Abstract

There is a high demand for the development of new carriers for pharmaceutical forms for human, veterinary, and animal-feeding use. One of the solutions might be bioactive compound-loading pellets for animal forage. The aim of the work was to assess the physical and sensory properties of forage with the addition of onion peel and off-spec onions as a source of quercetin. The feed was prepared using an expanding process (thermal–mechanical expanding process). Quercetin content was evaluated in raw onion and in final-product feed mixture samples (before and after expanding, and pelleting). The obtained feed was subjected to sensory analysis, testing for expanded pellet uniformity, water absorption index (WAI), the angle of a slide, and antioxidant activity. The results confirmed a high recovery of the quercetin after the expanding process (approximately 80%), and a significantly reduced intensity of onion odor, which was confirmed compared to the non-expanded onion, which is beneficial. Furthermore, digital and optical microscopy were applied for structure analysis. Microscopic imaging results confirmed that the onion structures were visible in the whole length of feed material and analyzed cross-sections. The results can be an introduction to further research on developing products that use the expanding and pelleting process to exploit the peel and off-spec onions, as well as other waste raw materials.

1. Introduction

Animal forage plays a key role in the final meat products. In that case, new carriers for bioactive forage compounds need to be developed. Pork meat is the most consumed in global meat consumption [1]. This product is a source of inexpensive, high-quality protein [2]. Pork, especially loin and tenderloin, is also a good source of thiamine [3]. One argument for reducing meat consumption, especially pork, is its high-fat content [4]. This argument applies particularly to saturated fatty acids. Therefore, in recent years, an increasing number of studies have examined the fatty acid composition of pork. These studies focus on increasing the content of unsaturated fatty acids in meat [1,5]. They indicate that the composition of fatty acids in meat can also be regulated by changing the feeding strategy [6]. One approach is to enrich feed with a natural source of omega-3 acids, i.e., flax products [7,8]. Therefore, in animal feeding, they are used as flax extrudates [9].

However, the high content of polyunsaturated n-3 fatty acids carries a risk associated with the potential intensification of oxidative reactions [10].

Therefore, many studies are concerned with enriching animal feed with antioxidants, especially those of natural origin [11,12].

Numerous studies confirm the beneficial effects of natural antioxidants, so attention should be paid to the high antioxidant potential of quercetin [13]. Quercetin is a natural plant polyphenol compound, and onion is one of its sources [14,15,16]. The highest content was reported in onion peel [17]. Therefore, onion peel and off-spec onions, such as those that are too small or misshapen, might be a significant source of quercetin. An additional advantage seems to be that onion peel and off-spec onions pose a significant problem in processing [14,18]. Therefore, the use of onion peel aligns with the zero-waste trend. It is a burdensome organic waste, so using it to produce an animal-feed component aligns with the assumptions of sustainable development. However, attention should be paid to selecting the processes used to obtain appropriate quality features for feed products. Another problem related to the possibility of using onion as a source of quercetin in animal feeding is its sensory-adverse aroma. It results from the presence of sulfur compounds (allyl propyl disulfide). Another ingredient is propane, a lachrymatory with a bitter taste. This compound degrades into volatile constituents responsible for the characteristic aroma of onion [19]. Therefore, it is important to use treatments that allow the production of a product with a limited intensity of volatile compounds characteristic of onions. One of the methods used in the production of feed mixtures is extrusion. Extrusion is one of the main methods of feed preservation [20]. The advantages of this method are high durability, reduced fines, and improved water stability [20]. However, improving the quality of extruded feed can be achieved by increasing the precision control over the processing conditions [21]. This method allows for increasing the stability of the active compounds contained, including phenolic compounds, which can increase the efficiency of animal feeding [22].

Another method is expanding and then pelleting. Feed expanding is a process that uses high-pressure steam to cook and extrude feed into a lower-density product [23]. The method consists in rapid heating to the temperature necessary to convert water into steam (e.g., 150 °C), which, unable to evaporate, increases the pressure inside the particle, causing it to swell. The main aim of pelleting is to agglomerate smaller feed particles by the use of mechanical pressure, moisture, and heat [24]. The use of expanders improves the quality and nutritional characteristics of the final product. Thanks to their high productivity and the ability to adjust pressure, expanders provide effective material processing while preserving their useful properties [25]. The method facilitates the formation of uniform and dense pellets that are easier for animals to consume. Pelleting can also help reduce feed waste and dust, leading to a more efficient and cleaner feeding process [26]. Feed pelleting promotes several benefits, such as easier handling, reduced feedstuff segregation, and reduced feed waste in the feeders compared with mash diets [26]. However, attention should be paid to assessing the method of producing the feed mixture that allows for the highest degree of reproduction of the introduced active ingredients, including quercetin, and the lowest intensity of unfavorable aroma descriptors.

Well-conducted pelletizing processes alter feed particles’ physicochemical properties, forming the inter-particle bonds required to produce a pellet that does not break during transport [27]. Feed composition affects the resulting physical pellet quality. An example of an ingredient that allows for positive effects is starch from cereal [28]. However, using cereal grains in pelleted animal feed is not in line with a sustainable economy. These animal feed sources do not have a “low opportunity cost” [27]. The study of Wang et al. [29] confirmed that the prudent use of food waste biomass as animal feed can support and sustain optimal productivity. The analysis of pig growth measurements indicated that, adjusted for the type of food waste, region, and life stage of the animals in the experiments, the average daily gain was similar between control and treatment diets of various food waste rate categories. However, they typically contain less starch and are rich in fibre, resulting in different physicochemical properties for pellets [30].

These approaches have never been applied to feed containing onion peel and off-spec onions. This study will allow us to determine the possibilities of designing feed with the lowest intensity of unfavorable onion-aroma descriptors, high quercetin content, and optimal functional features for expanded products. Therefore, the aim of the work was to assess the possibility of using the expanding and then pelleting process for a feed containing onion peel and off-spec onions. Our animal forage composition can be applied as a new carrier for quercetin delivery in animal feeding.

2. Materials and Methods

2.1. Materials

2.1.1. Samples Preparation

In this study, onion (Allium cepa L.) grown on a farm in Zawory (Wielkopolska, Poland) was used as a quercetin source. Our goal was to use onion peel and off-spec onions. In the first step, the vegetables were crushed to a particle size of 16 mm using a hydraulic ALLU (Pennala, Finland) sieving-and-crushing bucket. Then, the obtained raw material was dried in a drum dryer (ŁUKOMET; Całowanie, Karczew, Poland). The drying process was continued until the samples reached a moisture content that allowed for further storage (typically 10% ÷ 14%). After the drying process, the drying efficiency was assessed by measuring the mass loss. In this study, the efficiency reached 9.80 kg of dried onion per 100 kg of fresh onion.

2.1.2. Forage Manufacturing

The main components of the feed were rye meal (70%), barley meal (10%), dried onion (3%), dried apples (2%), beet pulp (2%), linseed, potato protein (4%), dried sweet whey (3%), and post-extraction rapeseed meal (4%). In total, 3.0% of the dried onion raw material was added to the feed mixture, corresponding to approximately 0.24 kg of fresh onion per 1 kg of complete feed. The composition was mixed. After mixing all the components, the feed was subjected to the expanding process using a single-screw Expander Insta Pro, model 2500 (AMANDUS KAHL, Reinbek, Germany).

