1. Introduction

Railway infrastructure is subject to inevitable natural wear and structural deterioration owing to long-term exposure to train loads. This degradation in performance, along with the frequent occurrence of defects, poses a direct threat to transportation safety. Timely detection and remediation of such defects are critical to ensuring the smooth and safe operation of trains. Track maintenance operations are inherently multidisciplinary, often requiring close coordination among various departments, including mechanical and electrical systems. These operations are highly susceptible to multiple external factors, including meteorological conditions and geological environments [

1] which significantly complicate safety risk management. Moreover, characteristics such as technical complexity, limited construction windows, and high-intensity workloads further elevate the likelihood of rule violations and safety incidents [

2]. Given these challenges, systematically identifying and analyzing the risk factors associated with track maintenance operations is essential. Developing a comprehensive risk assessment model, one that incorporates spatiotemporal information to accurately determine the time and location of potential risks during individual maintenance activities, is important for improving the safety management capabilities of the industry.

In the field of risk assessment for railway track maintenance and construction, most mainstream studies primarily utilize the analytic hierarchy process (AHP) and the fuzzy comprehensive evaluation (FCE) methods. Representative works include the following: Li [

3] systematically identified the risk factors involved in turnout replacement operations and developed a risk assessment model based on the fuzzy AHP. However, this study did not account for the specific spatiotemporal occurrence of risks, resulting in limited accuracy in risk localization. Jiang [

4] established a construction safety risk evaluation system for railway engineering mechanical sections, focusing on the operational characteristics of large-scale track maintenance machinery and applying AHP to assess the state of construction safety management. Nevertheless, this study also lacked refinement in the spatiotemporal positioning of risks. Zhang [

5] identified risk factors associated with construction and signal coordination maintenance operations on conventional-speed railways using an expert survey method and applied FCE to assess operational risks. However, this study did not clarify the specific timing or spatial coordinates of risk occurrences. Song [

6] developed a risk assessment system for large-scale railway marshaling station construction projects and validated it through a case study on a project along the Shanghai–Kunming Line. Nonetheless, the spatial analysis was limited to the overall project level, lacking precise localization of risk occurrence, and the temporal dimension was not addressed. Han [

7] identified influencing factors for operations involving large-scale railway track maintenance machinery through a questionnaire survey. The study evaluated a 20 d intensive maintenance period from Chawu to Pinggu on the Datong–Qinhuangdao Line, covering various operations such as turnout replacement, track tamping, and track grinding. However, the study’s consideration of the spatiotemporal dimension was relatively rough, failing to accurately identify the specific line mileage and time of risk occurrences. As a result, it could not clearly distinguish the risk characteristics of different operation types, limiting its effectiveness in supporting a refined evaluation of individual maintenance activities.

From a methodological perspective, researchers in other fields commonly adopt various weighting methods, such as the fuzzy AHP [

8], G1 method [

9], and entropy weight method (EWM) [

10], to achieve an optimized integration of subjective and objective weights. For example, Peng and Zhang [

10] used AHP and EWM to calculate the subjective and objective weights of risk indices. They then applied a game theory-based combined weighting approach and used index-weight weighting to assess urban disaster risks. Sun et al. [

11] used FAHP and EWM to calculate subjective and objective weights, adopted the minimum standard deviation method to determine optimal combination coefficients, and performed an urban flood risk assessment using the resulting integrated weights. Liu et al. [

12] proposed a comprehensive weighting algorithm that integrates AHP, the maximum absolute weighted residual method, and the maximum entropy method to evaluate risks associated with three typical signaling devices in railway systems. Song et al. [

13] used AHP to calculate subjective weights without incorporating objective weighting. Guo et al. [

14] used AHP, EWM, and the game theory combined weighting method (GTCWM) to calculate subjective, objective, and combined weights. Both studies [

13,

14] recognized the importance of accounting for the prominent influence of high-risk indices. However, when using AHP for subjective weighting, a consistency test is required, which adds complexity to the calculation process. Despite these limitations, the methodological innovations in these studies, particularly in weight optimization and the treatment of high-risk factors, offer valuable references for developing risk assessment models tailored to railway track maintenance operations.

