Design and Validation of an Edge-AI Fire Safety System with SmartThings Integration for Accelerated Detection and Targeted Suppression

Abstract

1. Introduction

2. Materials and Methods

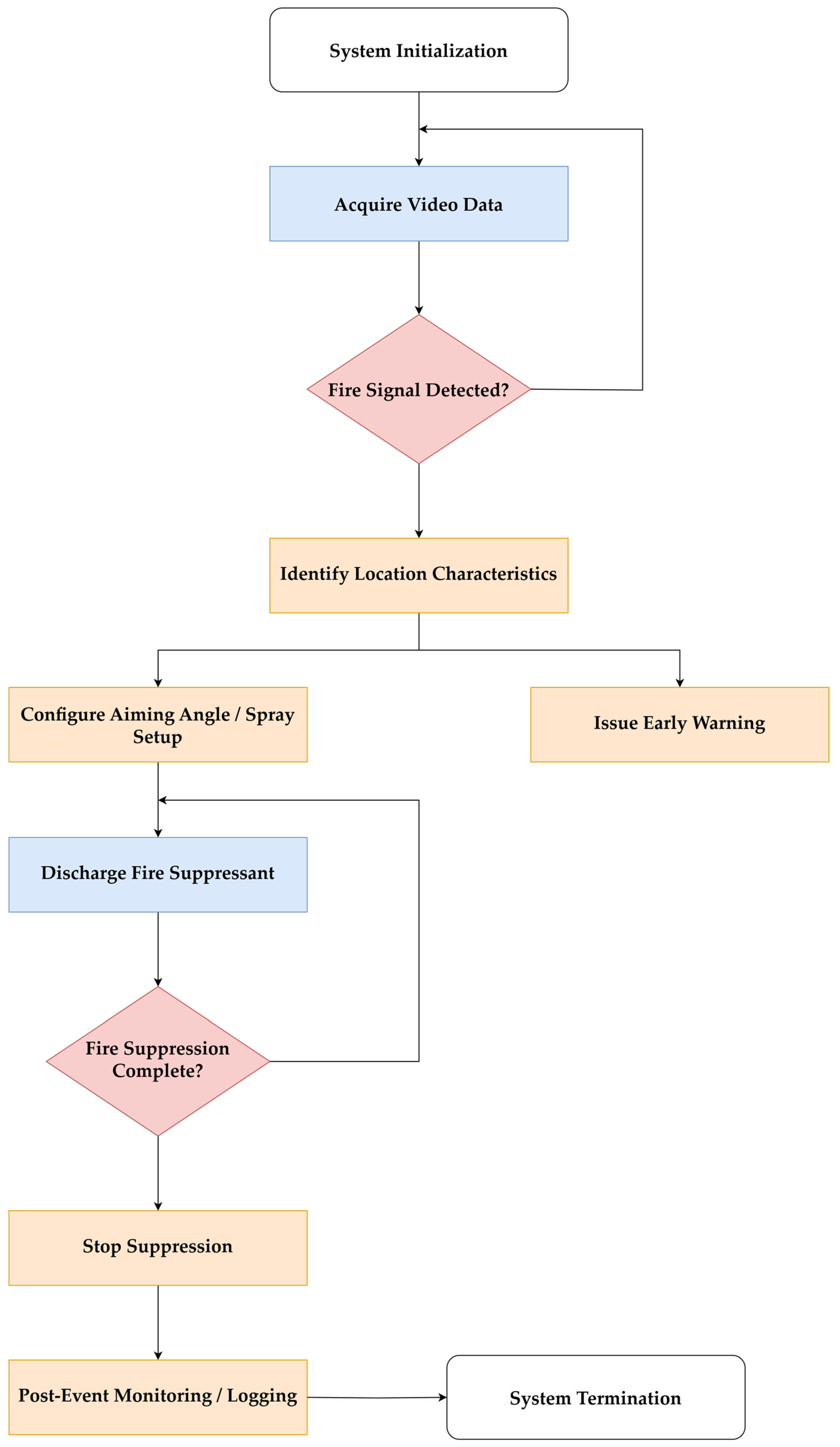

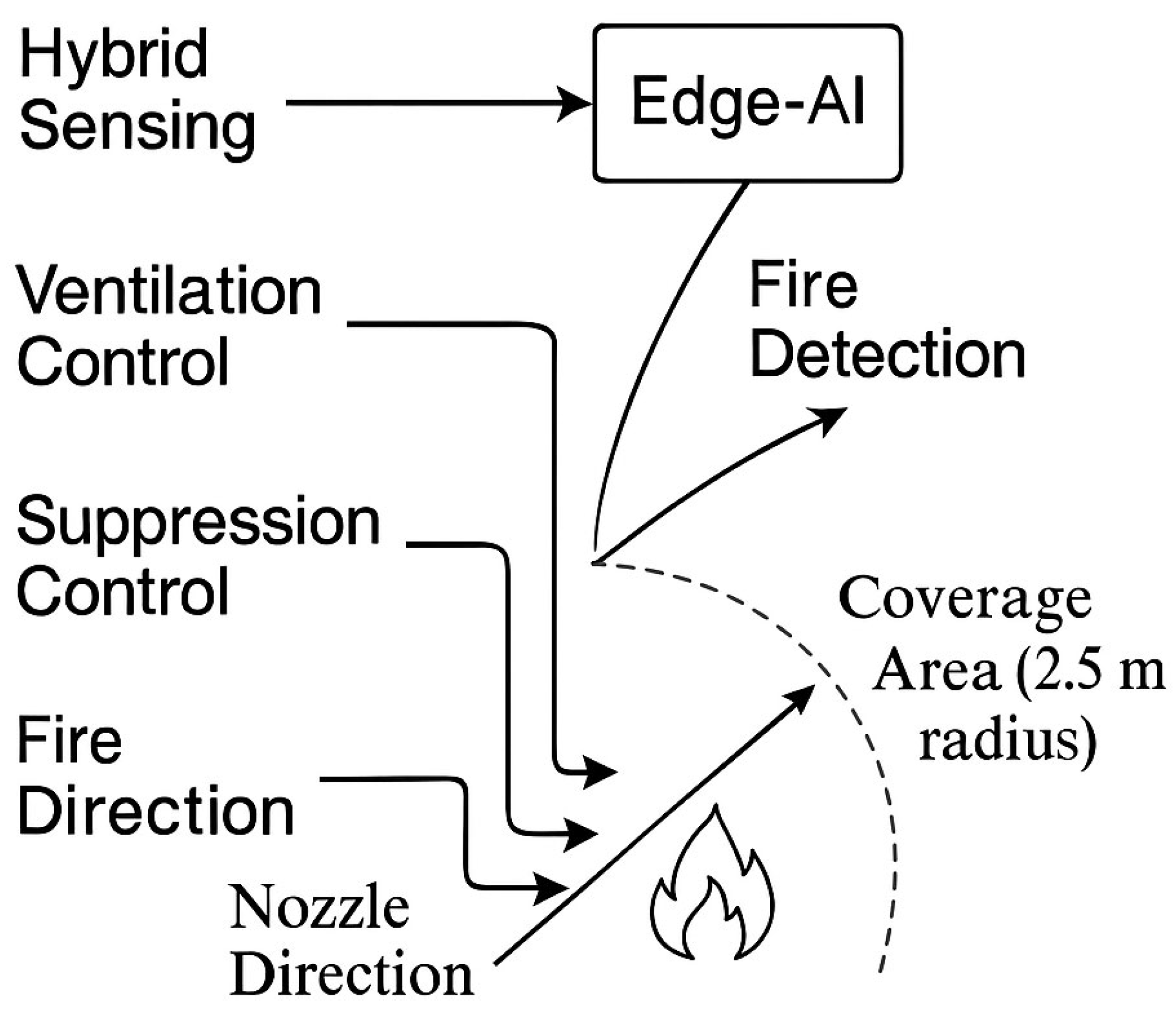

2.1. System Architecture Overview

2.2. Global Context Fusion Strategy

- Flexibility in Context Modeling: Existing methods (e.g., Swin Transformer, Global Context Pooling, Criss-Cross Attention) rely on predefined window structures or axis-aligned static attention mechanisms. In contrast, the GCF module dynamically infers global trends from real-time sensor inputs and responds immediately to local anomalies. This makes it highly effective for modeling nonlinear and uneven heat/smoke diffusion patterns typical in fire events.

- Optimization for Embedded Deployment: Prior methods often depend on high-performance GPUs and exhibit high computation and memory demands. GCF leverages a lightweight sensor-driven spatial encoder and localized computation, enabling robust real-time operation on edge platforms. This removes reliance on external servers and avoids communication delays—an essential distinction from existing solutions.

- Real-Time Fusion Responsiveness: GCF is designed for high-frequency decision-making, enabling multiple inferences per second. This temporal sensitivity is critical for mitigating fire spread. Pooling-based GCP or fixed-window approaches operate on static intervals and may fail to respond promptly to fast-evolving hazards.

- Application Context Suitability: Unlike prior techniques focused on general image understanding (e.g., semantic segmentation, salient object detection), the GCF module is structurally aligned with intelligent firefighting systems. It explicitly integrates environmental architecture (e.g., ventilation, nozzle directionality) into its spatial modeling, supporting actionable decisions in fire scenarios.

