldrum, P. Measurement and inversion schemes for single borehole-to-surface electrical resistivity tomography surveys. J. Geophys. Eng. 2011, 8, 487–497. [Google Scholar] [CrossRef]

- Hoversten, G.M.; Commer, M.; Haber, E.; Schwarzbach, C. Hydrofrac monitoring using ground time-domain electromagnetics. Geophys. Prospect. 2015, 63, 1508–1526. [Google Scholar] [CrossRef]

- Yang, K.; Torres-Verdín, C.; Yılmaz, A.E. Detection and quantification of three-dimensional hydraulic fractures with horizontal borehole resistivity measurements. IEEE Trans. Geosci. Remote Sens. 2015, 53, 4605–4615. [Google Scholar] [CrossRef]

- Weiss, C.J.; Aldridge, D.F.; Knox, H.A.; Schramm, K.A.; Bartel, L.C. The direct-current response of electrically conducting fractures excited by a grounded current source. Geophysics 2016, 81, E201–E210. [Google Scholar] [CrossRef]

- Fang, Y.; Dai, J.; Yu, Z.; Zhou, J.; Liu, Q.H. Through-casing hydraulic fracture evaluation by induction logging I: An efficient EM solver for fracture detection. IEEE Trans. Geosci. Remote Sens. 2017, 55, 1179–1188. [Google Scholar] [CrossRef]

- Dai, J.; Fang, Y.; Zhou, J.; Liu, Q.H. Analysis of electromagnetic induction for hydraulic fracture diagnostics in open and cased boreholes. IEEE Trans. Geosci. Remote Sens. 2018, 56, 264–271. [Google Scholar] [CrossRef]

- Kim, J.; Um, E.S.; Moridis, G.J. Integrated simulation of vertical fracture propagation induced by water injection and its borehole electromagnetic responses in shale gas systems. J. Pet. Sci. Eng. 2018, 165, 13–27. [Google Scholar] [CrossRef]

- Yan, L.J.; Chen, X.X.; Tang, H.; Xie, X.B.; Zhou, L.; Hu, W.B.; Wang, Z.X. Continuous TDEM for monitoring shale hydraulic fracturing. Appl. Geophys. 2018, 15, 26–34. [Google Scholar] [CrossRef]

- Fang, Y.; Dai, J.; Zhan, Q.; Hu, Y.; Liu, Q.H. A hybrid 3-D electromagnetic method for induction detection of hydraulic fractures through a tilted cased borehole in planar stratified media. IEEE Trans. Geosci. Remote Sens. 2019, 57, 4568–4576. [Google Scholar] [CrossRef]

- Wilt, M.J.; Um, E.S.; Nichols, E.; Weiss, C.J.; Nieuwenhuis, G.; MacLennan, K. Casing integrity mapping using top-casing electrodes and surface-based electromagnetic fields. Geophysics 2020, 85, E1–E13. [Google Scholar] [CrossRef]

- Li, Y.; Yang, D. Electrical imaging of hydraulic fracturing fluid using steel-cased wells and a deep-learning method. Geophysics 2021, 86, E315–E332. [Google Scholar] [CrossRef]

- Wilt, M.; Alumbaugh, D. Electromagnetic Methods for Development and Production: State of the art. Lead. Edge 1998, 17, 487–490. [Google Scholar] [CrossRef]

- Yee, K. Numerical solution of initial boundary value problems involving maxwell’s equations in isotropic media. IEEE Trans. Antennas Propag. 1966, 14, 302–307. [Google Scholar]

- Wait, J.R. Some solutions for electromagnetic problems involving spheroidal, spherical, and cylindrical bodies. J. Res. Natl. Bur. Stand. Sect. B Math. Math. Phys. 1960, 64B, 15–32. [Google Scholar] [CrossRef]

- Weiland, T. A Discretization Method for the Solution of Maxwell’s Equations for Six-Component Fields. Electron. C (AEU) 1977, 31, 116–120. [Google Scholar]

- Weiss, C.J. Finite-element analysis for model parameters distributed on a hierarchy of geometric simplices. Geophysics 2017, 82, E155–E167. [Google Scholar] [CrossRef]

- Li, Y.; Spitzer, K. Finite element resistivity modeling for three dimensional structures with arbitrary anisotropy. Phys. Earth Planet. Interiors. 2005, 150, 15–27. [Google Scholar] [CrossRef]

