1. Introduction

The performance of asphalt mixtures can be further improved with the addition of polymer and crumb rubber modifications. Due to increased traffic volume and axle loads, polymer and crumb-rubber-modified mixtures have proven to be useful, considering their higher advantages in terms of the increase in operational temperature range of the pavements, both in cold and hot climatic conditions. However, the use of SBS and polymer modifications leads to extended budget requirements, hindering the application of such modifications throughout the road infrastructure system.

During the pavement lifetime, based on the quality of design, material selection, and construction procedures employed, periodic maintenance is required after a certain specified time during the functional period of the pavement. Moreover, if there is a higher percentage of SBS used in asphalt mixtures, it will result in high initial construction costs as a result of costly material procurement. However, maintenance activities still need to be undertaken after a specified time, resulting in an overall increase in the operational cost of the pavement. However, compared to conventional asphalt mixtures, SBS-modified mixtures lead to fewer maintenance interventions and reduced costs. Costs during the pavement life cycle can be reduced by employing materials that are less costly for the same performance provided by SBS-modified bituminous mixture; however, they may yield better performance than the conventional SBS- or CR-modified asphalt mixtures.

An alternative solution is to use an asphalt binder with added fibers. Therefore, instead of increasing the percentage of SBS or CR in the mixture, a small percentage, usually 0.3% of fiber, can be added to the mixture, thereby increasing the mixture’s performance at a fraction of the cost. The different available fibers are ceramic fiber, glass fiber, and basalt fiber. Fibers offer different improvements to the properties of the asphalt mixtures, including higher resistance against permanent deformation, higher resistance against fatigue damage, increased operational temperature range, increased cohesion between bitumen and aggregates, increased high-temperature aging resistance, and increased mechanical stability for asphalt mixtures [

1,

2,

3,

4].

Ceramic fiber has been previously used for improving the performance of asphalt mixtures and offers high-temperature resistance at lower costs [

5]. Ceramic fibers offer high mechanical stability and oxidation resistance [

6,

7]. For the CF, a clinker consisting of silica and alumna is melted at high temperatures, and fibers are formed by cold air blown into the designated formworks and CF are known to share the same performance level as basalt fibers [

8]. Ceramic fibers can insulate the heat up to 1600 °C. The use of CF leads to increased interparticle friction and cohesion between the asphalt mixtures leading to better weight distribution of loads and decreased cracking [

9]. The diameter of the ceramic fiber ranges from 2 µm to 5 µm with the length usually around 20 mm [

10].

Basalt fiber originates from fine-grained volcanic rock and is then produced from fine fibers of basalt [

11]. Basalt fiber is an inorganic material providing high tensile strength, temperature resistance, and chemical stability [

12]. Basalt fibers have almost equivalent mechanical properties to that of steel fiber. Basalt fibers are considered environmentally friendly and the process of procurement and usage involves less CO

2 emissions [

13]. The addition of basalt fibers increases the fatigue and stripping resistance of asphalt mixtures [

14]. The addition of basalt fiber increases the tensile strength of the asphalt layer and its corresponding service life.

Glass fiber is a non-metallic inorganic material and offers high tensile strength and high temperature resistance. Glass fiber is known to improve the cohesion and interparticle friction between the aggregates and binder, thereby resulting in an increased resistance to fatigue [

15]. Glass fibers have been known to offer high fatigue cracking and rutting resistance [

16]. As the alternative option for SBS and crumb rubber modifications, glass fibers are usually low-cost, thereby offering increased pavement performance at a budget [

17]. Therefore, the utilization of high strength and high temperature resistance properties leads to an increase in the operational temperature range of asphalt mixtures with the addition of glass fiber.

2. Literature Review

In terms of the use of ceramic fibers in the improvement of asphalt mixtures performance, Liu et al. [

18] evaluated the effect of using 0.3% ceramic fiber with different grades on asphalt mixtures in terms of the higher temperature performance and low-temperature cracking resistance of asphalt mixtures. Dynamic stability tests and splitting tensile strength tests were performed to evaluate the mechanical properties of asphalt mixtures modified with ceramic fiber. Results showed the increased performance of asphalt mixtures in terms of the high temperature deformation resistance and low-temperature cracking resistance of asphalt mixtures. Arabani et al. [

8] used a PG 64-16 grade asphalt with different dosages of ceramic fibers in the range of 1%, 3%, and 5% premixed in the binder. Furthermore, samples were prepared using the Marshall mix design, and the Marshall flow and stability values were evaluated. Unlike the previous research, indirect tensile stiffness modulus tests and uniaxial dynamic creep tests were conducted to evaluate the mechanical properties of asphalt mixtures containing different percentages of ceramic fiber content. In terms of the number of passes to fatigue damage and increased stiffness modulus, the samples prepared with 5% ceramic fiber outperformed the other scenarios. Wang et al. [

5] further improved the research gap related to the performance testing of ceramic fibers with different dosage values of 0.1% to 0.5%. In this research, wheel-tracking tests were introduced along with splitting tests and low-temperature bending tests. Unlike the previous research, electron microscopy was introduced to understand the mechanism behind the modification of mixtures. Results showed an improved moisture susceptibility, and high- and low-temperature performance of asphalt mixtures with an optimum dosage of ceramic fibers at 0.4%.

Wan et al. [

10] have evaluated the performance of penetration-grade asphalt mortars with the addition of ceramic fibers. Therefore, two different penetration-grade bitumen samples consisting of pen 60/80 and pen 80/100 were used to perform penetration tests, softening point tests, ductility, and evaluation of dynamic viscoelastic behaviour. Results showed an increase in the stiffness of the binder with an addition of ceramic fiber with fewer induced strains at the same level of stress in the case of the base binder. Furthermore, using the dynamic shear rheometer tests, the binder modified with ceramic fibers showed improved complex modulus and phase angle values when compared to the base bitumen samples. Recently, Pang et al. [

19] have evaluated the combined addition of ceramic fibers and lignin fibers on stone matrix asphalt mixtures. Wheel-tracking tests, low-temperature cracking test and moisture susceptibility tests were conducted and the results showed an 11% increase in the dynamic stability and a 20% increase in fatigue life for samples modified with both ceramic and lignin fibers with a recommended ratio of LF to CF at 1:2. Hamedi et al. [

20] have evaluated the short- and long-term ageing as well as low-temperature cracking resistance of asphalt mixtures mixed with ceramic fibers. Results showed increased complex shear modulus values in mixtures prepared with using 5% ceramic fiber in the bitumen samples. Dehnad et al. [

21] have evaluated the effect of ceramic fiber on Glassphalt modified asphalt mixtures in terms of fatigue cracking and rutting using indirect tensile stiffness modulus tests, indirect tensile fatigue tests and repeated load axial tests. Results showed increased cohesion, deformation resistance and low-temperature performance of mixtures modified with ceramic fibers at temperature range of 30 °C to 50 °C.

