Systematic Review on the Use of CCPM in Project Management: Empirical Applications and Trends

Abstract

1. Introduction

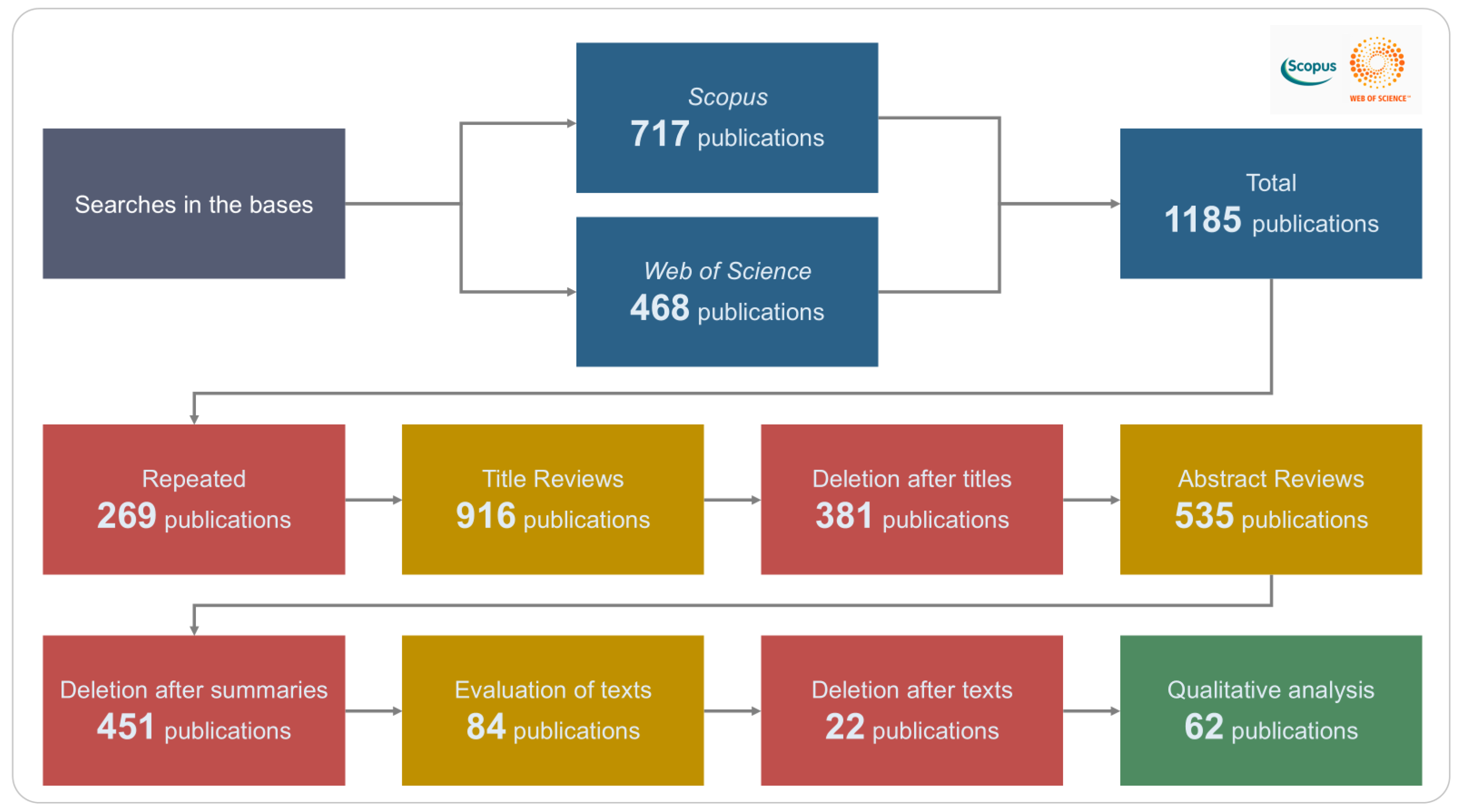

2. Materials and Methods

- (a)

- Repeated articles from different databases.

- (b)

- Articles without at least one of the following terms in the title were excluded: Critical Chain Project Management; CCPM; Critical Chain; TOC; Theory of Constraints; project management; project(s); scheduling; constraints.

- (c)

- Articles not excluded by the previous criteria were read in full. Papers unrelated to the Critical Chain and project management were excluded.