- Blome, M.; Maurer, H.R.; Schmidt, K. Advances in three-dimensional geoelectric forward solver techniques. Geophys. J. Int. 2009, 176, 740–752. [Google Scholar] [CrossRef]

- Dey, A.; Morrison, H.F. Resistivity modeling for arbitrarily shaped three-dimensional structures. Geophysics 1979, 44, 753–780. [Google Scholar] [CrossRef]

- Clemens, M.; Weiland, T. Discrete Electromagnetism with the Finite Integration Technique. J. Electromagn. Waves Appl. 2001, 15, 79–80. [Google Scholar] [CrossRef]

- Hong, D.; Xiao, J.; Zhang, G.; Yang, S. Characteristics of the sum of cross-components of triaxial induction logging tool in layered anisotropic formation. IEEE Trans. Geosci. Remote Sens. 2014, 52, 3107–3115. [Google Scholar] [CrossRef]

- Rocroi, J.P.; Koulikov, A.V. The Use of Vertical Line Sources in Electrical Prospecting for Hydrocarbon. Geophys. Prospect. 1985, 33, 138–152. [Google Scholar] [CrossRef]

- King, R.W.P.; Wu, T.T. The complete electromagnetic field of a three-phase transmission line over the earth and its interaction with the human body. J. Appl. Phys. 1995, 78, 668–683. [Google Scholar] [CrossRef]

- Wait, J.R. Note on: Fields of a horizontal wire antenna over a layered half-space. J. Electromagn. Wave 1996, 10, 1655–1662. [Google Scholar] [CrossRef]

- Rucker, C.; Gunther, T.; Spitzer, K. Three-dimensional modeling and inversion of dc resistivity data incorporating topography m I. Modelling. Geophys. J. Int. 2006, 166, 495–505. [Google Scholar] [CrossRef]

- Pardo, D.; Torres-Verdín, C.; Demkowicz, L.F. Feasibility study for 2D frequency-dependent electromagnetic sensing through casing. Geophysics 2007, 72, F111–F118. [Google Scholar] [CrossRef]

- Cuevas, N.H.; Pezzoli, M. On the effect of the metal casing in surface-borehole electromagnetic methods. Geophysics 2018, 83, E173–E187. [Google Scholar] [CrossRef]

- Kohnke, C.; Liu, L.; Streich, R.; Swidinsky, A. A method of moments approach to model the electromagnetic response of multiple steel casings in a layered Earth. Geophysics 2018, 83, WB81–WB96. [Google Scholar] [CrossRef]

- Stumpf, I. Pulsed vertical-electric-dipole excited voltages on transmission lines over a perfect ground—A closed-form analytical description. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 1656–1658. [Google Scholar] [CrossRef]

- Yang, D.; Oldenburg, D.W. Electric field data in inductive source electromagnetic surveys. Geophysics 2018, 66, 207–225. [Google Scholar] [CrossRef]

- Yang, D.; Oldenburg, D.W. Survey decomposition: A scalable framework for 3D controlled-source electromagnetic inversion. Geophysics 2016, 81, E69–E87. [Google Scholar] [CrossRef]

- Heagy, L.J.; Oldenburg, D.W. Direct current resistivity with steel-cased wells. Geophys. J. Int. 2019, 219, 1–26. [Google Scholar] [CrossRef]

- Heagy, L.J.; Oldenburg, D.W. Modeling electromagnetics on cylindrical meshes with applications to steel-cased wells. Comput. Geosci. 2019, 125, 115–130. [Google Scholar] [CrossRef]

- Orujov, G.; Anderson, E.; Streich, R.; Swidinsky, A. On the electromagnetic response of complex pipeline infrastructure. Geophysics 2020, 85, E241–E251. [Google Scholar] [CrossRef]

- Pardo, D.; Torres-Verdín, C.; Zhang, Z. Sensitivity study of borehole-to-surface and crosswell electromagnetic measurements acquired with energized steel casing to water displacement in hydrocarbon-bearing layers. Geophysics 2008, 73, F261–F268. [Google Scholar] [CrossRef]

- Pardo, D.; Torres-Verdín, C. Sensitivity analysis for the appraisal of hydrofractures in horizontal wells with borehole resistivity measurements. Geophysics 2013, 78, D209–D222. [Google Scholar] [CrossRef]

- Barsukov, P.O.; Fainberg, E.B. The field of the vertical electric dipole immersed in the heterogeneous half-space. Izv.-Phys. Solid Earth 2014, 50, 568–575. [Google Scholar] [CrossRef]

