Closed-Loop Control Strategies for a Modular Under-Actuated Smart Surface: From Threshold-Based Logic to Decentralized PID Regulation

Abstract

1. Introduction

1.1. State of the Art: Smart Surfaces

1.2. State of the Art: Control

1.3. Outline

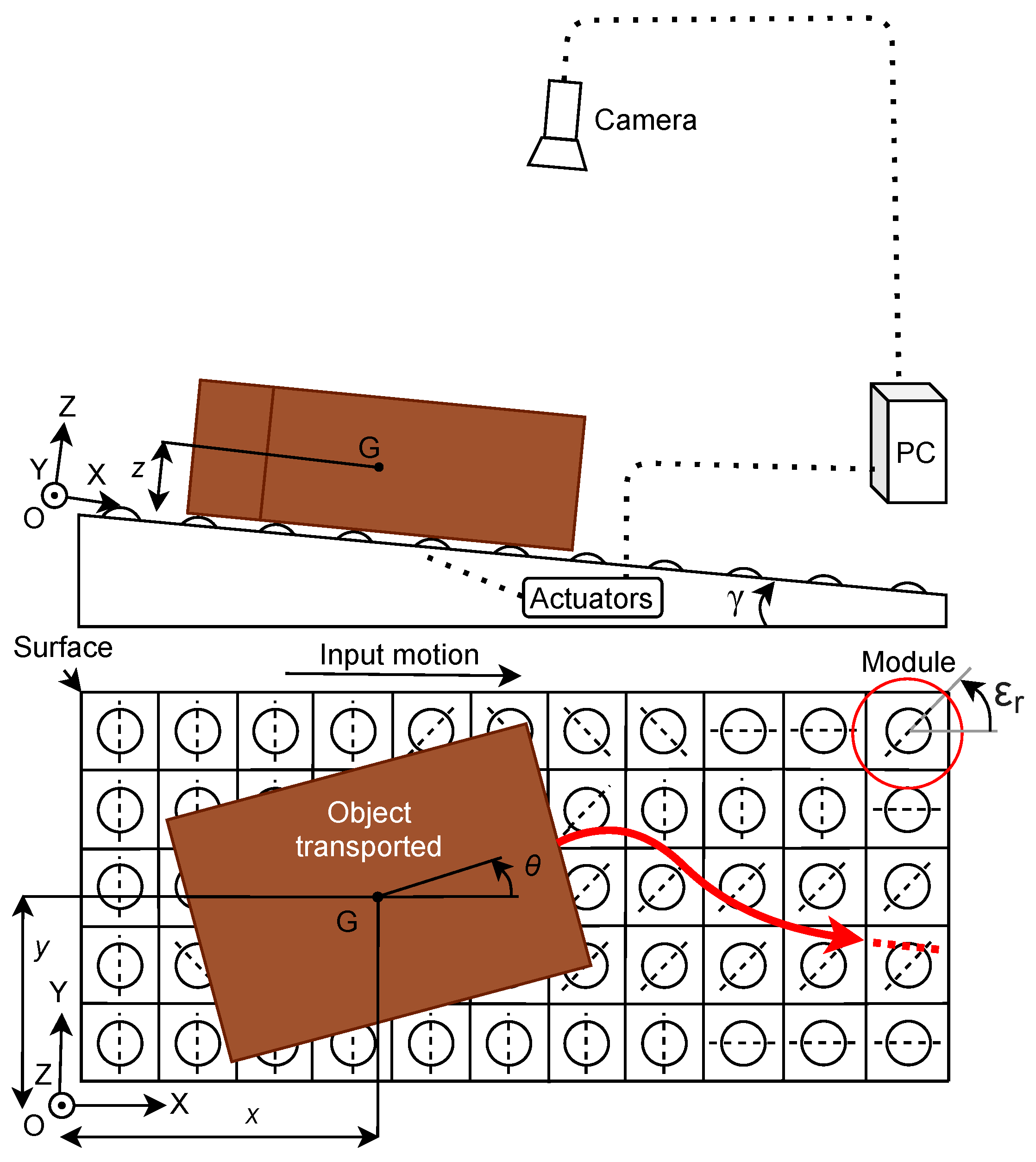

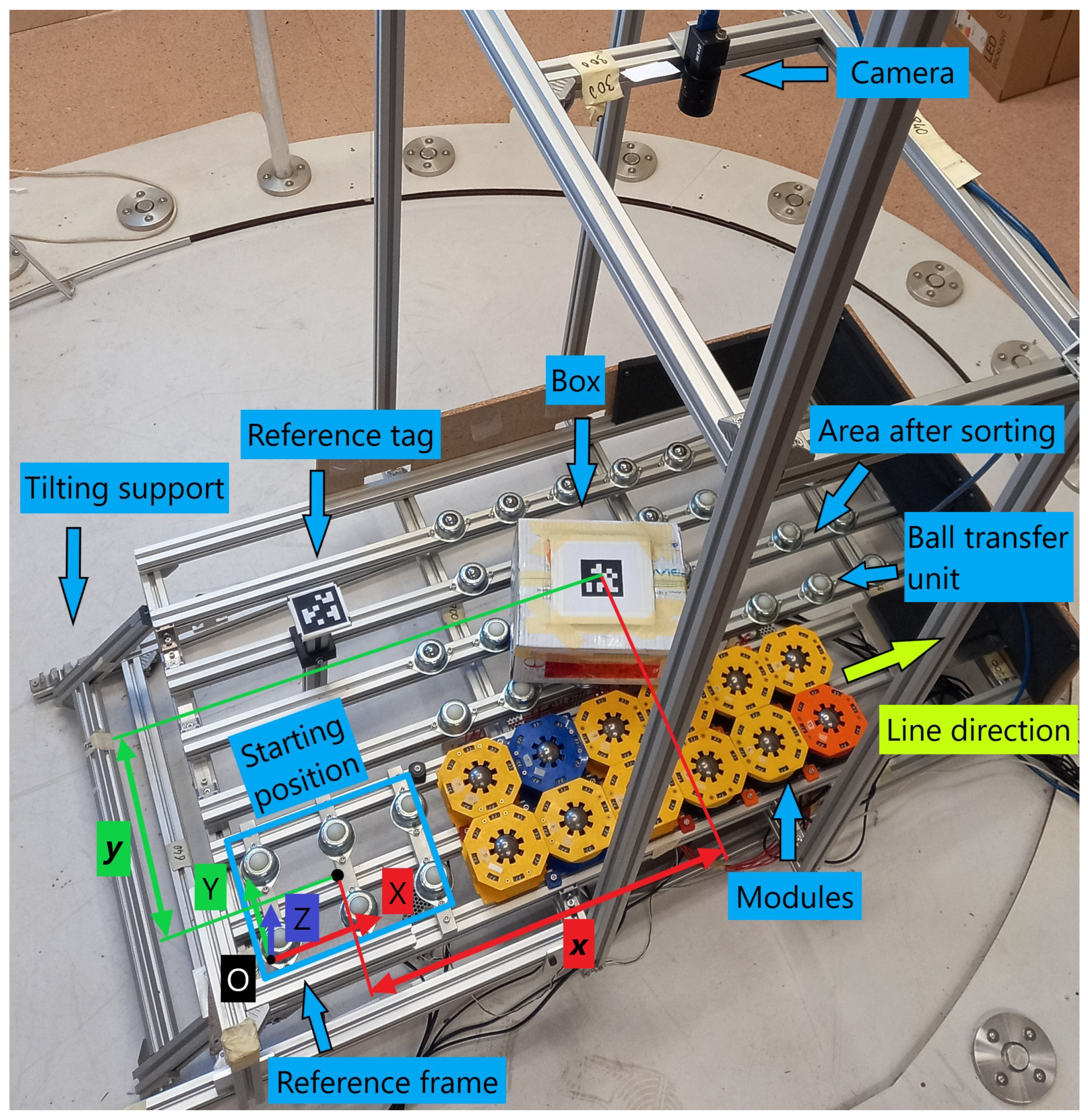

2. Materials

