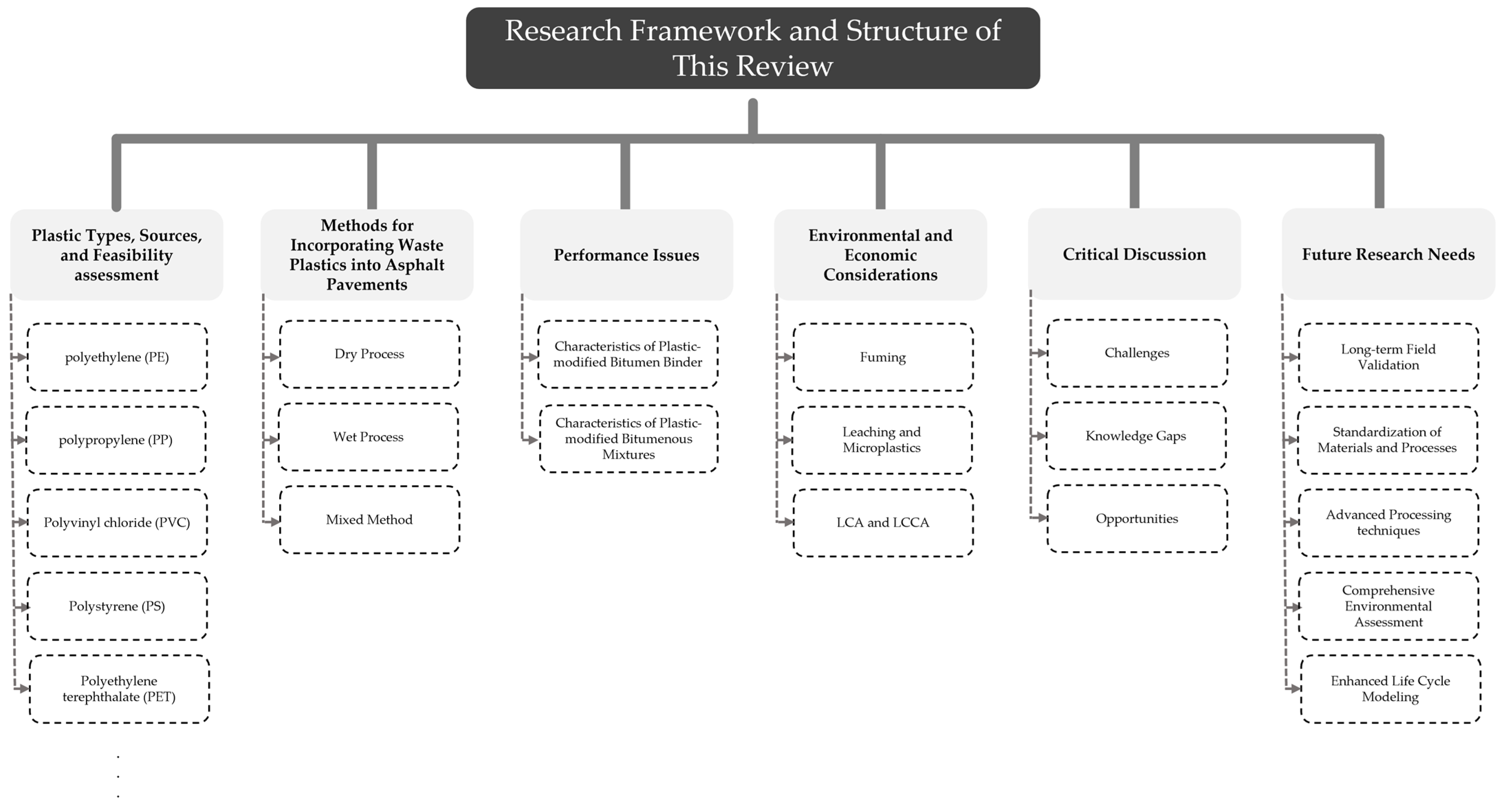

Incorporating Waste Plastics into Pavement Materials: A Review of Opportunities, Risks, Environmental Implications, and Monitoring Strategies

