Monte Carlo Simulation for Enhancing the Schedule Completion Forecast of Jakarta Central Railway Station Construction Project

Abstract

1. Introduction

- (a)

- What are the indicators that cause the risk of delay in completing the construction project (RQ1)?

- (b)

- How can the risk-based simulation of the project implementation scheduling be established to optimize the project’s completion time (RQ2)?

- (c)

- What are the appropriate risk response strategies and recommendations to respond to the risks that have a major impact on the construction schedule to optimize the project completion time (RQ3)?

2. Literature Review

2.1. Program Evaluation and Review Technique (PERT)

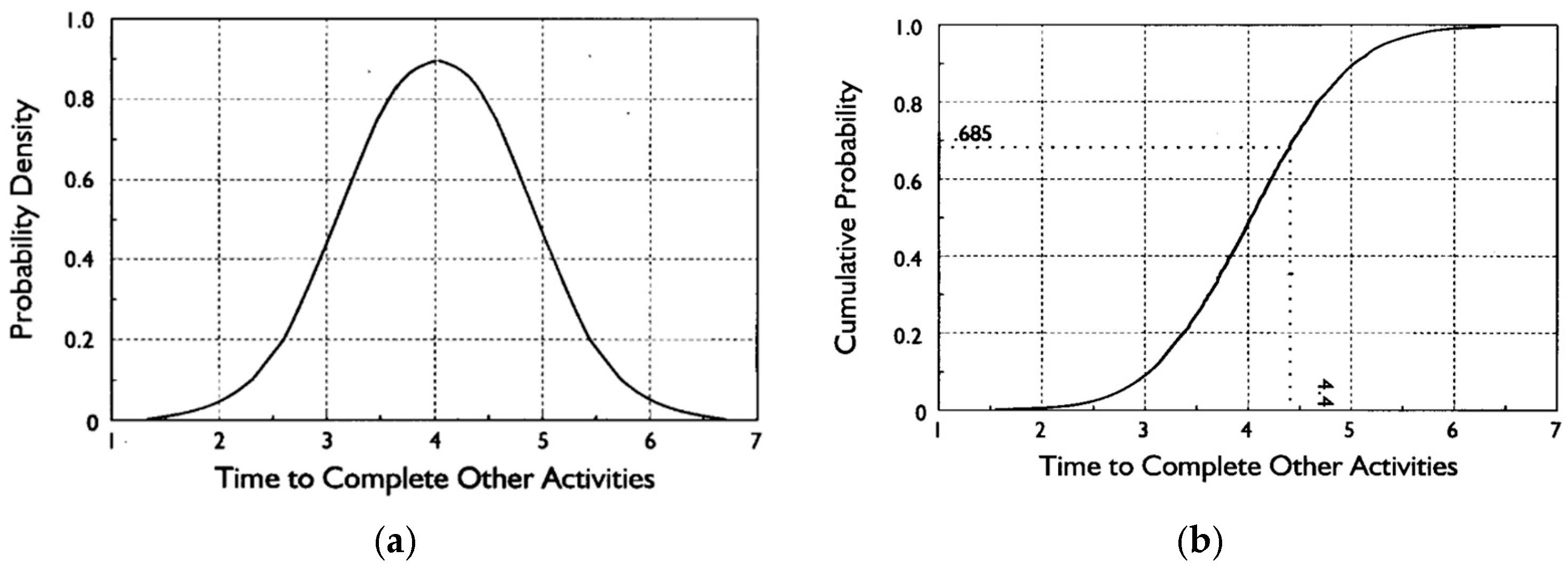

2.2. Monte Carlo Simulation (MCS)

3. Research Methodology

4. Discussion

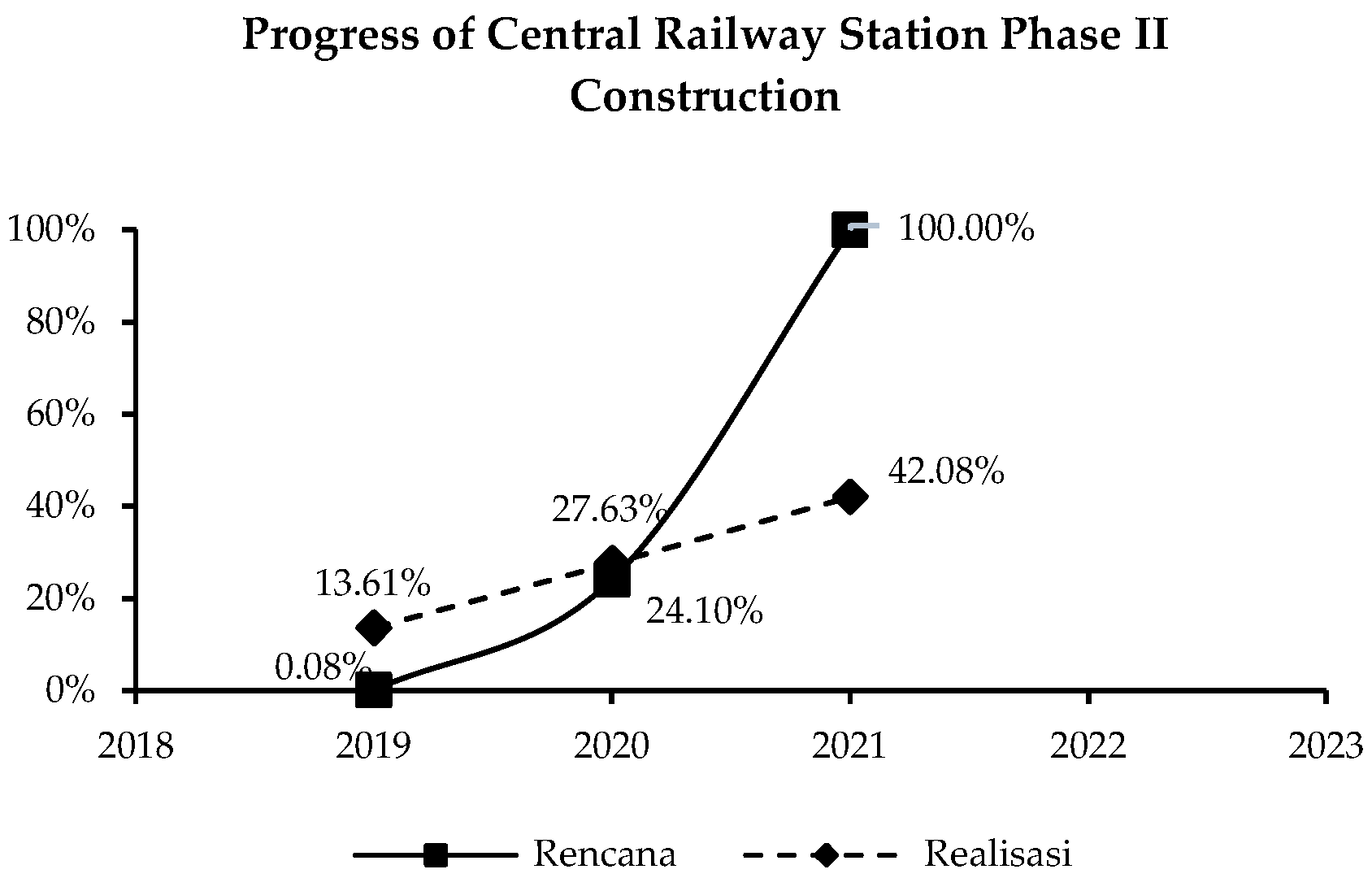

4.1. Data Collection for, and Analysis and Discussion of Research Question 1 (RQ 1)

4.2. Data Collection for, and Analysis and Discussion of Research Question 2 (RQ 2)

4.3. Data Collection for, and Analysis and Discussion of Research Question 3 (RQ 3)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meka’a, C.B.; Fotso, S.R.; Guemdjo Kamdem, B.R. Investments in Basic Public Infrastructure and Their Effects on Economic Growth in a Developing Country: The Case of Cameroon. Heliyon 2024, 10, e26504. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Cheng, L. The Role of Transport Infrastructure in Economic Growth: Empirical Evidence in the UK. Transp. Policy 2023, 133, 223–233. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, N.; Xu, L. Travelers on the Railway: An Economic Growth Model of the Effects of Railway Transportation Infrastructure on Consumption and Sustainable Economic Growth. Sustainability 2021, 13, 6863. [Google Scholar] [CrossRef]