2.1. Physical Overview

2.2. Software Overview

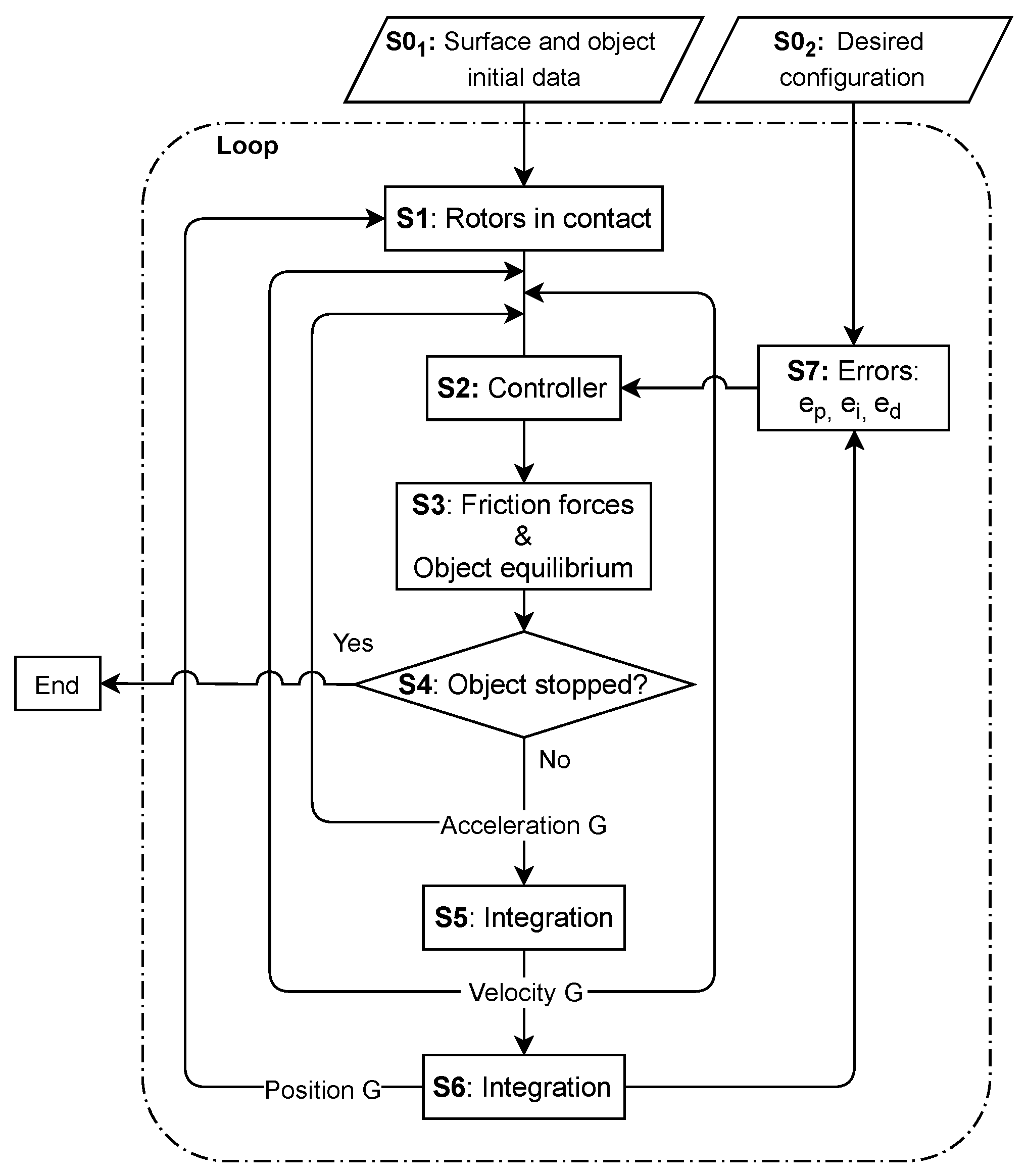

3. Control Method

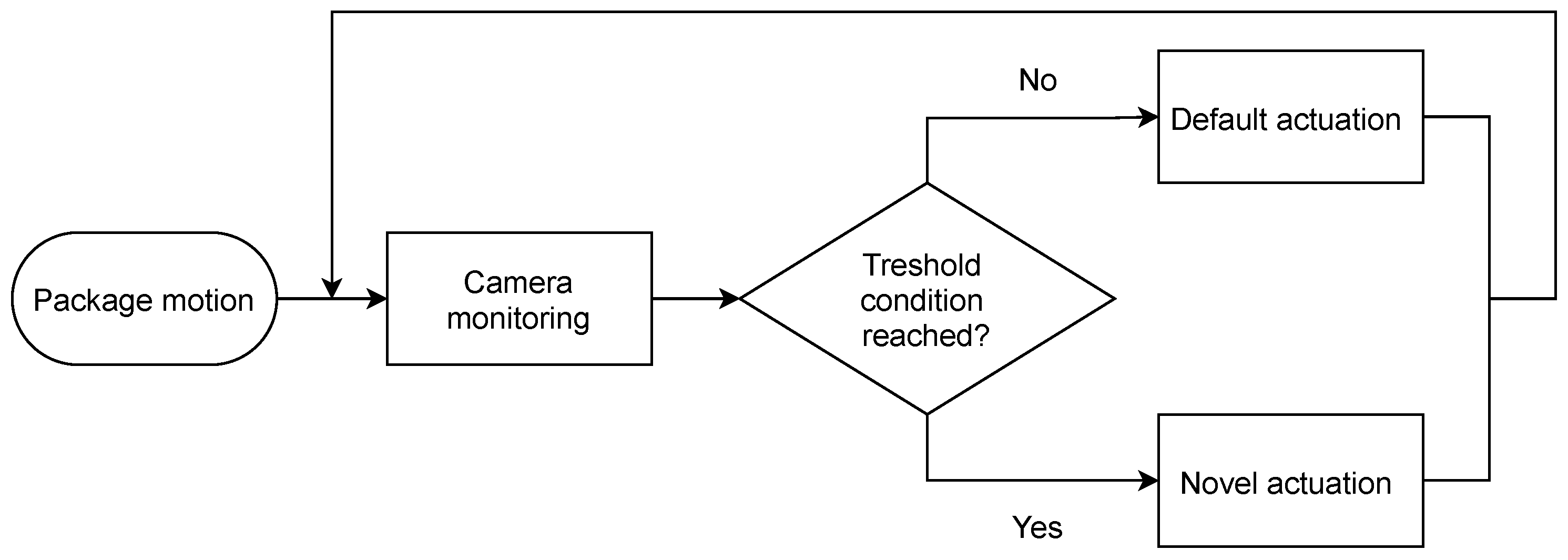

3.1. Threshold-Based Control

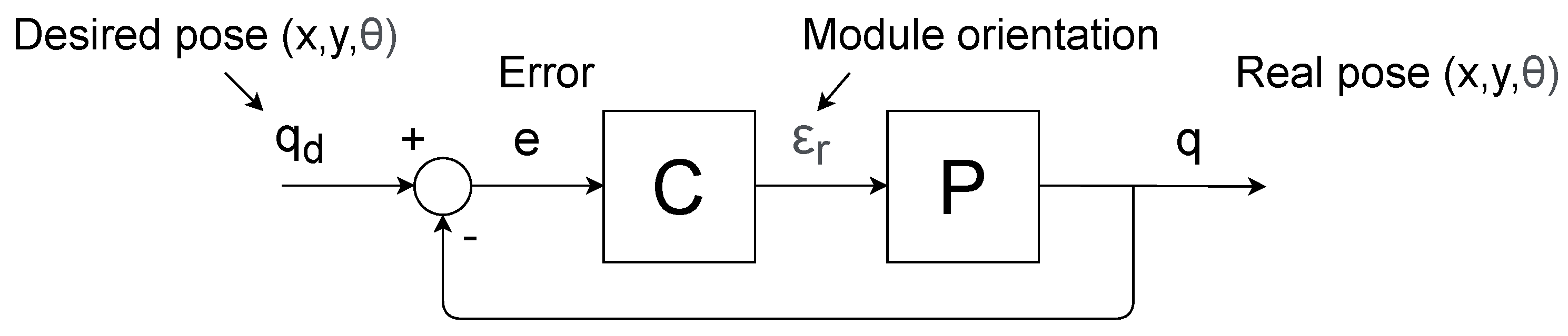

3.2. PID Control

4. Results

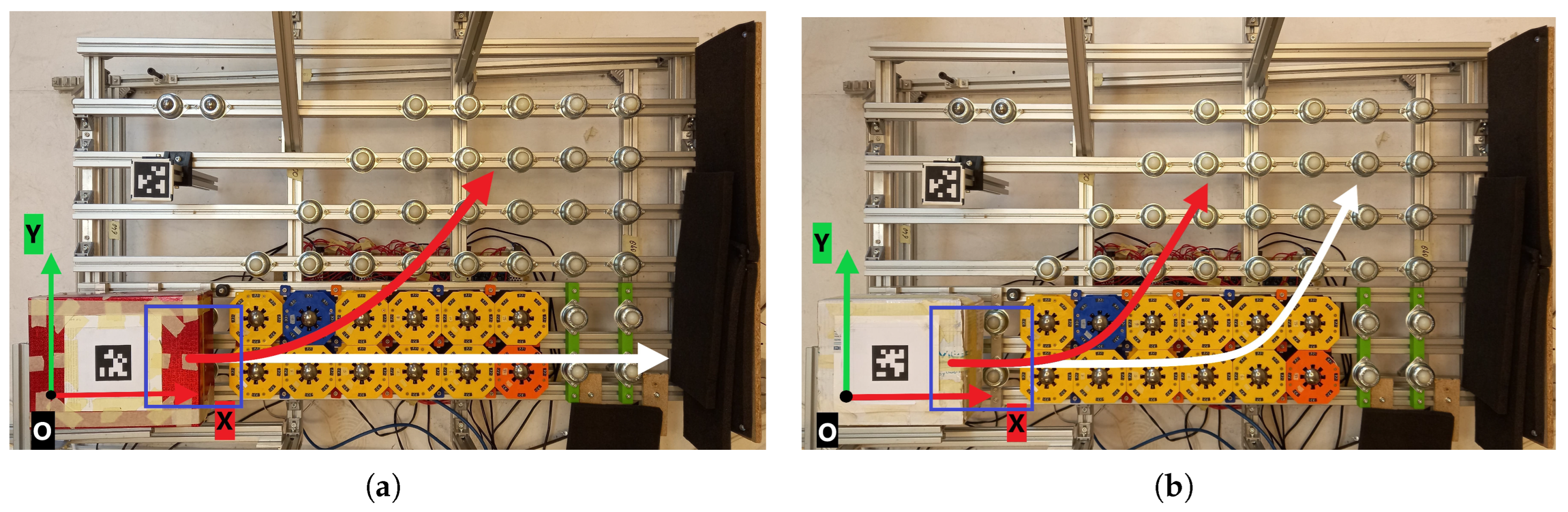

4.1. Threshold-Based—Experimental Results