Abstract

1. Introduction

2. Types and Sources of Waste Plastics Used in Pavement

3. Methods for Incorporating Waste Plastics into Asphalt Pavements

4. Performance of Waste-Plastic-Modified Bitumen Binder and Mixture

4.1. Characteristics of Plastic-Modified Bitumen Binder

4.1.1. Mechanical and Rheological Enhancements

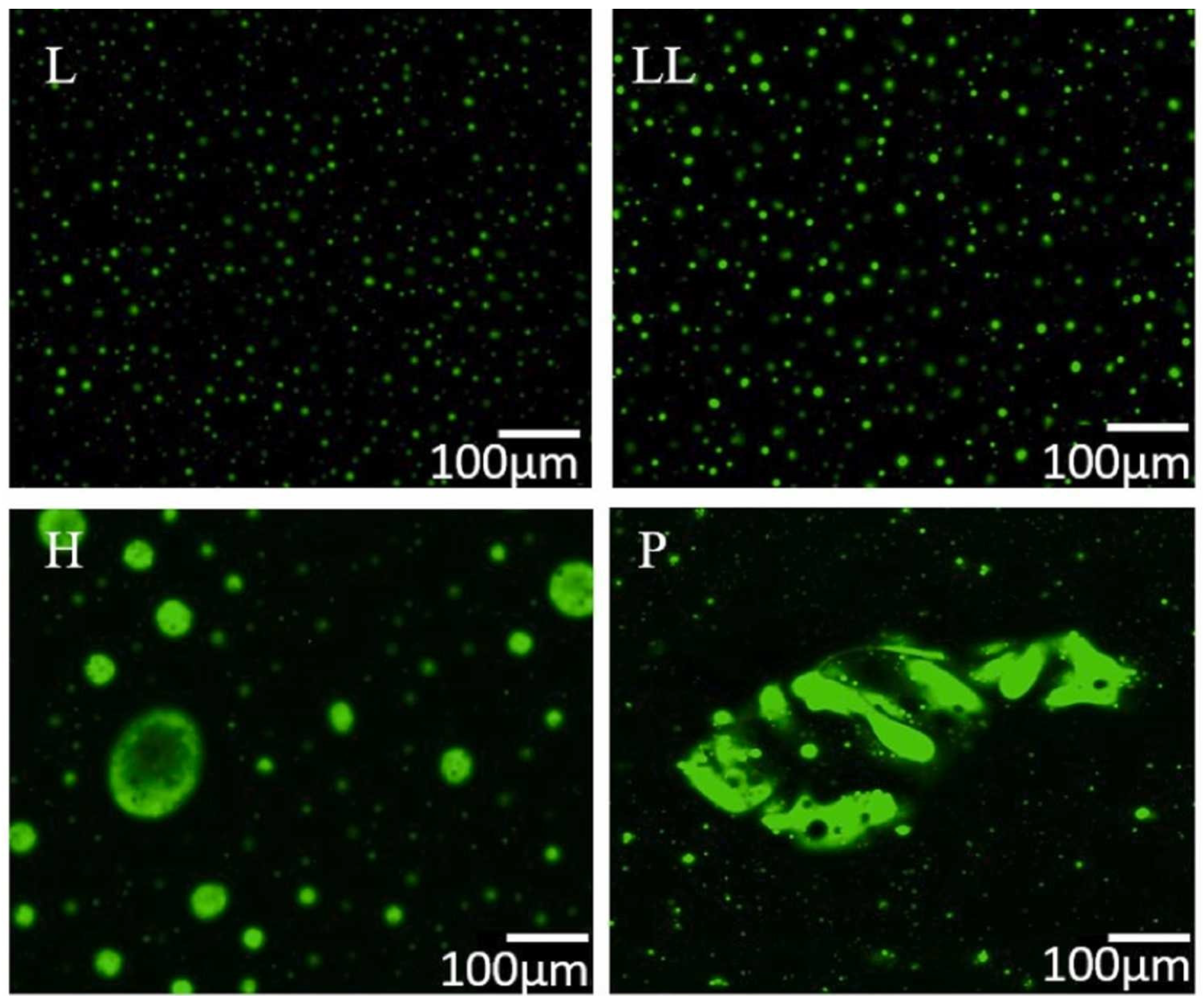

4.1.2. Enhancing Compatibility and Reducing Ageing

4.1.3. Effect of Bitumen Modification Mixing Parameters and Plastic Particle Size

4.2. Characteristics of Plastic-Modified Bituminous Mixtures

4.2.1. Mechanical and Durability Performance

4.2.2. Blending Methods and Processing Techniques

4.2.3. Hybrid and Composite Systems

4.2.4. Challenges and Practical Considerations

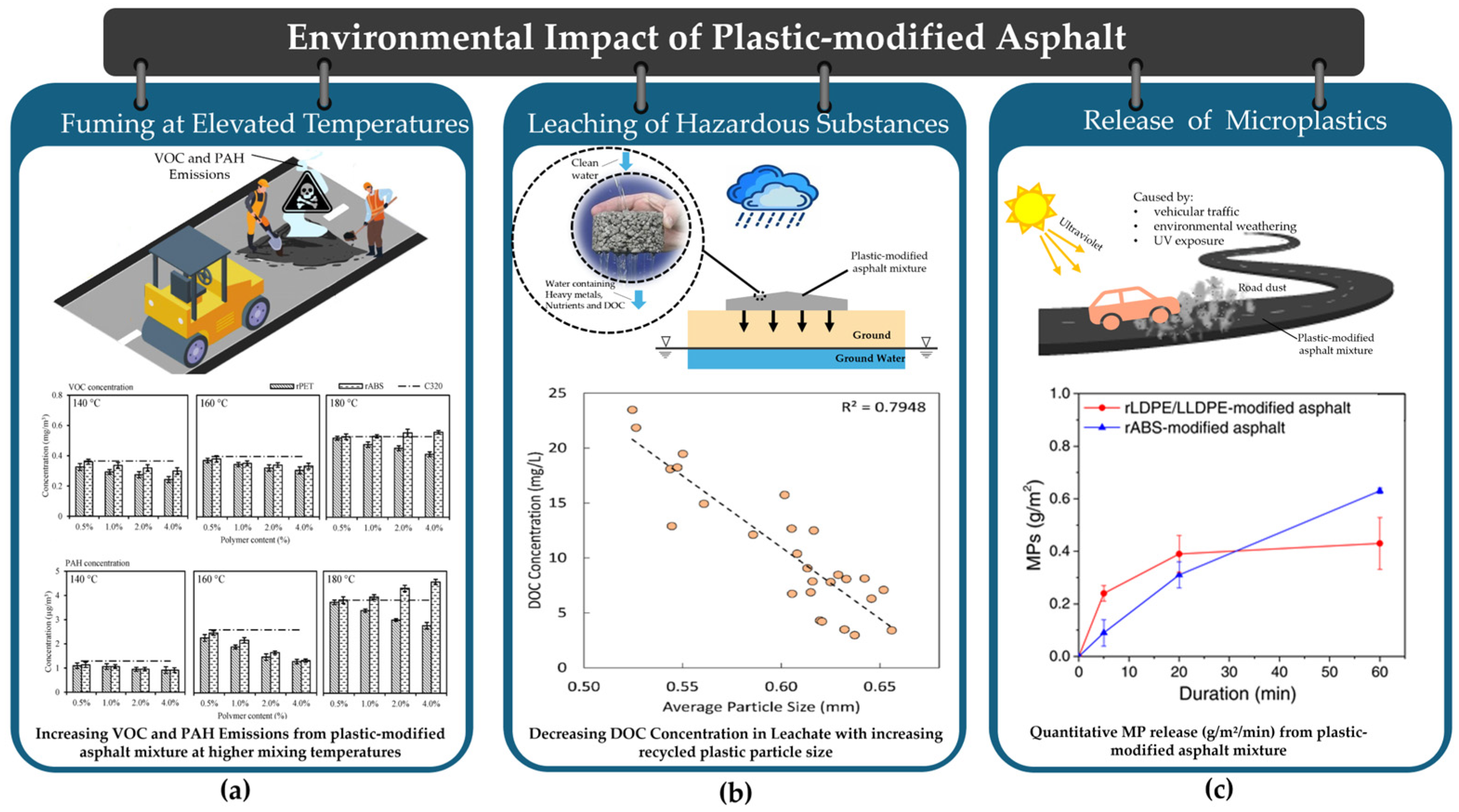

5. Environmental Aspects and Health Risks

5.1. Fuming

5.2. Leaching Characteristics and Release of MPs from Plastic-Modified Asphalt Mixtures

5.3. Life Cycle Environmental Impact and Life Cycle Cost Characteristics of Plastic-Modified Asphalt Pavement

6. Critical Discussion

7. Conclusions and Future Research Needs

7.1. Conclusions

7.2. Future Research Needs

- Long-term field validationExecute ongoing investigations for several years across varied climates and traffic situations to evaluate pavement durability, ageing characteristics, and environmental impacts (e.g., MP release, VOC/PAH emissions).

