Model Test on Excavation Face Stability of Shallow-Buried Rectangular Pipe Jacking in Sand Layer

Abstract

1. Introduction

2. Experimental Design

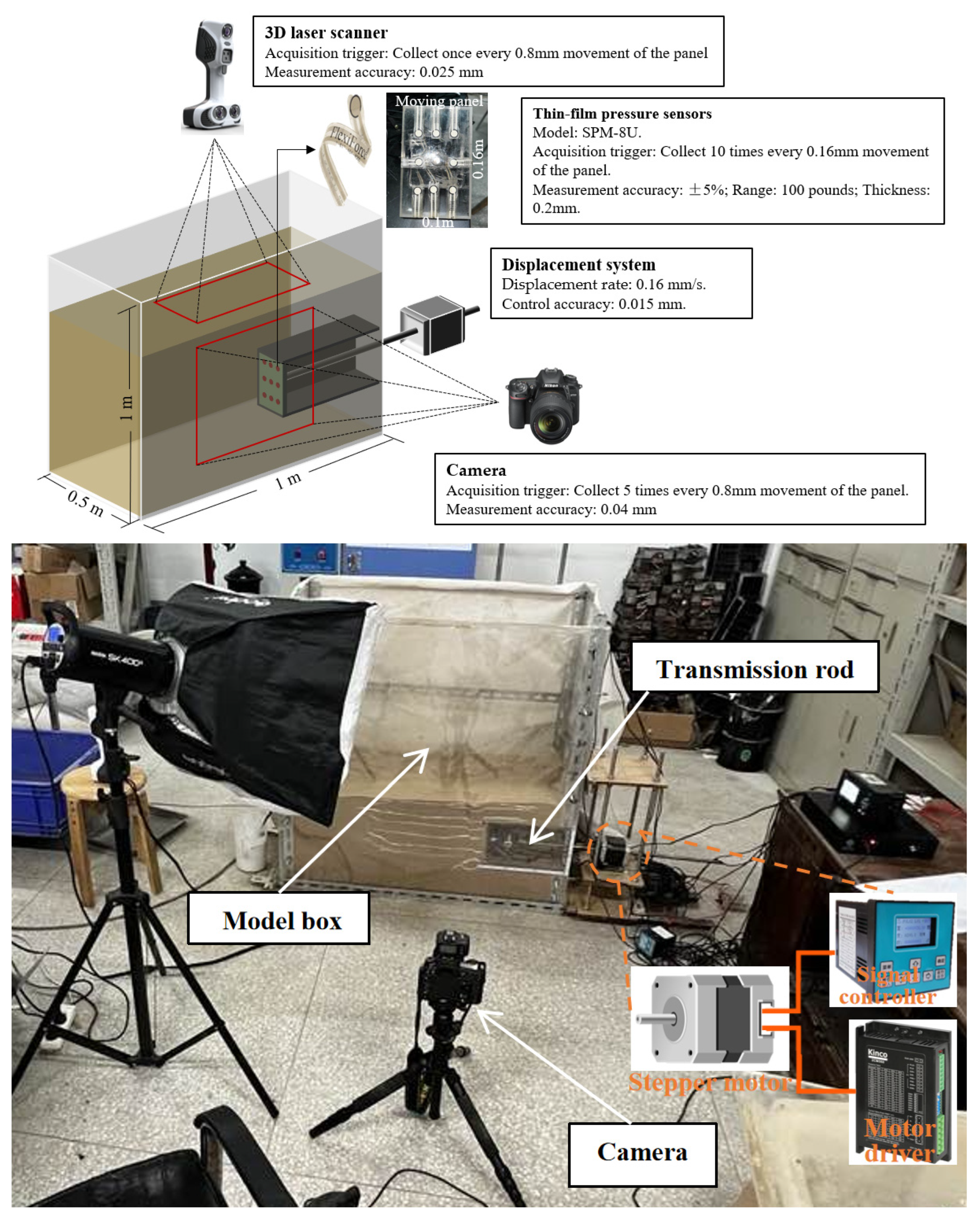

2.1. Experimental Device

2.2. Materials and Methods

- (1)

- Instrument Configuration (Shanghai Saisu Motor Technology Co., Ltd., Shanghai, China)

- Stereo cameras were configured for 1 Hz image acquisition over 5 s intervals.

- Calibrated thin-film pressure sensors were surface-mounted on the moving panel with 10 Hz sampling.

- Terrestrial laser scanning resolution was set to 0.025 mm.

- Stepper motor displacement rate was programmed at 0.16 mm/s (0.1%H/s) through closed-loop control.

- (2)

- Specimen Preparation

- (3)

- Baseline Measurement

- Initial deep soil images.

- Support pressure baseline values.

- Reference ground topography.

- (4)

- Kinematic Testing

- Temporal pressure fluctuations.

- Progressive soil displacement fields.

- (5)

- Intermittent Scanning

- (6)

- Termination Criteria

- (7)

- Post-processing

- Particle Image Velocimetry (PIV) analysis was performed using MATLAB (R2022a)-integrated PIVlab plugin to quantify soil displacement fields during instability progression. High-resolution 2D image sequences were processed to generate time-dependent displacement contour maps.

- Single point pressure test system SPM-8 was employed to process pressure–time histories.

- 3D ground deformation analysis was conducted in Geomagic Wrap v2021 software through the following sequential steps: point cloud registration using the iterative closest point algorithm; differential surface modeling; and deformation vector field visualization.

