Abstract

This study aims to provide a comprehensive overview of the application of artificial intelligence (AI) methods to solve real-world problems in the oil and gas sector. The methodology involved a two-step process for analyzing AI applications. In the first step, an initial exploration of scientific articles in the Scopus database was conducted using keywords related to AI and computational intelligence, resulting in a total of 11,296 articles. The bibliometric analysis conducted using VOS Viewer version 1.6.15 software revealed an average annual growth of approximately 15% in the number of publications related to AI in the sector between 2015 and 2024, indicating the growing importance of this technology. In the second step, the research focused on the OnePetro database, widely used by the oil industry, selecting articles with terms associated with production and drilling, such as “production system”, “hydrate formation”, “machine learning”, “real-time”, and “neural network”. The results highlight the transformative impact of AI on production operations, with key applications including optimizing operations through real-time data analysis, predictive maintenance to anticipate failures, advanced reservoir management through improved modeling, image and video analysis for continuous equipment monitoring, and enhanced safety through immediate risk detection. The bibliometric analysis identified a significant concentration of publications at Society of Petroleum Engineers (SPE) events, which accounted for approximately 40% of the selected articles. Overall, the integration of AI into production operations has driven significant improvements in efficiency and safety, and its continued evolution is expected to advance industry practices further and address emerging challenges.

1. Introduction

The importance of artificial intelligence (AI) in the oil and gas sector has been widely recognized, prompting a series of studies that discuss the challenges and opportunities associated with its adoption. Several systematic reviews have identified recurring issues such as data privacy, model explainability, and the shortage of qualified professionals [1,2,3]. In this context, the literature emphasizes the need for robust algorithms that can accurately detect operational failures and adapt to highly complex environments.

Studies have also investigated the role of AI in industry-specific applications, such as production forecasting, vulnerability assessment, and incident response. Ahmad et al. [4] and Su et al. [5] present comprehensive overviews of these applications, emphasizing the use of techniques such as machine learning (ML) and artificial intelligence. Taha et al. [6] and Xu et al. [7] focus on domains such as intrusion detection, seismic analysis, and risk assessment, highlighting the role of AI in operational safety. In line with these efforts, Ucar et al. [8] and Minh, D. et al. [9] discuss limitations, including algorithmic bias and ethical challenges, and propose technical and regulatory solutions.

Other studies reinforce the application of AI as a mechanism for automation and response to emerging threats. Chen [10] and Shah et al. [11] highlight how the combination of AI and ML has the potential to strengthen the security of cyber-physical systems. Zhu [12], Nishant et al. [13], Farivar et al. [14], and Elliot et al. [15] address techniques such as deep learning and natural language processing applied to anomaly detection network security, and user authentication. These works also discuss risks associated with the adoption of AI, such as lack of standardization and transparency in models.

In the field of advanced applications, the use of AI for phase equilibrium modeling and history matching has gained prominence. Sun et al. [1] proposed an approach based on deep neural networks to predict the thermodynamic behavior of complex mixtures in vapor-liquid equilibrium (VLE), significantly accelerating calculations compared to conventional methods. In the context of history matching. A hybrid system that combines particle swarm optimization with neural networks, reducing the calibration time of reservoir models and improving convergence in scenarios with geological uncertainties [16,17].

Currently, the exploitation of oil and natural gas is widespread and diverse, encompassing activities in complex environments such as deep-sea reservoirs, salt mines, and unconventional strata. These operations often face challenges related to high-pressure and high-temperature conditions, as well as heterogeneous geological formations [1]. In this context, the application of artificial intelligence (AI) has become increasingly relevant for supporting real-time decision-making, optimizing drilling paths, and enhancing reservoir characterization [4]. AI techniques such as deep learning and reinforcement learning are instrumental in complex extraction environments due to their ability to process large volumes of unstructured data and learn nonlinear relationships in subsurface modeling [18]. As noted by Zhu et al. [12], AI applications have demonstrated strong potential in automating critical processes in offshore and deep-water operations, reducing human error, and enhancing operational safety. Furthermore, initiatives to integrate AI with physics-based models have enabled hybrid approaches that preserve physical interpretability while enhancing computational efficiency [1].

In particular, the treatment of nonlinearity in reservoir modeling has been enhanced with the use of deep neural networks. Bastian et al. [19] demonstrated the effectiveness of supervised models, such as artificial neural networks (ANNs), in predicting productivity in environments with multiple correlated variables. For seismic interpretation, supervised approaches such as convolutional neural networks (CNNs) are effective in detecting spatial patterns. In contrast, unsupervised methods, such as Long Short-Term Memory (LSTM) networks, are better suited to identify temporal sequences associated with lithological variations or reservoir pressures [20].

Recent studies continue to expand the frontiers of artificial intelligence applications in the oil and gas industry, with a focus on developing robust solutions to complex challenges. Wei et al. [2] investigated the use of information fusion neural networks for real-time optimization of extraction processes in unconventional reservoirs, demonstrating operational improvements through the integration of multiple data sources. These studies complement and update the consolidated literature, highlighting the continuous evolution of AI techniques and their emerging applications in the energy sector.

The present study aimed to examine the application of digital transformation, focusing on artificial intelligence techniques in oil wells. To achieve this objective, the following goals were defined: to conduct a comprehensive literature review on AI applications in oil wells, to identify the techniques most widely used, and to evaluate the impact of these technologies on companies in the sector.

2. Materials and Methods

The primary objective is to provide a comprehensive overview of how artificial intelligence methods have been applied to real-world problems in the oil and gas sector. The methodology followed a process based on the analysis of AI applications, as described in journals and conference proceedings.

