Data-Driven Selection of Decontamination Robot Locomotion Based on Terrain Compatibility Scoring Models

Abstract

1. Introduction

2. Related Studies

2.1. Decontamination Robot

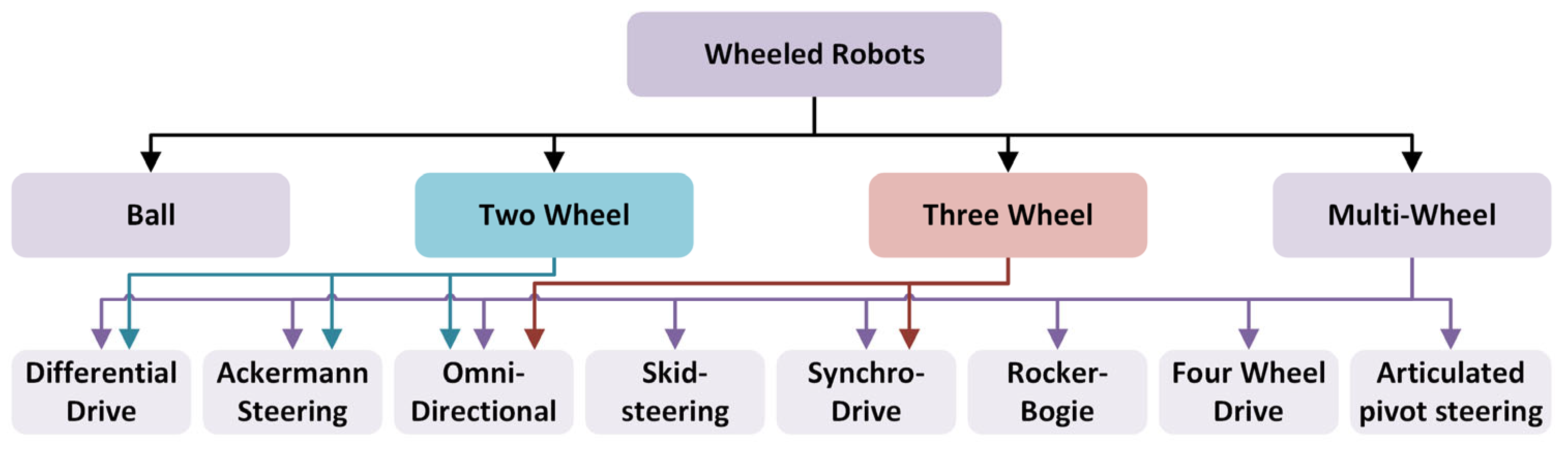

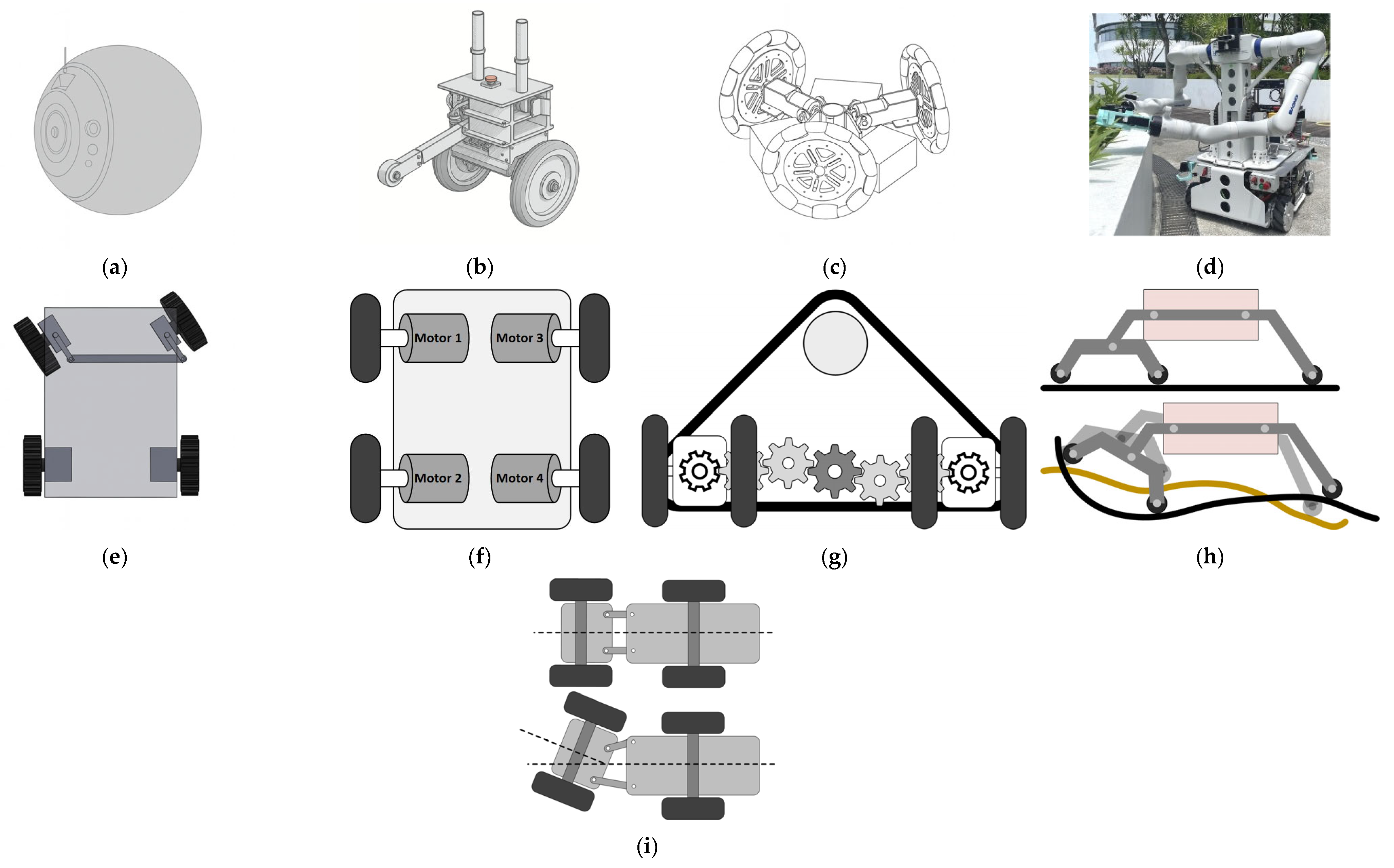

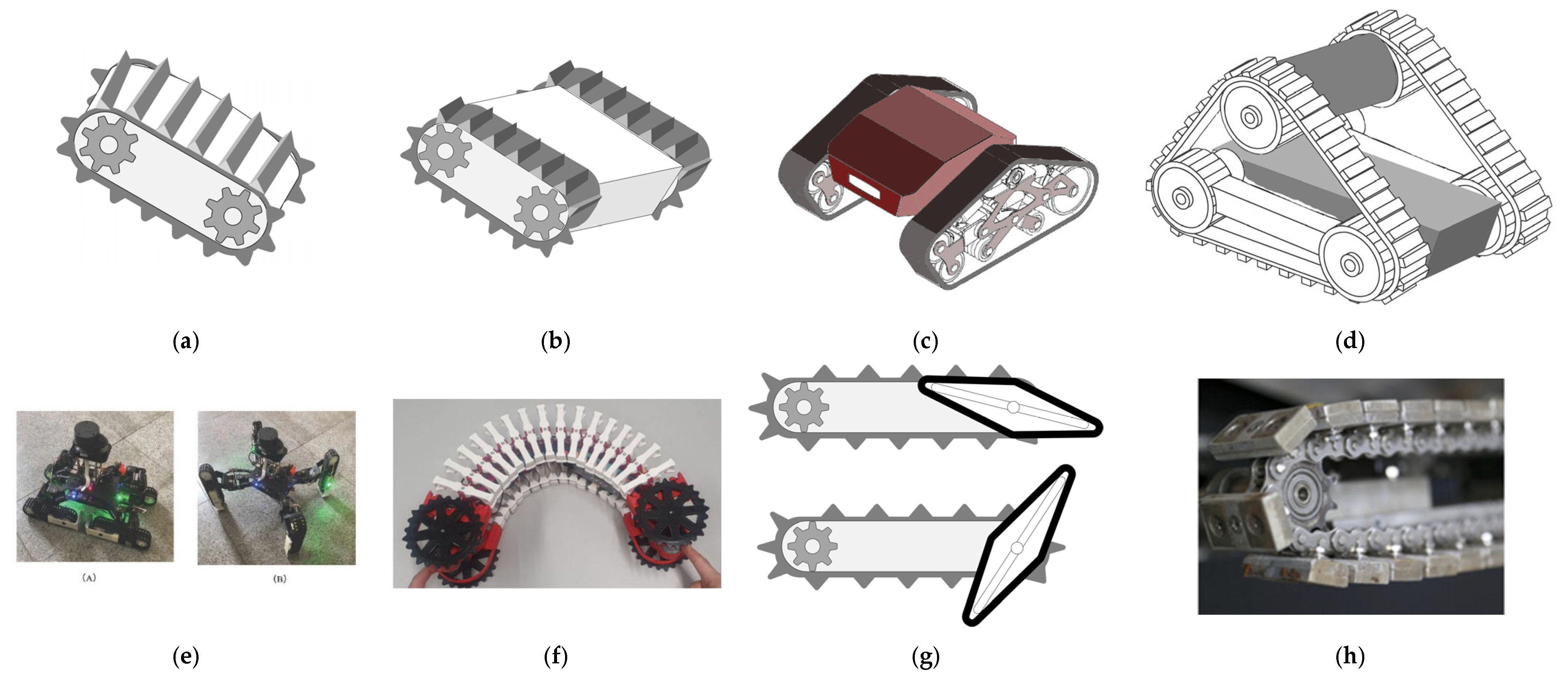

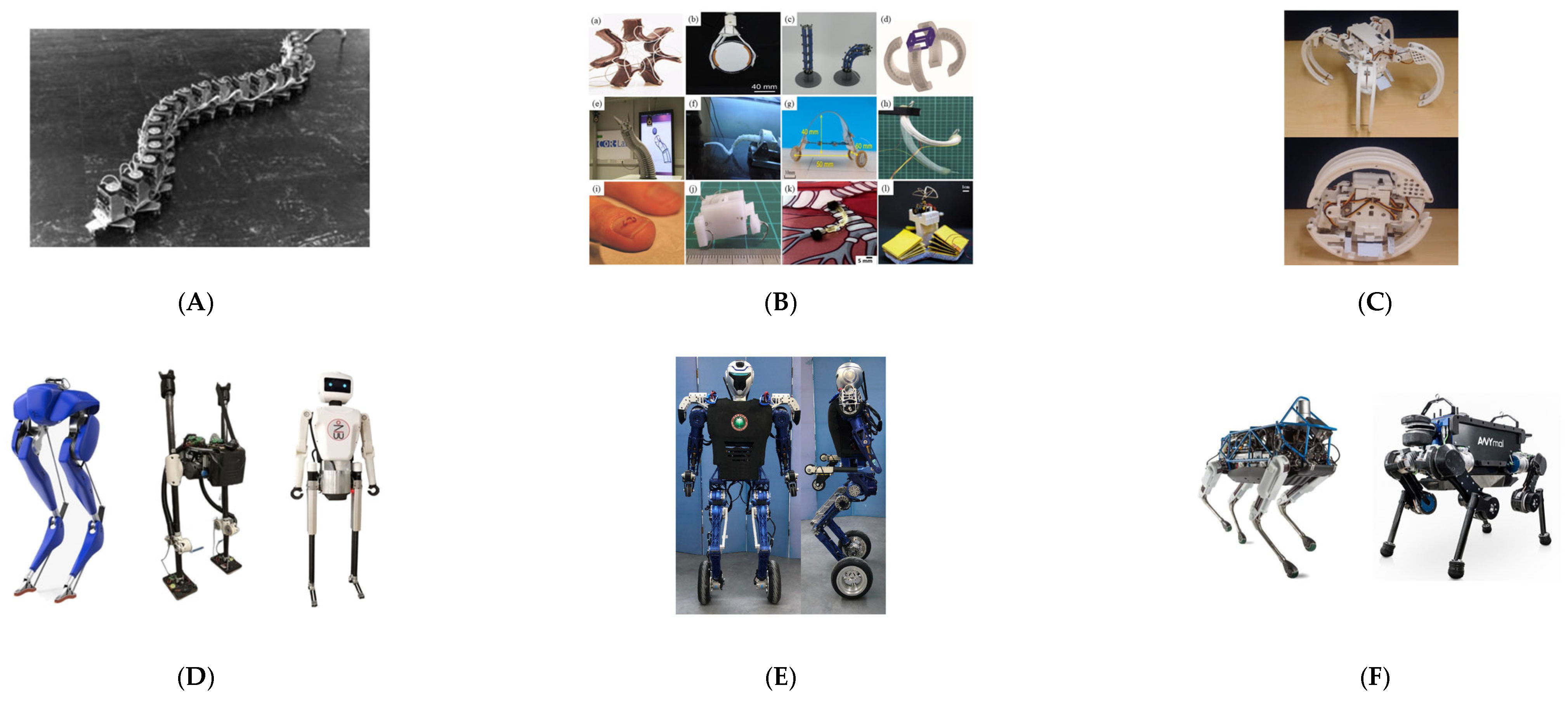

2.2. Locomotion

2.3. Large Language Models

- Identifying the optimal locomotion system for decontamination robots based on task requirements and environmental conditions to ensure efficiency in various settings.