Basalt fiber has been previously used for performance enhancement of asphalt mixtures. In term of research conducted on basalt fibers, Zhao et al. [

22] have compared the performance of Basalt fiber, Lignin fiber and Polyester using Marshall stability tests, three point bending tests and wheel-tracking tests. Results showed increased performance of basalt fiber when compared to other fiber types in terms of low-temperature performance, Marshall stability, and Tensile strength ratio, using an optimum dosage of 0.3%. Li et al. [

23] added basalt fiber with different contents of 0.25%, 0.35%, 4.9% and 5,2% to SBS-modified asphalt mixtures. Results showed increased high-temperature performance using the wheel-tracking tests when compared to SBS only modified mixture samples. Pei et al. [

24] have added the basalt fiber to different bitumen grades for performance evaluation of basalt fiber-reinforced asphalt mixtures. Results showed increased fracture resistance and a delay in the crack initiation of pavement structures. Liang et al. [

25] have evaluated the effect of adding basalt fiber on the fatigue life of asphalt mixtures. Fatigue damage for the basalt fiber-modified samples was calculated in the form of cumulative dissipative energy of the mixtures. Results showed good performance and increased fatigue life of asphalt mixtures with an addition of 0.3% basalt fiber. Zhu et al. [

26] have added basalt fiber and diatomite for the fatigue performance improvement of asphalt mixtures for various penetration-grade bitumen types. Results showed enhanced improvement of asphalt mixtures with the addition of basalt fibers and diatomite. Jiu et al. [

2] have evaluated the effect of basalt fibers on Marshall properties, dynamic stability, and deformation resistance of asphalt mixtures. Results showed increased permanent deformation resistance and decreased rutting of mixtures reinforced with basalt fiber. Xie et al. [

11] performed the dynamic shear rheometer testing of bitumen samples reinforced with basalt fiber and compared them against virgin binders. Results showed a higher complex modulus and a lower phase angle with a higher rutting factor when compared to the performance of virgin binders, thereby improving the high-temperature performance of asphalt mixtures.

Glass fiber has been previously used for performance enhancement of asphalt mixtures. Enieb et al. [

15] have used glass fibers to evaluate the long-term and short-term ageing of asphalt mixtures using indirect tensile strength, fracture energy, and moisture susceptibility tests. Result showed an increase in tensile strength, decreased susceptibility to moisture damage, and an increased resistance to rutting damage by using the glass fiber, but with an increase in costs for material procurement. Eisa et al. [

27] have used the glass fiber for improving the performance of asphalt mixtures. Marshall stability and flow tests were conducted on glass fiber-reinforced samples. Results showed an increase in Marshall stability and a decreased flow value with an optimum percentage of glass fiber at 0.25%. Ziari et al. [

28] have used glass fibers and different parts of recycled asphalt pavement for a performance enhancement of asphalt mixtures. The dosage of glass fiber used was 0.12% for improvement in crack resistance. Results showed increased cracking resistance of samples when tested under a semi-circular bending tests. Fajkri et al. [

29] have also performed rutting and moisture damage evaluation of glass fiber-modified asphalt mixtures for RAP mixtures. Results showed increased resistance to permanent deformation and moisture susceptibility of the asphalt mixtures with a higher percentage of RAP.

However, in the current research, the comparison based on costs of procurement of materials, including basalt fiber, ceramic fiber, and glass fiber, has not been evaluated, and no direct comparison between these fiber types has been performed in terms of fatigue rutting damage. The current research also lacks the use of finite element modelling for a performance comparison of different fiber types used in terms of rutting and fatigue damage. Therefore, in this research the cost of procurement as initial construction costs for a specified pavement section have been calculated along with the relevant costs during the functional period of the pavement. The objective of this research is to analyze the impacts of using various fiber types on the economic worth of a typical highway construction project, where different maintenance interventions are introduced to evaluate the performance efficiency of each scenario. This research provides a thorough understanding of the performance efficiency of using each fiber type in terms of pavement life cycle costs.

3. Experimental and Data for LCCA

This section provides information related to material properties, including binder, aggregates, and fiber types used. Furthermore, the calculation of initial construction costs and data used for life cycle cost analysis for each scenario has been performed. In this research, three types of fibers, including ceramic, glass, and basalt fiber are incorporated into the penetration grade (PG) 76-22 binder from OMV at an optimal dosage of 0.3%. The performance of these fiber-reinforced mixtures is compared to that of a conventional AC SBS-modified mixture with a nominal maximum aggregate size of 19 mm containing 7% SBS. Dynamic stability tests are conducted on all mixture types and dynamic modulus values are calculated using the modified Burger’s logit model. Furthermore, life cycle cost analysis is carried out for each mixture scenario.

Fibers are incorporated into the bitumen using the wet process before mixing the modified binder with aggregates. DSR tests have been conducted [

30]. Initially, both the fibers and bitumen are heated separately at 120 °C. The fibers were stirred at 500 rpm for 30 min to ensure even distribution. Afterward, the bitumen was heated to 165 °C to promote better uniformity in the final mixture.

3.1. Material Properties

OMV 76-22 grade bitumen has been used as a binder for the preparation of asphalt mixtures with properties shown in the

Table 1.

The properties of basalt fiber (BF), ceramic fiber (CF), and glass fiber (GF) used are shown in

Table 2. Wet process has been used to mix fibers with bitumen. Fibers are premixed with bitumen and later mixed with aggregates.

A nominal maximum aggregate size of 19 mm has been selected with the use of a well-graded aggregate mix, as shown in

Table 3.