2.2. Methods

2.2.1. Quercetin Content

The content of quercetin in the feed mixture was determined immediately before and after the expanding process, and after the pelleting process. Quercetin in the samples was analyzed after alkaline and acid hydrolysis [31,32]. Quantitative analysis was performed using an Acquity H-class UPLC system equipped with a Waters Acquity PDA detector (Waters, Milford, Massachusetts, USA). Chromatographic separation was performed on an Acquity UPLC® BEH C18 column (100 mm × 2.1 mm, particle size 1.7 μm) (Waters, Wexford, Ireland). The content of quercetin was determined using an external standard at a wavelength of λ = 320 nm. For reproducibility, the hydrolysis was carried out under controlled conditions: alkaline hydrolysis was performed at 60 °C for 30 min at pH ~9.0, followed by acid hydrolysis at 80 °C for 60 min at pH ~2.0. The injection volume was 2 μL, the column temperature was maintained at 35 °C, and the flow rate was set to 0.3 mL/min.

2.2.2. Antioxidant Activity

To analyze antioxidant activity, all samples of the feed mixture, immediately before and after the expanding process and the pelleting process, were taken.

The antioxidant activity was examined based on the free radical-scavenging indices (the ABTS-scavenging capability and the DPPH-scavenging capacity). Ethanol extracts of samples were prepared by macerating the feed mix (10 g) for two hours with 100 mL of 80% ethanol.

The DPPH•-scavenging capacity [33,34] was tested using spectrophotometric methods, using the DPPH radical. The resultant mixture was shaken thoroughly and allowed to stand at room temperature in the dark for 30 min, after which the solution’s absorbance was measured at 517 nm. The result was expressed as mg Trolox/100 g dry matter of extract.

The ABTS•+-scavenging capability [35] was tested using spectrophotometric measurement of changes in the concentration of ABTS radical cation (98%). The absorbance was measured at 734 nm. The DPPH- and ABTS-scavenging capabilities were tested for the scavenging capacity of Trolox (97%). The result was expressed as mg Trolox/100 g dry matter of extract.

2.2.3. Particle Size Homogeneity Analysis

The particle size homogeneity of the onion was evaluated using mechanical sieve analysis, following the ISO 3310-1 standards [36]. Particle size homogeneity of the onion was tested by mechanical sifting, using sieve analysis. The analysis used laboratory sieves (Sigma-Aldrich, Darmstadt, Germany) with diameters of 0.2, 0.4, 0.6, 0.8, 1.0, 1.2., 1.4, and 1.6 cm. The method separated the material into classes by particle size and determined their distribution (%).

2.2.4. Microscopic Analysis

The morphology of raw materials such as onion parts, as well as final forage, was evaluated using two types of optical microscopes. For the lower magnifications, the stereoscopic microscope ZEISS Stemi 305 (Zeiss, Shanghai, China) was used, equipped with an Olympus EP50 camera. For powdered samples, an inverted microscope ZEISS AxioVert.A1 (Zeiss, Shanghai, China) equipped with the color camera Axiocam 208 (Zeiss, Shanghai, China) was applied. For imaging in fluorescent mode, a Colibri 5 system LED light with green LED λ = 555 nm was applied. LD A-Plan 20×/0.35 (air) and LD A-Planx40/0.55 ph1 (air) objectives were used. The solid particles were placed directly on the microscopic glass without additional preparation. The resolution of the images was adjusted using ZEN3.1 software (Zeiss, Jena, Germany) for the presentation.

Detailed homogeneity studies of the final forge system digital microscope (DM) Keyence VHX-7000 series were used. The system contains a fully integrated objective head VHX-7100. The 3D profiles were obtained using dedicated software.

2.2.5. Water Absorption Index

Water absorption and water solubility indices (WAIs) were analyzed for feed after expanding and pelleting [37]. In total, 30 mL of water was added to 2.5 g of the powdered samples in Corning® 50 mL centrifuge tubes (Sigma-Aldrich, Darmstadt, Germany) and vortexed for 30 s (Corning® LSE™ vortex mixers; Sigma-Aldrich, Darmstadt, Germany). The suspension was then centrifuged at 3000× g for 15 min (Eppendorf® Centrifuge 5702 R, Berlin/Heidelberg, Germany). After centrifuge, the supernatant was transferred to a to a weighing bottle (ChemLand, Stargard, Poland) and dried at 135 °C to remove the moisture (samples were weighed at hourly intervals till constant mass of the sample was observed). WAI coefficient was calculated according to the following formula [37]:

WAI (g/g) = weight of wet sediment/weight of dried sample

2.2.6. The Angle of the Slide

The angle of repose was determined as the minimal angle formed between the plane and the horizontal base according to the tilting-box method (Figure 1). This is the angle at which the product starts sliding down on a flat plane due to its weight under the influence of gravity [38,39]. It was measured by placing powder samples on a flat, smooth horizontal surface that slowly inclined until the material began to move.

Figure 1.

The device for measuring the slide angle of mixed feed with onion peel and off-spec onions before and after expanding and pelleting.

2.2.7. Sensory Analysis

Sensory evaluation was performed on samples of the feed before and after expanding and pelleting. Sensory evaluation was conducted based on sensory profiling. Sensory analysis studies were conducted in the sensory analysis laboratory at the Department of Gastronomy Science and Functional Foods, Poznan University of Life Sciences, Poland. This laboratory is equipped with individual booths (at a controlled temperature of 21 ± 1 °C and combined natural/artificial light) designed according to ISO standards [40]. All analyses in this laboratory are carried out according to the 1975 Helsinki Declaration, which was revised in 2013. Participants were informed about the study’s aim and that participation was voluntary. All subjects gave written informed consent to participate in the analysis. The sensory profiling of aroma was conducted by an 8-member trained panel. A total of 7 descriptors were adapted for aroma (onion, essential oil, herbal, caramel, fruity, vinegary, and strange). The intensity of each descriptor was determined using a 10 cm linear scale with appropriate margin descriptions. A uniform scale was applied to the attributes, ranging from “undetectable” to “very intense”. All samples were assessed in two independent replications. The test was performed using red light to limit the identification of samples by visual means. The samples were served in plastic containers (100 mL) with lids. Dry (non-hydrated) and hydrated samples were assessed (before analysis, 10 g samples were mixed with 30 mL of distilled water and left in closed containers for 10 min).

Samples were coded with three-digit numbers and served in a randomized order using ANALSENS v.5.0 (Sopot, Poland).

2.2.8. Statistical Analysis

The statistical analysis was used to calculate significant differences between means (quercetin content, particle size homogeneity analysis, water absorption index, angle of the slide, and sensory analysis) using ANOVA and Tukey’s multiple range test (p < 0.05). These analyses were calculated using the software STATISTICA PL 13.3 (StatSoft, Cracow, Poland). All indicators were analyzed in 6 samples (3 measurements/2 independent series). To evaluate differences and similarities, sensory analysis indicators were tested for the tested samples, and the analysis of main components (PCA—principal component analysis) was used.

2.3. Limitation

One of the limitations of this study may be the variability of the quercetin content in the product, depending on the place of cultivation, the size of the vegetable, and the cultivation conditions. Similarly, before expanding, the samples were less uniform in terms of particle size. Therefore, a much larger number of samples were included in the studies, taken from different places in the mixture, and then mixed and crushed. From this large sample, smaller samples were taken for testing.

