The Study of Tribological Characteristics of YSZ/NiCrAlY Coatings and Their Resistance to CMAS at High Temperatures

Abstract

1. Introduction

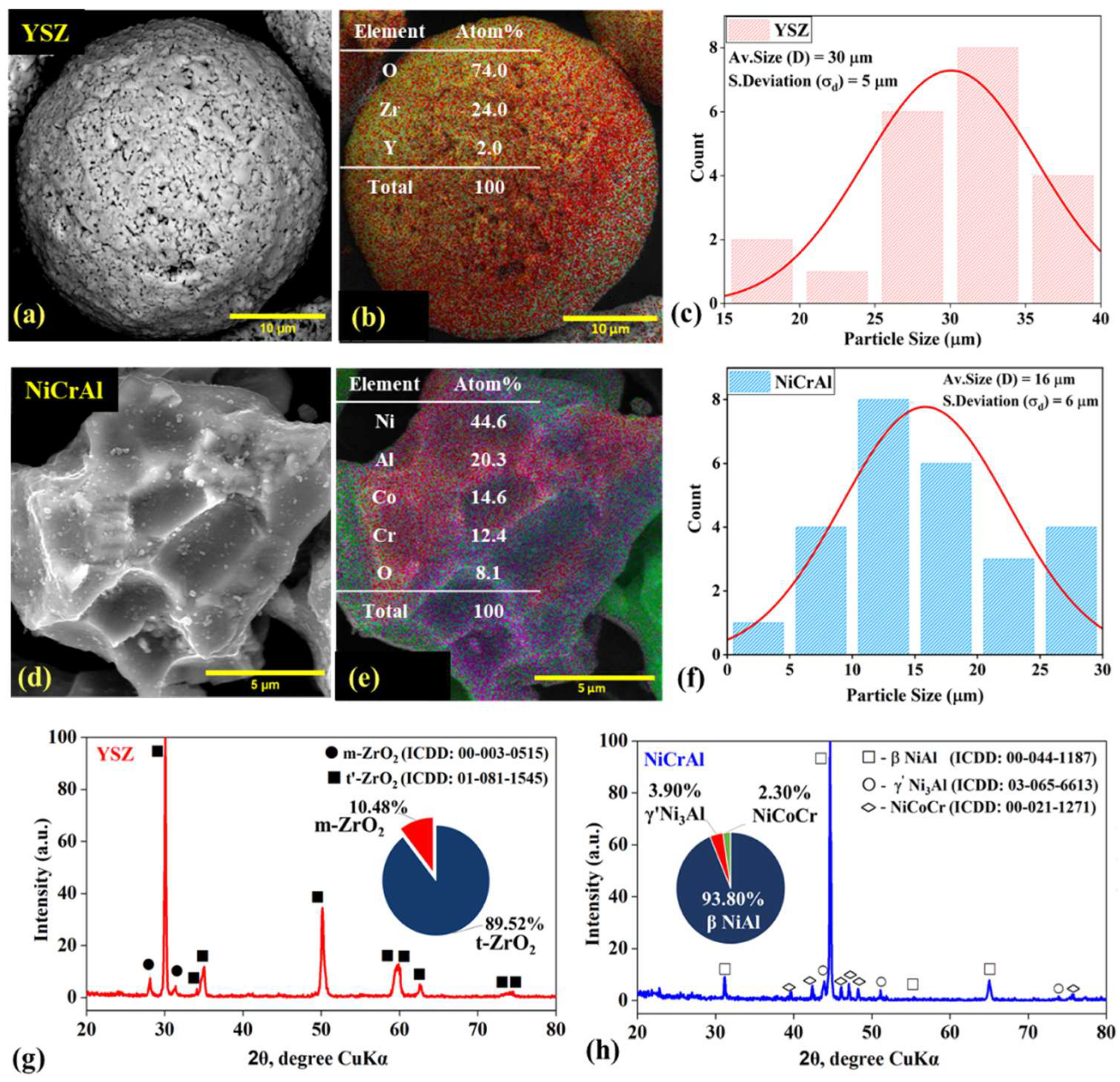

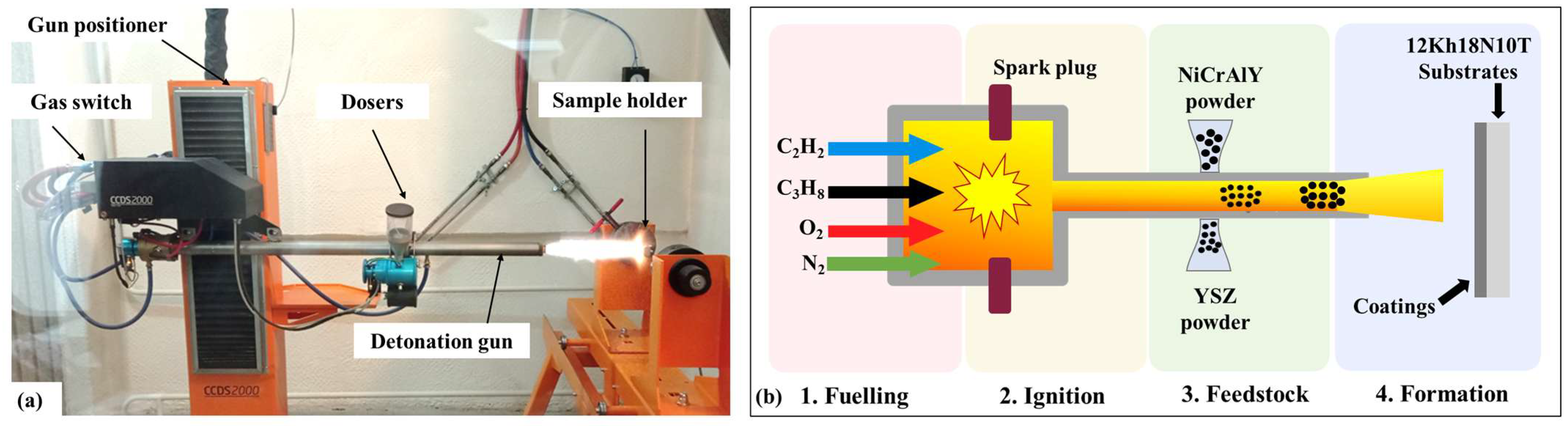

2. Materials and Methods

- V—volume of wear material [mm3],

- Fn—normal force applied to the sample [N],

- s—friction path [m].