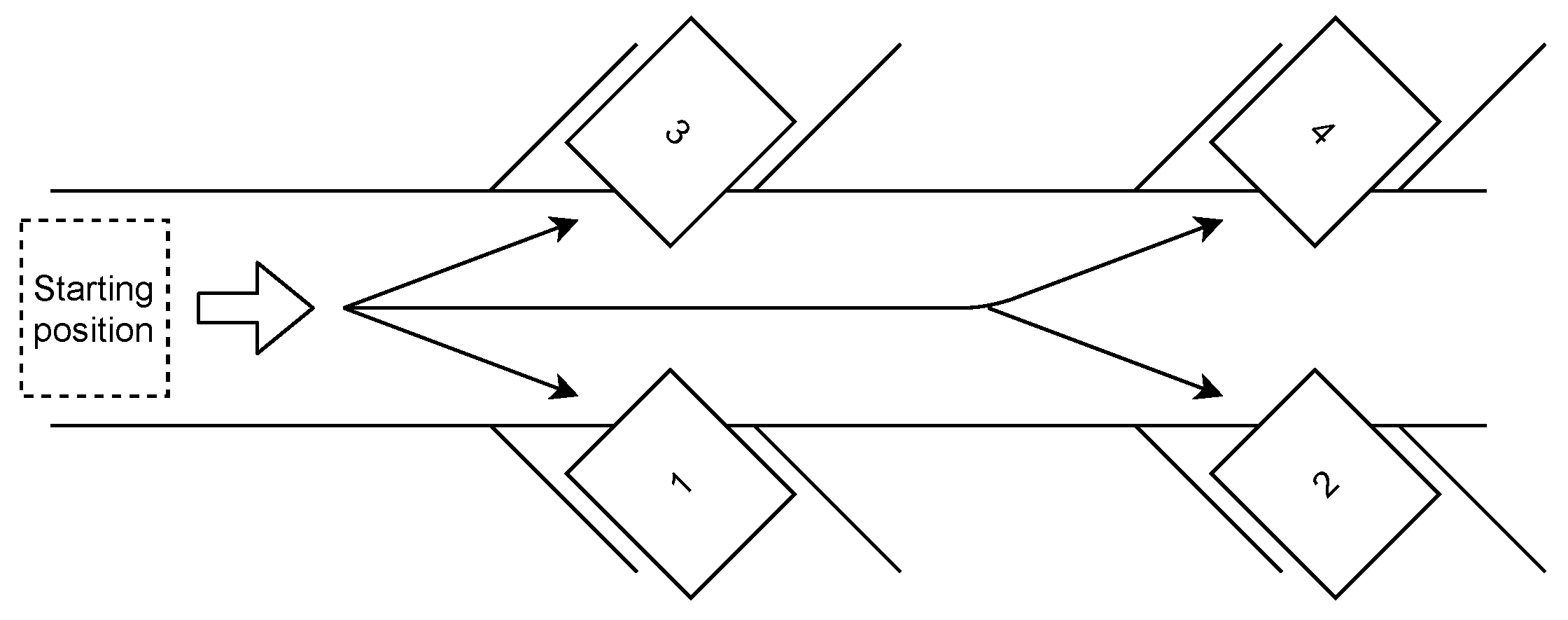

4.1.1. Sorting Results

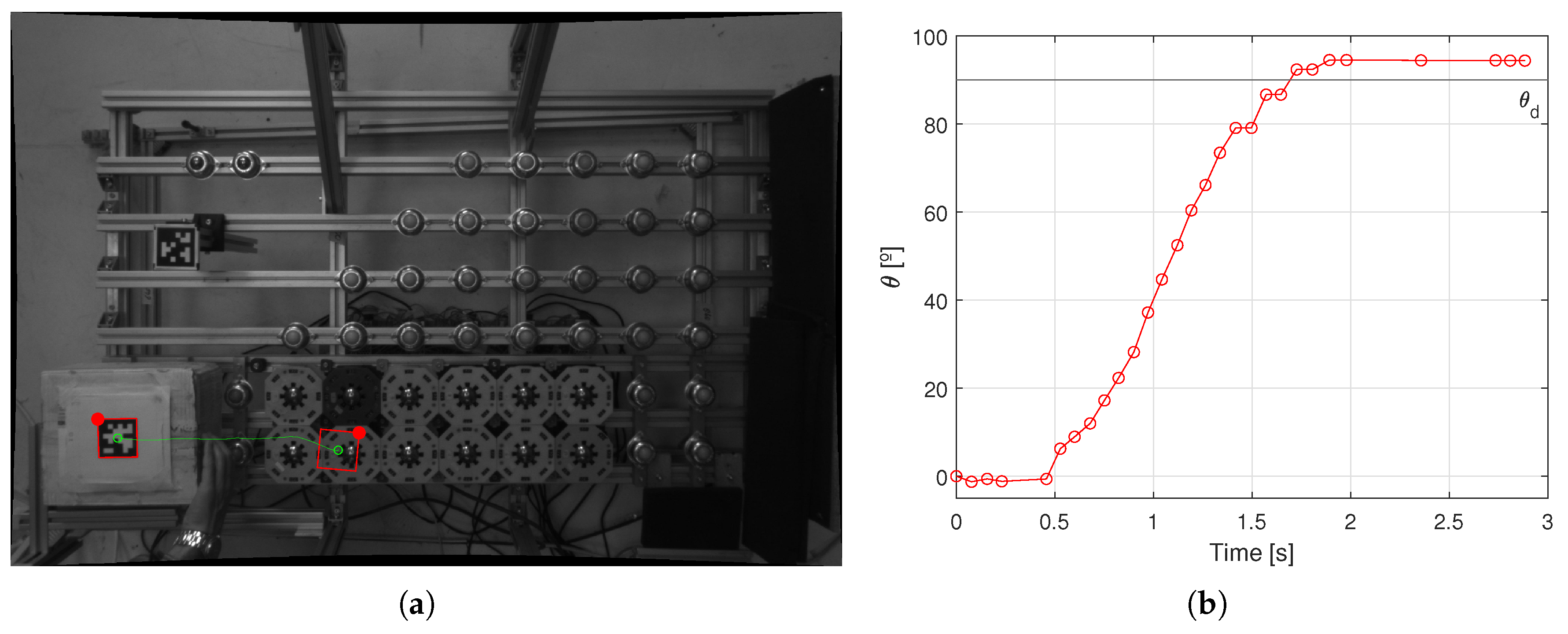

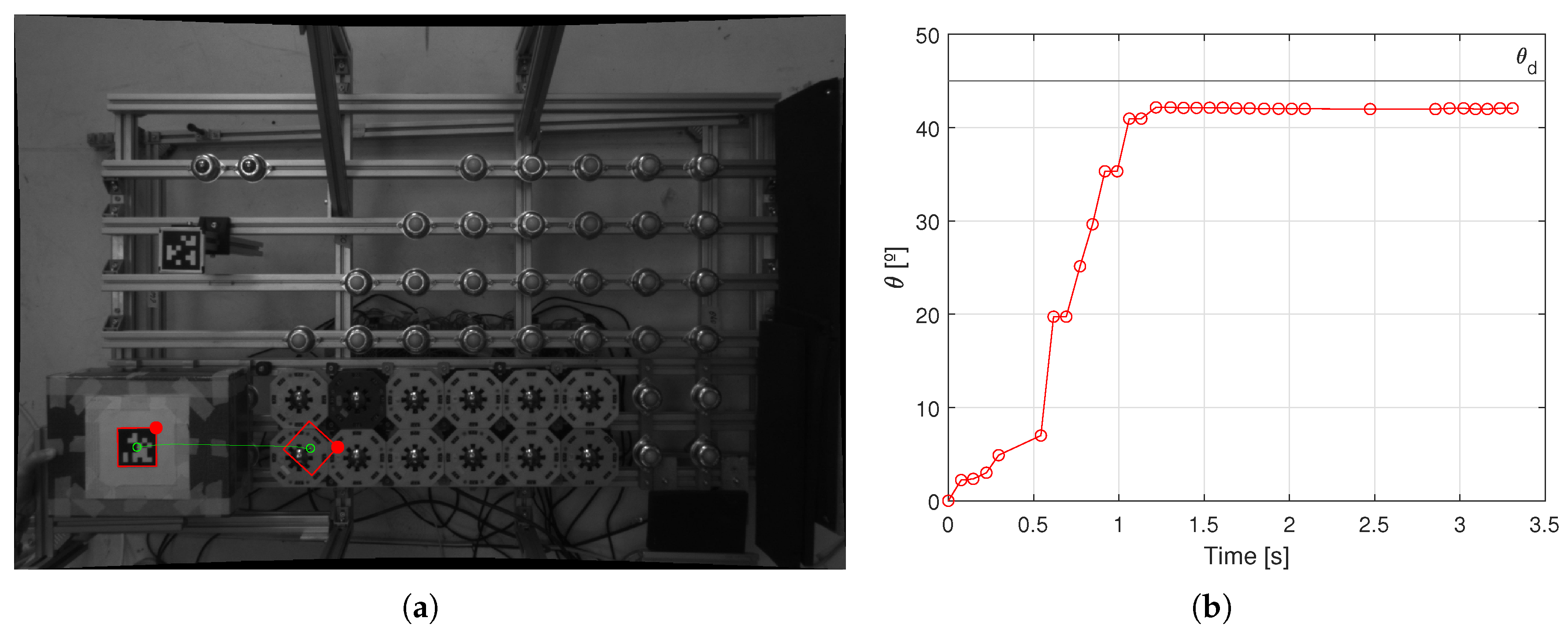

4.1.2. Orientation Results

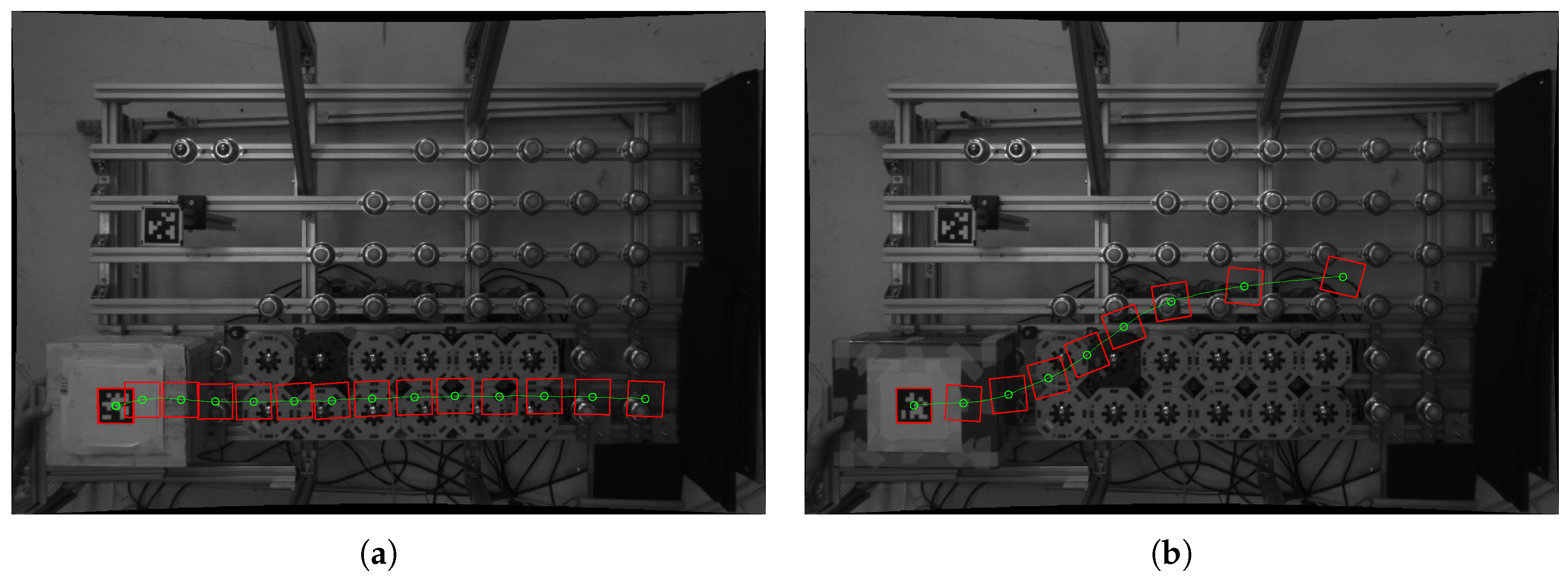

4.2. PID—Simulated Results

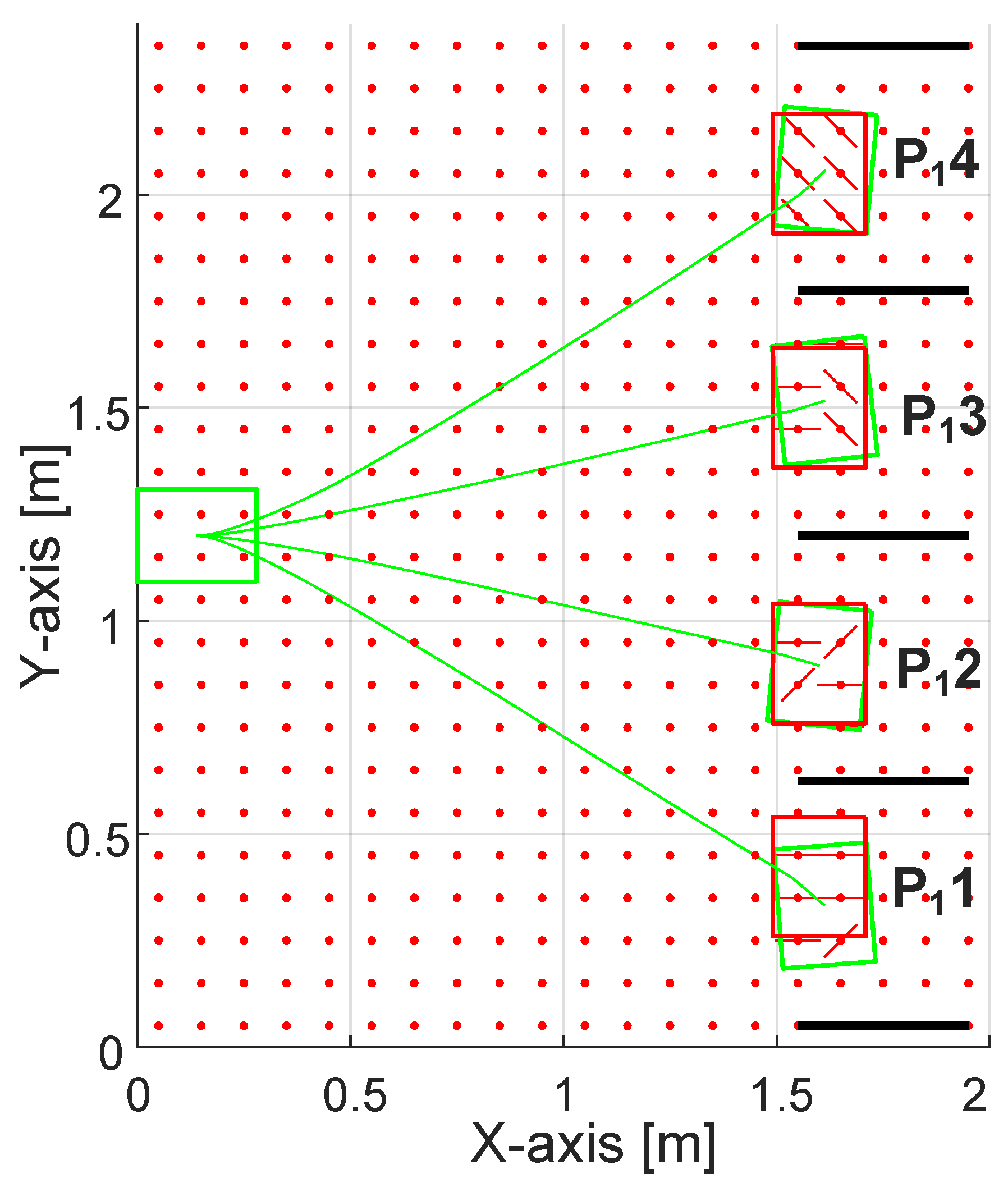

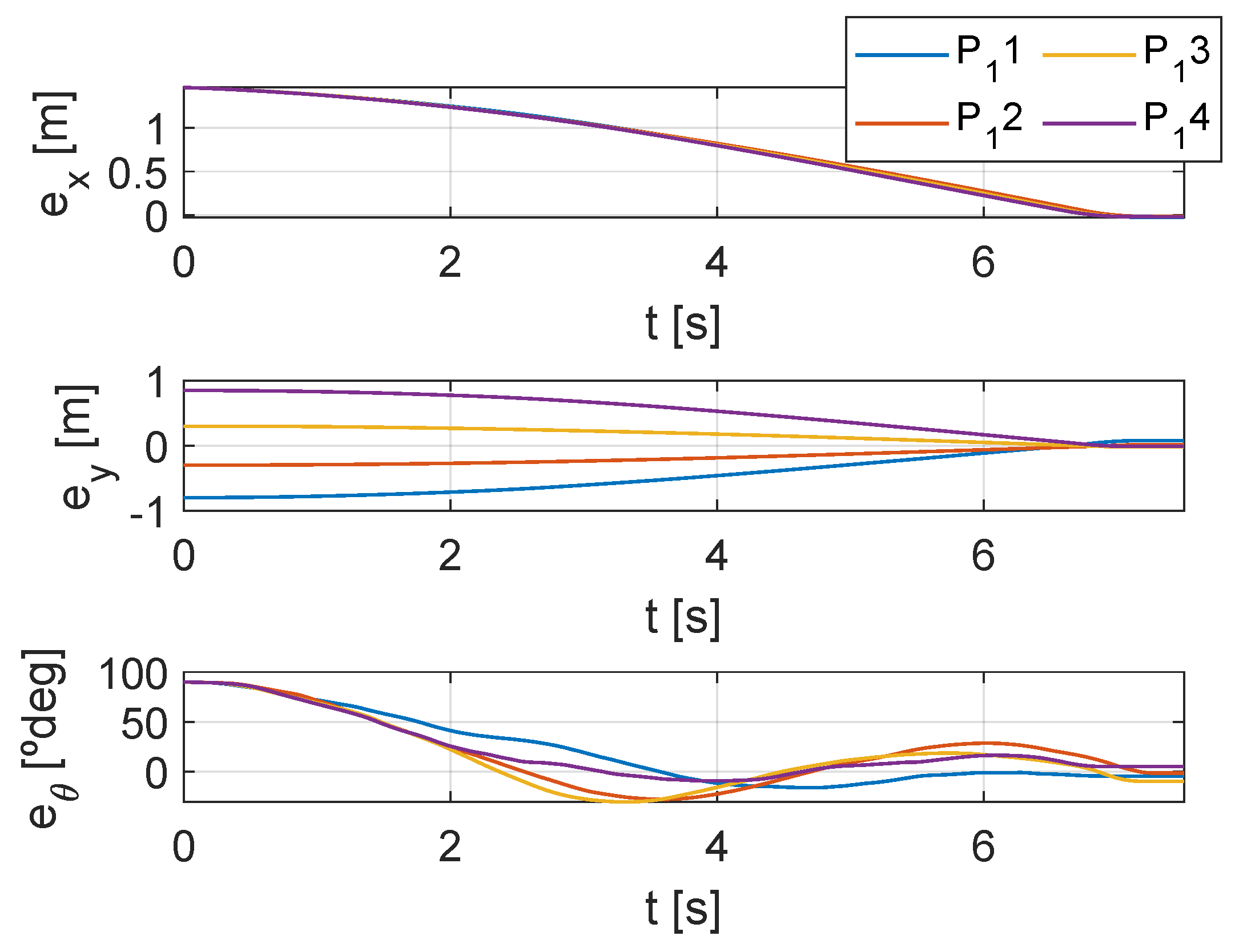