3.2. Initial Construciton Costs Calculation

For the initial construction of road pavements, initial construction costs are determined based on the unit value of each component of construction. Initial construction costs consist of production, transportation, and construction related costs. NPV provides the present value of all future cash flows during the pavement lifetime. It provides the net value of the project in the present currency’s value as shown in Equation (1),

where

is net presenta value,

is dicount rate,

is time period in years,

is number of years from intial contruction, and

is length of analysis period. Lower NPV corresponds to higher cost efficiency of rehabilitation strategies.

Salvage value provides the information about the remaining service life at the end of the analysis period. Salvage value is determined if the pavement structure still possesses a service life at the end of the analysis period. Salvage value for road pavements is measured in two different ways, one in the form of net present value after the last maintenance intervention, which reflects the value in monetary form, and the second one in the form of the remaining serviceable life of the pavement, where the pavement can continue to be used for traffic without any maintenance intervention, with a term called RSL (Remaining Service Life). Salvage value can be determined from Equation (2),

where

CLR is the cost of the last maintenance intervention. In this research, the major maintenance intervention consists of full depth asphalt reclamation in the mid-span of a total service life of 40 years as shown in

Table 4. For each fiber type used in the asphalt mixtures, each scenario is tested based on an increased pavement lifetime for a superior performing fiber reinforced mixture.

The initial construction costs for the pavement structure have been calculated based on the costs of the procurement and production of asphalt mixtures with different fiber types. All other costs related to construction, transportation, and placement remain identical, except for procurement costs. SBS-7% has the highest procurement costs when compared to fiber-reinforced mixtures. Dosage for fiber reinforcement has been kept constant, at 0.3%. Pavement structure consists of a 16 cm asphalt layer, 40 cm base course, 20 cm subbase course with a lane width of 3.75 m, and a section length of 100 km. Costs are generated for one lane only since the majority of AADT (Average Annual Daily Truck Traffic) will use the lane 100% of the time.

Furthermore, the rehabilitation costs are calculated based on the extent of repair conducted with reference to the thickness of each pavement layer. In some instances, in the beginning of analysis period, only the wearing course needs to be replaced, in the mid-analysis period, full depth reclamation is required based on the pavement performance where the rehabilitation costs significantly increase.

Since the method of preparation and mixing for SBS-modified asphalt mixture differs from the fiber-modified mixtures, the unit costs do not essentially reflect the same percentage increase or decrease in costs related to each fiber reinforced mixture. The present value of all the components of the construction cost based on the discount rate of 5% has been calculated and is shown in

Table 5.

As observed, due to varying procurement costs of each fiber type, the total initial construction costs for the section length of 100 km are different for each scenario of fiber-reinforced mixtures. SBS-3% is procured at 4 Eur/kg. SBS-7% mixture exhibits the highest construction costs at 347 million. The least construction costs are associated with basalt fiber due to ease of availability and local production. Among the fiber-reinforced asphalt mixtures, ceramic fiber has the highest costs at 285 million.

4. Finite Element Modelling

For finite element modelling, the modified Burger’s logit model has been used and data from the dynamic modulus testing has been obtained for each mixture scenario as shown in Equation (3),

where

is the creep strain of the modified Burger’s model,

is the dynamic modulus,

is the internal damper parameter,

n2,

and

are the model viscoelastic-fitted parameters, and

is the damage value. A material decay component is used in the form of an external damper and an external spring leading to an accurate simulation of creep behaviours of the materials under testing. Creep parameters are obtained at a temperature of 30 °C as shown in

Table 6. As observed, the highest magnitude of parameter A is exhibited by the BF mixture at 157.89 MPa, the magnitude, however, decreases in the case of GF at 154.96. BF and CF exhibit almost identical performance in terms of creep behavior showing dominant performance when compared to the fiber-reinforced SBS-7%, with the least magnitude of parameter A at 121.42 MPa.