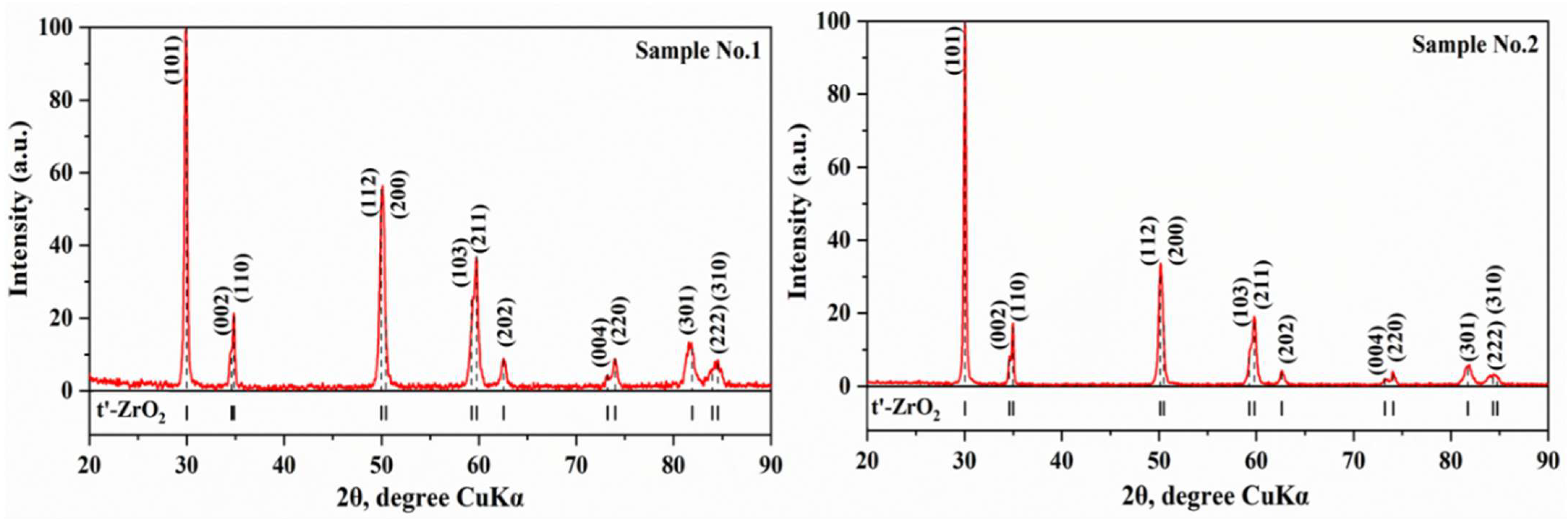

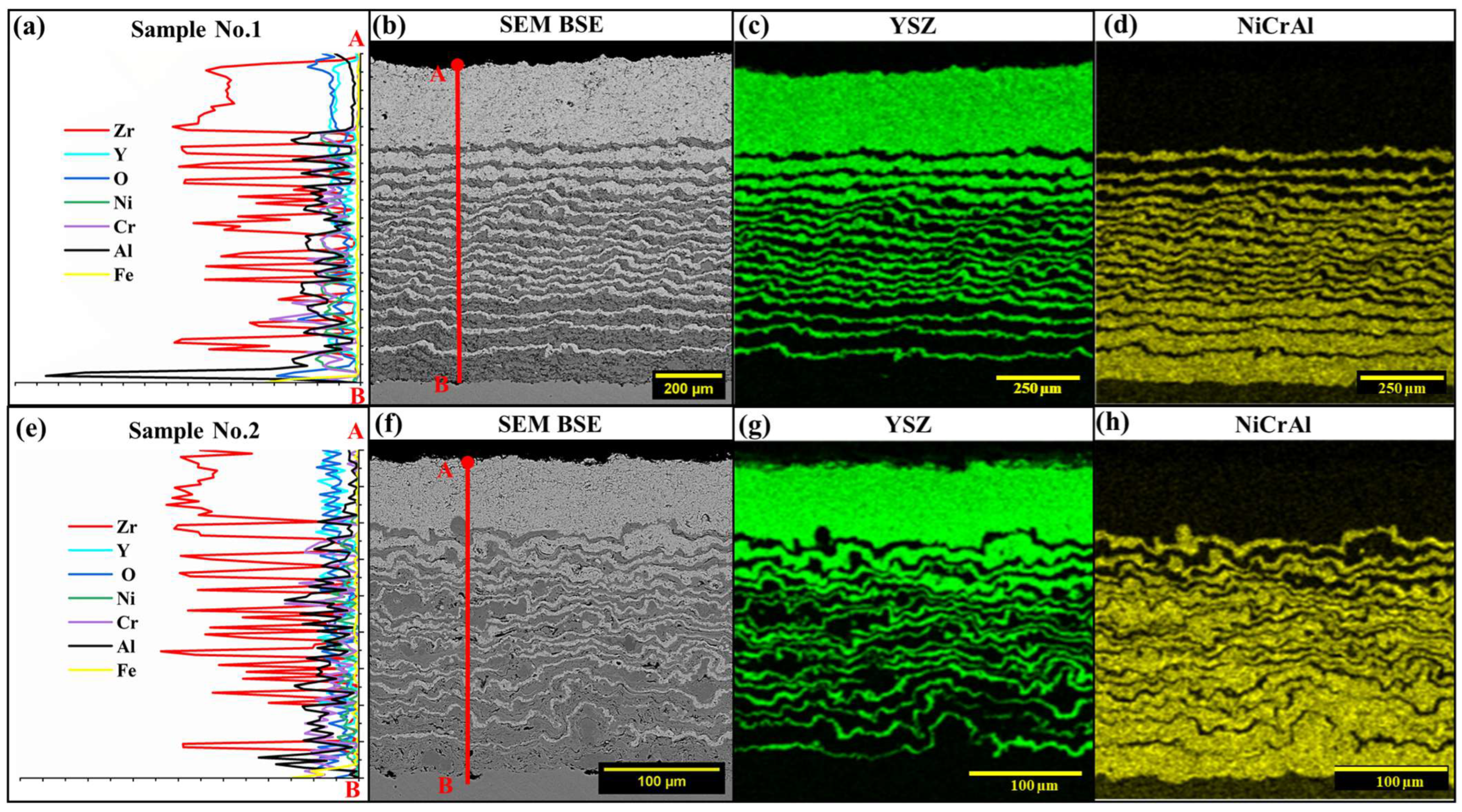

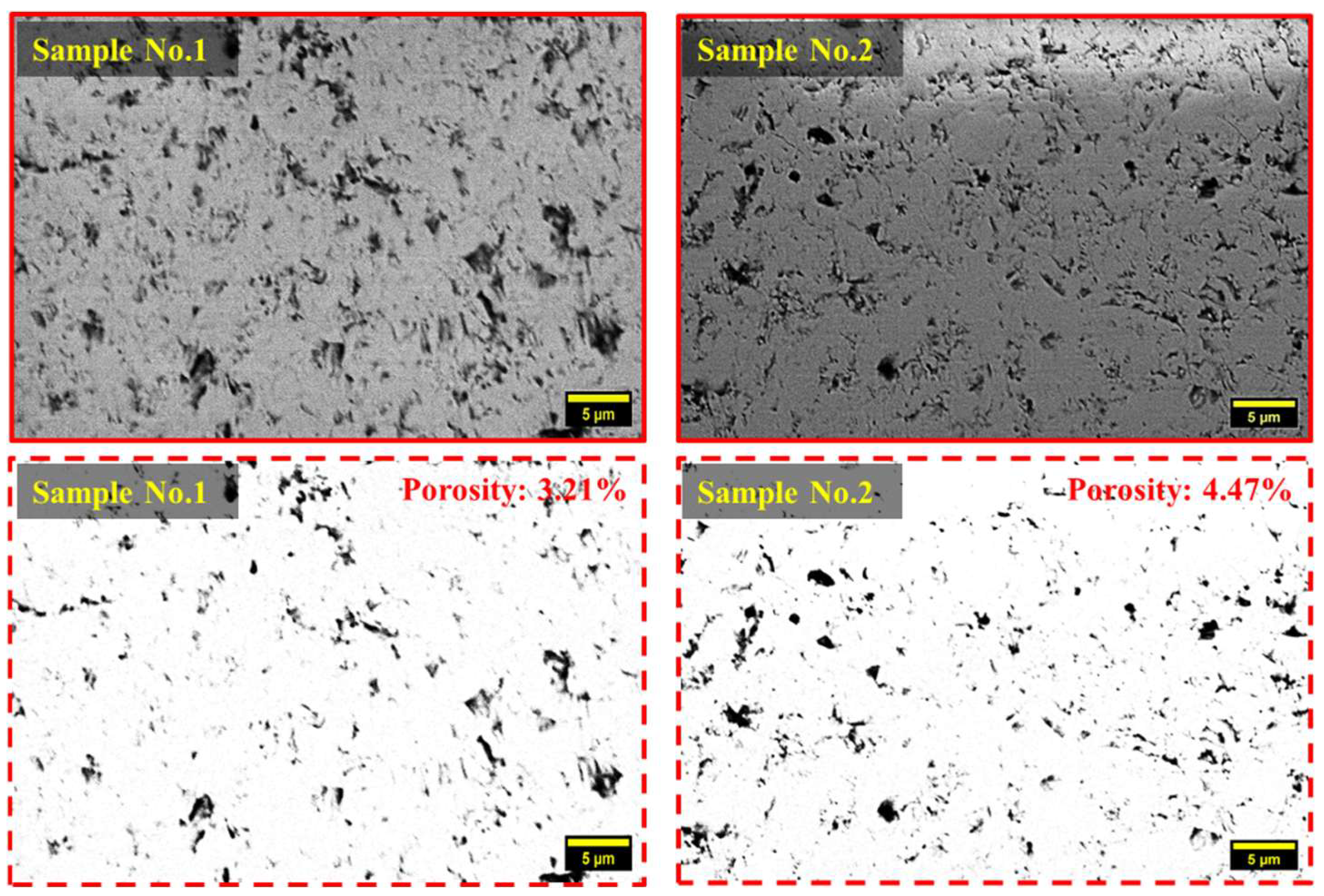

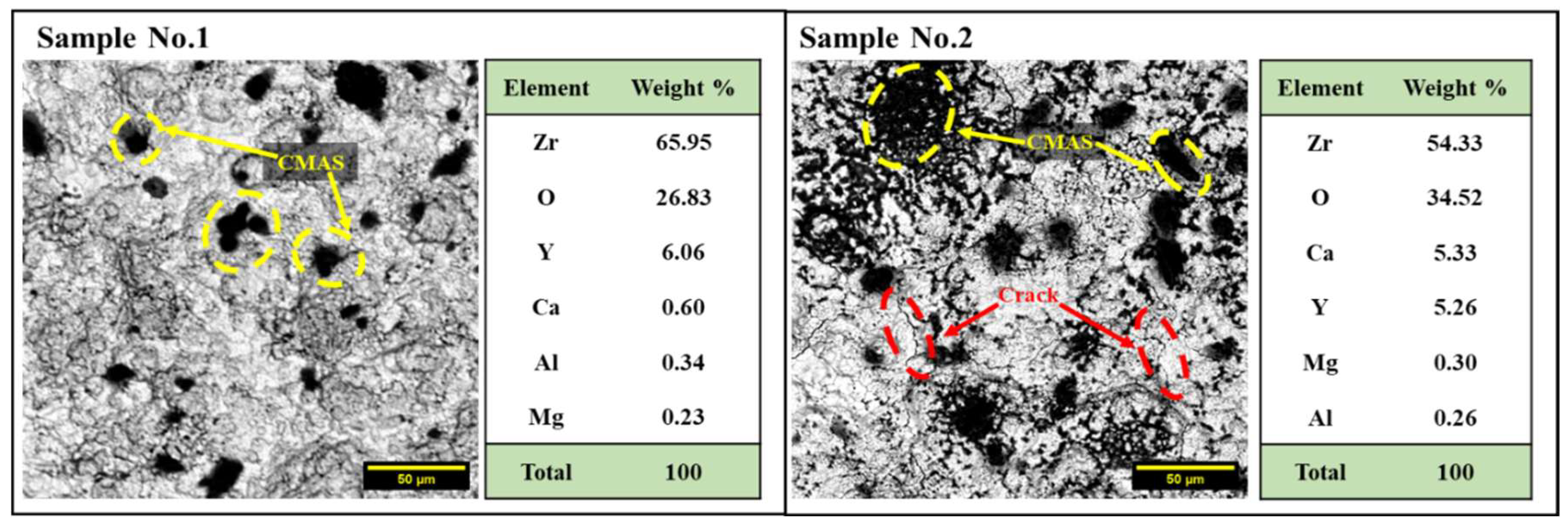