- Standardization of materials and processesDevelop globally accepted standards for plastic feedstock quality, incorporation methods, and performance evaluation to guarantee consistency and promote regulatory approval.

- Advanced processing techniquesInvestigate the use of functionalized plastics, hybrid modifiers (e.g., plastics combined with crumb rubber or nanomaterials), and optimized blending methods to enhance binder compatibility, dispersion, and long-term stability.

- Comprehensive environmental assessmentEnhance testing methodologies to more accurately measure MP emissions, leaching characteristics, and cumulative ecosystem impacts under realistic service and ageing conditions.

- Enhanced life cycle modellingRefine LCA frameworks to include dynamic factors such as maintenance practices, evolving vehicle impacts, recyclability, and integration with complementary sustainable technologies (e.g., RAP, WMA).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ANOVA | Analysis of Variance |

| BAET | Bis(2-aminoethyl) terephthalamide |

| BBR | Bending Beam Rheometer |

| BHETA | Bis(2-hydroxyethyl) terephthalamide |

| BMD | Balanced Mix Design |

| cPE | Commercial Polyethylene |

| DOC | Dissolved Organic Carbon |

| DSR | Dynamic Shear Rheometer |

| EVA | Ethylene Vinyl Acetate |

| FM | Fluorescence Microscopy |

| FTIR | Fourier-Transform Infrared Spectroscopy |

| GHG | Greenhouse Gas |

| HDPE | High-Density Polyethylene |

| LCA | Life Cycle Assessment |

| LDPE | Low-Density Polyethylene |

| LLDPE | Linear Low-Density Polyethylene |

| MCP | Microplastic Contaminant Particle |

| MP | Microplastic |

| PAHs | Polycyclic Aromatic Hydrocarbons |

| PAV | Pressure Aging Vessel |

| PE | Polyethylene |

| PET | Polyethylene Terephthalate |

| PP | Polypropylene |

| PS | Polystyrene |

| PU | Polyurethane |

| PVC | Polyvinyl Chloride |

| rABS | Recycled Acrylonitrile Butadiene Styrene |

| RTFOT | Rolling Thin-Film Oven Test |

| SBS | Styrene Butadiene Styrene |

| SCB | Semi-Circular Bending |

| SEM | Scanning Electron Microscopy |

| SPLP | Synthetic Precipitation Leaching Procedure |

| TCLP | Toxicity Characteristic Leaching Procedure |

| VOCs | Volatile Organic Compounds |

| WMA | Warm Mix Asphalt |

References

- OECD. Global Plastics Outlook: Policy Scenarios to 2060; OECD Publishing: Paris, France, 2022. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Azadgoleh, M.A.; Mohammadi, M.M.; Ghodrati, A.; Sharifi, S.S.; Palizban, S.M.M.; Ahmadi, A.; Vahidi, E.; Ayar, P. Characterization of contaminant leaching from asphalt pavements: A critical review of measurement methods, reclaimed asphalt pavement, porous asphalt, and waste-modified asphalt mixtures. Water Res. 2022, 219, 118584. [Google Scholar] [CrossRef] [PubMed]

- Ashish, P.K.; Sreeram, A.; Xu, X.; Chandrasekar, P.; Jagadeesh, A.; Adwani, D.; Padhan, R.K. Closing the Loop: Harnessing waste plastics for sustainable asphalt mixtures—A comprehensive review. Constr. Build. Mater. 2023, 400, 132858. [Google Scholar] [CrossRef]

- Wu, S.; Montalvo, L. Repurposing waste plastics into cleaner asphalt pavement materials: A critical literature review. J. Clean. Prod. 2021, 280, 124355. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; Farina, A.; Yang, B.; Ceylan, H.; Kim, S.; Tutumluer, E.; Cetin, B. The utilization of recycled plastics in the transportation infrastructure systems: A comprehensive review. Constr. Build. Mater. 2024, 411, 134448. [Google Scholar] [CrossRef]

- Li, H.; Xing, C.; Zhu, B.; Zhang, X.; Gao, Y.; Tang, S.; Cheng, H. Comparative analysis of four styrene-butadiene-styrene (SBS) structure repair agents in the rejuvenation of aged SBS-modified bitumen. Constr. Build. Mater. 2025, 476, 141232. [Google Scholar] [CrossRef]

- Singh, A.; Gupta, A. Upcycling of plastic waste in bituminous mixes using dry process: Review of laboratory to field performance. Constr. Build. Mater. 2024, 425, 136005. [Google Scholar] [CrossRef]

- Usman, I.U.; Kunlin, M. Influence of Polyethylene Terephthalate (PET) utilization on the engineering properties of asphalt mixtures: A review. Constr. Build. Mater. 2024, 411, 134439. [Google Scholar] [CrossRef]

- Grady, B.P. Waste plastics in asphalt concrete: A review. SPE Polym. 2021, 2, 4–18. [Google Scholar] [CrossRef]

- Xu, F.; Zhao, Y.; Li, K. Using waste plastics as asphalt modifier: A review. Materials 2021, 15, 110. [Google Scholar] [CrossRef] [PubMed]

- Diab, L.; Al-Qadi, I.L. Life cycle assessment for the use of waste plastics in asphalt concrete mixes. Transp. Res. Rec. 2024, 03611981241245674. [Google Scholar] [CrossRef]

- Abernathy, A.M.; Colosi, L.M.; Samaraee, A.A.; Ozbulut, O.E.; Lloyd, L.N.; Habbouche, J. Life Cycle Assessment of Recycled Plastic Modified Asphalt Pavements: A Case Study in Virginia. Transp. Res. Rec. 2024, 03611981241302338. [Google Scholar] [CrossRef]

- Enfrin, M.; Giustozzi, F. Recent advances in the construction of sustainable asphalt roads with recycled plastic. Polym. Int. 2022, 71, 1376–1383. [Google Scholar] [CrossRef]

- Cardoso, J.; Ferreira, A.; Almeida, A.; Santos, J. Incorporation of plastic waste into road pavements: A systematic literature review on the fatigue and rutting performances. Constr. Build. Mater. 2023, 407, 133441. [Google Scholar] [CrossRef]