4.1. Model Details

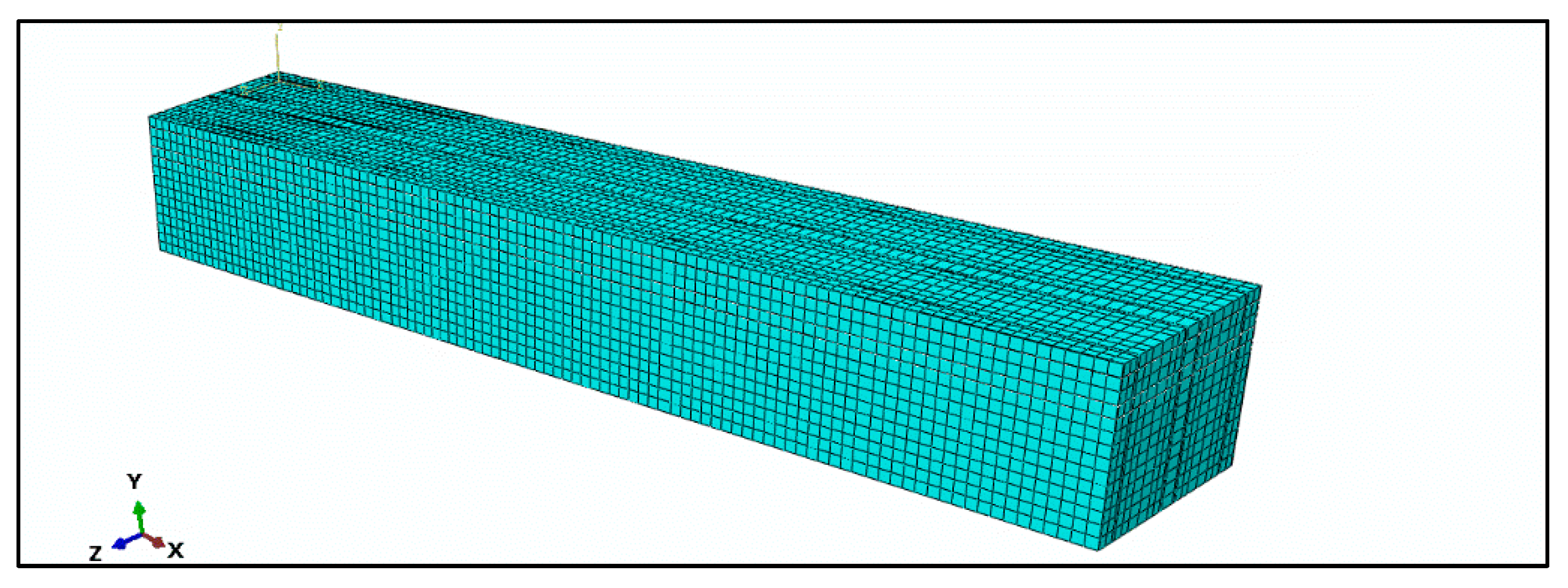

A flexile pavement section consisting of an asphalt layer with a thickness of 16 cm, a granular base course with a thickness of 40 cm, a granular subbase course with a thickness of 20 cm, and a natural subgrade have been used for simulations with a lane width of 3.75 m and a section length of 100 m. For loading considerations, a semi-truck trailer combination with tridem axles in the trailer has been used to exert the load on the pavement section. The number of trucks is kept at 11,000 per day, with a speed of 90 km/h and a total analysis period of 40 years. A 3D CPE8R model with 8-node linear brick elements, with reduced integration and hourglass control, has been used for simulations with a total number of elements at 28,365 and an element size of 10 for increased accuracy and simulation time based on the convergence study. Mesh details are shown in

Figure 1.

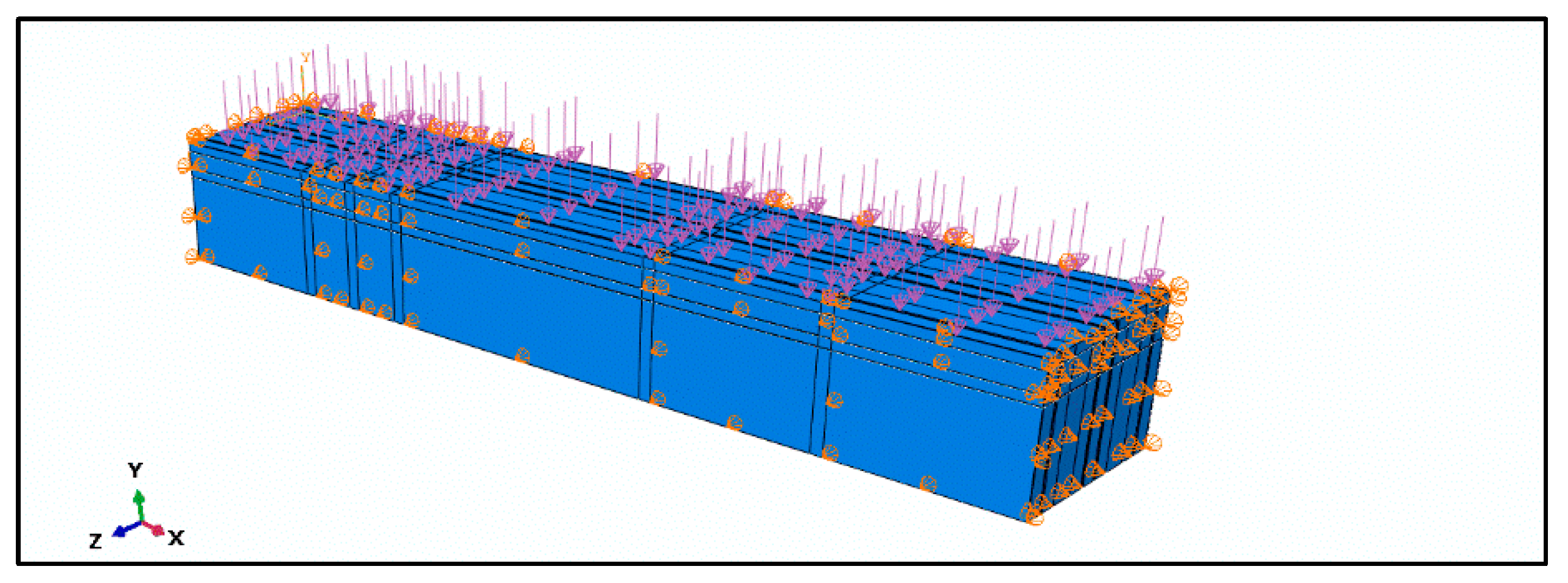

Loading and boundary conditions are shown in

Figure 2. As observed, the layer to layer characteristics are normal and continuous with frictionless characteristics. Nodes have no restriction of movement in normal vertical directions, but have restriction along perpendicular horizontal directions.