- Integrating with LLMs to generate a best-fit design for the decontamination robot based on user inputs and environmental factors.

- Developing the decontamination robot based on the best-fit design produced by the LLM integration, implementing the optimal locomotion system, decontamination methods, and safety features for autonomous operation in complex environments.

3. Proposed Data-Driven Locomotion Recommendation Algorithm

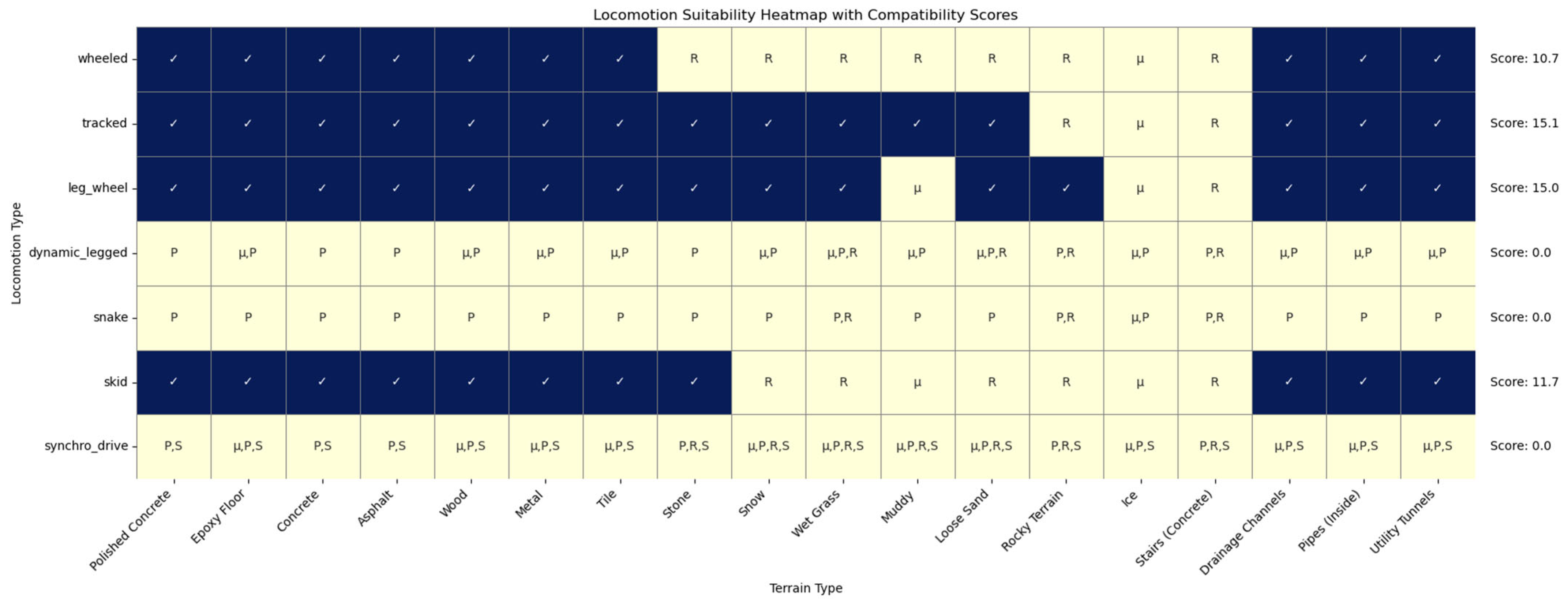

| Algorithm 1: To Propose a Detailed Locomotion Type based on the User’s Requirement |

| Input: 1. Input: user_prompt←Prompt with terrain, payload, slope, and friction. E.g., “Suggest me the right locomotion type for a decontamination robot that can navigate in <terrain> with a <payload in kg> payload and a maximum slope of <degrees of slope>.” 2. LLM_Response←Call LLM prompt to extract JSON from user_prompt 3. Parsed_JSON←extract JSON fields: terrain, payload, slope, friction |