3. Results and Discussion

3.1. Quercetin Content

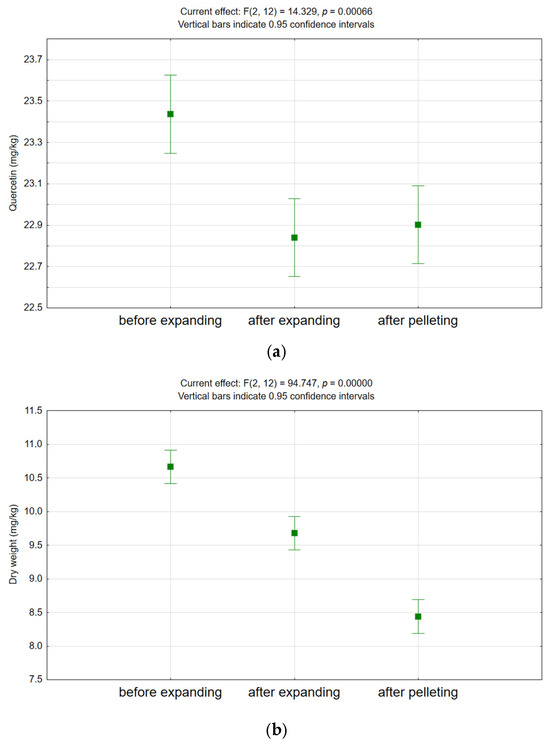

Onions contain very high amounts of quercetin, especially in the peel (48-fold more than the flesh) [41]. However, a significant problem is its high instability during variable technological processes [18,42]. Previous studies have indicated a significantly higher quercetin instability than other citrus-fruit flavonoids [6,43]. 3-glycosidic bonded sugars with quercetin from onion are especially temperature-sensitive compounds [44,45]. Therefore, after drying, the quercetin content was determined in the obtained dried products and after the applied expanding and pelletizing processes. These processes aimed to produce a product with desirable characteristics for efficient feed transportation. However, the stability of the contained quercetin should be confirmed. The behavior of polyphenols during drying depends on the preparation technique and process control, such as temperature [17]. Quercetin content was determined in dried onion and feed after expanding and pelleting. The results confirmed the high quercetin content in the final product after pelletizing (Figure 2). The final product contained quercetin in the amount of 22.73–23.06 mg/1000 g of feed, which seems to be high for an onion supplementation of 3%. The obtained quercetin content in the feed is at a similar level to that achieved by enriching the diet with extracts [46,47]. The greatest quercetin losses during expansion were relatively low (~3%) compared to the product before expanding. The analysis confirmed a higher content of quercetin after pelleting, compared to expanding the product, resulting from the higher content of dry matter. The presence of protein fractions and pectins may cause high quercetin content after pelletizing [48]. Expanding causes changes in the structure of proteins and pectins, and encapsulating quercetin in the spaces of proteins or pectins increases its stability. Earlier studies confirm that whey protein concentrate and quercetin were more likely to form stable covalent complexes. [49]. The expansion and pelleting process resulted in a higher dry matter content, which is confirmed by other studies. During compaction, the pellets decrease considerably in volume and form a structurally stable material with tensile strength [50,51,52], which may offer better storage and distribution options during animal feeding.

Figure 2.

The quercetin (a) and dry mass (b) content of mixed feed with onion peel and off-spec onions before and after expanding and pelleting.

3.2. Antioxidant Activity

The antioxidant activity (based on the free radical-scavenging indices) content was determined in the obtained dried products and after the applied expanding and pelletizing processes (Table 1). High antioxidant activity was confirmed at each stage of production of the mixture with the addition of dried onion. The ABTS radical-scavenging activity of the analyzed mix was higher than the DPPH radical-scavenging activity. The ABTS radical-scavenging activity was 99.87–97.98 mg Trolox/100 g. The DPPH radical-scavenging activity was measured to be between 79.98 and 74.69 mg Trolox/100 g. It was confirmed that the low decrease in activity occurred during expansion, amounting to only 2–6% compared to the product before expansion. The analysis confirmed a higher antioxidant stability in the DPPH radical-scavenging activity (2%). Onion waste is a rich source of total phenolic compounds and flavonoids, with quercetin and its derivatives being the main components contributing to their antioxidant activities [9,16,53]. The antioxidative effects of onion have also been evaluated in in vivo trials; for example, Batcioglu et al. [8] reported a protective effect against radiotherapy in rats based on the antioxidant activity. The results of our studies confirm that onion peel and root have promising potential for application as functional materials, owing to their rich antioxidant activity.

Table 1.

The DPPH• and ABTS•+ of mixed feed with onion peel and off-spec onions before and after expanding and pelleting (mg Trolox/100 g).

However, earlier studies confirm that high temperatures during the subsequent pelleting process, such as steam and extrusion [21,22], can also reduce the activity of probiotics in fermented feed ingredients. Therefore, it is important to control the temperature of these processes. According to Wang [23], the continuous improvement in aquafeed pelleting technology has significantly enhanced the stability of feed in water. The increase in antioxidant activity could also result from the presence of Maillard reaction products, most likely created during the expansion of the samples that contain suitable quantities of necessary substrates, such as reducing sugars and amino acids. Other authors [54] also noted an increase in antioxidant activity resulting from vegetable processing and attributed this increase to the effect of Maillard reactions. Additionally, [55] reported that the heating process enhanced the antioxidant activity of vegetable products.

3.3. Particle Size Analysis

Particle size distribution is a primary factor impacting flowability and other bulk product properties, such as bulk solids’ slide angle and compressibility [56].

This research confirms that even slight variations in particle size significantly impact flowability and cohesiveness [57]. Finer particle sizes and a broader distribution increase cohesive strength and reduce flowability [41].

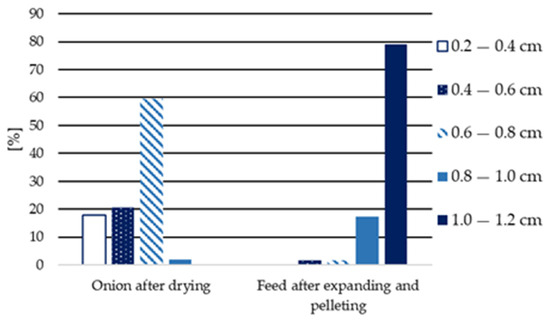

Particle size homogeneity was analyzed for onion after drying, and feed after expanding and pelleting. The particle size uniformity of the samples was analyzed using 3 kg of dried onion or feed. Five independent samples weighing 30 g were taken. Four fractions were separated for the onion after drying with particle sizes in the ranges of 0.2–0.4 cm, 0.4–0.6 cm, 0.6–0.8 cm, and 0.8–1.0 (Figure 3). The particle size analysis showed that 60% of dried onion particles ranged from 0.6 to 0.8 cm, followed by 21% in the 0.4–0.6 cm range, and 18% in the 0.2–0.4 cm range.

Figure 3.

The particle size uniformity of onions after drying, and feed with onion peel and off-spec onions (after expanding and pelleting).

For the feed after expanding and pelleting, four fractions were separated, with particle sizes ranging from 0.4 to 0.6 cm, 0.6 to 0.8 cm, 0.8 to 1.0 cm, and 1.0 to 1.2 cm (Figure 2). The analysis showed their high uniformity. It was found that 79% of the samples were particles with diameters ranging from 1.0 to 1.2 cm, and 17% of sizes were in the range of 0.8–1.0. Stronger fragmentation of the onion raw material could increase the uniformity of particle size. The influence of individual components on pelleting efficiency should also be investigated.

The obtained particle sizes of feed particles indicate that a product with high-quality features was obtained. The uniformity of the particle size indicates the durability of the obtained pellet during further storage and distribution. However, it should be noted that after expanding and pelleting, the feed particles had a cylindrical shape with a diameter of 0.32 cm. Therefore, the mechanical sifting using sieve analysis does not fully reflect the uniformity of particle size.

