1. Introduction

To achieve the goals of the Paris Climate Agreement, the CO

2 footprint of future products must be reduced. Lightweight construction is a key technology for this [

1], as it enables the full potential of materials to be utilized and thus the weight of components and systems to be reduced. Particularly in the case of components that are installed in vehicles or aircraft, the weight reduction goes hand in hand with a reduction in CO

2. One approach to lightweight construction is multi-material design, which specifically combines several materials in order to utilize the different properties of the materials to achieve an objective. However, this advantage is linked to additional effort during product development.

The structural optimization methods, such as topology optimization, support the product developer in creating weight optimized initial designs. The density-based approach to topology optimization was first introduced in the two publications by Bendsøe and Kikuchi [

2] and Bendsøe [

3]. Sethian and Wiegmann [

4], Wang et al. [

5] and Allaire et al. [

6] later developed the level set methods as an alternative approach for topology optimization. In this method, the geometry is represented by a level set function during optimization and the geometry is developed using Hamilton–Jacobi equation [

6]. The Velocity Field Level Set Method (VFLSM) [

7] is a level set topology optimization method that uses the Method of Moving Asymptotes (MMA) [

8] for the straightforward integration of several constraints into level set-based topology optimization [

7]. Further level set-based topology optimization methods are presented in [

9].

For the optimization of multi-material systems, Wang and Wang [

10] introduced the Color Level Set Method, which can represent

materials using

n level set functions. An alternative method for multi-material topology optimization is the Reconciled Level Set Method (RCLSM) [

11]. In the RCLSM, each material is described by one level set function. Chen et al. [

12] optimized smart energy harvesters employing the RCLSM, Vogiatzis et al. [

13] applied the RCLSM to optimize multi-material negative Poisson’s ratio metamaterials and Tian et al. [

14] used the RCLSM to design ferromagnetic soft active structures. In [

15], a new multi-material topology optimization method was developed based on RCLSM and VFLSM. Current publications on multi-material topology optimization focus on, e.g., additive manufacturing [

16,

17] and the integration of fiber-reinforced composites into multi-material topology optimization [

18]. In contrast to the articles on multi-material topology optimization listed above, the method developed in [

15] remeshes the current design in each iteration during the optimization and thus enables the accurate evaluation of quantities on the material interfaces between two materials.

Recently, various studies on the influence of interfaces on the optimization result in multi-material topology optimization have been carried out and published. Vermaak et al. [

19] were the first to investigate interface effects on multi-material optimization results in the context of level set topology optimization. Liu et al. [

20] used non-parametric shape optimization to optimize bimaterial interfaces in multi-material structures. For this purpose, they developed an objective function based on the quadratic strength criterion of Brewer and Lagace [

21]. Liu et al. [

22] integrated Brewer and Lagace’s strength criterion into a 2D multi-material topology optimization method as a stress boundary condition and used it for the optimization of bimaterial interfaces. To do this, they remesh the 2D geometry in each iteration. Behrou et al. [

23,

24] optimized bimaterial structures, taking into account the contact and cohesion between the two materials. They used an Extended Finite Element Method (XFEM) to determine the system response. In [

25], they use XFEM and cohesive behavior in 2D multi-material topology optimization to model the separation behavior of the interface. The aim is to obtain designs in which the position of the interface is optimal in terms of resistance to separation. Liu et al. [

26] used a very similar method to optimize embedded components in a 2D host structure. Kim et al. [

27] developed an objective function called Interfacial Tension Energy Density (ITED), which is based on the observation that bonded bimaterial interfaces in 2D primarily fail under tensile stress. The objective function ensures that the interfaces are shifted into the compression areas. It is used to optimize bonded bimaterial interfaces. The advantage of the method is that it does not require specialized Finite Element (FE) methods or computationally intensive non-linear behavior in the FE. In summary, it can be stated that all approaches for the optimization of interfaces in multi-material topology optimization have so far considered the 2D case. It is pointed out in [

22,

27], for example, that further research is required for the 3D case.

The following is a summary of the challenges for the development of methods for the consideration of interfaces in 3D. Numerous methods (see, e.g., [

23,

25]) use non-linear components in the FEM. On the one hand, the non-linear components greatly increase the computational effort, as additional inner iterations are required to solve each optimization iteration. Furthermore, the non-linear components make the optimization methods more sensitive to parameter settings, as they are generally less robust than purely linear methods. Furthermore, the methods (e.g., [

25]) also use immersed FEM, which is still relatively uncommon in practical use. If standard FEM is to be used in the optimization methods, this is only possible by means of remeshing. However, the approach developed in 2D (e.g., [

22]) cannot be transferred directly to 3D. In general, the optimization methods developed in 2D do not yet take into account the shear stress components on the interface.