3. Results

4. Discussion

5. Final Considerations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Miranda, S.; Sugarindra, M. Utilizing Project Management Software in Project Scheduling: A Case Study. IOP Conf. Ser. Mater. Sci. Eng. 2019, 528, 012037. [Google Scholar] [CrossRef]

- Azhar, K.; Mortadza, B.; Rizal, A.M. The Roll-Out of Project Management System to Improve Project Progress Reporting. Int. J. Acad. Res. Bus. Soc. Sci. 2024, 14. [Google Scholar] [CrossRef]

- Izmailov, A.; Korneva, D.; Kozhemiakin, A. Corrigendum to Project Management Using the Buffers of Time and Resources. Procedia Soc. Behav. Sci. 2016, 235, 817. [Google Scholar] [CrossRef]

- del Olmo, A.; López de Lacalle, L.N.; Martínez de Pissón, G.; Pérez-Salinas, C.; Ealo, J.A.; Sastoque, L.; Fernandes, M.H. Tool Wear Monitoring of High-Speed Broaching Process with Carbide Tools to Reduce Production Errors. Mech. Syst. Signal Process. 2022, 172, 109003. [Google Scholar] [CrossRef]

- Bahnas, N.; Adel, K.; Khallaf, R.; Elhakeem, A. Monitoring and Controlling Engineering Projects with Blockchain-Based Chain Project Management. Autom. Constr. 2024, 165, 105484. [Google Scholar] [CrossRef]

- Husin, A.E. Time Performance Upgrade by Critical Chain Project Management and BIM 4D Integration on Top Structural Work of a High Rise Building Construction Project. ARPN J. Eng. Appl. Sci. 2019, 14, 3063–3072. [Google Scholar]

- Ariyanti, F.D.; Putri, A.C.; Ningtyas, D.A. Implementation of Lean Construction and Critical Chain Project Management (CCPM) for Waste Management and Work Estimation on the Ciawi Dam Construction Project. In IOP Conference Series: Earth and Environmental Science; Mangindaan, D., Ed.; IOP Publishing Ltd.: Bristol, UK, 2021; Volume 794. [Google Scholar]

- Sinaga, T.; Husin, A.E. Analysis of Time Efficiency with CCPM Method and Bim in Construction Projects Construction of High-Rise Residential Building Basement. Civil. Eng. Archit. 2021, 9, 1465–1477. [Google Scholar] [CrossRef]

- Asgari, H. Buffer Estimation in the Critical Chain Method by Considering Internal and External Risks. Int. J. Adv. Oper. Manag. 2022, 14, 16–30. [Google Scholar] [CrossRef]

- Ghoddousi, P.; Ansari, R.; Makui, A. A Risk-Oriented Buffer Allocation Model Based on Critical Chain Project Management. KSCE J. Civ. Eng. 2017, 21, 1536–1548. [Google Scholar] [CrossRef]

- Tapia, E.; Lopez-Novoa, U.; Sastoque-Pinilla, L.; López-de-Lacalle, L.N. Implementation of a Scalable Platform for Real-Time Monitoring of Machine Tools. Comput. Ind. 2024, 155, 104065. [Google Scholar] [CrossRef]

- Goldratt, E.M. Corrente Crítica; Nobel: São Paulo, Brazil, 1997. [Google Scholar]

- Zhang, T. Methodology for Identifying Key Resources in the Critical Chain of Large-Scale Centralized Photovoltaic Power Plants and Construction Interspersed Modeling. In Proceedings of the 12th International Symposium on Project Management (ISPM2024), Beijing, China, 28–30 June 2024; Aussino Academic Publishing House (AAPH): Riverwood, NSW, Australia, 2024; pp. 427–434. [Google Scholar]

- de Souza, F.B.; de Moraes, A.A.C. Análise Da Aplicação Da Gestão de Projetos Por Corrente Crítica No Processo de Desenvolvimento de Produtos e Na Gestão de Portfólio de Um Fabricante de Aeronaves. Gestão Produção 2016, 23, 473–485. [Google Scholar] [CrossRef]

- Amran, T.G.; Saraswati, D.; Harahap, E.F. Evaluating Storage Tank Cap 10000L Manufacturer by Using Lean Project Management. IOP Conf. Ser. Mater. Sci. Eng. 2019, 528, 012052. [Google Scholar] [CrossRef]