- Acheampong, A.O.; Dzator, J.; Dzator, M.; Salim, R. Unveiling the Effect of Transport Infrastructure and Technological Innovation on Economic Growth, Energy Consumption and CO2 Emissions. Technol. Forecast. Soc. Change 2022, 182, 121843. [Google Scholar] [CrossRef]

- Tavassolirizi, M.; Sarvari, H.; Chan, D.W.M.; Olawumi, T.O. Factors Affecting Delays in Rail Transportation Projects Using Analytic Network Process: The Case of Iran. Int. J. Constr. Manag. 2022, 22, 2712–2723. [Google Scholar] [CrossRef]

- Nguyen, T.; Chileshe, N.; Ho, D.T.; Nguyen, V.T.; Tran, Q.P. Significant Risks That Trigger Cost Overruns and Delays in Urban Rail Projects: A Typical Case Study of Vietnam. Built Environ. Proj. Asset Manag. 2024, 14, 278–295. [Google Scholar] [CrossRef]

- Karim, S.; Isvara, W.; Ichsan, M. Factors Affecting Delayed Implementation of Railway Station Projects: Case Studies in Indonesia. Glob. Bus. Financ. Rev. 2024, 29, 46–60. [Google Scholar] [CrossRef]

- Oktaria, D.S.; Guilin, X.; Jiao, D.; Wang, Y. Juridical Review of Minimum Service Standards at Manggarai Station. Rechtsnormen J. Law 2023, 1, 85–94. [Google Scholar] [CrossRef]

- Khadilkar, H. Data-Enabled Stochastic Modeling for Evaluating Schedule Robustness of Railway Networks. Transp. Sci. 2017, 51, 1161–1176. [Google Scholar] [CrossRef]

- Goodwin, K.A.; Goodwin, C.J. Research in Psychology: Methods and Design, 8th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017. [Google Scholar]

- Hartono, B.; Ichsan, M.; Arini, H.M. Manajemen Risiko Pada Proyek Dan Bisnis Di Era Disrupsi: Konsep Kontemporer Dan Implementasi, 1st ed.; Gadjah Mada University Press: Yogyakarta, Indonesia, 2024. [Google Scholar]

- Jie, D.; Wei, J. Estimating Construction Project Duration and Costs upon Completion Using Monte Carlo Simulations and Improved Earned Value Management. Buildings 2022, 12, 2173. [Google Scholar] [CrossRef]

- Koulinas, G.K.; Xanthopoulos, A.S.; Sidas, K.A.; Koulouriotis, D.E. Risks Ranking in a Desalination Plant Construction Project with a Hybrid AHP, Risk Matrix, and Simulation-Based Approach. Water Resour. Manag. 2021, 35, 3221–3233. [Google Scholar] [CrossRef]

- Hu, Z.G. A New Progress in the Theory of PERT. In Proceedings of the 2011 IEEE 18th International Conference on Industrial Engineering and Engineering Management, Changchun, China, 3–5 September 2011; pp. 15–20. [Google Scholar] [CrossRef]

- US Department of the Navy. Summary Report: Program Evaluation Research Task; US Department of the Navy: Washington, DC, USA, 1958.

- Project Management Institute. Practice Standard for Scheduling; Project Management Institute, Inc.: Newtown Square, PA, USA, 2019. [Google Scholar]

- Project Management Institute. A Guide to Project Management Body of Knowledge, 6th ed.; Project Management Institute, Inc.: Newtown Square, PA, USA, 2017. [Google Scholar]

- Bagshaw, K.B. NEW PERT and CPM in Project Management with Practical Examples. Am. J. Oper. Res. 2021, 11, 215–226. [Google Scholar] [CrossRef]

- Riantini, L.S.; Ichsan, M.; Trigunarsyah, B.; Rarasati, A.D.; Handika, N.; Lolo, C.A. Optimization of Completion Schedule Forecasting in Case Study of Double-Double Track Development Project (Package A) Using the Probabilistic Pert Method. J. Infrastruct. Policy Dev. 2024, 8, 7798. [Google Scholar] [CrossRef]

- Ichsan, M.; Isvara, W.; Handibyanto, J.N.; Muhammad, F.A. Development of a Risk-Based Strategy Implementation of a Full Pre-Financed Contractor Scheme (CPF) in Toll Road Projects to Improve Time Performance. Cogent Eng. 2024, 11, 2307212. [Google Scholar] [CrossRef]