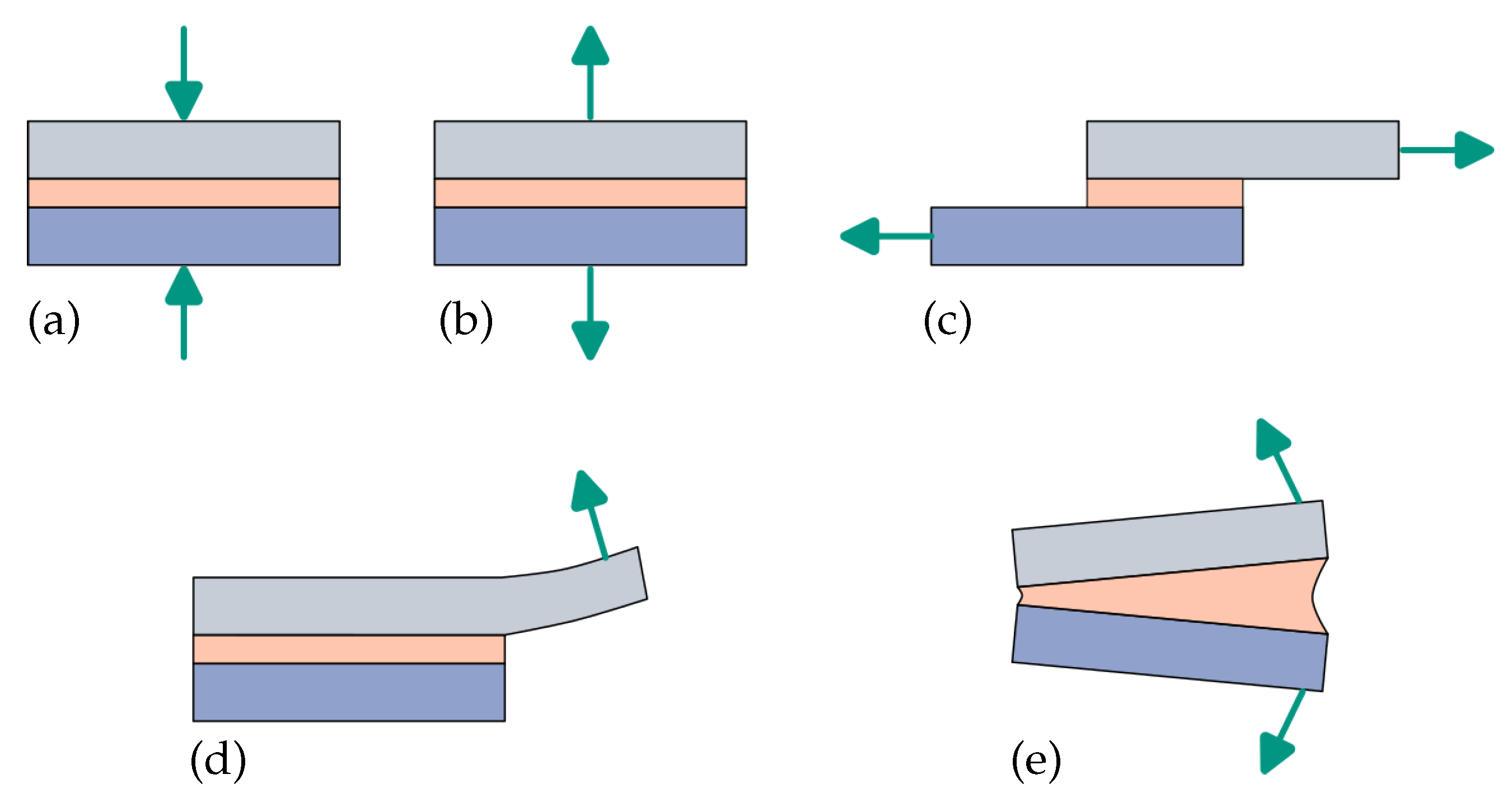

In this article, the approach first presented in [

28] for the consideration of adhesive surfaces in the three-dimensional case in multi-material topology optimization is further developed. In the first step, a system analysis of an adhesive surface between two materials is carried out. In this analysis, the common load cases are analyzed and requirements for the approach are derived. The most essential components of the optimization method developed in [

15] are then discussed. The requirements developed in the previous step are then used to motivate and describe the objective function. In

Section 3.7, the sensitivities are then derived for the developed objective function. Two numerical examples are used to validate the developed approach. In addition, a parameter study is carried out to investigate the influence of a newly introduced parameter in the developed objective function on the optimization results.