3. Results and Analysis

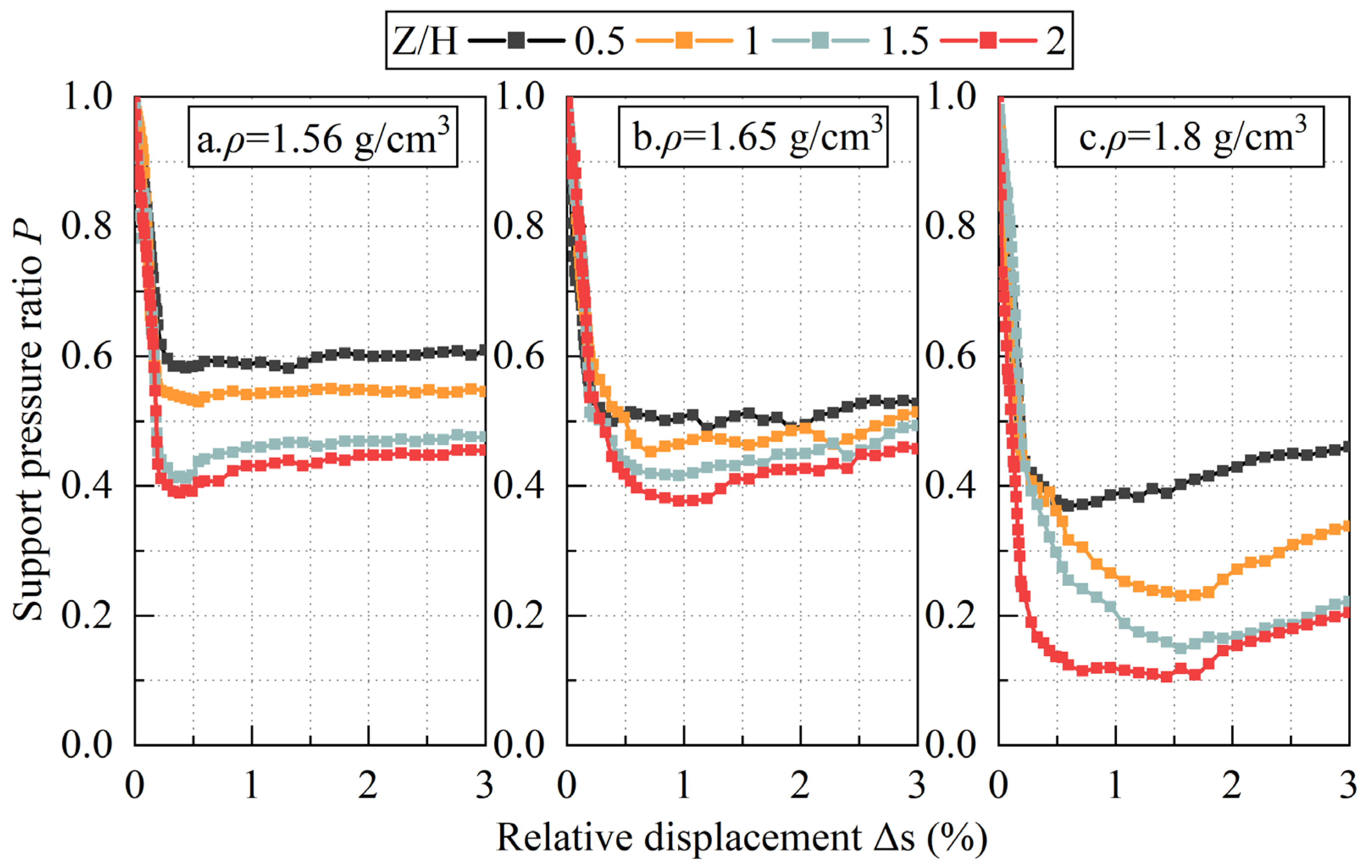

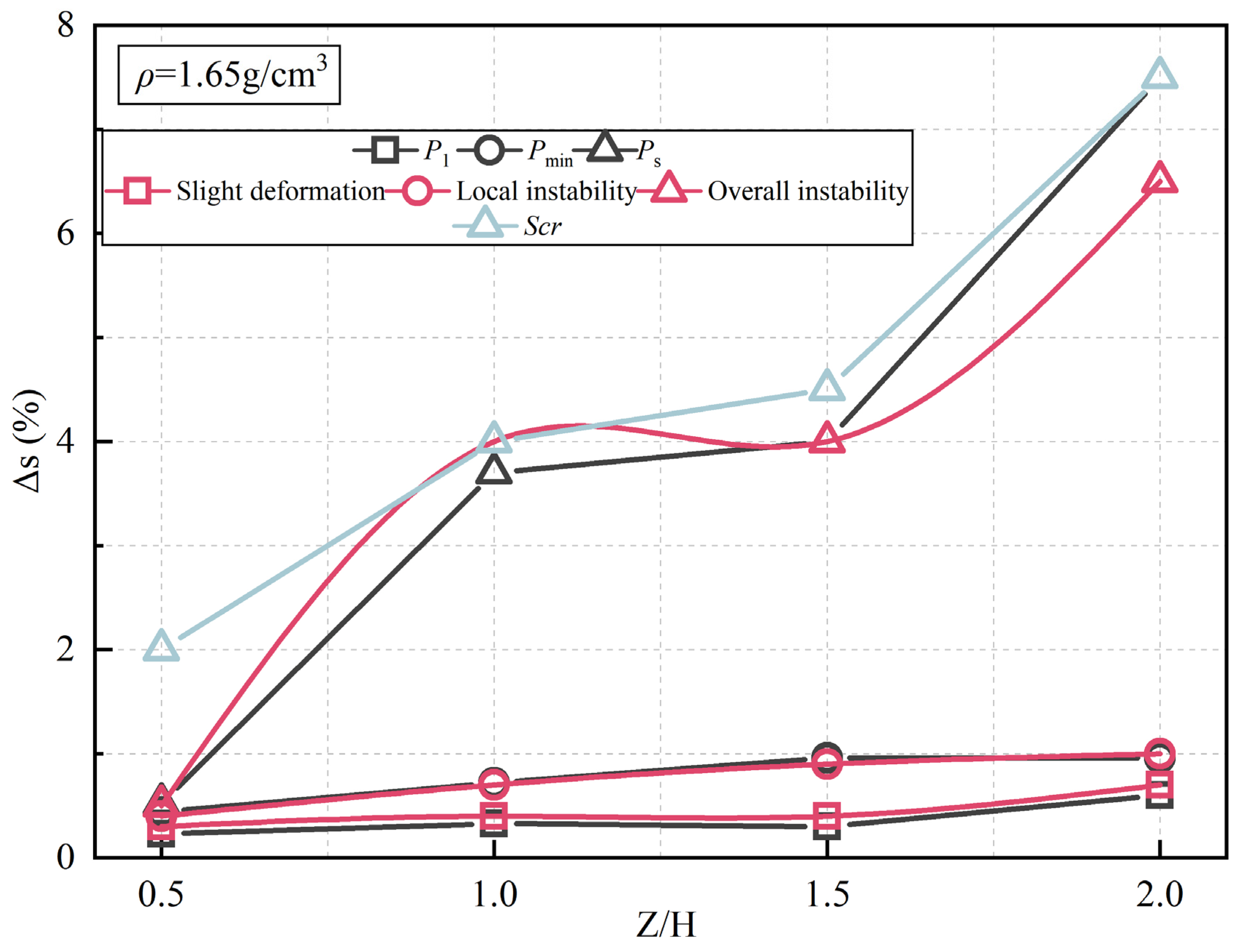

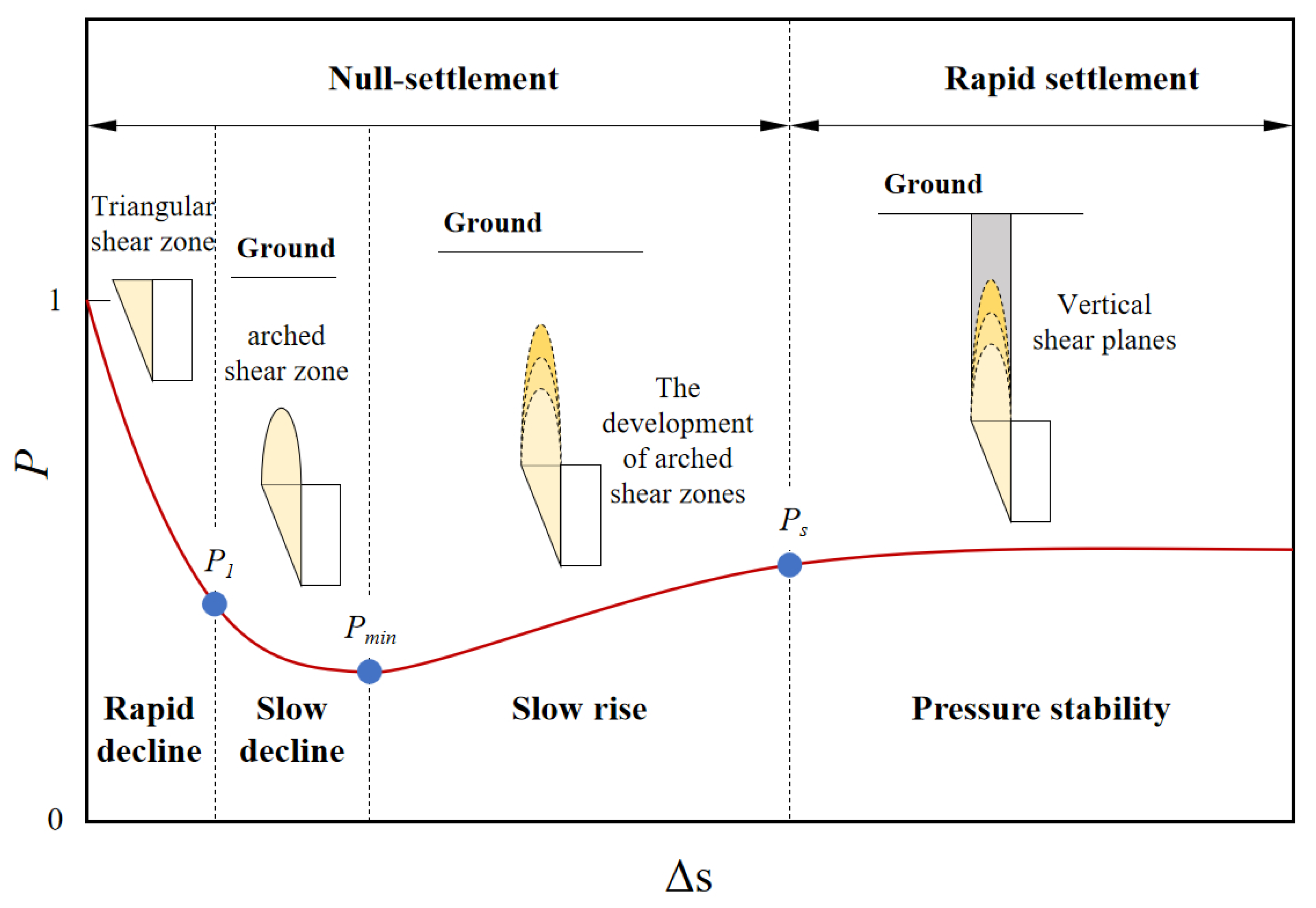

3.1. Support Pressure Variation Law

- (1)

- Pressure rapid decline stage: Small relative displacement causes significant support pressure drop. This stage mainly involves soil elastic deformation and gradual mobilization of sand shear strength, with the support pressure reaching failure value P1.

- (2)

- Pressure slow decline stage: Reduced pressure reduction rate. Mainly soil plastic deformation occurs, while soil arching effect develops. Upon reaching limit equilibrium state at certain displacement, the support pressure reaches minimum Pmin.

- (3)

- Pressure slow rise stage: Pressure shows gradual increase as displacement continues. Soil ahead reaches ultimate shear strength, arching effect diminishes, and local shear failure occurs.