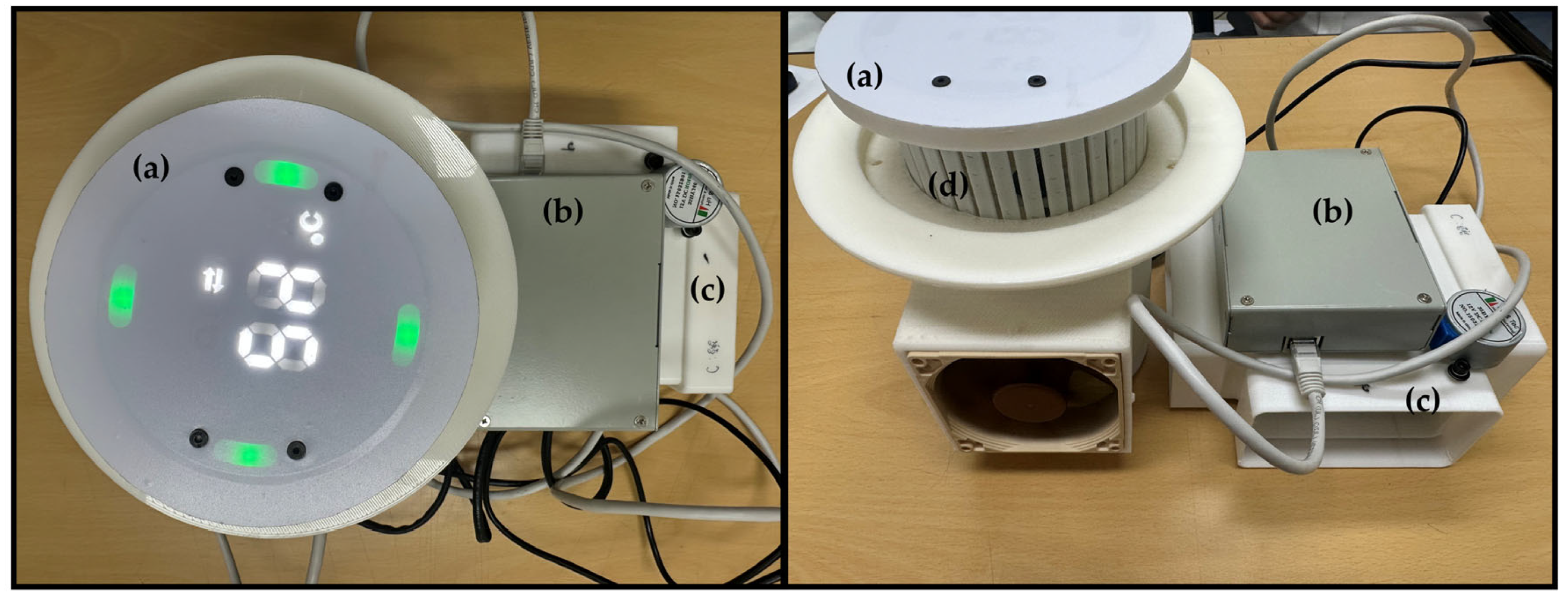

2.3. Hybrid Sensor Design and Edge AI Detection

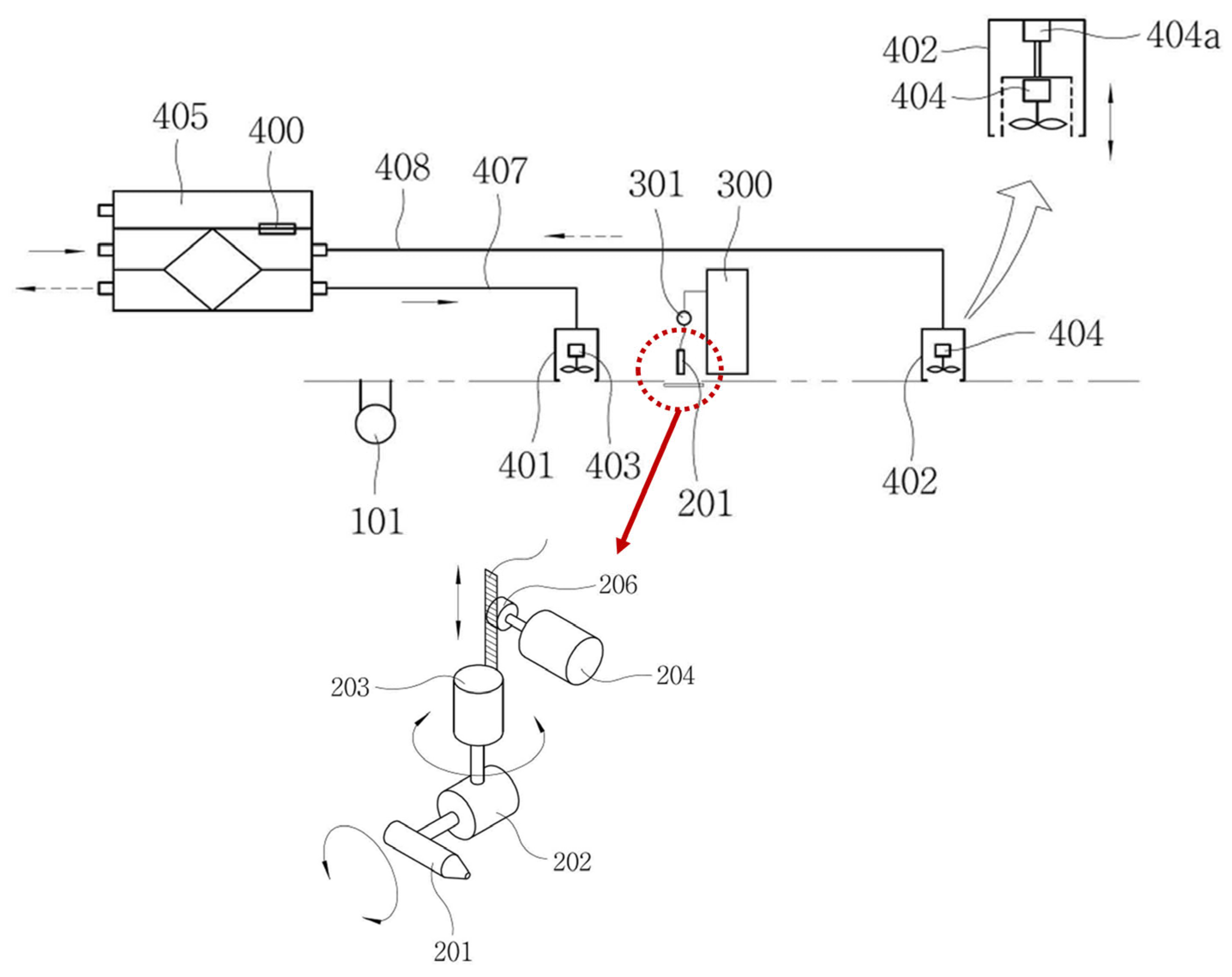

2.4. Smart Ventilation and Suppression Mechanism

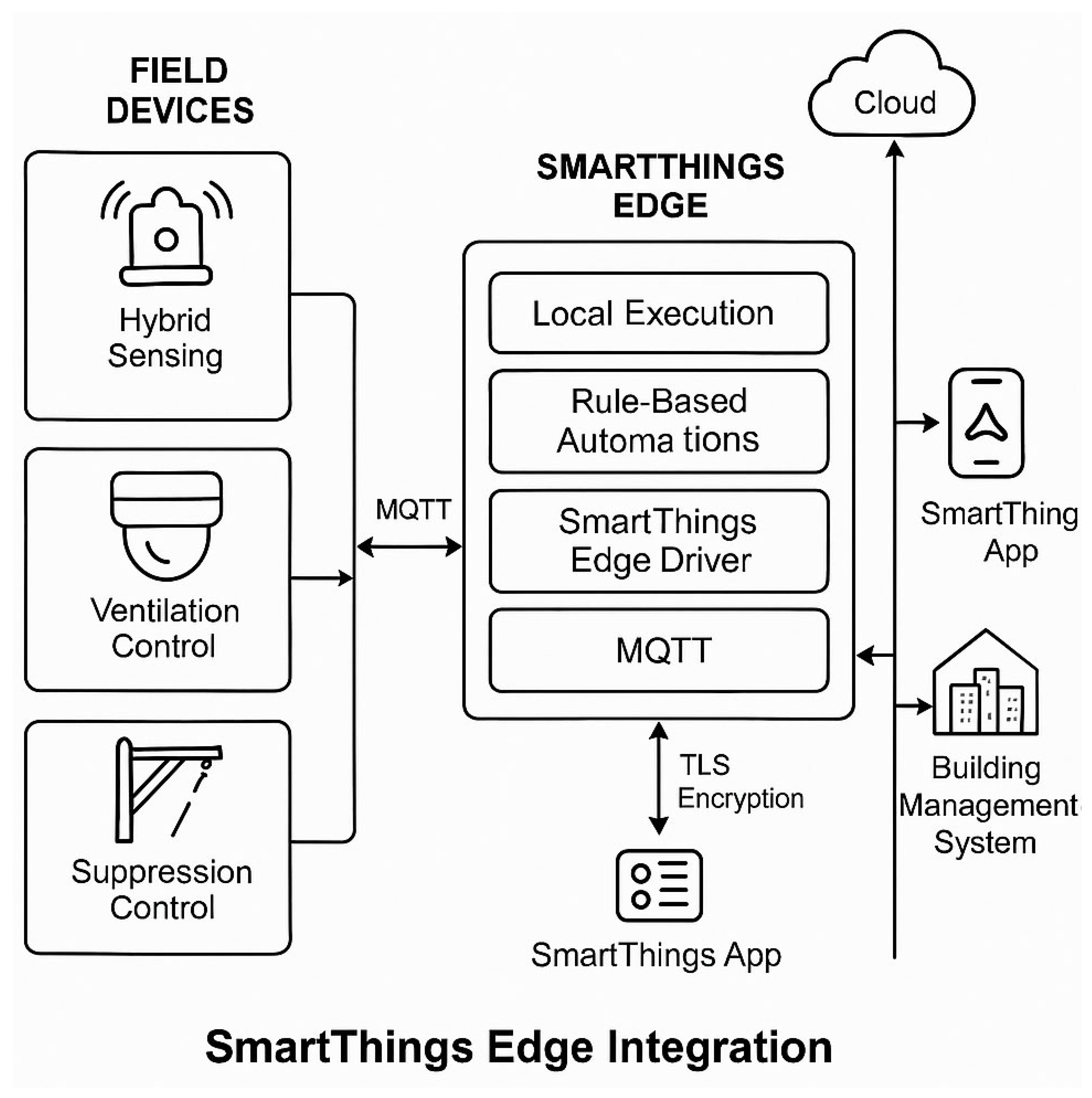

2.5. SmartThings Edge Integration and Data Flow

- Intra-system control loop: Real-time command dissemination between the detection unit, actuator modules, and SmartThings Edge hub to ensure synchronized mechanical response.