Current research on risk assessment for railway track maintenance operations faces three major challenges: (1) insufficient spatiotemporal precision, which makes it difficult to accurately identify the spatial location and temporal point of risk occurrences, thereby reducing the effectiveness and timeliness of early warning systems; (2) limited scenario coverage in evaluation frameworks—most existing studies focus on a single type of maintenance operation—result in poor generalizability across diverse operational contexts; and (3) inadequate assessment methodologies: conventional AHP approaches rely heavily on subjective judgment and require complex consistency checks, while FCE methods using linear weighting often underestimate the influence of high-risk factors.

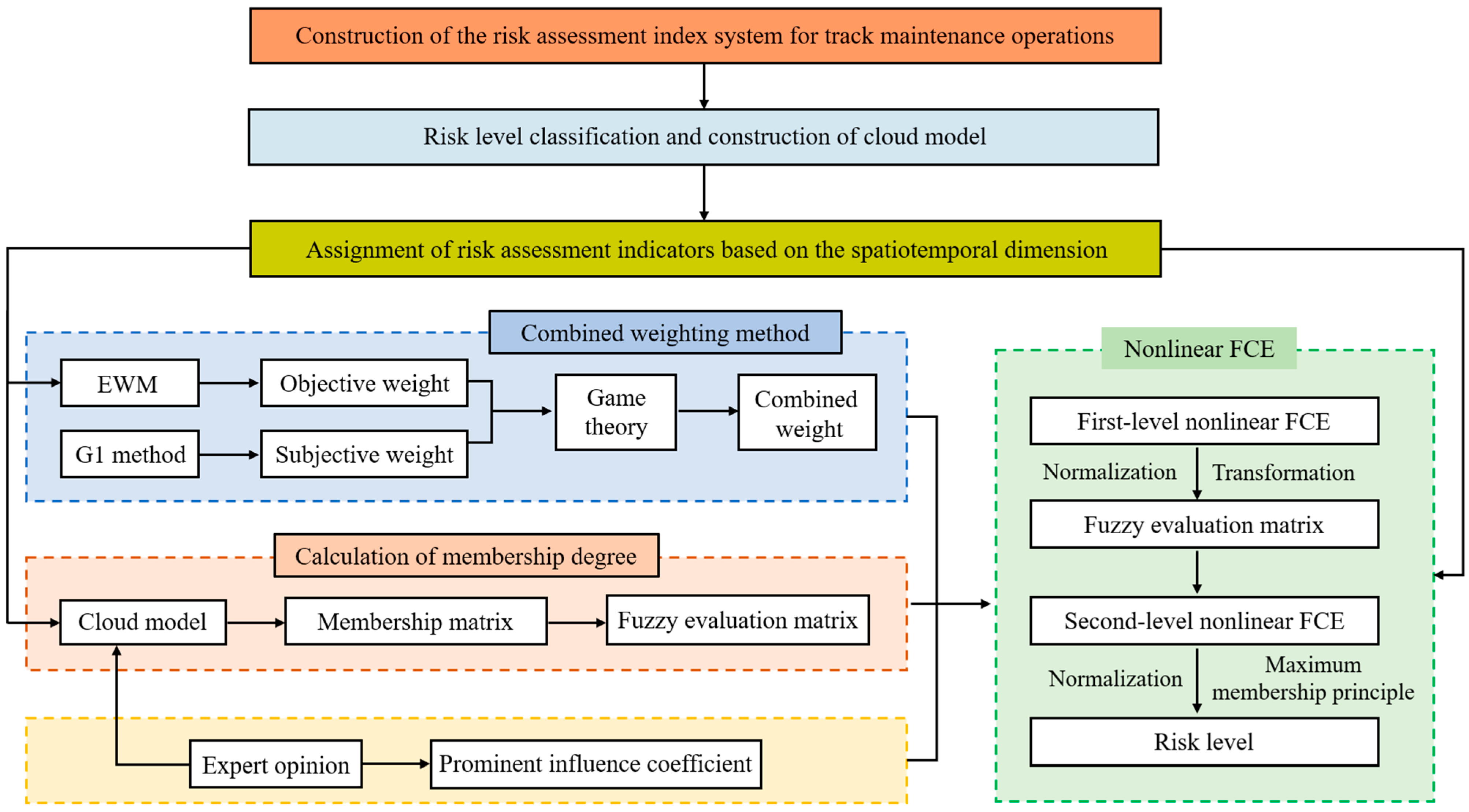

To address these challenges, this study proposes improvements in three key areas: (1) integration of spatiotemporal information—by embedding spatiotemporal data into the assessment process, a refined risk assessment model is developed that enables precise identification of both the location and timing of risk occurrences; (2) development of a cross-scenario risk index system—a comprehensive index system is constructed to enhance the model’s applicability across various maintenance scenarios, improving its versatility; and (3) implementation of a nonlinear FCE model with integrated weighting—a nonlinear FCE approach is proposed that combines subjective and objective weighting methods. Specifically, the G1 method and EWM are used in conjunction with a nonlinear weighting operator to enhance the model’s sensitivity and accuracy in evaluating high-risk factors.