Results PATH 1

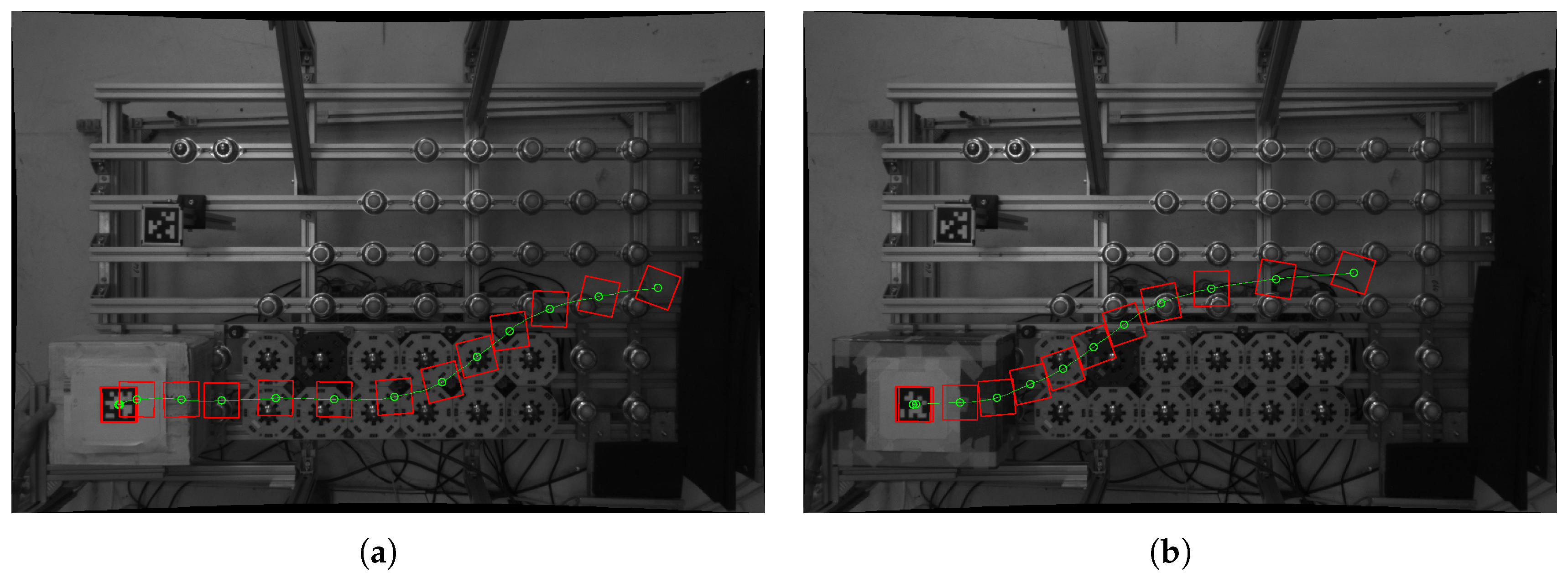

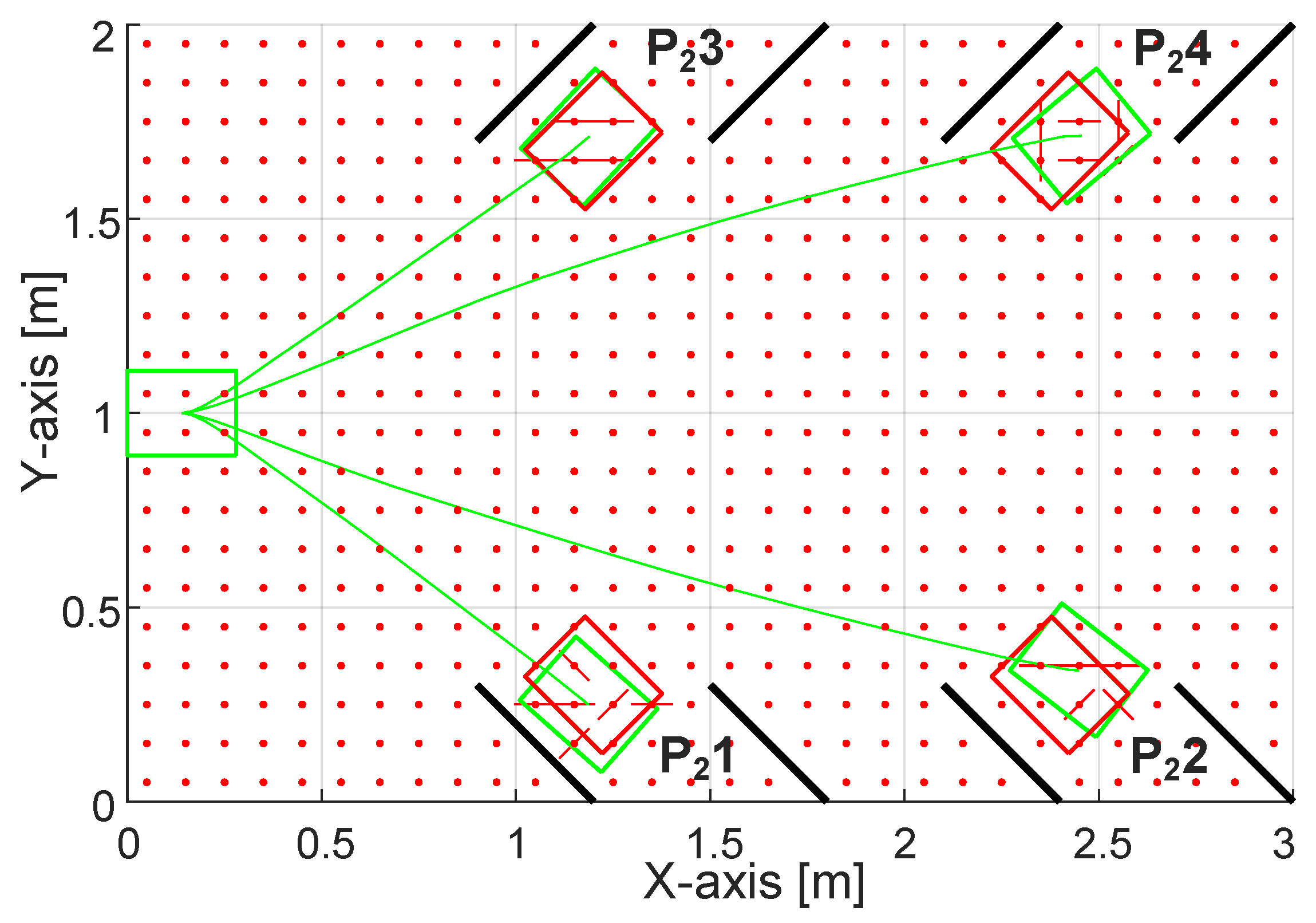

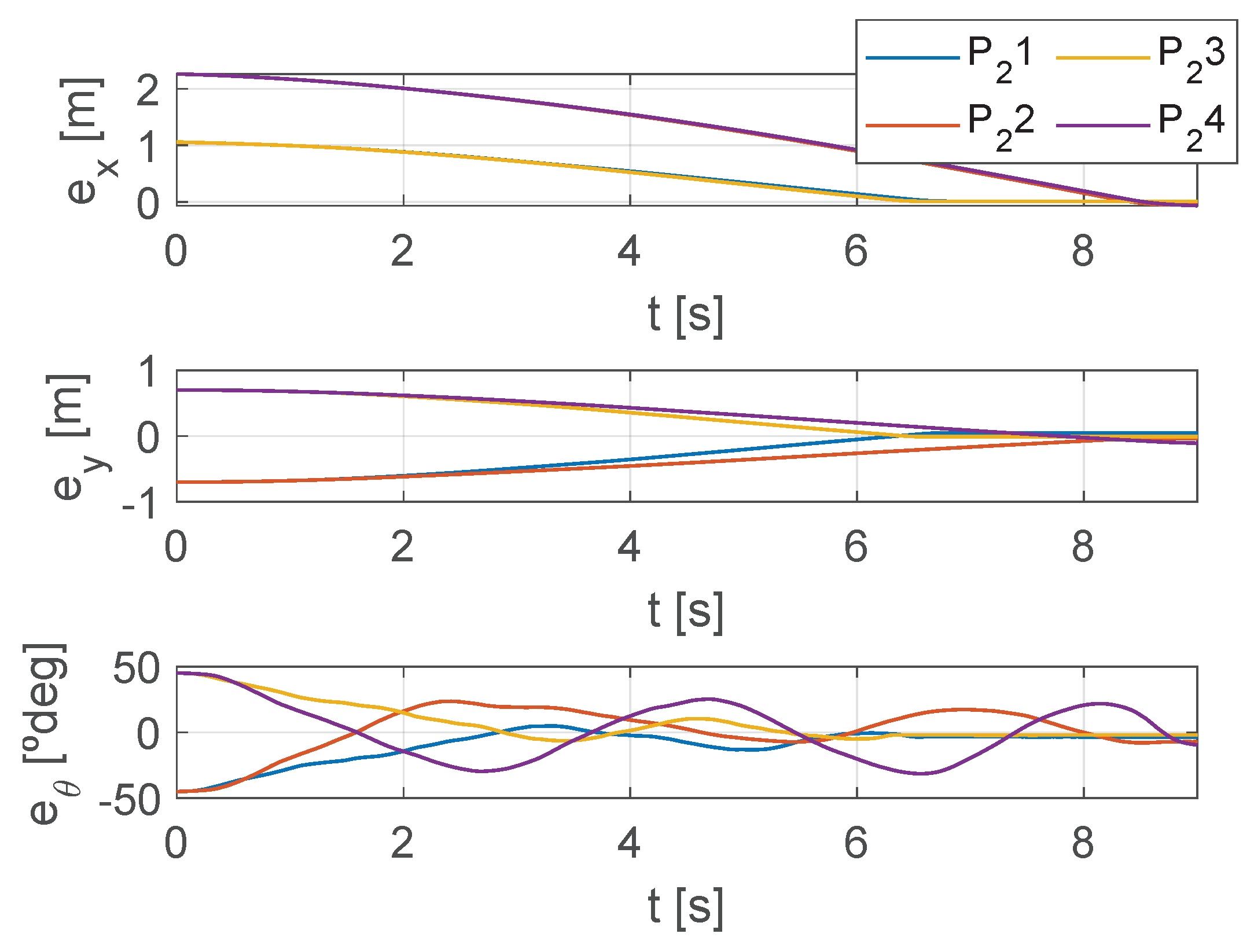

4.3. Results PATH 2

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Uriarte, C.; Asphandiar, A.; Thamer, H.; Thamer, H.; Benggolo, A.Y.; Freitag, M. Control strategies for small-scaled conveyor modules enabling highly flexible material flow systems. Procedia CIRP 2018, 79, 433–438. [Google Scholar] [CrossRef]

- Bianchi, E.; Fantoni, G.; Dueso, F.J.B.; Yagüe-Fabra, J.A. A novel underactuated smart surface for parts feeding and sorting. Int. J. Adv. Manuf. Technol. 2024, 135, 1221–1239. [Google Scholar] [CrossRef]

- Matignon, L.; Laurent, G.J.; Le Fort-Piat, N. Design of semi-decentralized control laws for distributed-air-jet micromanipulators by reinforcement learning. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Louis, MO, USA, 10–15 October 2009; pp. 3277–3283. [Google Scholar] [CrossRef]

- El Baz, D.; Boyer, V.; Bourgeois, J.; Dedu, E.; Boutoustous, K. Distributed part differentiation in a smart surface. Mechatronics 2012, 22, 522–530. [Google Scholar] [CrossRef]

- Boutoustous, K.; Laurent, G.J.; Dedu, E.; Matignon, L.; Bourgeois, J.; Le-Fort-Piat, N. Distributed control architecture for smart surfaces. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010. [Google Scholar] [CrossRef]