- User notification layer: Instantaneous push alerts are transmitted to registered mobile devices via the SmartThings app, accompanied by dynamic status dashboards that visualize event progress, device state, and manual override options.

- BMS/BAS interoperability: A custom-developed SmartThings-to-BMS bridge exposes key system metrics to legacy BACnet or Modbus systems through RESTful API endpoints and virtual device mirroring. This allows centralized facility managers to receive alarms, trend logs, and maintenance diagnostics in their existing interfaces without additional hardware.

2.6. Risk Assessment Framework (ISO 31000 and NFPA 551)

- Likelihood was derived from historical fire incident data and simulated detection delay distributions;

- Consequence was estimated through scenario-based analysis considering occupant egress time, smoke spread dynamics, property exposure, and system response duration.

- Life Safety Impact (e.g., delayed evacuation, toxic smoke exposure);

- Asset Loss Impact (e.g., fire propagation, collateral water damage);

- Business Disruption Impact (e.g., downtime duration, equipment loss).

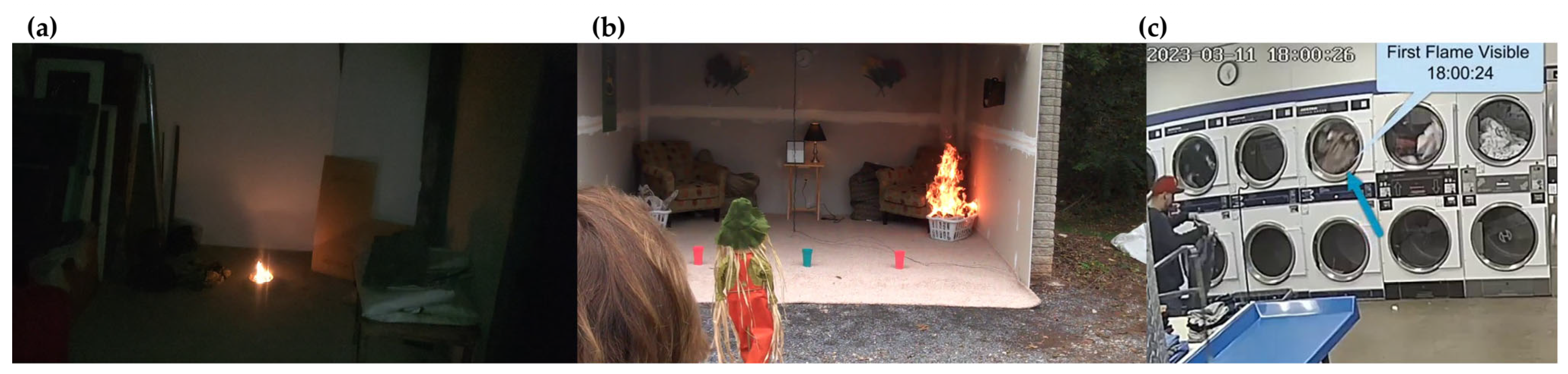

2.7. Experimental Setup and Evaluation Metrics

- Detection Time (s): Time elapsed from ignition to verified fire classification by the edge AI sensor.

- Ventilation Activation Time (s): Delay between fire detection and full deployment of motorized ceiling diffusers.

- Smoke Clearance Time (s): Time required to reduce visible smoke concentration below 10% optical density using ERV extraction.

- Suppression Duration (s): Time from nozzle discharge initiation to full flame extinguishment.

- False Alarm Rate (%): Incidence of non-fire events triggering suppression or ventilation.

- Power Consumption (W): Total energy usage by the sensing, actuation, and communication subsystems during active operation.

- System Uptime (%): Operational reliability under network-disrupted conditions using edge-only fallback control.