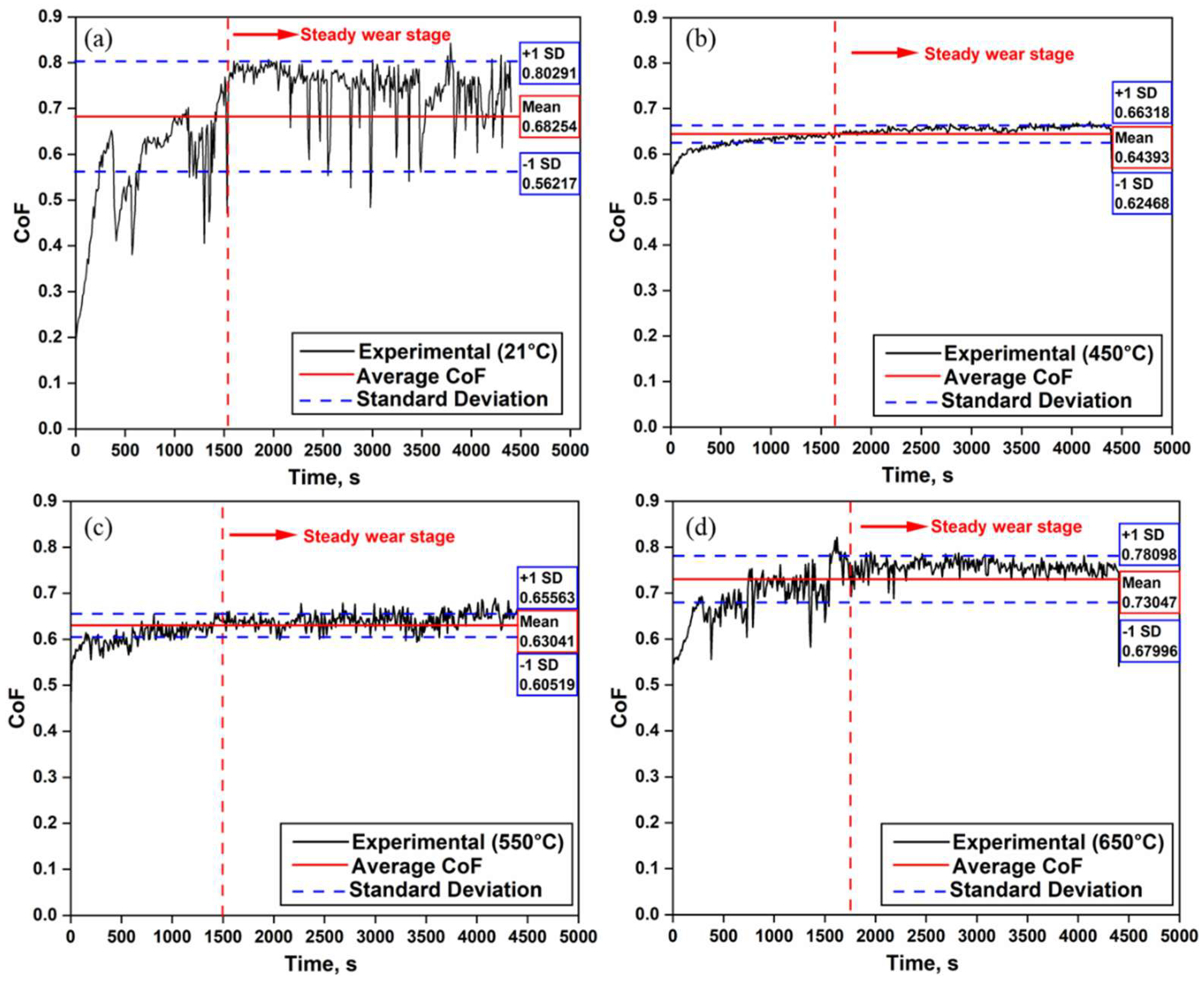

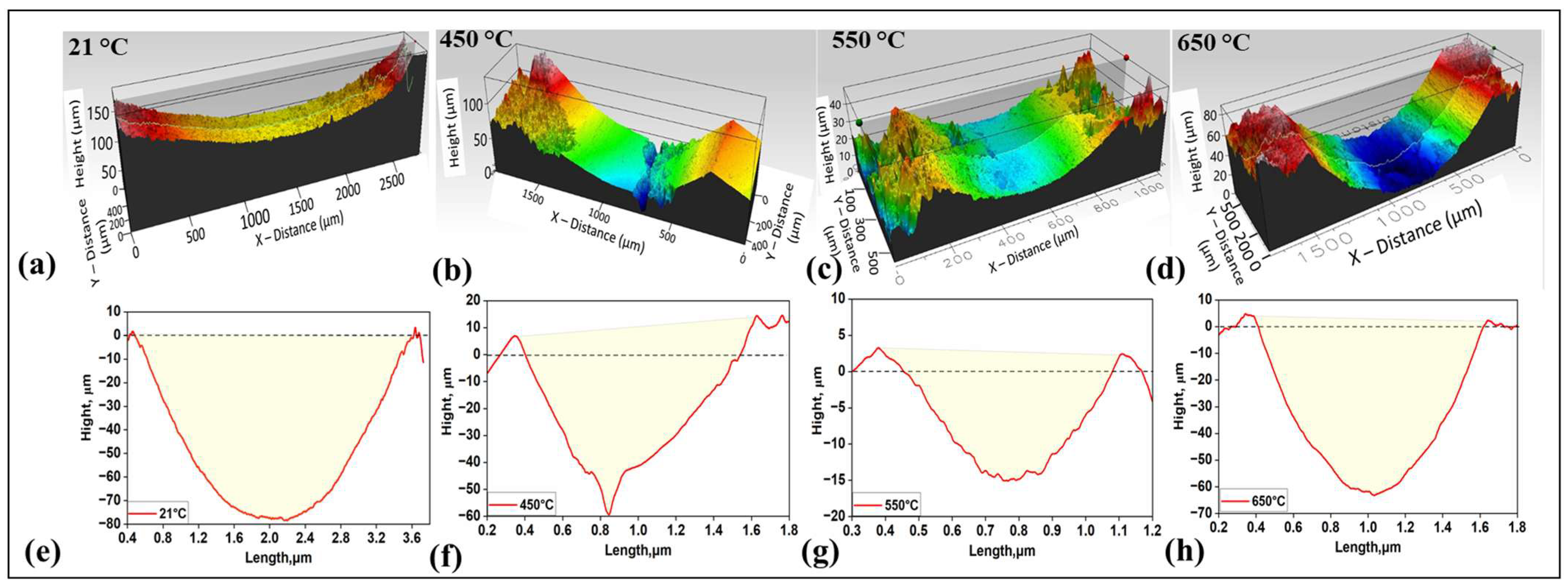

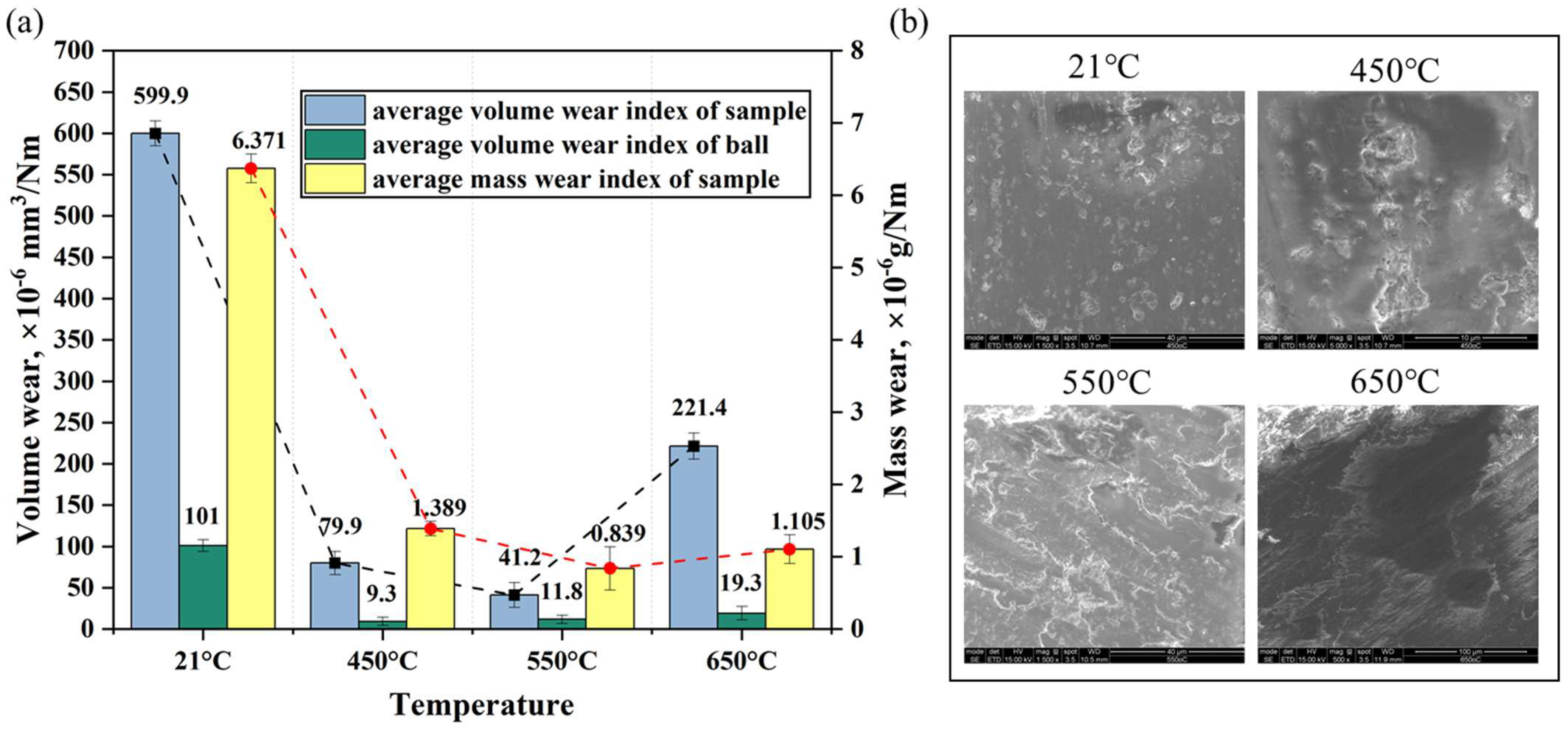

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Morelli, S.; Bursich, S.; Bolelli, G.; Puddu, P.; Rossi, E.; Mecca, F.G.; Bortolotti, L.; Lusvarghi, L. Thermal Conductivity and Micromechanical Properties of Plasma-Sprayed Yttria-Stabilized Zirconia Thermal Barrier Coatings. Available SSRN 2025, 39. [Google Scholar] [CrossRef]