- Jo, S.-H.; Lee, E.-B.; Pyo, K.-Y. Integrating a Procurement Management Process into Critical Chain Project Management (CCPM): A Case-Study on Oil and Gas Projects, the Piping Process. Sustainability 2018, 10, 1817. [Google Scholar] [CrossRef]

- Huihua, X.; Li, W.; Song, X. Research on Software Project Schedule Based on Critical Chain. In Proceedings of the 2019 5th International Conference on Energy Materials and Environment Engineering; IOP Publishing Ltd.: Bristol, UK, 2019; Volume 295. [Google Scholar]

- Sastoque Pinilla, L.; Llorente Rodríguez, R.; Toledo Gandarias, N.; López de Lacalle, L.N.; Ramezani Farokhad, M. TRLs 5–7 Advanced Manufacturing Centres, Practical Model to Boost Technology Transfer in Manufacturing. Sustainability 2019, 11, 4890. [Google Scholar] [CrossRef]

- Makarenko, Y.; Tereshchenko, S.; Metelenko, N.G.; Mykolenko, I.H.; Oliinyk, A.S. Strategic Risks Management in Implementation of It Projects. Acad. Strateg. Manag. J. 2019, 18. [Google Scholar]

- Cooper Ordonez, R.E.; Vanhoucke, M.; Coelho, J.; Anholon, R.; Novaski, O. A Study of the Critical Chain Project Management Method Applied to a Multiproject System. Proj. Manag. J. 2019, 50, 322–334. [Google Scholar] [CrossRef]

- Luiz, O.R.; de Souza, F.B.; Rojas Luiz, J.V.; Jugend, D.; Salgado, M.H.; da Silva, S.L. Impact of Critical Chain Project Management and Product Portfolio on New Product Development Performance. J. Bus. Ind. Mark. 2019, 34, 1692–1705. [Google Scholar] [CrossRef]

- Cruz Villazón, C.; Sastoque Pinilla, L.; Otegi Olaso, J.R.; Toledo Gandarias, N.; López de Lacalle, N. Identification of Key Performance Indicators in Project-Based Organisations through the Lean Approach. Sustainability 2020, 12, 5977. [Google Scholar] [CrossRef]

- Ma, G.; Wu, M.; Hao, K.; Shang, S. A DSM-Based CCPM-MPL Representation Method for Project Scheduling under Rework Scenarios. Adv. Civ. Eng. 2021, 2021. [Google Scholar] [CrossRef]

- Mathew, N.T.; Johansson, B. Production Planning and Scheduling Challenges in the Engineer-to-Order Manufacturing Segment—A Literature Study. Int. J. Innov. Manag. Technol. 2023, 14, 80–87. [Google Scholar] [CrossRef]

- Khan, K.S.; Kunz, R.; Kleijnen, J.; Antes, G. Five Steps to Conducting a Systematic Review. J. R. Soc. Med. 2003, 96, 118–121. [Google Scholar] [CrossRef] [PubMed]

- Tenera, A.; Rosas, J. Collaborative Networks Management from a Theory of Constraints. In Collaborative Networks and Digital Transformation; CamarinhaMatos, L.M., Afsarmanesh, H., Antonelli, D., Eds.; Springer International Publishing AG: Cham, Switzerland, 2019; pp. 271–282. [Google Scholar]

- Moradi, H.; Shadrokh, S. A Robust Scheduling for the Multi-Mode Project Scheduling Problem with a given Deadline under Uncertainty of Activity Duration. Int. J. Prod. Res. 2019, 57, 3138–3167. [Google Scholar] [CrossRef]

- Ma, C.; Hu, W.; Deng, Y. Application of Improved Critical Chain and Earned Value Technique in Software Engineering & Integrated Project Progress Control. In Proceedings of the 2019 IEEE 9th Symposium on Computer Applications & Industrial Electronics (ISCAIE), Kota Kinabalu, Malaysia, 27–28 April 2019; IEEE: New York, NY, USA, 2019; pp. 136–142. [Google Scholar]

- Salama, T.; Moselhi, O. Multi-Objective Optimization for Repetitive Scheduling under Uncertainty. Eng. Constr. Archit. Manag. 2019, 26, 1294–1320. [Google Scholar] [CrossRef]

- Hu, X.; Wang, J.; Leng, K. The Interaction Between Critical Chain Sequencing, Buffer Sizing, and Reactive Actions in a CC/BM Framework. ASIA-Pac. J. Oper. Res. 2019, 36, 1950010. [Google Scholar] [CrossRef]