3. Results

3.1. System Performance Evaluation

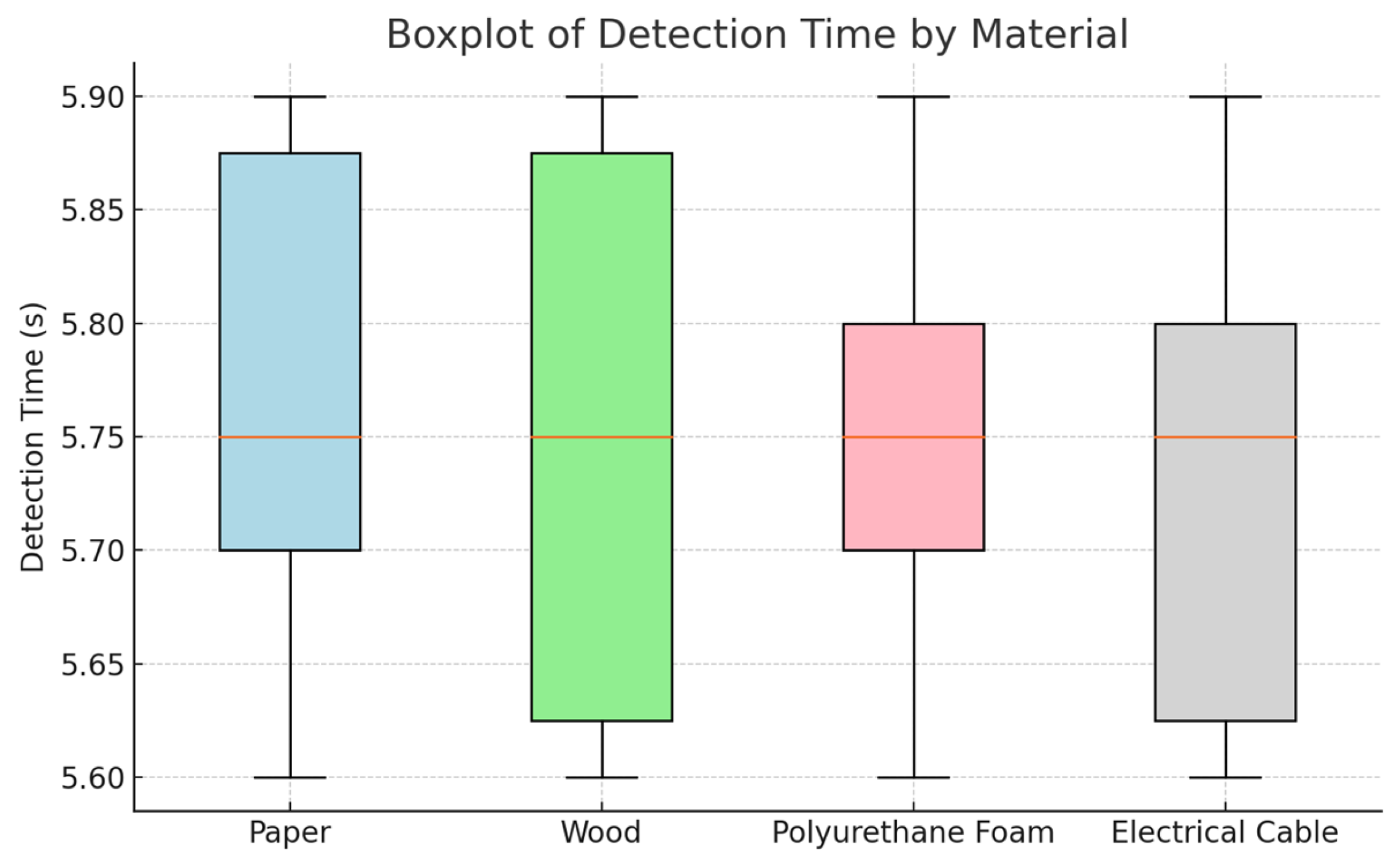

3.1.1. Fire Detection Responsiveness

3.1.2. Ventilation and Smoke Extraction Efficiency

3.1.3. Suppression Accuracy and Coverage

3.1.4. False Alarm and Environmental Robustness

3.1.5. Comparative Evaluation of Functional, Thermal, and Economic Performance Indicators

3.2. Risk Reduction Outcomes

3.2.1. Life Safety and Evacuation Improvement

3.2.2. Property and Business Continuity Benefits

3.2.3. Composite Risk Score Comparison

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

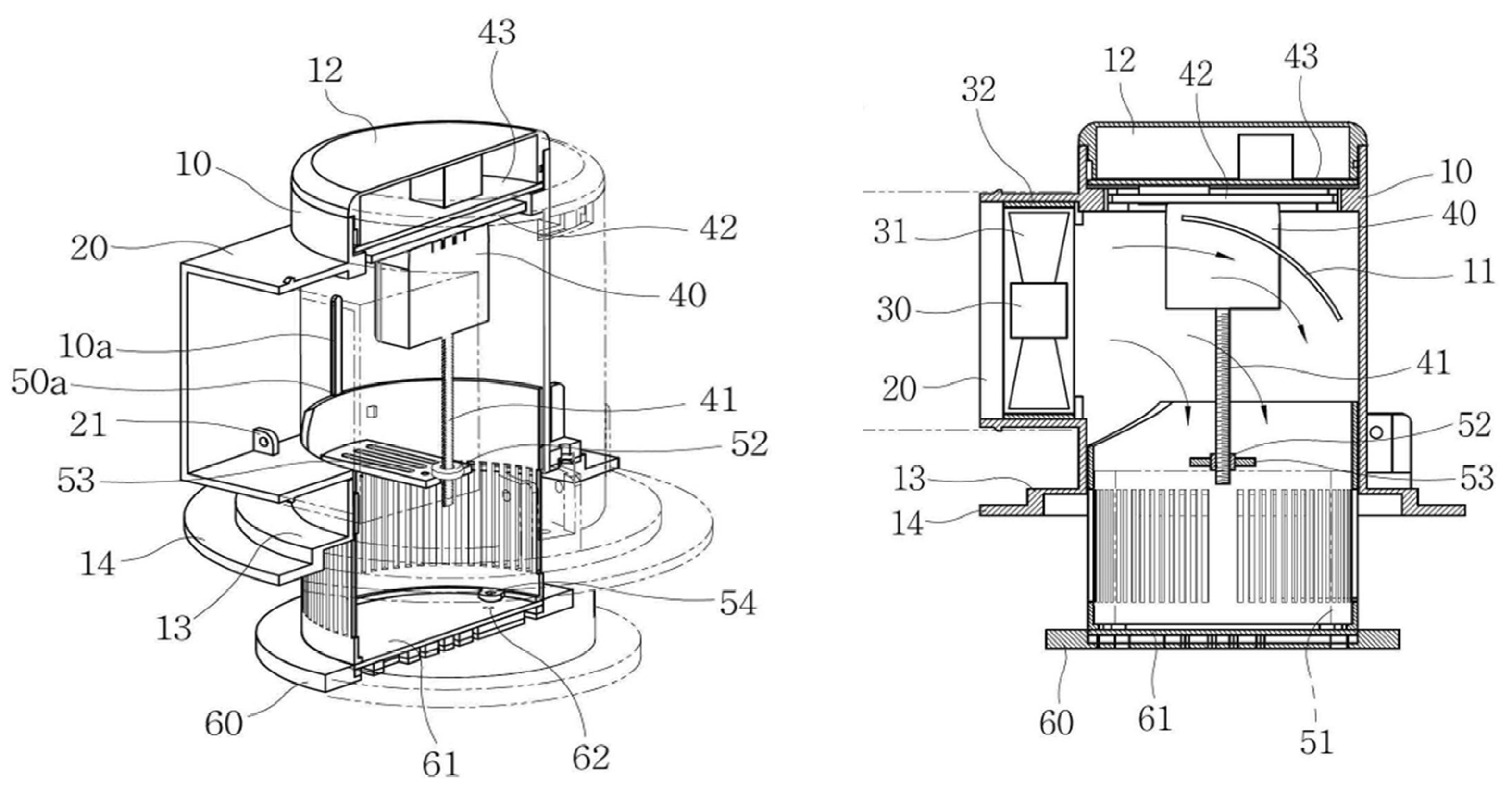

Appendix A. Technical Specifications of Module Components

- (10) Housing: The primary structural enclosure that supports all internal subsystems.

- (10a) Guide Rails: Linear guide elements embedded symmetrically along the inner wall of the housing, enabling stabilized vertical translation of the filter assembly.

- (12) Upper Cover: A removable lid allowing access to internal electronics, including the motor controller PCB (43).

- (13) Insertion Section: A recessed compartment designed to accommodate the display module (60) during filter retraction, allowing flush alignment with the ceiling surface.

- (14) Ceiling Mount Interface: Mechanical flange region at the housing base, configured for suspension-based mounting to overhead ceiling structures.

- (20) Duct Connector: Provides physical and aerodynamic coupling to HVAC or ERV ductwork; houses the fan assembly (30–32).

- (21) Internal Fastening Points: Threaded anchor positions for fixing the fan motor bracket (32) to the duct connector body.

- (30) Fan Motor, (31) Fan Blade, (32) Motor Bracket: These components form the forced-air circulation unit, with the motor and impeller secured externally to minimize thermal and vibrational interference with the filter mechanism.

- (40) Lifting Motor: A vertically mounted actuator fixed via a support bracket (42), tasked with controlling filter elevation.

- (41) Lead Screw: Coupled to the lifting motor to provide rotational-to-linear motion conversion.

- (42) Motor Bracket: Anchors the lifting motor to the upper housing wall; also serves as a vibration isolation interface.

- (43) Motor Control PCB: Mounted above the lifting motor to execute motion logic, position sensing, and overload protection.

- (50) Filter Housing: Cylindrical sleeve enclosing the air filter unit; externally vented via distributed perforations (50b).

- (50a) Rail Grooves: Precisely milled slots along the filter housing exterior, allowing guided motion along the housing rails (10a).

- (51) Cylindrical Filter Element: The primary particulate filtration medium, optimized for minimal pressure drop and maximal surface area.

- (52) Embedded Nut: Rigidly mounted within the screw bracket (53), this component travels along the lead screw (41) to elevate or retract the filter.

- (53) Screw Bracket: Connective support that transmits vertical motion to the filter housing; designed with minimal obstruction to airflow.

- (54) Lower Fastener Receptacles: Mechanical anchor points for securing the lower display module.

- (60) Display Module: A compact embedded display that provides real-time status indicators such as filter position, motor operation, and system diagnostics.

- (61) Display PCB: Hosts the control circuitry and status LEDs for the display unit.

- (62) Mounting Tabs: Threaded fixtures that fasten the display module (60) to the filter housing via the receptacles (54).

Appendix B. Evaluation Results and Dataset Description

| Test Item | Test Condition | Proposed System Result | Remarks |

|---|---|---|---|

| Suppression Time | Paper fire | 6.3 s | Fastest suppression |

| Wood fire | 9.1 s | Highest residual heat | |

| Polyurethane foam fire | 7.5 s | Moderate heat retention | |

| Smoke Clearance Time | Post-suppression (ERV + PURGE mode) | 128 s | Visibility restored per particle sensor |

| Peak Temperature | 90 s after ignition | 58 °C | Measured at 0.5 m from ignition source |

| Visibility Recovery | Distance: 1.5 m, Time: 120 s | Achieved | No residual smoke layer |

| Environmental Robustness | Steam interference | No false alarm | Correct detection only under real fire |

| Oil mist interference | No false positive | Stable sensor thresholds maintained | |

| Detection Speed vs. Baseline | Baseline: 9.0 s → Proposed: 6.0 s | 33% improvement | Hybrid sensor with CNN-based inference |