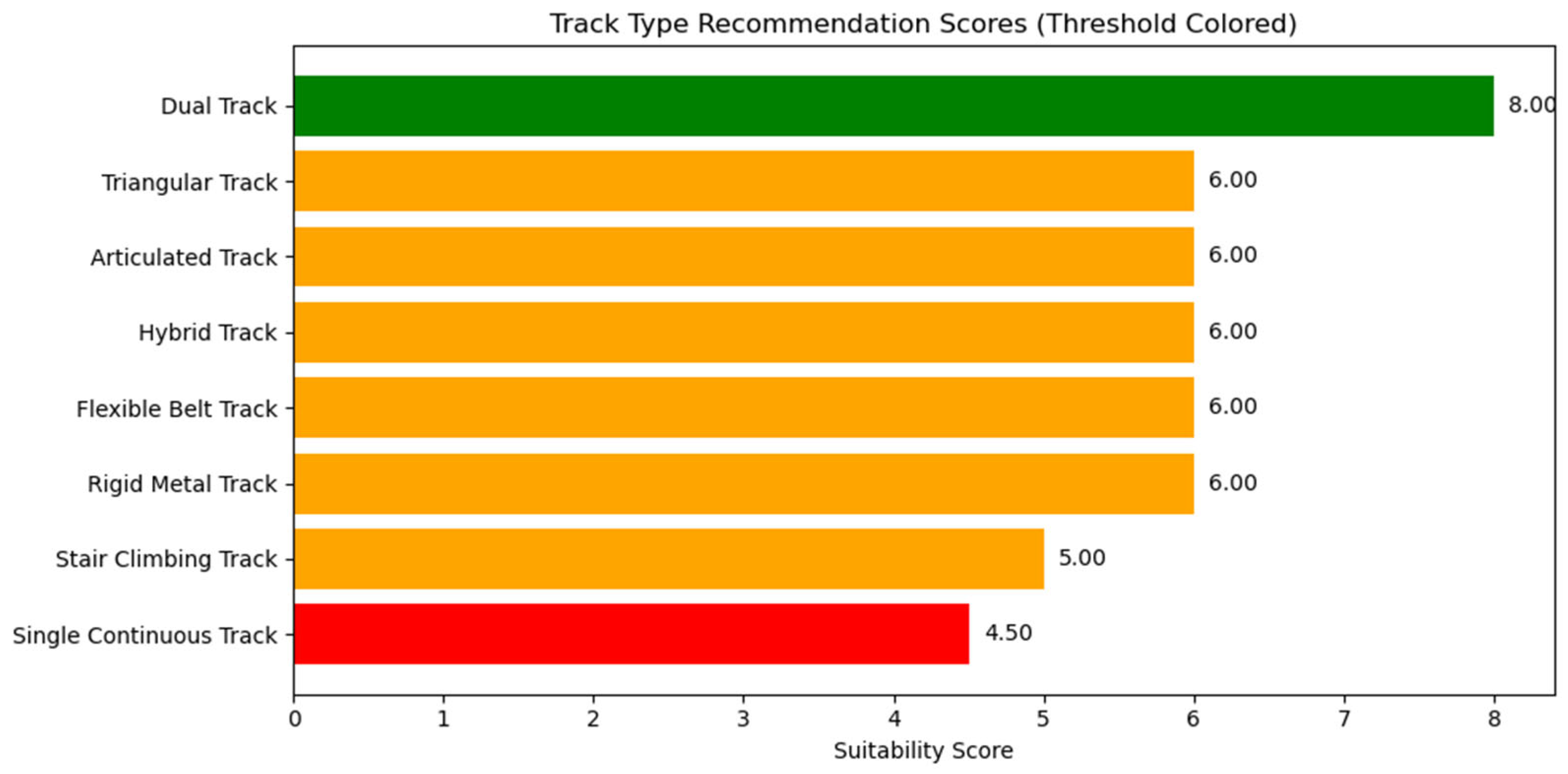

| Purpose: Part A: Validate mobile base (wheel/track locomotion) against all terrains Part B: Score specific track types based on user’s environment |

| Compare: A: locomotion limits (μ, payload, roughness, slope) vs. all terrain properties B: user requirements vs. track_type capability specs |

| Annotate: A: terrain-locomotion matrix with reasons: “μ”, “P”, “R”, “S”, or “✓” B: assign weighted scores for each track type (maximum 10) |

| Pseudocode: Sub-Routine A: Mobile Locomotion Evaluation 4. Load: terrain_data←list of terrain dicts with μ, roughness, slope, weight, type 5. Load: locomotion_specs←dictionary with payload, μ, slope, roughness limits 6. Initialize: score[locomotion]←0 for each locomotion type 7. Scaled Penalty: Let Pu be the user-specified payload and Pt be the track type’s maximum payload capacity. Similarly, for terrain, terrain roughness, and slope. 8. The compatibility score is updated as 9. For each locomotion_type in locomotion_specs: 10. For each terrain in terrain_data: 11. Check compatibility: 12. If terrain_μ < loco_μ_min → append “μ” 13. If payload > loco_payload_limit → append “P” 14. If terrain_roughness > max_roughness → append “R” 15. If slope > max_slope_deg → append “S” 16. If no fails: 17. Append “✓”, add terrain[“Weight”] to score[locomotion] 18. Annotate terrain matrix with reasons Sub-Routine B: Wheel/Track-Type Recommendation 19. Load: track_dataset←DataFrame with track types and attributes 20. Initialize: score[track_type]←0 for each track 21. For each track_type in track_dataset: 22. score += 2 if payload ≤ track[“Payload Capacity (kg)”] else scaled penalty 23. score += 2 if friction ≥ track[“Min Friction (μ)”] else scaled penalty 24. score += 2 if slope ≤ track[“Climb Angle (deg)”] else scaled penalty 25. score += 4 if terrain ∈ track[“Suitable Environments”], 2 if partial match 26. Rank track_types by descending score 27. Generate bar chart of scored track recommendations |

| Output: 28. Figure–Score matrix of locomotion compatibility vs. terrain (annotated) 29. Figure–Score list and printed reasons for locomotion suitability 30. Figure–Bar chart of track-type scores (threshold-colored) |