- Polonski, M. Calculation of the Auxiliary Buffers Time with Regard to the robustness of the Construction Schedule to Disruption. In Proceedings of the 64th Scientific Conference of the Committee for Civil Engineering of the Polish Academy of Sciences and the Science Committee of the Polish Association of Civil Engineers (PZITB) (KRYNICA 2018); Wilde, K., Niedostatkiewicz, M., Eds.; EDP Sciences: Les Ulis, France, 2019; Volume 262. [Google Scholar]

- Zarghami, S.A.; Gunawan, I.; de Zubielqui, G.C.; Baroudi, B. Incorporation of Resource Reliability into Critical Chain Project Buffer Sizing. Int. J. Prod. Res. 2020, 58, 6130–6144. [Google Scholar] [CrossRef]

- Sembiring, N.; Putra, A. Scheduling Evaluation in Construction Projects Using the Critical Chain Management Method. In Proceedings of the International Conference on Innovation in Engineering and Vocational Education 2019 (ICIEVE 2019), PTS 1–4, Chicago, IL, USA, 12–16 October 2025; Abdullah, A.G., Suhartanto, D., Widiaty, I., Aviasti, A.I.H., Usman, D.N., Nugraha, R.P.T.D., Warouw, F.F., Basyarudin, N.C., Eds.; IOP Publishing Ltd.: Bristol, UK, 2020; Volume 830. [Google Scholar]

- Putra, R.M.; Rembulan, G.D.; Tannady, H. Construction Project Evaluation Using CPM-Crashing, CPM-PERT and CCPM for Minimize Project Delays. In Journal of Physics: Conference Series; Rahim, R., Null, M., Null, S., Watrianthos, R., Hutahean, J., Eds.; IOP Publishing Ltd.: Bristol, UK, 2021; Volume 1933. [Google Scholar]

- Sarkar, D.; Jha, K.N.; Patel, S. Critical Chain Project Management for a Highway Construction Project with a Focus on Theory of Constraints. Int. J. Constr. Manag. 2021, 21, 194–207. [Google Scholar] [CrossRef]

- She, B.; Chen, B.; Hall, N.G. Buffer Sizing in Critical Chain Project Management by Network *. Omega-Int. J. Manag. Sci. 2021, 102, 102382. [Google Scholar] [CrossRef]

- Salama, T.; Salah, A.; Moselhi, O. Integrating Critical Chain Project Management with Last Planner system for Linear Scheduling of Modular Construction. Constr. Innov.-Engl. 2021, 21, 525–554. [Google Scholar] [CrossRef]

- Kulejewski, J.; Ibadov, N.; Roslon, J.; Zawistowski, J. Cash Flow Optimization for Renewable Energy Construction Projects with a New Approach to Critical Chain Scheduling. Energies 2021, 14, 5795. [Google Scholar] [CrossRef]

- Petroutsatou, K. A Proposal of Project Management Practices in Public Institutions through a Comparative Analyses of Critical Path Method and Critical Chain. Int. J. Constr. Manag. 2022, 22, 242–251. [Google Scholar] [CrossRef]

- Peng, J.; Peng, C. Buffer Sizing in Critical Chain Project Management by Brittle Risk Entropy. Buildings 2022, 12, 1390. [Google Scholar] [CrossRef]

- Li, H.; Cao, Y.; Lin, Q.; Zhu, H. Data-Driven Project Buffer Sizing in Critical Chains. Autom. Constr. 2022, 135, 104134. [Google Scholar] [CrossRef]

- Ansari, R.; Khalilzadeh, M.; Hosseini, M.R. A Multi-Objective Dynamic Optimization Approach to Project Schedule: A Case Study of a Gas Field Construction. KSCE J. Civ. Eng. 2022, 26, 1005–1013. [Google Scholar] [CrossRef]

- Anastasiu, L.; Campian, C.; Roman, N. Boosting Construction Project Timeline: The Case of Critical Chain Management (CCPM). Buildings 2023, 13, 1249. [Google Scholar] [CrossRef]

- Zhang, J.; Han, Q. Buffer Monitoring of Critical Chain Projects Based on Support Vector Prediction. KSCE J. Civ. Eng. 2023, 27, 2745–2755. [Google Scholar] [CrossRef]

