Analysis the Composition of Hydraulic Radial Force on Centrifugal Pump Impeller: A Data-Centric Approach Based on CFD Datasets

Abstract

1. Introduction

2. Numerical Simulation

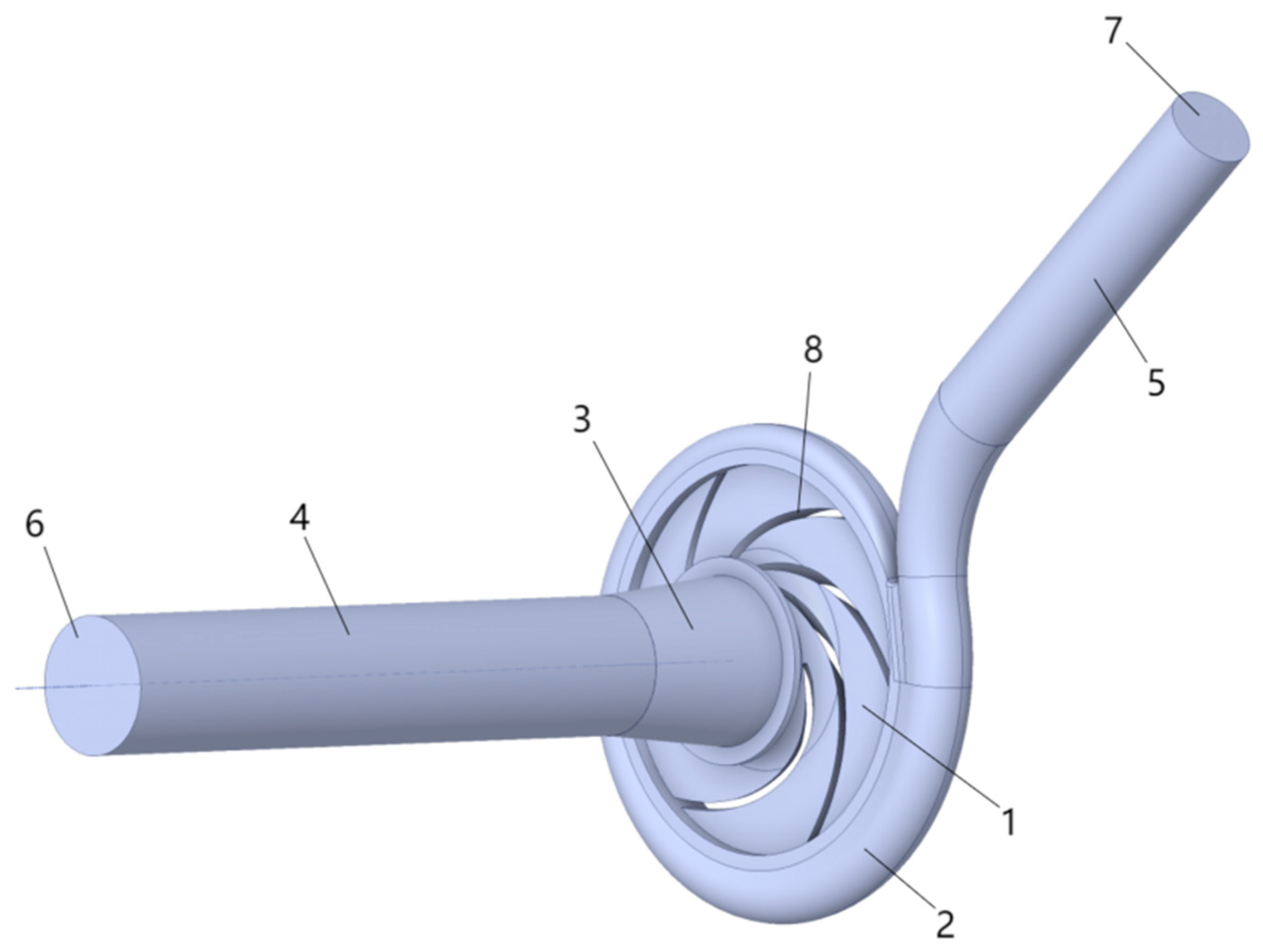

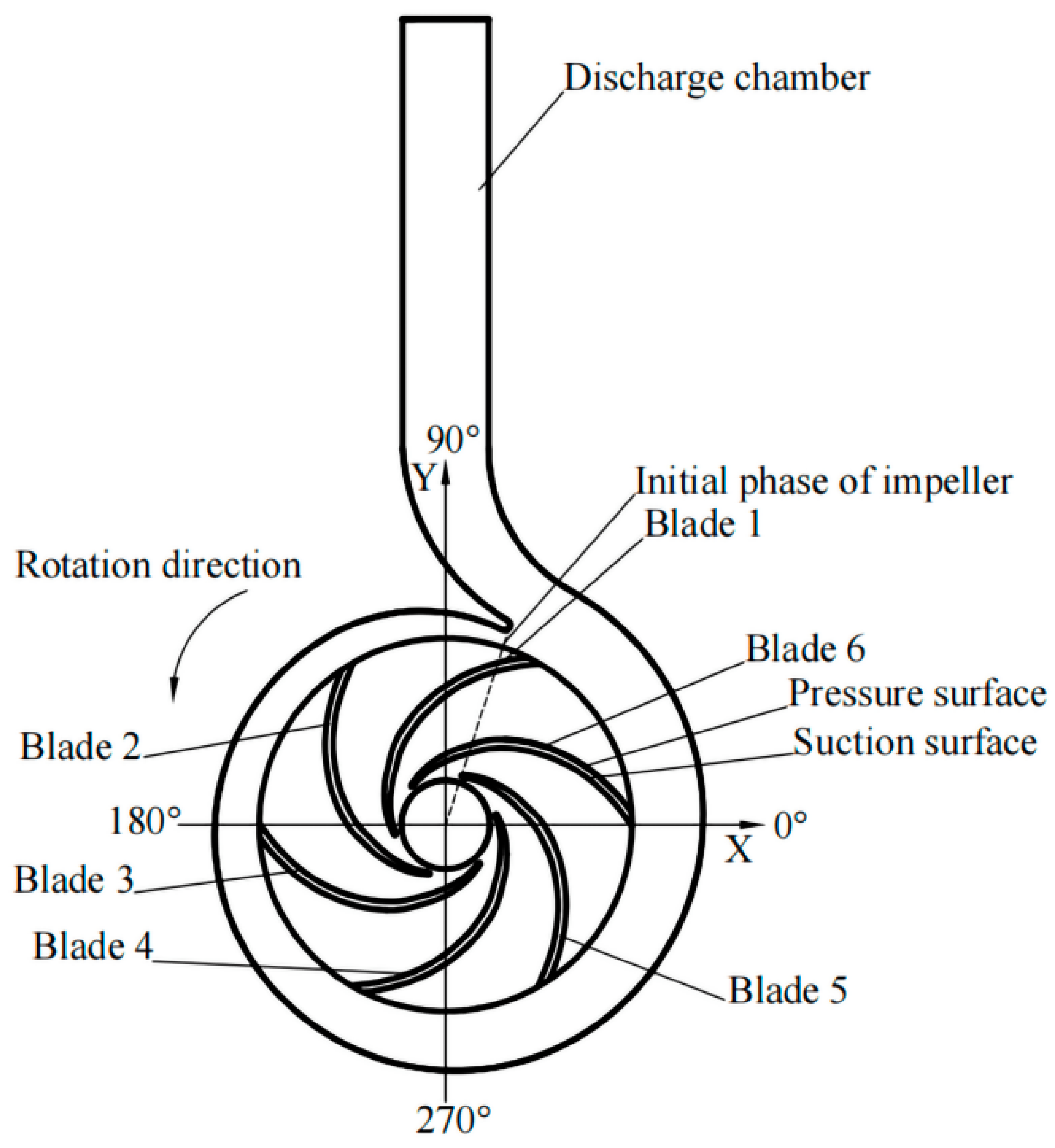

2.1. Research Object

2.2. Governing Equations and Turbulent Model

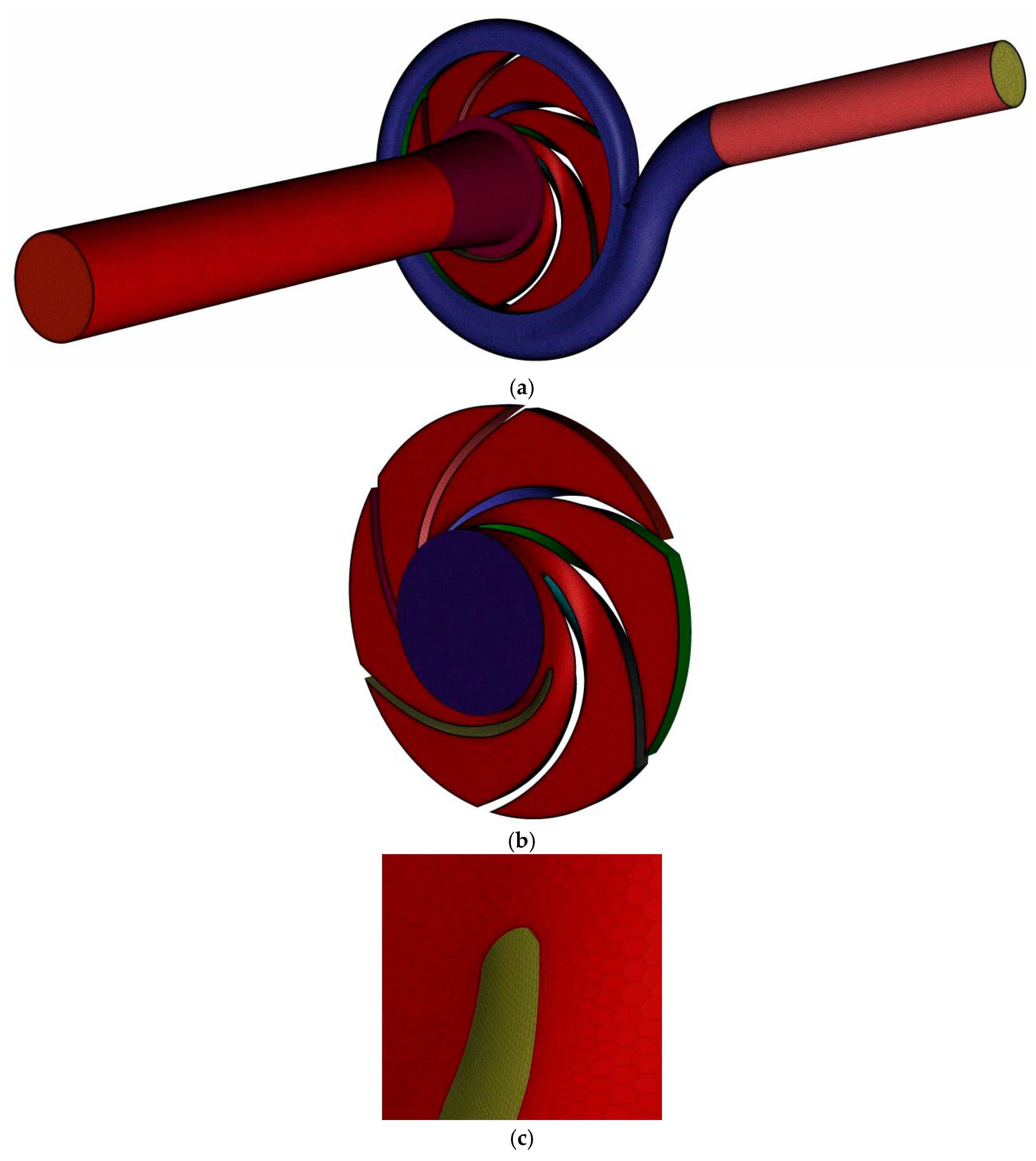

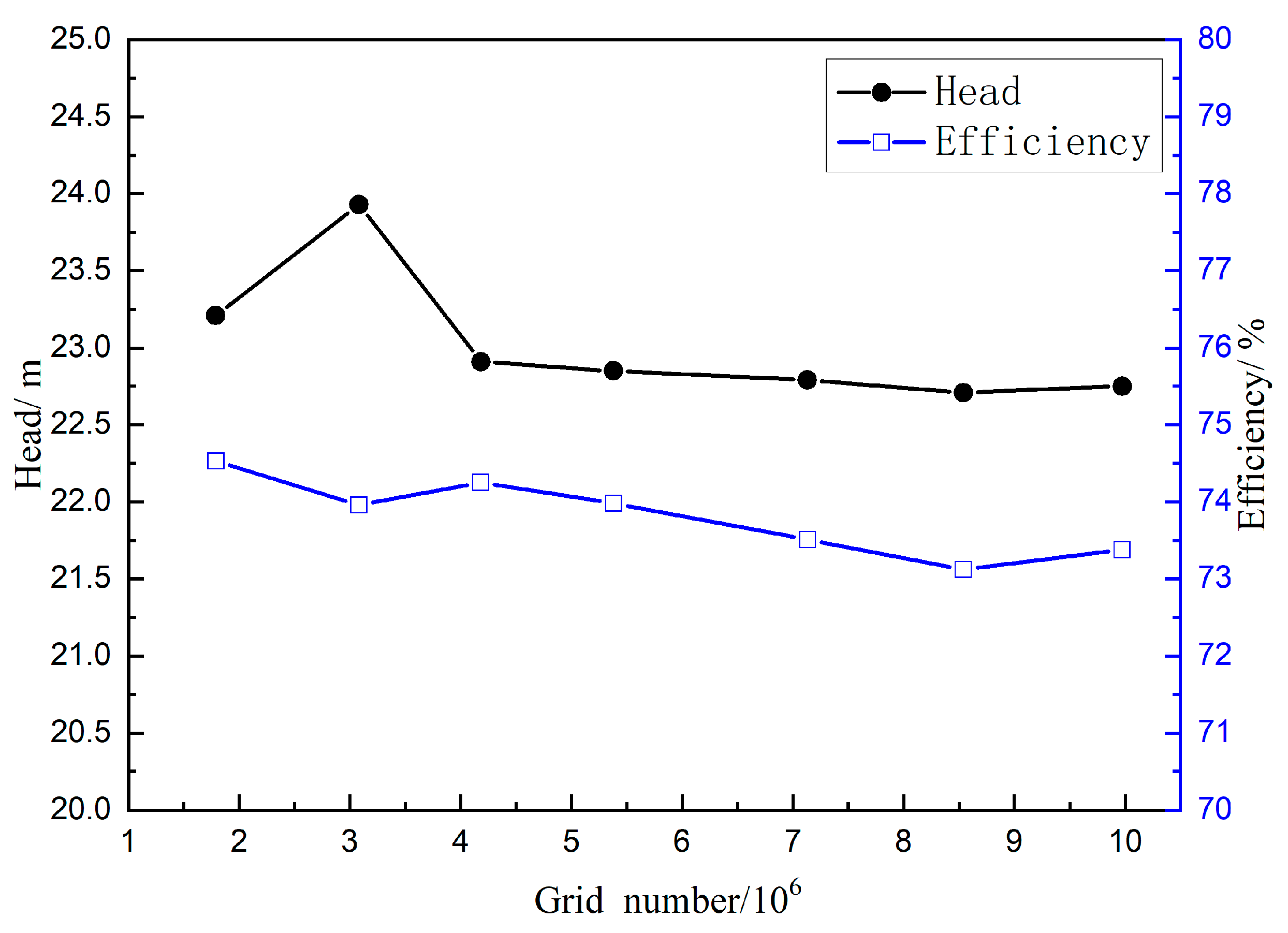

2.3. Mesh Generation and Independence Verification