The structure of the remainder of this paper is as follows:

Section 2 presents the core methodologies and theoretical foundations underlying the research.

Section 3 details the construction process of the proposed risk assessment model for track maintenance operations.

Section 4 applies the model to a case study involving track maintenance operations on the Lanzhou–Xinjiang Railway to verify its practical effectiveness.

Section 5 discusses the model’s accuracy, advantages, and limitations and proposes corresponding countermeasures.

Section 6 provides a comprehensive summary of the research findings.

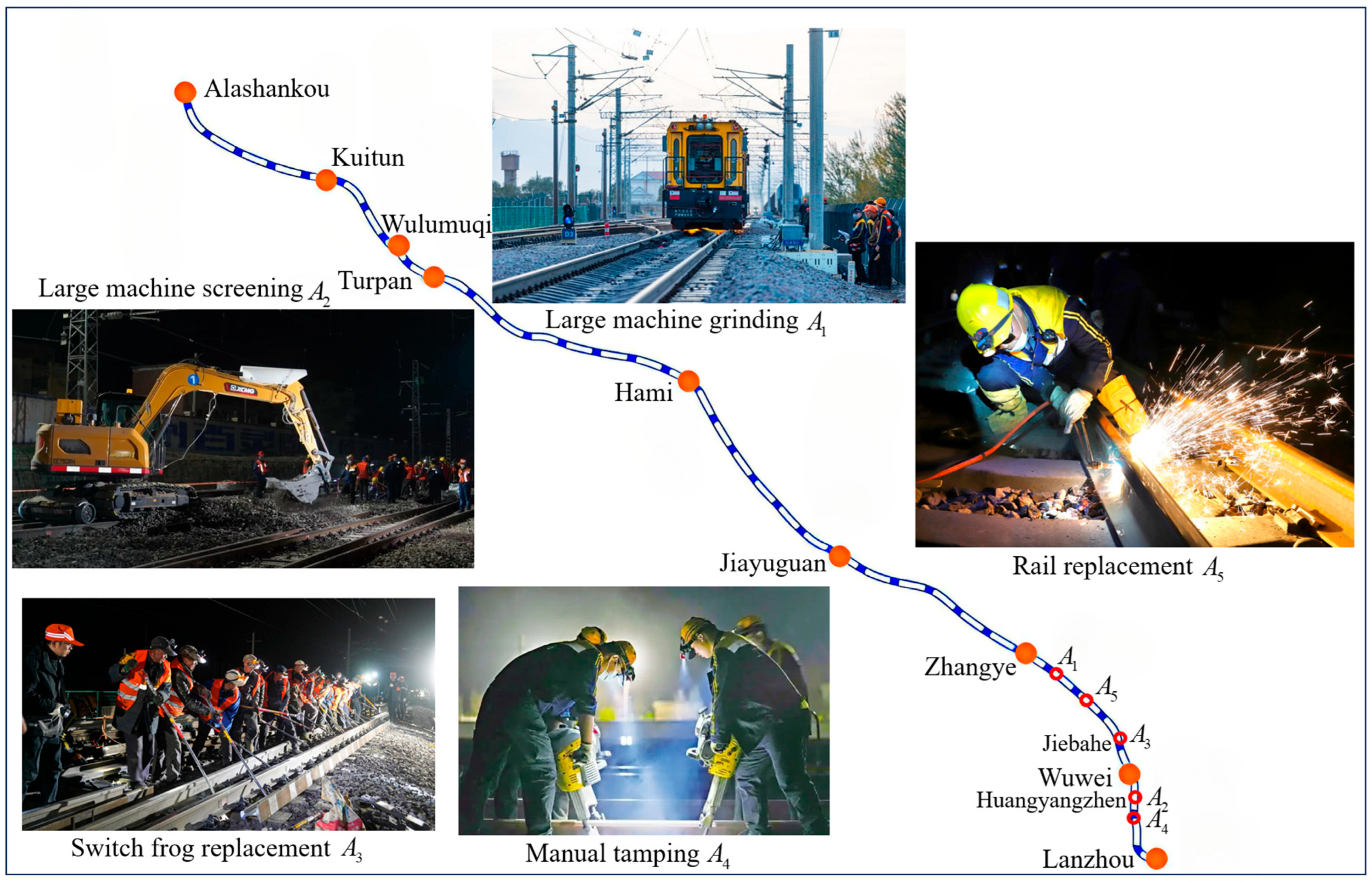

4. Case Study

In this section, an empirical analysis is conducted using track maintenance operations on the Lanzhou–Xinjiang Railway as the research object to evaluate the effectiveness of the proposed risk assessment model. The model integrates spatiotemporal dimensional information to enable precise risk assessment at the level of individual operations. Specifically, it can not only determine the exact timing of risk occurrence but also accurately identify the specific line mileage where the risk is located. This capability significantly enhances the granularity and precision of risk assessment and provides practical technical support for field applications, particularly in the formulation of targeted risk prevention and control strategies.

4.1. Case Description

The Lanzhou–Xinjiang Railway, with a total length of 2423 km, traverses complex and diverse terrains, including the Gobi Desert and alpine valleys. The line is subject to harsh climatic conditions year-round, such as extreme temperature fluctuations and frequent sandstorms. In addition, it plays a critical role in supporting heavy passenger and freight transportation in the region. The combination of long-term, high-frequency train operations and challenging environmental conditions significantly accelerates the wear and tear of track infrastructure. As a result, track maintenance operations along this corridor face exceptionally high safety risks, making it a representative and suitable case study for conducting research on risk assessment in railway track maintenance.

In railway track systems, rails are subjected to both vertical loads from train wheels and lateral horizontal forces. Under high-intensity cyclic loading, internal structural defects can develop, such as nuclear flaws, bolt hole cracks, transverse cracks at the rail base [

35], and rail weld defects [

36]. As these internal defects progress into deep cracks or fractures, they significantly increase the risk of train derailments. Turnouts represent particularly complex structures within the track system. Components such as the point rails and wing rails, especially near the frog gap, endure substantial impact forces from passing trains. These areas are highly prone to wear, deformation, and other structural defects [