Therefore, further studies aimed to analyze the homogeneity of particles using microscopic methods are recommended.

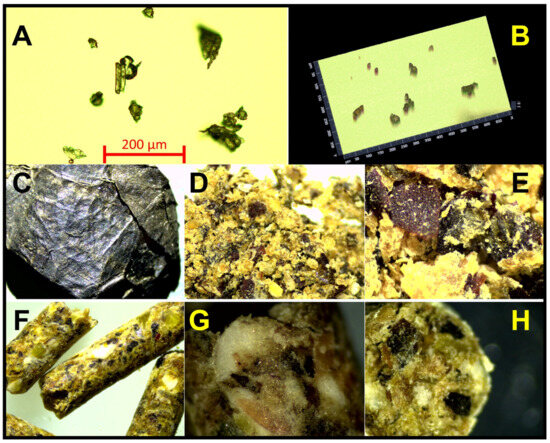

3.4. Microscopic Analysis

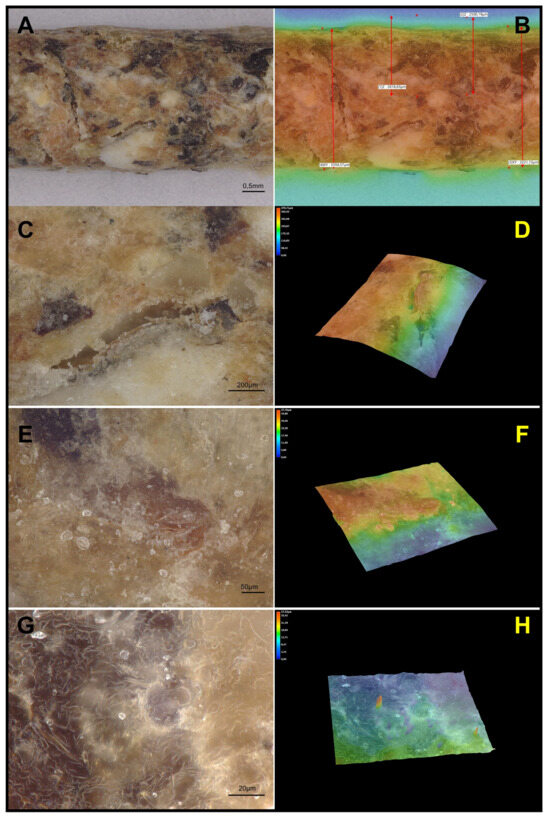

Optical microscopic analysis is one of the commonly used techniques for basic structure and shape studies. Figure 4 presents preliminary examinations of a major quercetin source—onion—at different processing stages. It can be observed in Figure 4A,B that after cutting the onion, particles were highly polydisperse, from micrometers up to a few millimeters, corresponding with the sieve analysis presented in Figure 2 and 2.5D imaging confirming that using an inverted microscope showed different sizes and shapes of the cut-onion particles. The irregular parts of onion are easy to distinguish in animal forage granulates on images taken from a stereoscopic microscope (Figure 4D,E), as well as in forage after expanding (Figure 4F–H). As was observed, the onion particles were quite homogeneously dispersed in the whole volume of the final pellets. The quercetin source was observed in cross-section, which is beneficial for its uniform distribution. Here, a stereoscopic microscope was used only for simple observations (detailed studies were performed using a digital microscope).

Figure 4.

Microscopic images: (A) onion particles after cutting and drying (2D image), (B) onion particles after cutting and drying (2.5D image), (C) onion parts, (D,E) granular material before expanding, (F–H) animal forage after expanding (full view and cross-section), and (C–H) magnifications of 0.8–4.0×.

Braglia et al. [58] highlighted that optical microscopy analysis supports manual sorting and identification of different plant components in animal forage. Furthermore, microscopy is one of the basic methods for possible contamination in food detection (pathogens or processing-related contaminants) [59]. Studies by Lin et al. [59] of selected 17 former food products (FFPs) revealed 441 packaging remnants, such as aluminum, cellulose, and plastics. Nowadays, the problem with microplastics, as well as nanoplastics, is of particular interest [60,61]. However, in this case, microscopic studies should be supported with a detailed composition evaluation using highly advanced techniques such as laser direct infrared (LDIR) [62].

For food quality and structure evaluation using microscopic analysis, Jarzębski et al. [63] suggested a step examination path according to their size and homogeneity, starting from optical microscopy up to advanced electron or atomic force microscopy. As a selection-criteria availability of the method, their costs and the amount of time consumed should be considered, as well as possible sample damage (i.e., during electron beam application).

A typical optical microscope is dedicated to flat, thin objects whose size is limited. Stereoscopic microscopy allows for imaging bigger objects; however, its resolution is also limited. New opportunities occurred with the development of digital microscope equipment (DM). DM allows the evaluation of the size and shape of quite large objects (up to a few centimeters) with high accuracy and requires no additional sample pretreatment, unlike electron microscopy imaging. Furthermore, DM allows for the studying of large objects in 3D.

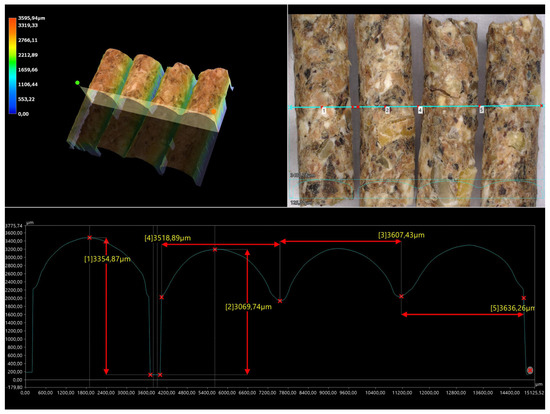

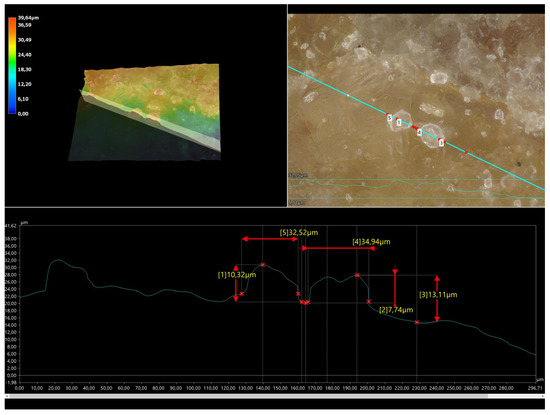

Figure 5 and Figure 6 present images obtained from DM of the forage pellets. The study of the diameter showed that the expanding process was repeatable. The investigated diameters varied from 3518 μm to 3636 μm (Figure 5). In Figure 6, one can easily observe the high roughness of the forage surface. Detailed examinations in higher magnification (presented in Figure 7) showed some material deficiencies. It can be observed that some parts of the material are missing (Figure 7A–D). It suggests that the used binder should be controlled, as well as the components’ pre-processing. The observed surface heterogeneity suggests potential issues with binding efficiency or pre-processing steps, which may affect pellet stability. For that reason, further forage optimization of cutting and grinding processes could be modified and controlled with microscopic imaging or simple sieve analysis.

Figure 5.

Digital microscopy images of final forage pellets. Three-dimensional, two-dimensional, and cross-section analysis.

Figure 6.

Digital microscopy images of final forage pellets. Three-dimensional, two-dimensional, and surface analysis.