- (4)

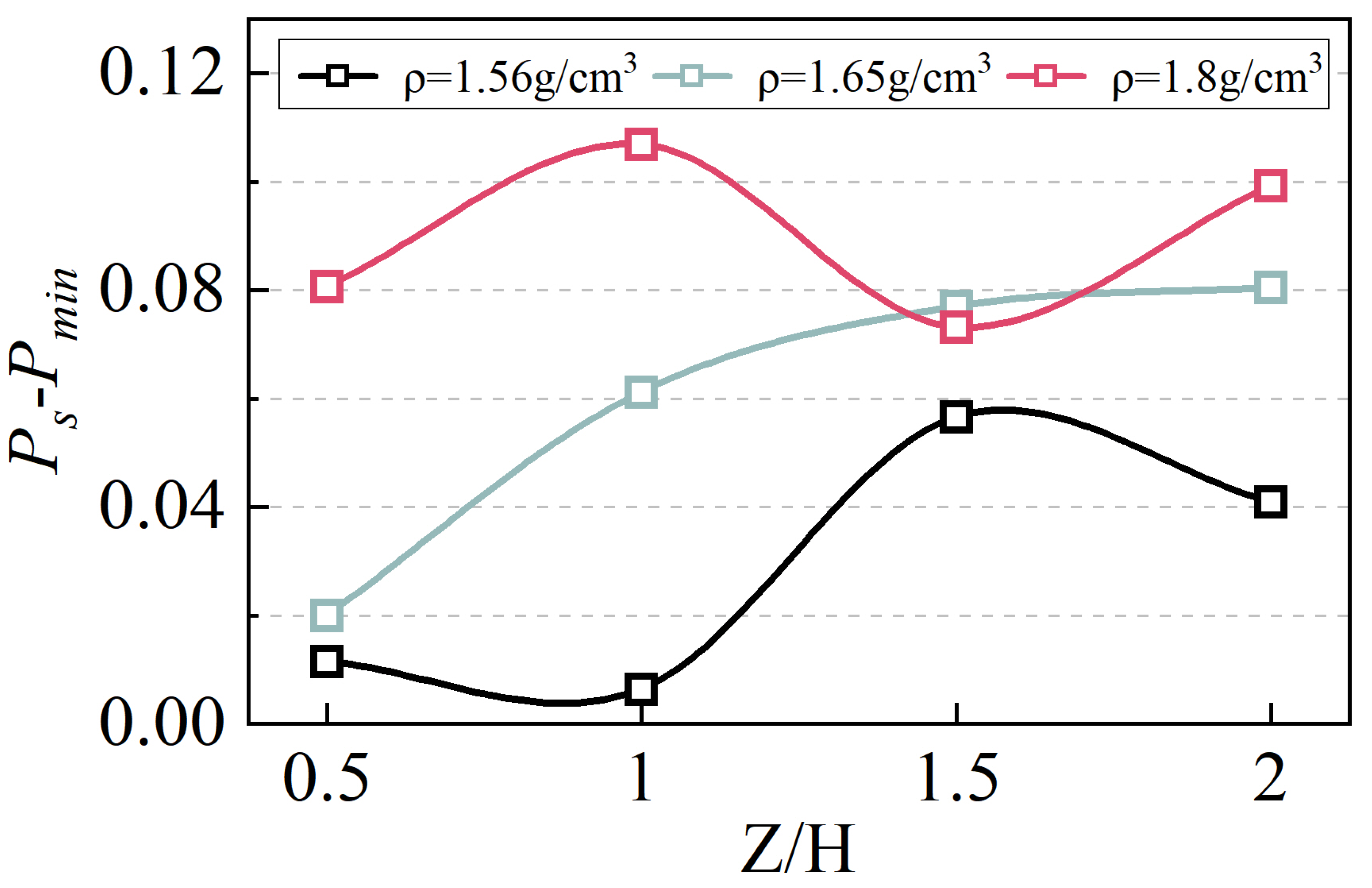

- Pressure stabilization stage: Support pressure stabilizes, remaining constant with displacement increase, while the support pressure reaches stable value Ps.