4.2. Simulation Results

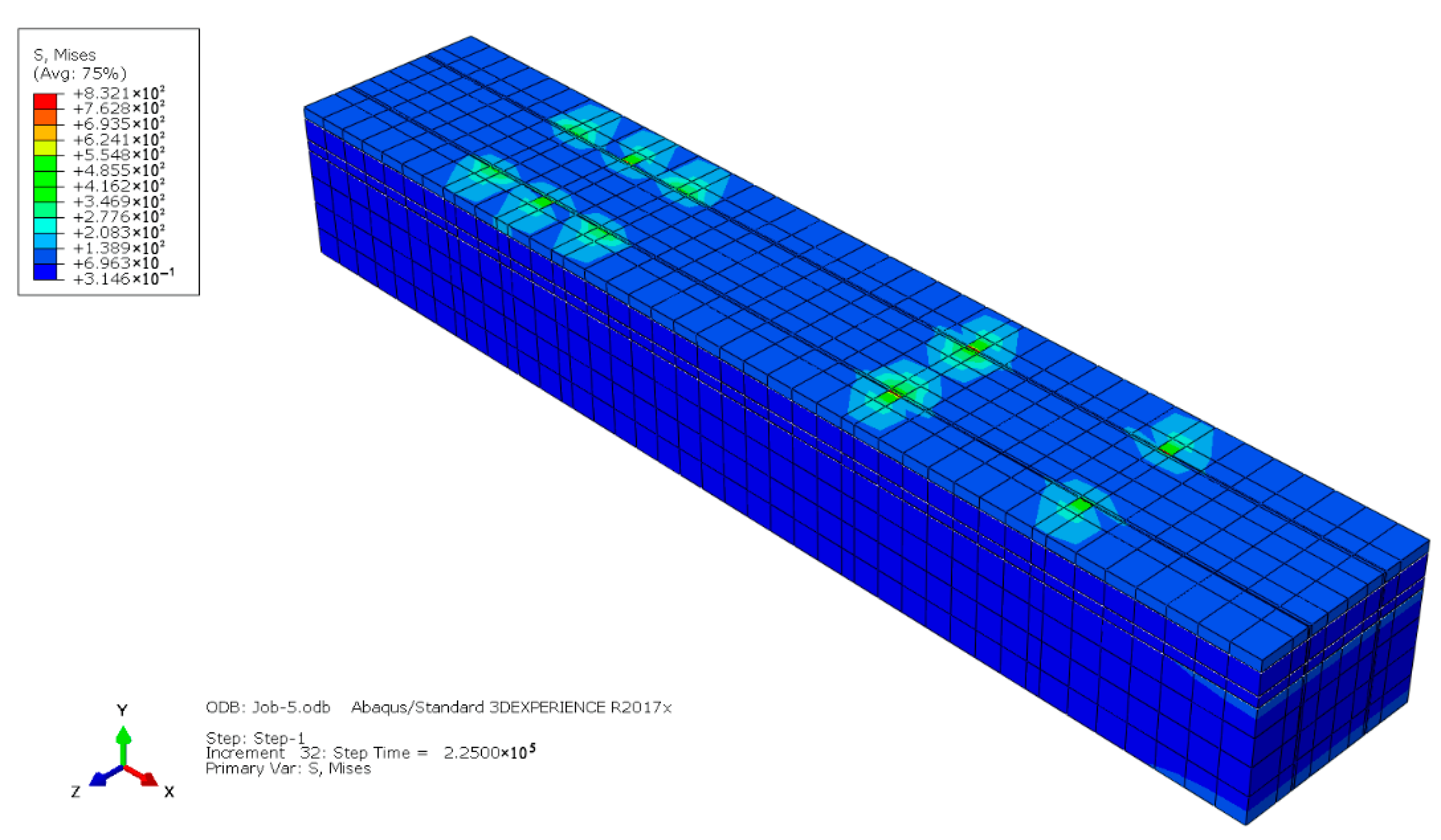

Simulations have been performed with AADT of 11,000 trucks per day on ABAQUS. Von Mises stress at various depth values under the loading areas have been calculated and recorded for each mixture type. The simulation results for the SBS-7% mixture are shown in

Figure 3.

Simulation results obtained from finite element modelling have been used to evaluate the Von Mises stress at depths of 50 mm, 450 mm, and 800 mm as shown in

Table 7. Von Mises stress values represent the yielding and deformation for materials under complex loading conditions. It accumulates the combined effect of all the stress on one point. As observed, the highest accumulation of stress exists for the SBS-7% mixture, with a sudden drop in stress values for fiber-reinforced mixtures with BF showing the least accumulation of stress values. Both BF and CF show almost identical performance, with GF showing an increase in the accumulation of stress values when compared to fiber-reinforced mixtures.

4.3. Fatigue and Rutting Damage Analysis

Fatigue and rutting damage in terms of number of passes have been evaluated for each mixture type. Due to increased loads and high-temperature conditions, shear deformation and densification of the asphalt mixture occur, leading to the occurrence of permanent deformation. Furthermore, in terms of fatigue, the Asphalt Institute model provides a relationship between the number of passes to fatigue damage and horizontal tensile strain at the bottom of asphalt layer using Equation (4),

where,

is the number of load repititon to fatigue damage,

is the horizontal temsile strain at the bottom of the asphalt layer, and

is the elastic modulus of the asphalt mixture in MPa. The Asphalt Institute model also provides a relationship between the number of passes to rutting damage and vertical compressive strain on top of the subgrade as shown in Equation (5),

where,

is the number of load repititon to rutting damage and

is the vertical compressive strain on top of subgrade. The number of passes to fatigue damage along with the corresponding et and ec values are shown