37], making them common locations for rail failures. Additionally, under repeated train loading, ballast beds may exhibit various forms of abnormal deformation, including bed deformation, ballast contamination, ballast pulverization, ballast collapse, mud pumping, and ballast hardening [

38]. To address these issues, maintenance activities such as rail grinding, rail replacement, frog replacement, large machine cleaning, and manual tamping are commonly performed. Accordingly, this study selected these types of maintenance operations as the focus of analysis. Based on the track maintenance records from the Lanzhou–Xinjiang Railway, five maintenance operations were randomly selected as evaluation samples. Detailed information regarding these samples is shown in

Figure 4 and

Table 4.

Operation

is large machine grinding, primarily aimed at eliminating defects such as rail corrugation, fish-scale cracks, and rail head flow, thereby reducing vibration and noise during train operations. Operation

is large machine cleaning, which focuses on addressing track bed defects such as hardening and mud pumping, replenishing clean ballast, and restoring the elasticity of the track structure. Operation

involves frog replacement. Due to the presence of cracks in the switch rail, the damaged frog components must be replaced promptly to ensure the safe and normal operation of the turnout area. Operation

is manual tamping, intended to eliminate longitudinal level irregularities in the track. By tamping the track, smooth and stable train operation is maintained. Operation

is rail replacement, necessitated by serious rail defects such as contact fatigue fractures and shelling. The damaged rail must be replaced in a timely manner to eliminate potential safety hazards. The operation times and locations are detailed in

Table 4.

4.2. Weight Calculation

To ensure the professionalism and reliability of the evaluation results when determining subjective weights using the G1 method and scoring subjective risk factors, experts were invited from multiple channels, including universities, research institutions, and field operations. Ultimately, an evaluation team of nine experienced individuals was assembled, comprising scholars, technical specialists, and on-site experts. The team included two experts with senior professional titles from leading universities in the field of railway engineering, both of whom have extensive experience in track safety research. Additionally, three experts held deputy senior professional titles, specializing in the R&D of railway track maintenance technologies. The team also included four on-site technical experts with senior engineer titles, each with over 10 years of experience in track maintenance management and all of whom had actively participated in maintenance operations on the Lanzhou–Xinjiang Railway.