- Peng, W.; Lin, X.; Li, H. Critical Chain Based Proactive-Reactive Scheduling for Resource-Constrained Project Scheduling Under Uncertainty. Expert Syst. Appl. 2023, 214, 119188. [Google Scholar] [CrossRef]

- Marek-Kołodziej, K.; Łapuńka, I. Determining a Fuzzy Model of Time Buffer Size in Critical Chain Project Management. Eng. Manag. Prod. Serv. 2024, 16, 41–55. [Google Scholar] [CrossRef]

- Mohamed Meabed, E.S.; Mahfouz, S.Y.; Alhady, A. Modified Critical Chain Scheduling for Construction Projects. HBRC J. 2025, 21, 127–143. [Google Scholar] [CrossRef]

- Zhang, J.; Song, X.; Díaz, E. Project Buffer Sizing of a Critical Chain Based on Comprehensive Resource Tightness. Eur. J. Oper. Res. 2016, 248, 174–182. [Google Scholar] [CrossRef]

- Hu, X.; Cui, N.; Demeulemeester, E.; Bie, L. Incorporation of Activity Sensitivity Measures into Buffer Management to Manage Project Schedule Risk. Eur. J. Oper. Res. 2016, 249, 717–727. [Google Scholar] [CrossRef]

- Wang, W.-X.; Wang, X.; Ge, X.-L.; Deng, L. Multi-Objective Optimization Model for Multi-Project Scheduling on Critical Chain. Adv. Eng. Softw. 2014, 68, 33–39. [Google Scholar] [CrossRef]

- Taheri Amiri, M.J.; Haghighi, F.R.; Eshtehardian, E.; Abessi, O. Multi-Project Time-Cost Optimization in Critical Chain with Resource Constraints. KSCE J. Civ. Eng. 2018, 22, 3738–3752. [Google Scholar] [CrossRef]

- Hutanu, A.; Prostean, G.; Badea, A. Integrating Critical Chain Method with AGILE Life Cycles in the automotive Industry. Procedia-Soc. Behav. Sci. 2015, 197, 1416–1421. [Google Scholar] [CrossRef]

- Petrochenko, M.V.; Velichkin, V.Z.; Kazakov, Y.N.; Zavodnova, Y.B. Reliability Assessment of the Construction Schedule by the Critical Chain Method. Mag. Civil. Eng. 2018, 81, 25–31. [Google Scholar] [CrossRef]

- Ghaffari, M.; Emsley, M.W. The Boundary between Good and Bad Multitasking in CCPM. J. Mod. Proj. Manag. 2016, 4, 105–110. [Google Scholar]

- Wang, D.; Li, X.; Fang, B.; Chou, J. Robust Optimization Model of Project Scheduling Problem Based on Genetic. In Proceedings of the 2016 3rd International Conference on Materials Engineering, Manufacturing Technology and Control; Ma, B., Zhou, D., Eds.; Atlantis Press: Paris, France, 2016; Volume 67, pp. 1455–1461. [Google Scholar]

- Cheng, P.; Liang, S. The Analysis of Bank Mobile Payment Project’s Schedule Management Based on Improved Critical Chain Method. In Proceedings of the 2nd International Symposium on Business Corporation and Development in South-East and South Asia Under B&R Initiative (ISBCD 2017); Fu, R., Liu, E., Zhong, C., Fei, Y., Zhu, L., Duan, Y., Zhang, Y., Eds.; Atlantis Press: Paris, France, 2017; Volume 42, pp. 20–24. [Google Scholar]

- Mansoorzadeh, S.; Yusof, S.M.; Mansoorzadeh, S.; Zeynal, H. A Comprehensive and Practical Framework for Reliable Scheduling in Project Management. Adv. Mat. Res. 2014, 903, 378–383. [Google Scholar] [CrossRef]

- Kulkarni, A.; Yadav, D.K.; Nikraz, H. Aircraft Maintenance Checks Using Critical Chain Project Path. Aircr. Eng. Aerosp. Technol. 2017, 89, 879–892. [Google Scholar] [CrossRef]

- Apaolaza, U.; Lizarralde, A. Comprehensive Reorganization of Project Management: A Case Study. In Project Management and Engineering Research, AEIPRO 2016; Munoz, J.L.A., Blanco, J.L.Y., CapuzRizo, S.F., Eds.; Springer International Publishing AG: Cham, Switzerland, 2017; pp. 3–17. [Google Scholar]