- -

- Step 1: The first step involved preliminary exploration of scientific articles using the Scopus database. Keywords related to artificial and computational intelligence techniques were used (the search query for the SCOPUS database is: (TITLE-ABS-KEY (“oil” AND “gas”) OR TITLE-ABS-KEY (“O&G” OR “Petroleum” OR “OIL & GAS” OR “KDD” OR “knowledge-discovery” OR “knowledge discovery”) AND TITLE-ABS-KEY (“crisp” OR “crisp-dm” OR “crisp dm” OR “Cross Industry Standard Process for Data Mining” OR “Cross Industry Standard Process”) AND TITLE-ABS-KEY (“Artificial intelligence” OR “Deep Learning” OR “Machine Learning” OR “Neural Networks” OR “Convolutional Neural Network” OR “Artificial Neural Networks”)) for the search and the criteria adopted included: publication period between 2010 and 2024, English language and document types restricted to peer-reviewed articles and conferences. A total of 11,296 articles were selected, and a co-occurrence map was created with VOS Viewer software, identifying key terms and emerging trends in artificial intelligence that would guide the next phase of research.

- -

- Step 2: Based on the relevant terms and insights identified in Step 1, the focus shifted to a more specific domain: the oil industry. The OnePetro database, a key resource for petroleum engineering research, was explored using keywords such as “production system”, “machine learning”, and “neural network.” This step aimed to connect broader AI applications with practical use cases in production optimization and well drilling.

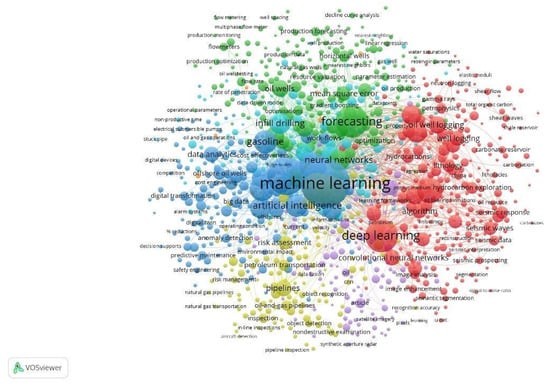

Machine learning has emerged as a cornerstone of technological advancement, bridging the gap between theoretical computation and practical applications across numerous fields. The relationships uncovered in Steps 1 and 2 highlight the role of machine learning in transforming industries, including oil and gas, through interdisciplinary collaboration and data-driven decision-making. The thematic word map (Figure 1) illustrates these connections. It sets the stage for understanding how machine learning integrates techniques, tools, and applications to solve complex problems in production and drilling processes.

Figure 1.

Initial research: artificial intelligence keywords.

The image illustrates a word map emphasizing the centrality of “machine learning” and its connections to various subtopics and application areas, such as deep learning, forecasting, neural networks, and the oil and gas industry.

Each color cluster represents a thematic group, highlighting the relationships between specific topics in artificial intelligence and data science., in the figure:

- -

- Blue: Indicates areas related to algorithms and techniques, such as neural networks and supervised learning.

- -

- Red: Represents practical applications, including computer vision and natural language processing.

- -

- Green: Relates to forecasting and statistical analysis.

- -

- Yellow: Suggests intersections with big data, cloud computing, and optimization.

- -

- Purple: Includes oil, satellite, and data fusion.

These connections demonstrate that machine learning is an interdisciplinary field with applications ranging from specific tasks to strategic areas, such as automation and business intelligence. In summary, the map highlights the pivotal role of machine learning in driving the development of emerging technologies and their integration across various industries.

3. Results

3.1. Oil and Gas Industry and AI

Offshore drilling and production exemplify these challenges, demanding a multidisciplinary range of specialties. In addition to the traditional knowledge of mechanical engineering applied to onshore activities, there is a need for expertise in logistics, naval engineering, automation, materials, and chemistry, among others. Logistics, for example, is critical due to the limited space in offshore facilities and the capacity constraints to support heavy loads [16].

Chemical engineering, in turn, seeks to resolve the thermal shock that occurs with fluids with a high concentration of water and gas, extracted from deep and hot reservoirs, which encounter the low temperatures on the seabed [17]. This contrast can lead to the formation of hydrates, solids that block the flow of fluids through pipelines [6].

With the advancement of artificial intelligence, these areas are gaining even more momentum. AI is being applied to predict failures and optimize processes, from drilling to production, analyzing large volumes of data in real time and proposing solutions autonomously [18]. Machine learning technologies are used to improve operational efficiency and predict the useful life of equipment, minimizing downtime [21].

Other advances, such as seismic processing, reservoir simulation and well automation, are trying to be widely integrated with AI to increase accuracy and safety. Oil companies, driven by these innovations, are shaping the industry’s technological paths, guiding suppliers and determining the future of market offerings [22]. Innovations, while expensive and risky, are essential to ensuring the industry’s longevity and success in an increasingly competitive landscape [23].

Drilling services in the oil and gas sector involve productive, non-productive and time-wasting activities. Productive activities are those that promote progress in the depth of the well, such as drilling. Non-productive operations, although they do not generate direct progress, are necessary for the execution of the well, such as casing, cementing and column testing. Optimizing these activities is essential to minimize operating time, always respecting safety conditions and best market practices [24,25,26].

On the other hand, there are activities that result in loss of time, commonly known as “invisible lost time” (ILT), which should be avoided. These losses include waiting due to adverse conditions at sea or delays in the arrival of materials and personnel, as well as repairs of equipment and facilities. Among the main problems that cause delays are [27,28,29]:

- -

- Reopening: Occurs when there is a need to reopen intervals that have already been drilled to correct problems with restrictions or reduction in the diameter of the well, which prevents the continuation of operations in a safe manner.

- -

- Diversion and re-drilling: When a section of the well is lost, it is necessary to place a plug and divert the route at a point above the incident in order to re-drill to the desired depth.

- -

- Loss of circulation: Occurs when the pressure in the well exceeds the resistance of the geological formations, leading to the invasion of drilling fluids. This can compromise the integrity of the well, damage possible reservoirs, and cause the column to jam.