4. Numerical Experiments

In this section, the effectiveness of the developed method is examined and validated using two numerical examples and a parameter study. The cases used are a cantilever clamped on one side and a bracket.

Parameters are listed in

Table 1 that are used in all the following numerical examples. The modulus of elasticity

,

and the Poisson’s ratio

,

of the materials used. The minimum and maximum normal velocity

and

already introduced above. Furthermore, a normal velocity

is defined in the non-design space, which guarantees that material is always present at the support surfaces.

The last parameter

describes the maximum volume reduction in one iteration analogous to [

38]. Numerical experiments have shown that an

leads to good convergence behavior of the optimization. This value results in a uniform reduction of the volumes, as the optimization is primarily controlled by the sensitivities of the objective function and not by the volume reduction. If the value of

is too high, the two materials separate and the optimization is aborted. The influence of the remaining parameters (e.g., filter radius) on the convergence behavior was investigated in [

15].

For the selection of , we recommend using the ratio between the two material parameters interface shear strength and normal tensile strength in analogy to the failure criterion of Brewer and Lagace. The two parameters are the only material parameters that are also used in this failure criterion and can also be determined experimentally. It should be noted that this is a recommendation based on an analogy that has led to good results in our numerical experiments, and not a theoretical derivation.

For the selection of , we recommend values of to and starting with a low value at the beginning. Values that are too high cause the optimization to be completely controlled by the ITED and lead to a separation of the two materials. Observing the first 10–20 iterations also provides relatively quick information as to whether the ITED alone is controlling the optimization.

The interface regularization term is activated in all experiments starting from iteration 110, which guarantees that it does not drive the optimization at the beginning. To determine convergence, a criterion is used which first forms the moving average of the objective function values of the previous five iterations. The percentage change in the moving average of two iterations is then calculated. If this change is less than and the two target volumes are met, the result is considered to be converged.