- Zhang, J.; Song, X.; Díaz, E. Critical Chain Project Buffer Sizing Based on Resource Constraints. Int. J. Prod. Res. 2017, 55, 671–683. [Google Scholar] [CrossRef]

- Iranmanesh, H.; Mansourian, F.; Kouchaki, S. Critical Chain Scheduling: A New Approach for Feeding Buffer Sizing. Int. J. Oper. Res. 2016, 25, 114–130. [Google Scholar] [CrossRef]

- De Souza, F.B.; De Moraes, A.A.C. Analysis of the Application of Critical Chain Project Management in the Product Development Process and Portfolio Management of an Aircraft Manufacturer. Gest. E Prod. 2016, 23, 473–485. [Google Scholar] [CrossRef]

- Zhang, J.; Jia, S.; Diaz, E. Dynamic Monitoring and Control of a Critical Chain Project Based on Phase Buffer Allocation. J. Oper. Res. Soc. 2018, 69, 1966–1977. [Google Scholar] [CrossRef]

- Su, Y.; Lucko, G.; Thompson, R.C. Evaluating Performance of Critical Chain Project Management to Mitigate Delays Based on Different Schedule Network Complexities. In Proceedings of the Proceedings Winter Simulation Conference, Washington, DC, USA, 11–14 December 2016; pp. 3314–3324. [Google Scholar]

- Yang, S.-M.; Liu, Y.-C.; Yen, T.-Y. Integration of Fuzzy Logic and QFD for Critical Chain in Project Scheduling with Uncertainties. In Proceedings of the 2018 International Conference on System Science and Engineering ICSSE 2018, New Taipei, Taiwan, 28–30 June 2018. [Google Scholar]

- Ma, G.; Gu, L.; Li, N. Scenario-Based Proactive Robust Optimization for Critical-Chain Project Scheduling. J. Constr. Eng. Manag. 2015, 141, 04015030. [Google Scholar] [CrossRef]

- Gwiazda, A.; Paprocka, I.; Baczkowicz, M. Estimation of the Resource Buffers in the Assembly Process of a Shearer Machine in the CPPM Method. Matec Web Conf. 2017, 94, 06012. [Google Scholar] [CrossRef]

- Paprocka, I.; Gwiazda, A.; Bączkowicz, M. Scheduling of an Assembly Process of a Chosen Technical Mean Using the Critical Chain Approach. MATEC Web Conf. 2017, 94, 06015. [Google Scholar] [CrossRef]

- Chen, H.-Y.; Xu, L.; Zhang, C.-S. Project Duration Risk Transmission and Control Based on CCPM. Res. J. Appl. Sci. Eng. Technol. 2014, 7, 619–624. [Google Scholar] [CrossRef]

- Hu, X.; Demeulemeester, E.; Cui, N.; Wang, J.; Tian, W. Improved Critical Chain Buffer Management Framework Considering Resource Costs and Schedule Stability. Flex. Serv. Manuf. J. 2017, 29, 159–183. [Google Scholar] [CrossRef]

- Salama, T.; Salah, A.; Moselhi, O. Integration of Linear Scheduling Method and the Critical Chain Project Management. Can. J. Civ. Eng. 2018, 45, 30–40. [Google Scholar] [CrossRef]

- Ansari, R.; Makui, A.; Ghoddousi, P. An Algorithmic Framework for Improving the Performance of the Critical Chain Buffer Sizing Method. Sci. Iran. 2018, 25, 74–92. [Google Scholar] [CrossRef]

- Zhang, A.L.; Geng, T.T. Study on the Schedule Management Methods of Projects Based on Critical Chain Technology. Appl. Mech. Mater. 2014, 488–489, 1454–1457. [Google Scholar] [CrossRef]

- Ghazvini, M.S.; Ghezavati, V.; Raissi, S.; Makui, A. An Integrated Efficiency-Risk Approach in Sustainable Project Control. Sustainability 2017, 9, 1575. [Google Scholar] [CrossRef]

- Zhang, J.; Song, X.; Díaz, E. Buffer Sizing of Critical Chain Based on Attribute Optimization. Concurr. Eng. Res. Appl. 2014, 22, 253–264. [Google Scholar] [CrossRef]