2.4. Boundary Conditions and Solver Settings

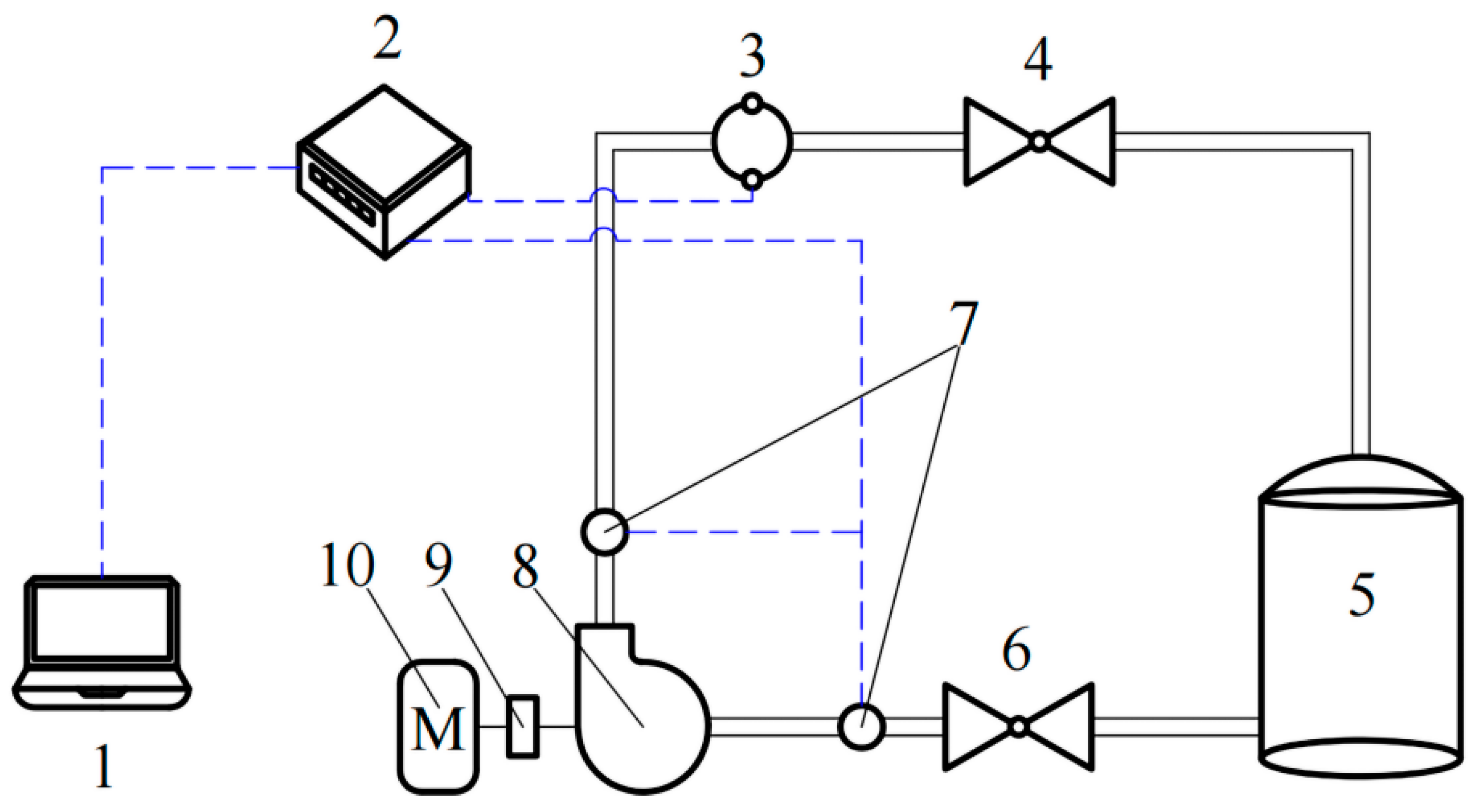

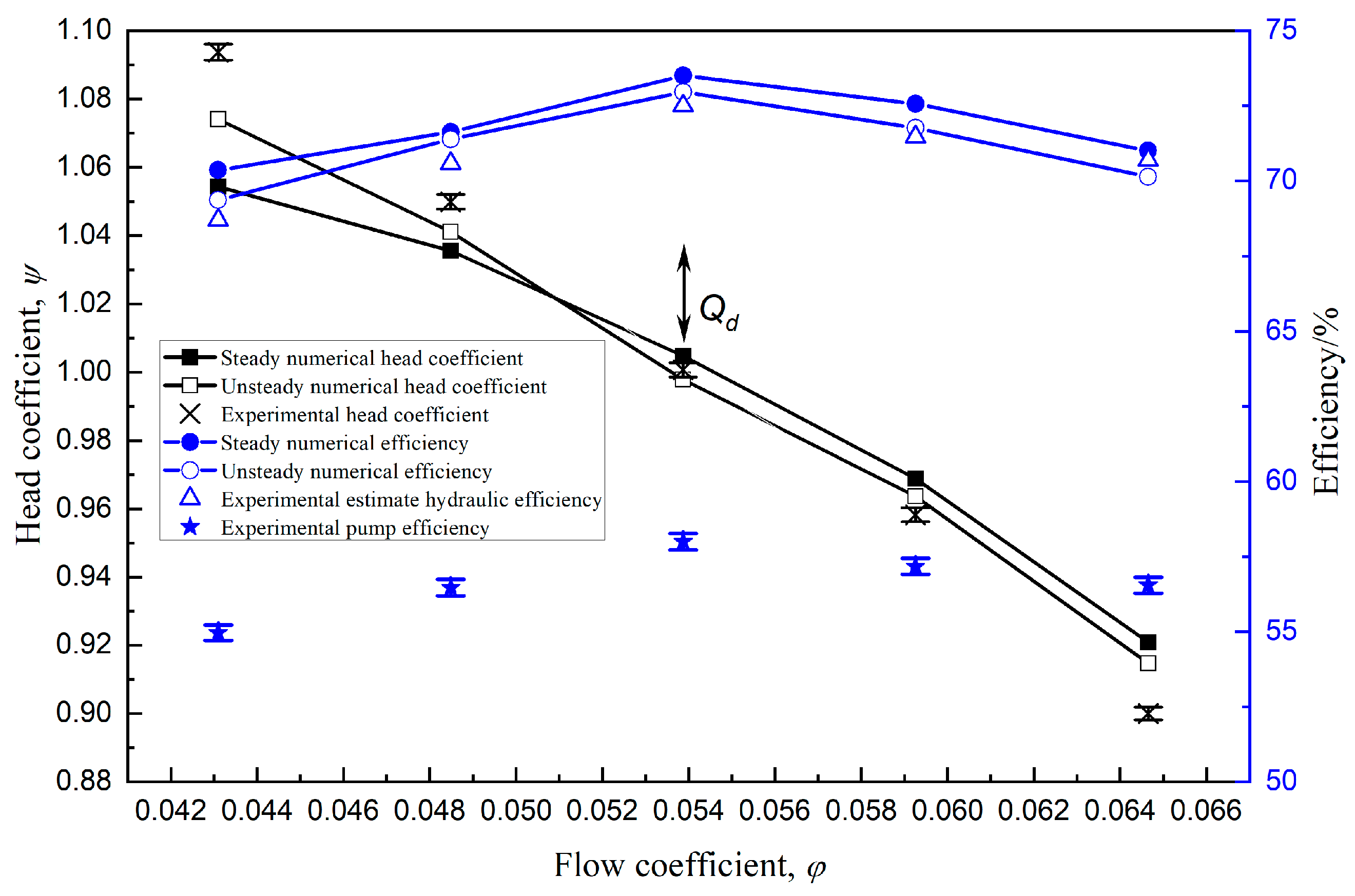

2.5. Experimental Validation

2.6. Dataset from CFD

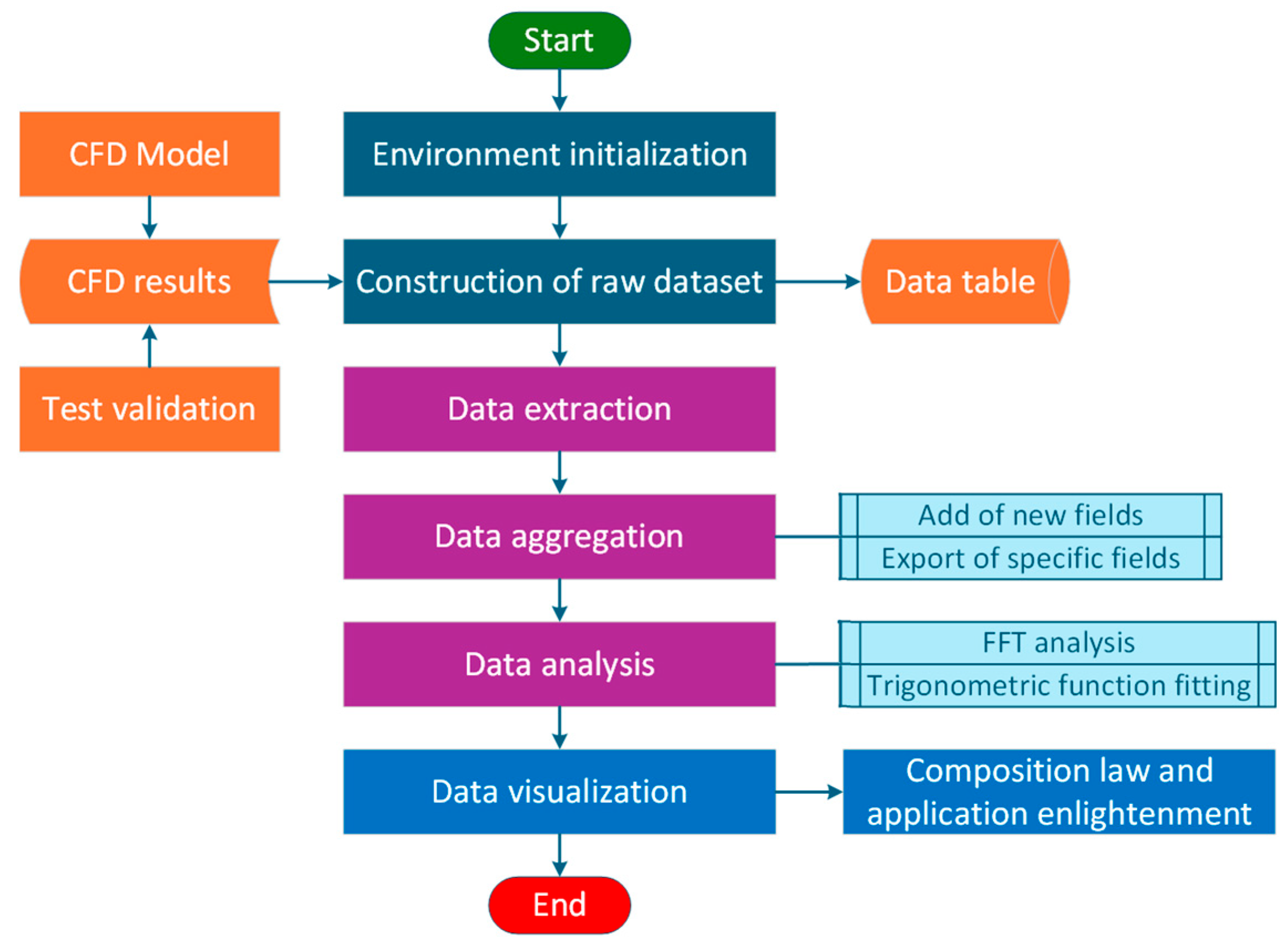

3. Data Analysis Method

3.1. Basic Procedure

3.2. Key Algorithms

4. Results and Discussion

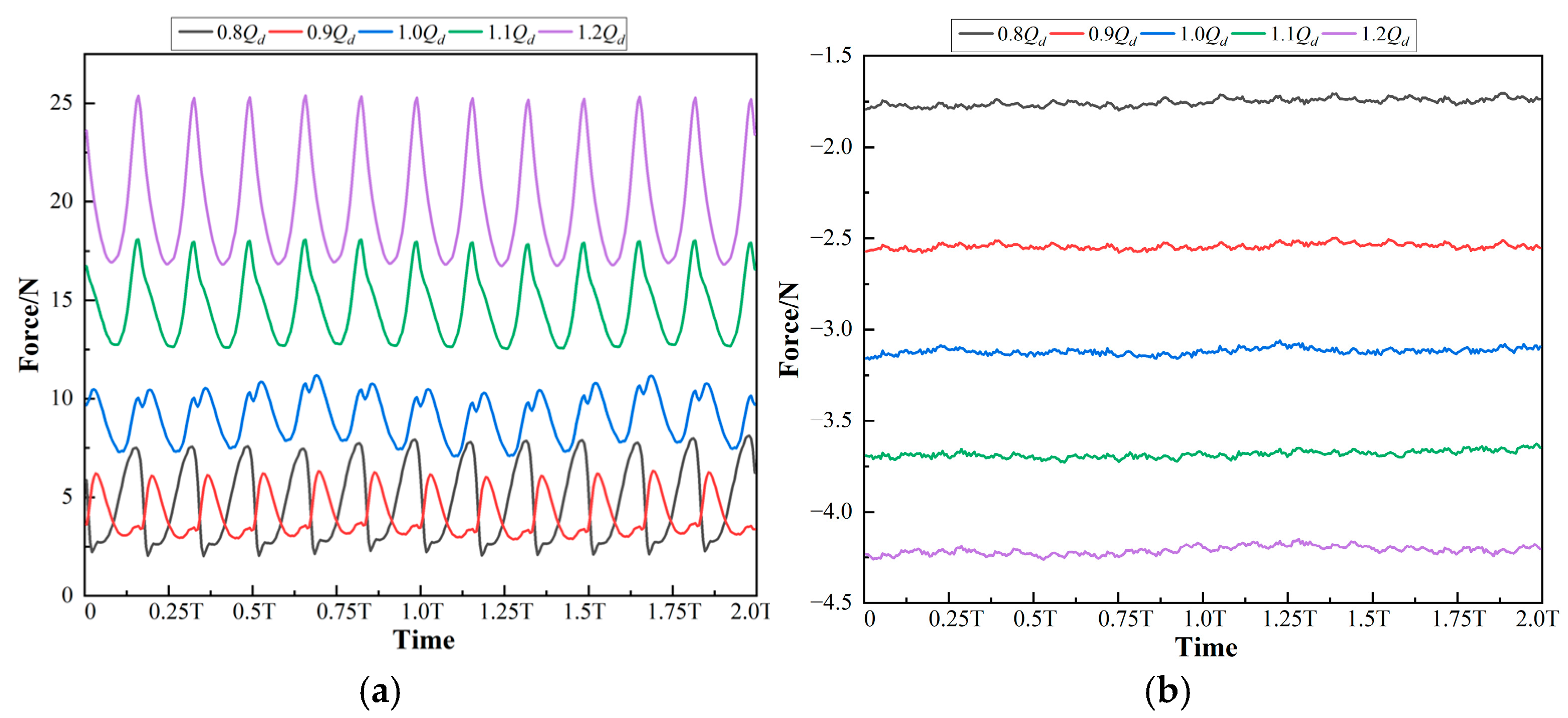

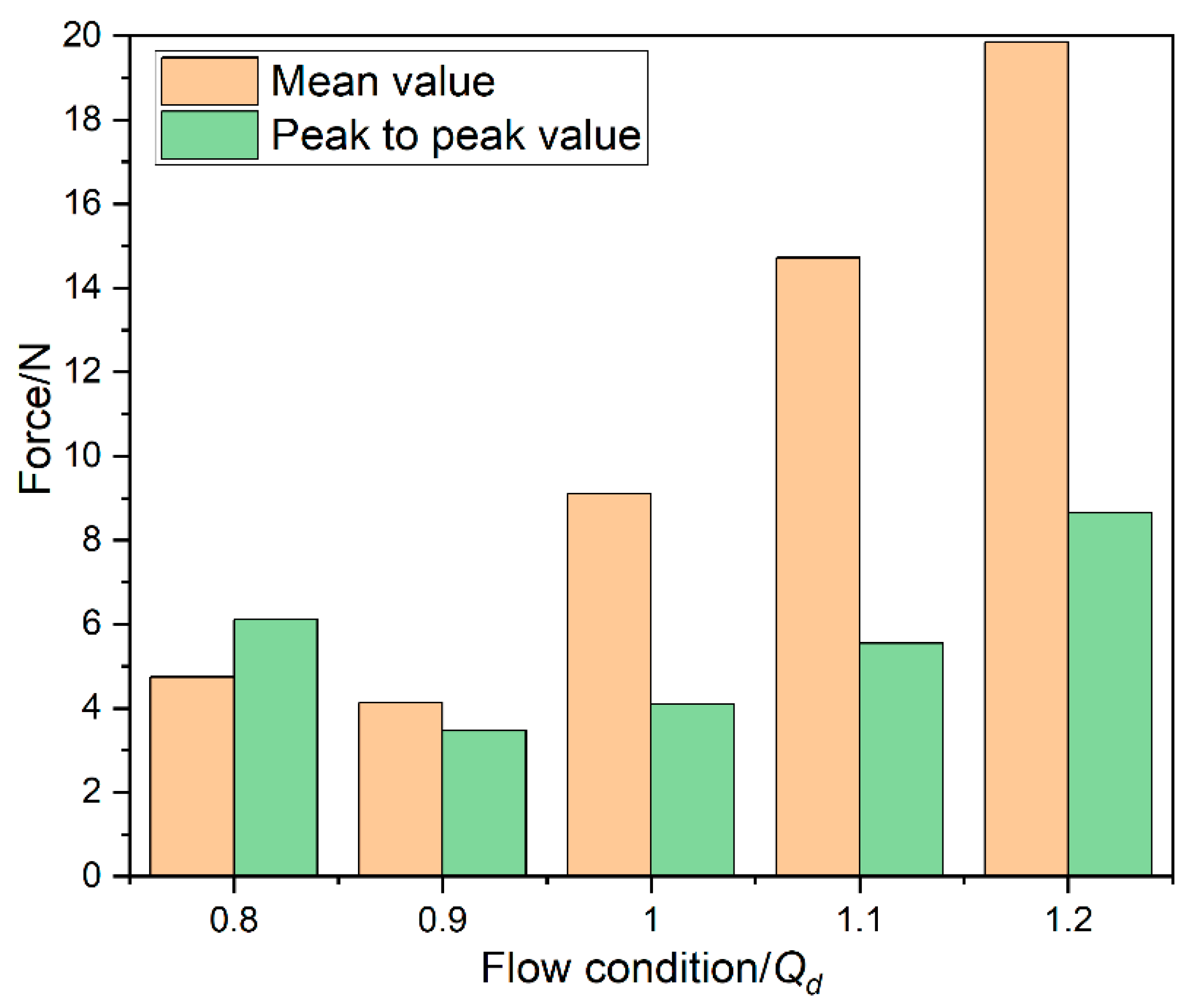

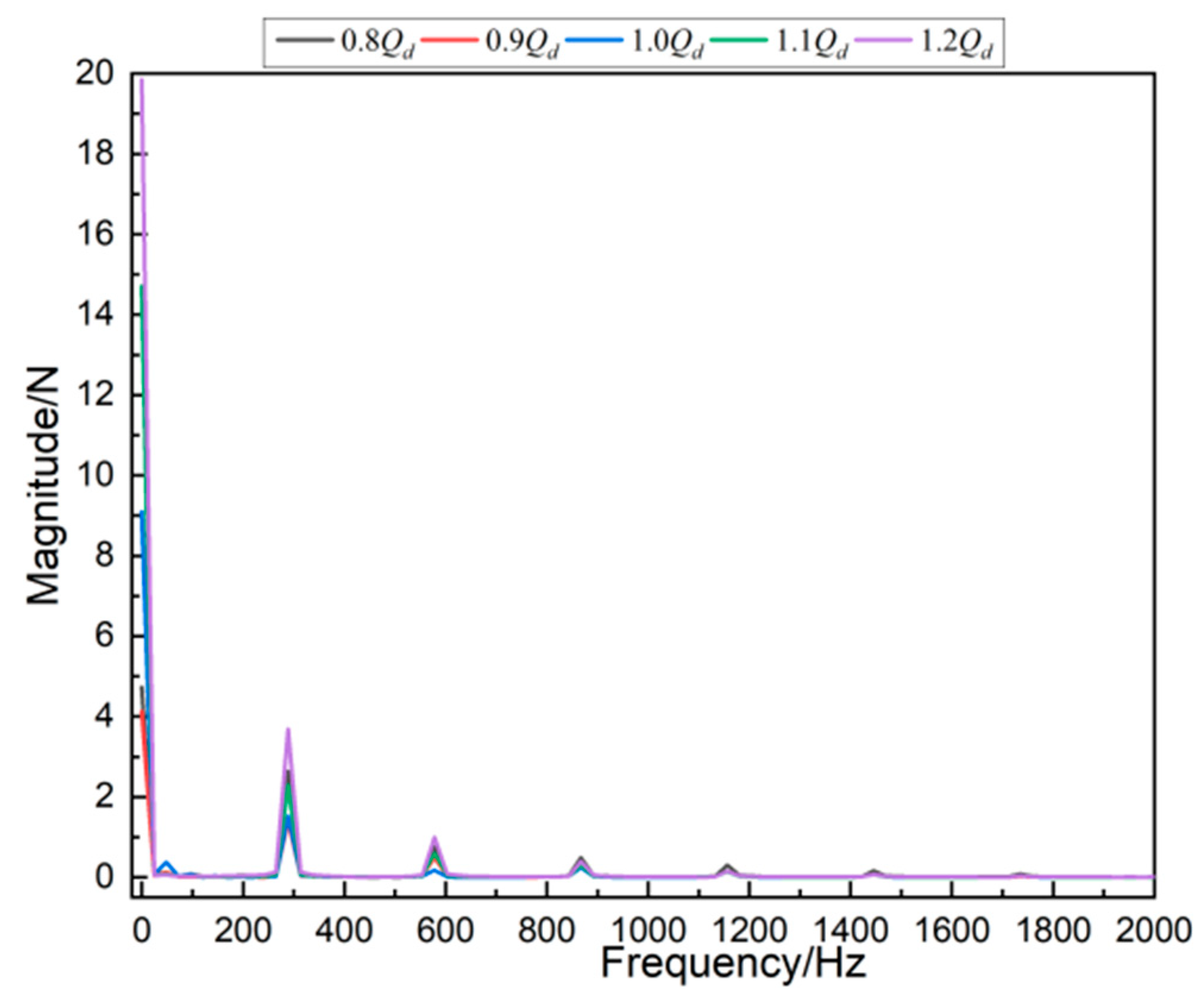