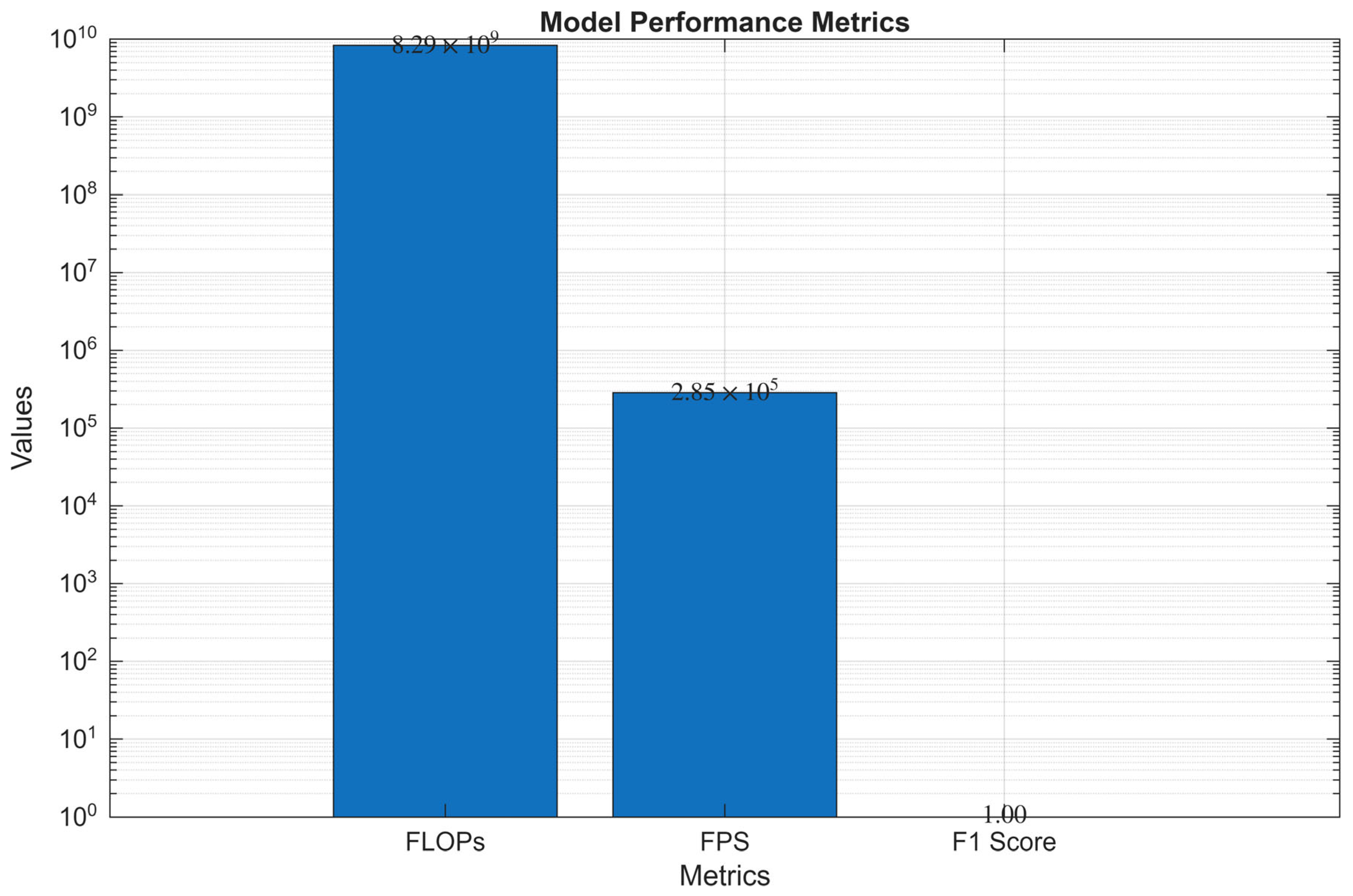

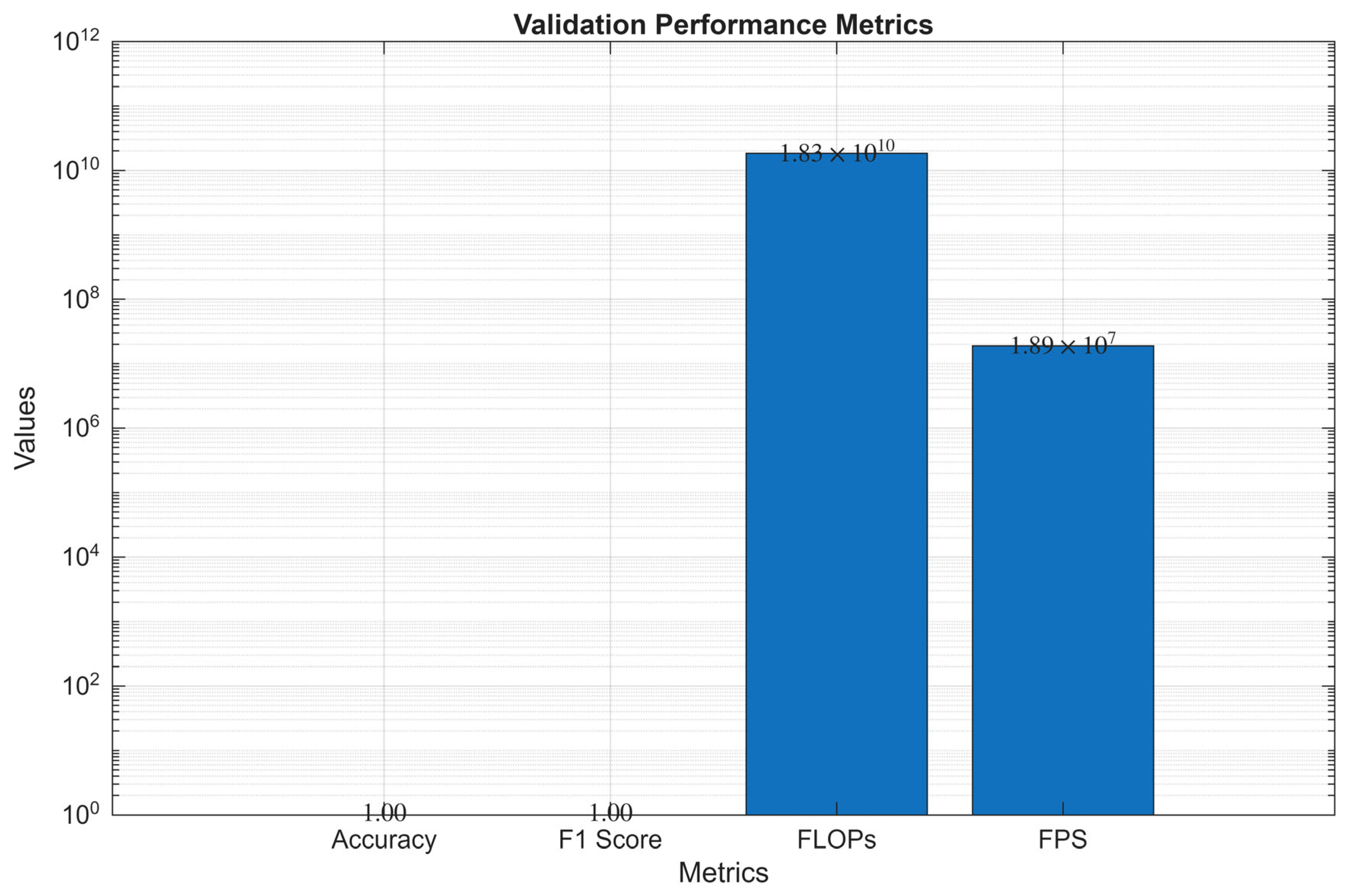

Appendix C. Code and Validation for Model Evaluation and Performance Metrics

| Test Matlab(2025a) code %% Step 1: Load test data testImageFolder = ‘C:\archive\test\images’; % Path to the test image folder testAnnotationFolder = ‘C:\archive\test\labels’; % Path to the test annotation folder testImds = imageDatastore(testImageFolder, ‘IncludeSubfolders’, true, ‘LabelSource’, ‘foldernames’); % Test image datastore % Load annotation files testAnnotationFiles = dir(fullfile(testAnnotationFolder, ‘*.txt’)); % Test annotation files numTestImages = numel(testImds.Files); numTestAnnotations = numel(testAnnotationFiles); disp([‘Number of test image files: ‘, num2str(numTestImages)]); disp([‘Number of test annotation files: ‘, num2str(numTestAnnotations)]); if numTestImages ~= numTestAnnotations error(‘The number of test image files and annotation files do not match.’); end %% Step 2: Load the model % Load the already trained model load(‘trainedFireModel.mat’, ‘fireModel’); % Load the trained model %% Step 3: Resize the test data imageSize = [224 224]; % Image size testData = zeros([224 224 3 numel(testImds.Files)], ‘uint8’); % Test data array testLabels = categorical(zeros(numel(testImds.Files), 1)); % Test label array for i = 1:numel(testImds.Files) img = imread(testImds.Files{i}); img = imresize(img, imageSize); % Resize the image testData(:,:,:,i) = img; % Store in the test data array % Check the annotation file and set the label annotationFile = fullfile(testAnnotationFolder, testAnnotationFiles(i).name); if isempty(readtable(annotationFile)) testLabels(i) = categorical(0); % If no annotation, set label as non-fire else testLabels(i) = categorical(1); % If annotation exists, set label as fire end end %% Step 4: Predict with the model predictedLabels = classify(fireModel, testData); % Classify the test data % Calculate accuracy accuracy = sum(predictedLabels == testLabels)/numel(testLabels); disp([‘Test Accuracy: ‘, num2str(accuracy)]); % Print confusion matrix confMat = confusionmat(testLabels, predictedLabels); disp(‘Confusion Matrix:‘); disp(confMat); % Calculate F1 score (based on Precision and Recall) precision = confMat(2, 2)/(confMat(2, 2) + confMat(1, 2)); % Precision recall = confMat(2, 2)/(confMat(2, 2) + confMat(2, 1)); % Recall f1Score = 2 * (precision * recall)/(precision + recall); % F1 score disp([‘F1 Score: ‘, num2str(f1Score)]); % Display F1 score %% Step 5: Calculate FLOPs and FPS % Example: Calculate FLOPs for the convolution layer convLayer = fireModel.Layers(2); % First convolution layer inputSize = [224, 224, 3]; % Input image size (224x224) filterSize = convLayer.FilterSize; % Filter size numFilters = convLayer.NumFilters; % Number of filters stride = convLayer.Stride; % Stride size % Approximate FLOP calculation flopsPerFilter = prod(filterSize) * prod(inputSize(1:2))/prod(stride); % FLOPs per filter totalFlops = flopsPerFilter * numFilters * numel(testData); % Total FLOPs disp([‘FLOPs: ‘, num2str(totalFlops)]); % Display FLOPs % Calculate FPS tic; % Start time predictedLabels = classify(fireModel, testData); % Inference inferenceTime = toc; % Time taken for inference fps = numel(testData)/inferenceTime; % Calculate FPS disp([‘Inference Speed (FPS): ‘, num2str(fps)]); % Display FPS %% Step 6: Visualize performance metrics graph metrics = [accuracy, f1Score, totalFlops, fps]; metricNames = {‘Accuracy’, ‘F1 Score’, ‘FLOPs’, ‘FPS’}; figure; bar(metrics); for i = 1:length(metrics) text(i, metrics(i) + 0.1, num2str(metrics(i), ‘%.2e’), ‘HorizontalAlignment’, ‘center’); end title(‘Test Performance Metrics’); xlabel(‘Metrics’); ylabel(‘Values’); xticks(1:length(metrics)); xticklabels(metricNames); grid on; % Save the graph at 600 DPI exportgraphics(gcf, ‘test_performance_metrics.png’, ‘Resolution’, 600); % Save the graph at 600 DPI |

References

- Ye, X.; Ma, J.; Shen, Y.; Lin, L. Suppression Effect of Sprinkler System on Fire Spread in Large Commercial Buildings. Procedia Eng. 2016, 135, 455–462. [Google Scholar] [CrossRef][Green Version]

- Jeong, W. A Study on Fire Factors Analysis Influencing Property Damage by the Use of Fire Extinguishing Equipment in Building and Structure Fires. J. Korea Acad.-Ind. Coop. Soc. 2021, 22, 138–145. [Google Scholar] [CrossRef]

- Liu, H.; Cachinho Cordeiro, I.M.D.; Yin Yuen, A.C.; Chan, Q.N.; Kook, S.; Yeoh, G.H. Application of Multi-Parametric Characterization to Water-Based Fire Suppression Systems in Compartment Fire Scenarios. Numer. Heat Transf. Part A Appl. 2023, 83, 1111–1129. [Google Scholar] [CrossRef]

