Thermal and Electrical Fault Diagnosis in Oil–Paper Insulation System: A Comparative Study of Natural Esters and Mineral Oil

Abstract

1. Introduction

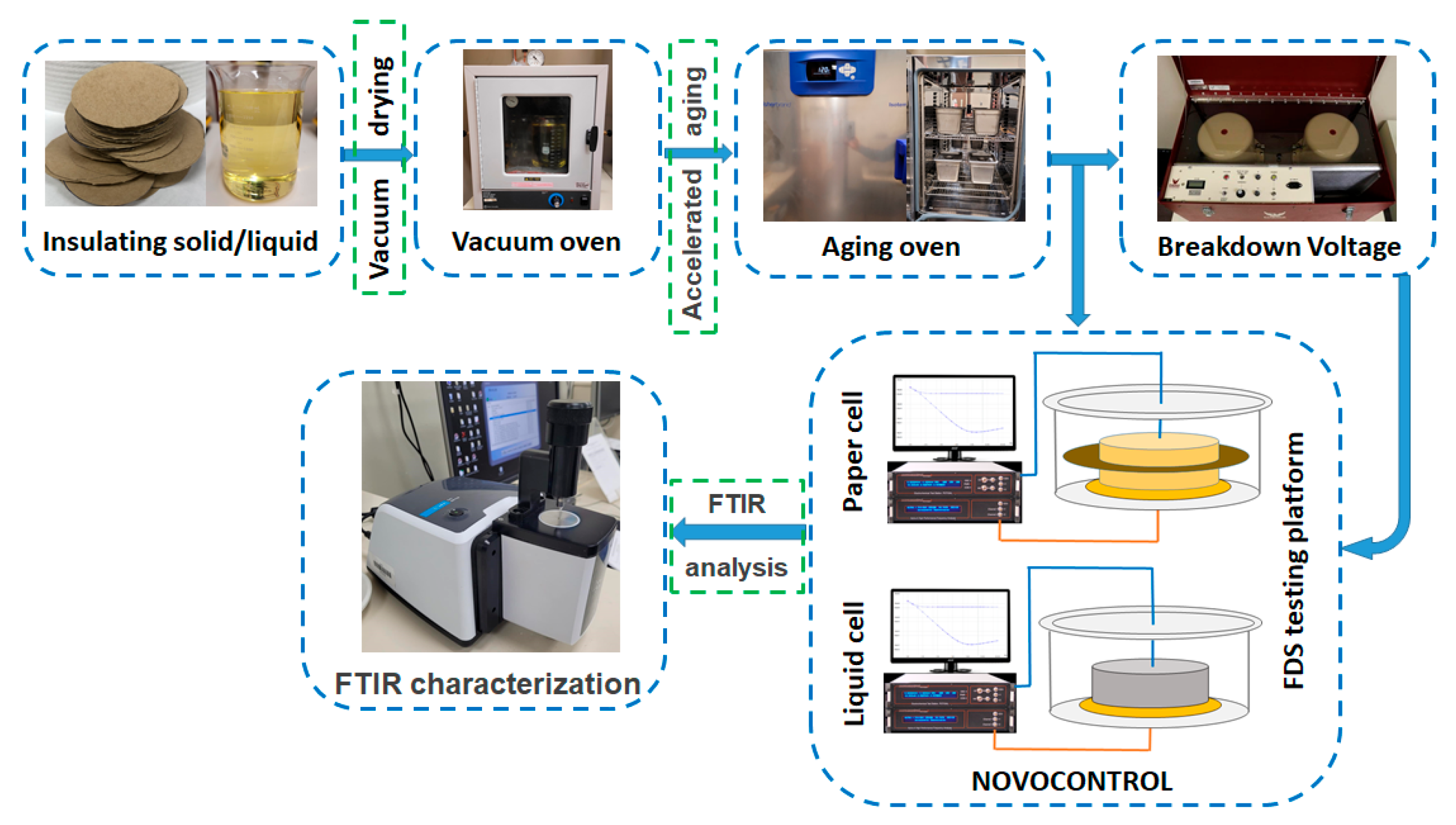

2. Materials and Methods

2.1. Selection and Design of Specimens

2.2. Aging Setup

2.3. Characterization

3. Results and Discussion

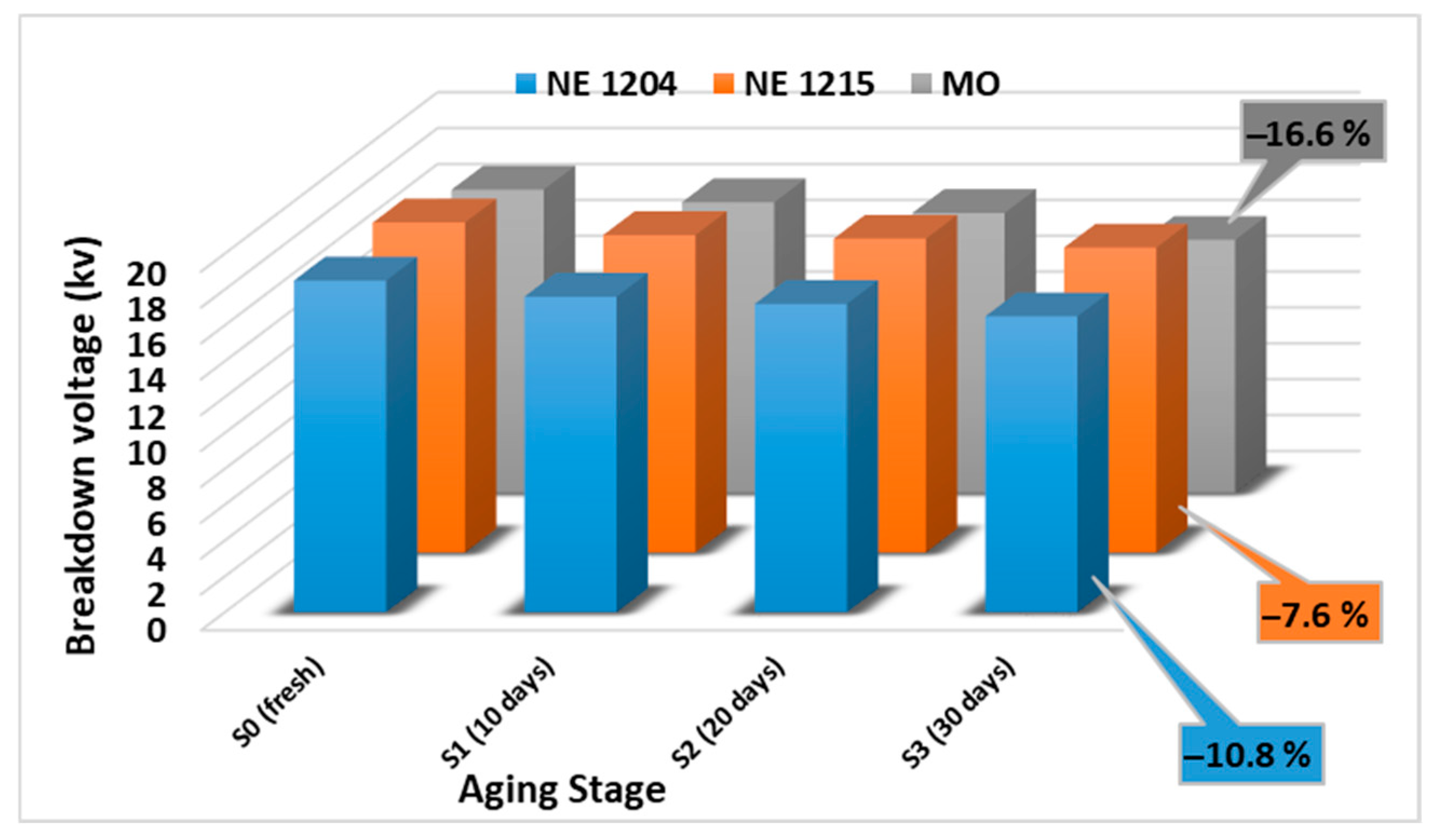

3.1. Breakdown Results

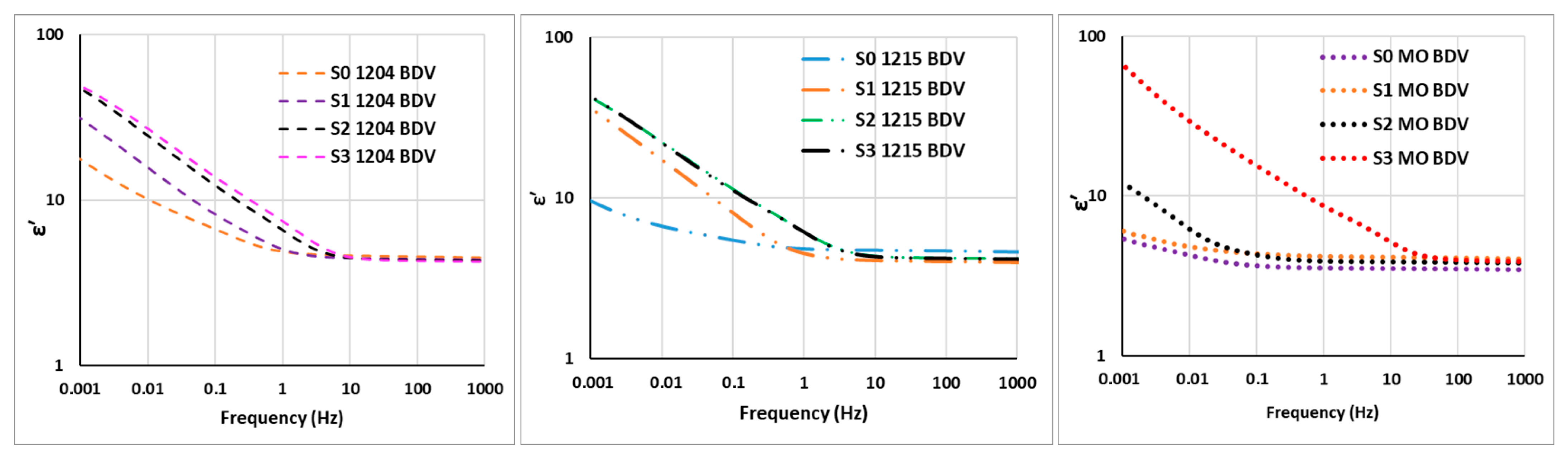

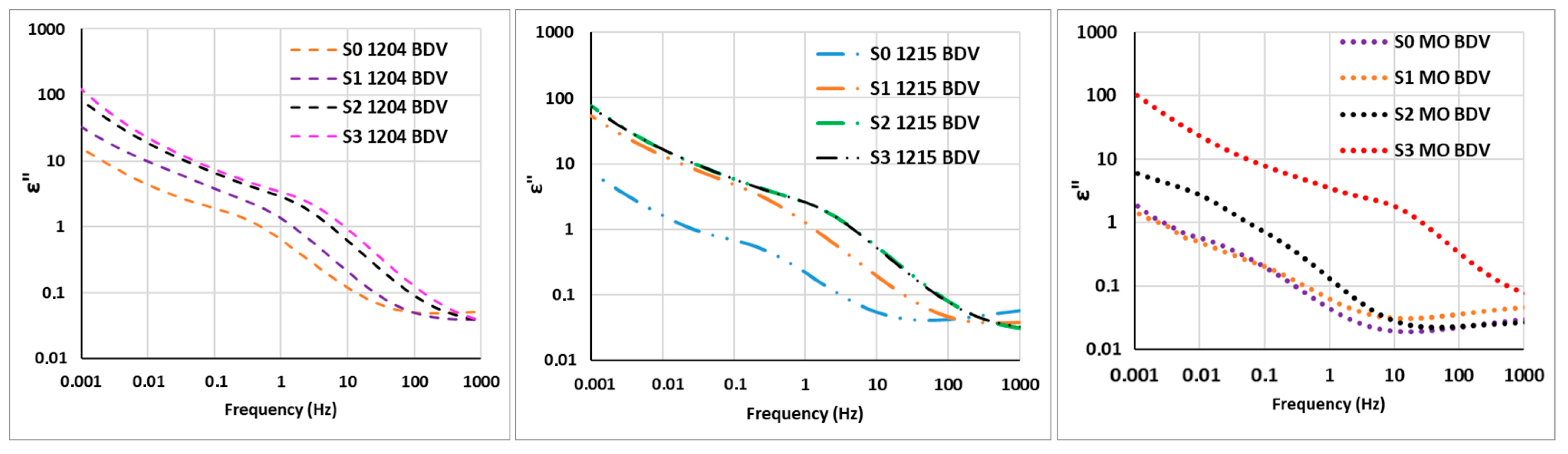

3.2. FDS Analysis of Oil/Paper Insulation

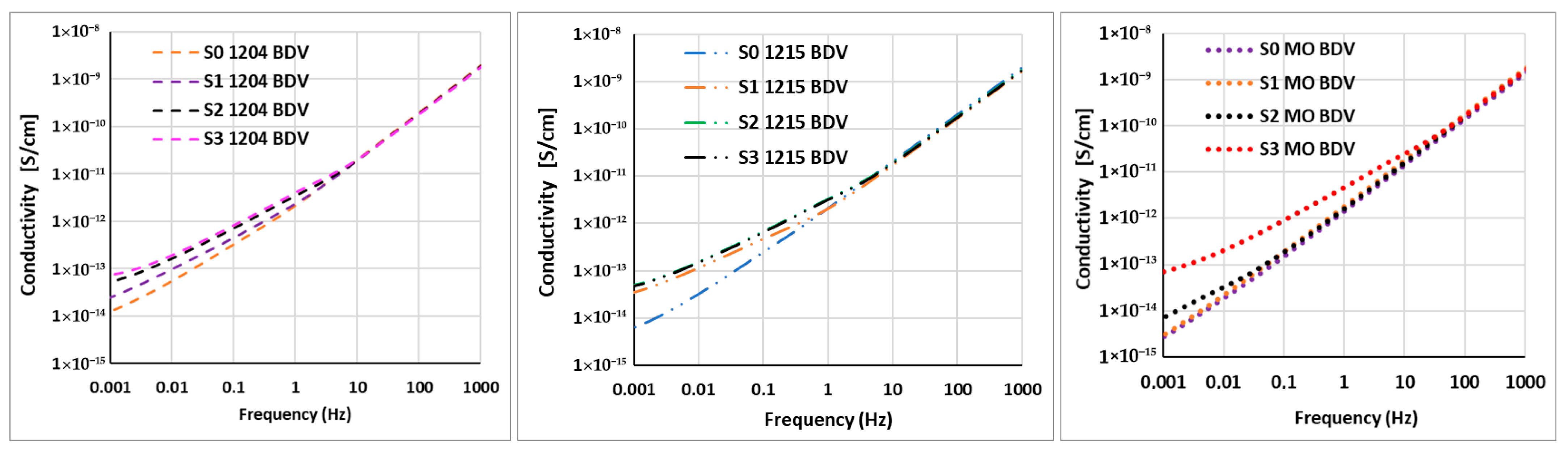

- ➢