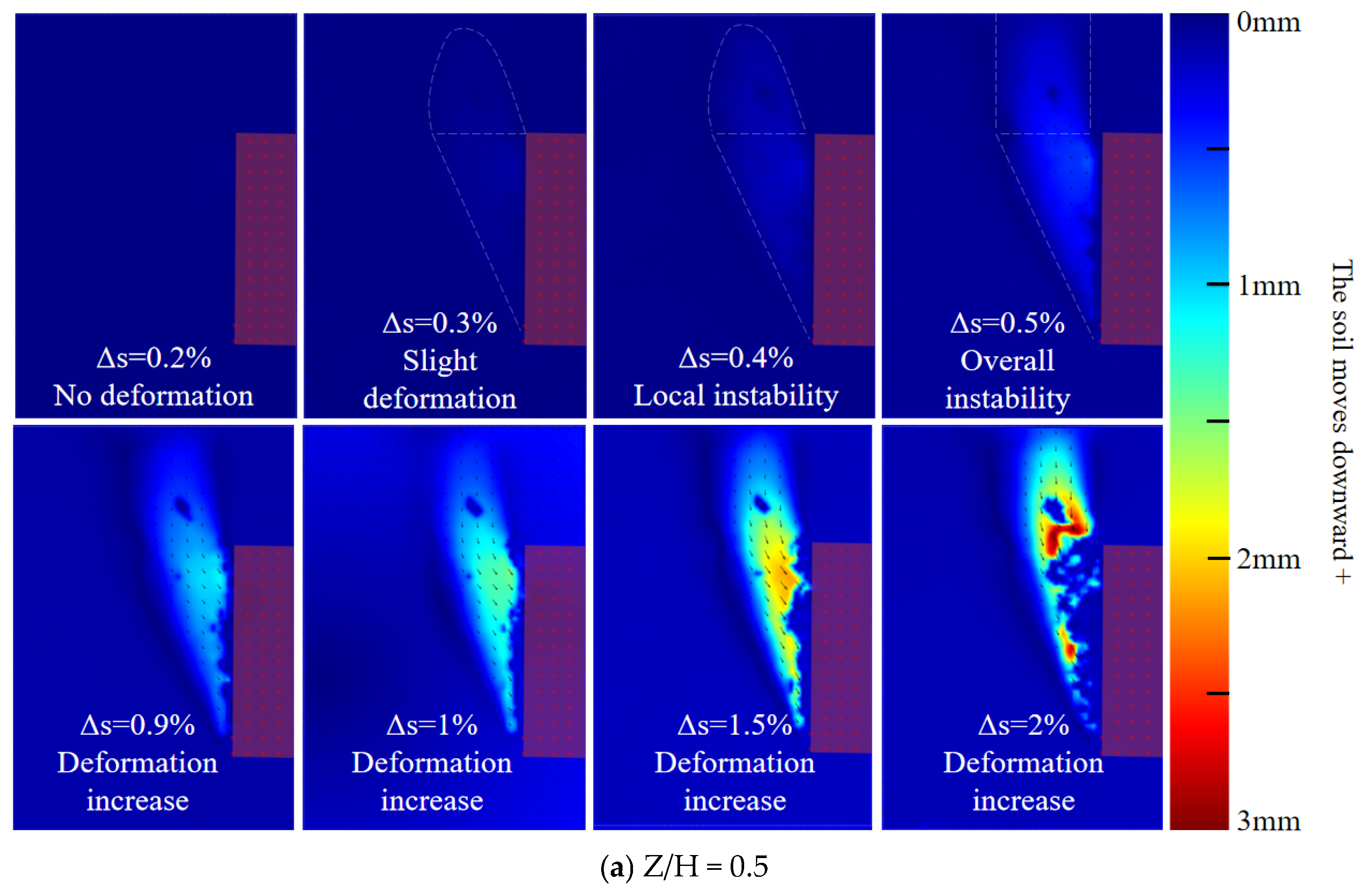

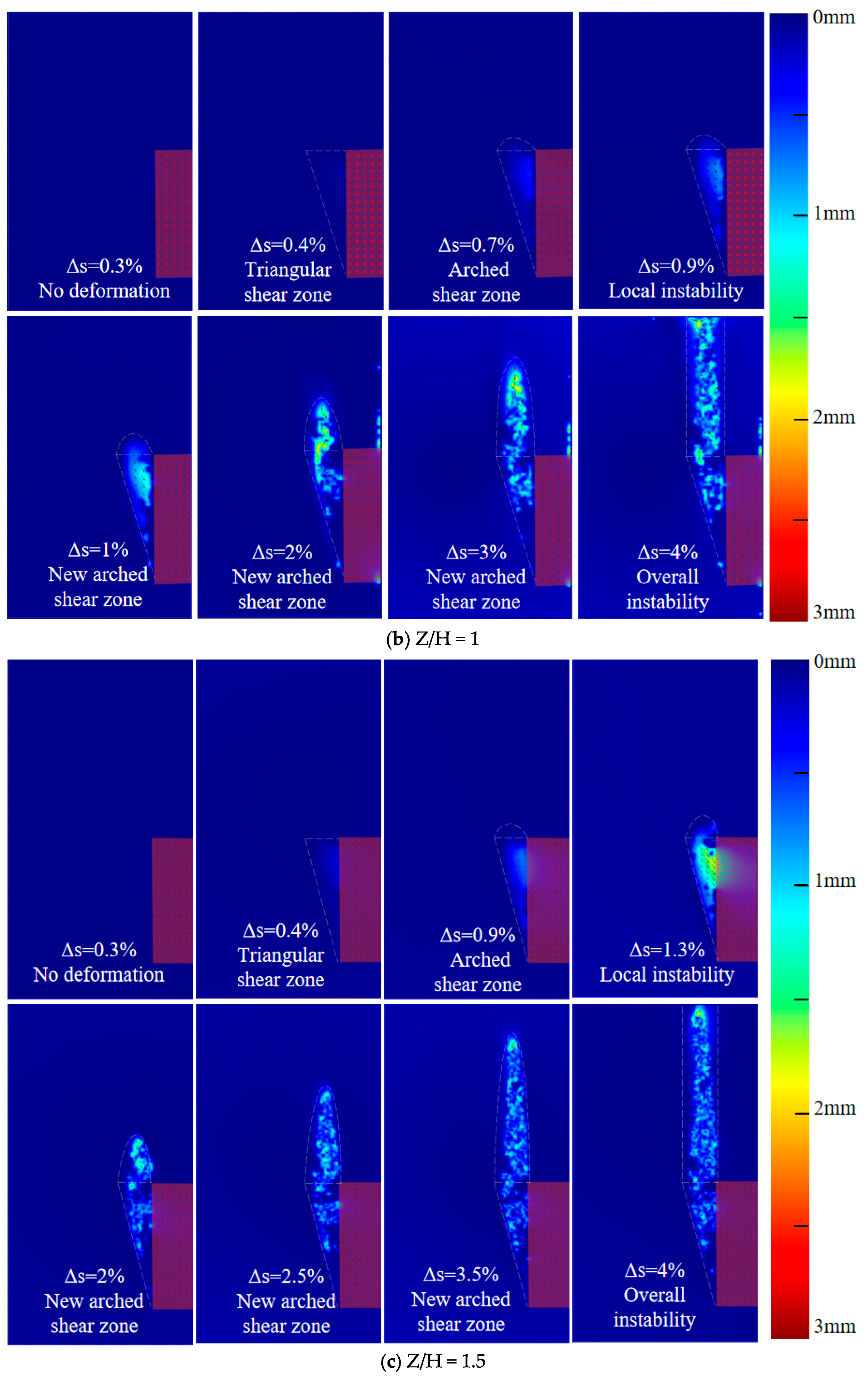

3.2. Deep Soil Deformation Process

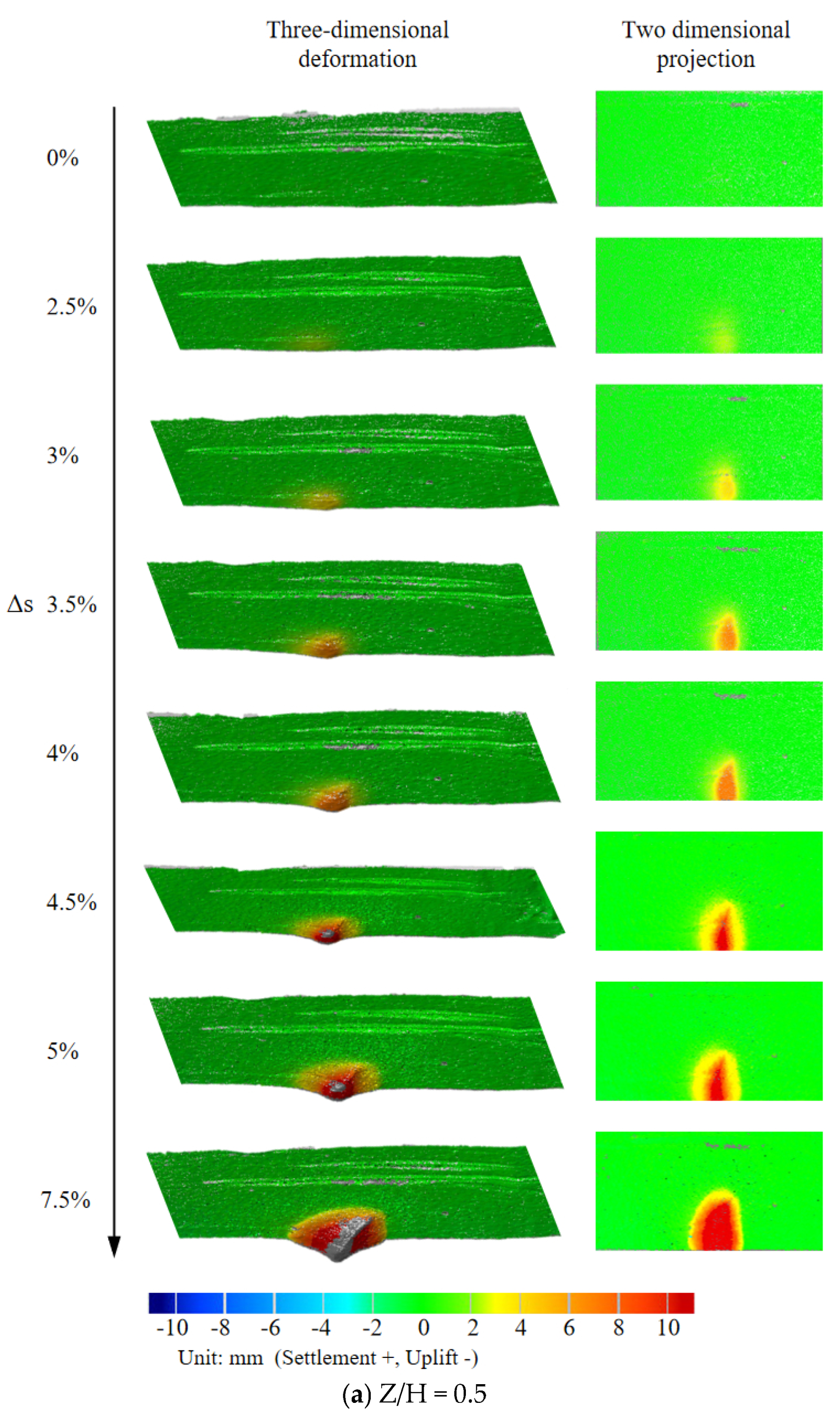

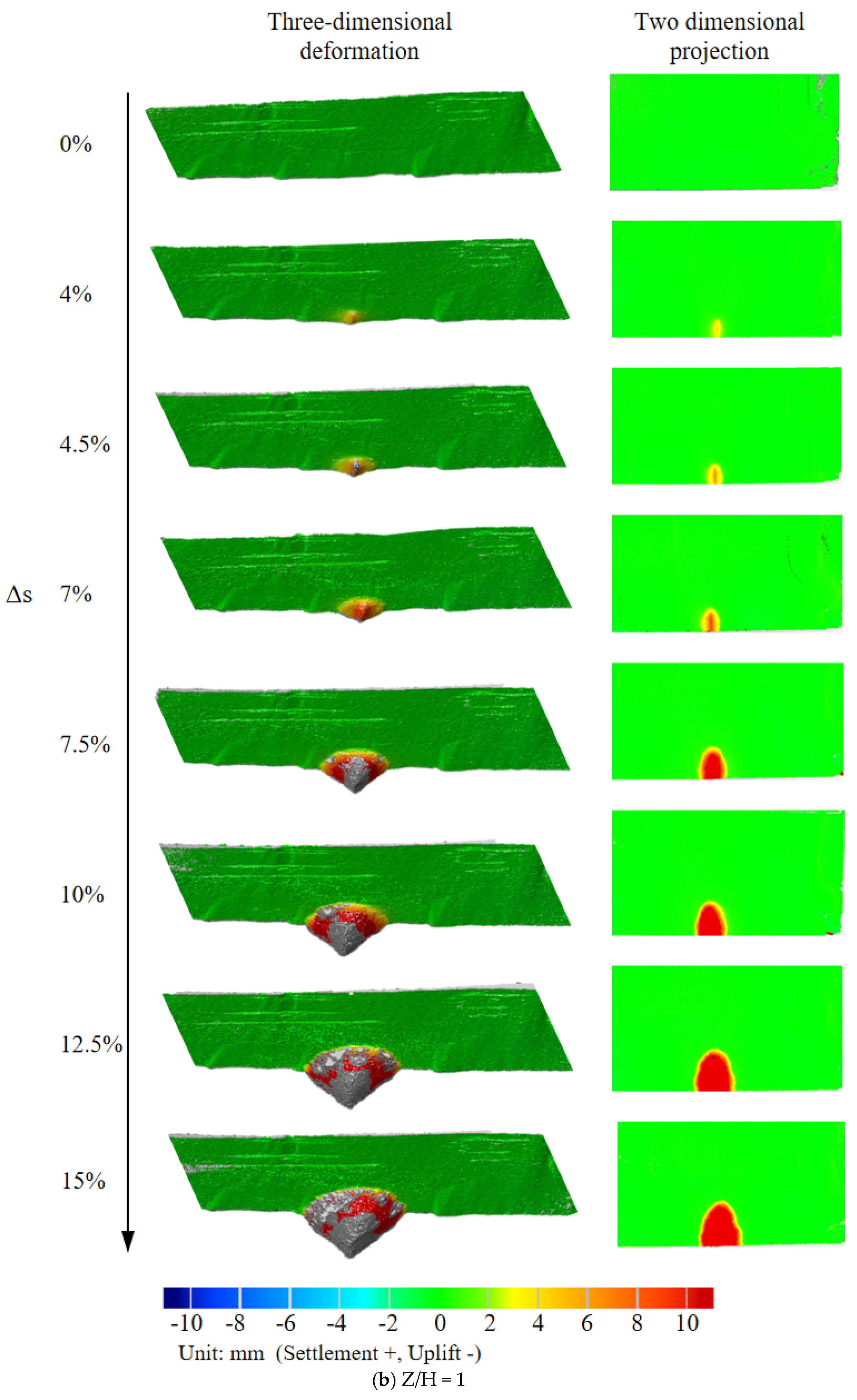

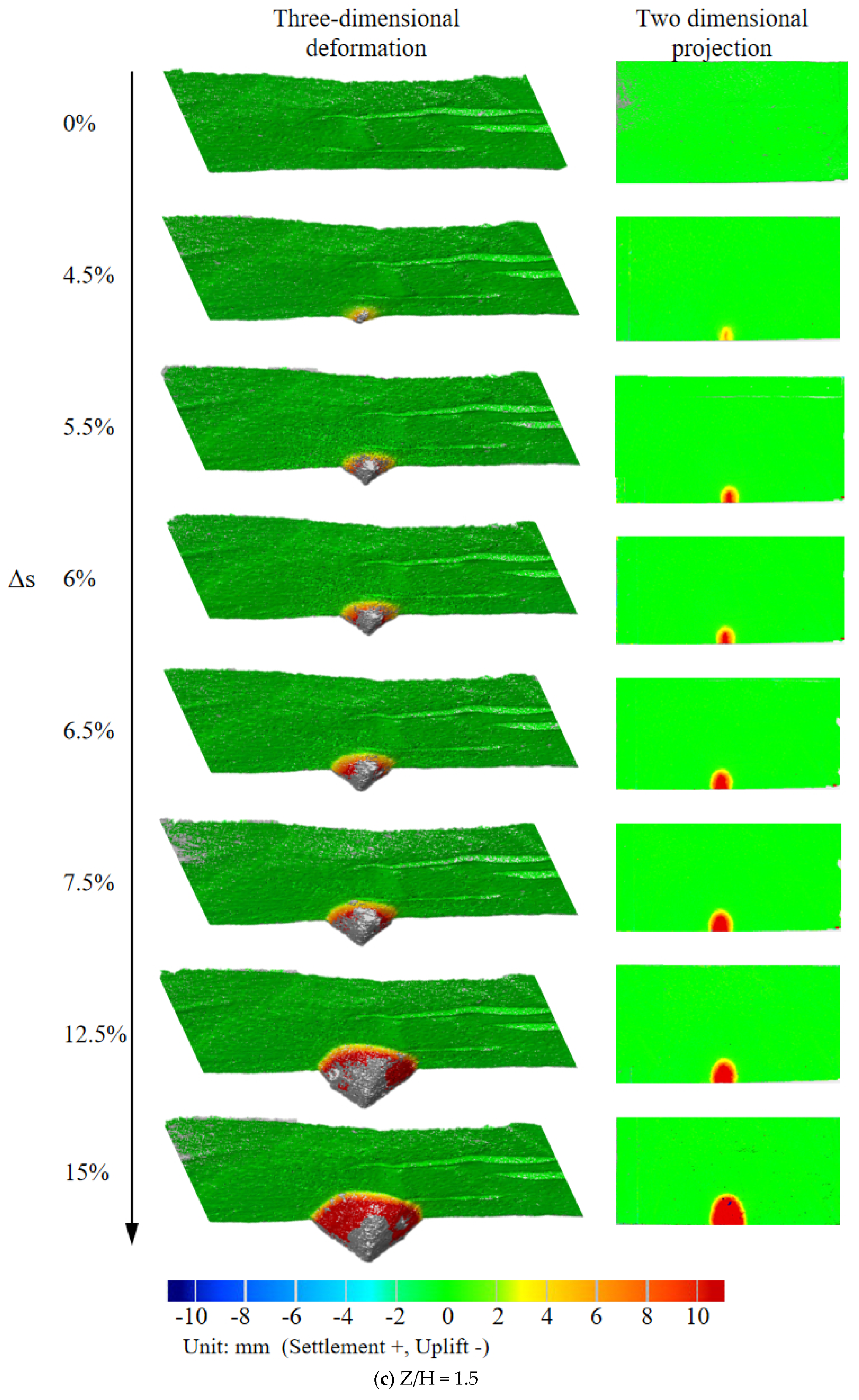

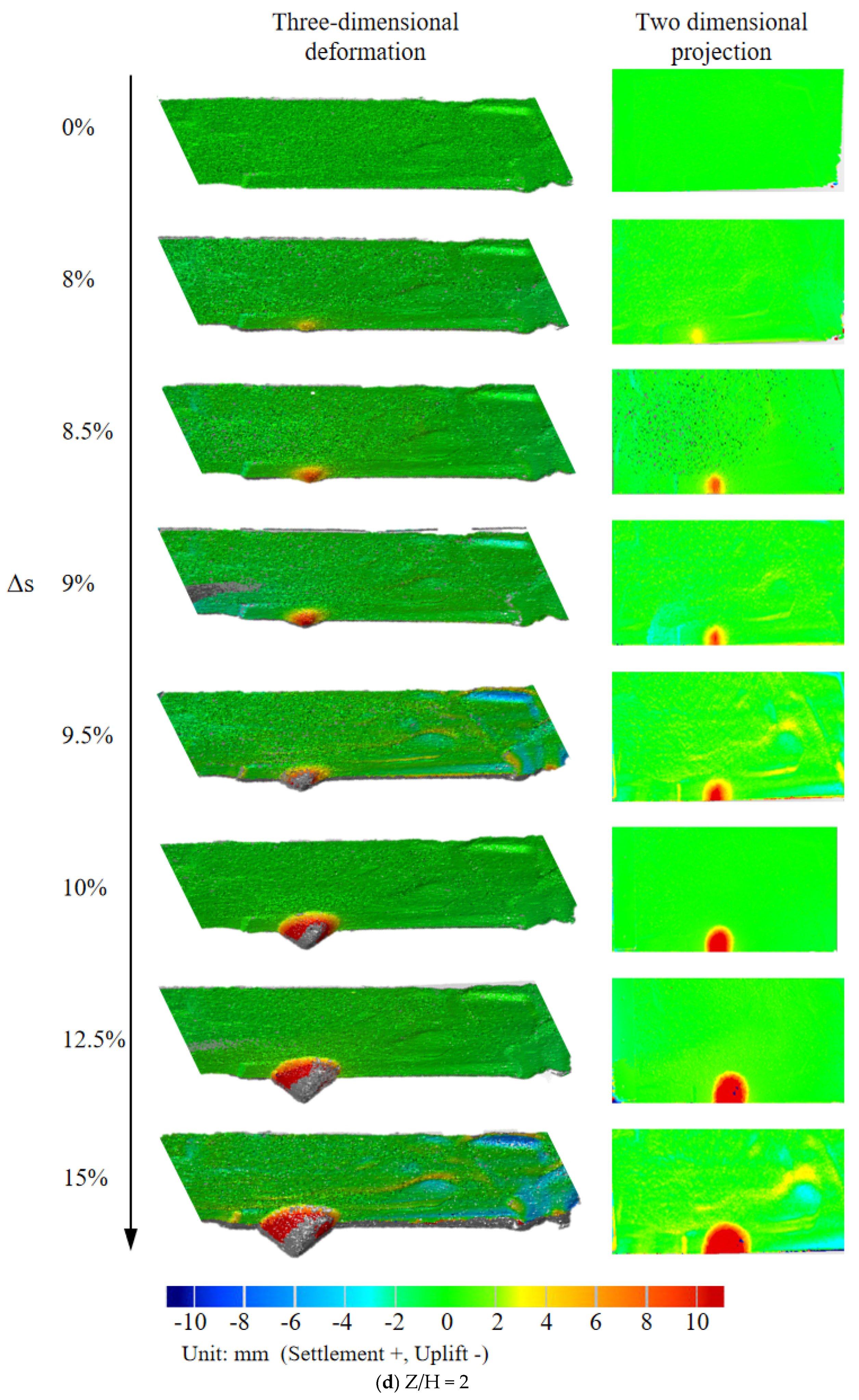

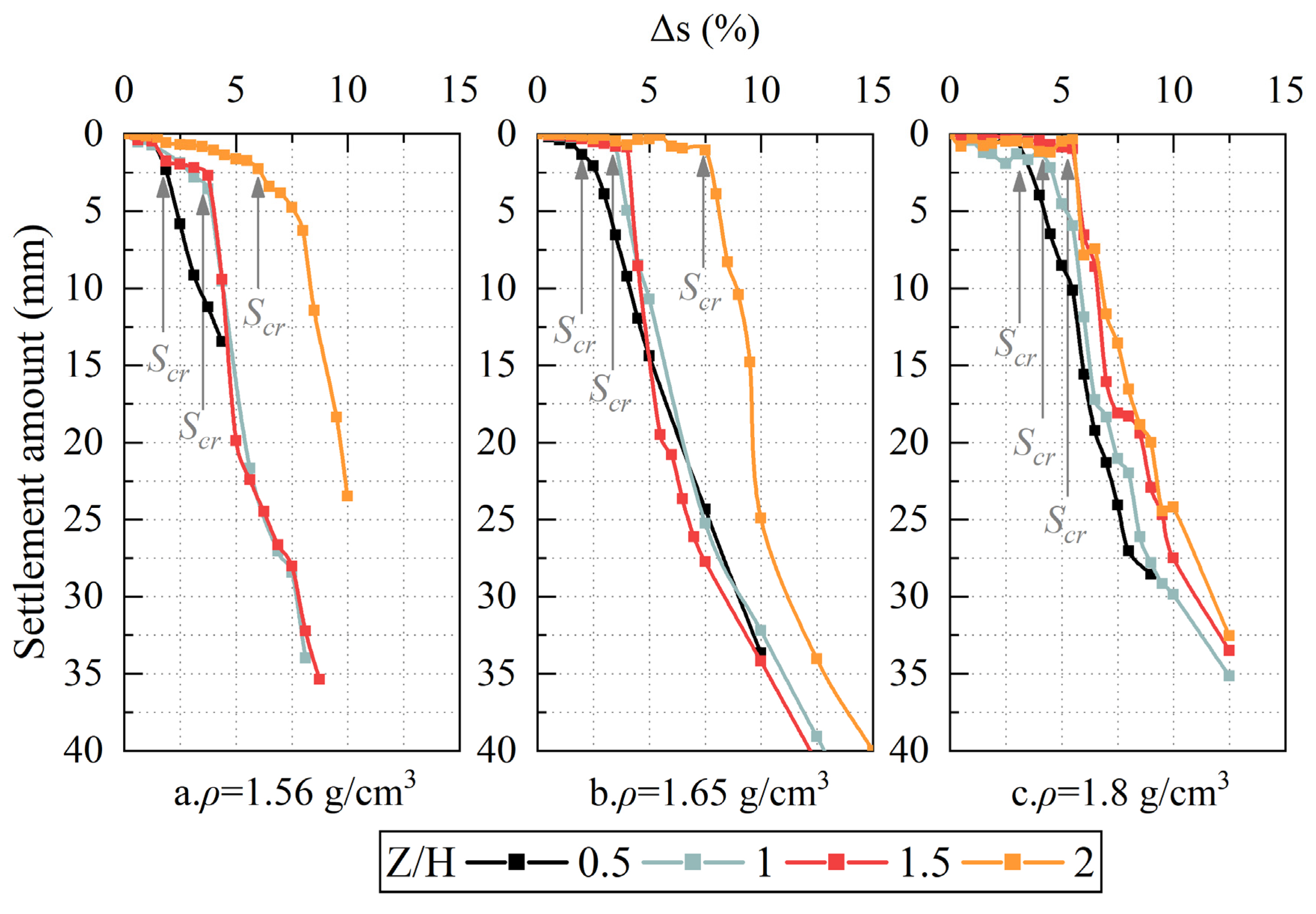

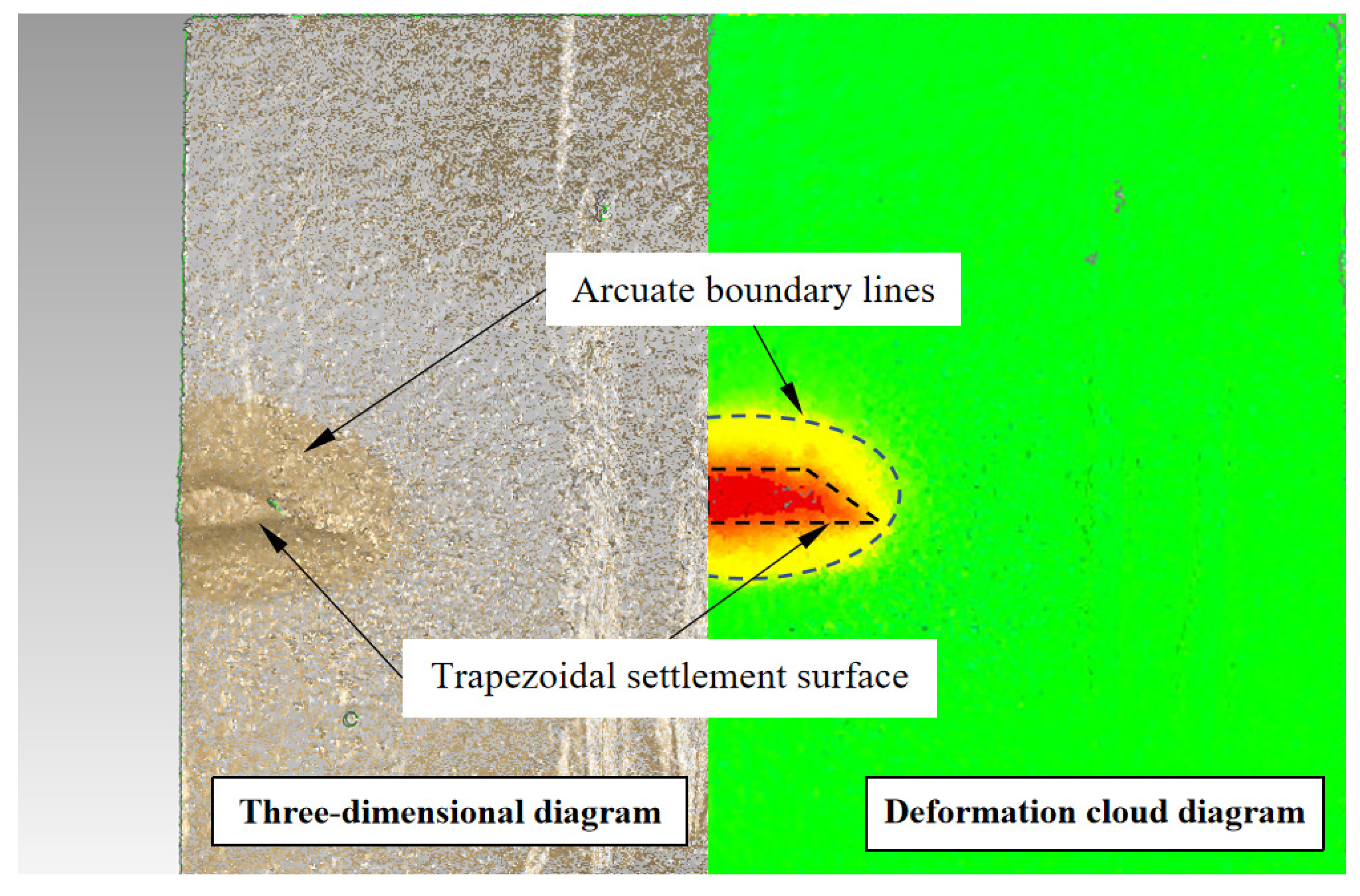

3.3. Ground Settlement Characteristics

4. Discussion

- (1)

- Rapid decline stage: When there is a slight movement in the excavation face, the soil is disturbed and undergoes misalignment and rearrangement. The interaction force shifts, gradually exerting the binding effect between soil particles. A triangular shear zone appears in front of the excavation, and the supporting force rapidly decreases and reaches the P1.

- (2)