- Gopinath, N.K.; Dan, A.; Aruna, S.T.; Govindarajan, K.V.; Jagadeesh, G.; Barshilia, H.C.; Roy Mahapatra, D. High Emittance Plasma Sprayed ZrO2-Y2O3/La2Zr2O7 Thermal Barrier Coatings for Potential Application in Scramjets. Appl. Surf. Sci. 2024, 652, 159324. [Google Scholar] [CrossRef]

- Cao, X.Q.; Vassen, R.; Stoever, D. Ceramic Materials for Thermal Barrier Coatings. J. Eur. Ceram. Soc. 2004, 24, 1–10. [Google Scholar] [CrossRef]

- Thibblin, A.; Jonsson, S.; Olofsson, U. Influence of Microstructure on Thermal Cycling Lifetime and Thermal Insulation Properties of Yttria-Stabilized Zirconia Thermal Barrier Coatings for Diesel Engine Applications. Surf. Coat. Technol. 2018, 350, 1–11. [Google Scholar] [CrossRef]

- Mishra, S.K.; Pandey, S.; Mahato, P.; Kumar, K.S.; Bysakh, S.; Sreemany, M.; Pathak, L.C. Microstructural Studies on EB-PVD Deposited NiCrAlY, YSZ and Lanthanum Zirconate for Thermal Barrier Applications. Surf. Coat. Technol. 2012, 207, 143–148. [Google Scholar] [CrossRef]

- Badea, T.-A.; Condruz, M.-R.; Paraschiv, A. A Study on Long-Term Oxidation and Thermal Shock Performance of Nanostructured YSZ/NiCrAlY TBC with a Less Dense Bond Coat. Materials 2023, 16, 5294. [Google Scholar] [CrossRef]

- Li, S.; An, Y.; Zhou, H.; Chen, J. Plasma Sprayed YSZ Coatings Deposited at Different Deposition Temperatures, Part 2: Tribological Performance. Surf. Coat. Technol. 2018, 349, 998–1007. [Google Scholar] [CrossRef]

- Curry, N.; Markocsan, N.; Li, X.-H.; Tricoire, A.; Dorfman, M. Next Generation Thermal Barrier Coatings for the Gas Turbine Industry. J. Therm. Spray Technol. 2011, 20, 108–115. [Google Scholar] [CrossRef]

- Sahith, M.S.; Giridhara, G.; Kumar, R.S. Development and Analysis of Thermal Barrier Coatings on Gas Turbine Blades–A Review. Mater. Today Proc. 2018, 5, 2746–2751. [Google Scholar] [CrossRef]

- Wu, S.; Zhao, Y.; Li, W.; Liu, W.; Wu, Y.; Liu, F. Research Progresses on Ceramic Materials of Thermal Barrier Coatings on Gas Turbine. Coatings 2021, 11, 79. [Google Scholar] [CrossRef]

- Vaßen, R.; Jarligo, M.O.; Steinke, T.; Mack, D.E.; Stöver, D. Overview on Advanced Thermal Barrier Coatings. Surf. Coat. Technol. 2010, 205, 938–942. [Google Scholar] [CrossRef]

- Gentleman, M.M.; Clarke, D.R. Concepts for Luminescence Sensing of Thermal Barrier Coatings. Surf. Coat. Technol. 2004, 188–189, 93–100. [Google Scholar] [CrossRef]

- Schulz, U.; Peters, M.; Bach, F.-W.; Tegeder, G. Graded Coatings for Thermal, Wear and Corrosion Barriers. Mater. Sci. Eng. A 2003, 362, 61–80. [Google Scholar] [CrossRef]

- Tkadletz, M.; Schalk, N.; Daniel, R.; Keckes, J.; Czettl, C.; Mitterer, C. Advanced Characterization Methods for Wear Resistant Hard Coatings: A Review on Recent Progress. Surf. Coat. Technol. 2016, 285, 31–46. [Google Scholar] [CrossRef]

- Hu, H.; Mao, L.; Yin, S.; Liao, H.; Zhang, C. Wear-Resistant Ceramic Coatings Deposited by Liquid Thermal Spraying. Ceram. Int. 2022, 48, 33245–33255. [Google Scholar] [CrossRef]

- Zhang, F.; Spies, B.C.; Vleugels, J.; Reveron, H.; Wesemann, C.; Müller, W.-D.; van Meerbeek, B.; Chevalier, J. High-Translucent Yttria-Stabilized Zirconia Ceramics Are Wear-Resistant and Antagonist-Friendly. Dent. Mater. 2019, 35, 1776–1790. [Google Scholar] [CrossRef]

- Deng, W.; Wu, X.; Xu, Z.; Liu, J.; Li, T.; Tang, L. Friction and Wear Behaviors of Perfluoropolyether-Impregnated Plasma-Sprayed Yttria-Stabilized Zirconia Coatings. J. Mater. Eng. Perform. 2024, 33, 1369–1379. [Google Scholar] [CrossRef]

- Hu, Y.; Cai, C.; Wang, Y.; Yu, H.; Zhou, Y.; Zhou, G. YSZ/NiCrAlY Interface Oxidation of APS Thermal Barrier Coatings. Corros. Sci. 2018, 142, 22–30. [Google Scholar] [CrossRef]

- Hu, X.; Kiet, A.T.; Deng, G.; Zhu, H.; Wang, P.; Lin, F.; Wang, L. Tribological Performance Evaluation of YSZ-NiCrAlY Gradient Materials by Tribometer and Nanoscratch. Tribol. Int. 2025, 202, 110292. [Google Scholar] [CrossRef]

- Zhao, C.; Zhao, M.; Shahid, M.; Wang, M.; Pan, W. Restrained TGO Growth in YSZ/NiCrAlY Thermal Barrier Coatings by Modified Laser Remelting. Surf. Coat. Technol. 2017, 309, 1119–1125. [Google Scholar] [CrossRef]