4. Design of Locomotion System of the Decontamination Robot

4.1. Identifying the Locomotion System

4.2. Response from the Algorithm

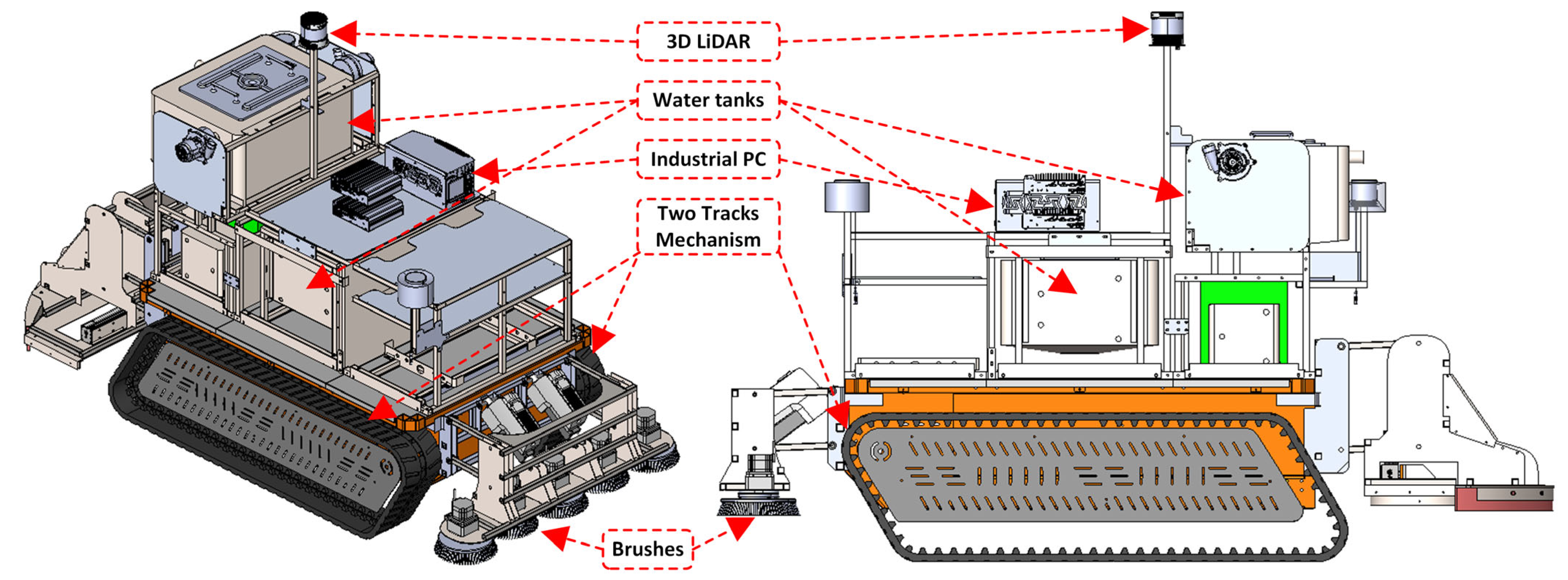

5. Developed Decontamination Robot Prototype

5.1. CAD Modeling

5.2. Developed Decontamination Robot

5.3. Limitations and Future Scope

- LLM Output Deviation: The LLM is currently used in a prompt-based inference mode without fine-tuning. As such, it may return outputs with missing fields, non-JSON formatting, or unexpected data types. A possible solution is to address this by implementing robust validation schemas and retry mechanisms, as well as refining prompt engineering techniques. Fine-tuning the LLM with more structured examples may also reduce inconsistency.

- Approximate Terrain Matching: The use of partial string matching (e.g., substring or fuzzy match) between user input and pre-defined terrain types can yield suboptimal results, especially for ambiguous or uncommon terrain descriptions. A possible solution is to use a semantic similarity model, which can improve contextual matching. Additionally, expanding the terrain dataset with synonyms and example scenarios will enhance accuracy.

- Fixed Thresholds: Hard-coded thresholds for payload, slope, and friction make the system rigid and less responsive to user-specific priorities. A possible solution is to add adaptive thresholding using rule-based scaling or reinforcement learning, based on user feedback and mission history, which can enable more dynamic, context-aware decision-making.

- No Multi-Terrain Aggregation: The current system architecture evaluates one terrain type at a time, which limits its utility in multi-environment deployments. A possible solution is to incorporate a multi-label terrain evaluation system, which can assess the feasibility across multiple terrains simultaneously and recommend hybrid locomotion solutions accordingly.

- Lack of Adaptability to Unstructured Terrain: The model is primarily trained on structured or semi-structured environments found in existing robot datasets. A possible solution is to incorporate data from field robotics and search-and-rescue robots operating in dynamic terrains, combined with few-shot learning, which can improve generalization to novel terrains.

- Cross-Platform Compatibility: Design an algorithm that is capable of functioning across various robotic platforms with minimal modifications.

- Explainable Recommendation Reports: Automatically generate comprehensive explanation reports that summarize the rationale behind each locomotion or track recommendation, thereby enhancing transparency for engineers and operators.

- Environment Clustering and Unseen Terrain Generalization: Utilize unsupervised learning techniques to cluster similar terrains and extrapolate recommendations, even when encountering terrains not included in the original terrain data list.

- Dynamic Learning with Feedback: Following deployment, gather operational data on the success or failure of recommendations and subsequently retrain the scoring system or recalibrate thresholds automatically.

- Reconfigurable Locomotion: Designing modular robots with transformable locomotion enables real-time terrain adaptation, enhancing versatility in complex decontamination environments.

- Hybrid Intelligence: Integrating ontology and LLMs enables adaptive, structured robot design for diverse decontamination tasks and dynamic environments.