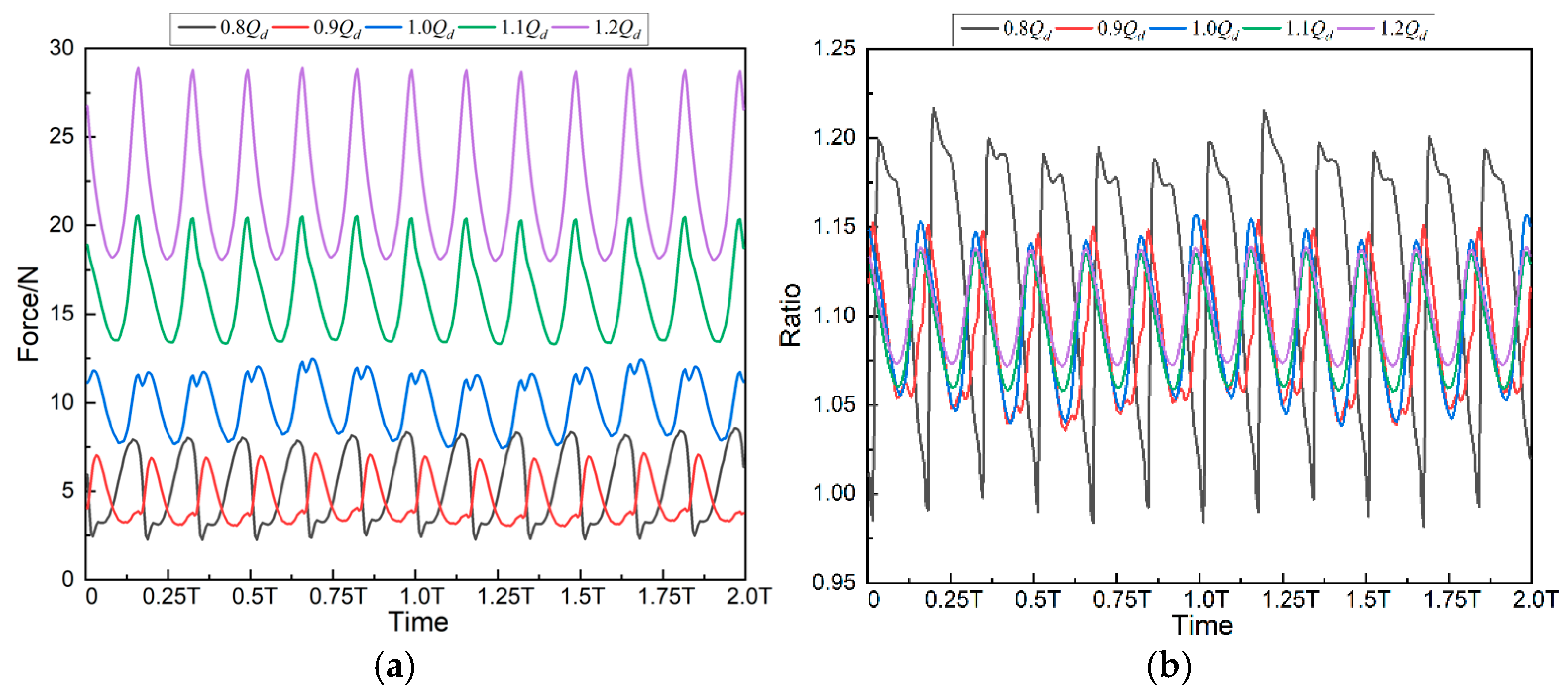

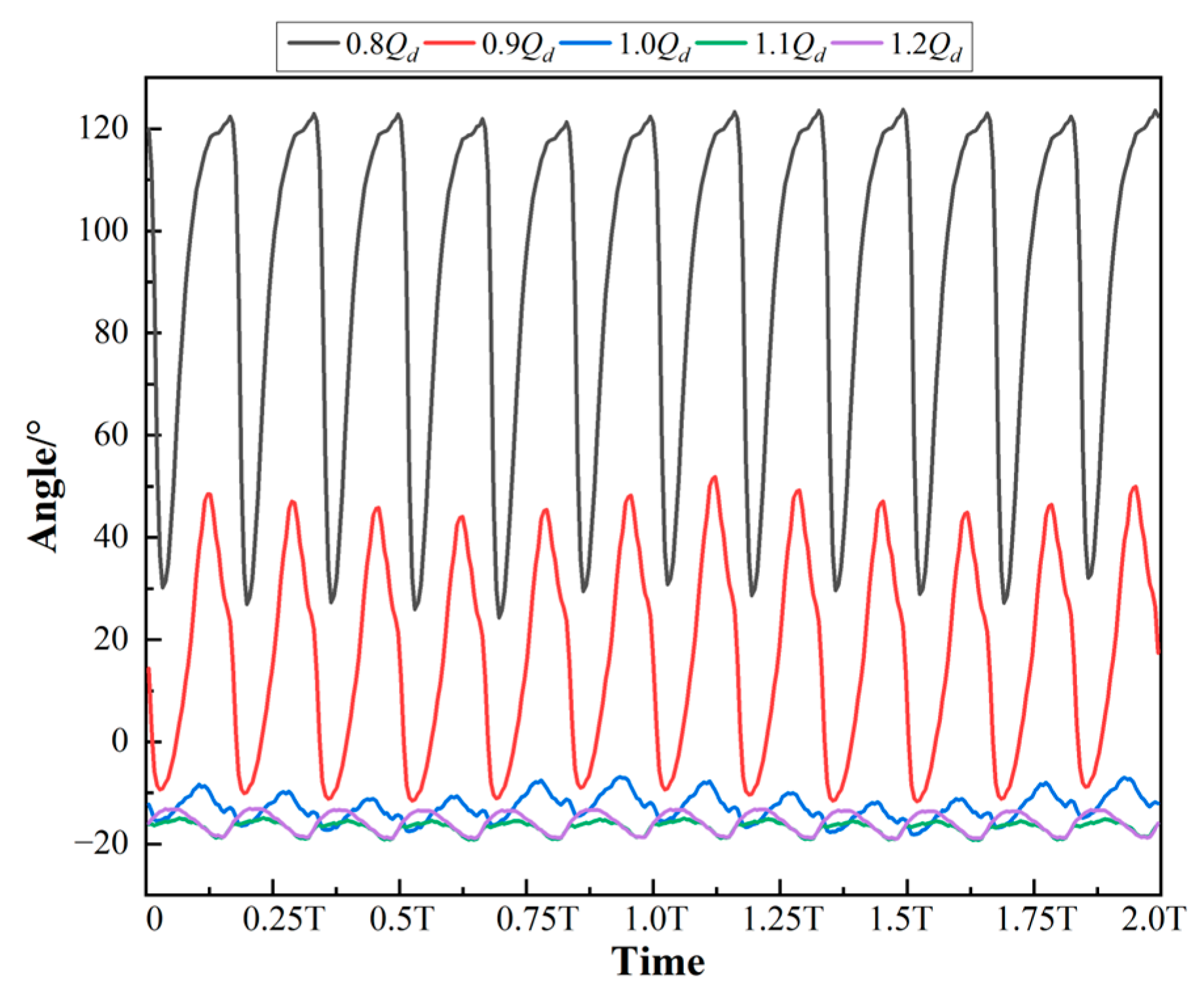

4.1. Hydraulic Force on the Whole Impeller

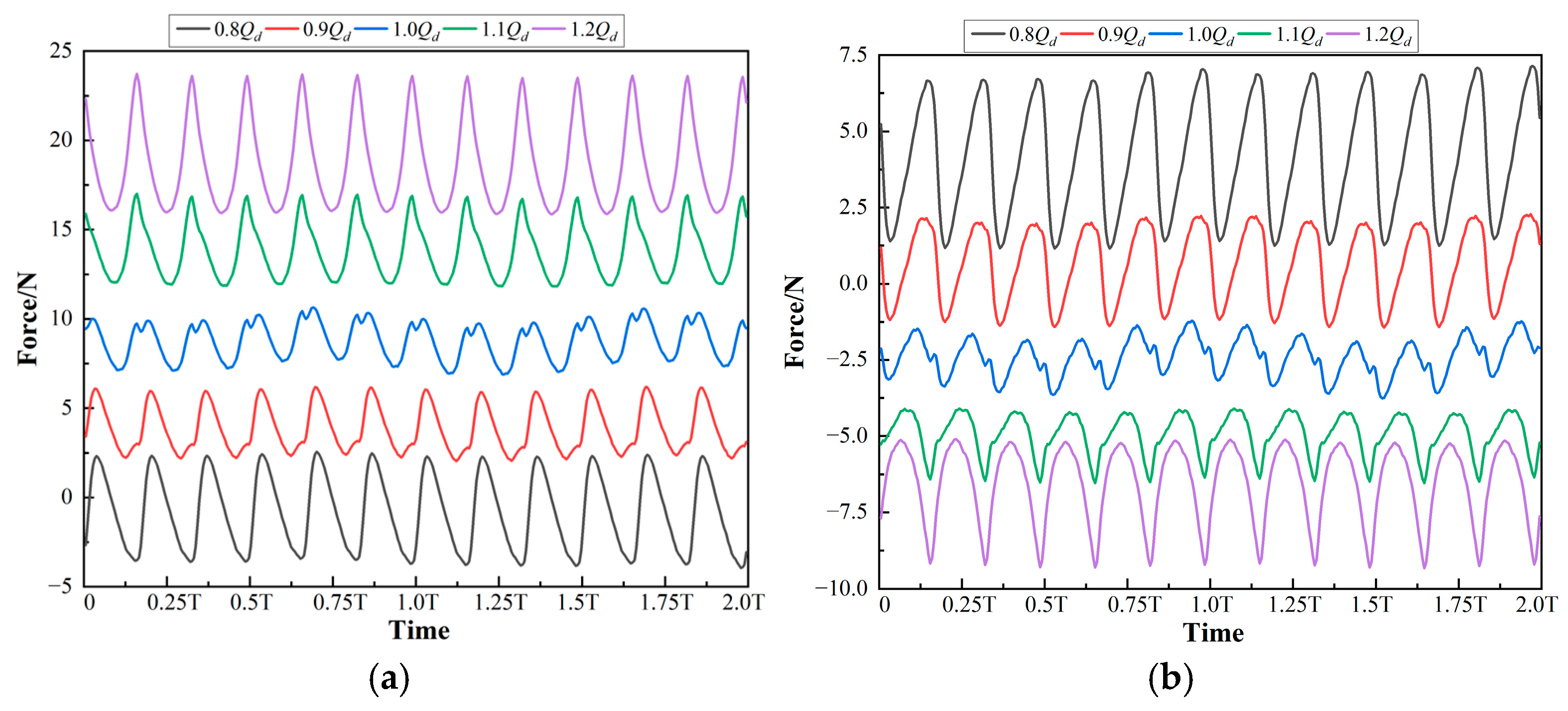

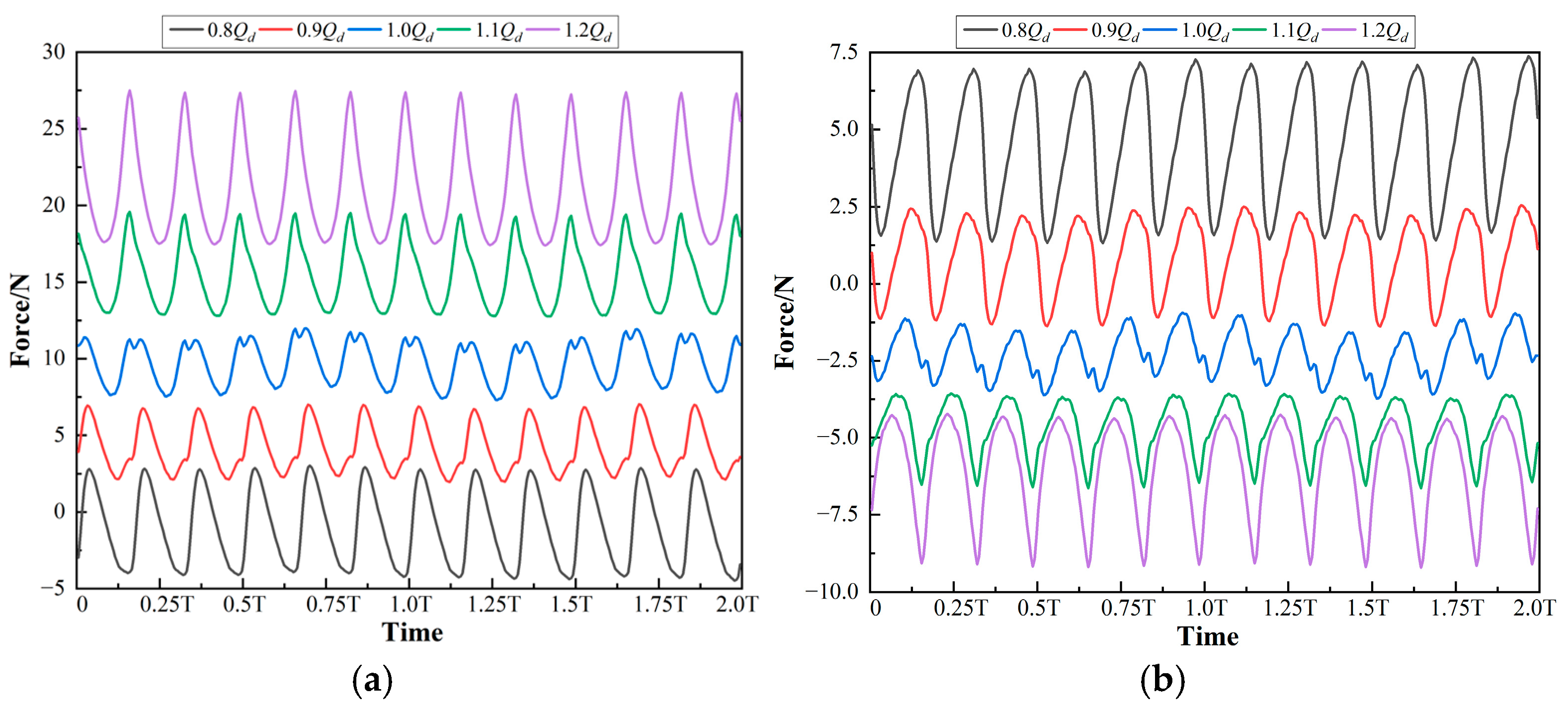

4.2. Hydraulic Radial Force on All Blades

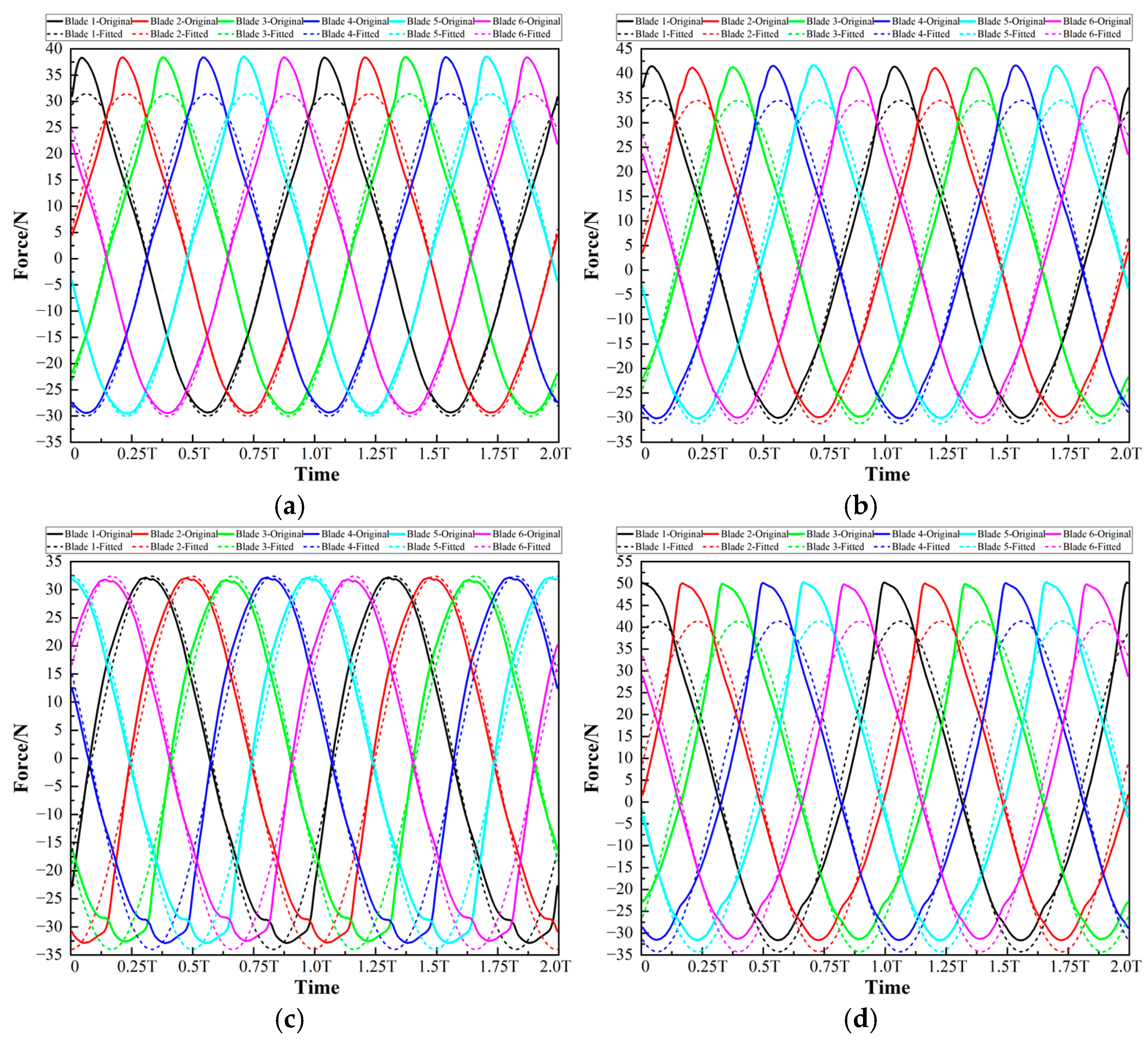

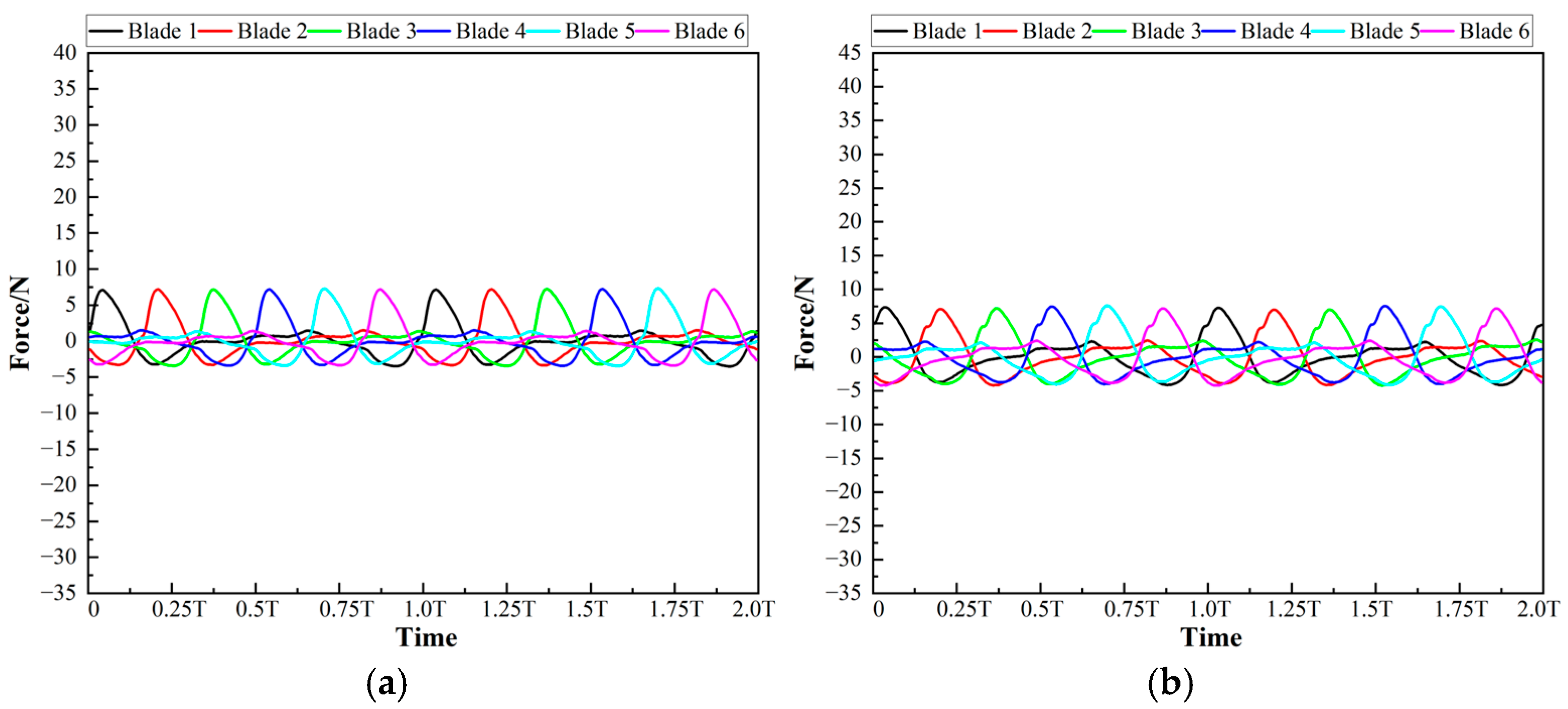

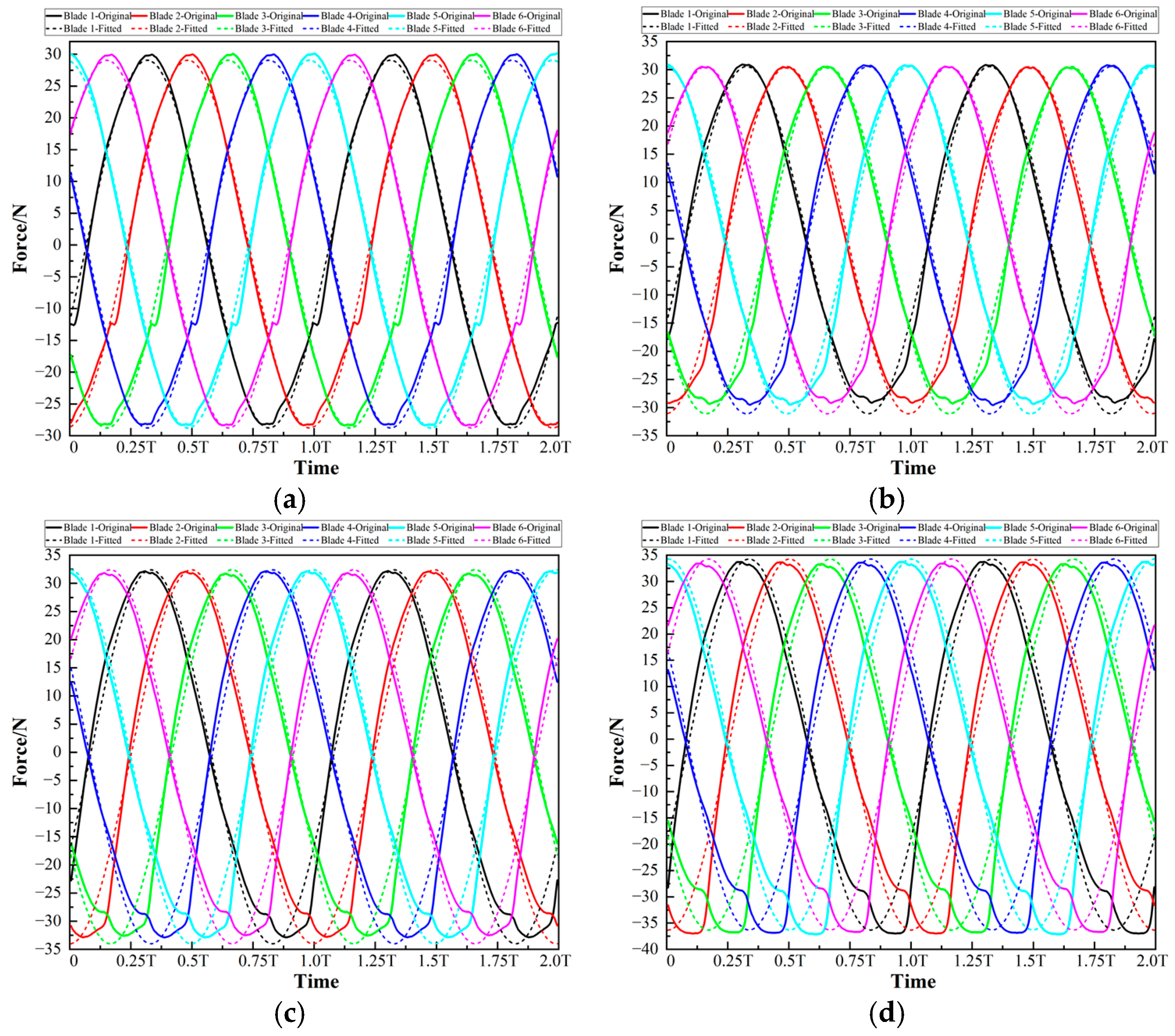

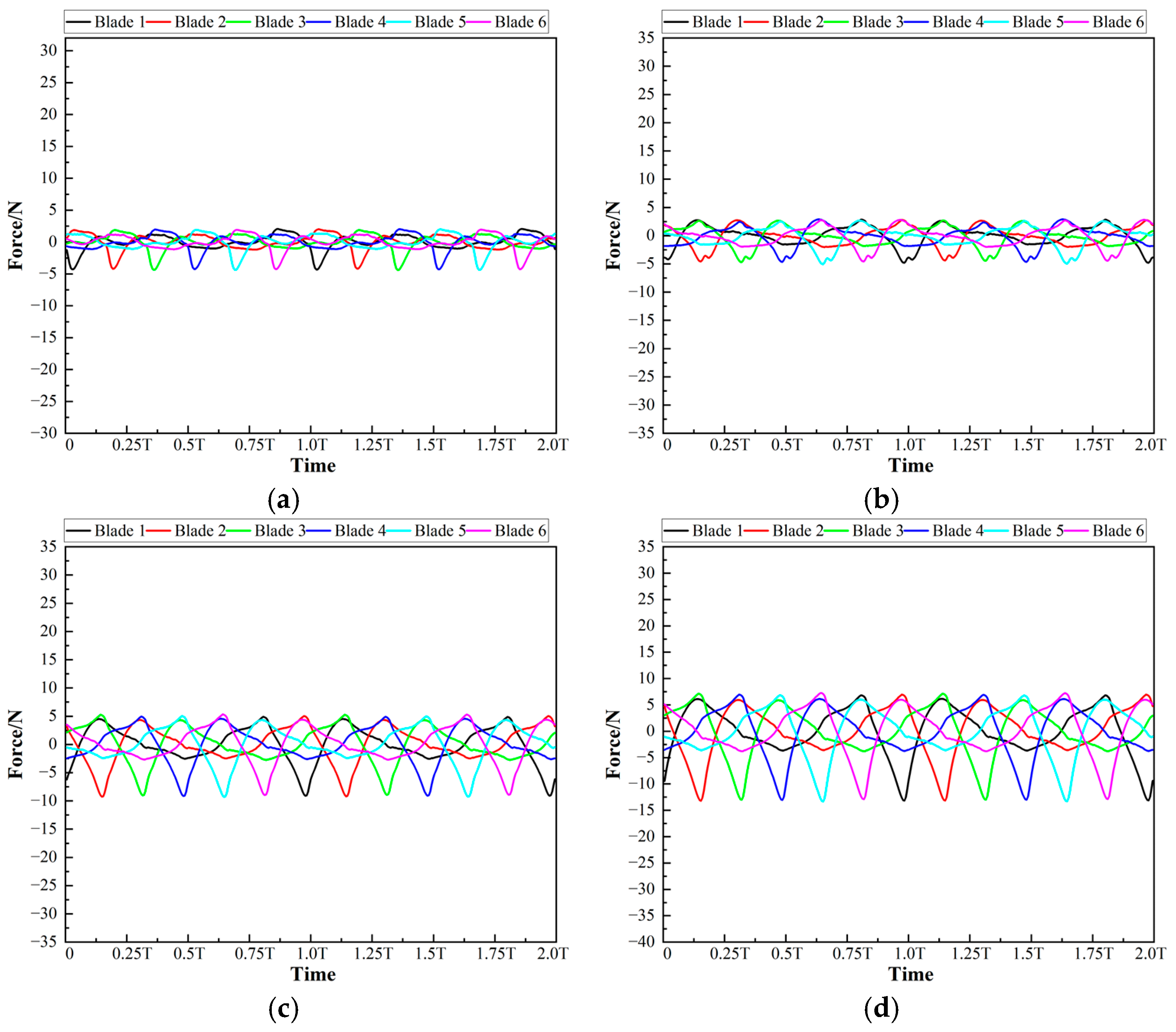

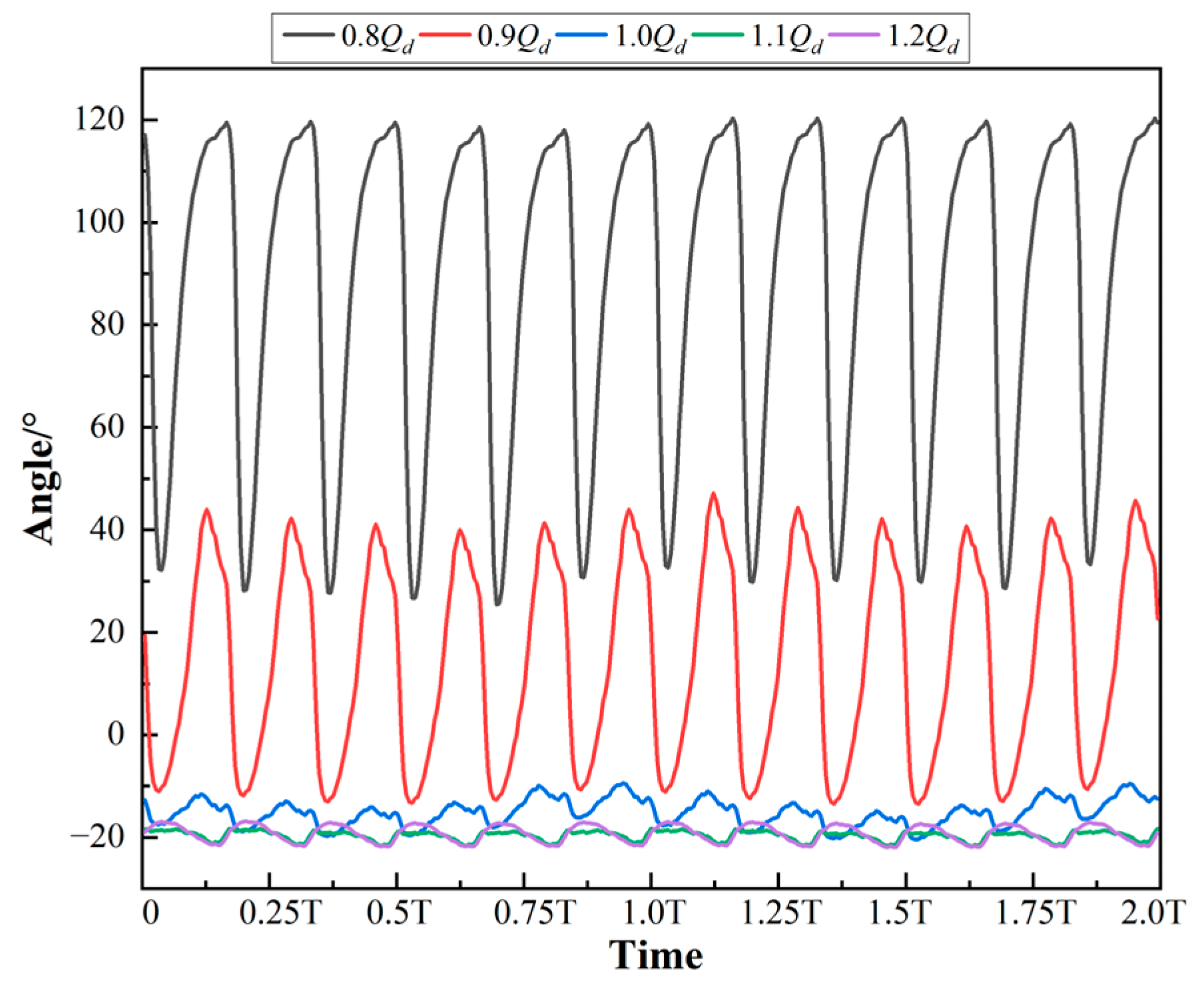