- Real Permittivity (ε′): A progressive increase in this parameter was observed, especially for mineral oil from stage S1. This rise indicates an enhanced ability of the material to polarize, likely due to an increase in polar groups and residual moisture as a result of aging. In contrast, the variation of ε′ for the natural esters remains lower and more gradual, reflecting better preservation of the cellulose structure.

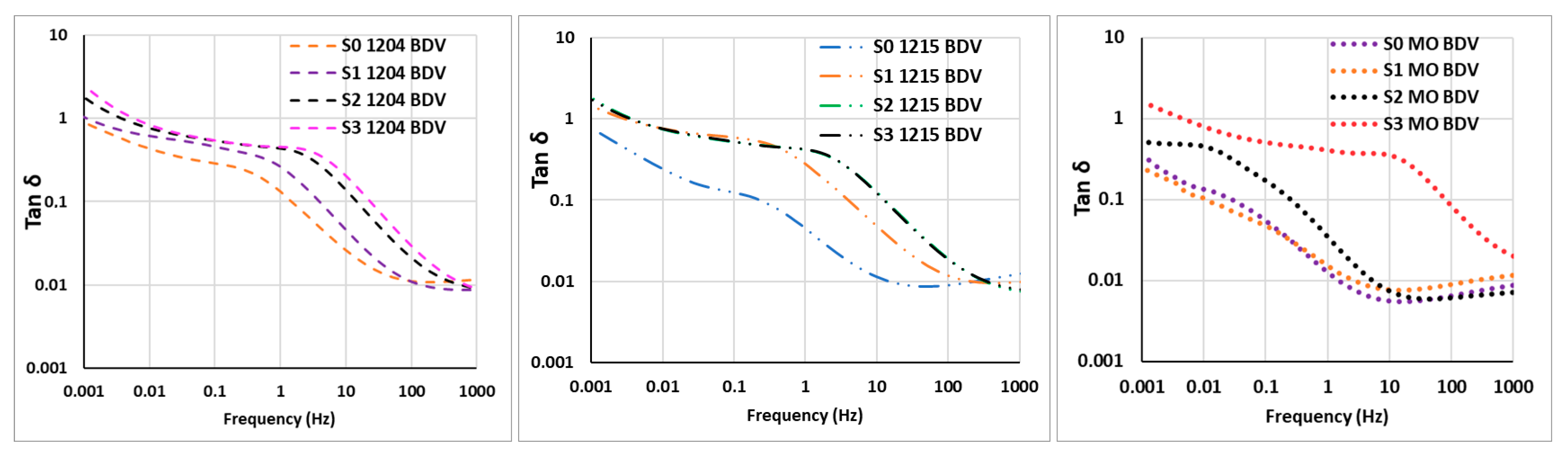

- ➢

- Dielectric Loss Tangent (tan δ): The evolution of tan δ, particularly in the low-frequency range (1 mHz–10 Hz), emerges as a key indicator of aging. For Polaris GX, a sharp rise begins from S2, suggesting the accumulation of conductive degradation products and moisture. NE 1204 shows a more moderate and gradual increase in the various analyzed parameters, whereas NE 1215 maintains stable tan δ values up to S2, with only a slight rise at S3, indicating very limited aging effects.

- ➢

- Imaginary Permittivity (ε″) and Frequency-Dependent Conductivity: Both ε″ and conductivity increase significantly for mineral oil starting from S2, highlighting greater dielectric losses due to Joule heating and a decline in insulating performance. In contrast, NE 1204 exhibits moderate changes, while NE 1215 consistently shows the lowest values up to S3.