Using the five track maintenance operations listed in

Table 4 as examples, the expert team assessed the subjective risk factors by combining first-hand operational knowledge, professional experience, and relevant industry standards. The resulting expert scores and assigned values are listed in

Table 5.

Subjective weight determination: The subjective weights of the indices were calculated following the G1 method steps outlined in

Section 2.1. For example, to calculate the subjective weights of

, they were ranked based on their relative importance in influencing the risk of track maintenance operations, resulting in the following order

, i.e.,

. The quantified values of the relative importance between adjacent indices, obtained through expert assessment, were 1.3, 1.4, and 1.2, respectively. Based on these values, the weights were computed using Equations (1) and (2).

Table 6 presents the ranking and quantified degree of importance for the first-level indices of track maintenance operations as provided by the expert panel. Following the same procedure, the subjective weights of the second-level indices were also calculated using the G1 method, with the results shown in

Table 7.

- (1)

Determination of objective weight: Following the calculation steps of the EWM, the index values from

Table 5 were first normalized and converted into a judgment matrix using Equations (3)–(5). Based on this matrix, the objective weights of the second-level indices were calculated. The objective weights of the first-level indices were then derived accordingly. The results are summarized in

Table 7.

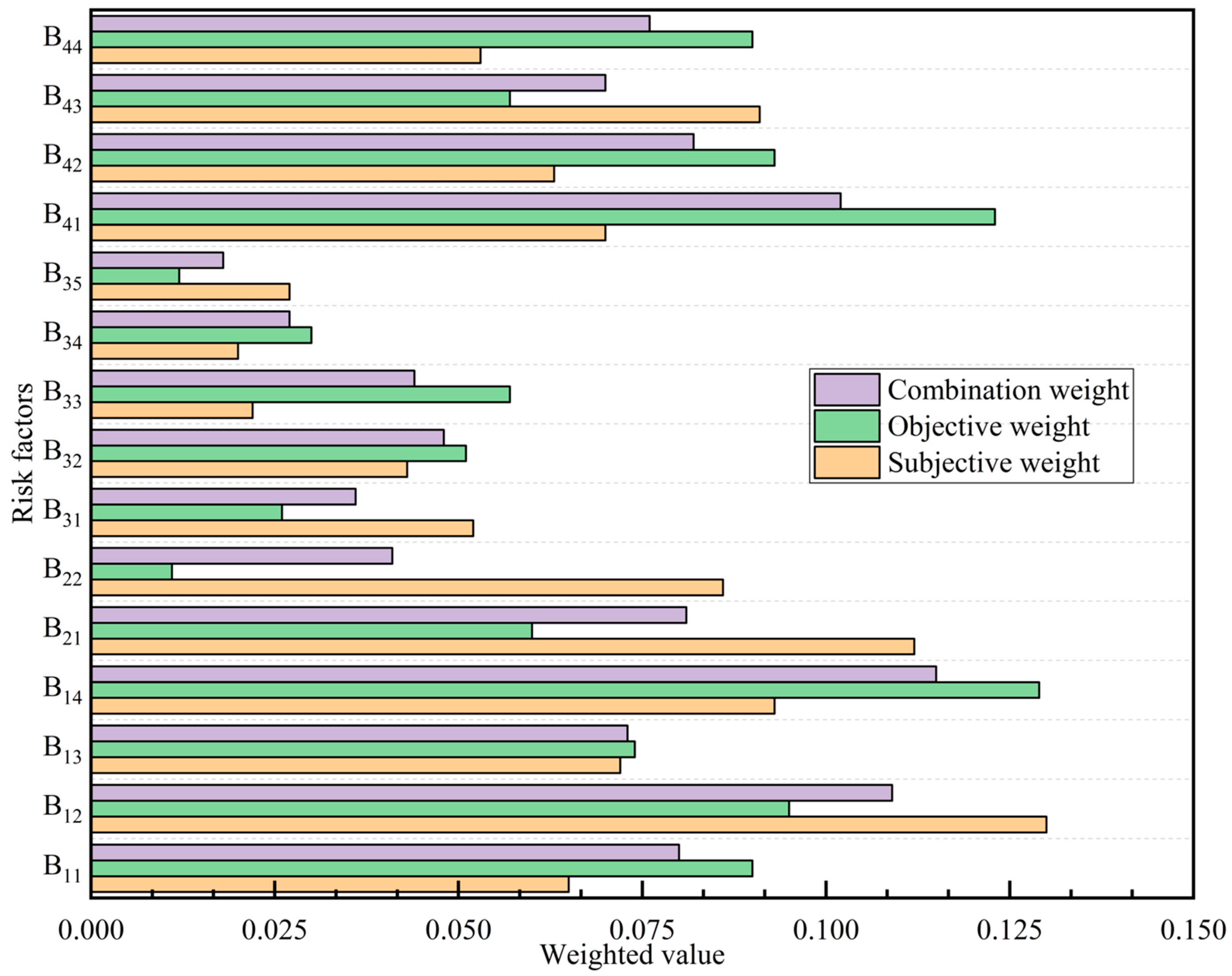

- (2)

Determination of combined weights: Using the steps outlined in the GTCWM, the combined weights were obtained using Equations (6)–(9), as listed in

Table 7. These combined weight values are also included in

Table 7. To visually compare the subjective, objective, and combined weights, a comparative chart is presented in

Figure 5.