Figure 7.

Digital microscopy images of final forage pellets. Detailed examination of surface in different magnifications ((A,C,E,G)—different magnification of the surface; (B,D,F,H)—different magnifications of 3D topography of the samples).

3.5. Water Absorption Index (WAI)

The water absorption index (WAI) criteria can be used to characterize quality feeds [64]. In the present study, the water absorption index (WAI) was similar between series but different between samples before and after pelleting (Table 1). The WAI was significantly higher in samples post-expansion and -pelleting (2.89–3.09 g/g) compared to pre-treated samples (1.88–2.35 g/g).

Lower WAI values indicate reduced water availability to the granules as a result of a more compact structure [65]. Furthermore, higher WAI values can suggest that more starch dextrinization occurred after pelleting [66]. The WAI is related to the amount of water absorbed by starch granules and can be used as an index of gelatinization degree [67].

3.6. The Angle of the Slide

The angle of the slide is a quantity that describes information about the flowability of granular material. The smaller the angle of repose, the better the transport properties. A lower angle of repose is also beneficial for transporting feed to feeders during feeding.

The samples (weighing 30 g) were tested in five independent collections.

The analysis found that the angle of slide ranged from 26.99° to 28.98° before expansion, and from 22.3° to 25.1° after processing, indicating improved flowability in processed feed (Table 2). Studies suggest that bulk products have good quality features at this index’s value of up to 30° [68]. The value of this angle is usually a few degrees lower than the angle of repose, and according to Carr [69], angles up to 35° indicate free flowability. This shows better quality characteristics of products after expanding and pelleting. Low slide angle indices may also suggest low roughness of the surface pellets [70] and smooth particle surfaces. This may be due to the transformation of pectins and sugars from the onion [71]. These properties enhance feed handling and transportation efficiency [72].

Table 2.

The slide angle and water absorption index (WAI) of feed with the addition of onion peel (after expanding and pelleting).

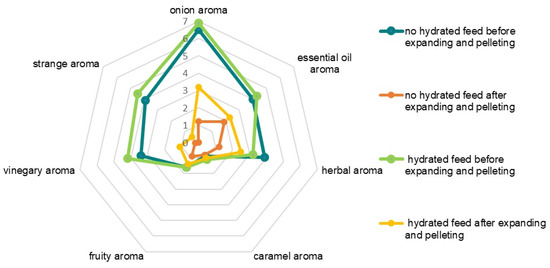

3.7. Sensory Analysis

The sensory evaluation showed statistically significant differences in aroma descriptors between untreated and treated samples (p < 0.05). The sensory profiling of the tested animal feed defined and determined the perception of the following descriptors: aroma (onion, essential oil, herbal, caramel, fruity, vinegary, and strange). The results of the sensory profiling of these products are presented in Table 3 and Figure 8.

Table 3.

Mean scores of aroma profiling of feed with the addition of onion peel and off-spec onions before and after expanding and pelleting were assessed in hydrated and non-hydrated forms.

Figure 8.

Mean scores of aroma profiling of feed with the addition of onion peel and non-assortment onion, before and after expanding and pelleting, assessed in hydrated and non-hydrated form.

The samples were evaluated in dry (non-hydrated) and hydrated form. Significantly higher intensities of all descriptors were confirmed in the hydrated samples. The dissolved substances showed the most volatility. The analysis of sensory profiling confirmed statistically significant differences between sample profiles (types of descriptors and their intensities) between samples before and after expanding and pelleting. The highest variability was confirmed for the onion aroma descriptor (1.2–6.9 points), strange descriptor (0.0–4.5 points), and vinegary aroma descriptor (0.2–4.2 points). Statistical analysis of predictors of variance models for changes in sensory profiling of the tested animal feed (Table 4) confirmed the relationship between the samples before and after expanding and pelleting for strange aroma (F = 102.31, p < 0.05), essential oil aroma (F = 67.24, p < 0.05), and onion aroma (F = 20.25, p < 0.05). The analysis of the sensory profile of the aroma confirmed a higher intensity of the onion, strange, and essential oil aroma for the samples before expanding and pelleting α ≤ 0.05. This relationship was confirmed for both dry (non-hydrated) and hydrated samples.

Table 4.

The characteristic of statistical analysis-of-variance predictor model changes in aroma profiling of feed with the addition of onion peel and non-assortment onion before and after expanding and pelleting, assessed in hydrated and non-hydrated form (one-way ANOVA test).

Protein denaturation is one reaction that may explain the reduction in the intensity of the pellet’s aroma. Similarly, changes in starch and interactions between proteins and polysaccharides should also be considered [73]. The reduced aroma intensity may result from matrix restructuring and reduced volatility due to surface changes. The results of the water absorption index and slide angle indicators confirm this. Other research results also confirm that pelleting reduced the emission of volatile organic compounds [74].

However, more research is needed to identify which factors positively or negatively affect aroma intensity after the pelleting process.

4. Conclusions

There is currently a high demand due to the development of new carriers for delivering bioactive compounds for animal and human feeding.

The feed mixture obtained had a high content of quercetin and antioxidant activity and a low intensity of unpleasant-aroma perception, especially of onion.

The obtained results indicate the possibility of using the expanding and pelleting process to simultaneously obtain a product with good feed transport properties, maintained stability of indicators (quercetin and antioxidant activity), and limited volatility of unfavorable aromatic components. These procedures allowed us to obtain a feed additive from onion peel and off-spec onions. The enrichment with the additive, at a level of 3%, allowed for delivery with diet (3 kg) quercetin at the level of ~75 mg per day.

It is known that the content of quercetin in the final product may be variable and result from the initial content of quercetin. However, the level of losses during expanding and pelleting indicated in the work allows determining the level of quercetin content in the final product. The applied expanding and pelleting process may constitute material for further research on preparing onion peel and off-spec onions as a component enriching the functional properties not only for feed.

The results also indicate the possibility of expanding and pelleting for other waste raw materials.

The promising results obtained in the present study suggest that onion waste has the potential to be used in animal feed.

However, further research is needed to optimize the conditions of production of the mixture with the addition of onion. Further research should concern the modification of drying parameters, which, to a large extent, generate quercetin losses and involve energy (heat and electricity).

An analysis of the content of anti-nutritional components at each production stage is also necessary.

Author Contributions

Conceptualization, J.W., K.S.-B., J.K.-C. and M.J.; methodology, J.W., K.S.-B., J.K.-C., K.S.-S. and M.J.; software, K.S.-B., K.S.-S., J.J. and M.J.; validation, J.W. and K.S.-B.; formal analysis, J.W. and K.S.-B.; investigation, J.W., K.S.-B., J.K.-C., K.S.-S., J.J. and M.J.; resources, J.W., K.S.-B. and J.K.-C.; data curation, K.S.-B.; writing—original draft preparation, J.W., K.S.-B., J.K.-C., K.S.-S., J.J., G.F., J.Z. and M.J.; writing—review and editing, J.W., K.S.-B., J.K.-C., K.S.-S., J.J., G.F., J.Z. and M.J.; visualization, K.S.-B., K.S.-S., J.J. and M.J.; supervision, J.W., K.S.-B. and J.K.-C.; project administration, K.S.-B.; funding acquisition, J.W. and J.K.-C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by “European Agricultural Fund for Rural Development: Europe investing in rural areas”. The operation entitled “Development of innovative technology for the production of high-quality meat from pigs fed with feed enriched with omega-3 acids and quercetin from waste onions” is co-financed by the European Union under the “Cooperation” action of the Rural Development Programme for 2014–2020; No. 00038.DDD.6509.00110.2022.15.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wood, J.D. Meat composition and nutritional value. In Lawrie’s Meat Science; Elsevier: Amsterdam, The Netherlands, 2023; pp. 665–685. [Google Scholar] [CrossRef]