- -

- Kick and blowout: The “kick” refers to the invasion of the well by formation fluids, which, if not controlled, can evolve into a “blowout”, a serious accident with risk to the well, the platform and the team. Although rare, these events have the potential to cause great damage.

- -

- Fishing: Involves the recovery of parts or materials that have fallen or become trapped in the well, blocking normal operation. The time dedicated to this activity can vary, and in some cases, the fishing operation is not successful, resulting in the loss of parts of the well.

In addition to mechanical challenges, production problems also occur throughout the life of the well. To ensure production continuity, interventions are often necessary, such as workovers, one of the most complex and costly operations in oil well maintenance. The most common production problems include [6,25]:

- -

- Solid formation: Such as hydrates, paraffins and asphaltenes, which can be deposited in the production line due to pressure and temperature variations, affecting the flow of oil.

- -

- Well integrity failures: Problems with components such as Christmas trees, valves and piping can compromise integrity and cause leaks, in addition to affecting production.

- -

- Reservoir problems: Include excessive production of gas or water, which can reduce the profitability of the well, and the presence of sand or fine particles, which can increase water and sediment levels, in addition to causing erosion in equipment.

The interaction of AI technologies in the oil and gas sector has been fundamental to optimizing production and predicting failures before they cause significant problems. Tools such as digital twins, predictive maintenance and remote monitoring are being applied to improve operational efficiency and ensure the integrity of artificial lift systems [8].

This digital transformation is redefining the way oil fields are managed, promoting greater efficiency and safety in operations, especially in complex environments such as hydrate formation zones.

3.2. Bibliometric Analysis

From the literature search, 142 articles were found, distributed between drilling and production activities. We performed a bibliometric analysis of the articles, the results of which are presented in Figure 2 and Figure 3.

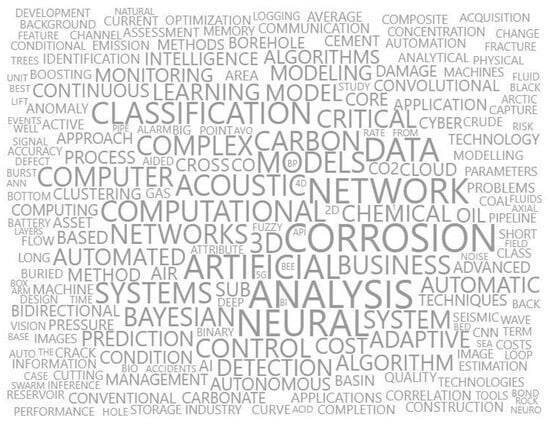

Figure 2.

Cloud of words.

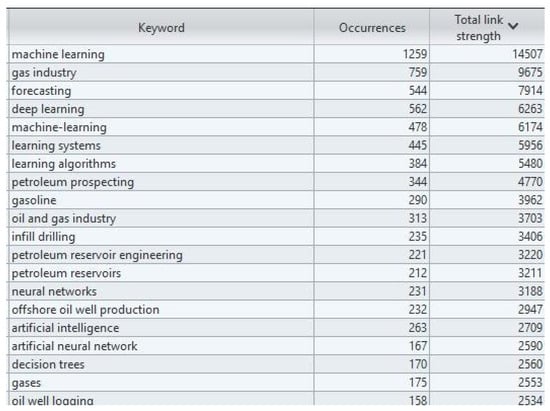

Figure 3.

Terms of publications.

When relating to the figures, a complementary view of machine learning becomes evident. Both figures were created using the same databases. Figure 2 helps to understand the connections between different areas and techniques within the field, enabling the identification of strategic interactions among concepts such as deep learning, neural networks, and forecasting. This approach is beneficial for visualizing the broader landscape of machine learning and the interdependencies between subdomains, which can be valuable for researchers, strategists, and decision-makers seeking to grasp the field’s structure and identify potential areas for innovation.

Figure 3, on the other hand, deepens this perspective by detailing the most relevant topics for specific applications, focusing on practical and technical problems encountered in industrial contexts. Terms like corrosion, acoustics, classification, and computational systems highlight specific challenges that machine learning can address, signaling its applicability in sectors such as engineering, healthcare, energy, and material sciences. This word cloud also reflects machine learning’s ability to adapt to a wide range of demands, from predicting failures to automating complex processes.

Together, these representations offer an integrated perspective on machine learning in the industry, combining the macro view of strategic connections with the micro view of practical applications. This complementarity is essential for understanding not only the theoretical potential of the field but also its tangible implications in solving real-world problems, making machine learning an indispensable tool across various areas of knowledge and industry.

The term “machine learning” occupies a central position, leading both in the number of occurrences and total link strength, confirming its importance as the core of technological development. Other terms such as “gas industry”, “forecasting”, and “deep learning” also stand out, emphasizing the focus on practical and advanced applications, particularly in the oil and gas sector. This centrality suggests that machine learning has been widely explored in critical and high-complexity industries.

Keywords like “petroleum prospecting”, “oil and gas industry”, and “offshore oil well production” demonstrate a strong intersection between machine learning and industrial activities. These terms highlight the significance of AI technologies in enhancing natural resource exploration processes, improving operational efficiency, and lowering costs. The total link strength of these topics suggests their interconnection with other areas, reinforcing the practical impact of machine learning solutions in these contexts.

Finally, the table also highlights specific techniques such as “neural networks” and “decision trees”, which appear among the main terms. This highlights the direct application of fundamental machine learning algorithms to industrial problems. The quantitative and qualitative analysis presented in the table is a powerful tool for identifying emerging research areas, connections between topics, and strategic priorities, making it useful for both researchers and companies looking to explore the potential of these technologies in high-relevance sectors.

For example, Zhang, Z et al. [21] conducted a bibliometric analysis that included the temporal evolution of publications between 2015 and 2021, showing an exponential growth in the use of deep neural networks in exploration and production applications. They highlight that interest in techniques such as deep learning and reinforcement learning increased particularly after 2018, reflecting advances in computational power and greater data availability [21].