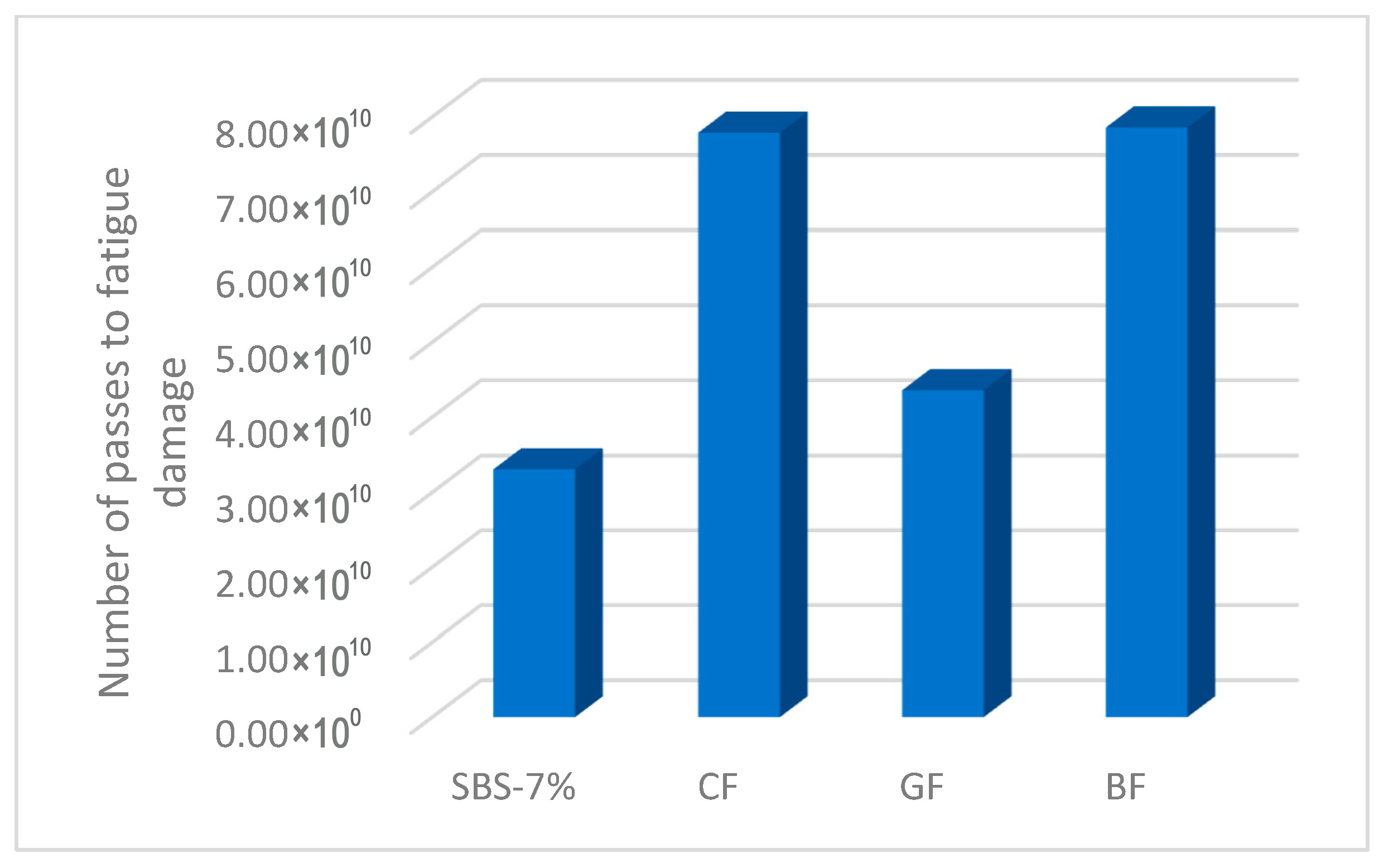

Table 8. As observed, the highest accumulation of both et and ec exist for SBS-7% at 34.1 MPa and 485.2 Mpa, respectively, leading to further decreases in the number of passes to fatigue damage. With the use of fiber-reinforced mixtures, the magnitude of et and ec drops down to 18.2 MPa and 433.5 MPa in the case of the BF mixture, with the maximum number of passes to fatigue damage at 7.86 × 10

10 and 8.96 × 10

6, respectively. CF shows almost identical performance for BF in terms of the number of passes to fatigue damage. GF, however, shows the worst performance among the fiber-reinforced mixtures, with the number of passes to fatigue damage at 4.36 × 10

10 and 5.84 × 10

6Visual representation of the comparison of number of passes to fatigue damage is shown in

Figure 4. As observed, the highest number of passes to fatigue damage exists for BF mixture at 7.86 × 10

10 passes. CF shows an almost identical performance at 6.79 × 10

10. Therefore, BF outperforms CF by 13% and GF by 25%. However, the highest difference exists between the BF and SBS-7%, with an increase in the number of passes to fatigue damage for the BF-modified mixture by 61%. Furthermore, in terms of fatigue damage, both CF and BF mixtures show almost identical performance, where the addition of CF further improves the carbon chain links and reinforces the bitumen mixtures, thereby improving the elasticity of the asphalt layer. GF on the other hand, exhibits slight improvement to the number of passes to fatigue damage when compared to SBS-7% mixture.

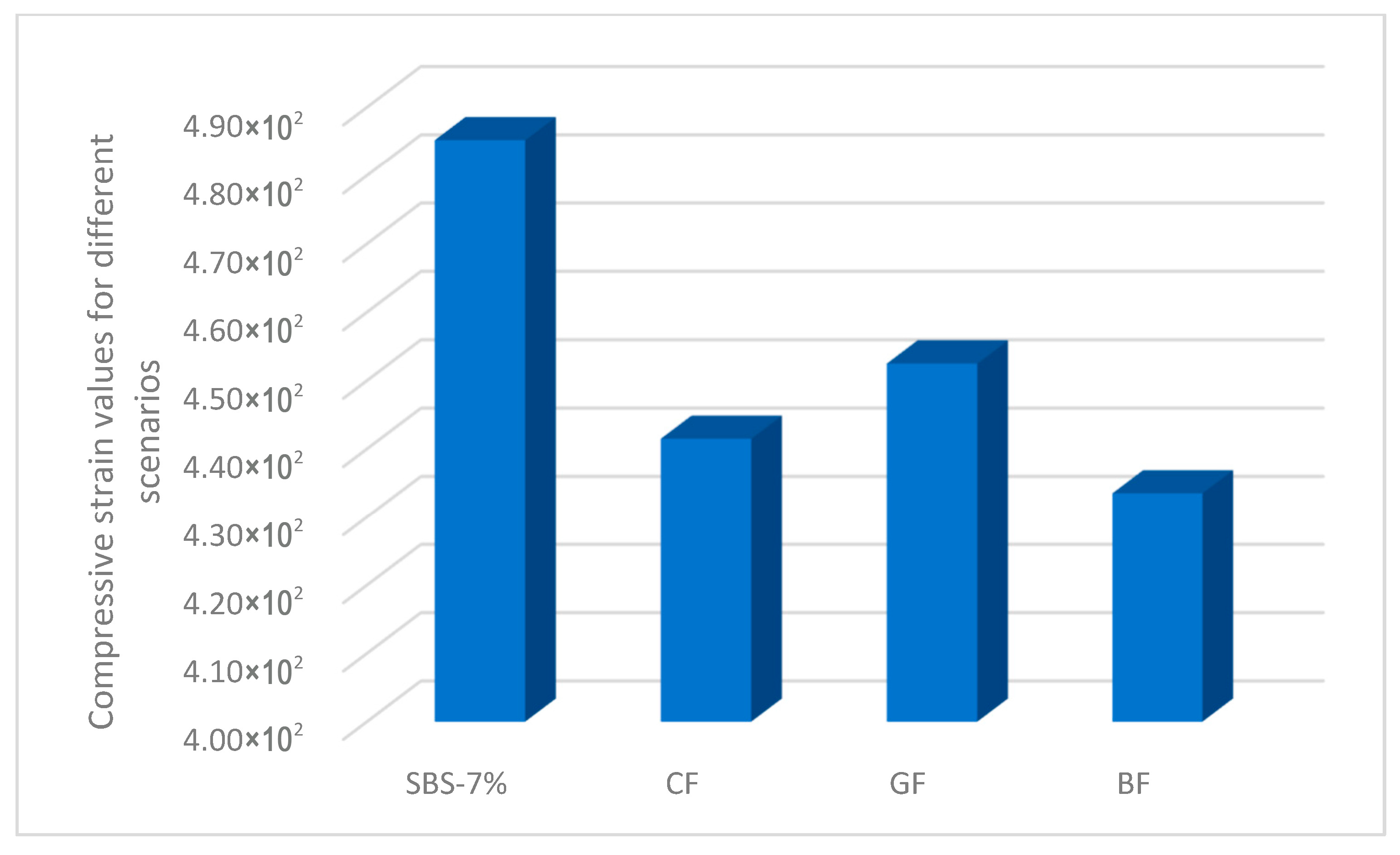

The visual representation of the comparison of compressive strain values is shown in

Figure 5. As observed, SBS-7% shows the highest microstrains at 485.2 microns. Furthermore, BF outperforms CF to show reduced microstrains at 433.5 microns and 441.5 microns. Although both BF and CF show almost identical performance in terms of accumulated microstrains, BF performs significantly better by 13% than the CF mixture. This is due to the improvement of the viscous portion during the shear testing of bitumen where BF provides better performance against permanent deformation than the CF mixture.