- Drewnowski, A. Perspective: The Place of Pork Meat in Sustainable Healthy Diets. Adv. Nutr. 2024, 15, 100213. [Google Scholar] [CrossRef] [PubMed]

- Szymandera, K. The quantitative and qualitative changes of thiamine in sterilized pork in the presence of selected technological additives. Polish J. Food Nutr. Sci. 2003, 12, 59–62. [Google Scholar]

- O’Connor, L.E.; Herrick, K.A.; Parsons, R.; Reedy, J. Heterogeneity in Meat Food Groups Can Meaningfully Alter Population-Level Intake Estimates of Red Meat and Poultry. Front. Nutr. 2021, 8, 778369. [Google Scholar] [CrossRef]

- Stadnik, J. Nutritional Value of Meat and Meat Products and Their Role in Human Health. Nutrients 2024, 16, 1446. [Google Scholar] [CrossRef]

- Ren, H.; Xiao, W.; Qin, X.; Cai, G.; Chen, H.; Hua, Z.; Cheng, C.; Li, X.; Hua, W.; Xiao, H.; et al. Myostatin regulates fatty acid desaturation and fat deposition through MEF2C/miR222/SCD5 cascade in pigs. Commun. Biol. 2020, 3, 612. [Google Scholar] [CrossRef]

- Czech, A.; Klimiuk, K.; Sembratowicz, I. Effect of the inclusion of extruded flaxseed in the diet of fattening pigs on lipid metabolism and tissue redox status. Sci. Rep. 2023, 13, 13312. [Google Scholar] [CrossRef]

- Bernardi, D.M.; Bertol, T.M.; Coldebella, A.; Cunha Junior, A.; Silveira-Almeida, B.C.; Rodrigues, J.B.; Barrera-Arellano, D.; Godoy, H.T.; Meinhart, A.D.; De Paris, L.D.; et al. Effects of dietary flaxseed oil with or without products with antioxidant properties on pig performance, carcass characteristics, meat quality and oxidative stability. Anim. Prod. Sci. 2022, 62, 1789–1804. [Google Scholar] [CrossRef]

- Choi, C.B.; Kwon, H.; Kim, S.I.; Yang, U.M.; Lee, J.H.; Park, E.K. Effects of rice bran, flax seed, and sunflower seed on growth performance, carcass characteristics, fatty acid composition, free amino acid and peptide contents, and sensory evaluations of native Korean cattle (Hanwoo). Asian-Australasian J. Anim. Sci. 2016, 29, 195–203. [Google Scholar] [CrossRef][Green Version]

- Lyberg, A.; Fasoli, E.; Adlercreutz, P. Monitoring the oxidation of docosahexaenoic acid in lipids. Lipids 2005, 40, 969. [Google Scholar] [CrossRef]

- Salami, S.A.; Guinguina, A.; Agboola, J.O.; Omede, A.A.; Agbonlahor, E.M.; Tayyab, U. Review: In vivo and postmortem effects of feed antioxidants in livestock: A review of the implications on authorization of antioxidant feed additives. Animal 2016, 10, 1375–1390. [Google Scholar] [CrossRef]

- Ponnampalam, E.N.; Kearns, M.; Kiani, A.; Santhiravel, S.; Vahmani, P.; Prache, S.; Monahan, F.J.; Mapiye, C. Enrichment of ruminant meats with health enhancing fatty acids and antioxidants: Feed-based effects on nutritional value and human health aspects—Invited review. Front. Anim. Sci. 2024, 5, 1329346. [Google Scholar] [CrossRef]

- Lesjak, M.; Beara, I.; Simin, N.; Pintać, D.; Majkić, T.; Bekvalac, K.; Orčić, D.; Mimica-Dukić, N. Antioxidant and anti-inflammatory activities of quercetin and its derivatives. J. Funct. Foods 2018, 40, 68–75. [Google Scholar] [CrossRef]

- Bains, A.; Sridhar, K.; Singh, B.N.; Kuhad, R.C.; Chawla, P.; Sharma, M. Valorization of onion peel waste: From trash to treasure. Chemosphere 2023, 343, 140178. [Google Scholar] [CrossRef]

- Németh, K.; Takàcsova, M.; Piskua, M.K. Effect of cooking on yellow onion quercetin. Polish J. Food Nutr. Sci. 2003, 12, 170–174. [Google Scholar]

- Kumar, M.; Barbhai, M.D.; Hasan, M.; Punia, S.; Dhumal, S.; Radha; Rais, N.; Chandran, D.; Pandiselvam, R.; Kothakota, A.; et al. Onion (Allium cepa L.) peels: A review on bioactive compounds and biomedical activities. Biomed. Pharmacother. 2022, 146, 112498. [Google Scholar] [CrossRef]

- Osojnik Črnivec, I.G.; Skrt, M.; Šeremet, D.; Sterniša, M.; Farčnik, D.; Štrumbelj, E.; Poljanšek, A.; Cebin, N.; Pogačnik, L.; Smole Možina, S.; et al. Waste streams in onion production: Bioactive compounds, quercetin and use of antimicrobial and antioxidative properties. Waste Manag. 2021, 126, 476–486. [Google Scholar] [CrossRef]

- Santiago, B.; Arias Calvo, A.; Gullón, B.; Feijoo, G.; Moreira, M.T.; González-García, S. Production of flavonol quercetin and fructooligosaccharides from onion (Allium cepa L.) waste: An environmental life cycle approach. Chem. Eng. J. 2020, 392, 123772. [Google Scholar] [CrossRef]

- Dnyaneshwari, A.; Mursalin, S.; Rushikesh, C. A Review: Onion (Allium cepa). Int. J. Pharm. Res. Appl. 2023, 8, 2305–2317. [Google Scholar]

- Glencross, B.; Fracalossi, D.M.; Hua, K.; Izquierdo, M.; Mai, K.; Øverland, M.; Robb, D.; Roubach, R.; Schrama, J.; Small, B.; et al. Harvesting the benefits of nutritional research to address global challenges in the 21st century. J. World Aquac. Soc. 2023, 54, 343–363. [Google Scholar] [CrossRef]

- Glencross, B.; Hawkins, W.; Evans, D.; Rutherford, N.; McCafferty, P.; Dods, K.; Hauler, R. A comparison of the effect of diet extrusion or screw-press pelleting on the digestibility of grain protein products when fed to rainbow trout (Oncorhynchus mykiss). Aquaculture 2011, 312, 154–161. [Google Scholar] [CrossRef]

- Gumienna, M.; Lasik-Kurdyś, M.; Szymandera-Buszka, K.; Górna-Szweda, B.; Walkowiak-Tomczak, D.; Jędrusek-Golińska, A. Innovative Application of Fermented Red Bean Seeds in Constructing Foods with Increased Biological Activity. Foods 2025, 14, 88. [Google Scholar] [CrossRef]

- Fancher, B.; Rollins, D.; Trimbee, B. Feed Processing Using the Annular Gap Expander and Its Impact on Poultry Performance’. Appl. Poult. Sci. 1996, 5, 386–394. [Google Scholar]