- Bohringer, K.F.; Donald, B.R.; MacDonald, N.C. Programmable force fields for distributed manipulation, with applications to MEMS actuator arrays and vibratory parts feeders. Int. J. Robot. Res. 1999, 18, 168–200. [Google Scholar] [CrossRef]

- Mobes, S.; Laurent, G.J.; Clevy, C.; Fort-Piat, N.L.; Piranda, B.; Bourgeois, J. Toward a 2D Modular and Self-Reconfigurable Robot for Conveying Microparts. In Proceedings of the 2012 Second Workshop on Design, Control and Software Implementation for Distributed MEMS, Besancon, France, 2–3 April 2012; pp. 7–13. [Google Scholar] [CrossRef]

- Skima, H.; Varnier, C.; Dedu, E.; Medjaher, K.; Bourgeois, J. Post-prognostics decision making in distributed MEMS-based systems. J. Intell. Manuf. 2019, 30, 1125–1136. [Google Scholar] [CrossRef]

- Bedillion, M.; Messner, W. Control for actuator arrays. Int. J. Robot. Res. 2009, 28, 868–882. [Google Scholar] [CrossRef]

- Murphey, T.D.; Burdick, J.W. Feedback control methods for distributed manipulation systems that involve mechanical contacts. Int. J. Robot. Res. 2004, 23, 763–781. [Google Scholar] [CrossRef]

- Keek, J.S.; Loh, S.L.; Chong, S.H. Design and Control System Setup of an E-Pattern OmniwheeledCellular Conveyor. Machines 2021, 9, 43. [Google Scholar] [CrossRef]

- Bianchi, E.; Brosed Dueso, F.J.; Yagüe-Fabra, J.A. In-Plane Material Handling: A Systematic Review. Appl. Sci. 2024, 14, 7302. [Google Scholar] [CrossRef]

- Krühn, T.; Falkenberg, S.; Overmeyer, L. Decentralized control for small-scaled conveyor modules with cellular automata. In Proceedings of the 2010 IEEE International Conference on Automation and Logistics, Hong Kong, China, 16–20 August 2010; pp. 237–242. [Google Scholar] [CrossRef]

- Bianchi, E.; Jorg, O.J.; Fantoni, G.; Brosed Dueso, F.J.; Yagüe-Fabra, J.A. Study and Simulation of an Under-Actuated Smart Surface for Material Flow Handling. Appl. Sci. 2023, 13, 1937. [Google Scholar] [CrossRef]

- Luntz, J.E.; Messner, W.; Choset, H. Distributed Manipulation Using Discrete Actuator Arrays. Int. J. Robot. Res. 2001, 20, 553–583. [Google Scholar] [CrossRef]

- Lynch, K.M.; Murphey, T.D. Control of nonprehensile manipulation. In Control Problems in Robotics; Springer: Berlin/Heidelberg, Germany, 2003; pp. 39–57. [Google Scholar]

- Elahidoost, A.; Keshmiri, M. Final position and trajectory control of an object on a distributed manipulation system. In Proceedings of the 2009 6th International Symposium on Mechatronics and its Applications, Sharjah, United Arab Emirates, 23–26 March 2009; pp. 1–6. [Google Scholar] [CrossRef]

- Bedillion, M.; Messner, W. Trajectory Tracking Control for Actuator Arrays. IEEE Trans. Control Syst. Technol. 2013, 21, 2341–2349. [Google Scholar] [CrossRef]

- Bianchi, E.; Jorg, O.J.; Fantoni, G.; Brosed Dueso, F.J.; Yagüe-Fabra, J.A. Design and development of a not actively driven modular device for parts feeding and sorting. Mech. Based Des. Struct. Mach. 2024, 52, 10124–10147. [Google Scholar] [CrossRef]

- Spindler, M.; Aicher, T.; Schütz, D.; Vogel-Heuser, B.; Günthner, W.A. Modularized control algorithm for automated material handling systems. In Proceedings of the 2016 IEEE 19th International Conference on Intelligent Transportation Systems (ITSC), Rio de Janeiro, Brazil, 1–4 November 2016; pp. 2644–2650. [Google Scholar] [CrossRef]

- Olson, E. AprilTag: A robust and flexible visual fiducial system. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 3400–3407. [Google Scholar] [CrossRef]

- Bianchi, E.; Yagüe Fabra, J.A.; Brosed Dueso, F.J. Design and Development of a Novel Under-Actuated Smart Surface for Material Flow Handling. Ph.D. Thesis, Universidad de Zaragoza, Zaragoza, Spain, 7 November 2024. [Google Scholar]

- Visioli, A. Practical PID Control; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- MATLAB Documentation Set, Version 2022b; The MathWorks: Natick, MA, USA, 2022.

- Euzébio, T.A.M.; Silva, M.T.D.; Yamashita, A.S. Decentralized PID Controller Tuning Based on Nonlinear Optimization to Minimize the Disturbance Effects in Coupled Loops. IEEE Access 2021, 9, 156857–156867. [Google Scholar] [CrossRef]

- Torga, D.S.; da Silva, M.T.; Reis, L.A.; Euzébio, T.A. Simultaneous tuning of cascade controllers based on nonlinear optimization. Trans. Inst. Meas. Control 2022, 44, 3118–3131. [Google Scholar] [CrossRef]

- Wai, R.J.; Lee, J.D.; Chuang, K.L. Real-Time PID Control Strategy for Maglev Transportation System via Particle Swarm Optimization. IEEE Trans. Ind. Electron. 2011, 58, 629–646. [Google Scholar] [CrossRef]

| tm1 [s] | tm2 [s] | tm3 [s] | tm4 [s] | |||||

|---|---|---|---|---|---|---|---|---|

| Box A | ||||||||

| Box B | ||||||||

| tm1 [s] | tm2 [s] | tm3 [s] | tm4 [s] | |||||

|---|---|---|---|---|---|---|---|---|

| Box A | ||||||||

| Box B | ||||||||

| [s] | [s] | [s] | |

|---|---|---|---|

| [s] | [s] | [s] | |

|---|---|---|---|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bianchi, E.; Brosed Dueso, F.J.; Yagüe-Fabra, J.A. Closed-Loop Control Strategies for a Modular Under-Actuated Smart Surface: From Threshold-Based Logic to Decentralized PID Regulation. Appl. Sci. 2025, 15, 7628. https://doi.org/10.3390/app15147628

Bianchi E, Brosed Dueso FJ, Yagüe-Fabra JA. Closed-Loop Control Strategies for a Modular Under-Actuated Smart Surface: From Threshold-Based Logic to Decentralized PID Regulation. Applied Sciences. 2025; 15(14):7628. https://doi.org/10.3390/app15147628

Chicago/Turabian StyleBianchi, Edoardo, Francisco Javier Brosed Dueso, and José A. Yagüe-Fabra. 2025. "Closed-Loop Control Strategies for a Modular Under-Actuated Smart Surface: From Threshold-Based Logic to Decentralized PID Regulation" Applied Sciences 15, no. 14: 7628. https://doi.org/10.3390/app15147628

APA StyleBianchi, E., Brosed Dueso, F. J., & Yagüe-Fabra, J. A. (2025). Closed-Loop Control Strategies for a Modular Under-Actuated Smart Surface: From Threshold-Based Logic to Decentralized PID Regulation. Applied Sciences, 15(14), 7628. https://doi.org/10.3390/app15147628