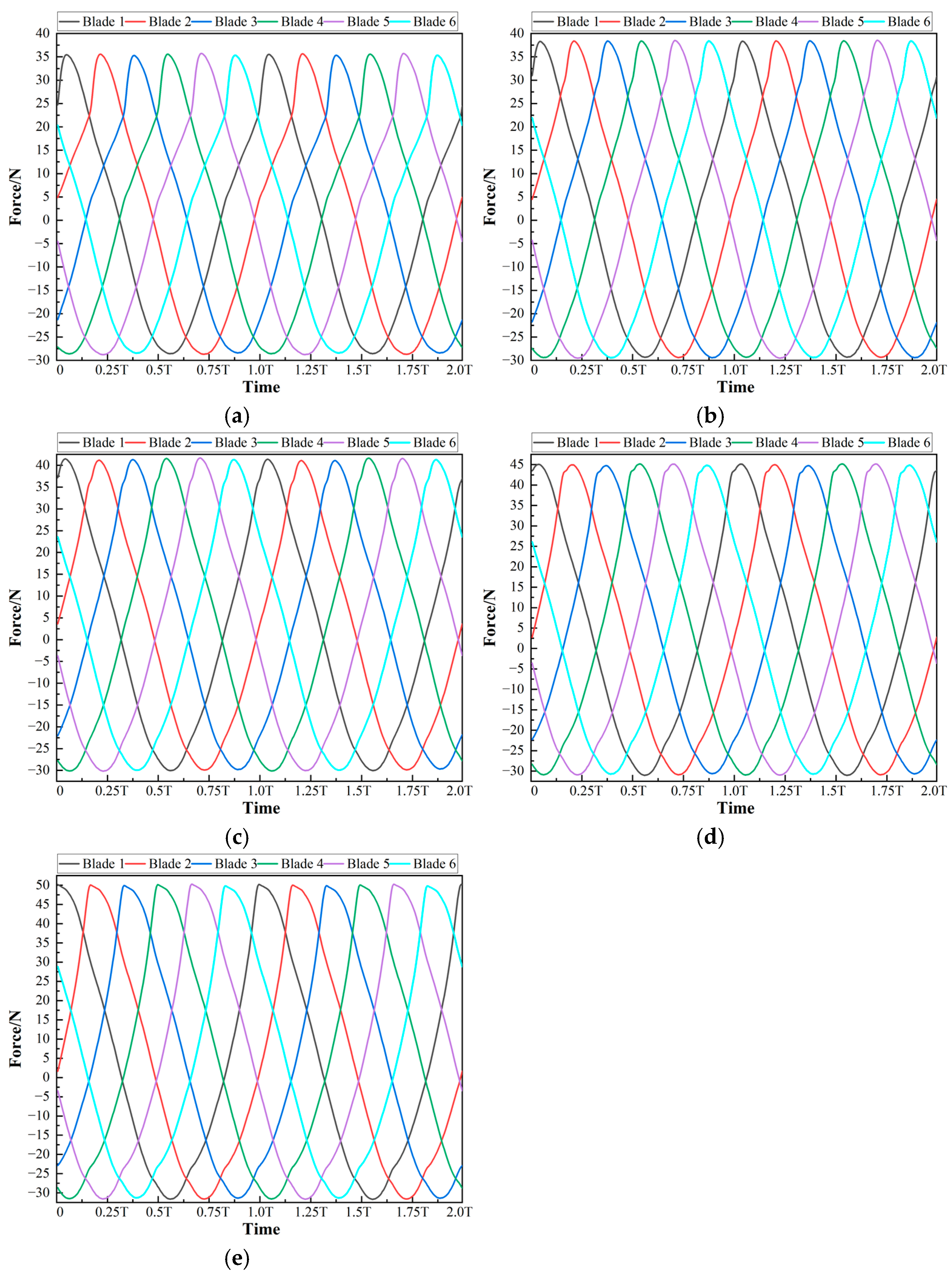

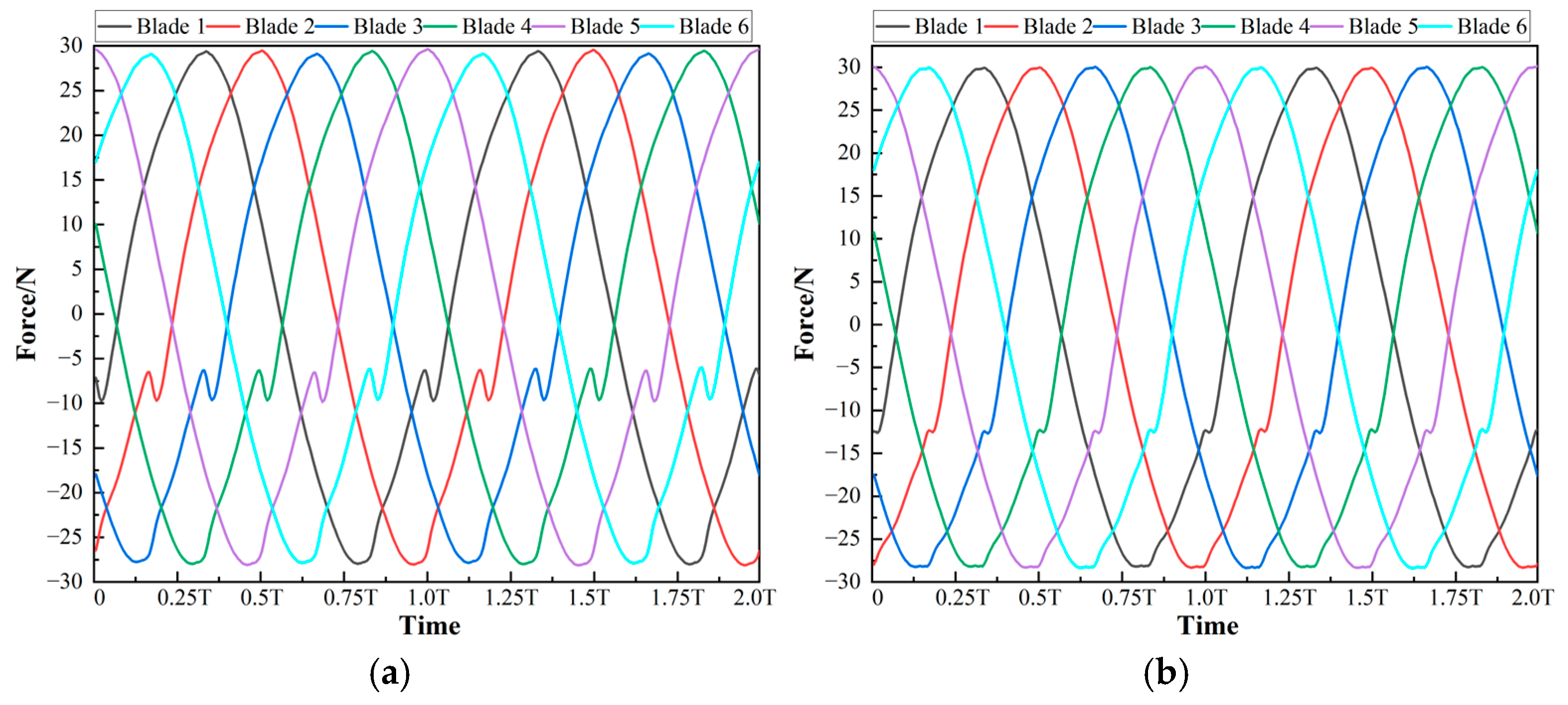

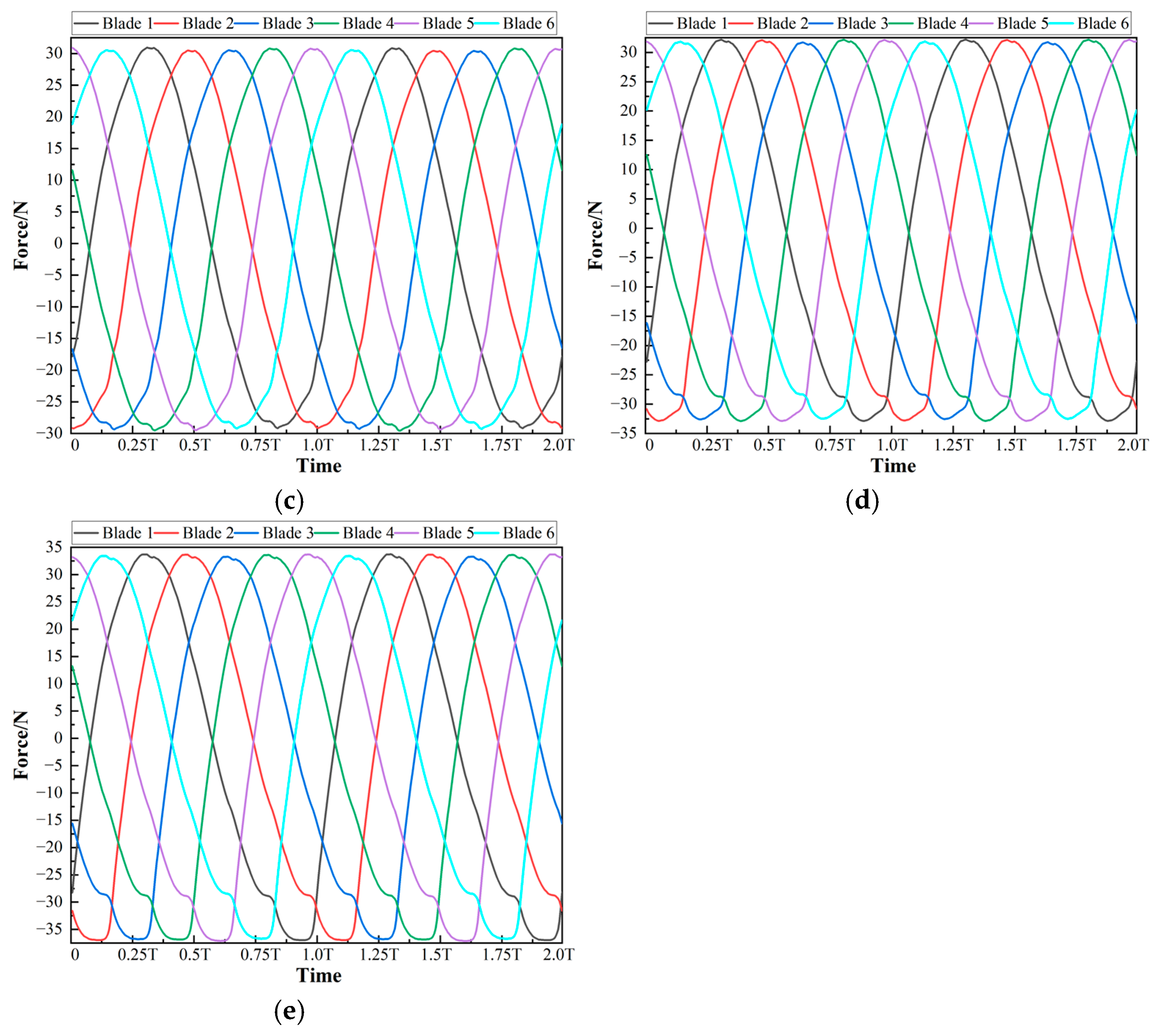

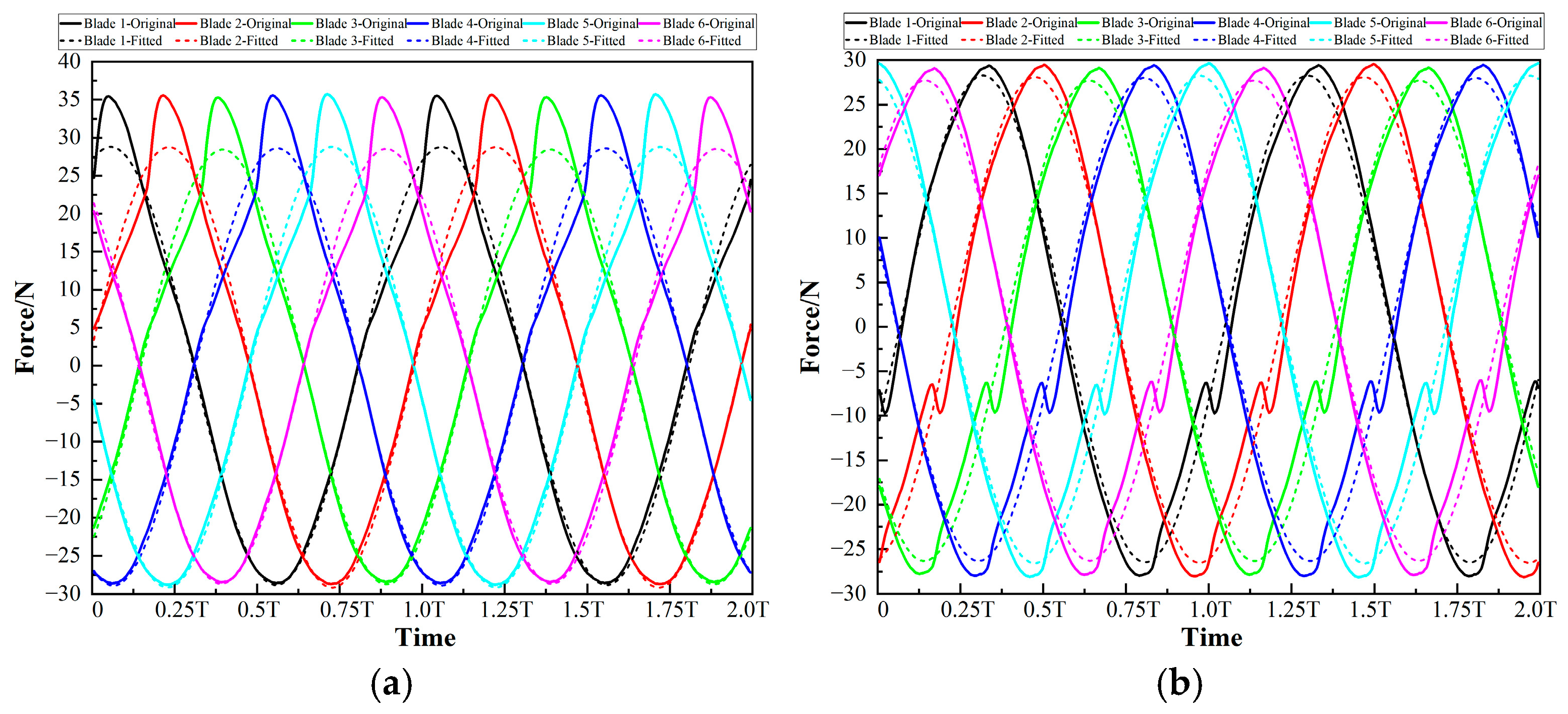

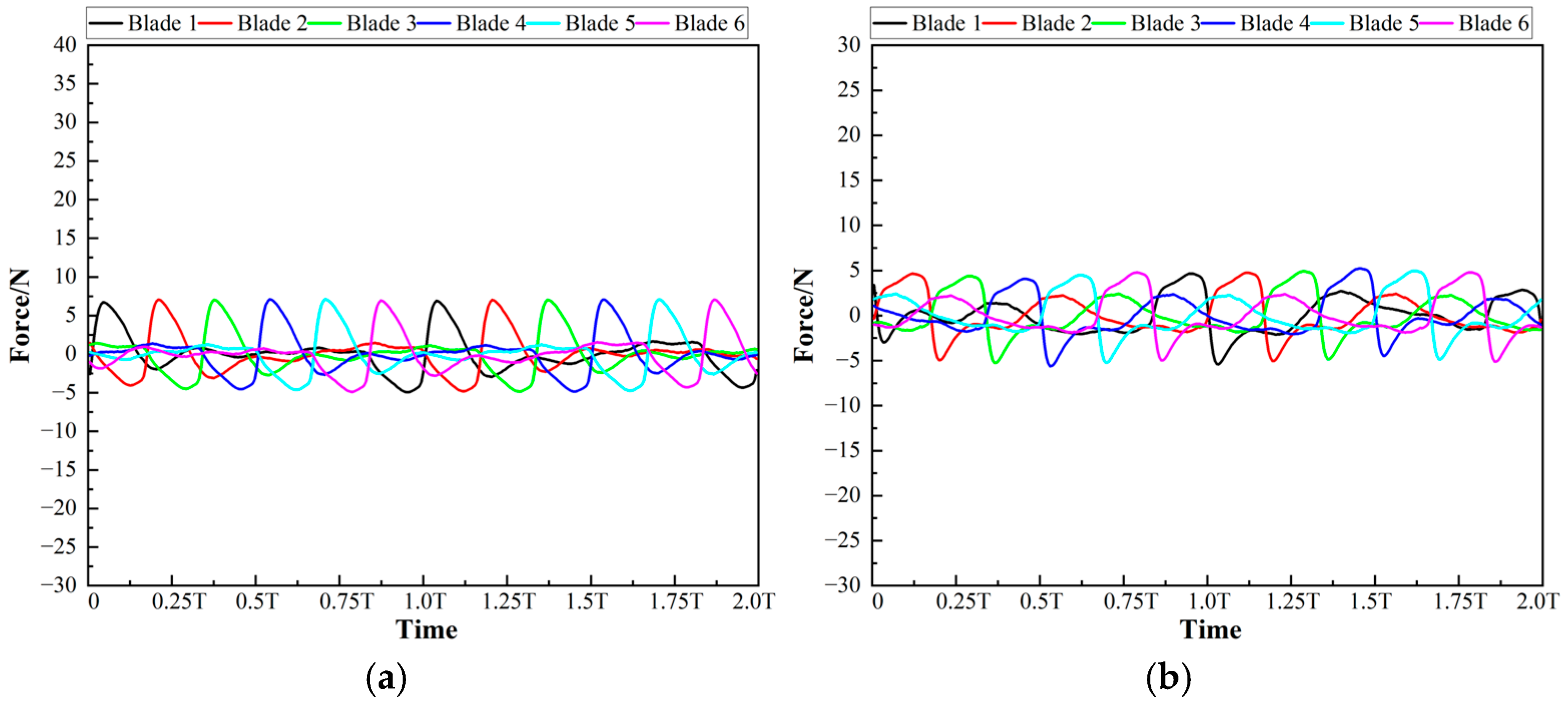

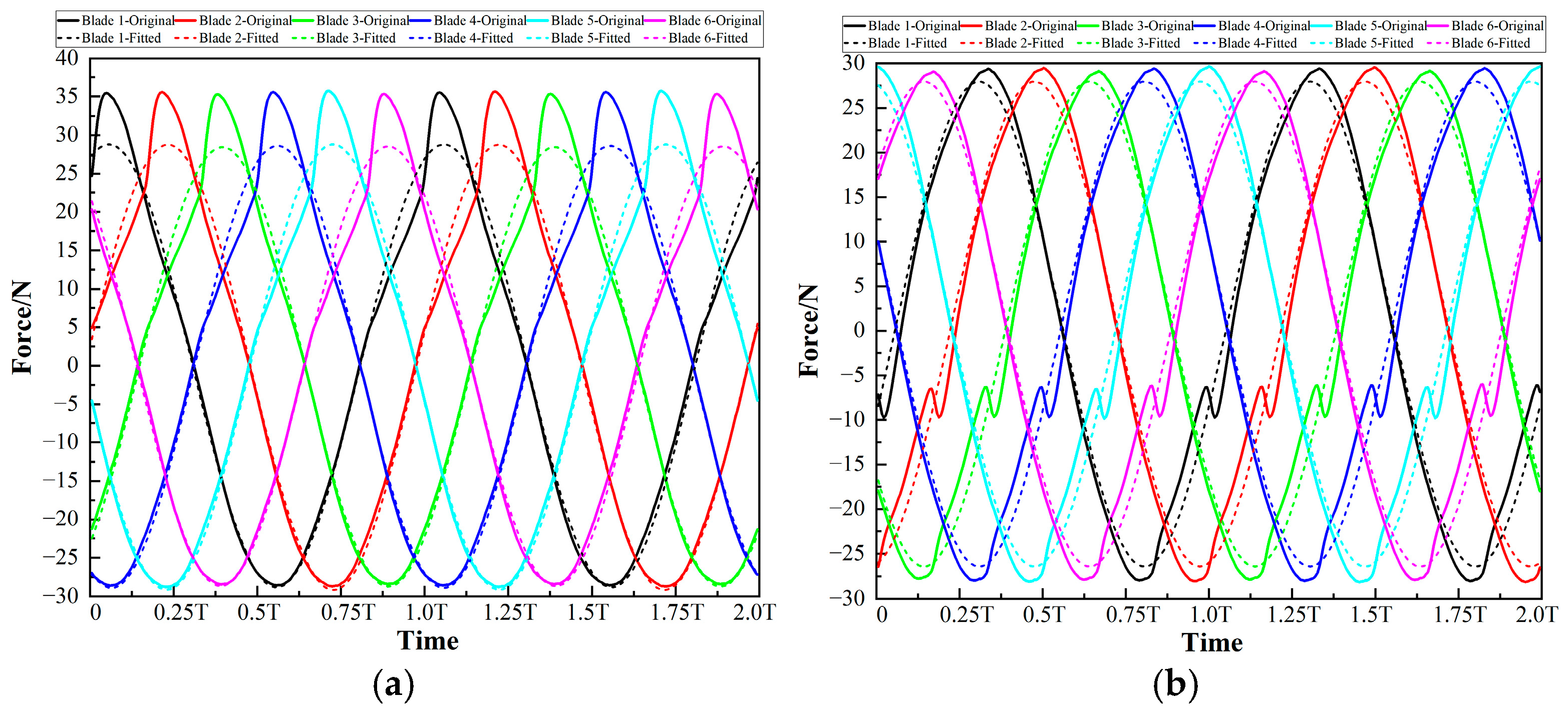

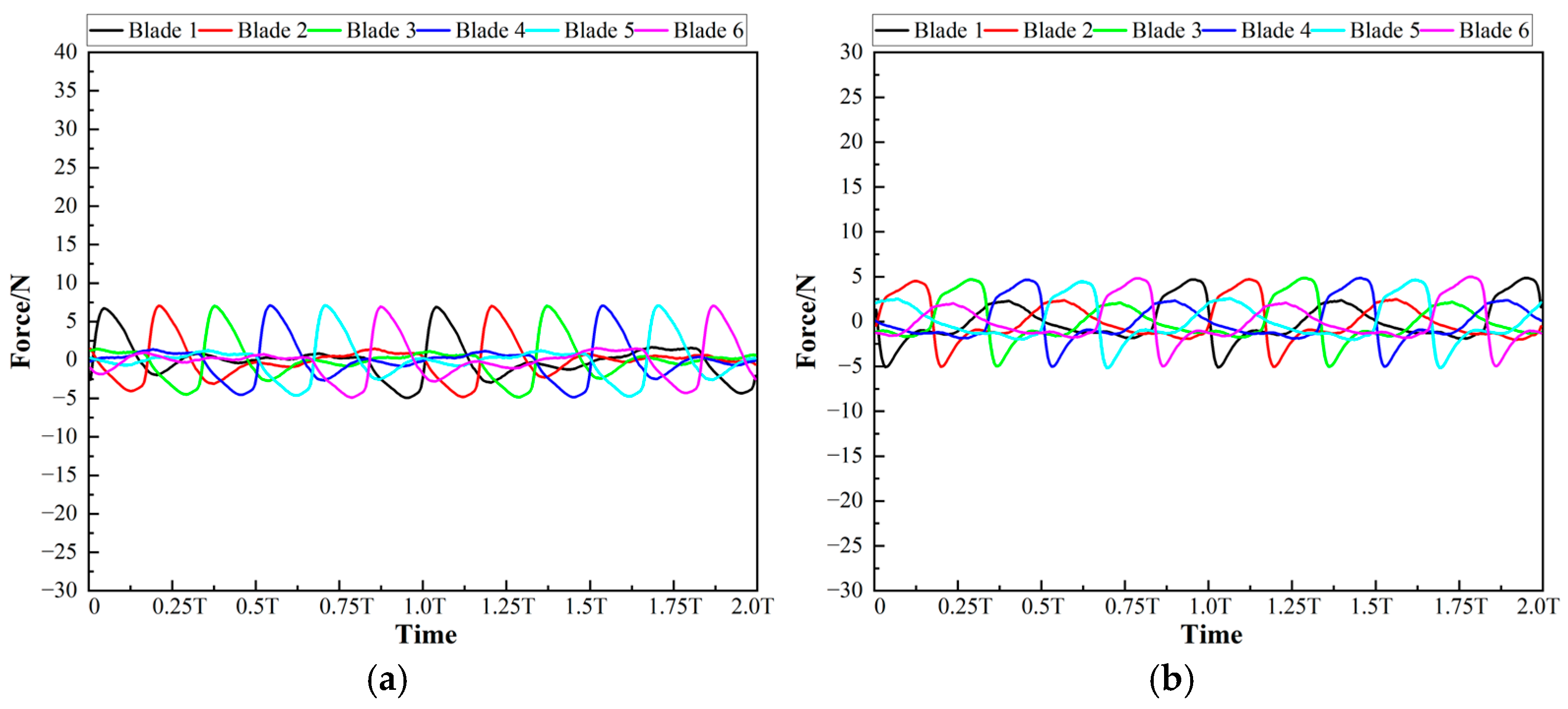

4.3. Hydraulic Radial Force on Each Blade

- (1)

- Cancel the fitting of the angular frequency ω, and fix its value as 2π/T, that is, set ω as the angular frequency corresponding to the impeller rotation, and its value is uniformly set as 303.687 rad/s.

- (2)

- Only fit the force curve of Blade 1 to obtain its corresponding amplitude a, constant term b, and initial phase Φ. While for the force curves of other blades, no fitting operation is carried out. Instead, directly use the fitting parameter results obtained from the force curve of Blade 1. Among them, for the amplitude a and constant term b corresponding to the force curves of other blades, directly use the fitting results of Blade 1, and the initial phase Φ decreases by 60° (approximately 1.047 radians) from that of Blade 1.

- (3)

- Although the fitting parameters of the force curves of Blade 2 to Blade 6 are derived from the fitting results of that of Blade 1, the reliability and accuracy of this method are still evaluated from the perspectives of the goodness of fit and fitting residuals.