The figure provides a summary of recent articles that apply machine learning to various challenges in the oil and gas industry. These studies illustrate the growing role of modern AI techniques in solving specific problems ranging from flow measurement and production forecasting to the structural optimization of complex environments.

The study by Khodayari-Rostamabad et al. [30] explores the application of machine learning techniques to analyze Magnetic Flux Leakage (MFL) data, a crucial method for pipeline inspection in the oil and gas sector. By employing methods such as support vector regression and kernelization, the research enhances the detection and severity evaluation of pipeline defects. These advancements enhance the reliability and safety of pipeline maintenance, thereby reducing risks such as environmental damage and financial losses resulting from pipeline failures. This contribution underscores the role of advanced computational techniques in maintaining the integrity of critical infrastructure.

Nwachukwu et al. [31] addressed the challenge of optimizing well placement in geologically complex reservoirs by incorporating spatial and geological data into the machine learning model.

This research is significant because it reduces the computational costs associated with traditional full-physics simulations, which are time-intensive and resource-heavy. By enabling faster and more accurate decision-making in reservoir management and optimization, the proposed methodology helps operators maximize returns on investment while managing uncertainties in subsurface conditions.

Zheng et al. [20] present the following two case studies: one on automated fault detection in seismic images and another on constructing elastic models for seismic inversion. The study demonstrates that synthetic data can effectively train CNNs to produce accurate predictions, even for real-world field data. The research is particularly relevant to the oil and gas industry because it automates seismic interpretation tasks, such as fault detection, which are traditionally time-consuming and labor-intensive. By enhancing efficiency and reducing subjectivity in geophysical analysis, the study contributes to accelerating exploration activities and lowering associated costs.

Paltrinieri et al. [32] address the challenges of dynamic risk assessment in safety-critical industries, including the oil and gas sector. Their study introduces machine learning-based tools to continuously monitor and adapt to risks in real time, a significant need in high-risk environments. By improving the capacity for ongoing analysis and dynamic response to evolving conditions, the study supports the optimization of safety protocols and risk management strategies. This ensures better decision-making and accident prevention, making it a valuable contribution to risk governance in the oil and gas industry.

Barbosa et al. [26] highlight the advantages of data-driven models, such as artificial neural networks, over traditional physics-based models, which struggle to capture the complex, nonlinear relationships between drilling variables. Accurate ROP prediction is crucial in reducing drilling time and costs, particularly in challenging environments such as offshore exploration. The paper also discusses the potential of real-time optimization systems based on artificial intelligence, encouraging the adoption of innovative drilling technologies in the oil and gas sector.

Bastian et al. [19] present a novel deep learning-based approach for detecting and classifying external corrosion in pipelines, a critical issue in oil and gas operations. Using Convolutional Neural Networks (CNNs), their method automates corrosion monitoring, reducing reliance on manual inspections and intrusive techniques. This approach not only enhances the precision and efficiency of inspections but also lowers costs and minimizes operational disruptions. By enabling early and accurate identification of corrosion, this work significantly contributes to ensuring the safety and longevity of oil and gas infrastructure.

Chen et al. [33] introduced a machine learning framework utilizing a multilayer Long Short-Term Memory (LSTM) network to predict reservoir porosity. Their study addresses the high costs and technical challenges associated with traditional coring methods, which become increasingly complex as drilling depths increase. The model uses well-log data to predict porosity with higher accuracy and lower costs compared to conventional methods.

Orrù et al. [34] explored the application of machine learning models, specifically Multilayer Perceptron (MLP) and Support Vector Machine (SVM), for fault prediction in centrifugal pumps within the oil and gas industry. The study highlights the importance of predictive maintenance in preventing equipment failures and minimizing unplanned downtime. Using real-world data from operating machinery, the authors demonstrated the efficacy of these algorithms in identifying potential faults early and accurately.

Zhang, X et al. [35] proposed a deep learning-based method to locate small earthquakes induced by industrial activities, such as fluid injection, in Oklahoma. Using a fully convolutional neural network (FCN) and data from a network of seismic stations, the study demonstrated the ability to predict the location of seismic events in real-time accurately. This capability is significant for events with low magnitudes (ML < 3), which are often overlooked by traditional methods due to their low signal-to-noise ratio.

Peng et al. [36] introduce a hybrid algorithm that integrates support vector regression, principal component analysis, and chaos particle swarm optimization to improve prediction accuracy. The findings are crucial for maintaining pipeline integrity, reducing operational risks, and preventing costly failures. By enhancing the ability to foresee corrosion issues, this work supports safer and more efficient pipeline operations.

The oil and gas industry generates vast amounts of data across various operations, creating challenges in efficiently processing and analyzing data. Sircar et al. [37] review the application of artificial intelligence (AI) and machine learning (ML) in addressing these challenges. By highlighting AI’s potential to enhance data interpretation and decision-making in exploration, drilling, and production, the authors emphasize the role of technology in optimizing processes, mitigating risks, and reducing costs. The study illustrates how AI-driven solutions can transform industry practices, making operations more intelligent and adaptive.

External corrosion of oil and gas pipelines is a critical threat to their structural integrity and operational reliability. Wasim and Djukic [38] comprehensively examine external corrosion mechanisms, including hydrogen-induced cracking, stress corrosion cracking, and microbiologically influenced corrosion. By exploring predictive prevention strategies and assessing the effectiveness of current monitoring tools, the study provides valuable insights for improving pipeline longevity and safety. Its emphasis on transitioning from corrosion protection to predictive and preventive measures marks a significant advancement in pipeline management practices.

Table 1, demonstrate the importance articles about the ML and oil and gas industry.

Table 1.

Syntex of publications.