- Sami, G.M.; Al-Najim, F.A. The Transient Electromagnetic Field Created by Electric Line Source on a Plane Conducting Earth. Int. J. Mech. Appl. 2015, 5, 16–22. [Google Scholar]

- Tietze, K.; Ritter, O.; Veeken, P. Controlled-source electromagnetic monitoring of reservoir oil saturation using a novel borehole-to-surface configuration. Geophysics 2015, 63, 1468–1490. [Google Scholar]

- Commer, M.; Hoversten, G.M.; Um, E.S. Transient-electromagnetic finite-difference time-domain Earth modeling over steel infrastructure. Geophysics 2015, 80, E147–E162. [Google Scholar] [CrossRef]

- Tang, W.; Li, Y.; Swidinsky, A.; Liu, J. Three-dimensional controlled-source electromagnetic modelling with a well casing as a grounded source: A hybrid method of moments and finite element scheme. Geophys. Prospect. 2015, 63, 1491–1507. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, Q.H. Three-dimensional scattering and inverse scattering from objects with simultaneous permittivity and permeability contrasts. IEEE Trans. Geosci. Remote Sens. 2015, 53, 429–439. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, R.; Zhan, Q.; Liu, Q.H. Multiscale hydraulic fracture modeling with discontinuous Galerkin frequency-domain method and impedance transition boundary condition. IEEE Trans. Geosci. Remote Sens. 2017, 55, 6566–6573. [Google Scholar] [CrossRef]

- Fang, Y.; Hu, Y.; Zhan, Q.; Liu, Q.H. Electromagnetic forward and inverse algorithms for 3-D through-casing induction mapping of arbitrary fractures. IEEE Geosci. Remote Sens. Lett. 2018, 15, 996–1000. [Google Scholar] [CrossRef]

- Um, E.S.; Kim, J.; Wilt, M.J.; Commer, M.; Kim, S.S. Finite-element analysis of top-casing electric source method for imaging hydraulically active fracture zones. Geophysics 2019, 84, E23–E35. [Google Scholar] [CrossRef]

- Um, E.S.; Kim, J.; Wilt, M. 3D borehole-to-surface and surface electromagnetic modeling and inversion in the presence of steel infrastructure. Geophysics 2020, 85, E139–E152. [Google Scholar] [CrossRef]

- Bergmann, P.; Ivandic, M.; Norden, B.; Rücker, C.; Kiessling, D.; Lüth, S.; Schmidt-Hattenberger, C.; Juhlin, C. Combination of Seismic Reflection and Constrained Resistivity Inversion with an Application to 4D Imaging of the CO2 Storage Site, Ketzin, Germany. Geophysics 2014, 79, B37–B50. [Google Scholar] [CrossRef]

- Mulder, W.A. A multigrid solver for 3D electromagnetic diffusion. Geophys. Prospect. 2006, 54, 633–649. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Tan, M.; Yue, J.; Zou, Y.; Wang, B.; Teng, X.; Zhao, H.; Deng, P. Three-Dimensional Numerical Study on Fracturing Monitoring Using Controlled-Source Electromagnetic Method with Borehole Casing. Appl. Sci. 2025, 15, 8312. https://doi.org/10.3390/app15158312

Yang Q, Tan M, Yue J, Zou Y, Wang B, Teng X, Zhao H, Deng P. Three-Dimensional Numerical Study on Fracturing Monitoring Using Controlled-Source Electromagnetic Method with Borehole Casing. Applied Sciences. 2025; 15(15):8312. https://doi.org/10.3390/app15158312

Chicago/Turabian StyleYang, Qinrun, Maojin Tan, Jianhua Yue, Yunqi Zou, Binchen Wang, Xiaozhen Teng, Haoyan Zhao, and Pin Deng. 2025. "Three-Dimensional Numerical Study on Fracturing Monitoring Using Controlled-Source Electromagnetic Method with Borehole Casing" Applied Sciences 15, no. 15: 8312. https://doi.org/10.3390/app15158312

APA StyleYang, Q., Tan, M., Yue, J., Zou, Y., Wang, B., Teng, X., Zhao, H., & Deng, P. (2025). Three-Dimensional Numerical Study on Fracturing Monitoring Using Controlled-Source Electromagnetic Method with Borehole Casing. Applied Sciences, 15(15), 8312. https://doi.org/10.3390/app15158312