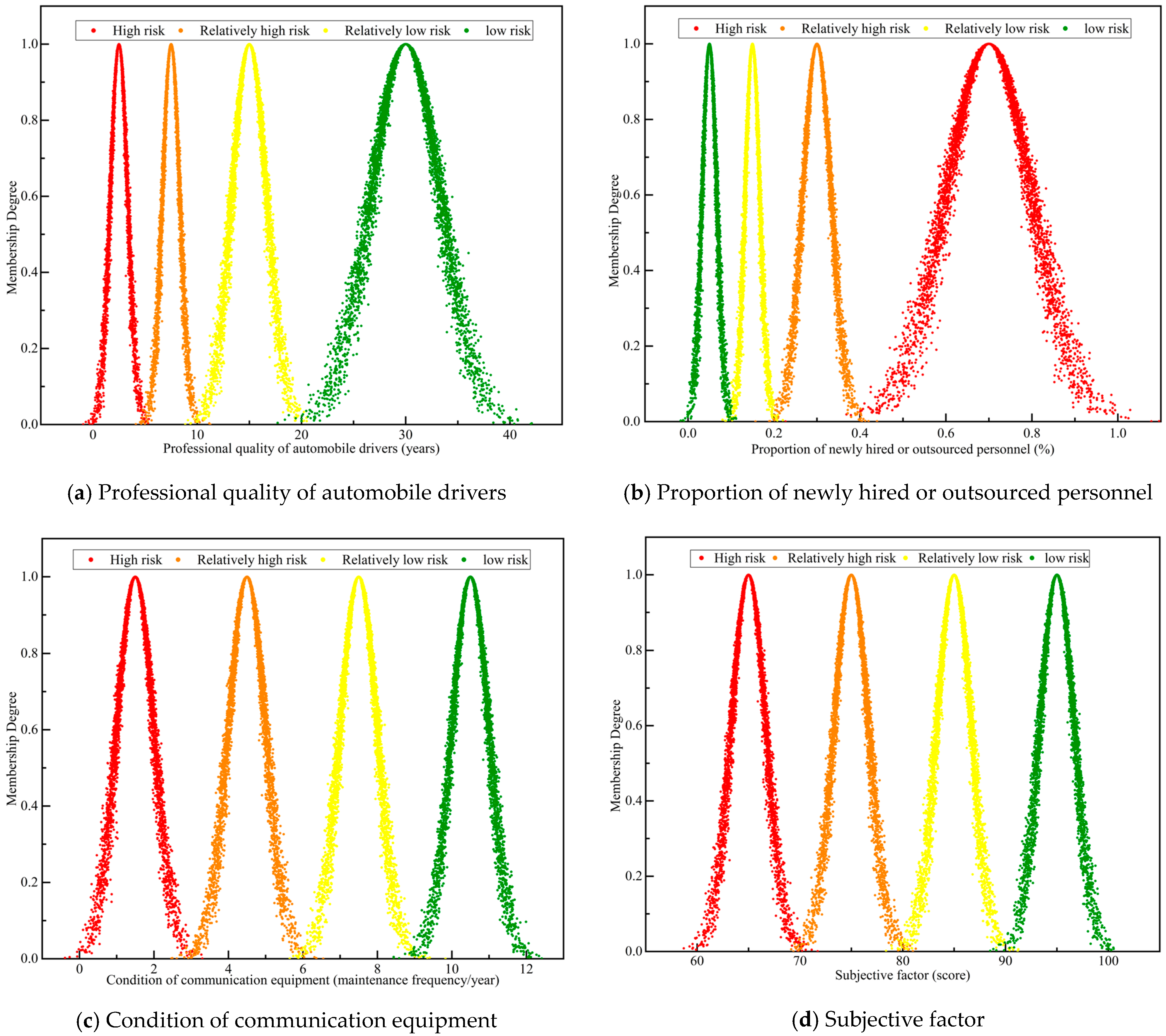

4.3. Membership Degree Calculation

To eliminate the influence of randomness in the final risk assessment values during the calculation of membership degrees using the cloud model, this study repeated the calculations 2000 times using Equation (11), based on the index values given in

Table 5. The average value of these iterations was then used to determine the membership degrees of each index within the cloud model, forming the membership degree matrix. Taking maintenance operation

as an example,

Table 8 shows the membership degree values for the 15 risk indices in relation to the cloud model. These values were subsequently converted into a fuzzy evaluation matrix using Equation (13), and the results are shown in

Table 9.

4.4. Nonlinear FCE

First, the prominent influence coefficients of the risk indices must be determined. According to the literature [

13,

14,

22], these coefficients are typically established based on expert judgment. In this study, the coefficients were derived from a combination of expert experience, the value standards outlined in

Table 2, and practical insights gained from track maintenance operations. Based on these inputs, the prominent influence coefficients for both first-level and second-level indices were determined, as shown in Equation (14).

Secondly, a first-level nonlinear FCE is conducted. Based on

Table 7, the combined weight vectors of the risk indices are

. The corresponding fuzzy evaluation matrices

are shown in

Table 9, and the prominent influence coefficient vectors

are as shown in Equation (14). Use Equation (12) to conduct a first-level nonlinear FCE. Taking maintenance operation

as an example, the first-level nonlinear FCE is applied to the second-level indexes

,

,

, and

. The calculation process is as shown in Equation (15). After obtaining

, normalization processing is required, and the risk evaluation result vector

of the human factor (

) in the maintenance operation

is obtained. Following the same procedure, the risk evaluation result vectors for the equipment factor (

), environmental factor (

), and management factor (

) are as shown in Equation (16).

Finally, a second-level nonlinear FCE is performed. Based on the previously obtained risk evaluation result vectors

(

) for the first-level indexes

,

,

, and

, these vectors are assembled into a matrix

, and the matrix

is transformed into a fuzzy evaluation matrix

by using Equation (13). According to

Table 7 and Equation (14), the combined weight vector

and the corresponding prominent influence coefficient vector