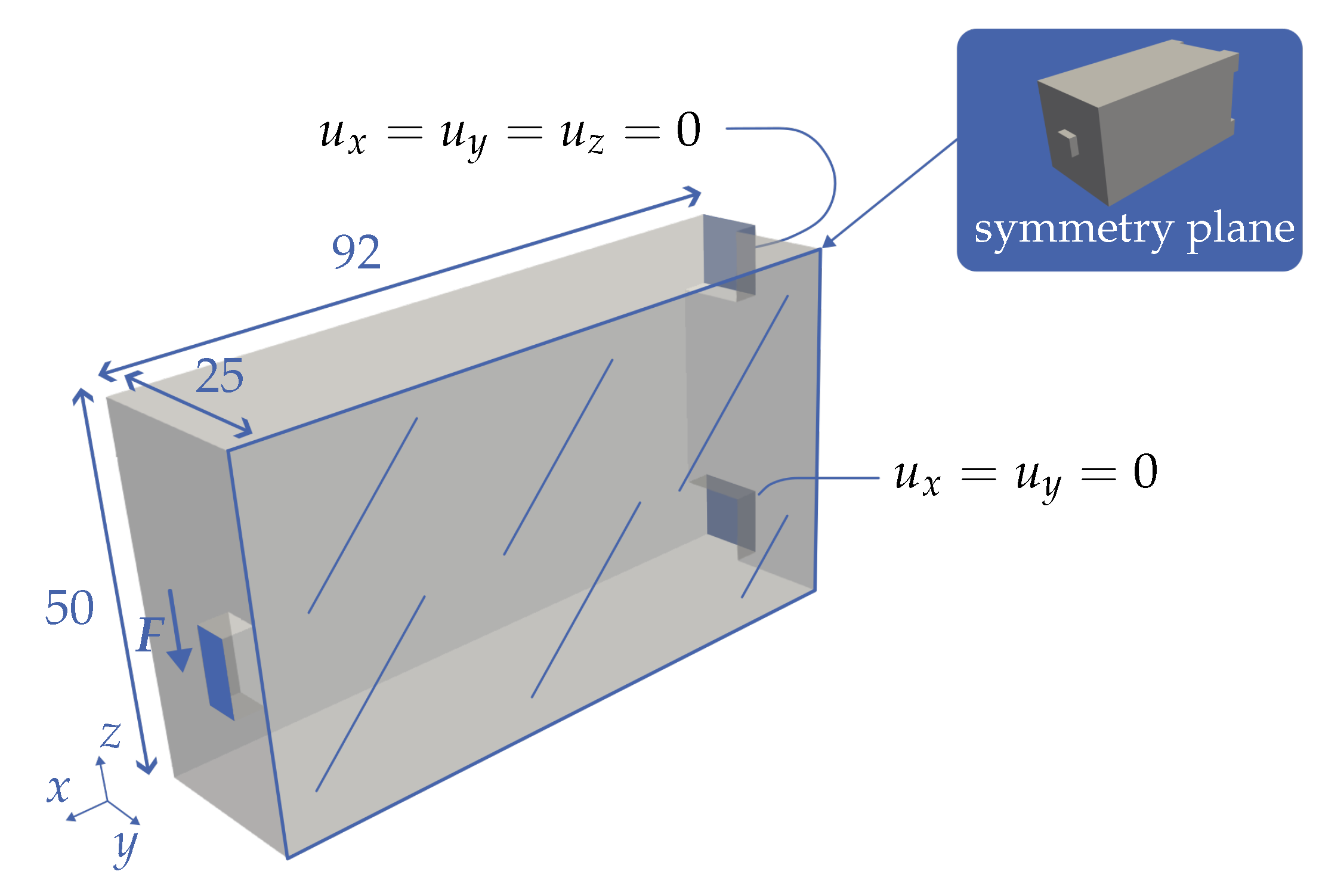

4.1. Cantilever

As a first case, we consider the cantilever shown in

Figure 4. This is loaded on the front surface with a load

F in negative z-direction and is supported on the rear surface. The load application and the support surfaces are square and protrude slightly. They are defined as non-design space for the optimization. For the nodes of the upper support surface,

and for the nodes of the lower support surfaces,

. As the aim is to obtain symmetrical designs, only half of the design space is simulated and a symmetry boundary condition is defined on the symmetry plane (see

Figure 4).

Two different optimizations are carried out below. One multi-material topology optimization without taking the ITED into account and one with it. The parameters for the two optimizations can be found in

Table 2.

Figure 5a shows the optimization result of the pure multi-material topology optimization and in

Figure 5b the optimization result with consideration of the ITED. It is clearly visible that the pure multi-material topology optimization result (see

Figure 5a) distributes the second material (lower modulus of elasticity) over the entire cross-section (along the z-direction). The second material is present both in the tensile and compressive areas. The same applies to the first material. Consequently, the interfaces are also present both in the compression area and, in particular, in the tensile area (upper interfaces). As described above, the latter has a negative effect on the component strength.

The optimization result with consideration of the ITED (see

Figure 5b) shifts the second material into the compressive area of the beam, whereby all three existing interfaces are primarily subjected to pressure, which corresponds to the intended behavior.