- Bai, L.; Wan, S.; Yi, G.; Sun, H. Exploring the Influences of the Counterpart Materials on Friction and Wear Behaviors of Atmospheric Plasma-Sprayed YSZ Coating. Ceram. Int. 2022, 48, 29601–29613. [Google Scholar] [CrossRef]

- Tailor, S.; Upadhyaya, R.; S.Y., M.; Dub, A.V.; Modi, A.; Modi, S.C. Atmospheric Plasma Sprayed 7%-YSZ Thick Thermal Barrier Coatings with Controlled Segmentation Crack Densities and Its Thermal Cycling Behavior. Ceram. Int. 2018, 44, 2691–2699. [Google Scholar] [CrossRef]

- Ozgurluk, Y.; Gulec, A.; Ozkan, D.; Binal, G.; Cahit Karaoglanli, A. Structural Characteristics, Oxidation Performance and Failure Mechanism of Thermal Barrier Coatings Fabricated by Atmospheric Plasma Spraying and Detonation Gun Spraying. Eng. Fail. Anal. 2023, 152, 107499. [Google Scholar] [CrossRef]

- Thakare, J.G.; Pandey, C.; Mahapatra, M.M.; Mulik, R.S. Thermal Barrier Coatings—A State of the Art Review. Met. Mater. Int. 2021, 27, 1947–1968. [Google Scholar] [CrossRef]

- Jang, B.-K.; Matsubara, H. Surface Roughness and Microstructure of Yttria Stabilized Zirconia EB-PVD Coatings. Surf. Coat. Technol. 2006, 200, 4594–4600. [Google Scholar] [CrossRef]

- Braue, W. Environmental Stability of the YSZ Layer and the YSZ/TGO Interface of an in-Service EB-PVD Coated High-Pressure Turbine Blade. J. Mater. Sci. 2009, 44, 1664–1675. [Google Scholar] [CrossRef]

- Sezavar, A.; Sajjadi, S.A.; Babakhani, A.; Peng, R.L. Thermal Cyclic Fatigue Behavior of Nanostructured YSZ/NiCrAlY Compositionally Graded Thermal Barrier Coatings. Oxid. Met. 2019, 92, 89–107. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Z.; Li, W.; Qiu, Z.; Zheng, Z.; Wang, G.; Huang, J.; Zeng, D. Structural Evolution and Enhanced Thermal Cycling Life of HVAF-Sprayed NiCrAlY Bond Coat Modified by YSZ. J. Mater. Res. Technol. 2024, 30, 5133–5144. [Google Scholar] [CrossRef]

- Dragomirescu, A.; Constantin, N.; Ştefan, A.; Manoliu, V.; Truşcă, R. Advanced Study of Thermal Behaviour of CSZ Comparing with the Classic YSZ Coating. IOP Conf. Ser. Mater. Sci. Eng. 2017, 163, 012040. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Muktanova, N.; Kakimzhanov, D.; Adilkanova, M.; Kurbanbekov, S.; Abdulina, S. Influence of Varying the Spraying Distance on the Structural-Phase State and Mechanotribological Properties of 86WC-10Co-4Cr-Based Coatings Obtained by the HVOF Method. Coatings 2024, 14, 264. [Google Scholar] [CrossRef]

- Liu, T.; Qiu, Y.; Liu, Y.; Liu, Z.; Deng, Z.; Guo, Z.; Wang, F.; Liu, Y.; Yu, C.; Wang, S.; et al. Fabrication and Characterization of Multilayer YSZ Thermal Barrier Coating by Detonation Spraying and Atmospheric Plasma Spraying. Ceram. Int. 2025. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Buitkenov, D.; Sagdoldina, Z.; Idrisheva, Z.; Zhamanbayeva, M.; Kakimzhanov, D. Preparation and Characterization of NiCr/NiCr-Al2O3/Al2O3 Multilayer Gradient Coatings by Gas Detonation Spraying. Coatings 2021, 11, 1524. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Kakimzhanov, D.; Seitkhanova, A.; Kengesbekov, A.; Muktanova, N. The Influence of Distance Pulsed Plasma Treatment on the Structure and Properties of Detonation Coatings from Eutectic Alloy Fe-TiB2-CrB2. Coatings 2024, 14, 1049. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Buitkenov, D.; Idrisheva, Z.; Zhamanbayeva, M.; Pazylbek, S.; Baizhan, D. Effect of Pulsed-Plasma Treatment on the Structural-Phase Composition and Tribological Properties of Detonation Coatings Based on Ti–Si–C. Coatings 2021, 11, 795. [Google Scholar] [CrossRef]

- Bauyrzhan, R.; Alexander, P.; Zhuldyz, S.; Dastan, B.; Vyacheslav, B.; Mukhamedova, A. Effect of Bilayer Thickness and Bias Potential on the Structure and Properties of (TiZr/Nb)N Multilayer Coatings as a Result of Arc-PVD Deposition. Materials 2022, 15, 7696. [Google Scholar] [CrossRef]

- Buitkenov, D.; Nabioldina, A.; Raisov, N. Development of Method for Applying Multilayer Gradient Thermal Protective Coatings Using Detonation Spraying. Coatings 2024, 14, 899. [Google Scholar] [CrossRef]

- Buitkenov, D.; Rakhadilov, B.; Nabioldina, A.; Mukazhanov, Y.; Adilkanova, M.; Raisov, N. Investigation of Structural Phase, Mechanical, and Tribological Characteristics of Layer Gradient Heat-Protective Coatings Obtained by the Detonation Spraying Method. Materials 2024, 17, 5253. [Google Scholar] [CrossRef]

- Buitkenov, D.B.; Nabioldina, A.B.; Bolatov, S.D. Method for Producing Layer-Gradient Detonation Heat Protective Coatings. KZ Utility Model Patent No. 10058, Application No. 2024/1401/2, 29 October 2025. (In Russian). [Google Scholar]

- Mamaeva, A.; Kenzhegulov, A.; Panichkin, A.; Abdulvaliyev, R.; Kshibekova, B.; Arynbayev, T. Mechanical Grinding of Hydroxyapatite and Its Interaction with Titanium. Coatings 2024, 14, 333. [Google Scholar] [CrossRef]

- ASTM E2109-01; Standard Test Method for Determining Area Percentage of Coating Porosity in Thermal Sprayed Coatings. ASTM International: West Conshohocken, PA, USA, 2001.