5. LCCA and Performance Efficiency

Maintenance interventions based on the performance of each mixture type from finite element modelling and dynamic modulus tests have been scheduled for the analysis period of 40 years. In the first option, Salvage value until the analysis period of 40 years is evaluated for all the scenarios as shown in

Table 9 and

Figure 6. As observed, the least salvage value is exhibited by SBS-7% mixture due to extensive costs and less remaining service life. The SBS-7% scenario requires the first intervention in the 6th year, which is 3 years earlier than the BF scenario. Furthermore, a second full reclamation for the SBS-7% scenario is required on the 31st year, which is not the case for the fiber-modified mixtures, thereby adding further expenses to pavement life cycle costs. BF, on the other hand, performs the best with the longest maintenance-free period after the initial costs when compared to other scenarios. CF shows almost identical performance in terms of the increased duration of the maintenance free period with a reduction of only 1 year for the first maintenance intervention at the 8th year. GF shows superior performance against the SBS-7% mixture; however, when compared to BF and CF, the first maintenance intervention is required at the 7th year, which is two years earlier than that of BF. Furthermore, an extra maintenance intervention in terms of general maintenance is required to make it to 40 years for the GF scenario, yielding a salvage value of 25.6 million. The highest salvage value is exhibited by BF at 34.1 millions.

In the second option, additional service life based on the same maintenance intervention schedule for each scenario is evaluated as shown in

Table 10. The BF scenario outperforms the SBS-7% option by 13 years with the same extent of maintenance interventions employed. SBS-7% makes it to the 40 year pavement service life with the remaining salvage value in this scenario at 15.1 million. However, the fiber-reinforced scenario still outperforms the SBS-7% slightly in terms of salvage value but extensively in terms of added service life. CF also outperforms the SBS-7% scenario by 7 years and GF by 4 years. The least performance gain in terms of added service life to the pavement by fiber-reinforced mixtures is shown by the GF scenario. Therefore, pavement life can be further extended with the use of fiber reinforcement, especially the BF, if the identical pavement maintenance intervention schedule is used. Furthermore, the duration of the maintenance-free period is longer by an average of 2.5 years among all the fiber-reinforced scenarios when compared to SBS-7% scenario.

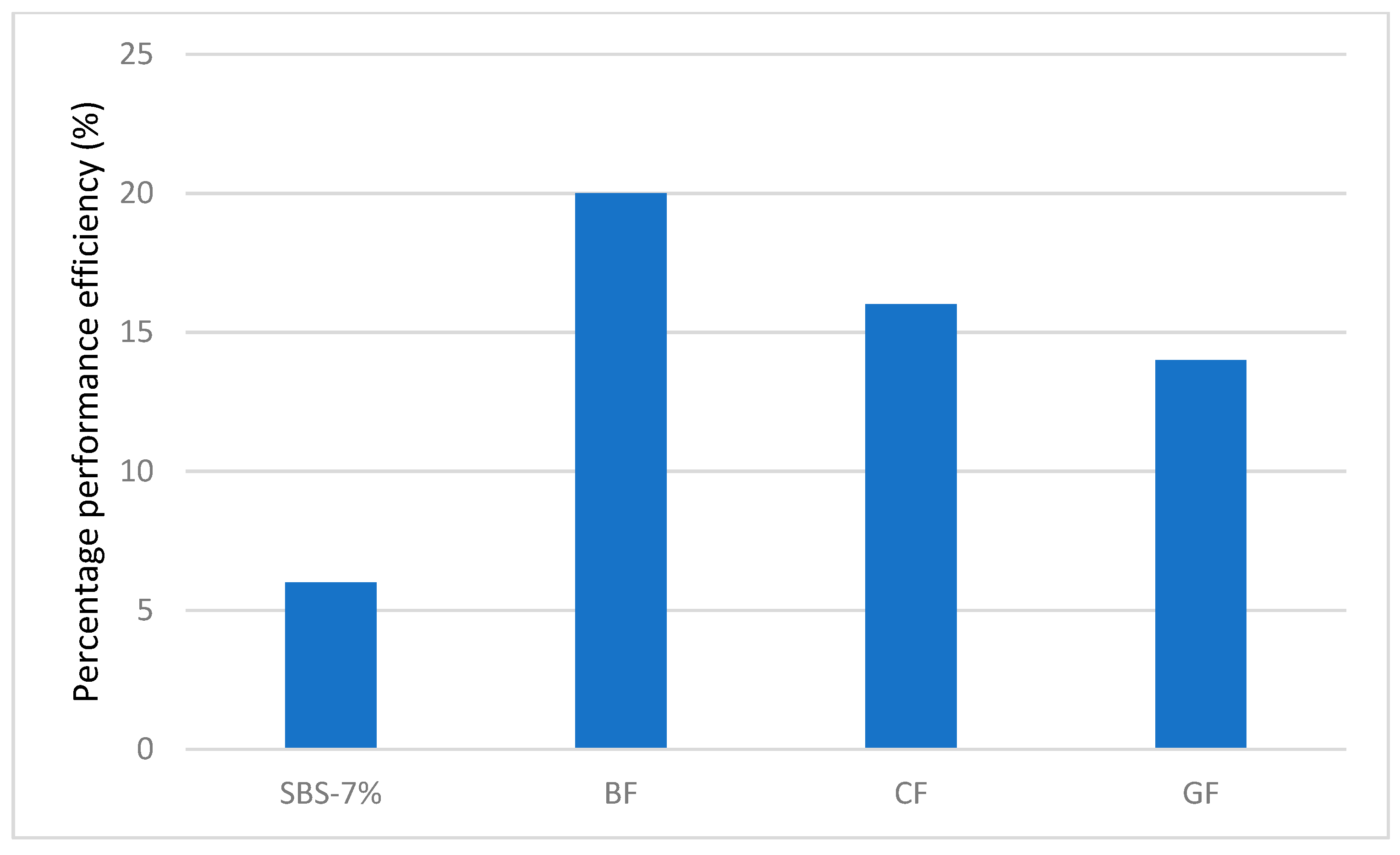

The percentage performance efficiency of each scenario based on the construction costs, maintenance interventions, and performance in terms of rutting and fatigue damage has been calculated and shown in