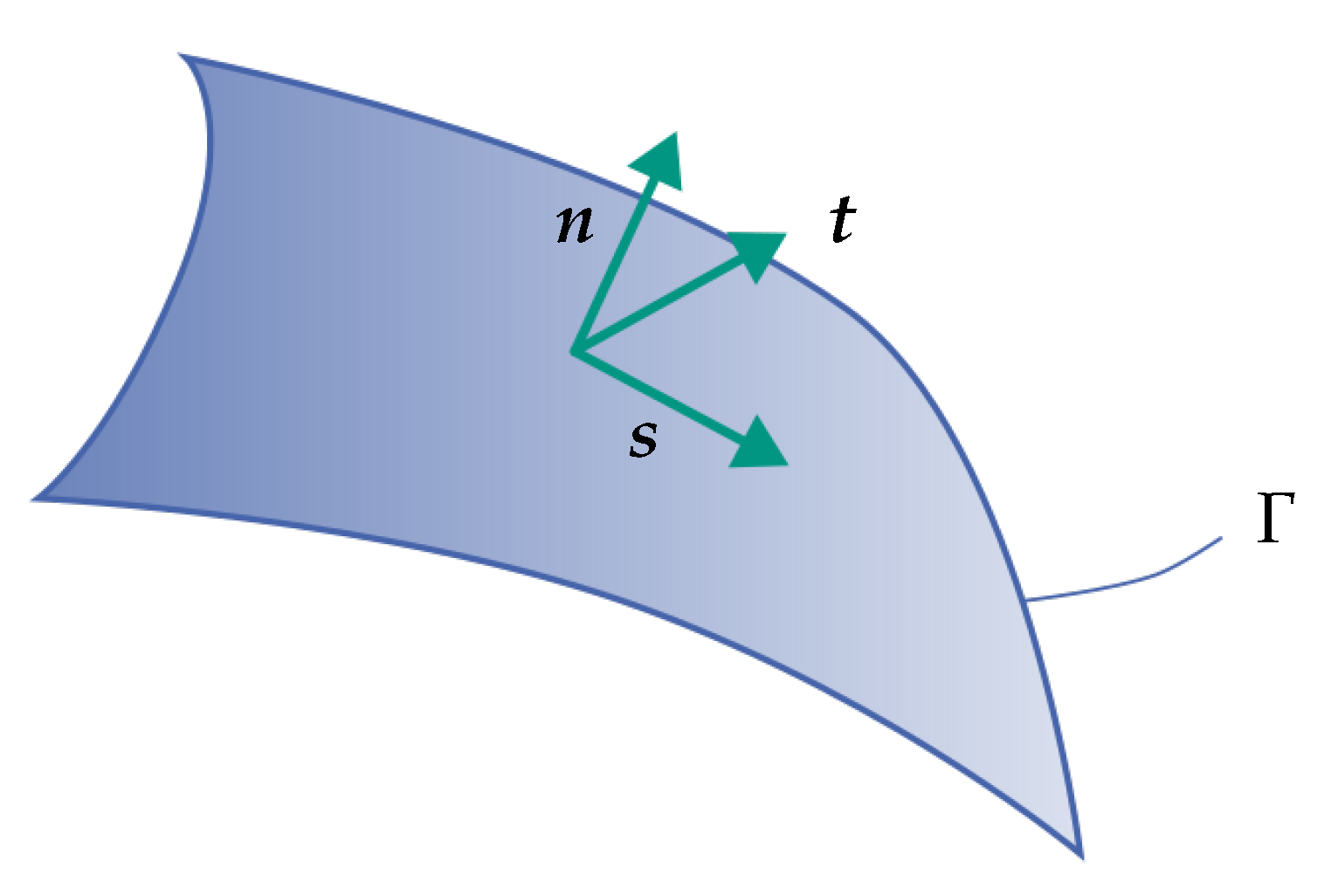

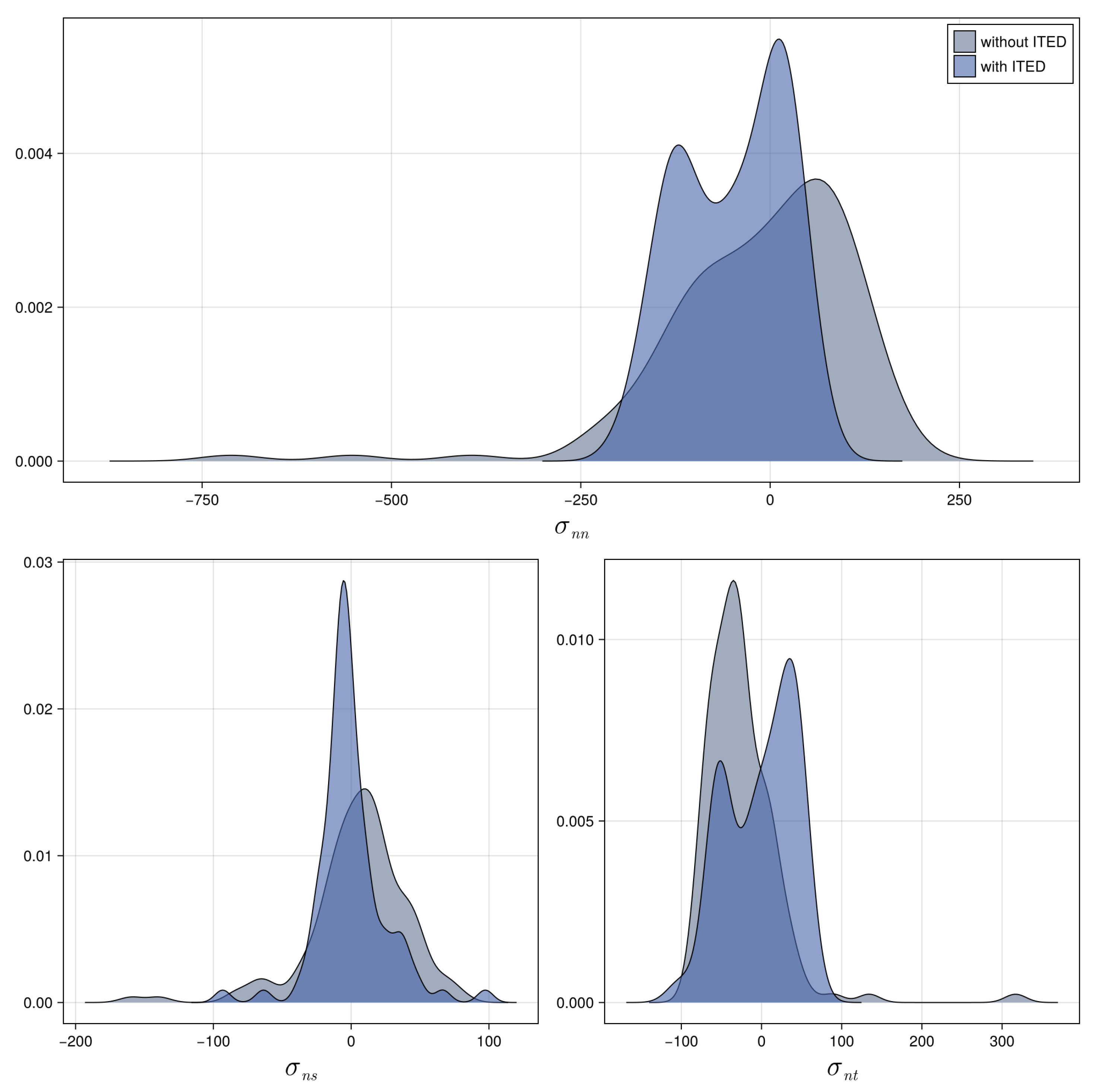

The latter is also illustrated by

Figure 6. This shows the density distribution of the normal and shear stresses on the interfaces for the two optimizations. In the first step, the interface surfaces of the tetrahedrons were derived, the three stresses were determined on them and the diagrams were created from this. In each of these, the stress values are plotted on the x-axis and the respective occurrences on the y-axis.

The diagram of the normal stress clearly shows that the interfaces are subjected to greater compressive stress when the ITED is taken into account (density distribution shifts from the positive area to the negative area). In addition, the maximum tensile stress (maximum value in the positive range) is reduced compared to pure multi-material topology optimization. Consequently, in the case of the cantilever, the developed method fulfills requirement 1.

The two shear stress diagrams ( and ) show that the maximum shear stress (maximum value in the negative or positive range) is also reduced for both when the ITED is taken into account. The variance of the density distribution is lower when the ITED is taken into account. It can also be seen that the majority of the density accumulates around the value 0 (corresponds to low shear stresses on the surfaces of the interface). Consequently, the developed method also fulfills requirement 2 in the case of the cantilever.

At this point we would also like to provide some information about the computation effort. The numerical experiments were carried out on an AMD 6 Core Processor with 5.4 GHz. The computational effort can be easily estimated from the first iteration. The FE mesh consists of 26,573 nodes and 146,614 tetrahedra. Remeshing takes the longest at 21 s, followed by solving the FE problem and the adjoint problem, each of which takes 1.4 s. The remaining points require less than 2 s combined. It should also be noted that the individual iterations become smaller as the optimization progresses. Since the volume decreases and thus, due to the constant edge length, the number of tetrahedra. As a result, the number of degrees of freedom in both the FE and the adjoint problem decreases. Further studies on the influence of the mesh can be found in [

15].