The reduction of computational costs is essential to demonstrate the practical impact of AI models objectively. Several recent studies have advanced in this direction. For example, Bastian et al. [19] reported an accuracy of above 94% in the automatic detection of external corrosion in pipelines using convolutional neural networks (CNN), validating the model’s potential to replace time-consuming manual inspections. Similarly, Peng et al. [36] developed a hybrid model to predict the internal corrosion rate in multiphase pipelines, achieving a root mean square error (RMSE) of only 0.112, which demonstrates high predictive capacity despite the nonlinear complexity of the problem. In the context of predictive maintenance, Orrù et al. [34] applied MLP and SVM models to predict failures in centrifugal pumps, achieving F1-scores above 0.89, significantly reducing unexpected downtime and operating costs. These results confirm that, beyond conceptual applications, AI models have demonstrated quantifiable and replicable performance with real impacts on safety, reliability, and operational efficiency.

These articles highlight the growing integration of machine learning in oil and gas exploration and production, leading to increased precision, cost efficiency, and operational effectiveness. Each study showcases how AI techniques are reshaping the industry by tackling traditional challenges and fostering innovation.

4. Discussion

The application of Artificial Intelligence (AI) in the oil and gas industry is significantly transforming production operations, offering substantial improvements in efficiency, safety, and decision-making. The following are some of the key applications of AI in the production context [8,15]:

- Operations Optimization: AI is utilized to optimize production processes by analyzing vast amounts of operational data. Machine learning algorithms can predict demand patterns, adjust operational parameters in real-time, and identify opportunities to increase the efficiency of equipment and systems. This results in better resource allocation and maximization of production.

- Predictive Maintenance: Instead of adopting a reactive approach to maintenance, AI enables the implementation of predictive maintenance, allowing for proactive maintenance strategies. AI models analyze sensor data and historical failures to predict when and where potential failures are likely to occur. This enables proactive interventions, reducing downtime and costs associated with unexpected repairs.

- Reservoir Management: AI enhances reservoir management through advanced modeling and simulation techniques. AI algorithms can analyze seismic, drilling, and production data to create more accurate reservoir models. These models help predict reservoir behavior and optimize extraction strategies.

- Image and Video Analysis: AI-based computer vision techniques are utilized to monitor and inspect equipment and facilities in real time. Automatic analysis of images and videos helps identify flaws, corrosion, or other visual issues that may impact operations. This contributes to more efficient maintenance and rapid response to emerging problems.

- Safety and Control: AI improves operational safety by analyzing real-time data to identify patterns and early warning signs that may indicate hazardous conditions. AI systems can predict and prevent accidents by continuously monitoring working conditions and implementing automatic controls to mitigate risks.

Integrating AI into production operations in the oil and gas sector not only improves efficiency and safety but also contributes to greater sustainability and cost reduction. As technology advances, AI is expected to play an increasingly crucial role in evolving production practices and addressing emerging industry challenges.

Digital transformation in the oil and gas industry has driven profound changes in drilling and production operations, significantly enhancing efficiency, safety, and predictability. This study examined the latest and most innovative applications of artificial intelligence (AI) and other digital technologies in exploration and production (E&P) processes, focusing on solutions for recurring problems and optimization of resources and equipment [39].

The key findings of this research highlight how AI, combined with advanced sensors, the Internet of Things (IoT), and big data technologies, is reshaping operations in oil fields. Machine learning applications have proven especially effective in identifying and predicting equipment failures, such as in drilling, where AI-based systems can forecast pipe sticking and instabilities, allowing real-time adjustments [28].

In production operations, digital technologies facilitate the anticipation of flow issues and the formation of blockages, such as hydrates and scaling, which can disrupt production. Deep learning techniques applied to real-time data from sensors installed on production equipment enable the prediction of these occurrences, allowing for preventive measures. This process results in more efficient maintenance and reduced downtime, ensuring a more continuous and reliable production [22].

The importance of the oil and gas sector in creating jobs and investment in local economies is highlighted. Companies in the sector must implement social responsibility management systems that align with the 17 Sustainable Development Goals (SDGs), including a commitment to social well-being and inclusion, as well as best practices in the oil industry.

The oil and gas sector plays a crucial role in socioeconomic progress. The creation of direct and indirect jobs, combined with tax collection and investment in infrastructure, boosts local economies and establishes favorable conditions for sustainable development. These measures align with Sustainable Development Goals 8 (Decent Work and Economic Growth), which promotes fair working conditions, and 9 (Industry, Innovation and Infrastructure), which emphasizes the importance of robust infrastructure for economic growth [15,40].

In the exploration field, Zheng et al. [20] demonstrated the use of convolutional neural networks (CNNs) in supervised seismic interpretation, including the construction of elastic geological models. This approach is instrumental in the automatic classification of sedimentary facies from well logs, replacing time-consuming manual analyses and enabling greater accuracy and scalability in reservoir characterization.

Regarding the downstream segment, although less addressed in traditional literature, Sircar et al. [37] highlight the use of machine learning techniques for process optimization in refineries, particularly in modeling complex processes and controlling critical variables in real time. This application enables the reduction in energy losses and improvement of operational efficiency through intelligent systems that continuously adjust process parameters, thereby meeting safety and productivity criteria. Thus, the inclusion of these studies enriches the review by showing that the gains provided by AI are not limited to the middle of the production chain but extend from the discovery of reservoirs to the final transformation of hydrocarbons.

Furthermore, the implementation of ESG in the sector fosters a community relationship based on dialogue and transparency. Through guidelines such as the Code of Ethics for Suppliers and its commitment to diversity, inclusion, and human rights, the industry has made progress on issues including gender equality, racial equality, and the inclusion of individuals with disabilities. This aligns with global commitments, such as the UN Global Compact and the United Nations Empowerment Principles for Women [40,41].