- Abdollahi, M.R.; Ravindran, V.; Svihus, B. Pelleting of broiler diets: An overview with emphasis on pellet quality and nutritional value. Anim. Feed Sci. Technol. 2013, 179, 1–23. [Google Scholar] [CrossRef]

- Bashyal, S.; Poudel, P.B.; Magar, J.B.; Dhakal, L.; Chad, S.; Khadka, B.; Bohara, S.L. Effect of Nutrient Management on Two Varieties (Hybrid and Local) of Maize in Western Inner Terai of Nepal. Int. J. Appl. Sci. Biotechnol. 2020, 8, 191–198. [Google Scholar] [CrossRef]

- Almeida, L.M.; Bassi, L.S.; Santos, R.O.; Orlando, U.A.D.; Maiorka, A.; Oliveira, S.G. Effect of feed form and heat processing on the growth performance of growing and finishing pigs. Livest. Sci. 2021, 245, 104430. [Google Scholar] [CrossRef]

- Bastiaansen, T.M.M.; de Vries, S.; Martens, B.M.J.; Benders, R.T.; Vissers, E.; Dijksman, J.A.; Hendriks, W.H.; Thomas, M.; Bosch, G. Identifying feed characteristics that affect the pellet manufacturing of livestock diets containing different coproducts. Clean. Circ. Bioeconomy 2024, 7, 100073. [Google Scholar] [CrossRef]

- Roos, Y.H. Glass transition temperature and its relevance in food processing. Annu. Rev. Food Sci. Technol. 2010, 1, 469–496. [Google Scholar] [CrossRef]

- Wang, Y.; Rassler, S.; Stefanovski, D.; Bender, J.; Deutsch, J.; Chen, T.; Cui, Z.; Dou, Z. Evidence of animal productivity outcomes when fed diets including food waste: A systematic review of global primary data. Resour. Conserv. Recycl. 2024, 203, 107411. [Google Scholar] [CrossRef]

- Thomas, M.; van der Poel, A.F.B. Fundamental factors in feed manufacturing: Towards a unifying conditioning/pelleting framework. Anim. Feed Sci. Technol. 2020, 268, 114612. [Google Scholar] [CrossRef]

- Stuper-Szablewska, K.; Kurasiak-Popowska, D.; Nawracała, J.; Perkowski, J. Response of non-enzymatic antioxidative mechanisms to stress caused by infection with Fusarium fungi and chemical protection in different wheat genotypes. Chem. Ecol. 2017, 33, 949–962. [Google Scholar]

- Przybylska-Balcerek, A.; Szablewski, T.; Szwajkowska-Michałek, L.; Świerk, D.; Cegielska-Radziejewska, R.; Krejpcio, Z.; Suchowilska, E.; Tomczyk, Ł.; Stuper-Szablewska, K. Sambucus Nigra Extracts–Natural Antioxidants and Antimicrobial Compounds. Molecules 2021, 26, 2910. [Google Scholar] [CrossRef]

- Nuutila, A.M.; Puupponem-Pimia, R.; Aarni, M.; Oksman-Caldentey, K.M. Comparision of antioxidant activities of onion and garlic extracts by inhibition of lipid peroxidation and radical scavenging activity. Food Chem. 2003, 81, 485–493. [Google Scholar]

- Chu, Y.H.; Chang, C.L.; Hsu, H.F. Flavonoid content of several vegetables and their antioxidant activity. J. Sci. Food Agric. 2000, 80, 561–566. [Google Scholar]

- Re, R.; Pellegrini, N.; Protegente, A.; Pannala, A.; Yang, M.C.; Rice-Evans, C. Antioxidant activity an improved ABTS radical cation decolorization assay. Free Rad. Biol. Med. 1999, 26, 1231–1237. [Google Scholar]

- ISO 3310-1:2016; Test Sieves—Technical Requirements and Testing—Part 1: Test Sieves of Metal Wire Cloth. ISO: Geneva, Switzerland, 2016.

- Pavani, M.; Singha, P.; Rajamanickam, D.T.; Singh, S.K. Impact of extrusion processing on bioactive compound enriched plant-based extrudates: A comprehensive study and optimization using RSM and ANN-GA. Futur. Foods 2024, 9, 100286. [Google Scholar] [CrossRef]

- Skonecki, S.; Potręć, M.; Laskowski, J. Physical and chemical properties of agricultural wastes. Acta Agrophys. 2011, 18, 443–455. [Google Scholar]

- Datta, A.K. Food Process Engineering: Heat and Mass Transfer. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 1994. [Google Scholar] [CrossRef]

- ISO 8589; Sensory Analysis—General Guidance for the Design of Test Rooms. ISO: Geneva, Switzerland, 2009.

- Kwak, J.H.; Seo, J.M.; Kim, N.H.; Arasu, M.V.; Kim, S.; Yoon, M.K.; Kim, S.J. Variation of quercetin glycoside derivatives in three onion (Allium cepa L.) varieties. Saudi J. Biol. Sci. 2017, 24, 1387–1391. [Google Scholar] [CrossRef]

- Qiao, L.; Sun, Y.; Chen, R.; Fu, Y.; Zhang, W.; Li, X.; Chen, J.; Shen, Y.; Ye, X. Sonochemical effects on 14 flavonoids common in citrus: Relation to stability. PLoS ONE 2014, 9, e105647. [Google Scholar] [CrossRef]

- Savitha, S.; Chakraborty, S.; Thorat, B.N. Microbial Contamination and Decontamination of Onion and its Products. Appl. Food Res. 2022, 2, 100032. [Google Scholar] [CrossRef]

- Schulze, B.; Hubbermann, E.M.; Schwarz, K. Stability of quercetin derivatives in vacuum impregnated apple slices after drying (microwave vacuum drying, air drying, freeze drying) and storage. LWT-Food Sci. Technol. 2014, 57, 426–433. [Google Scholar] [CrossRef]

- Rohn, S.; Buchner, N.; Driemel, G.; Rauser, M.; Kroh, L.W. Thermal Degradation of Onion Quercetin Glucosides under Roasting Conditions. J. Agric. Food Chem. 2007, 55, 1568–1573. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Wei, H.K.; Xiang, Q.H.; Wang, J.; Zhou, Y.F.; Peng, J. Protective effect of quercetin on pig intestinal integrity after transport stress is associated with regulation oxidative status and inflammation. J. Vet. Med. Sci. 2016, 78, 1487–1494. [Google Scholar] [CrossRef] [PubMed]

- Park, J.H.; Sureshkumar, S.; Kim, I.H. Influences of dietary flavonoid (quercetin) supplementation on growth performance and immune response of growing pigs challenged with Escherichia coli lipopolysaccharide. J. Anim. Sci. Technol. 2020, 62, 605–613. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Wei, Z.; Sun, Y.; Luo, T.; Xue, C. Preparation of core–shell hordein/pectin nanoparticles as quercetin delivery matrices: Physicochemical properties and colon-specific release analyses. Food Res. Int. 2023, 170, 112971. [Google Scholar] [CrossRef]

- Cheng, J.; Dudu, O.E.; Zhang, J.; Wang, Y.; Meng, L.; Wei, W.; Li, X.; Yan, T. Impact of binding interaction modes between whey protein concentrate and quercetin on protein structural and functional characteristics. Food Hydrocoll. 2023, 142, 108787. [Google Scholar] [CrossRef]

- Massuquetto, A.; Panisson, J.C.; Marx, F.O.; Surek, D.; Krabbe, E.L.; Maiorka, A. Effect of pelleting and different feeding programs on growth performance, carcass yield, and nutrient digestibility in broiler chickens. Poult. Sci. 2019, 98, 5497–5503. [Google Scholar] [CrossRef]