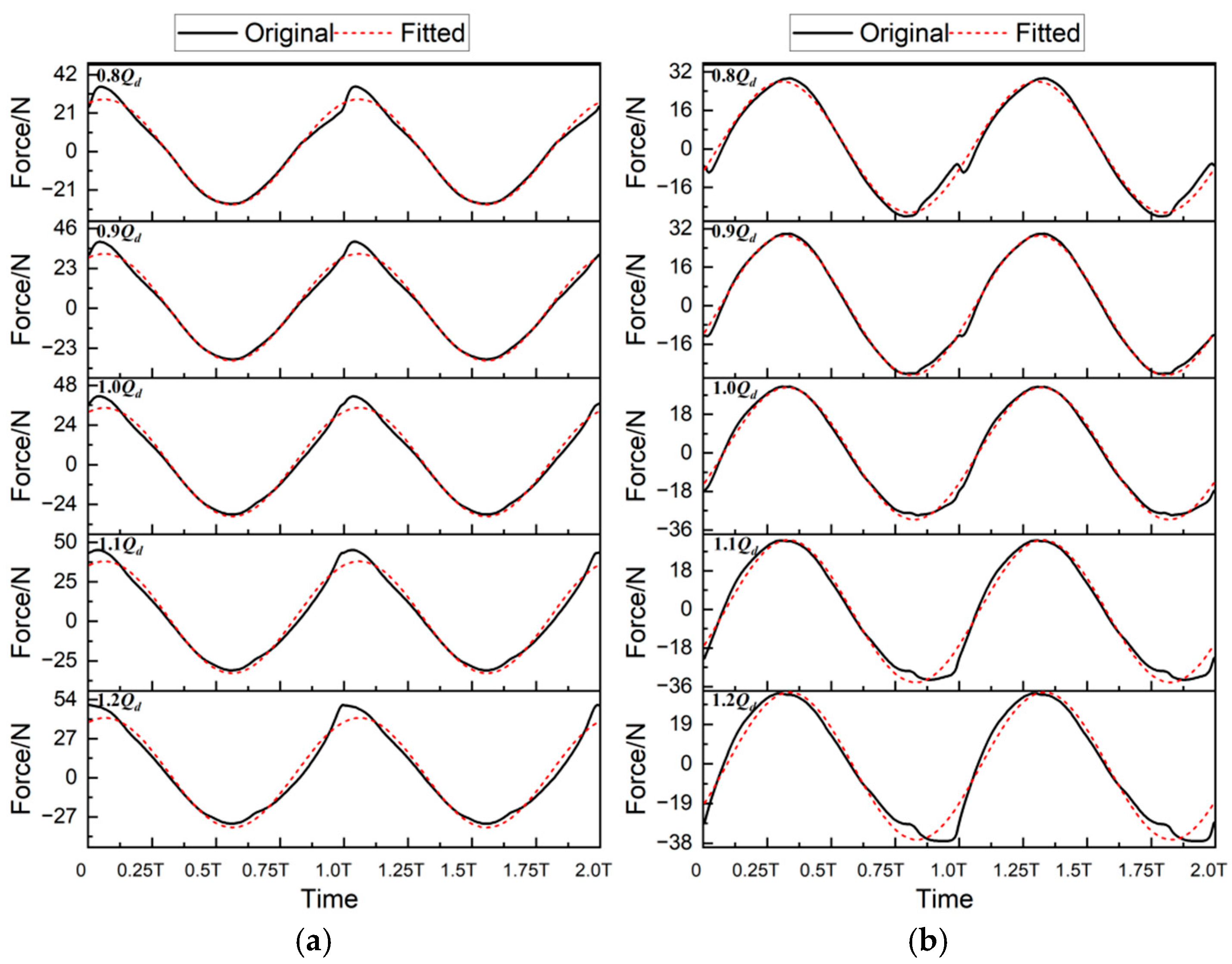

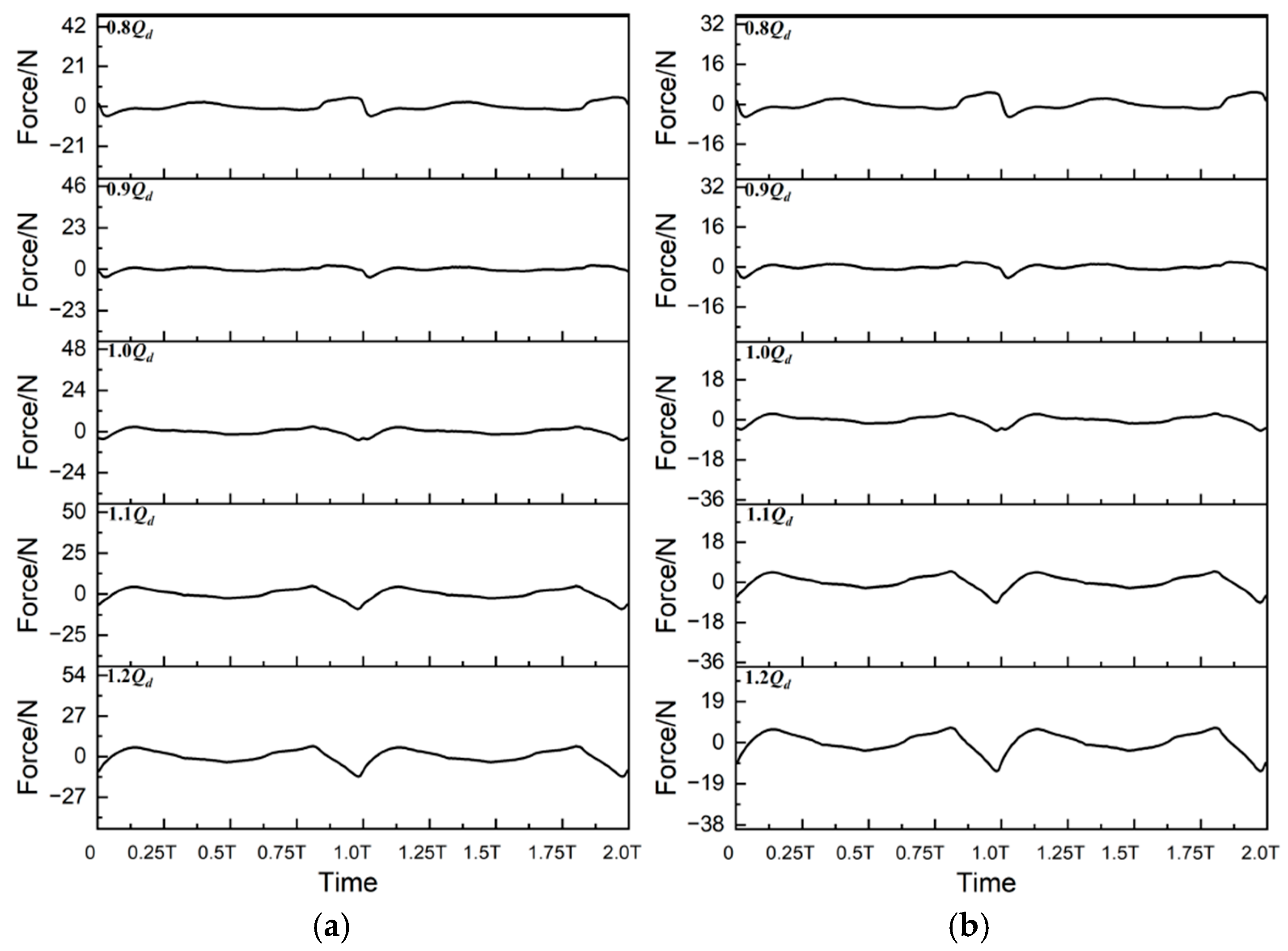

4.4. Hydraulic Radial Force on Blade 1

4.5. CFD Results

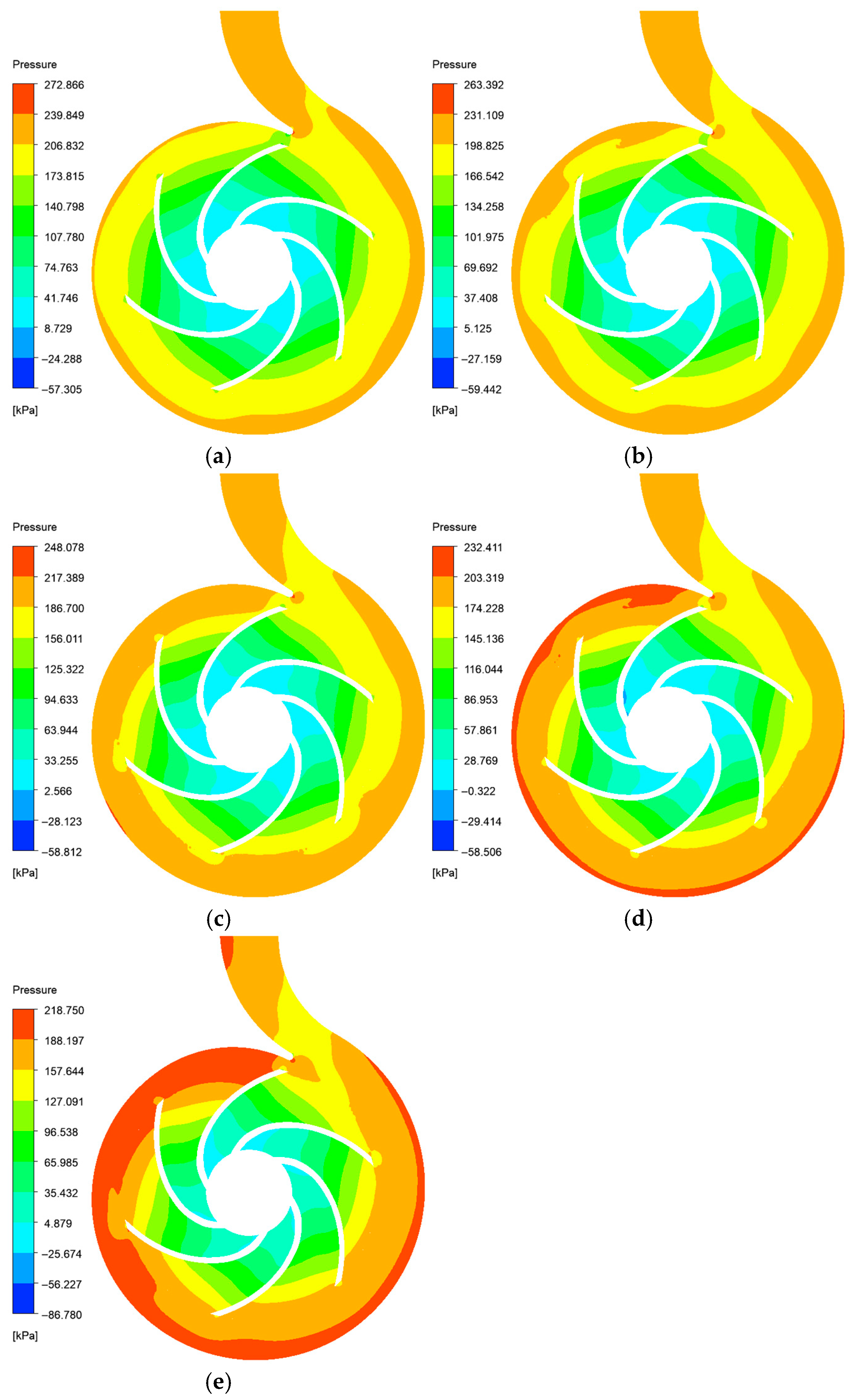

- (1)

- Pressure Trend with Flow Rate: As the flow rate increases from 0.8Qd to 1.2Qd, the overall static pressure magnitude within the impeller and volute exhibits a gradual decrease. This aligns with the pump’s characteristic performance curve (see Figure 6), where the head declines with increasing flow rate due to the combined effects of hydraulic losses (e.g., friction and turbulence) and reduced energy conversion efficiency in the impeller-volute interaction.

- (2)

- Pressure Uniformity at Rated Flow: Around the rated flow condition (i.e., 1.0 Qd), the pressure distribution demonstrates optimal circumferential symmetry. The interaction between the impeller blades and the volute tongue is minimized, leading to balanced pressure gradients around the impeller periphery. This aligns with the earlier findings in Section 4.1, Section 4.2, Section 4.3 and Section 4.4, where the hydraulic radial force around 1.0Qd exhibited minimal fluctuations and a near-constant angle.

- (3)

- Increased Non-Uniformity at Off-Design Conditions: When the flow deviates from the rated point, the pressure asymmetry intensifies. However, distinct pressure distribution characteristics are observed between high-flow (e.g., 1.2Qd) and low-flow (e.g., 0.8Qd) conditions. Specifically, under the 1.2Qd condition, the pressure non-uniformity becomes significantly more pronounced compared to the 0.8Qd case. This discrepancy can be partially attributed to the amplified hydraulic radial forces on the impeller at higher flow rates, as illustrated in Figure 8a, where the intensified circumferential pressure gradients directly correlate with the elevated force magnitudes.

5. Composition Law and Application Enlightenment

5.1. Composition Law of Hydraulic Radial Force on Impeller

- (1)

- The hydraulic radial force on the entire impeller can be decomposed into two parts: the force on all the blades and that on the other parts except the blades. It is found that the hydraulic radial force on the blades accounts for the vast majority of that on the entire impeller.

- (2)

- The curves of the hydraulic radial forces are all periodic curves, and the period is equal to the impeller rotation period T.

- (3)

- Arbitrarily select a blade as the reference blade, and tits next blade in the rotation direction is the adjacent blade. The curve of the hydraulic radial force on the adjacent blade changing with time lags behind the curve of the reference blade by exactly T/N in time. That is, if the curve of the adjacent blade changing with time is translated by T/N in the direction of decreasing on the time axis, it can completely coincide with that of the reference blade. Here, N is the total number of blades.

- (4)

- The curves of the components of the hydraulic radial forces on each blade can all be fitted into sine function curves with a high goodness of fit. Specifically, the angular frequencies obtained by fitting each sine function are all equal to the angular frequency of the impeller rotation. Under the same flow condition, the amplitudes and constant terms obtained by fitting each sine function are equal. The initial phases of the sine functions corresponding to each blade decrease successively by 2π/N in the order of blade rotation. That is, if a blade is arbitrarily selected as the reference blade, then the initial phase of the sine function of its adjacent blade in the rotation direction lags behind to it by 2π/N.

5.2. Application Enlightenment

5.3. Research Innovation

6. Conclusions

- (1)

- Periodic Behavior and Dominant Frequency: The hydraulic radial force exhibited periodic behavior with a dominant frequency corresponding to the blade passing frequency (BPF). This finding aligns with previous studies and confirms the significance of BPF in unsteady flow phenomena.

- (2)

- Force Decomposition and Symmetry: The hydraulic radial force on the impeller could be decomposed into the contributions from each blade, with the main parts of the fitting functions of centrally symmetric blades canceling each other out. This left only the constant terms and fitting residuals, which determined the overall force curve. This discovery offers a deeper understanding of the force composition and provides a foundation for targeted blade optimization.

- (3)

- Flow Condition Impact: The study demonstrated that the hydraulic radial force varied significantly with flow conditions. At the rated flow rate, the force components showed minimal fluctuations, while deviations from the rated flow rate led to increased fluctuations. This insight is crucial for designing pumps that operate efficiently across a range of flow conditions.

- (4)

- Data-Driven Insights: The application of FFT and trigonometric function fitting revealed detailed frequency characteristics and potential variation patterns in the hydraulic radial force. This data-driven approach enhances the ability to predict and mitigate unsteady flow phenomena, offering a robust framework for future research.

- (5)

- Optimization Implications: The findings suggest that focusing on the constant terms and fitting residuals in the force components can lead to more effective optimization of blade structures. This targeted approach can significantly help to reduce the hydraulic radial force and improve the operational stability and efficiency of centrifugal pumps.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Qd | [m3/h] | Rated flow |

| Hd | [m] | Rated head |

| nd | [rev/min] | Rated rotating speed |

| NPSHr | [m] | Required net positive suction head |

| D1 | [m] | Impeller inlet diameter |

| D2 | [m] | Impeller outlet diameter |

| b2 | [m] | Impeller outlet width |

| N | Number of blades | |

| D3 | [m] | Volute base diameter |

| D4 | [m] | Pump inlet diameter |

| D5 | [m] | Pump outlet diameter |

| t | [s] | Time |

| u | [m/s] | Fluid velocity |

| p | [Pa] | Pressure |

| ρ | [kg/m3] | Density |

| µ | [kg/(m·s)] | Effective viscosity |

| f | [N/m3] | Body force |

| g | [m/s2] | Gravity constant |

| F1 | Function value of the SST k-ω turbulence model | |

| φ | Coefficients of the SST k-ω turbulence model | |

| φ1 | Coefficients of the SST k-ω turbulence model | |

| φ2 | Coefficients of the SST k-ε turbulence model | |

| Z | [m] | Height difference between inlet and outlet center points |

| η | [%] | Efficiency |

| H | [m] | Head |

| Qv | [m3/h] | Flow rate |

| Ps | [kw] | Shaft power |

| Ψ | Diffusion coefficient of flow scalar | |

| F | [N] | Force |

| T | [s] | Impeller rotation period |

| θ | [°] | Hydraulic radial force Angle |

| a | [N] | Amplitude |

| ω | [rad/s] | Angular velocity |

| Φ | [rad] | Initial· phase |

| b | [N] | Constant terms |

| R2 | Goodness of fit | |

| S1 | Fit residuals |

Appendix A

| Direction | Blade No. | a [N] | ω [rad/s] | Φ [rad] | b [N] | R2 |

|---|---|---|---|---|---|---|

| X | 1 | 30.719 | 303.687 | 1.172 | 0.698 | 0.989 |

| 2 | 30.719 | 303.687 | 0.125 | 0.698 | 0.989 | |

| 3 | 30.719 | 303.687 | −0.922 | 0.698 | 0.989 | |

| 4 | 30.719 | 303.687 | −1.969 | 0.698 | 0.989 | |

| 5 | 30.719 | 303.687 | −3.017 | 0.698 | 0.989 | |

| 6 | 30.719 | 303.687 | −4.064 | 0.698 | 0.989 | |

| Y | 1 | 28.922 | 303.687 | −0.436 | 0.145 | 0.997 |

| 2 | 28.922 | 303.687 | −1.483 | 0.145 | 0.997 | |

| 3 | 28.922 | 303.687 | −2.530 | 0.145 | 0.997 | |

| 4 | 28.922 | 303.687 | −3.577 | 0.145 | 0.997 | |

| 5 | 28.922 | 303.687 | −4.624 | 0.145 | 0.997 | |

| 6 | 28.922 | 303.687 | −5.672 | 0.145 | 0.997 |

| Direction | Blade No. | a [N] | ω [rad/s] | Φ [rad] | b [N] | R2 |

|---|---|---|---|---|---|---|

| X | 1 | 32.852 | 303.687 | 1.161 | 1.651 | 0.986 |

| 2 | 32.852 | 303.687 | 0.114 | 1.651 | 0.986 | |

| 3 | 32.852 | 303.687 | −0.933 | 1.651 | 0.986 | |

| 4 | 32.852 | 303.687 | −1.981 | 1.651 | 0.986 | |

| 5 | 32.852 | 303.687 | −3.028 | 1.651 | 0.986 | |

| 6 | 32.852 | 303.687 | −4.075 | 1.651 | 0.986 | |

| Y | 1 | 30.831 | 303.687 | −0.495 | −0.267 | 0.993 |

| 2 | 30.831 | 303.687 | −1.542 | −0.267 | 0.994 | |

| 3 | 30.831 | 303.687 | −2.589 | −0.267 | 0.994 | |

| 4 | 30.831 | 303.687 | −3.637 | −0.267 | 0.994 | |

| 5 | 30.831 | 303.687 | −4.684 | −0.267 | 0.994 | |

| 6 | 30.831 | 303.687 | −5.731 | −0.267 | 0.993 |

| Direction | Blade No. | a [N] | ω [rad/s] | Φ [rad] | b [N] | R2 |

|---|---|---|---|---|---|---|

| X | 1 | 35.392 | 303.687 | 1.162 | 2.587 | 0.980 |

| 2 | 35.392 | 303.687 | 0.115 | 2.587 | 0.980 | |

| 3 | 35.392 | 303.687 | −0.932 | 2.587 | 0.980 | |

| 4 | 35.392 | 303.687 | −1.979 | 2.587 | 0.980 | |

| 5 | 35.392 | 303.687 | −3.026 | 2.587 | 0.980 | |

| 6 | 35.392 | 303.687 | −4.074 | 2.587 | 0.980 | |

| Y | 1 | 33.207 | 303.687 | −0.529 | −0.795 | 0.982 |

| 2 | 33.207 | 303.687 | −1.576 | −0.795 | 0.982 | |

| 3 | 33.207 | 303.687 | −2.623 | −0.795 | 0.982 | |

| 4 | 33.207 | 303.687 | −3.670 | −0.795 | 0.982 | |

| 5 | 33.207 | 303.687 | −4.717 | −0.795 | 0.983 | |

| 6 | 33.207 | 303.687 | −5.765 | −0.795 | 0.982 |

| Direction | Blade No. | a [N] | ω [rad/s] | Φ [rad] | b [N] | R2 |

|---|---|---|---|---|---|---|

| X | 1 | 37.809 | 303.687 | 1.152 | 3.557 | 0.972 |

| 2 | 37.809 | 303.687 | 0.105 | 3.557 | 0.972 | |

| 3 | 37.809 | 303.687 | −0.942 | 3.557 | 0.972 | |

| 4 | 37.809 | 303.687 | −1.989 | 3.557 | 0.972 | |

| 5 | 37.809 | 303.687 | −3.036 | 3.557 | 0.972 | |

| 6 | 37.809 | 303.687 | −4.084 | 3.557 | 0.972 | |

| Y | 1 | 35.301 | 303.687 | −0.562 | −1.025 | 0.968 |

| 2 | 35.301 | 303.687 | −1.609 | −1.025 | 0.968 | |

| 3 | 35.301 | 303.687 | −2.656 | −1.025 | 0.968 | |

| 4 | 35.301 | 303.687 | −3.704 | −1.025 | 0.968 | |

| 5 | 35.301 | 303.687 | −4.751 | −1.025 | 0.968 | |

| 6 | 35.301 | 303.687 | −5.798 | −1.025 | 0.967 |

References

- Yuan, Z.Y.; Zhang, Y.X.; Zhou, W.B.; Zhang, J.Y.; Zhu, J.J. Optimization of a centrifugal pump with high efficiency and low noise based on fast prediction method and vortex control. Energy 2024, 289, 129835. [Google Scholar] [CrossRef]

- Han, R.; Zhang, X.; Ge, R.; Geng, H.; Xu, H.; Lin, H.; Jiang, Y.; Zhang, J.; Sang, M.; Zhao, T.; et al. Design, construction and testing of the prototype cryogenic circulation centrifugal pump for the high energy photon source. Cryogenics 2024, 142, 103900. [Google Scholar] [CrossRef]

- Cui, B.; Shi, M. Analysis of unsteady flow characteristics near the cutwater by cutting impeller hub in a high-speed centrifugal pump. J. Mar. Sci. Eng. 2024, 12, 587. [Google Scholar] [CrossRef]

- Long, Y.; Xu, Y.; Zhou, Z.; Wang, R.; Zhu, R.S.; Fu, Q. Study on cavitation flow and high-speed vortex interference mechanism of high-speed inducer centrifugal pump based on full flow channel. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 683. [Google Scholar] [CrossRef]

- Jang, H.; Suh, J. Flow characteristic analysis of the impeller inlet diameter in a double-suction pump. Energies 2024, 17, 1989. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, Z.M.; Han, S.Q.; Zhu, B.S. Study on the unsteady flow characteristics of a pump turbine in pump mode. Processes 2024, 12, 41. [Google Scholar] [CrossRef]

- Yuan, Y.; Junejo, A.R.; Wang, J.; Chen, B. Unsteady flow behaviors and vortex dynamic characteristics of a marine centrifugal pump under the swing motion. Machines 2024, 12, 687. [Google Scholar] [CrossRef]

- Sun, C.; Dai, Y.X.; Cai, Y.L.; Wang, Z.L.; Zhang, H. Numerical investigation of the effect of the non-uniform intake flow on the unsteady flow and the excitation of the pump in a water-jet propulsion. J. Phys. Conf. Ser. 2024, 2854, 012051. [Google Scholar] [CrossRef]