- Sastoque-Pinilla, L.; Artelt, S.; Burimova, A.; Lopez de Lacalle, N.; Toledo-Gandarias, N. Project Success Criteria Evaluation for a Project-Based Organization and Its Stakeholders—A Q-Methodology Approach. Appl. Sci. 2022, 12, 11090. [Google Scholar] [CrossRef]

| Author and Year of Publication | Application | Method | Study Objective |

|---|---|---|---|

| Makarenko et al., 2019 [19] | IT projects | Modeling and Simulation | Risk reduction and monitoring |

| Husin, 2019 [6] | Construction | Case Study | Reduction in project time |

| Cooper Ordonez et al., 2019 [20] | Manufacturing industry | Action Research | Reduction in project time |

| Tenera & Rosas, 2019 [26] | No application | Theoretical Study | Risk reduction and monitoring |

| Luiz et al., 2019 [21] | Manufacturing industry | Survey | Reduction in project time |

| Moradi & Shadrokh, 2019 [27] | No application | Modeling and Simulation | Reduction in project time |

| Ma et al., 2019 [28] | No application | Theoretical Study | Risk reduction and monitoring |

| Salama & Moselhi, 2019 [29] | No application | Modeling and Simulation | Cost reduction |

| Huihua et al., 2019 [17] | IT projects | Modeling and Simulation | Reduction in project time |

| Hu et al., 2019 [30] | No application | Modeling and Simulation | Risk reduction and monitoring |

| Polonski, 2019 [31] | No application | Modeling and Simulation | Reduction in project time |

| Zarghami et al., 2020 [32] | No application | Modeling and Simulation | Risk reduction and monitoring |

| Sembiring et al., 2020 [33] | Construction | Modeling and Simulation | Reduction in project time |

| Ariyanti et al., 2021 [7] | Construction | Design Science Research | Risk reduction and monitoring |

| Putra et al., 2021 [34] | No application | Modeling and Simulation | Reduction in project time |

| Sinaga et al., 2021 [8] | No application | Modeling and Simulation | Risk reduction and monitoring |

| Sarkar et al., 2021 [35] | No application | Modeling and Simulation | Reduction in project time |

| She et al., 2021 [36] | Construction | Case Study | Cost reduction |

| Salama et al., 2021 [37] | Energy industry | Modeling and Simulation | Reduction in project time |

| Ma et al., 2021 [23] | No application | Modeling and Simulation | Reduction in project time |

| Kulejewski et al., 2021 [38] | Construction | Modeling and Simulation | Reduction in project time |

| Asgari, 2022 [9] | Construction | Modeling and Simulation | Reduction in project time |

| Petroutsatou, 2022 [39] | No application | Modeling and Simulation | Reduction in project time |

| Peng & Peng, 2022 [40] | Energy industry | Modeling and Simulation | Risk reduction and monitoring |

| Li et al., 2022 [41] | No application | Modeling and Simulation | Risk reduction and monitoring |

| Ansari et al., 2022 [42] | No application | Modeling and Simulation | Reduction in project time |

| Anastasiu et al., 2023 [43] | No application | Modeling and Simulation | Risk reduction and monitoring |

| Zhang & Han, 2023 [44] | Energy industry | Case Study | Risk reduction and monitoring |

| Peng et al., 2023 [45] | Construction | Modeling and Simulation | Risk reduction and monitoring |

| Marek & Łapuńka, 2024 [46] | Construction | Modeling and Simulation | Risk reduction and monitoring |

| Bahnas et al., 2024 [5] | Construction | Modeling and Simulation | Reduction in project time |

| Mohamed et al., 2025 [47] | Construction | Case Study | Reduction in project time |

| Zhang et al. [48] | No application | Modeling and Simulation | Reduction in project time |

| Hu et al. [49] | No application | Modeling and Simulation | Risk reduction and monitoring |

| Wang et al. [50] | No application | Modeling and Simulation | Reduction in project time |

| Amiri et al. [51] | Construction | Modeling and Simulation | Cost reduction |

| Ghoddousi et al. [10] | Construction | Modeling and Simulation | Risk reduction and monitoring |

| Hutanu et al. [52] | IT projects | Theoretical Study | Reduction in project time |

| Petrochenko et al. [53] | Construction | Modeling and Simulation | Risk reduction and monitoring |

| Ghaffari et al. [54] | No application | Modeling and Simulation | Reduction in project time |

| Wang et al. [55] | No application | Modeling and Simulation | Risk reduction and monitoring |

| Cheng and Liang [56] | IT projects | Case Study | Reduction in project time |

| Mansoorzadeh et al. [57] | Energy industry | Case Study | Risk reduction and monitoring |