- Norrapoke, T.; Pongjongmit, T. Effect of high-quality pellet feed level on voluntary feed intake, nutrient digestibility and rumen fermentation in beef cattle. Sci. Rep. 2025, 15, 15343. [Google Scholar] [CrossRef]

- Suwignyo, B.; Subagya, R.D.; Astuti, A. Physical and chemical quality of forage feed pellets with different types of materials and compositions. IOP Conf. Ser. Earth Environ. Sci. 2022, 951, 012035. [Google Scholar] [CrossRef]

- Celano, R.; Docimo, T.; Piccinelli, A.L.; Gazzerro, P.; Tucci, M.; Di Sanzo, R.; Carabetta, S.; Campone, L.; Russo, M.; Rastrelli, L. Onion peel: Turning a food waste into a resource. Antioxidants 2021, 10, 304. [Google Scholar] [CrossRef]

- Nicoli, M.C.; Anese, M.; Parpinel, M. Infuence of processing on the antioxidant properties of fruit and vegetables. Trends Food Sci. Technol. 1999, 10, 94–100. [Google Scholar]

- Dewanto, V.; Wu, X.; Adom, K.K.; Liu, R.H. Thermal Processing Enhances the Nutritional Value of Tomatoes by Increasing Total Antioxidant Activity. J. Agric. Food Chem. 2002, 50, 3010–3014. [Google Scholar] [PubMed]

- Suhag, R.; Kellil, A.; Razem, M. Factors Influencing Food Powder Flowability. Powders 2024, 3, 65–76. [Google Scholar] [CrossRef]

- Yousf, N.; Nazir, F.; Salim, R.; Ahsan, H.; Sirwal, A. Water solubility index and water absorption index of extruded product from rice and carrot blend. J. Pharmacogn. Phytochem. 2017, 6, 2165–2168. [Google Scholar]

- Braglia, L.; Morello, L.; Gavazzi, F.; Gianì, S.; Mastromauro, F.; Breviario, D.; Cardoso, H.G.; Valadas, V.; Campos, M.D. Interlaboratory comparison of methods determining the botanical composition of animal feed. J. AOAC Int. 2018, 101, 227–234. [Google Scholar] [CrossRef]

- Lin, P.; Fearn, T.; Mazzoleni, S.; Ottoboni, M.; Luciano, A.; Moradei, A.; Tretola, M.; Pinotti, L. Size and shape attributes of packaging remnants commonly detected in former food products. Ital. J. Anim. Sci. 2024, 23, 1–10. [Google Scholar] [CrossRef]

- Bianchi, M.G.; Casati, L.; Sauro, G.; Taurino, G.; Griffini, E.; Milani, C.; Ventura, M.; Bussolati, O.; Chiu, M. Biological Effects of Micro- / Nano-Plastics in Macrophages. Nanomaterials 2025, 15, 394. [Google Scholar] [CrossRef]

- Zheng, D.; AlAteah, A.H.; Alsubeai, A.; Mostafa, S.A. Integrating micro- and nanowaste glass with waste foundry sand in ultra-high-performance concrete to enhance material performance and sustainability. Rev. Adv. Mater. Sci. 2024, 63, 20240012. [Google Scholar] [CrossRef]

- Ourgaud, M.; Phuong, N.N.; Papillon, L.; Panagiotopoulos, C.; Galgani, F.; Schmidt, N.; Fauvelle, V.; Brach-Papa, C.; Sempéré, R. Identification and Quantification of Microplastics in the Marine Environment Using the Laser Direct Infrared (LDIR) Technique. Environ. Sci. Technol. 2022, 56, 9999–10009. [Google Scholar] [CrossRef]

- Jarzȩbski, M.; Wieruszewski, M.; Kościński, M.; Rogoziński, T.; Kobus-Cisowska, J.; Szablewski, T.; Perła-Kaján, J.; Waszkowiak, K.; Jakubowicz, J. Heme iron as potential iron fortifier for food application-characterization by material techniques. Rev. Adv. Mater. Sci. 2023, 62, 20230128. [Google Scholar] [CrossRef]

- Neder-Suárez, D.; Amaya-Guerra, C.A.; Quintero-Ramos, A.; Pérez-Carrillo, E.; Alanís-Guzmán, M.G.D.J.; Báez-González, J.G.; García-Díaz, C.L.; Núñez-González, M.A.; Lardizábal-Gutiérrez, D.; Jiménez-Castro, J.A. Physicochemical changes and resistant-starch content of extruded cornstarch with and without storage at refrigerator temperatures. Molecules 2016, 21, 1064. [Google Scholar] [CrossRef]

- Elejalde, C.C.; Kokini, J.L. The Psychophysics of Pouring, Spreading and in-Mouth Viscosity. J. Texture Stud. 1992, 23, 315–336. [Google Scholar] [CrossRef]

- Pérez-Viveros, K.J.; Gutiérrez-Dorado, R.; Téllez-Jurado, A.; Gómez- Aldapa, C.A.; Reyes-Moreno, C.; Navarro-Cortez, R.O.; Bautista-Monroy, S.S.; Cadena Ramírez, A. Effect of extrusion in the elaboration of an animal feed based on Moringa oleifera Lam and Zea mays as a partial substitute of fishmeal in the diet of the adult stage of Oreochromis niloticus. Acta Univ. 2019, 29, 1–17. [Google Scholar] [CrossRef]

- Rodríguez-Miranda, J.; Ruiz-López, I.I.; Herman-Lara, E.; Martínez-Sánchez, C.E.; Delgado-Licon, E.; Vivar-Vera, M.A. Development of extruded snacks using taro (Colocasia esculenta) and nixtamalized maize (Zea mays) flour blends. LWT-Food Sci. Technol. 2011, 44, 673–680. [Google Scholar] [CrossRef]

- Bahnasawy, A.H.; Mostafa, H.M. Some Engineering Properties of Different Feed Pellets. Misr J. Agric. Eng. 2011, 28, 947–960. [Google Scholar] [CrossRef]

- Beakawi Al-Hashemi, H.M.; Baghabra Al-Amoudi, O.S. A review on the angle of repose of granular materials. Powder Technol. 2018, 330, 397–417. [Google Scholar] [CrossRef]

- Madrid, M.A.; Fuentes, J.M.; Ayuga, F.; Gallego, E. Determination of the Angle of Repose and Coefficient of Rolling Friction for Wood Pellets. Agronomy 2022, 12, 424. [Google Scholar] [CrossRef]

- Holm, K.; Wendin, K.; Hermansson, A.M. Sweetness and texture perception in mixed pectin gels with 30% sugar and a designed rheology. LWT-Food Sci. Technol. 2009, 42, 788–795. [Google Scholar] [CrossRef]

- Jafari, S.M.; Malekjani, N. Transporting Operations of Food Materials Within Food Factories; Elsevier: Amsterdam, The Netherlands, 2019; Volume 11, ISBN 9788578110796. [Google Scholar]

- Loar, R.E.; Corzo, A. Effects of feed formulation on feed manufacturing and pellet quality characteristics of poultry diets. Worlds Poult. Sci. J. 2011, 67, 19–28. [Google Scholar] [CrossRef]

- Białowiec, A.; Micuda, M.; Szumny, A.; Łyczko, J.; Koziel, J.A. The proof-of-the-concept of application of pelletization for mitigation of volatile organic compounds emissions from carbonized refuse-derived fuel. Materials 2019, 12, 1692. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).