- Luo, Z.Y.; Feng, Y.; Sun, X.Y.; Gong, Y.; Lu, J.X.; Zhang, X.W. Research on the unsteady flow and vortex characteristics of cavitation at the tongue in centrifugal pump. J. Appl. Fluid. Mech. 2024, 17, 646–657. [Google Scholar] [CrossRef]

- Nie, L.; Liu, Z.Q.; Yang, W.; Li, Y.J. Comparative study of the cavitation situation and the non-cavitation situation under unsteady flow phenomena of a centrifugal pump. J. Phys. Conf. Ser. 2024, 2707, 012054. [Google Scholar] [CrossRef]

- Zhang, H.H.; You, H.L.; Lu, H.S.; Li, K.; Zhang, Z.Y.; Jiang, L.X. CFD-Rotordynamics sequential coupling simulation approach for the flow-induced vibration of rotor system in centrifugal pump. Appl. Sci. 2020, 10, 1186. [Google Scholar] [CrossRef]

- Lu, J.Q.; Yao, X.L.; Zheng, H.X.; Yan, X.W.; Liu, H.L.; Wu, T.X. Analysis of unsteady internal flow and its induced structural response in a circulating water pump. Water 2024, 16, 1294. [Google Scholar] [CrossRef]

- Sakran, H.; Abdul Aziz, M.S.; Khor, C.Y. Effect of blade number on the energy dissipation and centrifugal pump performance based on the entropy generation theory and fluid–structure interaction. Arab. J. Sci. Eng. 2023, 49, 11031–11052. [Google Scholar] [CrossRef]

- Zhai, L.J.; Chen, H.X.; Gu, Q.; Ma, Z. Investigation on performance of a marine centrifugal pump with broken impeller. Mod. Phys. Lett. B 2022, 36, 2250174. [Google Scholar] [CrossRef]

- Zhang, H.H.; You, H.L.; Lu, H.S. Mechanical–thermal sequential coupling simulation for predicting the temperature distribution of seal rings—Part I. Seal. Technol. 2020, 2020, 5–8. [Google Scholar] [CrossRef]

- Zhang, H.H.; Deng, C.; Chang, C.C.; You, H.L. Novel dual synergistic sealing ring design for a high-pressure pump–Part I. Seal. Technol. 2022, 2022, 9–17. [Google Scholar] [CrossRef]

- Jia, X.Q.; Yu, Y.F.; Li, B.; Wang, F.C.; Zhu, Z.C. Effects of incident angle of sealing ring clearance on internal flow and cavitation of centrifugal pump. Proc. Inst. Mech. Eng. Part. E J. Process Mech. Eng. 2023, 238, 2867–2882. [Google Scholar] [CrossRef]

- Zeng, J.L.; Liu, Z.L.; Huang, Q.; Quan, H.; Shao, A.C. Research on the modified mathematical prediction model of impeller cover side cavity liquid pressure for centrifugal pumps. J. Appl. Fluid. Mech. 2022, 15, 673–685. [Google Scholar] [CrossRef]

- Cao, J.; Luo, Y.; Deng, L.; Liu, X.; Yan, S.; Zhai, L.; Wang, Z. Thermo-hydrodynamic lubrication and energy dissipation mechanism of a pump-turbine thrust bearing in load-rejection process. Phys. Fluids 2024, 36, 37138. [Google Scholar] [CrossRef]

- Qian, C.; Yang, L.H.; Qi, Z.P.; Yang, C.X. Study on the balance force regulation method of multi-stage pump balance drum system. Proc. Inst. Mech. Eng. Part. A J. Power Energy 2023, 237, 985–998. [Google Scholar] [CrossRef]

- Qian, C.; Yang, L.H.; Qi, Z.P.; Yang, C.X.; Niu, C.H. Mechanism analysis of double helical balance drum to improve axial force of multistage pump. Mod. Phys. Lett. B 2023, 36, 2250185. [Google Scholar] [CrossRef]

- Cui, B.L.; Li, J.C.; Zhang, C.L.; Zhang, Y.B. Analysis of radial force and vibration energy in a centrifugal pump. Math. Probl. Eng. 2020, 2020, 1–12. [Google Scholar] [CrossRef]

- Zhang, Z.C.; Chen, H.X.; Ma, Z.; Wei, Q.; He, J.W.; Liu, H.; Liu, C. Application of the hybrid RANS/LES method on the hydraulic dynamic performance of centrifugal pumps. J. Hydrodyn. 2018, 31, 637–640. [Google Scholar] [CrossRef]

- Zhang, Z.C.; Chen, H.X.; Ma, Z.; He, J.W.; Liu, H.; Liu, C. Research on Improving the dynamic performance of centrifugal pumps with twisted gap drainage blades. J. Fluids Eng. 2019, 141, 1–15. [Google Scholar] [CrossRef]

- Wang, J.Q.; Duan, J.D.; Yang, D.W.; Ren, T.H.; Zhu, R.S.; Fu, Q. Effect of baffles on internal flow characteristics of double-inhalation centrifugal pumps under low flow conditions. Phys. Fluids 2024, 36, 105158. [Google Scholar] [CrossRef]

- Zhou, R.Z.; Liu, H.L.; Dong, L. Effect of volute geometry on radial force characteristics of centrifugal pump during startup. J. Appl. Fluid. Mech. 2022, 15, 25–36. [Google Scholar] [CrossRef]

- Song, X.Y.; Shi, Y.X.; Zheng, K.X.; Luo, X.W. Pressure oscillations and radial forces for centrifugal pumps with single- or double-suction impellers. J. Mech. Sci. Technol. 2024, 38, 3009–3025. [Google Scholar] [CrossRef]

- Cui, B.L.; Liu, J.X.; Zhai, L.L.; Han, A.D. Analysis of the performance and pressure pulsation in a high-speed centrifugal pump with different hub-cutting angles. Mod. Phys. Lett. B 2023, 37, 2350117. [Google Scholar] [CrossRef]

- Gan, G.C.; Duan, Y.C.; Yi, J.B.; Fu, Q.; Zhu, R.S.; Shi, W.H. Effect of tip clearance on the cavitation performance of high-speed pump-jet propeller. Processes 2023, 11, 3050. [Google Scholar] [CrossRef]

- Jia, X.; Zhang, J.; Chen, D.; Tang, Z.; Huang, Q.; Zhou, C.; Ma, Y.; Zhao, Q.; Lin, Z. Impact of key airfoil blade parameters on the internal flow and vibration characteristics of centrifugal pumps. Phys. Fluids 2025, 37, 015134. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Dai, Y.R.; Shi, W.D.; Yang, Y.F.; Xie, Z.S.; Zhang, Q.H. Numerical analysis of unsteady internal flow characteristics in a bidirectional axial flow pump. Sustainability 2024, 16, 224. [Google Scholar] [CrossRef]

- Dong, W.; Fan, X.G.; Dong, Y.; He, F. Transient internal flow characteristics of centrifugal pump during rapid start-up. Iran. J. Sci. Technol. Trans. Mech. Eng. 2023, 48, 821–831. [Google Scholar] [CrossRef]

- Luo, Y.Y.; Wang, Z.W.; Liang, Q.W. Stress of Francis turbine runners under fluctuant work conditions. J. Tsinghua Univ. 2005, 45, 235–237. [Google Scholar] [CrossRef]

- Chen, X.P.; Zhang, W.J.; Wang, S.L.; Zhu, Z.C. Effects of cryogenic medium on the weakly compressible flow characteristics of a high-speed centrifugal pump at a low flow rate. J. Mech. Sci. Technol. 2023, 37, 6537–6546. [Google Scholar] [CrossRef]

- Jadhav, A.R.; Jadhav, R.D.; Jadhav ASingh, C. Netflix Data Analysis Using EDA. In Proceedings of the International Conference on Internet of Things and Connected Technologies, Ocean Flower Island, China, 17–21 December 2023; Lin, F., Pastor, D., Kesswani, N., Patel, A., Bordoloi, S., Koley, C., Eds.; Lecture Notes in Networks and Systems. Springer: Singapore; Volume 1072. [Google Scholar] [CrossRef]

- Rathore, R.; Kaur, N. Comparison study of DIT and DIF radix-2 FFT algorithm. Int. J. Comput. Appl. 2016, 150, 25–28. [Google Scholar] [CrossRef]

- Budil, D.E.; Lee, S.; Saxena, S.; Freed, J.H. Nonlinear-least-squares analysis of slow-motion EPR spectra in one and two dimensions using a modified levenberg–marquardt algorithm. J. Magn. Reson. Ser. A 1996, 120, 155–189. [Google Scholar] [CrossRef]

- Yang, F.; Chang, P.C.; Li, C.; Shen, Q.R.; Qian, J.; Li, J.D. Numerical analysis of pressure pulsation in vertical submersible axial flow pump device under bidirectional operation. AIP Adv. 2022, 12, 025107. [Google Scholar] [CrossRef]

- Dong, W.; Dong, Y.; Sun, J.; Zhang, H.C.; Chen, D.Y. Analysis of the internal flow characteristics, pressure pulsations, and radial force of a centrifugal pump under variable working conditions. Iran. J. Sci. Technol. Trans. Mech. Eng. 2023, 47, 397–415. [Google Scholar] [CrossRef]

- Li, Y.F.; Su, H.L.; Wang, Y.W.; Jiang, W.; Zhu, Q.P. Dynamic characteristic analysis of centrifugal pump impeller based on fluid-solid coupling. J. Mar. Sci. Eng. 2022, 10, 880. [Google Scholar] [CrossRef]

- Tan, Z.S.; Duan, X.X.; Zhou, C.J. The influence of blade fracture on the internal flow characteristics androtor system of horizontal centrifugal pumps. J. Vib. Control. 2023, 30, 3706–3718. [Google Scholar] [CrossRef]

- Zhang, N.; Dong, H.Z.; Zheng, F.K.; Gad, M.N.; Li, D.L.; Gao, B. Investigation of the impact of rotor- stator matching modes on the pressure pulsations of the guide vane centrifugal pump. Ann. Nucl. Energy 2025, 214, 111189. [Google Scholar] [CrossRef]

- Zhu, X.; Han, X.; Xie, C.; Zhang, H.; Jiang, E. Numerical investigation of clocking effect on fluctuating characters and radial force within impeller for a centrifugal pump. J. Appl. Fluid. Mech. 2025, 18, 549–566. Available online: https://www.magiran.com/p2814120 (accessed on 2 July 2025).

- Zhao, J.T.; Pei, J.; Yuan, J.P.; Wang, W.J. Structural optimization of multistage centrifugal pump via computational fluid dynamics and machine learning method. J. Comput. Des. Eng. 2023, 10, 1204–1218. [Google Scholar] [CrossRef]

- Wang, C.; Yao, Y.L.; Yang, Y.; Chen, X.H.; Wang, H.; Ge, J.; Cao, W.D.; Zhang, Q.Q. Automatic optimization of centrifugal pump for energy conservation and efficiency enhancement based on response surface methodology and computational fluid dynamics. Eng. Appl. Comput. Fluid. Mech. 2023, 17, 2227686. [Google Scholar] [CrossRef]

- Sakran, H.K.; Abdul Aziz, M.S.; Abdullah, M.Z.; Khor, C.Y. Effects of blade number on the centrifugal pump performance: A review. Arabian J. Sci. Eng. 2022, 47, 7945–7961. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value |

|---|---|---|

| Rated flow | Qd | 12.5 m3/h |

| Rated head | Hd | 22.7 m |

| Rated speed | nd | 2900 r/min |

| Specific speed | Ns | 2.97 |

| NPSH required | NPSHr | 4.0 m |

| Impeller inlet diameter | D1 | 0.061 m |

| Impeller outlet diameter | D2 | 0.139 m |

| Impeller outlet width | b2 | 0.007 m |

| Number of blades | N | 6 |

| Volute base diameter | D3 | 0.15 m |

| Pump inlet diameter | D4 | 0.05 m |

| Pump outlet diameter | D5 | 0.032 m |

| Fluid Domain | Element Number | Node Number |

|---|---|---|

| Inlet pipe | 1,093,640 | 2,806,035 |

| Suction region | 423,445 | 1,089,239 |

| Impeller region | 2,349,537 | 6,029,682 |

| Discharge chamber | 4,224,759 | 10,842,508 |

| Outlet pipe | 447,719 | 1,157,567 |

| Total | 8,539,100 | 21,925,031 |

| Direction | Blade No. | a [N] | ω [rad/s] | Φ [rad] | b [N] | R2 |

|---|---|---|---|---|---|---|

| X | 1 | 28.799 | 301.705 | 1.215 | −0.009 | 0.987 |

| 2 | 28.956 | 305.445 | 0.090 | −0.196 | 0.987 | |

| 3 | 28.577 | 304.349 | −0.934 | −0.132 | 0.986 | |

| 4 | 28.754 | 304.127 | −1.976 | −0.133 | 0.986 | |

| 5 | 28.952 | 303.642 | −3.017 | −0.167 | 0.986 | |

| 6 | 28.594 | 301.777 | −4.024 | −0.055 | 0.987 | |

| Y | 1 | 27.373 | 307.990 | −0.466 | 0.896 | 0.990 |

| 2 | 27.311 | 303.867 | −1.432 | 0.782 | 0.987 | |

| 3 | 27.022 | 302.914 | −2.458 | 0.688 | 0.987 | |

| 4 | 27.168 | 301.636 | −3.481 | 0.830 | 0.988 | |

| 5 | 27.420 | 303.051 | −4.560 | 0.838 | 0.987 | |

| 6 | 27.016 | 303.994 | −5.621 | 0.702 | 0.987 |

| Direction | Blade No. | a [N] | ω [rad/s] | Φ [rad] | b [N] | R2 |

|---|---|---|---|---|---|---|

| X | 1 | 28.722 | 303.687 | 1.172 | −0.185 | 0.986 |

| 2 | 28.722 | 303.687 | 0.125 | −0.185 | 0.986 | |

| 3 | 28.722 | 303.687 | −0.922 | −0.185 | 0.986 | |

| 4 | 28.722 | 303.687 | −1.969 | −0.185 | 0.986 | |

| 5 | 28.722 | 303.687 | −3.017 | −0.185 | 0.986 | |

| 6 | 28.722 | 303.687 | −4.064 | −0.185 | 0.986 | |

| Y | 1 | 27.187 | 303.687 | −0.381 | 0.769 | 0.987 |

| 2 | 27.187 | 303.687 | −1.428 | 0.769 | 0.987 | |

| 3 | 27.187 | 303.687 | −2.475 | 0.769 | 0.987 | |

| 4 | 27.187 | 303.687 | −3.523 | 0.769 | 0.987 | |

| 5 | 27.187 | 303.687 | −4.570 | 0.769 | 0.987 | |

| 6 | 27.187 | 303.687 | −5.617 | 0.769 | 0.987 |

| Direction | Flow Condition | a [N] | ω [rad/s] | Φ [rad] | b [N] | R2 |

|---|---|---|---|---|---|---|

| X | 0.8Qd | 28.722 | 303.687 | 1.172 | −0.185 | 0.986 |

| 0.9Qd | 30.719 | 303.687 | 1.172 | 0.698 | 0.989 | |

| 1.0Qd | 32.852 | 303.687 | 1.161 | 1.651 | 0.986 | |

| 1.1Qd | 35.392 | 303.687 | 1.162 | 2.587 | 0.980 | |

| 1.2Qd | 37.809 | 303.687 | 1.152 | 3.557 | 0.972 | |

| Y | 0.8Qd | 27.187 | 303.687 | −0.381 | 0.769 | 0.987 |

| 0.9Qd | 28.922 | 303.687 | −0.436 | 0.145 | 0.997 | |

| 1.0Qd | 30.831 | 303.687 | −0.495 | −0.267 | 0.993 | |

| 1.1Qd | 33.207 | 303.687 | −0.529 | −0.795 | 0.982 | |

| 1.2Qd | 35.301 | 303.687 | −0.562 | −1.025 | 0.968 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Li, K.; Liu, T.; Liu, Y.; Hu, J.; Zuo, Q.; Jiang, L. Analysis the Composition of Hydraulic Radial Force on Centrifugal Pump Impeller: A Data-Centric Approach Based on CFD Datasets. Appl. Sci. 2025, 15, 7597. https://doi.org/10.3390/app15137597

Zhang H, Li K, Liu T, Liu Y, Hu J, Zuo Q, Jiang L. Analysis the Composition of Hydraulic Radial Force on Centrifugal Pump Impeller: A Data-Centric Approach Based on CFD Datasets. Applied Sciences. 2025; 15(13):7597. https://doi.org/10.3390/app15137597

Chicago/Turabian StyleZhang, Hehui, Kang Li, Ting Liu, Yichu Liu, Jianxin Hu, Qingsong Zuo, and Liangxing Jiang. 2025. "Analysis the Composition of Hydraulic Radial Force on Centrifugal Pump Impeller: A Data-Centric Approach Based on CFD Datasets" Applied Sciences 15, no. 13: 7597. https://doi.org/10.3390/app15137597

APA StyleZhang, H., Li, K., Liu, T., Liu, Y., Hu, J., Zuo, Q., & Jiang, L. (2025). Analysis the Composition of Hydraulic Radial Force on Centrifugal Pump Impeller: A Data-Centric Approach Based on CFD Datasets. Applied Sciences, 15(13), 7597. https://doi.org/10.3390/app15137597