- Slow decline stage: As the relative displacement further increases, an arched shear zone appears in the overlying soil. The uneven displacement of the soil causes the soil arch effect to share part of the soil pressure. When the shear stress is fully activated, the maximum arch effect is exerted, and the support pressure ratio reduces to the Pmin.

- (3)

- Slow rise stage: The relative displacement continues to increase, causing the soil within the arched shear zone to slide downward. When the volume expansion of the soil within the arched shear zone is insufficient to compensate for the soil loss caused by the movement of the excavation face, the arched shear zone is disrupted, and some of the soil directly collapses, resulting in local instability. When the soil cover is relatively small, it directly develops into a vertical shear zone. However, when the soil cover is relatively large, a new arched shear zone appears and gradually develops towards the ground, resulting in a slow increase in the support force.

- (4)

- Stabilization stage: The overlying soil on the excavation face formed a vertical shear zone running through the ground. The continuous increase in relative displacement led to the overall movement of the soil within the shear zone, resulting in rapid settlement of the ground, with the Ps remaining basically constant.

5. Conclusions

- (1)

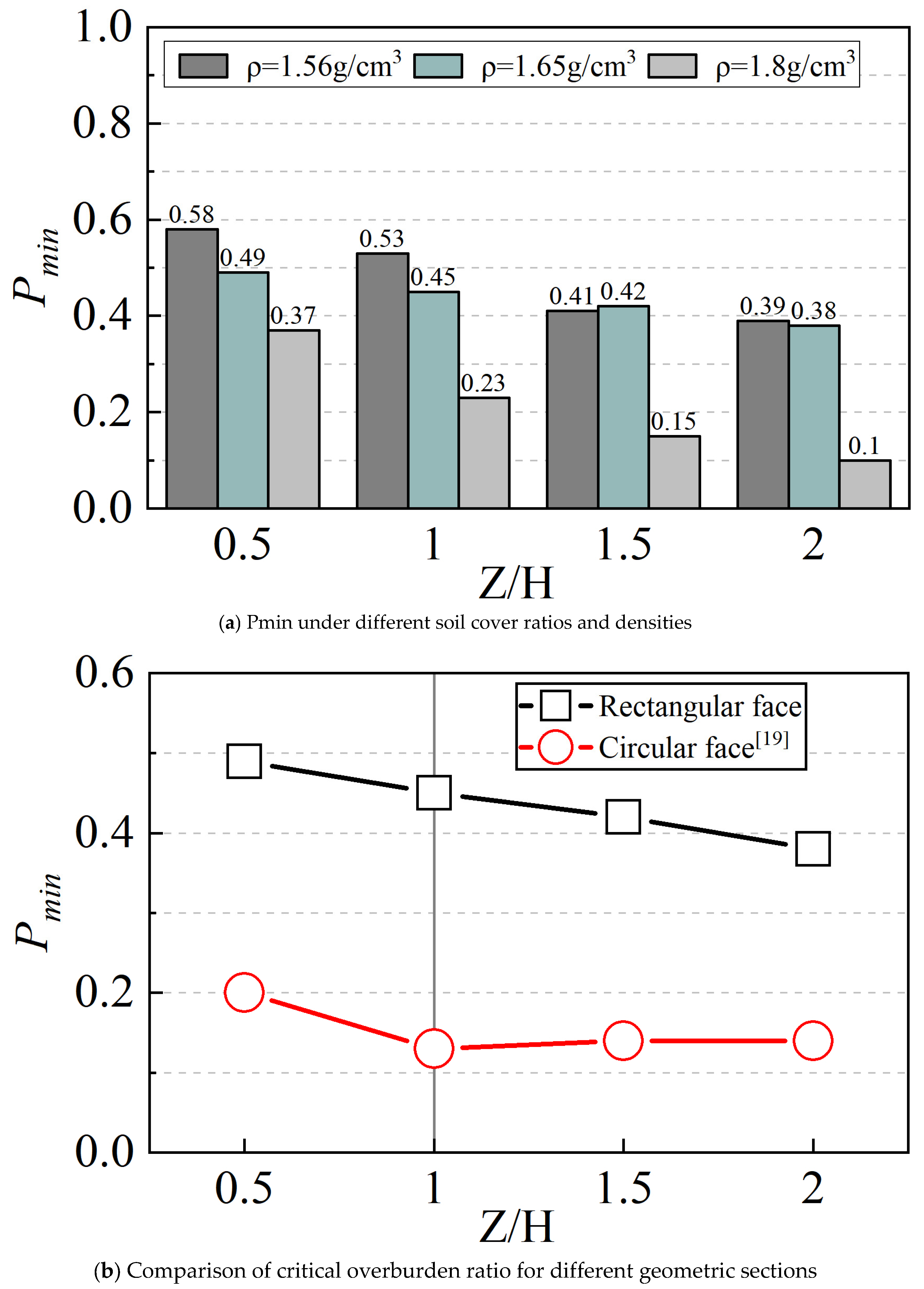

- Support pressure evolves through consistent stages irrespective of overburden ratio or density, and it shows nonlinear changes due to the influence of soil arch. And enhanced density intensifies soil arching, reducing support pressure while amplifying its post-failure rebound.