- Ko, Y.J.; Elsagan, N. Investigation of the Performance of Fire Suppression Systems in Protection of Mass Timber Residential Buildings. Indoor Built Environ. 2023, 32, 230–241. [Google Scholar] [CrossRef]

- Meraner, C.; Skilbred, E.S.; Arsava, K.S. Experimental Investigation of Water-Based Fire Suppression Systems on External Façade Fires. Fire Technol. 2024, 60, 3629–3648. [Google Scholar] [CrossRef]

- Liu, H.; Wang, C.; De Cachinho Cordeiro, I.M.; Yuen, A.C.Y.; Chen, Q.; Chan, Q.N.; Kook, S.; Yeoh, G.H. Critical Assessment on Operating Water Droplet Sizes for Fire Sprinkler and Water Mist Systems. J. Build. Eng. 2020, 28, 100999. [Google Scholar] [CrossRef]

- Jiang, L.; Zeinali, D.; Arsava, K.S.; Snersrud, D.O. The Impact of Water-Based Fire Suppression Systems on Combustion Products. Fire Technol. 2025, 61, 2441–2465. [Google Scholar] [CrossRef]

- De Cachinho Cordeiro, I.M.; Liu, H.; Yuen, A.C.Y.; Chen, T.B.Y.; Li, A.; Wang, C.; Cao, R.; Yeoh, G.H. On the Large Eddy Simulation Modelling of Water Suppression Systems Droplet Impact and Coverage Area. Fire 2022, 5, 165. [Google Scholar] [CrossRef]

- Santangelo, P.E.; Tarozzi, L.; Tartarini, P. Full-Scale Experiments of Fire Control and Suppression in Enclosed Car Parks: A Comparison Between Sprinkler and Water-Mist Systems. Fire Technol. 2016, 52, 1369–1407. [Google Scholar] [CrossRef]

- Arora, N.; Yadav, S.; Singh, Y.R.; Mishra, K. IoT & AI Enabled Fire Detection System. Int. J. Res. Appl. Sci. Eng. Technol. 2025, 13, 1862–1869. [Google Scholar] [CrossRef]

- Mukhiddinov, M.; Abdusalomov, A.B.; Cho, J. Automatic Fire Detection and Notification System Based on Improved YOLOv4 for the Blind and Visually Impaired. Sensors 2022, 22, 3307. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Chung, J.H.; Chung, H.; Kim, J.-H.; Yoo, Y.; Lim, G.H.; Ruy, W.-S. AI-Enhanced Fire Detection and Suppression System for Autonomous Ships. Int. J. Nav. Archit. Ocean Eng. 2024, 16, 100628. [Google Scholar] [CrossRef]

- Tian, S.; Zhang, Y.; Feng, Y.; Elsagan, N.; Ko, Y.; Mozaffari, M.H.; Xi, D.D.Z.; Lee, C.-G. Time Series Classification, Augmentation and Artificial-Intelligence-Enabled Software for Emergency Response in Freight Transportation Fires. Expert Syst. Appl. 2023, 233, 120914. [Google Scholar] [CrossRef]

- Boroujeni, S.P.H.; Razi, A.; Khoshdel, S.; Afghah, F.; Coen, J.L.; ONeill, L.; Fule, P.Z.; Watts, A.; Kokolakis, N.-M.T.; Vamvoudakis, K.G. A Comprehensive Survey of Research towards AI-Enabled Unmanned Aerial Systems in Pre-, Active-, and Post-Wildfire Management. Inf. Fusion 2024, 108, 102369. [Google Scholar] [CrossRef]

- Nan, Z.; Orabi, M.A.; Huang, X.; Jiang, Y.; Usmani, A. Structural-Fire Responses Forecasting via Modular AI. Fire Saf. J. 2023, 140, 103863. [Google Scholar] [CrossRef]

- ISO 834; Fire Resistance Tests—Elements of Building construction—Part 11: Specific Requirements for the Assessment of Fire Protection to Structural Steel Elements. ISO: Geneva, Switzerland, 2014.

- ASTM E119; Standard Test Methods for Fire Tests of Building Construction and Materials. ASTM: West Conshohocken, PA, USA, 2024.

- Oliveira, P.N.; Fonseca, E.M.M.; Campilho, R.D.S.G.; Piloto, P.A.G. Analytical Equations Applied to the Study of Steel Profiles under Fire According to Different Nominal Temperature-Time Curves. Math. Comput. Appl. 2021, 26, 48. [Google Scholar] [CrossRef]

- Dwaikat, M.M.S.; Kodur, V.K.R. A Simplified Approach for Predicting Temperatures in Fire Exposed Steel Members. Fire Saf. J. 2013, 55, 87–96. [Google Scholar] [CrossRef]

- Subramanian, C.M.E.; Sujith, D.; Anish, M.; Dhanu Deepak, P.; Manoj, P. AI Based Automatic Fire Extinguisher System in Vehicle. Int. Adv. Res. J. Sci. Eng. Technol. 2024, 11, 34–40. [Google Scholar] [CrossRef]

- Remmelzwaal, L. An AI-Based Early Fire Detection System Utilizing HD Cameras and Real-Time Image Analysis. Artif. Intell. Appl. 2023, 1–6. [Google Scholar] [CrossRef]

- Lee, M.; Mesicek, L.; Bae, K.; Ko, H. AI Advisor Platform for Disaster Response Based on Big Data. Concurr. Comput. 2023, 35, e6215. [Google Scholar] [CrossRef]

- Li, L.; Du, L.; Zong, X.; Liu, Y. VIS-NIR TMOKE Enhanced Dielectric-Metal Hybrid Structure for High Performance Dual-Channel Sensing. Opt. Express 2023, 31, 35880. [Google Scholar] [CrossRef]

- Lehnert, A.; Gawantka, F.; During, J.; Just, F.; Reichenbach, M. XplAInable: Explainable AI Smoke Detection at the Edge. Big Data Cogn. Comput. 2024, 8, 50. [Google Scholar] [CrossRef]

- Xiao, S.; Wan Liu, Z.; Tan, Y.; He, Q.; Xiao, Y. SwinNet: Swin Transformer Drives Edge-Aware RGB-D and RGB-T Salient Object Detection. IEEE Trans. Circuits Syst. Video Technol. 2022, 32, 4486–4497. [Google Scholar] [CrossRef]

- Zidan, U.; Gaber, M.; Abdelsamea, M. SwinCup: Cascaded Swin Transformer for Histopathological Structures Segmentation in Colorectal Cancer. Expert Syst. Appl. 2022, 216, 119452. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Y.; Wang, J.; Xu, Z.; Liu, D. Dual Attention Transformers: Adaptive Linear and Hybrid Cross Attention for Remote Sensing Scene Classification. IET Image Process. 2025, 19, e70076. [Google Scholar] [CrossRef]

- Chen, R.; He, S.; Xie, J.; Wang, T.; Xu, Y.; Fang, J.; Zhao, X.; Zhang, S.; Wang, G.; Lu, H.; et al. MedFuseNet: Fusing Local and Global Deep Feature Representations with Hybrid Attention Mechanisms for Medical Image Segmentation. Sci. Rep. 2025, 15, 12345. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, J.; Cao, S.; Zhu, M.; Sun, J.; Hao, Z.; Jiang, X. SRBPSwin: Single-Image Super-Resolution for Remote Sensing Images Using a Global Residual Multi-Attention Hybrid Back-Projection Network Based on the Swin Transformer. Remote Sens. 2024, 16, 2252. [Google Scholar] [CrossRef]

- Dong, X.; Bao, J.; Chen, D.; Zhang, W.; Yu, N.; Yuan, L.; Chen, D.; Guo, B. CSWin Transformer: A General Vision Transformer Backbone with Cross-Shaped Windows. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), New Orleans, LA, USA, 19–24 June 2022; pp. 12114–12124. [Google Scholar] [CrossRef]

- Zhao, S.; Chen, H.; Zhang, X.; Xiao, P.; Bai, L.; Ouyang, W. RS-Mamba for large remote sensing image dense prediction. IEEE Trans. Geosci. Remote Sens. 2024, 62, 1–14. [Google Scholar] [CrossRef]

- Xiao, Y.; Yuan, Q.; Jiang, K.; He, J.; Lin, C.; Zhang, L. TTST: A top-k token selective Transformer for remote sensing image super-resolution. IEEE Trans. Image Process. 2024, 33, 738–752. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.; Wang, Y.; Mei, S. Rethinking Transformers for semantic segmentation of remote sensing images. IEEE Trans. Geosci. Remote Sens. 2023, 61, 1–15. [Google Scholar] [CrossRef]

- Mo, N.; Zhu, R. A novel Transformer-based object detection method with geometric and object co-occurrence prior knowledge for remote sensing images. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2025, 18, 2383–2400. [Google Scholar] [CrossRef]

- Song, X.; Hua, Z.; Li, J. Remote sensing image change detection Transformer network based on dual-feature mixed attention. IEEE Trans. Geosci. Remote Sens. 2022, 60, 1–16. [Google Scholar] [CrossRef]

- Xiao, S.; Wang, S.; Ge, L.; Weng, H.; Fang, X.; Peng, Z.; Zeng, W. Hybrid Feature Fusion-Based High-Sensitivity Fire Detection and Early Warning for Intelligent Building Systems. Sensors 2023, 23, 859. [Google Scholar] [CrossRef]

- Gaur, A.; Singh, A.; Kumar, A.; Kulkarni, K.S.; Lala, S.; Kapoor, K.; Srivastava, V.; Kumar, A.; Mukhopadhyay, S.C. Fire Sensing Technologies: A Review. IEEE Sens. J. 2019, 19, 3191–3202. [Google Scholar] [CrossRef]