| Kulkarni et al. [58] | Aircraft maintenance | Case Study | Reduction in project time |

| Apaolaza and Lizarralde [59] | Manufacturing industry | Case Study | Reduction in project time |

| Zhang et al. [60] | No application | Modeling and Simulation | Risk reduction and monitoring |

| Iranmanesh et al. [61] | No application | Modeling and Simulation | Risk reduction and monitoring |

| Souza and Moraes [62] | Aircraft industry | Case Study | Reduction in project time |

| Zhang et al. [63] | No application | Modeling and Simulation | Risk reduction and monitoring |

| Su et al. [64] | Construction | Modeling and Simulation | Risk reduction and monitoring |

| Yang et al. [65] | No application | Modeling and Simulation | Risk reduction and monitoring |

| Ma et al. [66] | Construction | Modeling and Simulation | Risk reduction and monitoring |

| Gwiazda et al. [67] | Manufacturing industry | Case Study | Reduction in project time |

| Paprocka et al. [68] | Manufacturing industry | Case Study | Reduction in project time |

| Hong-Yi et al. [69] | No application | Theoretical Study | Risk reduction and monitoring |

| Hu et al. [70] | No application | Modeling and Simulation | Risk reduction and monitoring |

| Salama et al. [71] | Construction | Modeling and Simulation | Reduction in project time |

| Ansari et al. [72] | Construction | Modeling and Simulation | Risk reduction and monitoring |

| Zhang and Geng [73] | No application | Theoretical Study | Risk reduction and monitoring |

| Ghazvini et al. [74] | Sustainable projects | Case Study | Risk reduction and monitoring |

| Jo et al. [16] | Oil and gas projects | Case Study | Reduction in project time |

| Zhang et al. [75] | No application | Modeling and Simulation | Risk reduction and monitoring |

| Year of Publication | Number of Texts Evaluated |

|---|---|

| 2014 | 5 |

| 2015 | 2 |

| 2016 | 8 |

| 2017 | 8 |

| 2018 | 7 |

| 2019 | 11 |

| 2020 | 2 |

| 2021 | 8 |

| 2022 | 5 |

| 2023 | 3 |

| 2024 | 2 |

| 2025 | 1 |

| Research Method | Quantity |

|---|---|

| Modeling and simulation | 41 |

| Case study | 13 |

| Theoretical study | 5 |

| Design science research | 1 |

| Action research | 1 |

| Survey | 1 |

| Application | Study Objective | ||

|---|---|---|---|

| Cost Reduction | Reduction in Project Time | Risk Reduction and Monitoring | |

| Construction | 1 | 6 | 3 |

| Road construction | - | - | 1 |

| Energy industry | - | 1 | 2 |

| IT projects | - | 3 | 1 |

| Manufacturing industry | - | 5 | - |

| No application | 1 | 10 | 17 |

| Aircraft maintenance | - | 1 | - |

| Oil and gas projects | - | 1 | - |

| Sustainable projects | - | - | 1 |

| Aircraft manufacturing | - | 1 | - |

| Total | 3 | 29 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Oliveira Martins, A.; Benetti, V.G.; dos Anjos, F.E.V.; da Silva, D.O.; Alves, C.J.R. Systematic Review on the Use of CCPM in Project Management: Empirical Applications and Trends. Appl. Sci. 2025, 15, 8147. https://doi.org/10.3390/app15158147

de Oliveira Martins A, Benetti VG, dos Anjos FEV, da Silva DO, Alves CJR. Systematic Review on the Use of CCPM in Project Management: Empirical Applications and Trends. Applied Sciences. 2025; 15(15):8147. https://doi.org/10.3390/app15158147

Chicago/Turabian Stylede Oliveira Martins, Adriano, Vanderlei Giovani Benetti, Fernando Elemar Vicente dos Anjos, Débora Oliveira da Silva, and Charles Jefferson Rodrigues Alves. 2025. "Systematic Review on the Use of CCPM in Project Management: Empirical Applications and Trends" Applied Sciences 15, no. 15: 8147. https://doi.org/10.3390/app15158147

APA Stylede Oliveira Martins, A., Benetti, V. G., dos Anjos, F. E. V., da Silva, D. O., & Alves, C. J. R. (2025). Systematic Review on the Use of CCPM in Project Management: Empirical Applications and Trends. Applied Sciences, 15(15), 8147. https://doi.org/10.3390/app15158147