4.2. Bracket

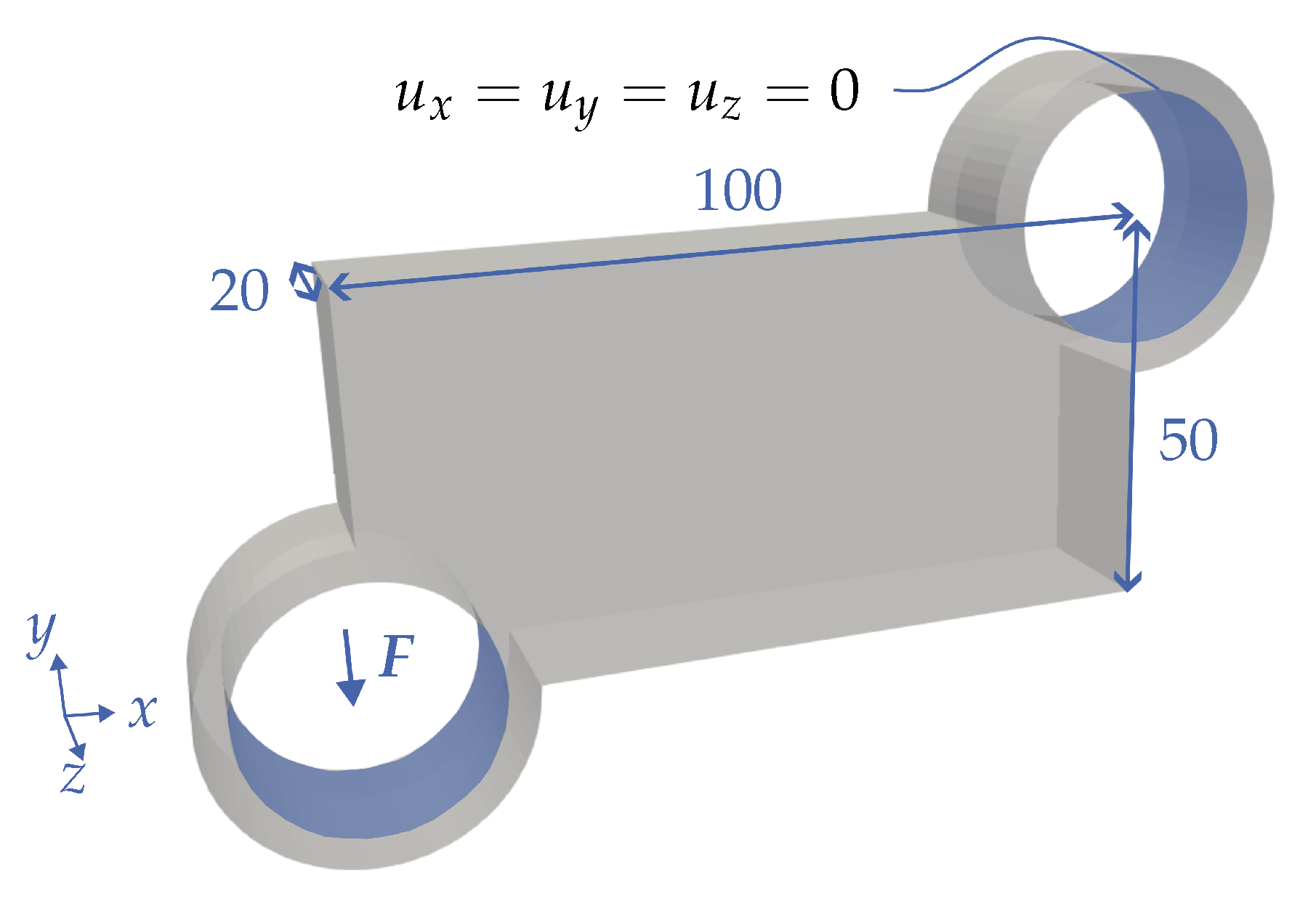

The second case is the bracket shown in

Figure 7, which is often used in the topology optimization literature (see [

39]). As a load, a force acting in the negative y-direction is applied via the inner surface of the lower left perforated cylinder. The inner surface of the upper right cylinder serves as the support. The following applies to the nodes of the inner surface:

. The drilled-through cylinders on the inner surfaces of which the load is applied and the support is provided are considered as non-design space in the context of the optimization. The dimensions can be taken from

Figure 7.

Analogous to the cantilever, the comparison between pure multi-material topology optimization and multi-material topology optimization with consideration of the ITED is shown below. The parameters of the two optimizations can be found in

Table 3.

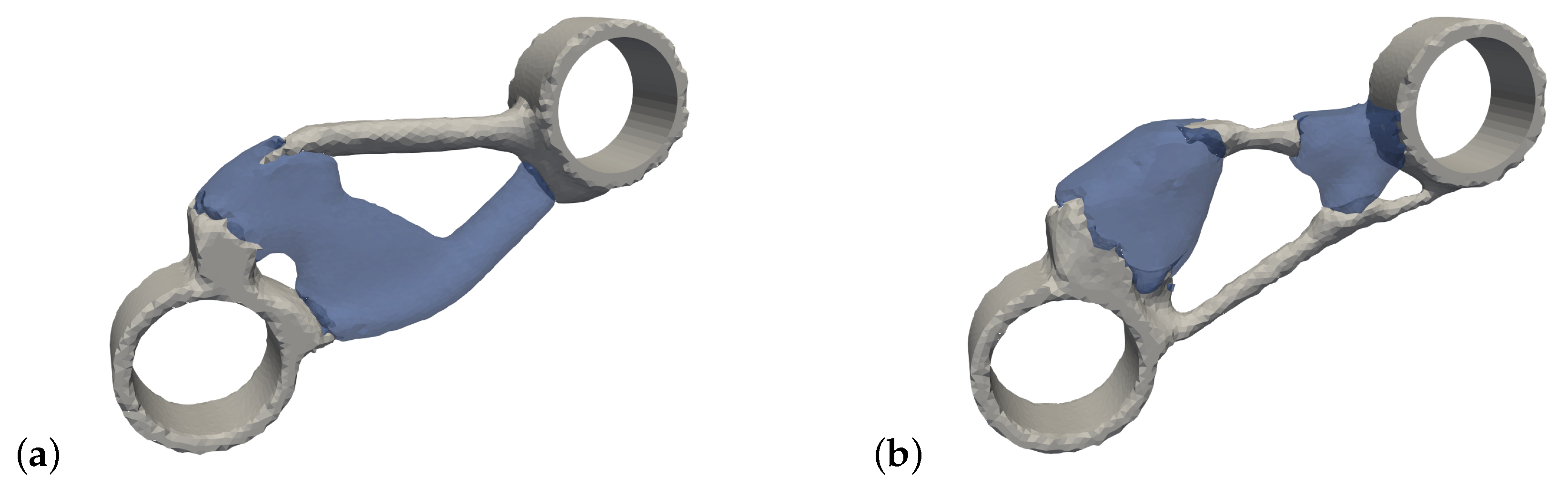

Figure 8a shows the result of the pure multi-material topology optimization and in

Figure 8b that with consideration of the ITED. Analogous to the cantilever, it can again be seen that the second material is distributed over the cross-section (y-direction) in the pure multi-material topology optimization and that the second material is primarily located in the upper area when the ITED is taken into account. It is also noticeable that the second material consists of two components in the optimization with consideration of the ITED compared to one in the pure multi-material topology optimization.