for the first-level indices are identified. The second-level nonlinear FCE is conducted using Equation (12), with the detailed calculation process shown in Equation (17):

Normalize

to obtain

, and this vector is the risk evaluation result vector of maintenance operation

. According to the principle of maximum membership degree, the risk level of maintenance operation

is relatively large risk (Level II). Similarly, the risk evaluation result vectors and risk levels of operations

are presented in

Table 10.

5. Discussion

5.1. Comparative Analysis

To verify the effectiveness of the proposed risk assessment model for track maintenance operations, both linear and nonlinear FCE were used to assess the risks of the operations

. A comparative analysis of the risk assessment results was then conducted. In the linear FCE method, all influence coefficients for the risk indices were uniformly set to 1. From the resulting risk levels, as presented in

Table 10, the risk levels of operations

are “General risk (III)”, and operation

is “Minor risk (IV)”. However, when the nonlinear FCE method was applied for risk assessment, the results for

,

, and

showed significant differences. This variation is attributed to the nonlinear FCE method’s consideration of the dominant influence of certain risk factors in determining overall risk. As a result, the risk levels of operations

,

, and

were higher than those assessed using the linear FCE method. Specifically, operations

and

were classified as “Relatively large risk (II)”, while operation

is “General Risk (III)”.

Operations and involve multi-department collaboration, complex pre-operation preparations, high technical difficulty, and intricate work procedures. However, in practice, challenges such as high proportion of outsourced personnel, insufficient safety education, and inadequate protective measures are commonly observed. The nonlinear FCE method accounts for the substantial influence of key risk indices, including the proportion of newly hired or outsourced personnel (), safety education and training (), and safety protection measures (). To enhance the accuracy of risk assessment, we revised the model by assigning higher prominent influence coefficients to these key indices. For example, the status values of risk factors for operation are at levels I, II, IV, and IV, respectively. When using linear FCE, the final status value for is Level IV, which significantly underestimates the risks stemming from inadequate safety education and protective measures. By contrast, by applying nonlinear FCE and incorporating the dominant effects of risk factors and , the status value of is adjusted to Level I. This adjustment allows the model to more accurately reflect the risk level of the operation.