- Veropalumbo, R.; Russo, F.; Oreto, C.; Buonocore, G.G.; Verdolotti, L.; Muiambo, H.; Biancardo, S.A.; Viscione, N. Chemical, thermal, and rheological performance of asphalt binder containing plastic waste. Sustainability 2021, 13, 13887. [Google Scholar] [CrossRef]

- Mturi, G.; Ncolosi, N.; O’Connell, J.; Simelane, M. The incorporation of the plastic-coated aggregates into a South African asphalt mixture. Road Mater. Pavement Des. 2025, 1–16. [Google Scholar] [CrossRef]

- Shah, M.M.; Yousaf, J.; Khalid, U.; Li, H.; Yee, J.-J.; Naqvi, S.A.Z. Plastic roads: Asphalt mix design and performance. Discov. Appl. Sci. 2024, 6, 195. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Dassanayake, C. Rutting and Aging Properties of Recycled Polymer-Modified Pavement Materials. Recycling 2025, 10, 60. [Google Scholar] [CrossRef]

- Boom, Y.J.; Enfrin, M.; Grist, S.; Robert, D.; Giustozzi, F. Laboratory evaluation of PAH and VOC emission from plastic-modified asphalt. J. Clean. Prod. 2022, 377, 134489. [Google Scholar] [CrossRef]

- Joohari, I.B.; Maniam, S.; Giustozzi, F. Effect of long-term aging on polymer degradation and fatigue resistance of hybrid polymer-modified bitumen. J. Mater. Civ. Eng. 2022, 34, 04022286. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Chegenizadeh, A.; Nikraz, H.; Rezagholilou, A. Investigating the engineering properties of asphalt binder modified with waste plastic polymer. Ain Shams Eng. J. 2021, 12, 1569–1574. [Google Scholar] [CrossRef]

- Lim, S.M.; He, M.; Hao, G.; Ng, T.C.A.; Ong, G.P. Recyclability potential of waste plastic-modified asphalt concrete with consideration to its environmental impact. Constr. Build. Mater. 2024, 439, 137299. [Google Scholar] [CrossRef]

- Method 1311; Toxicity Characteristic Leaching Procedure. US Environmental Protection Agency: Washington, DC, USA, 1992.

- Lim, S.M.; Ng, T.C.A.; He, M.; Amio, B.E.C.; Hao, G.; Zulkati, A.; Kapilan, S.; Ng, H.Y.; Ong, G.P. Refining leaching protocols of waste-plastic incorporated asphalt mixes for environmental impact assessment. J. Clean. Prod. 2025, 487, 144610. [Google Scholar] [CrossRef]

- Rangelov, M.; Dylla, H.; Sivaneswaran, N. Life-cycle assessment of asphalt pavements with recycled post-consumer polyethylene. Transp. Res. Rec. 2021, 2675, 1393–1407. [Google Scholar] [CrossRef]

- Vargas, C.; El Hanandeh, A. Systematic literature review, meta-analysis and artificial neural network modelling of plastic waste addition to bitumen. J. Clean. Prod. 2021, 280, 124369. [Google Scholar] [CrossRef]

- Polacco, G.; Filippi, S.; Merusi, F.; Stastna, G. A review of the fundamentals of polymer-modified asphalts: Asphalt/polymer interactions and principles of compatibility. Adv. Colloid. Interface Sci. 2015, 224, 72–112. [Google Scholar] [CrossRef] [PubMed]

- Salehi, S.; Arashpour, M.; Kodikara, J.; Guppy, R. Comparative life cycle assessment of reprocessed plastics and commercial polymer modified asphalts. J. Clean. Prod. 2022, 337, 130464. [Google Scholar] [CrossRef]

- Nouali, M.; Ghorbel, E.; Derriche, Z. Phase separation and thermal degradation of plastic bag waste modified bitumen during high temperature storage. Constr. Build. Mater. 2020, 239, 117872. [Google Scholar] [CrossRef]

- Duarte, G.M.; Faxina, A.L. Asphalt concrete mixtures modified with polymeric waste by the wet and dry processes: A literature review. Constr. Build. Mater. 2021, 312, 125408. [Google Scholar] [CrossRef]

- Al-Abdul Wahhab, H.; Dalhat, M.; Habib, M. Storage stability and high-temperature performance of asphalt binder modified with recycled plastic. Road Mater. Pavement Des. 2017, 18, 1117–1134. [Google Scholar] [CrossRef]

- Joohari, I.B.; Giustozzi, F. Chemical and high-temperature rheological properties of recycled plastics-polymer modified hybrid bitumen. J. Clean. Prod. 2020, 276, 123064. [Google Scholar] [CrossRef]

- Zoorob, S.; Suparma, L.B. Laboratory design and investigation of the properties of continuously graded Asphaltic concrete containing recycled plastics aggregate replacement (Plastiphalt). Cem. Concr. Compos. 2000, 22, 233–242. [Google Scholar] [CrossRef]

- Enfrin, M.; Boom, Y.J.; Giustozzi, F. Future recyclability of hot mix asphalt containing recycled plastics. Constr. Build. Mater. 2023, 368, 130396. [Google Scholar] [CrossRef]

- Lu, D.X.; Enfrin, M.; Masood, H.; Giustozzi, F. Performance Evaluation of Post-Consumer and Post-Industrial Recycled Plastics as Binder Modifier in Asphalt Mixes. Int. J. Pavement Res. Technol. 2024, 1–14. [Google Scholar] [CrossRef]

- Capuano, L.; Magatti, G.; Dettori, M.; Mantecca, P. Use of recycled plastics as a second raw material in the production of road pavements: An example of circular economy evaluated with LCA methodology. Procedia Environ. Sci. Eng. Manag. 2020, 7, 37–43. [Google Scholar]

- Boom, Y.J.; Enfrin, M.; Grist, S.; Giustozzi, F. Analysis of possible carcinogenic compounds in recycled plastic modified asphalt. Sci. Total Environ. 2023, 858, 159910. [Google Scholar] [CrossRef] [PubMed]

- Tahmoorian, F.; Liyanapathirana, S.; Yeaman, J.; Egwurube, J. Performance of hot-mix asphalt and modified binders containing polyethylene. J. Transp. Eng. Part B Pavements 2023, 149, 04023001. [Google Scholar] [CrossRef]

- Zanjirani Farahani, H.; Palassi, M.; Sadeghpour Galooyak, S. Using response surface methodology to optimize rubber and LDPE contents in bitumen at low-temperature performance. Pet. Sci. Technol. 2022, 41, 139–158. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, Y.; Hu, K.; Zhang, W.; Chen, G. Investigating the compatibility mechanism of bitumen modified with photo-oxidative aging of polyethylene using molecular dynamics simulation. J. Mater. Civ. Eng. 2023, 35, 04023424. [Google Scholar] [CrossRef]