Figure 9 again shows the normal and shear stress density distributions on the interfaces of the two optimization results. Analogous to the cantilever, it can again be seen that the tensile stress on the interfaces decreases when the ITED is taken into account. On the one hand, the maximum normal stress decreases (maximum positive value) and the majority of the density distribution is shifted to the left. Consequently, in the case of the bracket, the developed method also fulfills requirement 1.

The shear stress diagrams also show that the maximum shear stress is also minimized. The density distribution of shear stress must be considered in particular, as its values are higher than . The maximum value of the density distribution of decreases when ITED is taken into account compared to pure multi-material topology optimization. In addition, a reduction in the variance can be observed when considering the ITED compared to the pure multi-material topology optimization. Consequently, the developed method also fulfills requirement 2 in the case of the bracket.

4.3. Parameter Study

In this section, the influence of the parameter on the optimization result is determined using a parameter study. For this purpose, the bracket is used as an optimization case and the parameter is varied in the three levels 0, and . The remaining optimization parameters are identical to the previous section.

Figure 10 shows the optimization results for the three values of beta. It is noticeable that the optimization with

(partial mapping a) differs greatly from the other two optimizations (partial mapping b and c). Material 2 in the optimization with

consists of one component, whereas it consists of two components in the other two optimizations. In the optimization with

, the interface between the materials is such that it is primarily subjected to shear. This is logical, as this optimization with

does not take into account the shear components in the objective function. The two optimization results with consideration of the shear components (

and

) differ only in the shape of the left interface. When increasing

(partial figure c), two additional struts develop and the area of the interface is also reduced.

Figure 11 illustrates the normal and shear stress density distributions on the interfaces of the three optimization results. When examining the shear stresses, it is noticeable that, analogous to the previous section, the shear stress

is higher and is therefore focused on by the optimization method. It is evident that the maximum shear stress decreases with an increase in

. Furthermore, it can be seen that the variance of the density distribution also decreases with an increase in

.

When considering the normal stress, it can be seen that although the majority of the density distribution is lower for the lowest value than for the other two density distributions, there are individual surfaces with higher normal stress. This is probably due to the fact that the interface behavior is considered as an objective function and not as a hard boundary condition.

In summary, it can be stated that the parameter enables qualitative control of the ratio between normal and shear stress in the interface of the optimization result.

5. Conclusions

In this article, a topology optimization method was developed for the optimization of multi-material structures in which the individual materials are adhesively bonded. For this purpose, two requirements for the optimization method were established based on the analysis of the known load cases of a bonded joint. Based on, the ITED introduced in [

27] for 2D problems was further developed for the 3D case by integrating shear stresses, for example. Subsequently, the optimization problem was set up and the sensitivities were derived for it using the Lagrange method. The effectiveness of the optimization method was then demonstrated by applying the method and comparing the optimization results of the multi-material optimization with and without ITED. In addition, a parameter study was used to show that the behavior of different adhesives (different ratios between tensile and shear strengths) can be qualitatively adjusted by varying a newly introduced parameter.

The optimization method developed in [

15] can be extended to integrate explicit interface stress constraints based on the Brewer and Lagace failure criterion in 3D. Further research regarding the comparison of the two methods as well as regarding their combined use. Here, for example, strategies are conceivable that initially the interfaces are displaced from the tensile regions (based on the ITED) and subsequently explicit stress constraints ensure that maximum interfacial stresses are maintained. In addition, further research is required on the method to take heterogeneous adhesive properties into account. Moreover, further research is required regarding the validation of the approach. Here, for example, the comparison of the optimization results with and without consideration of the interfaces after previous redesign is beneficial.

The optimization method developed in this article should be extendable to the optimization of more than two materials. Both the RCLSM and the remeshing method can individually handle more than two materials through adaptations already shown in the state-of-the-art. An extension of the ITED for more than two materials can be realized by setting up a density for each pair of materials analogous to Equation (

14). However, further research is required in this case as well.

In summary, the developed method was able to solve the challenges of taking into account the interfaces in 3D as described in the introduction.