For operation , although the overall status of most risk factors is favorable, there remains room for improvement in the proportion of newly hired or outsourced personnel () and in safety education and training (). Owing to the current situation, characterized by a high proportion of temporary workers and insufficient safety education prior to the operation, the nonlinear FCE method enhances the influence of these specific indices by introducing prominent influence coefficients. As a result, the risk level is adjusted from “minor risk (IV)” to “general risk (III)”, effectively addressing the tendency of the linear FCE to underestimate the impact of these critical factors owing to uniform weighting.

A comparison of the above risk assessment results shows that the nonlinear FCE method significantly improves the accuracy and reliability of risk assessments by accounting for the prominent impacts of key risk factors. Conventional FCE tend to dilute critical risk factors’ influence. In contrast, nonlinear FCE effectively captures their dominance in risk determination. This reduces potential safety hazard oversight and better aligns with practical risk management needs. Consequently, it provides a more robust and scientific basis for decision-making in track maintenance risk control.

Based on the risk assessment results and the actual conditions of each maintenance operation, targeted management measures were formulated as follows:

Management of new employees or outsourced personnel: Prior to operations, specialized job adaptation training is conducted, focusing on the equipment, operation types, processes, and environmental characteristics involved. Safety education is strengthened to ensure that outsourced personnel are fully aware of operational risks and safety requirements. Outsourced personnel are strictly prohibited from working alone or operating independently of the designated team. Designated supervisors are assigned to monitor the operation process in real time, ensuring compliance with safety protocols and maintaining overall operational safety.

Management of large-scale track maintenance machinery operations: Clear guidelines are established regarding train formations, designated sections for disassembly and coupling, and the assignment of responsible personnel. Prohibited operation zones are clearly marked, and both operational process and communication mechanism are standardized. When large-scale track maintenance machinery enters or exits a blocked section, enhanced lookout measures are required, and speed must be strictly controlled. Onboard personnel must promptly report train movements to enable on-site workers to avoid danger in a timely manner. During operations, safety regulations must be strictly enforced, including maintaining a minimum distance of 10 m between vehicles to prevent mechanical collisions and ensure operational safety.

5.2. Advantages and Limitations

In this study, spatiotemporal dimensional information is innovatively introduced into the risk assessment of track maintenance operations, enabling precise identification of the location and time of risk occurrences within individual maintenance activities. This facilitates the development of differentiated risk response strategies, thereby significantly enhancing the relevance and effectiveness of risk prevention and control measures. The constructed risk assessment index system transcends limitations related to specific operation types and is adaptable to a variety of track maintenance scenarios, including line maintenance and turnout inspections. To optimize the weighting of risk factors, the GTCWM was employed. This approach effectively integrates expert experience with objective data, addressing the limitations of purely subjective or objective weighting methods. To overcome the limitations of conventional linear weighted average methods, particularly their tendency to dilute the influence of high-risk factors, a nonlinear FCE method was introduced. By incorporating prominent influence coefficients, the evaluation process preserves the impact of critical risk factors, ensuring that the final risk assessment more accurately reflects actual risk levels. This enhances both the precision and reliability of the overall risk assessment.

To further improve the accuracy and reliability of the risk assessment results, future research can be optimized in the following three areas.

- (1)

Correlation analysis of risk factors: Develop a correlation analysis model to explore the coupling mechanism among various risk factors in greater depth. At the same time, expand the identification scope and continuously improve the evaluation index system.

- (2)

Intelligent data collection and quantification: Address the subjective limitations of expert scoring by developing an intelligent data acquisition system capable of dynamically and automatically capturing risk factor values. A scientific risk factor quantification model can be established by combining multi-source data such as industry standards, historical data, and real-time monitoring information.

- (3)

Expansion of sample data for objective weighting: Collect a larger volume of sample data through multiple channels to enhance the accuracy of calculating objective weights by the EWM.

The risk assessment method proposed in this study has been integrated with real-world track maintenance scenarios, forming a practical solution that directly supports the optimization of maintenance operation processes.