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Petereit, J.; Beyerer, J.; Asfour, T.; Gentes, S.; Hein, B.; Hanebeck, U.D.; Kirchner, F.; Dillmann, R.; Götting, H.H.; Weiser, M. ROBDEKON: Robotic systems for decontamination in hazardous environments. In Proceedings of the 2019 IEEE International Symposium on Safety, Security, and Rescue Robotics (SSRR), Würzburg, Germany, 2 September 2019; pp. 249–255. [Google Scholar]

- Woock, P.; Petereit, J.; Frey, C.; Beyerer, J. ROBDEKON–competence center for decontamination robotics. at-Automatisierungstechnik 2022, 70, 827–837. [Google Scholar] [CrossRef]

- Whitworth, C.; Martin, M.; Gallagher, M.; Worthington, H. A comparison of decontamination methods used for dental burs. Br. Dent. J. 2004, 197, 635–640. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Fraser, V.J.; Zuckerman, G.; Clouse, R.E.; O’Rourke, S.; Jones, M.; Klasner, J.; Murray, P. A prospective randomized trial comparing manual and automated endoscope disinfection methods. Infect. Control Hosp. Epidemiol. 1993, 14, 383–389. [Google Scholar] [CrossRef] [PubMed]

- Petereit, J.; Bretthauer, G.; Beyerer, J. Robotic systems for decontamination in hazardous environments: To boldly go where many still work today. at-Automatisierungstechnik 2022, 70, 823–825. [Google Scholar] [CrossRef]

- Trevelyan, J.; Hamel, W.R.; Kang, S.-C. Robotics in hazardous applications. In Springer Handbook of Robotics; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1521–1548. [Google Scholar]

- Kas, K.A.; Johnson, G.K. Using unmanned aerial vehicles and robotics in hazardous locations safely. Process Saf. Prog. 2020, 39, e12066. [Google Scholar] [CrossRef]

- Liu, S.; He, Y.; Xie, H.; Ge, Y.; Lin, Y.; Yao, Z.; Jin, M.; Liu, J.; Chen, X.; Sun, Y. A state-of-the-art review of radioactive decontamination technologies: Facing the upcoming wave of decommissioning and dismantling of nuclear facilities. Sustainability 2022, 14, 4021. [Google Scholar] [CrossRef]

- Al-Dubooni, M.; Wong, C.; Althoefer, K. Hybrid Continuum-Eversion Robot: Precise Navigation and Decontamination in Nuclear Environments using Vine Robot. In Proceedings of the 2024 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Abu Dhabi, United Arab Emirates, 14–18 October 2024; pp. 12443–12449. [Google Scholar]

- Miura, R.; Tozaki, S.; Mikado, I.; Takei, T.; Ogake, S.; Kobayashi, K.; Mitsui, S.; Satake, T.; Igo, N. Development of a decommissioning robot with a simple structure capable of traversing steps using two different drive systems. J. Robot. Mechatron. 2024, 36, 95–106. [Google Scholar] [CrossRef]

- Llontop, L.; Ramos, N.M. Optimization of Rocker–Bogie Suspension System for Robustness Improvement of Autonomous Rover by Numerical Simulations for Irregular Surfaces in Precision Agriculture. Eng. Proc. 2025, 83, 20. [Google Scholar]

- Zhang, Z.; Chai, W.; Wang, J. Mani-GPT: A generative model for interactive robotic manipulation. Procedia Comput. Sci. 2023, 226, 149–156. [Google Scholar] [CrossRef]

- Zhu, Q.; Luo, J. Generative transformers for design concept generation. J. Comput. Inf. Sci. Eng. 2023, 23, 041003. [Google Scholar] [CrossRef]

- Konstantinou, C.; Antonarakos, D.; Angelakis, P.; Gkournelos, C.; Michalos, G.; Makris, S. Leveraging Generative AI Prompt Programming for Human-Robot Collaborative Assembly. Procedia CIRP 2024, 128, 621–626. [Google Scholar] [CrossRef]

- Vemprala, S.H.; Bonatti, R.; Bucker, A.; Kapoor, A. Chatgpt for robotics: Design principles and model abilities. IEEE Access 2024, 12, 55682–55696. [Google Scholar] [CrossRef]

- Fitriawijaya, A.; Jeng, T. Integrating multimodal generative AI and blockchain for enhancing generative design in the early phase of architectural design process. Buildings 2024, 14, 2533. [Google Scholar] [CrossRef]

- Ghariblu, H.; Moharrami, A.; Ghalamchi, B. Design and prototyping of autonomous ball wheel mobile robots. Mob. Robot. Curr. Trends 2011, 12, 363–374. [Google Scholar] [CrossRef]

- Chan, R.P.M.; Stol, K.A.; Halkyard, C.R. Review of modelling and control of two-wheeled robots. Annu. Rev. Control 2013, 37, 89–103. [Google Scholar] [CrossRef]

- Moreno, J.; Clotet, E.; Lupiañez, R.; Tresanchez, M.; Martínez, D.; Pallejà, T.; Casanovas, J.; Palacín, J. Design, implementation and validation of the three-wheel holonomic motion system of the assistant personal robot (APR). Sensors 2016, 16, 1658. [Google Scholar] [CrossRef]

- Vikram, C.; Jeyabal, S.; Chittoor, P.K.; Pookkuttath, S.; Elara, M.R.; You, W. KOALA: A Modular Dual-Arm Robot for Automated Precision Pruning Equipped with Cross-Functionality Sensor Fusion. Agriculture 2024, 14, 1852. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Y.; Liu, C.; Zhang, Z. Energy efficient path planning for autonomous ground vehicles with ackermann steering. Robot. Auton. Syst. 2023, 162, 104366. [Google Scholar] [CrossRef]

- Liao, J.; Chen, Z.; Yao, B. Performance-oriented coordinated adaptive robust control for four-wheel independently driven skid steer mobile robot. IEEE Access 2017, 5, 19048–19057. [Google Scholar] [CrossRef]

- Tătar, M.O.; Haiduc, F.; Mândru, D. Design of a synchro-drive omnidirectional mini-robot. Solid State Phenom. 2015, 220, 161–167. [Google Scholar] [CrossRef]