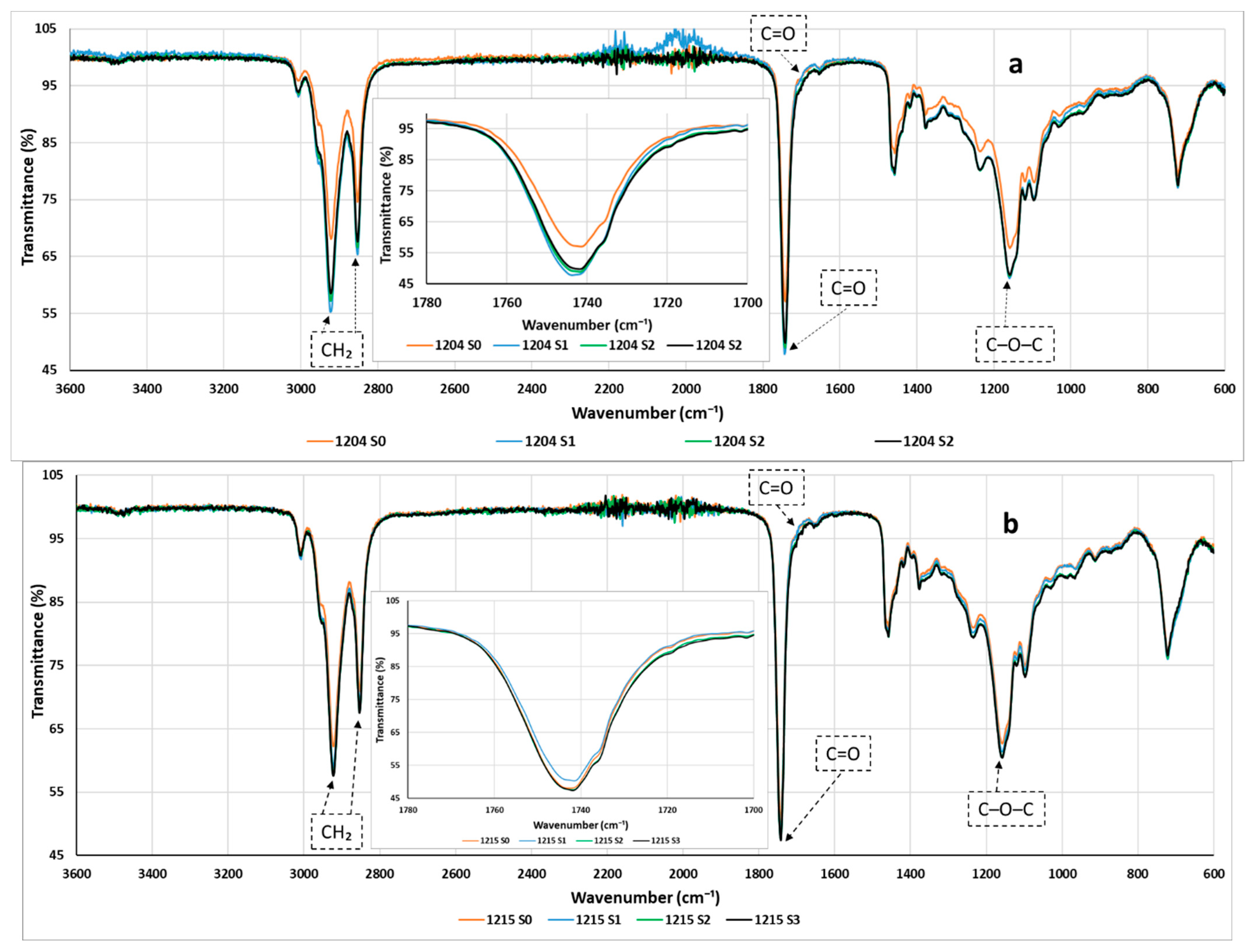

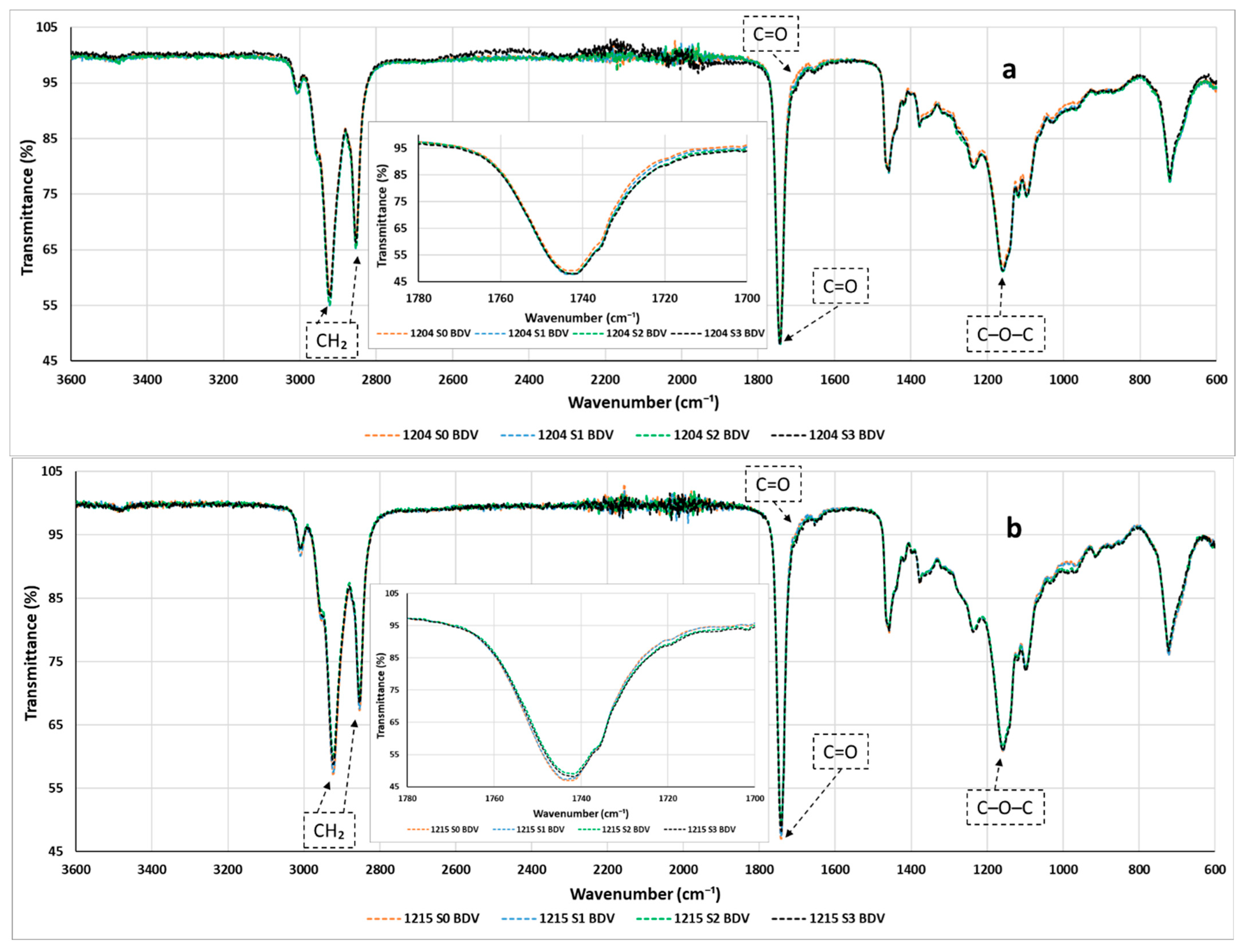

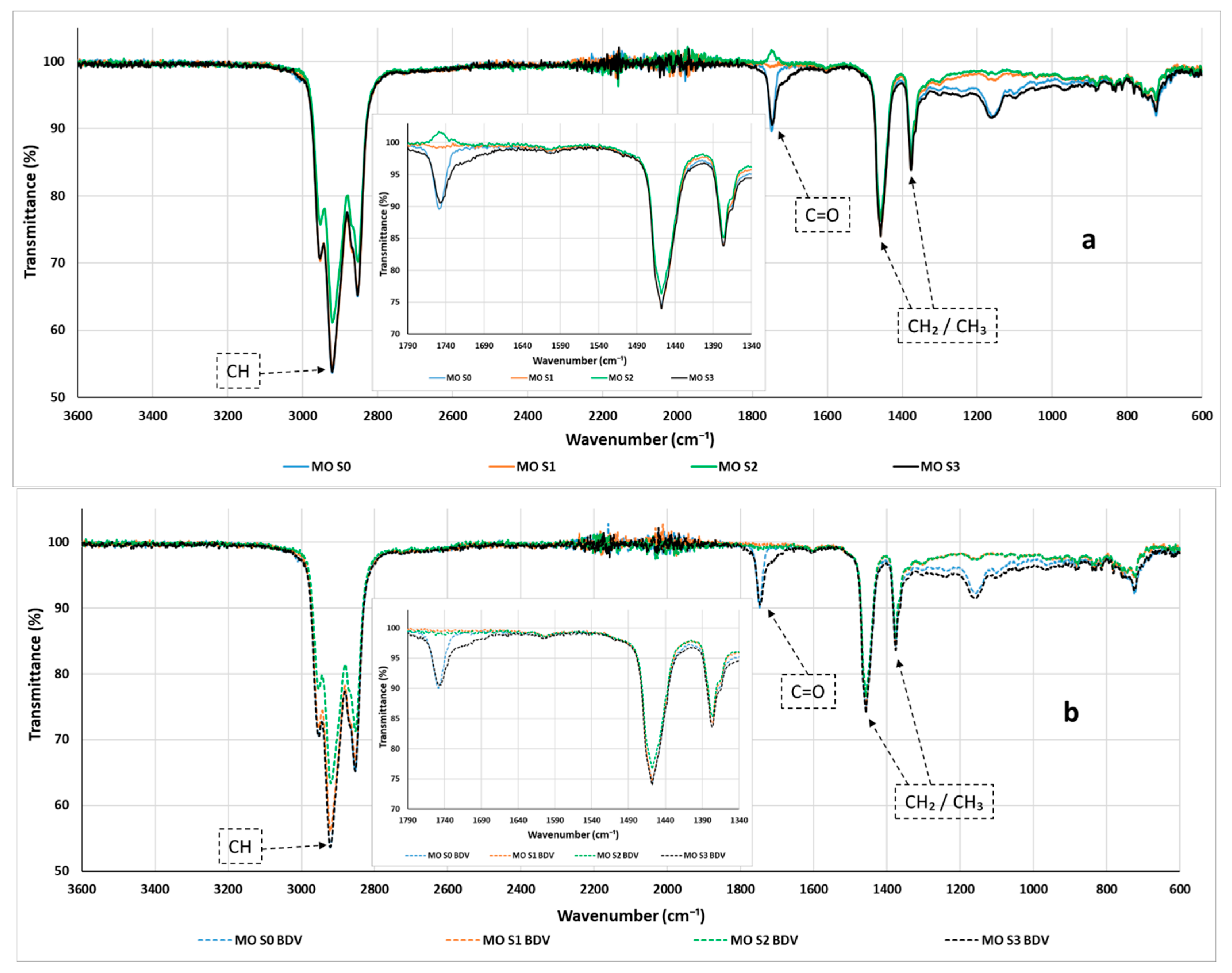

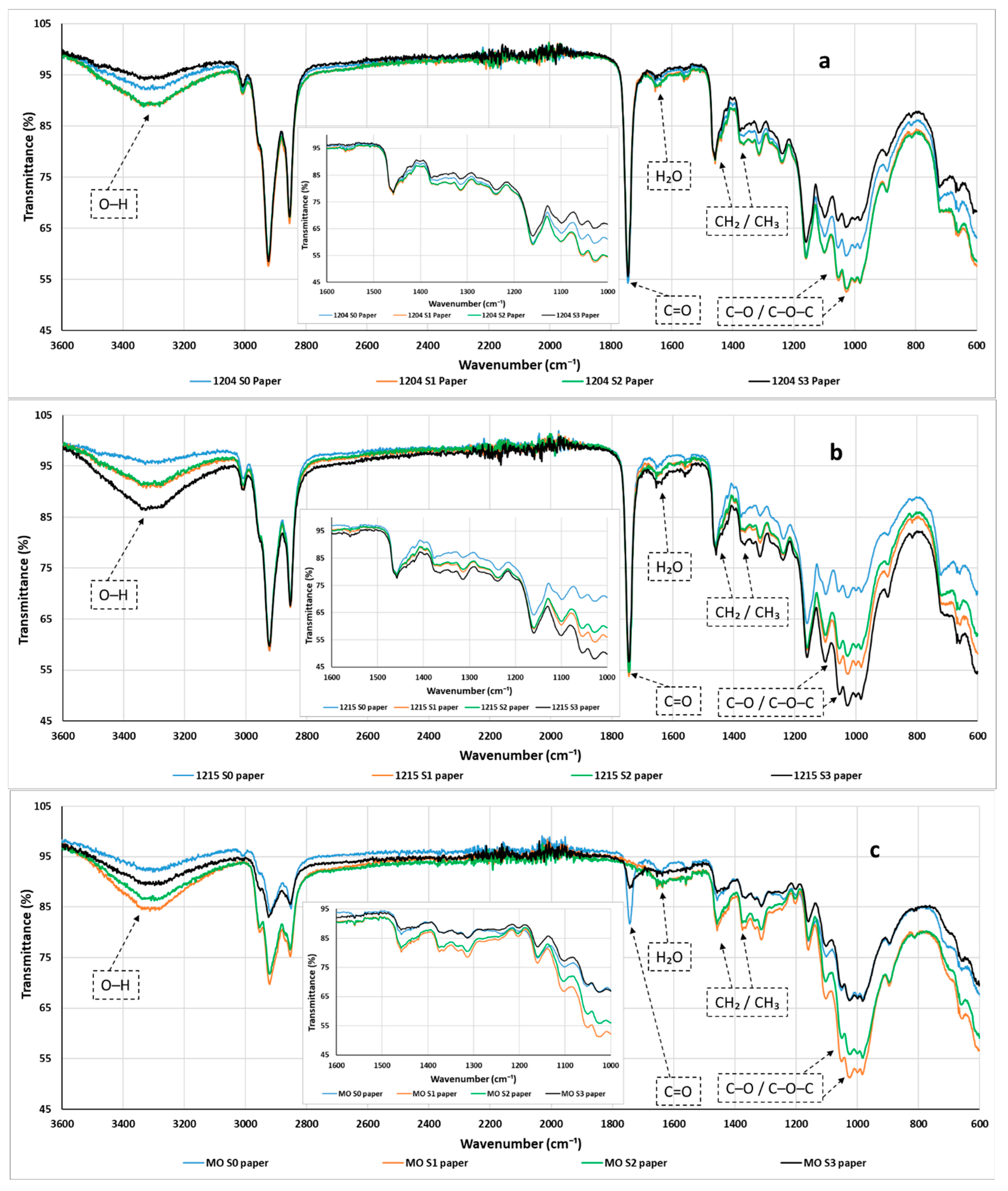

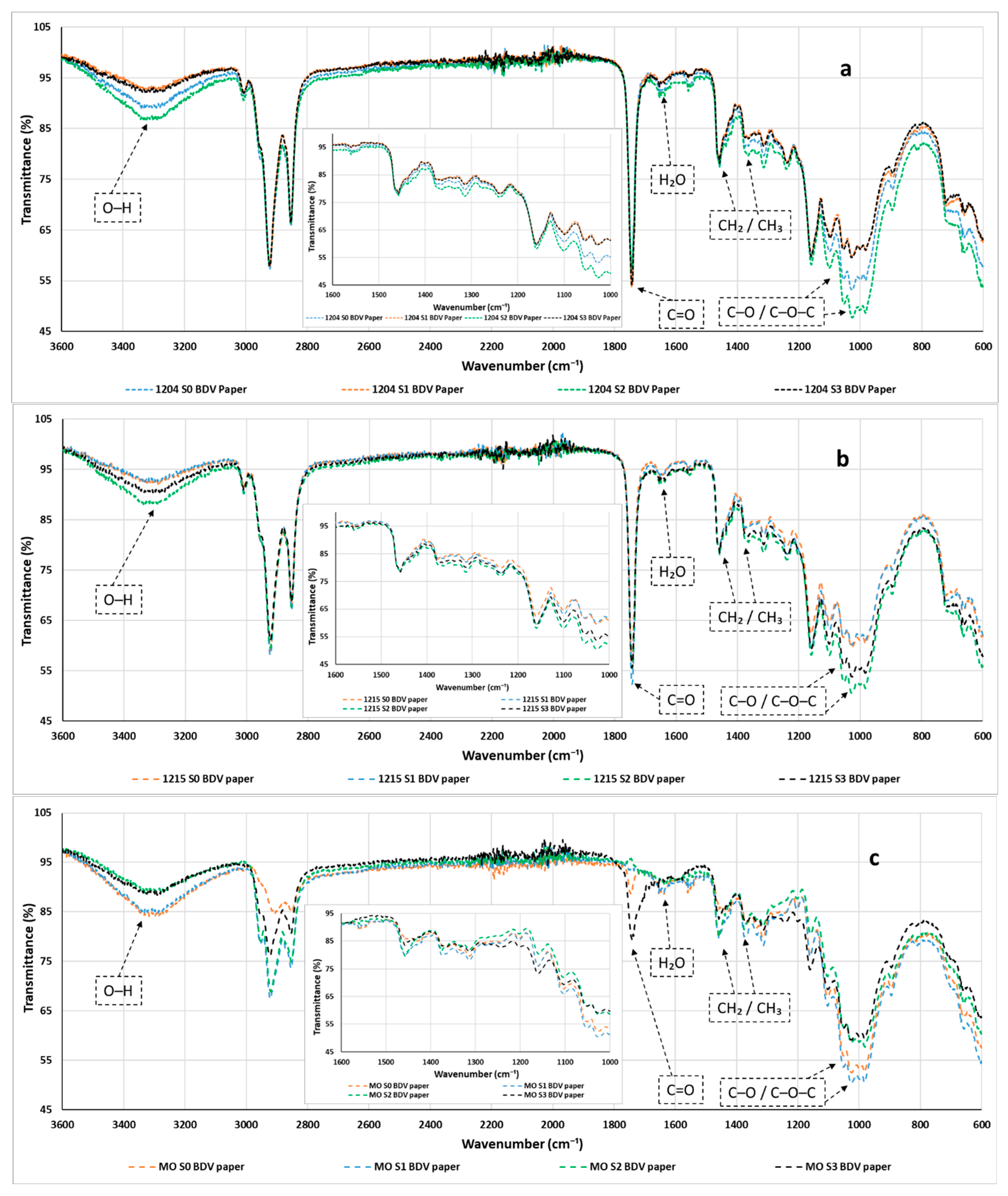

3.3. Analysis of FTIR Spectroscopy

- ➢

- For NE 1204 and NE 1215, a progressive attenuation of the ester carbonyl band (C=O ~1740 cm−1) occurs alongside the emergence or enhancement of a carboxylic acid band (~1710 cm−1), particularly from stage S2 onward. These changes reflect partial hydrolysis of triglycerides [33]. The quantitative analysis revealed that the relative intensity of the 1710 cm−1 band increases more significantly in NE 1204, reaching a ratio of 0.82 at S3, compared to 0.60 for NE 1215. This finding suggests a more pronounced acid formation in NE 1204.

- ➢

- For mineral oil, characteristic oxidation bands in the 1650–1750 cm−1 range appear as early as S1, with increasing intensity through to S3. It was observed that a peak at 1705 cm−1, associated