In the environmental area, Peng et al. [36] proposed a hybrid model to predict internal corrosion rates in multiphase pipelines, which contributes to preventing leaks and mitigating environmental impacts, such as soil and aquifer contamination. Similarly, Nwachukwu et al. [31] developed predictive models for rapid assessment of ideal good positioning, which reduces unnecessary drilling and, consequently, the carbon footprint associated with the mobilization of equipment and intensive use of natural resources. These applications demonstrate how AI can optimize drilling routes and minimize associated emissions, aligning with the climate commitments assumed by companies in the sector.

Regarding the prediction of environmental impacts of techniques such as hydraulic fracturing, Paltrinieri et al. [32] applied machine learning to dynamic risk analysis in critical industries, suggesting models that can be adapted to anticipate ecological, seismic, or social risks arising from these operations. These systems enhance the capacity for proactive responses to potential environmental damage, promoting transparency and responsible resource management.

However, the incorporation of AI into operational and strategic decisions also poses significant ethical challenges. One example is the risk of algorithmic bias in resource allocation, such as in the automated prioritization of infrastructure maintenance or replacement in different areas, which can reflect or exacerbate social inequalities.

As highlighted by Sircar et al. [37], data governance and model explainability are crucial to ensure that critical decisions, whether automated or assisted by AI, align with the principles of justice, equity, and social responsibility. Thus, in addition to technical efficiency, it is essential to integrate ethical principles into the development and implementation of AI solutions, particularly in sectors with significant environmental and social impacts.

The results indicated that the AI-based model was able to reduce computational time by up to 95% while maintaining an average error of less than 1% compared to conventional methods. This type of gain is critical in large-scale compositional simulations, where response time directly influences the feasibility of sensitivity and uncertainty studies [37].

Another example is presented by Chen et al. [33], who used LSTM networks to predict reservoir porosity. The study demonstrated that the AI-based model achieved a coefficient of determination (R2) exceeding 0.95, whereas methods based on multivariate linear regression (MLR) yielded values below 0.80. Additionally, the LSTM model reduced prediction time by more than 90%, underscoring its suitability in environments that require rapid responses with a high degree of confidence.

Still, in the area of prediction and optimization, Barbosa et al. [26] reported that techniques such as Random Forest and SVM applied to drilling penetration rate (ROP) obtained improvements of up to 18% in predictive accuracy when compared to adjusted physical models in addition to requiring less manual calibration and less computational effort for new simulations.

The oil and gas sector plays a crucial role in the global energy economy, supplying a substantial portion of the energy demand, particularly in sectors such as transportation, petrochemicals, and thermal power generation [16]. The increasing complexity of exploration, production, and distribution operations has driven the adoption of artificial intelligence (AI) and machine learning techniques to increase efficiency, reduce costs, and mitigate risks. For example, machine learning techniques have been used to predict failures in centrifugal pumps, optimize predictive maintenance, and reduce unscheduled shutdowns [34], as well as to estimate reservoir porosity with greater accuracy and lower cost [33]. The economic impact of these solutions is reflected in improvements in well productivity, operational safety, and the reduction in losses associated with pipeline corrosion [38]. In addition, the application of deep neural networks for seismic interpretation and location of induced earthquakes has allowed faster and more informed decisions about safe and sustainable exploration [35]. Taken together, these advances indicate that the strategic use of AI not only transforms internal processes but also strengthens the role of the oil and gas sector in the global energy matrix through greater reliability, productivity, and resilience.

The results of this research underscore the importance of digital technologies, particularly artificial intelligence (AI), as essential tools for overcoming the complex challenges of E&P operations. Digital transformation is driving a structural shift in operational practices, providing a safer, more efficient, and data-driven approach that can meet the demands of a competitive and constantly evolving market.

5. Conclusions

This study aimed to present a comprehensive overview of how artificial intelligence (AI) methods have been applied to real-world problems in the oil and gas sector. The methodology adopted involved a detailed analysis of AI applications described in scientific articles and conferences, divided into two main stages. Initially, scientific articles were explored through the database Scopus, creating a co-occurrence map to identify relevant terms. In the second stage, the analysis focused on the OnePetro database, resulting in the selection and analysis of specific articles on production and drilling.

The results demonstrate the growing impact of AI on production operations in the oil and gas sector, particularly in areas such as process optimization, predictive maintenance, reservoir management, image and video analysis, and operational safety [28]. For example, AI-based models using multilayer long short-term memory (LSTM) networks achieved high accuracy in predicting reservoir porosity, significantly reducing the need for costly field measurements [33]. Predictive models using support vector machines (SVMs) and multilayer perceptrons (MLPs) demonstrated strong performance in anticipating faults in centrifugal pumps, thereby helping to avoid unplanned shutdowns and reduce maintenance costs [34]. Convolutional neural networks (CNN) have also been successfully applied to corrosion detection [19,36,38], improving the speed and reliability of visual inspections in pipeline infrastructure.

The bibliometric analysis revealed that the Society of Petroleum Engineers (SPE) serves as the central hub of dissemination, concentrating a significant portion of publications related to AI applications. This reflects the high level of interest and investment from both academia and industry in leveraging digital solutions to tackle persistent challenges.

Overall, the integration of AI into production operations has led to measurable improvements in efficiency, accuracy, and safety. Deep learning algorithms for seismic interpretation [20,35] and earthquake detection [35] have enabled faster and more accurate analysis of subsurface conditions, supporting safer and more informed decision-making processes. These examples confirm that AI is not only a theoretical promise but a practical and impactful tool already in use across multiple domains of the oil and gas production chain.

Continued collaboration between oil companies, universities, and research centers is recommended, expanding the development and application of digital solutions that address the industry’s emerging challenges. With the ongoing evolution of AI technologies and their expanded adoption, digital transformation in the oil and gas sector is expected to play an increasingly crucial role in optimizing operations and sustaining long-term production.