- (2)

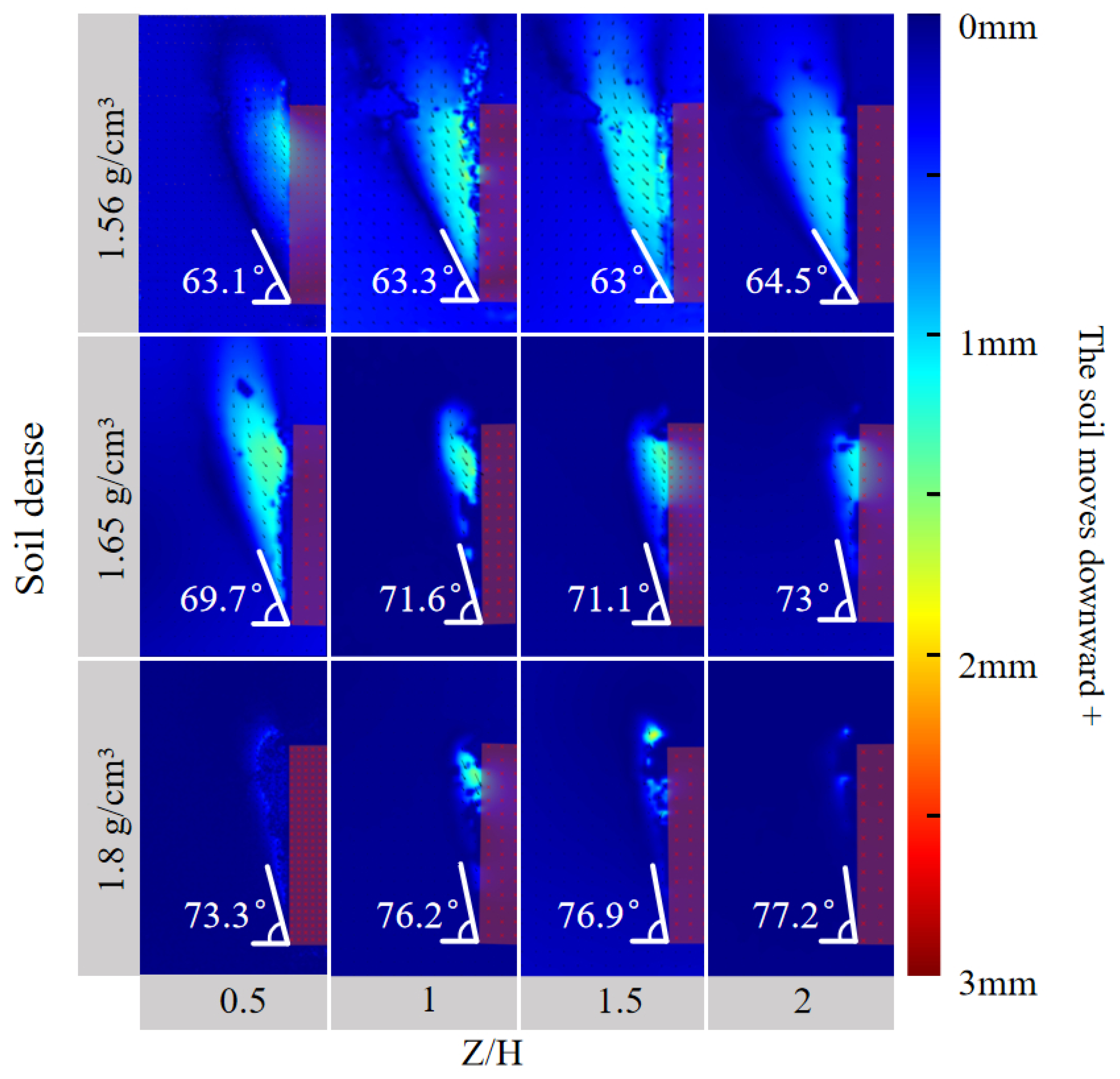

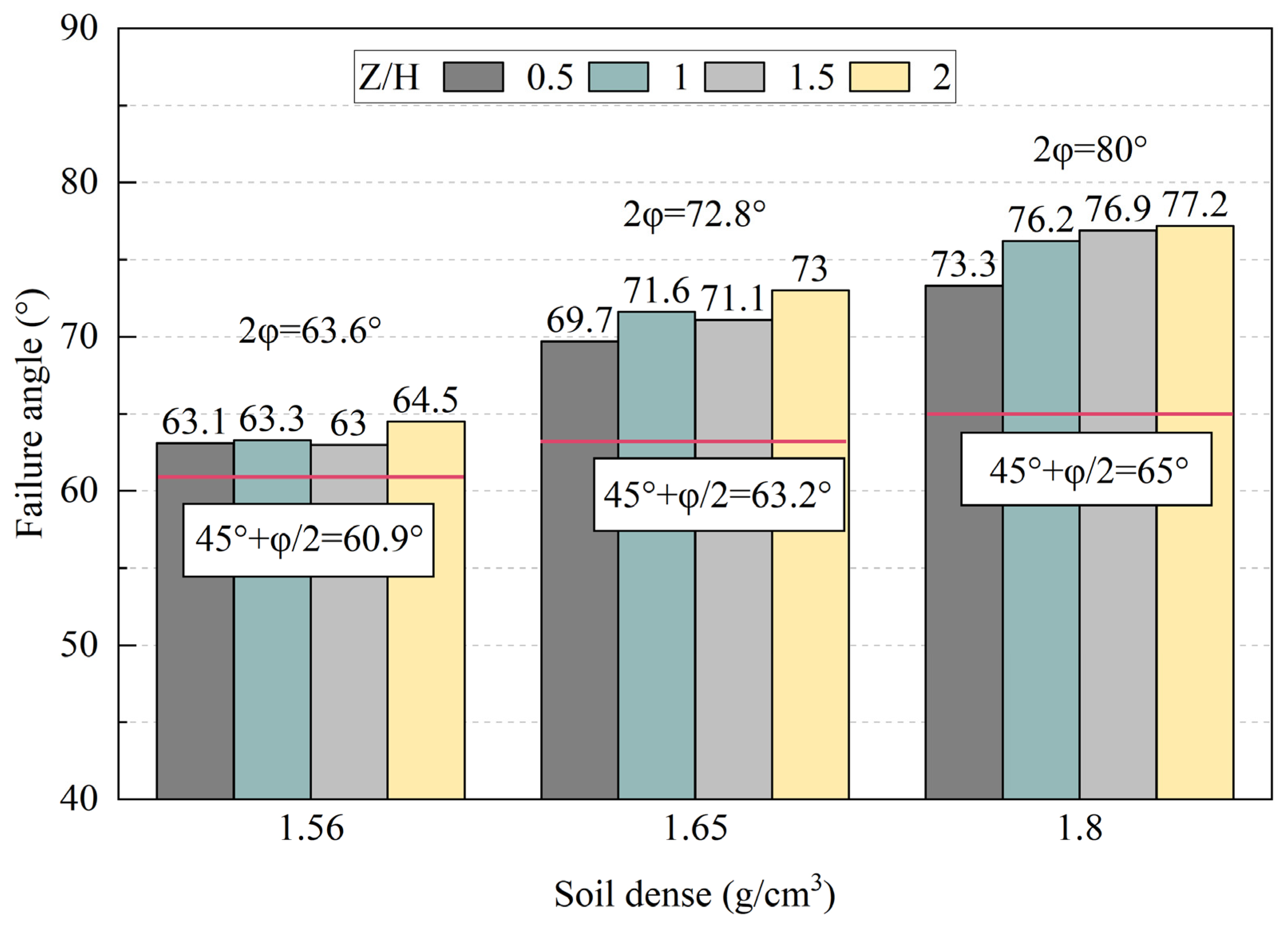

- Shear bands propagate progressively from excavation base to the ground during instability. The deep soil successively develops into non-deformation, triangular shear zone (slight deformation), arched shear zone (local instability), and vertical shear zone (overall instability). Meanwhile, the failure angle increases with soil density but is depth-independent, approximating twice the internal friction angle (≈2φ) for rectangular excavation faces.