- Odubela, C.A.; Yaacob, H.; Warid, M.N.B.M.; Karim, K.J.A.; Kamaruddin, N.H.B.M.; Al-Saffar, Z.H.; Rahim, M.I.K. Rheological and chemical properties of reclaimed asphalt pavement using polyethylene terephthalate (PET) additive as a modifier. Environ. Sci. Pollut. Res. 2025, 32, 8025–8034. [Google Scholar] [CrossRef] [PubMed]

- Padhan, R.K.; Mohanta, C.; Sreeram, A.; Gupta, A. Rheological evaluation of bitumen modified using antistripping additives synthesised from waste polyethylene terephthalate (PET). Int. J. Pavement Eng. 2020, 21, 1083–1091. [Google Scholar] [CrossRef]

- Akkouri, N.; Bourzik, O.; Haddaji, Y.; Sadiq Bhat, F.; Baba, K.; Agzenai ben salem, Y. Impact of solar exposure on chemical and rheological properties of hybrid polymer modified bitumen with recycled plastics. Road Mater. Pavement Des. 2024, 1–24. [Google Scholar] [CrossRef]

- Joohari, I.B.; Maniam, S.; Giustozzi, F. Influence of compatibilizers on the storage stability of hybrid polymer-modified bitumen with recycled polyethylene. In Plastic Waste for Sustainable Asphalt Roads; Elsevier: Amsterdam, The Netherlands, 2022; pp. 215–232. [Google Scholar]

- Javadi, N.H.S.; Hajimohammadi, A.; Heydari, S.; Ng, J.J.K.C.; Kypreos, J.E.; Khalili, N. Investigating the applicability of storage stability test for waste plastic modified bitumen: Morphological analyses. Constr. Build. Mater. 2024, 441, 137451. [Google Scholar] [CrossRef]

- Lanotte, M.; Desidery, L. Rutting of waste plastic-modified bitumen. In Plastic Waste for Sustainable Asphalt Roads; Elsevier: Amsterdam, The Netherlands, 2022; pp. 97–114. [Google Scholar]

- Ben Zair, M.M.; Jakarni, F.M.; Muniandy, R.; Hassim, S. A brief review: Application of recycled polyethylene terephthalate in asphalt pavement reinforcement. Sustainability 2021, 13, 1303. [Google Scholar] [CrossRef]

- Ma, Y.; Zhou, H.; Jiang, X.; Polaczyk, P.; Xiao, R.; Zhang, M.; Huang, B. The utilization of waste plastics in asphalt pavements: A review. Clean. Mater. 2021, 2, 100031. [Google Scholar] [CrossRef]

- Baradaran, S.; Rahimi, J.; Ameri, M.; Maleki, A. Mechanical performance of asphalt mixture containing eco-friendly additive by recycling PET. Case Stud. Constr. Mater. 2024, 20, e02740. [Google Scholar] [CrossRef]

- Ghos, S.; Sumter, C.R.; Arevalo, P.C.; Ali, S.A.; Zaman, M.; Hobson, K.R.; Kalicki, G.; Metzer, D. Performance of asphalt mixes containing postconsumer recycled plastic using balanced mix design approach and dry process. Transp. Res. Rec. 2022, 2676, 720–732. [Google Scholar] [CrossRef]

- Ma, J.; Hesp, S.A. Effect of recycled polyethylene terephthalate (PET) fiber on the fracture resistance of asphalt mixtures. Constr. Build. Mater. 2022, 342, 127944. [Google Scholar] [CrossRef]

- Ma, J.; Yuan, H.; Nawarathna, H.M.; Hesp, S.A. Sustainable application of recycled plastics in asphalt pavement: Case study of a trial in Newtonville, Ontario, Canada. Can. J. Civ. Eng. 2024, 52, 597–612. [Google Scholar] [CrossRef]

- Radeef, H.R.; Hassan, N.A.; Katman, H.Y.; Mahmud, M.Z.H.; Abidin, A.R.Z.; Ismail, C.R. The mechanical response of dry-process polymer wastes modified asphalt under ageing and moisture damage. Case Stud. Constr. Mater. 2022, 16, e00913. [Google Scholar] [CrossRef]

- Yin, F.; Kmetz, M.; Timm, D.; West, R.; Taylor, A. Laboratory and Field Performance Characterization of Recycled-Plastic-Modified Asphalt Mixtures at the National Center for Asphalt Technology Test Track. Transp. Res. Rec. 2025, 03611981251318331. [Google Scholar] [CrossRef]

- Chiang, C.-L.; Mivehchi, M.; Wen, H. Towards a use of waste polyethylene in asphalt mixture as a compaction aid. J. Clean. Prod. 2024, 440, 140989. [Google Scholar] [CrossRef]

- La Macchia, J.N.; Baglieri, O.; Dalmazzo, D.; Santagata, E. Engineering Properties of Road Paving Mixtures with High Content of Reclaimed Asphalt and Recycled Waste Plastics. Materials 2024, 17, 5681. [Google Scholar] [CrossRef] [PubMed]

- Alemu, G.M.; Melese, D.T.; Mahdi, T.W.; Negesa, A.B. Combined performance of polyethylene terephthalate waste plastic polymer and crumb rubber in modifying properties of hot mix asphalt. Adv. Mater. Sci. Eng. 2023, 2023, 6320490. [Google Scholar] [CrossRef]

- Liu, T.; Li, X.; Li, R.; Pei, J.; Zhao, X. Performance of dry mixed rubber–plastic composite modified asphalt mixture. J. Mater. Civ. Eng. 2022, 34, 04022243. [Google Scholar] [CrossRef]

- Qabur, A.; Baaj, H.; El-Hakim, M. A Laboratory Study on Enhancing Asphalt Mixture Properties through Dry Mixing with High-Dose Multilayer Plastic Packaging Pellet Additives. J. Mater. Civ. Eng. 2025, 37, 04025049. [Google Scholar] [CrossRef]

- Pourfeiz, A.; Modarres, A.; Ghodrati, A.; Ayar, P.; Yousefi, A.A. Study on mode I, mode II and mixed mode I/II fracture behavior of hot mix asphalt containing silane crosslinkable polyethylene waste. Theor. Appl. Fract. Mech. 2023, 124, 103810. [Google Scholar] [CrossRef]