Figure 7. As observed, due to the worst performance in terms of the base scenario of SBS-7% asphalt mixture, the performance efficiency stays at 6% when compared to a perfect scenario where no intervention is required throughout the analysis period. CF shows almost identical performance to BF in terms of fatigue damage and slightly less improvement when it comes to rutting damage; however, due to higher initial construction costs with the use of CF, the performance efficiency remains at 16% for the CF mixture. GF shows promising performance at lower costs when compared to CF; however, based on the number of passes to fatigue and rutting damage, as well as the requirement of extra maintenance interventions, GF mixture provides only a 14% performance efficiency. BF mixtures perform the best among the other options with a highest performance efficiency of 20% in terms of initial construction costs, maintenance interventions, and performance in terms of fatigue and rutting damage.

Each fiber type has distinct physical and mechanical properties, as well as their interaction with the binder and aggregate matrix. Although both CF and BF exhibit similar fatigue performance, the superior rutting resistance of BF can be linked to its relatively higher surface roughness and better thermal stability, which enhances the interlocking and bonding within the asphalt matrix. BFs possess a higher melting point and excellent resistance to deformation under high temperatures, which contributes to their enhanced performance under loading. In contrast, CFs have a smoother surface and lower strain tolerance which may limit their effectiveness in resisting permanent deformation under repeated loading. GF mixtures demonstrated the weakest performance in both fatigue and rutting resistance due to their lower tensile strength, lower thermal stability, and susceptibility to breakage during mixing and compaction. Additionally, the bond between glass fibers and the asphalt binder is generally weaker, which could result in less effective load transfer and reinforcement.

6. Conclusions

In this research the performance and costs efficiency of three different fiber-modified mixtures including BF, CF, and GF have been compared against the SBS-7% only mixture. Since procurement costs for the polymer-modified mixtures are higher, such mixtures are only used on major highways or airfields. Fiber-modified mixtures can provide an alterative to the increased costs of polymer-modified mixtures. Therefore, life cycle cost analysis has been performed based on the procurement costs and corresponding initial construction costs for each scenario. Initial construction costs for each scenario consisting of BF, CF, and GF have been calculated for a pavement section of 100 km. Furthermore, the relevant maintenance interventions have been scheduled based on the performance characteristics of each fiber type taken from lab tests and finite element modelling. The performance efficiency of each scenario has been evaluated based on the degree of performance enhancement each scenario has to offer depending on the initial construction and maintenance costs. Pavement life cycle analysis has been performed in two different forms. In the first part maintenance interventions are performed to yield a maximum salvage value at the end of the analysis period. In the second part, maintenance interventions are scheduled to yield an extended pavement life for each scenario under consideration.

Based on the cost component and performance efficiency of each scenario, BF mixtures offer higher performance when compared to fiber-modified mixtures, including CF and GF mixtures, at lower costs. Fiber-modified mixtures, however, perform significantly better than the SBS-7% mixture, where further maintenance interventions are required to keep the pavement functional until the analysis period of 40 years. All the fiber-modified mixtures required fewer maintenance interventions and have a longer maintenance free period, with an average of 4 years more than that of the SBS-7% mixture due to the least number of passes to fatigue and rutting damage to the pavement. Furthermore, extra major maintenance interventions are required for the SBS-7% mixture that lead to a further increase in pavement life cycle costs by 63%. The BF-modified mixture, however, provides a good balance in terms of reduced initial construction costs, pavement life cycle costs, and increase in pavement life in terms of higher number of passes to fatigue and rutting damage with longer maintenance-free period.

Currently, the fibers lack standardization and are mostly used in research based scenarios. Moreover, these fiber types are not mass produced; therefore, they might not be available in some regions, whereas SBS is mass produced and available with any major petroleum supplier. Fibers still need more standardization and specific and approved testing methods to be used more globally. Furthermore, another reason is the limited awareness of the significance of fibers when it comes to the improvement in the asphalt mixture’s performance.

The research highlights the economic worth of the usage of each fiber scenario when it comes to project scheduling and creating a budget for highway construction projects. The costs for material procurement play a big role in defining the budget constraints for any project; however, the performance efficiency of each scenario also affects the selection of a particular binder type scenario. In terms of the limitations of this research, the effect of temperature variations in the extremes of high and low ranges has not been included as part of the scope of this research. Future research includes an evaluation of environmental impact of each scenario, where further interventions lead to higher greenhouse gas emissions.

7. Findings

The findings are as follows:

The first maintenance intervention in terms of general maintenance advances by 3 years when compared to the BF mixture.

Full depth reclamation is required for the second round at the 30th year of the analysis period for the SBS-7% scenario with additional costs of 9.4 million euros.

BF mixture delays the first intervention in terms of general maintenance by 3 years when compared to SBS-7%, 2 years when compared to GF, and 1 year when compared to CF.

Glass fibers exhibit the worst performance among the fiber-reinforced scenarios with one extra general maintenance intervention required, adding additional costs of 1.2 million euros.

BF exhibits the highest salvage value at 58.3 million euros.

BF mixture can add up to 13 years of service life more than that of SBS-7% if the maintenance intervention schedule is kept the same for all the scenarios.

The SBS-7% scenario leads to the highest maintenance costs with the least salvage value for the analysis period of 40 years when compared to fiber-reinforced mixtures, with a 53% increase in costs when compared to the BF scenario.

Significant cost savings can be achieved using the BF-modified asphalt mixtures over the SBS-7% mixtures with a 20% higher slavge value for a 40 year analysis period with identical schedule of maintenance interventions.