with ketones and weak acids, becomes predominant, with a ratio of 1.21 at S3, indicating advanced and early oxidation processes that are not solely moisture-induced.

- ➢

- Progressive reduction of the O–H band (~3300 cm−1) indicates the breaking of hydrogen bonds, reflecting a loss of molecular cohesion and hydrophilicity. We found this decrease is most pronounced for Polaris GX (−38% between S0 and S3), compared to −22% for NE 1204 and only −13% for NE 1215.

- ➢

- Decline of C–O bands (~1030–1060 cm−1), associated with the glucosidic structure of cellulose, signals a degradation of the polysaccharide backbone. The measurements show the intensity loss reaches −40% at S3 for Polaris GX, indicating accelerated depolymerization. In contrast, we observed the reductions are moderate for NE 1204 (−27%) and minimal for NE 1215 (−14%), demonstrating better preservation of cellulose chains.

- ➢

- An increase in carbonyl (C=O) bands on the paper is most evident with Polaris GX, as confirmed by the C=O/C–O intensity ratio, which rises from 0.28 at S0 to 0.71 at S3 (+154%). Notably, this increase is lower for NE 1204 (+92%) and NE 1215 (+49%), confirming that paper oxidation is significantly more advanced when impregnated with mineral oil.

3.4. Comparative Spectral and Multimodal Analysis

- ➢

- Breakdown behavior: it was observed that the mineral oil Polaris GX leads to the greatest reduction in breakdown voltage, indicating accelerated degradation of the solid insulation. This loss in dielectric strength aligns closely with the early chemical deterioration of the paper that we observed via FTIR.

- ➢

- Dielectric properties (FDS): Through the analyses, the ranking of the oils based on key dielectric parameters (loss tangent, conductivity, and permittivity) follows the order of decreasing performance: NE 1215 > NE 1204 > Polaris GX. This hierarchy directly reflects the extent of aging experienced by each oil–paper system.