- Zhang, J.; Li, H.; Liu, P.; Liang, M.; Jiang, H.; Yao, Z.; Airey, G. Experimental exploration of influence of recycled polymer components on rutting resistance and fatigue behavior of asphalt mixtures. J. Mater. Civ. Eng. 2020, 32, 04020129. [Google Scholar] [CrossRef]

- Mishra, B.; Gupta, M.K. Performance study on bituminous concrete mixes using varying content and sizes of shredded polyethylene terephthalate. J. Mater. Civ. Eng. 2021, 33, 04020436. [Google Scholar] [CrossRef]

- Fonseca, M.; Capitão, S.; Almeida, A.; Picado-Santos, L. Influence of plastic waste on the workability and mechanical behaviour of asphalt concrete. Appl. Sci. 2022, 12, 2146. [Google Scholar] [CrossRef]

- Haider, S.; Hafeez, I.; Ullah, R. Sustainable use of waste plastic modifiers to strengthen the adhesion properties of asphalt mixtures. Constr. Build. Mater. 2020, 235, 117496. [Google Scholar] [CrossRef]

- Boom, Y.J.; Enfrin, M.; Grist, S.; Giustozzi, F. Recycled plastic modified bitumen: Evaluation of VOCs and PAHs from laboratory generated fumes. Sci. Total Environ. 2022, 832, 155037. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Xiao, Y.; Long, Y.; Chen, Z.; Cui, P.; Wu, R.; Chang, X. VOCs reduction in bitumen binder with optimally designed Ca (OH) 2-incorporated zeolite. Constr. Build. Mater. 2021, 279, 122485. [Google Scholar] [CrossRef]

- Xiao, Y.; Wan, M.; Jenkins, K.; Wu, S.; Cui, P. Using activated carbon to reduce the volatile organic compounds from bituminous materials. J. Mater. Civ. Eng. 2017, 29, 04017166. [Google Scholar] [CrossRef]

- Cui, P.; Wu, S.; Li, F.; Xiao, Y.; Zhang, H. Investigation on using SBS and active carbon filler to reduce the VOC emission from bituminous materials. Materials 2014, 7, 6130–6143. [Google Scholar] [CrossRef] [PubMed]

- Rasoulzadeh, Y.; Mortazavi, S.; Yousefi, A.; Khavanin, A. Decreasing polycyclic aromatic hydrocarbons emission from bitumen using alternative bitumen production process. J. Hazard. Mater. 2011, 185, 1156–1161. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-Y.; Kim, K.-W.; Yun, Y.-m.; Le, T.H.M. Evaluation of eco-friendly asphalt mixtures incorporating waste plastic aggregates and additives: Magnesium, fly ash, and steel slag. Case Stud. Constr. Mater. 2024, 20, e02756. [Google Scholar] [CrossRef]

- Duan, Y.; Wu, K.; Serrat, C.; Arteaga-Larios, F.; Brown, H.; DuBois, C.; Buttlar, W.G.; Deng, B. Assessment of microplastics production from waste plastics-modified asphalt pavement. Resour. Conserv. Recycl. 2024, 202, 107329. [Google Scholar] [CrossRef]

- Bualuang, T.; Jitsangiam, P.; Jakrawatana, N.; Teeratitayangkul, P.; Vongruang, P.; Thienchai, C.; Wongchana, P.; Prommarin, J. Utilization of plastic waste in hot mix asphalt using dry mixing processes: Laboratory assessment of airborne microplastics. Results Eng. 2025, 25, 104464. [Google Scholar] [CrossRef]

- Method 1312; Synthetic Precipitation Leaching Procedure. US Environmental Protection Agency: Washington, DC, USA, 1994.

- Mohammadi, R.; Ameri, M. A systematic review on sustainable utilization of plastic waste in asphalt: Assessing environmental and health impact, performance, and economic viability. Environ. Sci. Pollut. Res. 2024, 31, 62676–62701. [Google Scholar] [CrossRef] [PubMed]

- Enfrin, M.; Myszka, R.; Giustozzi, F. Paving roads with recycled plastics: Microplastic pollution or eco-friendly solution? J. Hazard. Mater. 2022, 437, 129334. [Google Scholar] [CrossRef] [PubMed]

- Golgoli, M.; Farahbakhsh, J.; Najafi, M.; Khiadani, M.; Johns, M.L.; Zargar, M. Resilient forward osmosis membranes against microplastics fouling enhanced by MWCNTs/UiO-66-NH2 hybrid nanoparticles. Chemosphere 2024, 359, 142180. [Google Scholar] [CrossRef] [PubMed]

- Rosso, B.; Bravo, B.; Gregoris, E.; Barbante, C.; Gambaro, A.; Corami, F. Quantification and chemical characterization of plastic additives and small microplastics (<100 μm) in highway road dust. Toxics 2023, 11, 936. [Google Scholar] [CrossRef] [PubMed]

- Myszka, R.; Enfrin, M.; Giustozzi, F. Microplastics in road dust: A practical guide for identification and characterisation. Chemosphere 2023, 315, 137757. [Google Scholar] [CrossRef] [PubMed]

- Boom, Y.J.; Enfrin, M.; Swaney, M.; Masood, H.; Pramanik, B.K.; Robert, D.; Giustozzi, F. Engineering properties, microplastics and emissions assessment of recycled plastic modified asphalt mixtures. Sci. Total Environ. 2023, 893, 164869. [Google Scholar] [CrossRef] [PubMed]

- Praticò, F.G.; Giunta, M.; Mistretta, M.; Gulotta, T.M. Energy and environmental life cycle assessment of sustainable pavement materials and technologies for urban roads. Sustainability 2020, 12, 704. [Google Scholar] [CrossRef]

- Khan, S.; Li, H.; Ncube, M.H.; Butt, A.A.; Han, Y.; Harvey, J. Environmental implications of recycled materials in pavement construction: A comprehensive review and future research directions. Transp. Res. Part D Transp. Environ. 2025, 140, 104642. [Google Scholar] [CrossRef]

- Ghodrati, A.; Asadi Azadgoleh, M.; Zalnezhad, M.; Mohammadi, M.M.; Ayar, P.; Vahidi, E. Performance improvement of slurry seal by glass powder: Mechanical evaluation and life cycle assessment. Road Mater. Pavement Des. 2025, 1–23. [Google Scholar] [CrossRef]

- Zeiada, W.; Al-Khateeb, G.; Hajj, E.Y.; Ezzat, H. Rheological properties of plastic-modified asphalt binders using diverse plastic wastes for enhanced pavement performance in the UAE. Constr. Build. Mater. 2024, 452, 138922. [Google Scholar] [CrossRef]