Author Contributions

Validation, S.V.M.N.; Investigation, J.F.M.; Investigation e Writing—original draft, M.d.S.P.; Writing—review & editing, C.A.d.S.C. and B.S.C.; Supervision, A.L.A.G.; Project administration, G.B.A.L. All authors have read and agreed to the published version of the manuscript.

Funding

The author Gilson B A Lima wishes to acknowledge his support by the Brazilian National Council for Scientific and Technological Development (CNPq) through grant 311961/2023-1. The author Freire, J. acknowledge the support by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sun, Y.; Pang, S.; Zhang, Y. Enhancing Fluid Identification via an Innovative Transformer Model with Bidirectional Recurrent Units Network Leveraging Well Logging Data. Phys. Fluids 2024, 36, 076626. [Google Scholar] [CrossRef]

- Wei, S.; Huang, X.; Su, Y.; Li, J.; Peng, S. Application of Machine Learning Algorithm in Predicting Estimated Ultimate Reserves of Shale Gas. In Computational and Experimental Simulations in Engineering; Li, S., Ed.; Springer Nature: Cham, Switzerland, 2024; pp. 1151–1161. [Google Scholar] [CrossRef]

- Morovat, K.; Panda, B. A Survey of Artificial Intelligence in Cybersecurity. In Proceedings of the 2020 International Conference on Computational Science and Computational Intelligence (CSCI), Las Vegas, NV, USA, 16–18 December 2020; pp. 109–115. [Google Scholar] [CrossRef]

- Ahmad, S.F.; Rahmat, M.K.; Mubarik, M.S.; Alam, M.M.; Hyder, S.I. Artificial Intelligence and Its Role in Education. Sustainability 2021, 13, 12902. [Google Scholar] [CrossRef]

- Su, Q.; Zhang, Q.; Xu, Q.; Yan, J.; Lu, Q.; Yin, Y.; Sævik, S.; Ye, N. Deep Learning-Driven Optimization Design for the Configuration of Lazy-Wave Umbilical Cables. Appl. Ocean Res. 2024, 150, 104097. [Google Scholar] [CrossRef]

- Taha, A.; Amani, M. Overview of Water Shutoff Operations in Oil and Gas Wells; Chemical and Mechanical Solutions. ChemEngineering 2019, 3, 51. [Google Scholar] [CrossRef]

- Xu, K.; Liu, Z.; Chen, Q.; Zhang, Q.; Ling, X.; Cai, X.; He, Q.; Yang, M. Application of Machine Learning in Wellbore Stability Prediction: A Review. Geoenergy Sci. Eng. 2024, 232, 212409. [Google Scholar] [CrossRef]

- Ucar, A.; Karakose, M.; Kırımça, N. Artificial Intelligence for Predictive Maintenance Applications: Key Components, Trustworthiness, and Future Trends. Appl. Sci. 2024, 14, 898. [Google Scholar] [CrossRef]

- Minh, D.; Wang, H.X.; Li, Y.F.; Nguyen, T.N. Explainable Artificial Intelligence: A Comprehensive Review. Artif. Intell. Rev. 2022, 55, 3503–3568. [Google Scholar] [CrossRef]

- Chen, Z. Deep Learning for Cybersecurity: A Review. In Proceedings of the 2020 International Conference on Computing and Data Science (CDS), Stanford, CA, USA, 1–2 August 2020; pp. 7–18. [Google Scholar] [CrossRef]

- Shah, P.; Kendall, F.; Khozin, S.; Goosen, R.; Hu, J.; Laramie, J.; Ringel, M.; Schork, N. Artificial Intelligence and Machine Learning in Clinical Development: A Translational Perspective. NPJ Digit. Med. 2019, 2, 69. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Gui, J.; Wang, H.; Cheng, S.; Li, Z.; Ran, L. Application of Machine Learning in On-Line Calibration of Flow Measurement Errors. AIP Adv. 2024, 14, 085131. [Google Scholar] [CrossRef]

- Nishant, R.; Kennedy, M.; Corbett, J. Artificial Intelligence for Sustainability: Challenges, Opportunities, and a Research Agenda. Int. J. Inf. Manag. 2020, 53, 102104. [Google Scholar] [CrossRef]

- Farivar, F.; Sayad Haghighi, M.; Jolfaei, A.; Alazab, M. Artificial Intelligence for Detection, Estimation, and Compensation of Malicious Attacks in Nonlinear Cyber Physical Systems and Industrial IoT. IEEE Trans. Ind. Inform. 2019, 16, 1551–3203. [Google Scholar] [CrossRef]

- Elliot, K.; Damingo, L. Application of artificial intelligence in the oil and gas industry. Int. Res. J. Mod. Eng. Technol. Sci. 2024, 6, 2582–5208. [Google Scholar] [CrossRef]

- Mancini, L.; Paz, M.J. Oil Sector and Technological Development: Effects of the Mandatory Research and Development (R&D) Investment Clause on Oil Companies in Brazil. Resour. Policy 2018, 58, 131–143. [Google Scholar] [CrossRef]

- Kumar, P.; Sonawane, A.K. Engineering Significance and Consequences of Gas Hydrates in Deep and Ultra Deep Water Development. In Proceedings of the Fourteenth International Offshore and Polar Engineering Conference, Toulon, France, 23–28 May 2004. [Google Scholar]

- Wang, H.; Guo, Z.; Kong, X.; Zhang, X.; Wang, P.; Shan, Y. Application of machine learning for shale oil and gas “sweet spots” prediction. Energies 2024, 17, 2191. [Google Scholar] [CrossRef]

- Bastian, B.T.; Jaspreeth, N.; Ranjith, S.K.; Jiji, C.V. Visual Inspection and Characterization of External Corrosion in Pipelines Using Deep Neural Network. NDT E Int. 2019, 107, 102134. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, Q.; Yusifov, A.; Shi, Y. Applications of supervised deep learning for seismic interpretation and inversion. Lead. Edge 2019, 38, 526–533. [Google Scholar] [CrossRef]