- Seidla, A. Actively articulated suspension for a four-wheeled vehicle. In Proceedings of the DS 50: Proceedings of NordDesign 2008 Conference, Tallinn, Estonia, 21–23 August 2008. [Google Scholar]

- Schempf, H. AURORA—Minimalist Design for Tracked Locomotion. In Robotics Research, Proceedings of the Tenth International Symposium, Lorne, Victoria, Australia, 9–12 November 2001; Springer: Berlin/Heidelberg, Germany, 2003; pp. 453–465. [Google Scholar]

- Deshmukh, D.; Kumutham, A.R.; Pratihar, D.K.; Deb, A.K. Accurate path tracing of a tracked robot: A modified PID approach with slip compensation. Eng. Res. Express 2025, 7, 015203. [Google Scholar] [CrossRef]

- Ugenti, A.; Galati, R.; Mantriota, G.; Reina, G. Analysis of an all-terrain tracked robot with innovative suspension system. Mech. Mach. Theory 2023, 182, 105237. [Google Scholar] [CrossRef]

- Malik, S.M.; Lin, J.; Goldenberg, A.A. Virtual prototyping for conceptual design of a tracked mobile robot. In Proceedings of the 2006 Canadian Conference on Electrical and Computer Engineering, Ottawa, ON, Canada, 7–10 May 2006; pp. 2349–2352. [Google Scholar]

- Guo, W.; Qiu, J.; Xu, X.; Wu, J. Talbot: A track-leg transformable robot. Sensors 2022, 22, 1470. [Google Scholar] [CrossRef]

- Ben-Tzvi, P.; Saab, W. A hybrid tracked-wheeled multi-directional mobile robot. J. Mech. Robot. 2019, 11, 041008. [Google Scholar] [CrossRef]

- Kinugasa, T.; Otani, Y.; Haji, T.; Yoshida, K.; Osuka, K.; Amano, H. A proposal of flexible mono-tread mobile track—A new mobile mechanism using one track and spine-like structure—. In Proceedings of the 2008 IEEE/RSJ International Conference on Intelligent Robots and Systems, Nice, France, 22–26 September 2008; pp. 1642–1647. [Google Scholar]

- Dong, L.; Zhang, R.; Liu, X.; Li, J.; Wang, X.; Mengqian, T. High climbing and obstacle-crossing performance intelligent tracked inspection robot for cable trenches. Ind. Robot Int. J. Robot. Res. Appl. 2025, 52, 58–72. [Google Scholar] [CrossRef]

- Liu, W.; Cheng, K. An Analytical Model for Predicting Ground Pressure under a Rigid-Flexible Tracked Vehicle on Soft Ground. Math. Probl. Eng. 2020, 2020, 6734121. [Google Scholar] [CrossRef]

- Nodehi, S.E.; Bruzzone, L.; Lalegani Dezaki, M.; Zolfagharian, A.; Bodaghi, M. Porcospino Flex: A Bio-Inspired Single-Track Robot with a 3D-Printed, Flexible, Compliant Vertebral Column. Robotics 2024, 13, 76. [Google Scholar] [CrossRef]

- Chen, X.; Wu, Y.; Hao, H.; Shi, H.; Huang, H. Tracked wall-climbing robot for calibration of large vertical metal tanks. Appl. Sci. 2019, 9, 2671. [Google Scholar] [CrossRef]

- Li, N.; Wang, F.; Ren, S.; Cheng, X.; Wang, G.; Li, P. A Review on the Recent Development of Planar Snake Robot Control and Guidance. Mathematics 2025, 13, 189. [Google Scholar] [CrossRef]

- Li, W.; Hu, D.; Yang, L. Actuation mechanisms and applications for soft robots: A comprehensive review. Appl. Sci. 2023, 13, 9255. [Google Scholar] [CrossRef]

- Yanagida, T.; Elara Mohan, R.; Pathmakumar, T.; Elangovan, K.; Iwase, M. Design and implementation of a shape shifting rolling-crawling-wall-climbing robot. Appl. Sci. 2017, 7, 342. [Google Scholar] [CrossRef]

- Xue, J.; Huangfu, J.; Hou, Y.; Mou, H. Combining Prior Knowledge and Reinforcement Learning for Parallel Telescopic-Legged Bipedal Robot Walking. Mathematics 2025, 13, 979. [Google Scholar] [CrossRef]

- Qiu, X.; Yu, Z.; Meng, L.; Chen, X.; Zhao, L.; Huang, G.; Meng, F. Upright and crawling locomotion and its transition for a wheel-legged robot. Micromachines 2022, 13, 1252. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Cicirelli, F.; Vinci, A.; Guerrieri, A.; Qi, W.; Fortino, G. Quadruped Robots: Bridging Mechanical Design, Control, and Applications. Robotics 2025, 14, 57. [Google Scholar] [CrossRef]

| Terrain Type | Recommended Locomotion Type | Subtype/Example | Justification |

|---|---|---|---|

| Flat Indoor Surfaces | Wheeled Locomotion | Differential Drive, Ackermann Steering | Efficient, fast, low-energy use on smooth, predictable surfaces |

| Confined/ Cluttered Areas | Omni-Directional Wheels | Mecanum Wheels, Swedish Wheels | Enhanced maneuverability, zero turning radius |

| Sandy/ Uneven Outdoor | Tracked Locomotion | Flexible Belt, Flipper Track | Greater ground contact, better traction, and stability |

| Rocky/ Rugged Terrain | Hybrid (Wheel-Leg, Tracked-Leg) | Rocker-Bogie, Transformable Track-to-Leg Mechanism | Combines mobility and terrain adaptability |

| Pipeline/ Ventilation | Magnetic Wheeled, Snake-like Robots | Multi-link Magnetic Wheels | Adaptability to curved/narrow environments, wall climbing capability |

| Stairs/ Elevations | Articulated or Triangular Tracked | Triangular Track with Stair-Climbing Kinematics | Designed to overcome vertical height changes and obstacles |

| Urban Debris/ Disaster | Legged or Wheel-Leg Hybrid | Biped, Hexapod, Scorpio (rolling + crawling + climbing) | Ability to navigate unpredictable, obstructed, or destroyed environments |

| High-Slip/ Slippery | Skid-Steering with Sensor Feedback | 4-Wheel Skid-Steer Robot | Tolerant to wheel slip, simple mechanism, suited with proper slip control logic |

| Cleanroom/ Laboratories | Wheeled or Synchro-Drive | Synchro-Drive with Sterile Design | Precise control, low noise, clean-surface compatible |