- ➢

- Chemical degradation (FTIR): The FTIR spectra corroborate these trends, with increasing levels of oxidation and hydrolysis observed from NE 1215 (most stable) to Polaris GX (most degraded), both in the oil and the impregnated paper.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbol | Parameter Name |

| ε′ | Real part of permittivity |

| ε″ | Imaginary part of permittivity |

| tan δ | Dielectric loss tangent |

| FDS | Frequency domain spectroscopy |

| FTIR | Fourier-transform infrared spectroscopy |

| C=O | Carbonyl group |

| O–H | Hydroxyl group |

| MO | Mineral oil (Polaris GX) |

| NE 1204 | Natural ester derived from rapeseed |

| NE 1215 | Natural ester derived from soybean |

| S0–S3 | Aging stages (0, 10, 20, and 30 days, respectively) |

References

- Oparanti, S.O.; Yapi, K.M.L.; Fofana, I.; Rao, U.M. Preliminary studies on Improving the Properties of Canola Oil by Addition of Methyl Ester from a Saturated Vegetable Oil. In Proceedings of the 2023 IEEE Electrical Insulation Conference (EIC), Quebec, QC, Canada, 18–21 June 2023; pp. 1–4. [Google Scholar]

- Brahami, Y.; Betie, A.; Meghnefi, F.; Fofana, I.; Yeo, Z. Development of a Comprehensive Model for Drying Optimization and Moisture Management in Power Transformer Manufacturing. Energies 2025, 18, 789. [Google Scholar] [CrossRef]

- Oria, C.; Ortiz, A.; Ferreño, D.; Carrascal, I.; Fernández, I. State-of-the-art review on the performance of cellulosic dielectric materials in power transformers: Mechanical response and ageing. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 939–954. [Google Scholar]

- Adekunle, A.A.; Oparanti, S.O.; Fofana, I. Performance assessment of cellulose paper impregnated in nanofluid for power transformer insulation application: A review. Energies 2023, 16, 2002. [Google Scholar] [CrossRef]

- Gmati, G.; Fofana, I.; Picher, P.; Meghnefi, F.; Arroyo-Fernàndez, O.; Rebaine, D.; Brahami, Y.; Kouba, Y.M.L. Bubbling Inception Temperature in Power Transformers–Part 1: Comparative Study of Kraft Paper, Thermally Upgraded Kraft Paper, and Aramid Paper with Mineral Oil. IEEE Access 2025, 13, 51287–51299. [Google Scholar]

- Fofana, I. 50 years in the development of insulating liquids. IEEE Electr. Insul. Mag. 2013, 29, 13–25. [Google Scholar]

- Jiang, Z.; Li, X.; Zhang, H.; Zhang, E.; Liu, C.; Fan, X.; Liu, J. Research progress and prospect of condition assessment techniques for oil–paper insulation used in power systems: A review. Energies 2024, 17, 2089. [Google Scholar] [CrossRef]

- Malaquias, P.E.; Pissolato, J.; Carriel, L.P.; Bassetto, A.; Marques, M.; Galdeano, C.A. Assessment of insulating kraft paper aged with service-aged insulating mineral oils in accelerated laboratory aging experiments. IEEE Electr. Insul. Mag. 2017, 33, 33–45. [Google Scholar]

- Shen, Z.; Wang, F.; Wang, Z.; Li, J. A critical review of plant-based insulating fluids for transformer: 30-year development. Renew. Sustain. Energy Rev. 2021, 141, 110783. [Google Scholar]

- Madan, R.; Su, P. Thermal Class of Natural Ester/Thermally Upgraded Kraft Paper Insulation System. In Proceedings of the 2023 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), East Rutherford, NJ, USA, 15–19 October 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–8. [Google Scholar]

- Naidu, G.T.; Rao, U.M.; Suresh, S. Influence of ester liquids on dielectric strength of cellulose kraft paper. Energies 2022, 15, 762. [Google Scholar] [CrossRef]

- Mihajlovic, D.; Vasovic, V.; Lukic, J. Development of New Accelerated Aging Test for Comparison of the Quality of Different Insulating Papers Based on Cellulose. Polymers 2023, 15, 2556. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, H.; Fan, X.; Zhang, Y.; Zhang, C. Aging evaluation for transformer oil-immersed cellulose insulation by using frequency dependent dielectric modulus technique. Cellulose 2021, 28, 2387–2401. [Google Scholar]

- Rafiq, M.; Shafique, M.; Ateeq, M.; Zink, M.; Targitay, D. Natural esters as sustainable alternating dielectric liquids for transformer insulation system: Analyzing the state of the art. Clean Technol. Environ. Policy 2023, 26, 623–659. [Google Scholar]

- Boudraa, S.; Benabed, F.; Fofana, I.; Mokhnache, L. FTIR and FDS assessment of mineral oil under low electrical discharge. Diagnostyka 2022, 23, 2449–5220. [Google Scholar]

- Carcedo, J.; Fernandez, I.; Ortiz, A.; Delgado, F.; Renedo, C.J.; Arroyo, A. Quantitative study on the aging of kraft paper in vegetable oils. IEEE Electr. Insul. Mag. 2016, 32, 29–35. [Google Scholar]

- Sari, Y.E.; Ritonga, A.D. Comparative study of Kraft paper aged in natural ester with XRD and TG/DTG analysis. In Proceedings of the 2019 International Conference on Electrical Engineering and Informatics (ICEEI), Bandung, Indonesia, 9–10 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 564–569. [Google Scholar]

- Thavasilingam, S.; Venugopal, N.P.; Paramasivan, M.; Rathinam, M.; Manikandan, S.; Thankaswamy, J. Thermal ageing study on palm oil methyl ester-impregnated thermally upgraded kraft paper insulation for reliable application in HVDC converter transformers. Electr. Eng. 2024, 107, 4271–4288. [Google Scholar]

- Martins, M.A.G. Vegetable oils, an alternative to mineral oil for power transformers-experimental study of paper aging in vegetable oil versus mineral oil. IEEE Electr. Insul. Mag. 2010, 26, 7–13. [Google Scholar]

- Yang, L.; Liao, R.; Sun, C.; Yin, J.; Zhu, M. Influence of vegetable oil on the thermal aging rate of Kraft paper and its mechanism. In Proceedings of the 2010 International Conference on High Voltage Engineering and Application, New Orleans, LA, USA, 11–14 October 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 381–384. [Google Scholar]

- Méndez, C.; Olmo, C.; Renedo, C.J.; Ortiz, A.; García, D. Kinetic Assessment of Kraft and Thermally Upgraded Kraft Papers Aged in Five Alternative Dielectric Fluids. Polymers 2024, 16, 1196. [Google Scholar] [CrossRef] [PubMed]

- Ye, W.; Hao, J.; Gao, C.; Zhang, J.; Yang, L.; Liao, R. Natural ester replacement effect on thermal degradation of cellulose insulation from macroscopic behavior to atomic-scale mechanism. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 1582–1589. [Google Scholar]

- Münster, T.; Werle, P.; Hämel, K.; Preusel, J. Thermally accelerated aging of insulation paper for transformers with different insulating liquids. Energies 2021, 14, 3036. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 2016, 29, 786–794. [Google Scholar]

- ASTM D1934–95; Standard Test Method for Oxidative Aging of Electrical Insulating Petroleum Oils by Open-Beaker Method. Annual Book of ASTM Standards 10 (2012). ASTM: West Conshohocken, PA, USA, 2012.