- Assaf, H.; Abdo, A.A. Life cycle assessment of incorporating recycled materials in pavement design. J. King Saud. Univ.-Eng. Sci. 2024, 36, 473–484. [Google Scholar] [CrossRef]

- Rispoli, O.; Ajibade, O.O. Comparative life cycle assessment of a novel sustainable road pavement system adopting recycled plastic from PET bottles and carbonated aggregate. Heliyon 2024, 10, e24354. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, M.M.; Azadgoleh, M.A.; Ghodrati, A.; Zalnezhad, M.; Ayar, P.; Fini, E. Introducing waste glass powder as a sustainable constituent in microsurfacing. Constr. Build. Mater. 2023, 395, 132271. [Google Scholar] [CrossRef]

- Yousefi, A.A.; Underwood, B.S.; Ghodrati, A.; Behnood, A.; Vahidi, E.; Nowrouzi, A.; Ayar, P.; Haghshenas, H.F. Towards a durable and sustainable warm mix asphalt: Techno-economic and environmental evaluation considering balanced mix design approach. J. Clean. Prod. 2025, 486, 144311. [Google Scholar] [CrossRef]

- Yao, L.; Leng, Z.; Lan, J.; Chen, R.; Jiang, J. Environmental and economic assessment of collective recycling waste plastic and reclaimed asphalt pavement into pavement construction: A case study in Hong Kong. J. Clean. Prod. 2022, 336, 130405. [Google Scholar] [CrossRef]

- Santos, J.; Pham, A.; Stasinopoulos, P.; Giustozzi, F. Recycling waste plastics in roads: A life-cycle assessment study using primary data. Sci. Total Environ. 2021, 751, 141842. [Google Scholar] [CrossRef] [PubMed]

- Piao, Z.; Bueno, M.; Poulikakos, L.D.; Hellweg, S. Life cycle assessment of rubberized semi-dense asphalt pavements; A hybrid comparative approach. Resour. Conserv. Recycl. 2022, 176, 105950. [Google Scholar] [CrossRef]

| References | Plastic Type | Density (g/cm3) | Melting Point (°C) | Common Waste Sources | Key Advantages | Key Disadvantages |

|---|---|---|---|---|---|---|

| [11,14,27,31] | LDPE | 0.91–0.94 | 110–120 | Bottles, packaging films, bags | Good compatibility, flexibility, easy processing | UV degradation, lower strength |

| [11,14,31,32] | HDPE | 0.94–0.97 | ~130 | Containers, pipelines, industrial packaging | Elevated strength, moisture resistance | Fragile at low temperatures |

| [10,11,28] | PP | 0.90–0.91 | 145–165 | Straws, furnishings, automotive parts | superior chemical resistance, improves high-temp performance | Inadequate adhesion with bitumen unless compatibilized |

| [11,14,27] | PVC | 1.34–1.39 | 160–210 (decomposes) | Pipes, cables, window frames | Flame resistance, stiffness | Releases toxic gases (e.g., HCl), poor thermal cracking resistance |

| [10,11] | PS | 1.04–1.07 | 210–249 | Food containers, cutlery, CD cases | Elevated rigidity, enhanced rutting resistance | Extremely brittle, poor low-temp performance |

| [9,11,14,27] | PET | 1.16–1.58 | ~260 | Beverage containers, fabrics | High tensile strength, chemical resistance | Requires substantial energy to melt, brittle at low temperatures |

| [11,14,33] | EVA | 0.93–0.95 | 65–80 | Sole materials, films, cables | Elastomeric properties, good low-temp performance | High viscosity, phase separation risks above 2 wt% |

| [11,27] | rABS | 1.03–1.07 | No true melting pt | E-waste, electronics | Improves viscosity and thermal characteristics | Limited compatibility, minimal recyclability |

| [11,28] | PU | 1.2–1.3 | No true melting pt | Upholstery, insulation, footwear | High strength | Decomposes, environmental risk when subjected to heating |

| Reference | Incorporation Method | Plastic Type | Plastic Dosage (% by wt. Binder) | Mixing Temp (°C) | Application Scale | Benefits | Limitations/Drawbacks |

|---|---|---|---|---|---|---|---|

| [17] | Dry (Plastic-Coated Aggregates) | LDPE | 7% by weight of reference (unmodified) binder | 190 | Lab South African dense-graded asphalt mixtures) | Enhanced bonding and volumetric consistency; applicable in existing plants | Restricted to low-melting plastics; no change in optimum binder content; issues with phase uniformity |

| [37] | Wet (Binder Modifier) | Hard plastics with graphene | 0.5% by weight of binder | Not specified | LCA Case Study (Europe) | Extended maintenance-free operating periods (MFOP); up to 70% environmental impact reduction | Necessitates preprocessing and quality control infrastructure |

| [35] | Mixed | RLDPE | 1.5% by weight of total mix | Aggregate at 185, RAP/P-RAP at 95, Binder at 155 | Lab scale | Superior rutting resistance among P-RAP mixes, adequate compatibility, fracture energy, and fatigue resistance | Requires precise control of mixing order and temperature for effective blending |

| References | Plastic Type | Dosage (wt%) | Particle Size | Mixing Temp (°C) | Shear Rate/Time | Key Performance Impacts | Compatibility/Aging |

|---|---|---|---|---|---|---|---|

| [39,41] | LDPE | Up to 5% (by weight of the unmodified binder) | <1 mm (shredded flakes) | 160–180 | ≥3000 rpm/≥90 min | ↑ Softening point (57–68.5 °C), ↓ penetration (up to 63%), ↑ viscosity, improved rutting resistance | Moderate compatibility: phase stability depends on particle size and dosage |

| [39] | HDPE | Up to 5% (by weight of the unmodified binder) | <1 mm (shredded flakes) | 160–180 | ≥3000 rpm/≥90 min | ↑ Softening point (51–79 °C), ↑ stiffness, ↓ penetration | Reduced compatibility resulting from elevated crystallinity; susceptible to phase separation |

| [41] | Photo-oxidized PE | Not specified | Not specified | 170 | 5000 rpm/60 min | ↑ G*/sinδ, ↑ stiffness, ↑ compatibility and homogeneity, ↓ diffusion coefficient | Elevated compatibility attributed to polar groups; improved dispersion and interaction |