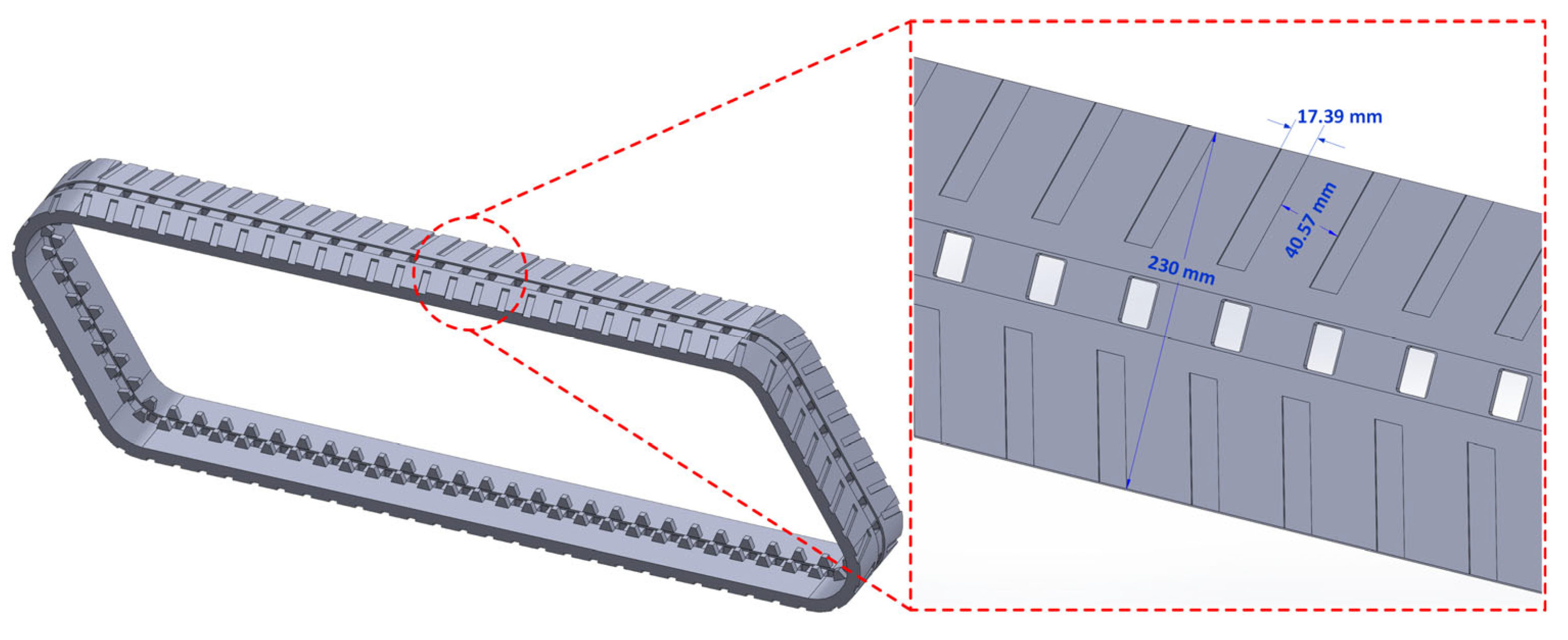

| Parameters | Specifications | Parameters | Specifications |

|---|---|---|---|

| Track Material | Rubber | Driving Motor (Each) | 2 kW |

| Track width | 230 mm | Maximum Speed | 2 km/h |

| Dimensions | 2000 × 1300 × 710 mm | Maximum Slope | ≤30° |

| Self-Weight | 450 kg (Excluding battery) | Battery | LiFePO4 48 V, 200 Ah |

| Loading Capacity | 1200 kg (Including robot weight) | Brush Type | Nylon bristles |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chittoor, P.K.; Jayasurya, A.; Konduri, S.; Cruz, E.S.; Samarakoon, S.M.B.P.; Muthugala, M.A.V.J.; Elara, M.R. Data-Driven Selection of Decontamination Robot Locomotion Based on Terrain Compatibility Scoring Models. Appl. Sci. 2025, 15, 7781. https://doi.org/10.3390/app15147781

Chittoor PK, Jayasurya A, Konduri S, Cruz ES, Samarakoon SMBP, Muthugala MAVJ, Elara MR. Data-Driven Selection of Decontamination Robot Locomotion Based on Terrain Compatibility Scoring Models. Applied Sciences. 2025; 15(14):7781. https://doi.org/10.3390/app15147781

Chicago/Turabian StyleChittoor, Prithvi Krishna, A. Jayasurya, Sriniketh Konduri, Eduardo Sanchez Cruz, S. M. Bhagya P. Samarakoon, M. A. Viraj J. Muthugala, and Mohan Rajesh Elara. 2025. "Data-Driven Selection of Decontamination Robot Locomotion Based on Terrain Compatibility Scoring Models" Applied Sciences 15, no. 14: 7781. https://doi.org/10.3390/app15147781

APA StyleChittoor, P. K., Jayasurya, A., Konduri, S., Cruz, E. S., Samarakoon, S. M. B. P., Muthugala, M. A. V. J., & Elara, M. R. (2025). Data-Driven Selection of Decontamination Robot Locomotion Based on Terrain Compatibility Scoring Models. Applied Sciences, 15(14), 7781. https://doi.org/10.3390/app15147781