- ASTM D149–20; Standard Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at Commercial Power Frequencies. Annual Book of Standards Volume: 10.01 (2020). ASTM: West Conshohocken, PA, USA, 2020.

- Kurzweil, P.; Schell, C.; Haller, R.; Trnka, P.; Hornak, J. Environmental impact and aging properties of natural and synthetic transformer oils under electrical stress conditions. Adv. Sustain. Syst. 2021, 5, 2100079. [Google Scholar]

- Hadjadj, Y.; Ghunem, R.A.; Alqudsi, A.Y. Monitoring Oxidation in Natural Ester Insulating Liquids Through FTIR Spectroscopy Analysis. In Proceedings of the 2024 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Auburn, AL, USA, 6–9 October 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–4. [Google Scholar]

- Qian, Y.-H.; Li, Z.; Zhao, Y.-H.; Wang, Q. Infrared spectroscopy for ageing assessment of insulating oils via dielectric loss factor and interfacial tension. Open Phys. 2023, 21, 20220260. [Google Scholar]

- Sai, R.S.; Rafi, J.; Farook, S.; Kumar, N.M.G.; Parthasarathy, M.; Bakkiyaraj, R.A. Degradation studies of electrical, physical and chemical properties of aged transformer oil. J. Phys. Conf. Ser. 2020, 1706, 012056. [Google Scholar]

- Cichosz, S.; Masek, A.; Dems-Rudnicka, K. Original study on mathematical models for analysis of cellulose water content from absorbance/wavenumber shifts in ATR FT-IR spectrum. Sci. Rep. 2022, 12, 19739. [Google Scholar]

- Popescu, M.-C.; Froidevaux, J.; Navi, P.; Popescu, C.-M. Structural modifications of Tilia cordata wood during heat treatment investigated by FT-IR and 2D IR correlation spectroscopy. J. Mol. Struct. 2013, 1033, 176–186. [Google Scholar]

- Obebe, E.O.; Hadjadj, Y.; Oparanti, S.O.; Fofana, I. Enhancing the Performance of Natural Ester Insulating Liquids in Power Transformers: A Comprehensive Review on Antioxidant Additives for Improved Oxidation Stability. Energies 2025, 18, 1690. [Google Scholar] [CrossRef]

| Oil Type | |||

|---|---|---|---|

| Aging Stage | NE 1204 | NE 1215 | MO |

| S0 (fresh oil) | 18.5 | 18.4 | 16.9 |

| S1 (10 days) | 17.6 | 17.7 | 16.2 |

| S2 (20 days) | 17.2 | 17.5 | 15.6 |

| S3 (30 days) | 16.5 | 17 | 14.1 |

| Wavenumber (cm−1) | Functional Group | Vibration Type |

|---|---|---|

| ~1740 | C=O (ester) | Carbonyl stretching |

| ~2920 | Aliphatic CH2 | Asymmetric stretching |

| ~2850 | Aliphatic CH2 | Symmetric stretching |

| ~1465 | CH2/CH3 | Bending (scissoring) |

| ~1230–1170 | C–O–C (ester linkage) | Stretching |

| ~3400 | O–H (alcohols, acids, water) | Broad stretching band (hydrogen bonding) |

| Wavenumber (cm−1) | Functional Group | Vibration Type |

|---|---|---|

| 2921 | C-H (alkanes) | Asymmetric stretching |

| 2853 | C-H (alkanes) | Symmetric stretching |

| 1458 | C-H (methylene) | Bending (scissoring) |

| 1376 | C-H (methyl) | Symmetric bending |

| 722 | C-C (chaînes longues) | Rocking of methylene |

| Wavenumber (cm−1) | Functional Group | Vibration Type |

|---|---|---|

| ~3330 | O–H (cellulose) | Broad stretching (H-bonded hydroxyl) |

| ~2900 | Aliphatic C–H | Stretching |

| ~1640 | Adsorbed H2O | Stretching of bound water |

| ~1430 | CH2 (amorphous cellulose) | Bending |

| ~1375 | C–H/CH3 (carbohydrate backbone) | Bending (symmetric) |

| ~1160–1030 | C–O/C–O–C (carbohydrate structure) | Stretching (cellulose polysaccharide network) |

| Oil Type | Δε′ (Relative Increase) | ΔTan δ (Low Frequency) | O–H Band (~3300 cm−1) | C=O Band (~1705–1740 cm−1) | Interpretation |

|---|---|---|---|---|---|

| Mineral oil | High | High | −38% | +154% | Strong degradation (dielectric and chemical) |

| NE 1204 | Moderate | Moderate | −22% | +92% | Partial degradation, moderate oxidation |

| NE 1215 | Low | Slight | −13% | +49% | Good stability, limited aging effects |

| Oil | Breakdown Voltage Drop (S0→S3) | tan δ Evolution (FDS) | Paper Oxidation (ATR-FTIR) | Oil Chemical State (ATR-FTIR) | Aging Rate | Overall Performance |

|---|---|---|---|---|---|---|

| Polaris GX | −16.6% | Significant rise from S2 to S3 | Marked from S1, accentuated at S3 | Significant oxidation from S1 | Fast | Low |

| NE 1204 | −10.8% | Gradual increase | Moderate, mainly from S2 | Mild acid formation | Moderate | Good |

| NE 1215 | −7.6% | Slight increase only at S3 | Low, visible only at S3 | Stable, minimal evolution | Slow | Very good |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brahami, Y.; Oparanti, S.O.; Fofana, I.; Fethi, M. Thermal and Electrical Fault Diagnosis in Oil–Paper Insulation System: A Comparative Study of Natural Esters and Mineral Oil. Appl. Sci. 2025, 15, 7676. https://doi.org/10.3390/app15147676

Brahami Y, Oparanti SO, Fofana I, Fethi M. Thermal and Electrical Fault Diagnosis in Oil–Paper Insulation System: A Comparative Study of Natural Esters and Mineral Oil. Applied Sciences. 2025; 15(14):7676. https://doi.org/10.3390/app15147676

Chicago/Turabian StyleBrahami, Youssouf, Samson Okikiola Oparanti, Issouf Fofana, and Meghnefi Fethi. 2025. "Thermal and Electrical Fault Diagnosis in Oil–Paper Insulation System: A Comparative Study of Natural Esters and Mineral Oil" Applied Sciences 15, no. 14: 7676. https://doi.org/10.3390/app15147676

APA StyleBrahami, Y., Oparanti, S. O., Fofana, I., & Fethi, M. (2025). Thermal and Electrical Fault Diagnosis in Oil–Paper Insulation System: A Comparative Study of Natural Esters and Mineral Oil. Applied Sciences, 15(14), 7676. https://doi.org/10.3390/app15147676