| [40] | LDPE + Crumb Rubber | 3% LDPE + 2% CR | LDPE <1 mm; rubber <1 mm | ~170 | 3000 rpm/90 min | Optimized low-temp performance (↓ stiffness, ↑ m-value); improved fatigue and rutting resistance | Effective synergistic interaction; refined by response surface methodology |

| References | Plastic Type | Dosage | Incorporation Method | Performance Outcomes | Notable Insights |

|---|---|---|---|---|---|

| [50] | PET (chemically recycled) | 1–3% by wt. of binder | Wet method (aminolysis) | ↑ Rutting and moisture resistance; ↓ low-temp cracking; optimal dynamic creep at 1% | Dosage–performance trade-off; ANOVA confirmed significance |

| [51] | LDPE/LLDPE | 0.25–1.0% by wt. of aggregate | Dry method | ↑ Rutting resistance, CTIndex (LLDPE); ↑ moisture resistance (LDPE) | LLDPE showed better crack tolerance; LDPE showed better moisture resistant |

| [52,53] | PET fibres | Not specified (18 mm fibres) | Dry method (fibre reinforcement) | ↑ Cracking resistance and toughness in SCB tests | More effective at low loading rates and cold climates |

| [55] | LLDPE | 0.5% by wt. of aggregate (dry); 1.0% by wt. of binder ( ) | Both dry and wet methods | Wet: comparable to SBS; dry: ↓ CTIndex, ↑ stiffness | Wet method showed more balanced overall performance; dry method leads to brittleness |

| [56] | LDPE/HDPE | Unspecified; flakes/powder | Modified dry method (PlasticAid) | ↑ Compactability, ↓ rut depth, ↑ crack resistance (flakes) | Powder less effective than flakes |

| [57] | Waste plastic granules + RAP | 0.3–0.5% granules | Hybrid (mixed method | Maintained strength; ↑ sustainability | No compromise in volumetrics or workability |

| [58] | PET + crumb rubber | 2% PET + 10% rubber | Dry method | ↑ Marshall stability, stiffness, ITS | Synergistic effects observed (PET enhances stiffness and temperature resistance; crumb rubber improves elasticity and fatigue life) |

| [59] | PE + rubber | Not specified | Dry–mixed composite | ↑ Rutting resistance; balanced fatigue life | Twin-screw extrusion improved integration |

| [60] | Multilayered Plastic | High dose (unspecified) | Dry method | ↑ Air voids, ↓ moisture resistance | High content increases compaction challenges |

| References | Plastic Type | Incorporation Method | Key Findings | Conditions | Environmental Impacts |

|---|---|---|---|---|---|

| [20] | cPE, LDPE, rABS | Wet method | VOC and PAH emissions increased with temperature; 6% cPE at 140 °C reduced VOC by 11.2%; rABS at 180 °C increased PAH by 19.5% | 140–180 °C, 6% cPE, rABS variants | Temperature-sensitive fume emissions; cPE shows mitigation potential |

| [38] | Various, incl. LDPE, HDPE | Wet and dry methods | MPs generated via mechanical wear (e.g., from traffic); wet method embeds more uniformly in the bitumen, which reduces exposure; dry method leaves surface more exposed to plastics, increasing the risk of MP release | Simulated traffic and abrasion | Wet: less MP release; dry: method more susceptible to MP shedding |

| [25] | Unspecified plastic particles | Dry | Cantabro abrasion yielded realistic leachate with low nutrient/heavy metal levels but noted DOC mobility | Leaching post-Cantabro abrasion | Low metals; DOC remains concern for aquatic systems |

| [4] | Various | Wet and dry | Poor compatibility leads to phase separation and plastic loss; increases leaching and MPs | Environmental exposure, field sim. | Elevated risk of MPs from poorly compatible blends |

| [13] | PET, HDPE | Dry | RPM increased pavement life by 14–65%, reducing maintenance; road roughness raised vehicle emissions | FlexPave™, AASHTOWare simulations | Net benefit only if roughness is controlled; major landfill diversion |

| [12] | LDPE, PS | Wet and dry | Plastic-modified asphalt outperformed SBS in all except for ozone depletion; transport and processing energy contributes significantly to the total environmental impact | Full LCA: cradle to installation | Using waste plastics generally better than SBS in terms of environmental impacts; wet method tends to result in cleaner environmental outcomes over the long term |

| [90] | PE (LDPE, HDPE) | Wet and dry methods | Wet process showed stronger environmental gains than dry; recycling locally amplifies benefits | Case study in Victoria, Australia | Wet method better for GHG; dry method is constrained by synthetic aggregate replacement efficiency |

| [39] | PE | Not specified | 5% PE saved >1 ton bitumen and diverted 1.125 million plastic bags/km | 5% PE binder | Significant plastic waste diversion and material savings |

| [89] | PET | Dry method with up to 40% RAP | 2% PET + 40% RAP reduced life cycle costs by 31.8% and GHG emissions by 37.6% | 2% PET binder, up to 40% RAP | Significant reduction in both cost and emissions with recycled content synergy |

| [37] | Hard polyolefins + graphene | Wet (modifier granulate) | Impact reductions of ~70% (standard thickness scenario) and ~30% (reduced thickness) | 0.5% plastic modifier; 20-year LCA | Circular use of hard plastics enables substantial impact mitigation and durability gains |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghodrati, A.; Mashaan, N.S.; Paraskeva, T. Incorporating Waste Plastics into Pavement Materials: A Review of Opportunities, Risks, Environmental Implications, and Monitoring Strategies. Appl. Sci. 2025, 15, 8112. https://doi.org/10.3390/app15148112

Ghodrati A, Mashaan NS, Paraskeva T. Incorporating Waste Plastics into Pavement Materials: A Review of Opportunities, Risks, Environmental Implications, and Monitoring Strategies. Applied Sciences. 2025; 15(14):8112. https://doi.org/10.3390/app15148112

Chicago/Turabian StyleGhodrati, Ali, Nuha S. Mashaan, and Themelina Paraskeva. 2025. "Incorporating Waste Plastics into Pavement Materials: A Review of Opportunities, Risks, Environmental Implications, and Monitoring Strategies" Applied Sciences 15, no. 14: 8112. https://doi.org/10.3390/app15148112

APA StyleGhodrati, A., Mashaan, N. S., & Paraskeva, T. (2025). Incorporating Waste Plastics into Pavement Materials: A Review of Opportunities, Risks, Environmental Implications, and Monitoring Strategies. Applied Sciences, 15(14), 8112. https://doi.org/10.3390/app15148112