- Dalal, S.; Lilhore, U.K.; Radulescu, M.; Simaiya, S.; Jaglan, V.; Sharma, A. A hybrid LBP-CNN with YOLO-v5-based fire and smoke detection model in various environmental conditions for environmental sustainability in smart city. Environ. Sci. Pollut. Res. 2024, 1–18. [Google Scholar] [CrossRef]

- De Venâncio, P.V.A.B.; Campos, R.J.; Rezende, T.M.; Lisboa, A.C.; Barbosa, A.V. A Hybrid Method for Fire Detection Based on Spatial and Temporal Patterns. Neural Comput. Appl. 2023, 35, 9349–9361. [Google Scholar] [CrossRef]

- Yar, H.; Khan, Z.A.; Ullah, F.U.M.; Ullah, W.; Baik, S.W. A Modified YOLOv5 Architecture for Efficient Fire Detection in Smart Cities. Expert Syst. Appl. 2023, 231, 120465. [Google Scholar] [CrossRef]

- Cheknane, M.; Bendouma, T.; Boudouh, S.S. Advancing Fire Detection: Two-Stage Deep Learning with Hybrid Feature Extraction Using Faster R-CNN Approach. Signal Image Video Process. 2024, 18, 5503–5510. [Google Scholar] [CrossRef]

- Nguyen, D.-L.; Putro, M.D.; Jo, K.-H. Lightweight Convolutional Neural Network for Fire Classification in Surveillance System. IEEE Access 2023, 11, 101604–101615. [Google Scholar] [CrossRef]

- Daoud, Z.; Ben Hamida, A.; Ben Amar, C. FireClassNet: A Deep Convolutional Neural Network Approach for PJF Fire Images Classification. Neural Comput. Appl. 2023, 35, 19069–19085. [Google Scholar] [CrossRef]

- Mao, W.; Wang, W.; Dou, Z.; Li, Y. Fire Recognition Based on Multi-Channel Convolutional Neural Network. Fire Technol. 2018, 54, 531–554. [Google Scholar] [CrossRef]

- Jeon, M.; Choi, H.-S.; Lee, J.; Kang, M. Multi-Scale Prediction for Fire Detection Using Convolutional Neural Network. Fire Technol. 2021, 57, 2533–2551. [Google Scholar] [CrossRef]

- Roh, J.; Kim, Y.; Kong, M. Fire Image Classification Based on Convolutional Neural Network for Smart Fire Detection. Int. J. Fire Sci. Eng. 2022, 36, 51–61. [Google Scholar] [CrossRef]

- Mahmoudi, S.; Gloesener, M.; Benkedadra, M.; Lerat, J.-S. Edge AI System for Real-Time and Explainable Forest Fire Detection Using Compressed Deep Learning Models. In Proceedings of the 20th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications, Porto, Portugal, 25–27 February 2025; SCITEPRESS—Science and Technology Publications: Porto, Portugal, 2025; pp. 847–854. [Google Scholar]

- Titu, M.F.S.; Pavel, M.A.; Michael, G.K.O.; Babar, H.; Aman, U.; Khan, R. Real-Time Fire Detection: Integrating Lightweight Deep Learning Models on Drones with Edge Computing. Drones 2024, 8, 483. [Google Scholar] [CrossRef]

- Muhammad, K.; Khan, S.; Elhoseny, M.; Hassan Ahmed, S.; Wook Baik, S. Efficient Fire Detection for Uncertain Surveillance Environment. IEEE Trans. Ind. Inf. 2019, 15, 3113–3122. [Google Scholar] [CrossRef]

- Aramendia, J.; Cabrera, A.; Martín, J.; Gumiel, J.Á.; Basterretxea, K. Neural Network Implementation for Fire Detection in Critical Infrastructures: A Comparative Analysis on Embedded Edge Devices. Electronics 2025, 14, 1809. [Google Scholar] [CrossRef]

- Fouda, M.M.; Sakib, S.; Fadlullah, Z.M.; Nasser, N.; Guizani, M. A Lightweight Hierarchical AI Model for UAV-Enabled Edge Computing with Forest-Fire Detection Use-Case. IEEE Netw. 2022, 36, 38–45. [Google Scholar] [CrossRef]

- ISO 31000; Risk Management—Guidelines. ISO: Geneva, Switzerland, 2018.

- NEPA 551; Guide for the Evaluation of Fire Risk Assessments. NEPA: Quincy, MA, USA, 2022.

- ISO 9705; Reaction to Fire Tests—Room Corner Test for Wall and Ceiling Lining Products—Part 1: Test Method for a Small Room Configuration. ISO: Geneva, Switzerland, 2016.

- Cleary, T. Performance of Dual Photoelectric/Ionization Smoke Alarms in Full-Scale Fire Tests. Fire Technol. 2014, 50, 753–773. [Google Scholar] [CrossRef]

- National Fire Protection Association (NFPA). NFPA 92: Standard for Smoke Control Systems; NFPA: Quincy, MA, USA, 2024; Available online: https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=92 (accessed on 1 July 2025).

- Tamura, G.T.; McGuire, J.H. Smoke Movement in High-Rise Buildings. Can. Build. Dig. 1971, CBD-133, 1–17. [Google Scholar] [CrossRef]

- UL 2127; Inert Gas Clean Agent Extinguishing System Units. UL: Evanston, IL, USA, 2024.

- ISO 14520; Gaseous Fire-Extinguishing Systems—Physical Properties and System Design—Part 1: General Requirements. ISO: Geneva, Switzerland, 2023.

- ISO 7240; Fire Detection and Alarm Systems—Part 1: General and Definitions. ISO: Geneva, Switzerland, 2014.

- Ali, K.; Sokri, M.S.A.M.; Rifai, D.; Raja Aris, R.S.N.A.; Besar, M.B.; Abdul Halim, M.Z.; Koh Siaw Paw, J.; Chong, T.Y.; Tan, J.D.; Mohd Noor, A.H. Low Power Consumption for O2 and Co Gases Measuring Based IoT System at Confined Space Area. Int. J. Innov. Ind. Revolut. 2025, 7, 302–316. [Google Scholar] [CrossRef]

- Wilson, E.; Tomasallo, C.; Meiman, J. Notes from the Field: Occupational Carbon Monoxide Exposure in an Industrial Kitchen Facility—Wisconsin, 2017. MMWR Morb. Mortal. Wkly. Rep. 2018, 67, 786. [Google Scholar] [CrossRef]

- PD 7974-7; Application of Fire Safety Engineering Principles to the Design of Buildings. Probabilistic Risk Assessment (+A1:2021). NBS Enterprises Ltd.: Tyne, UK, 2019.

- NFPA 1250; Recommended Practice in Fire and Emergency Services Organization Risk Management. NEPA: Quincy, MA, USA, 2020.

- Zhang, J.; Chen, B.; Zhao, Y.; Cheng, X.; Hu, F. Data Security and Privacy-Preserving in Edge Computing Paradigm: Survey and Open Issues. IEEE Access 2018, 6, 18209–18237. [Google Scholar] [CrossRef]

- Wang, T.; Bhuiyan, M.Z.A.; Wang, G.; Qi, L.; Wu, J.; Hayajneh, T. Preserving Balance Between Privacy and Data Integrity in Edge-Assisted Internet of Things. IEEE Internet Things J. 2020, 7, 2679–2689. [Google Scholar] [CrossRef]

- Zhukabayeva, T.; Zholshiyeva, L.; Karabayev, N.; Khan, S.; Alnazzawi, N. Cybersecurity Solutions for Industrial Internet of Things–Edge Computing Integration: Challenges, Threats, and Future Directions. Sensors 2025, 25, 213. [Google Scholar] [CrossRef]

- Garagad, V.G.; Iyer, N.C.; Wali, H.G. Data Integrity: A Security Threat for Internet of Things and Cyber-Physical Systems. In Proceedings of the 2020 International Conference on Computational Performance Evaluation (ComPE), Shillong, India, 2–4 July 2020; pp. 244–249. [Google Scholar]

- Okunlola, O.A.; Olaoye, J.; Samuel, O.O.; Okunlola, A.O.; Alao, O. Cybersecurity Strategies for Integrating Industrial IoT and Edge Computing: Challenges, Risks, and Future Perspectives. Int. J. Future Eng. Innov. 2025, 2, 87–95. [Google Scholar] [CrossRef]

- Ferrag, M.A.; Friha, O.; Hamouda, D.; Maglaras, L.; Janicke, H. Edge-IIoTset: A New Comprehensive Realistic Cyber Security Dataset of IoT and IIoT Applications for Centralized and Federated Learning. IEEE Access 2022, 10, 40281–40306. [Google Scholar] [CrossRef]

- Cui, G.; He, Q.; Li, B.; Xia, X.; Chen, F.; Jin, H.; Xiang, Y.; Yang, Y. Efficient Verification of Edge Data Integrity in Edge Computing Environment. IEEE Trans. Serv. Comput. 2022, 15, 3233–3244. [Google Scholar] [CrossRef]

- Tong, W.; Chen, W.; Jiang, B.; Xu, F.; Li, Q.; Zhong, S. Privacy-Preserving Data Integrity Verification for Secure Mobile Edge Storage. IEEE Trans. Mob. Comput. 2022, 22, 5463–5478. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, J.; Lin, Y.; Huang, H. ZSS Signature Based Data Integrity Verification for Mobile Edge Computing. In Proceedings of the 2021 IEEE/ACM 21st International Symposium on Cluster, Cloud and Internet Computing (CCGrid), Melbourne, Australia, 10–13 May 2021; pp. 356–365. [Google Scholar]

- Zhao, Y.; Xu, C.; Qu, Y.; Xiang, Y.; Chen, F.; Gao, L. A Learning-Based Hierarchical Edge Data Corruption Detection Framework in Edge Intelligence. IEEE Internet Things J. 2024, 11, 18366–18380. [Google Scholar] [CrossRef]