- (3)

- During face instability, abrupt trapezoidal settlement surfaces emerge. Negligible settlement occurs prior to arched shear band penetration, but post-penetration triggers overall instability, forming these trapezoidal surfaces that exhibit progressively increasing settlement magnitude, rate, and extent. The critical settlement Scr depends on soil density but not overburden ratio. While the settlement rate is invariant to both parameters, larger overburden ratio increases displacement to reach Scr. Critically, the trapezoid geometry is governed by horizontal soil arching, where the equilibrium arch angle β, at a range of 41°~48°, correlates with the excavation aspect ratio and is independent of both soil density and overburden thickness.

- (4)

- Mechanistic linkages exist among support pressure, deep soil displacement, and ground settlement. Triangular shear band initiation causes pressure to drop to P1. Subsequent arched shear band development activates arching, minimizing pressure. Arch disruption induces localized instability, initiating pressure ascent while triggering new peripheral arched bands. These ultimately evolve into vertical surface-penetrating shear bands, coinciding with rapid ground settlement and pressure stabilization.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Feng, X.; Zhou, H.; Zhang, P.; Ma, B.; Tan, L.; Wang, J. Pressure characteristics of rectangular box jacking considering box-soil-lubricant interaction. Tunn. Undergr. Space Technol. 2022, 126, 104569. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, P.; Liu, K.; Xu, T.; Xu, Y.; Mei, J. A Segmented Calculation Method for Friction Force in Long-Distance Box Jacking Considering the Effect of Lubricant. Appl. Sci. 2024, 14, 2111. [Google Scholar] [CrossRef]

- Wang, Y.; Xiang, Y. Complex Function Solution of Stratum Displacements and Stresses in Shallow Rectangular Pipe Jacking Excavation Considering the Convergence Boundary. Appl. Sci. 2024, 14, 1154. [Google Scholar] [CrossRef]

- Xu, Y.; Liang, W.; Liu, X.; Cui, G.; Bai, X. Research on soil stability of large section rectangular pipe jacking tunnel excavation face. Mod. Tunn. Technol. 2017, 54, 70–77+85. (In Chinese) [Google Scholar] [CrossRef]

- Xie, X.; Zhao, M.; Shahrour, I. Experimental Study of the Behavior of Rectangular Excavations Supported by a Pipe Roof. Appl. Sci. 2019, 9, 2082. [Google Scholar] [CrossRef]

- Pan, W.; Wang, Z.; Diao, Y.; Zheng, G.; Zhou, H.; Zhang, T. Stability Analysis and Safety Factors of the Excavation Face of a Pipe Screen Tunnel in a Soft Soil Area. Appl. Sci. 2023, 13, 11120. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, D.; Fang, Q.; Liu, X.; Wang, J. Analytical Solution on Ground Deformation Caused by Parallel Construction of Rectangular Pipe Jacking. Appl. Sci. 2022, 12, 3298. [Google Scholar] [CrossRef]

- Ding, W.; Wang, Z.; Guo, X.; Chen, R. Calculation method of limit support pressure for large diameter rectangular pipe jacking tunnel face. Sci. Technol. Eng. 2021, 21, 9563–9569. (In Chinese) [Google Scholar] [CrossRef]

- Liu, W.; Yu, M.; Wu, Y.; Shi, P.; Wu, B. Formation stability analysis during the opening operation of the box pipe boxing. Harzard Control. Tunn. Undergr. Eng. 2022, 4, 92–98. (In Chinese) [Google Scholar] [CrossRef]

- Yu, M.; Liu, W.; Shi, P.; Jia, P. Analysis of stability and support pressure of driving face in shallow buried rectangular pipe jacking with large section. J. Jiansu Univ. (Nat. Sci. Ed.) 2022, 43, 612–620. (In Chinese) [Google Scholar] [CrossRef]

- Ding, J.; Peng, L.; Lei, M.; Zhu, L.; Tang, Z. Three-dimensional limit analysis method for excavation surface stability of rectangular pipe jacking tunnel with large section. J. Railw. Sci. Eng. 2022, 19, 2369–2380. (In Chinese) [Google Scholar] [CrossRef]

- Qu, K. Face stability analysis of shallow rectangular pipe jacking tunnel considering fluid-solid coupling effect. Sci. Technol. Eng. 2022, 22, 2055–2062. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, M.; Dai, Z.; Zhang, X.; Javadi, A.A. Active failure characteristics and earth pressure distribution around deep buried shield tunnel in dry sand stratum. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2022, 124, 104479. [Google Scholar] [CrossRef]

- He, J.; Yang, Z.; Zhang, X. Effect of Undercrossing Shield Tunnels Excavation on Existing Rectangular Pipe-Jacking Tunnels. Appl. Sci. 2023, 13, 12235. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, M.; Cao, M. Study on the Effect of Large Cross-Section Quasi-Rectangular Pipe Jacking near Side Crossing Viaduct Piles in Soft Soil Areas. Appl. Sci. 2023, 13, 9799. [Google Scholar] [CrossRef]

- Xu, Y.; Huang, Z.; Zhang, C.; Pang, Y.; Liu, T. Bearing Capacities and Failure Behaviors of F-Type Socket Joint in Rectangular Pipe Jacking Tunnel. Appl. Sci. 2023, 13, 5442. [Google Scholar] [CrossRef]

- Garnier, J.; Gaudin, C.; Springman, S.M.; Culligan, P.J.; Goodings, D.; Konig, D.; Kutter, B.; Phillips, R.; Randolph, M.F.; Thorel, L. Catalogue of scaling laws and similitude questions in geotechnical centrifuge modeling. Int. J. Phys. Model. Geotech. 2007, 7, 1–23. [Google Scholar] [CrossRef]

- Chambon, P.; Corte, J.F. Shallow tunnels in cohesionless soil: Stability of tunnel face. J. Geotech. Eng. 1994, 120, 1148–1165. [Google Scholar] [CrossRef]

- Chen, R.; Li, J.; Chen, Y.; Kong, L. Large-scale tests on face stability of shield tunnelling in dry cohesionless soil. Chin. J. Geotech. Eng. 2011, 33, 117–122. (In Chinese) [Google Scholar]

- Li, J.; Liu, W.; Zou, J.; Zhao, Y.; Gong, X. Large-scale model tests on face instability of shallow shield tunnels in sand. Chin. J. Geotech. Eng. 2018, 40, 562–567. (In Chinese) [Google Scholar] [CrossRef]

- Zhao, Y.; Gong, Q.; Wu, Y.; Zhao, Y.; Gong, X. Evolution of active arching in granular materials: Insights from load, displacement, strain, and particle flow. Powder Technol. 2021, 384, 160–175. [Google Scholar] [CrossRef]

- Liang, L.; Xu, C.; Chen, Q.; Chen, Q. Experimental and Theoretical Investigations on Evolution of Soil-Arching Effect in 2D Trapdoor Problem. Int. J. Geomech. 2020, 20, 06020007. [Google Scholar] [CrossRef]

- Zhang, M.; Dai, Z.; Zhang, X.; Wn, H.; Fu, Z. A calculation method of active limit support pressure for deep shield tunnels considering principal stress axis rotation. Chin. J. Rock Mech. Eng. 2021, 40, 2366–2376. (In Chinese) [Google Scholar] [CrossRef]

- Zhu, J.; Lin, Q.; Kang, Y. Research on dip angle of sliding surface of wedge model in shield tunneling. Rock Soil Mech. 2015, 36, 327–332. (In Chinese) [Google Scholar] [CrossRef]

- Hu, W.; Lv, X.; Huang, M. Three-Dimensional Limit Equilibrium Solution of the Support Pressure on the Shield Tunnel Face. Chin. J. Undergr. Space Eng. 2011, 7, 853–856+862. (In Chinese) [Google Scholar] [CrossRef]

- Wei, G.; He, F. Calculation of minimal support pressure acting on shield face during pipe jacking in sandy soil. Chin. J. Undergr. Space Eng. 2007, 3, 903–908. (In Chinese) [Google Scholar] [CrossRef]

| Soil Compactness | Loose | Medium-Dense | Dense |

|---|---|---|---|

| Relative density Dr | 0.2~0.33 | 0.33~0.67 | 0.67~1 |

| Dry density ρd (g/cm3) | 1.53~1.57 | 1.57~1.68 | 1.68~1.80 |

| Experimental control density (g/cm3) | 1.56 | 1.65 | 1.8 |

| Internal friction angle φ (°) | 31.8 | 36.4 | 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhang, P.; Xu, Y.; Mei, J. Model Test on Excavation Face Stability of Shallow-Buried Rectangular Pipe Jacking in Sand Layer. Appl. Sci. 2025, 15, 7847. https://doi.org/10.3390/app15147847

Zhang Y, Zhang P, Xu Y, Mei J. Model Test on Excavation Face Stability of Shallow-Buried Rectangular Pipe Jacking in Sand Layer. Applied Sciences. 2025; 15(14):7847. https://doi.org/10.3390/app15147847

Chicago/Turabian StyleZhang, Yunlong, Peng Zhang, Yong Xu, and Jiahao Mei. 2025. "Model Test on Excavation Face Stability of Shallow-Buried Rectangular Pipe Jacking in Sand Layer" Applied Sciences 15, no. 14: 7847. https://doi.org/10.3390/app15147847

APA StyleZhang, Y., Zhang, P., Xu, Y., & Mei, J. (2025). Model Test on Excavation Face Stability of Shallow-Buried Rectangular Pipe Jacking in Sand Layer. Applied Sciences, 15(14), 7847. https://doi.org/10.3390/app15147847