- Wang, Y.; Gong, X.; Yuan, X.; Zou, L.; Wu, R.; Long, B.; Wang, W.; Guo, L. Superior Performance of Gd0.75Yb0.25PO4 in Resisting CMAS + Sea Salt Corrosion. Surf. Coat. Technol. 2025, 497, 131739. [Google Scholar] [CrossRef]

- Nair, R.B.; Brabazon, D. Calcia Magnesia Alumino Silicate (CMAS) Corrosion Attack on Thermally Sprayed Thermal Barrier Coatings: A Comprehensive Review. NPJ Mater. Degrad. 2024, 8, 44. [Google Scholar] [CrossRef]

- ISO 20808:2016; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Friction and Wear Characteristics of Monolithic Ceramics by Ball-On-Disc Method. International Organization for Standardization: Geneva, Switzerland, 2016.

- Bahamirian, M.; Hadavi, S.M.M.; Farvizi, M.; Keyvani, A.; Rahimipour, M.R. Microstructure and Cyclic Oxidation of Yttria-Stabilized Zirconia/Nanostructured ZrO2 9.5Y2O3 5.6Yb2O3 5.2Gd2O3 Thermal Barrier Coating at 1373 K. J. Mater. Eng. Perform. 2020, 29, 7080–7093. [Google Scholar] [CrossRef]

- Alipovna, M.A.; Karaulovich, K.A.; Vladimirovich, P.A.; Zhanuzakovich, A.Z.; Bolatovna, K.B.; Wieleba, W.; Leśniewski, T.; Bakhytuly, N. The Study of the Tribological Properties under High Contact Pressure Conditions of TiN, TiC and TiCN Coatings Deposited by the Magnetron Sputtering Method on the AISI 304 Stainless Steel Substrate. Mater. Sci.-Pol. 2023, 41, 1–14. [Google Scholar] [CrossRef]

| Coatings | Ratio, O2/C2H2 | Barrel Filling Volume, % | Spraying Distance, mm | Coating Dose, µm/Shot |

|---|---|---|---|---|

| NiCrAlY | 0.97 | 35 | 200 | 2.3 |

| YSZ | 2.529 | 61 | 200 | 1.7 |

| Layer | Material | Regime I (Sample No. 1) | Regime II (Sample No. 2) | ||

|---|---|---|---|---|---|

| Doser 1 (NiCrAlY) | Doser 2 (YSZ) | Doser 1 (NiCrAlY) | Doser 2 (YSZ) | ||

| Number of Shots | |||||

| Substrate | 12Kh18N10T | - | - | - | - |

| Layer 1 | NiCrAlY/YSZ | 5 | 1 | 10 | 2 |

| Layer 2 | YSZ/NiCrAlY | 3 | 1 | 6 | 2 |

| Layer 3 | NiCrAlY/YSZ | 2 | 1 | 4 | 2 |

| Layer 4 | YSZ/NiCrAlY | 2 | 1 | 4 | 2 |

| Layer 5 | NiCrAlY/YSZ | 1 | 1 | 2 | 2 |

| Layer 6 | YSZ/NiCrAlY | 1 | 1 | 2 | 2 |

| Layer 7 | NiCrAlY/YSZ | 1 | 1 | 2 | 2 |

| Layer 8 | YSZ/NiCrAlY | 1 | 1 | 2 | 2 |

| Layer 9 | NiCrAlY/YSZ | 1 | 1 | 2 | 2 |

| Layer 10 | YSZ/NiCrAlY | 1 | 1 | 2 | 2 |

| Layer 11 | NiCrAlY/YSZ | 1 | 1 | 2 | 2 |

| Layer 12 | YSZ/NiCrAlY | 1 | 2 | 2 | 4 |

| Layer 13 | NiCrAlY/YSZ | 1 | 2 | 2 | 4 |

| Layer 14 | YSZ/NiCrAlY | 1 | 3 | 2 | 6 |

| Layer 15 | NiCrAlY/YSZ | 1 | 20 | 2 | 40 |

| Parameter | Sample No. 1 | Sample No. 2 |

|---|---|---|

| Space group: | P42/nmc | P42/nmc |

| Phase composition: | 100 wt.% tetragonal | 100 wt.% tetragonal |

| Lattice Parameters | ||

| a = b, Å: | 3.6082 | 3.6117 |

| c, Å: | 5.1436 | 5.1539 |

| Tetragonality | 1.008 | 1.009 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buitkenov, D.; Sagdoldina, Z.; Nabioldina, A.; Drenda, C. The Study of Tribological Characteristics of YSZ/NiCrAlY Coatings and Their Resistance to CMAS at High Temperatures. Appl. Sci. 2025, 15, 8109. https://doi.org/10.3390/app15148109

Buitkenov D, Sagdoldina Z, Nabioldina A, Drenda C. The Study of Tribological Characteristics of YSZ/NiCrAlY Coatings and Their Resistance to CMAS at High Temperatures. Applied Sciences. 2025; 15(14):8109. https://doi.org/10.3390/app15148109

Chicago/Turabian StyleBuitkenov, Dastan, Zhuldyz Sagdoldina, Aiym Nabioldina, and Cezary Drenda. 2025. "The Study of Tribological Characteristics of YSZ/NiCrAlY Coatings and Their Resistance to CMAS at High Temperatures" Applied Sciences 15, no. 14: 8109. https://doi.org/10.3390/app15148109

APA StyleBuitkenov, D., Sagdoldina, Z., Nabioldina, A., & Drenda, C. (2025). The Study of Tribological Characteristics of YSZ/NiCrAlY Coatings and Their Resistance to CMAS at High Temperatures. Applied Sciences, 15(14), 8109. https://doi.org/10.3390/app15148109