- Zhang, Z.; Ning, H.; Shi, F.; Farha, F.; Xu, Y.; Xu, J.; Zhang, F.; Choo, K.-K.R. Artificial Intelligence in Cyber Security: Research Advances, Challenges, and Opportunities. Artif. Intell. Rev. 2022, 55, 1029–1053. [Google Scholar] [CrossRef]

- Al-Rbeawi, S. A Review of Modern Approaches of Digitalization in Oil and Gas Industry. Upstream Oil Gas Technol. 2023, 11, 100098. [Google Scholar] [CrossRef]

- Collins, C.; Dennehy, D.; Conboy, K.; Mikalef, P. Artificial Intelligence in Information Systems Research: A Systematic Literature Review and Research Agenda. Int. J. Inf. Manag. 2021, 60, 102383. [Google Scholar] [CrossRef]

- Assi, A.H. Non-Productive Time Reduction during Oil Wells Drilling Operations. J. Pet. Res. Stud. 2022, 12, 34–50. [Google Scholar] [CrossRef]

- D’Almeida, A.L.; Bergiante, N.C.R.; de Souza Ferreira, G.; Leta, F.R.; de Campos Lima, C.B.; Lima, G.B.A. Digital Transformation: A Review on Artificial Intelligence Techniques in Drilling and Production Applications. Int. J. Adv. Manuf. Technol. 2022, 119, 5553–5582. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, L.F.F.M.; Nascimento, A.; Mathias, M.H.; de Carvalho, J.A. Machine Learning Methods Applied to Drilling Rate of Penetration Prediction and Optimization—A Review. J. Pet. Sci. Eng. 2019, 183, 106332. [Google Scholar] [CrossRef]

- Kaur, R.; Gabrijelčič, D.; Klobučar, T. Artificial Intelligence for Cybersecurity: Literature Review and Future Research Directions. Inf. Fusion 2023, 97, 101804. [Google Scholar] [CrossRef]

- Ohalete, N.C.; Aderibigbe, A.O.; Ani, E.C.; Ohenhen, P.E.; Akinoso, A. Advancements in Predictive Maintenance in the Oil and Gas Industry: A Review of AI and Data Science Applications. World J. Adv. Res. Rev. 2023, 20, 167–181. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. Roles of Artificial Intelligence in Construction Engineering and Management: A Critical Review and Future Trends. Autom. Constr. 2021, 122, 103517. [Google Scholar] [CrossRef]

- Khodayari-Rostamabad, A.; Reilly, J.P.; Nikolova, N.K.; Hare, J.R.; Pasha, S. Machine Learning Techniques for the Analysis of Magnetic Flux Leakage Images in Pipeline Inspection. IEEE Trans. Magn. 2009, 45, 3073–3084. [Google Scholar] [CrossRef]

- Nwachukwu, A.; Jeong, H.; Pyrcz, M.; Lake, L.W. Fast Evaluation of Well Placements in Heterogeneous Reservoir Models Using Machine Learning. J. Pet. Sci. Eng. 2018, 163, 463–475. [Google Scholar] [CrossRef]

- Paltrinieri, N.; Comfort, L.; Reniers, G. Learning about Risk: Machine Learning for Risk Assessment. Saf. Sci. 2019, 118, 475–486. [Google Scholar] [CrossRef]

- Chen, W.; Yang, L.; Zha, B.; Zhang, M.; Chen, Y. Deep Learning Reservoir Porosity Prediction Based on Multilayer Long Short-Term Memory Network. Geophysics 2020, 85, WA213–WA225. [Google Scholar] [CrossRef]

- Orrù, P.F.; Zoccheddu, A.; Sassu, L.; Mattia, C.; Cozza, R.; Arena, S. Machine Learning Approach Using MLP and SVM Algorithms for the Fault Prediction of a Centrifugal Pump in the Oil and Gas Industry. Sustainability 2020, 12, 4776. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Yuan, C.; Liu, S.; Chen, Z.; Li, W. Locating Induced Earthquakes with a Network of Seismic Stations in Oklahoma via a Deep Learning Method. Sci. Rep. 2020, 10, 1941. [Google Scholar] [CrossRef] [PubMed]

- Peng, S.; Zhang, Z.; Liu, E.; Liu, W.; Qiao, W. A New Hybrid Algorithm Model for Prediction of Internal Corrosion Rate of Multiphase Pipeline. J. Nat. Gas Sci. Eng. 2021, 85, 103716. [Google Scholar] [CrossRef]

- Sircar, A.; Yadav, K.; Rayavarapu, K.; Bist, N.; Oza, H. Application of Machine Learning and Artificial Intelligence in Oil and Gas Industry. Pet. Res. 2021, 6, 379–391. [Google Scholar] [CrossRef]

- Wasim, M.; Djukic, M.B. External Corrosion of Oil and Gas Pipelines: A Review of Failure Mechanisms and Predictive Preventions. J. Nat. Gas Sci. Eng. 2022, 100, 104467. [Google Scholar] [CrossRef]

- Anaba, D.C.; Kess-Momoh, A.J.; Ayodeji, S.A. Digital Transformation in Oil and Gas Production: Enhancing Efficiency and Reducing Costs. Int. J. Manag. Entrep. Res. 2024, 6, 2153–2161. [Google Scholar] [CrossRef]

- De Souza, K.A.; De Moraes, J.B.; Barbosa, L.C.M. Social responsibility in the context of the oil and gas industry: Lessons from offshore decommissioning. In Proceedings of the Rio Oil & Gas Expo and Conference, Rio de Janeiro, Brazil, 26–29 September 2022; pp. 478–479. [Google Scholar] [CrossRef]

- Vieira, G.V. Eficiência Energética Através da Implementação da Cultura ESG. 2022. Available online: http://hdl.handle.net/11449/238455 (accessed on 30 June 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).