- Hayajneh, A.A.; Alam Bhuiyan, M.Z.; McAndrew, I. Security of Broadcast Authentication for Cloud-Enabled Wireless Medical Sensor Devices in 5G Networks. Comput. Inf. Sci. 2020, 13, 13–26. [Google Scholar] [CrossRef]

- Javeed, D.; Saeed, M.S.; Adil, M.; Kumar, P.; Jolfaei, A. A Federated Learning-Based Zero Trust Intrusion Detection System for Internet of Things. Ad Hoc Netw. 2024, 162, 103540. [Google Scholar] [CrossRef]

- Karunamurthy, A.; Vijayan, K.; Kshirsagar, P.R.; Tan, K.T. An Optimal Federated Learning-Based Intrusion Detection for IoT Environment. Sci. Rep. 2025, 15, 8696. [Google Scholar] [CrossRef]

- Sarhan, M.; Layeghy, S.; Moustafa, N.; Portmann, M. Cyber Threat Intelligence Sharing Scheme Based on Federated Learning for Network Intrusion Detection. J. Netw. Syst. Manag. 2023, 31, 3. [Google Scholar] [CrossRef]

- Aldweesh, A. Blockchain-Based Secure Firmware Updates for Electric Vehicle Charging Stations in Web of Things Environments. World Electr. Veh. J. 2025, 16, 226. [Google Scholar] [CrossRef]

- Shi, L.; Wang, T.; Xiong, Z.; Wang, Z.; Liu, Y.; Li, J. Blockchain-Aided Decentralized Trust Management of Edge Computing: Toward Reliable Off-Chain and On-Chain Trust. IEEE Netw. 2024, 38, 182–188. [Google Scholar] [CrossRef]

- Hasan, M.W.; Shanto, S.; Nayeema, J.; Rahman, R.; Helaly, T.; Rahman, Z.; Mehedi, S.T. An Explainable AI-Based Modified YOLOv8 Model for Efficient Fire Detection. Mathematics 2024, 12, 3042. [Google Scholar] [CrossRef]

- Negi, P.; Pathani, A.; Bhatt, B.C.; Swami, S.; Singh, R.; Gehlot, A.; Thakur, A.K.; Gupta, L.R.; Priyadarshi, N.; Twala, B.; et al. Integration of Industry 4.0 Technologies in Fire and Safety Management. Fire 2024, 7, 335. [Google Scholar] [CrossRef]

- Xie, W.; Zeng, Y.; Zhang, X.; Wong, H.Y.; Zhang, T.; Wang, Z.; Wu, X.; Shi, J.; Huang, X.; Xiao, F.; et al. AIoT-Powered Building Digital Twin for Smart Firefighting and Super Real-Time Fire Forecast. Adv. Eng. Inform. 2025, 65, 103117. [Google Scholar] [CrossRef]

- Chen, X.-S.; Liu, C.-C.; Wu, I.-C. A BIM-Based Visualization and Warning System for Fire Rescue. Adv. Eng. Inform. 2018, 37, 42–53. [Google Scholar] [CrossRef]

- Wehbe, R.; Shahrour, I. A BIM-Based Smart System for Fire Evacuation. Future Internet 2021, 13, 221. [Google Scholar] [CrossRef]

| Method | Global Context Coverage | Computational Efficiency | Spatial Fusion Pattern | Suitability for Edge Deployment |

|---|---|---|---|---|

| Swin Transformer | Hierarchical, multi-scale | Moderate–High | Shifted overlapping windows | Moderate |

| Global Context Pooling | Global summary via pooling | High | Omnidirectional (coarse) | High |

| Criss-Cross Attention | Long-range (axis-aligned) | Moderate | Horizontal + Vertical stripes | Moderate |

| Proposed GCF Module | Dynamic: local + inferred global | Very High | Sensor-driven spatial encoder | High |

| Task | Notable Model(s) | Key Improvement/Result | Citation |

|---|---|---|---|

| Object Detection | Geometric Prior DETR | +5% mAP over deformable DETR | [34] |

| Semantic Segmentation | RS-Mamba, GLOTS, CG-Swin | SOTA accuracy, efficient on large images | [31,33] |

| Change Detection | AMTNet, DMATNet | Outperforms previous SOTA on 4 datasets | [33,35] |

| Super-Resolution | TTST | Higher PSNR, lower computation | [36] |

| Trial No. | Paper (s) | Wood (s) | Polyurethane Foam (s) | Electrical Cable (s) |

|---|---|---|---|---|

| 1 | 5.7 | 5.9 | 5.8 | 5.6 |

| 2 | 5.9 | 5.6 | 5.7 | 5.9 |

| 3 | 5.8 | 5.8 | 5.6 | 5.7 |

| 4 | 5.6 | 5.9 | 5.9 | 5.8 |

| 5 | 5.9 | 5.7 | 5.7 | 5.8 |

| 6 | 5.7 | 5.6 | 5.8 | 5.9 |

| 7 | 5.8 | 5.9 | 5.6 | 5.6 |

| 8 | 5.6 | 5.8 | 5.9 | 5.7 |

| 9 | 5.9 | 5.7 | 5.7 | 5.6 |

| 10 | 5.7 | 5.6 | 5.8 | 5.8 |

| Paper (s) | Wood (s) | Polyurethane Foam (s) | Electrical Cable (s) | |

|---|---|---|---|---|

| Paper (s) | - | 0.8569 | 0.8451 | 0.7077 |

| Wood (s) | 0.8569 | - | 1 | 0.8569 |

| Polyurethane Foam (s) | 0.8451 | 1 | - | 0.8451 |

| Electrical Cable (s) | 0.7077 | 0.8569 | 0.8451 | - |

| Category | Baseline System | Proposed System | Improvement Effect |

|---|---|---|---|

| Fire Suppression Medium | Water-based Sprinkler | Residue-Free Clean Extinguishing Agent | Minimizes electrical damage; no water supply required |

| Control Mechanism | Mechanical Ventilation + Exhaust Fan | ERV 100% + PURGE 120% | Improved exhaust and heat removal |

| Diffuser Type | Fixed-type Ceiling Diffuser | 250 mm Motorized Rotation + 360° Nozzle | Targeted spray at fire core |

| Sensor Type | Photoelectric Smoke + Thermal Sensor | ISO 7240 [60] Composite + AI-integrated | Avg. detection time reduced by 2.8 s |

| Detection-to-Activation Time | 9 s | 6 s | 33% faster |

| Spray Duration | 60–90 s | 3 s | 20× faster |

| Flame Height (60 s) | 1.25 m | 1.80 m | 46% |

| Peak Temperature (90 s) | 110 °C | 58 °C | −52 °C |

| Visibility at 120 s | Not Achieved | Achieved | Secured evacuation visibility |

| Installation Cost (Office) | Approx. 230 M USD (334,451 m2) | Approx. 311 M USD (334,451 m2) | Increased by 35% |

| Insurance Discount | None | 14–18% | Reduced operational expenditure |

| Maintenance | Head: 10 yrs, Fan: Prone to corrosion | Cylinder: 10 yrs, Packing: 1 yr | Lower component failure rate and maintenance risk |

| Stage | Applicable Standard | Core Activities | Deliverables |

|---|---|---|---|

| Risk Identification | ISO 31000:2018, Clause 7.2.2 | Derivation of five fire scenarios (electrical, cooking, smoldering, flashover, fuel spill) | Event List |

| Risk Analysis | NFPA 551:2022, Section 5 | Event-tree and fault-tree modeling using 10,000 Monte Carlo simulations based on PD 7974-7 with 1% failure rate | Probability (λ) and consequence (C) distributions |

| Risk Evaluation | ISO 31000:2018, Clause 7.2.4 | 5 × 5 risk matrix (Likelihood–Impact), selection using ALARP (As Low As Reasonably Practicable) criteria | Risk Ranking |

| Risk Treatment | NFPA 1250:2020 [64], Section 4 | Deployment of the proposed system with RV × CV strategies (detection, suppression, isolation, clean agent) | Mitigation measures, residual risk levels |

| Category | Frequency (F) | Impact (I) | Baseline Score | Proposed Score | Risk Level Change |

|---|---|---|---|---|---|

| Fatalities | 4 | 4 | 16 | 4 | H → L |

| Property Damage | 3 | 4 | 12 | 5 | H → M |

| Business Interruption | 3 | 3 | 9 | 3 | M → L |

| Environmental (CO2) | 2 | 3 | 6 | 4 | M → L |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-J.; Yun, H.-S.; Sim, Y.-B.; Lee, S.-H. Design and Validation of an Edge-AI Fire Safety System with SmartThings Integration for Accelerated Detection and Targeted Suppression. Appl. Sci. 2025, 15, 8118. https://doi.org/10.3390/app15148118

Lee S-J, Yun H-S, Sim Y-B, Lee S-H. Design and Validation of an Edge-AI Fire Safety System with SmartThings Integration for Accelerated Detection and Targeted Suppression. Applied Sciences. 2025; 15(14):8118. https://doi.org/10.3390/app15148118

Chicago/Turabian StyleLee, Seung-Jun, Hong-Sik Yun, Yang-Bae Sim, and Sang-Hoon Lee. 2025. "Design and Validation of an Edge-AI Fire Safety System with SmartThings Integration for Accelerated Detection and Targeted Suppression" Applied Sciences 15, no. 14: 8118. https://doi.org/10.3390/app15148118

APA StyleLee, S.-J., Yun, H.-S., Sim, Y.-B., & Lee, S.-H. (2025). Design and Validation of an Edge-AI Fire Safety System with SmartThings Integration for Accelerated Detection and Targeted Suppression. Applied Sciences, 15(14), 8118. https://doi.org/10.3390/app15148118