- Sackey, S.; Kim, B.S. Schedule Risk Analysis Using a Proposed Modified Variance and Mean of the Original Program Evaluation and Review Technique Model. KSCE J. Civ. Eng. 2019, 23, 1484–1492. [Google Scholar] [CrossRef]

- Handoko, J.R.; Gondokusumo, O. Comparison of PERT and M-PERT Scheduling for a Construction Project in Malang, Indonesia. IOP Conf. Ser. Mater. Sci. Eng. 2019, 508, 012034. [Google Scholar] [CrossRef]

- Zhang, S.; Jin, L. Research on Software Project Schedule Management Method Based on Monte Carlo Simulation. In Proceedings of the 2020 IEEE 5th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 12–14 June 2020; pp. 1605–1608. [Google Scholar] [CrossRef]

- Andrić, J.M.; Wang, J.; Zhong, R. Identifying the Critical Risks in Railway Projects Based on Fuzzy and Sensitivity Analysis: A Case Study of Belt and Road Projects. Sustainability 2019, 11, 1302. [Google Scholar] [CrossRef]

- Abbasi, O.; Noorzai, E.; Gharouni Jafari, K.; Golabchi, M. Exploring the Causes of Delays in Construction Industry Using a Cause-and-Effect Diagram: Case Study for Iran. J. Archit. Eng. 2020, 26, 05020008. [Google Scholar] [CrossRef]

- Djohim, M.F.N.; Nugroho, A.S.B.; Handayani, T.N. Risk Analysis of Modest Housing Projects Scheduling Using Monte Carlo Simulation. Civ. Eng. Dimens. 2024, 26, 160–172. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research and Applications: Design and Methods, 8th ed.; SAGE Publication Inc.: London, UK, 2018. [Google Scholar]

- Hendradewa, A.P. Schedule Risk Analysis by Different Phases of Construction Project Using CPM-PERT and Monte-Carlo Simulation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 528, 012035. [Google Scholar] [CrossRef]

- Paz de Sousa, K.M.; Rosana de Araújo Oliveira, S.; Alencar Sousa Macau Furtado, B.M.; Ribeiro de Vasconcelos, A.L.; Gomes de Medeiros, S.; Cazarin, G.; Soares Sampaio, A.; Ridde, V. Hospital Resilience in Three COVID-19 Referral Hospitals in Brazil. Heal. Syst. Reform. 2023, 9, 2205726. [Google Scholar] [CrossRef] [PubMed]

- Han, S.H.; Yun, S.; Kim, H.; Kwak, Y.H.; Park, H.K.; Lee, S.H. Analyzing Schedule Delay of Mega Project: Lessons Learned from Korea Train Express. IEEE Trans. Eng. Manag. 2009, 56, 243–256. [Google Scholar] [CrossRef]

- Sharma, M.K. Monte Carlo Simulation Applications for Construction Project Management. Int. J. Civ. Eng. Technol. 2020, 11, 88–100. [Google Scholar] [CrossRef]

- Gashaw, T.; Jilcha, K. Design Risk Modeling and Analysis for Railway Construction Projects. Int. J. Constr. Manag. 2023, 23, 2488–2498. [Google Scholar] [CrossRef]

- Mittal, Y.K.; Paul, V.K. Identification of Critical Factors for Delay in Metro Rail Projects in India. Int. J. Stud. Res. Technol. Manag. 2018, 6, 30–39. [Google Scholar] [CrossRef]

- Ramli, M.Z.; Abidin, M.Z.Z.; Hamid, N.B.; Razman, R.; Noh, N.A.M. Ranking of Railway Construction Project Delay Factors in Malaysia by Using Relative Importance Index (RII). AIP Conference Proceedings 2021, 2339, 020114. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, H.; Cheng, T. Causes of Delay in the Construction Projects of Subway Tunnel. Adv. Civ. Eng. 2020, 2020, 8883683. [Google Scholar] [CrossRef]

- Danisworo, B.; Latief, Y. Estimation Model of Jakarta MRT Phase 1 Project Cost Overrun for the Risk Based next Phase Project Funding Purpose. IOP Conf. Ser. Earth Environ. Sci. 2019, 258, 012049. [Google Scholar] [CrossRef]

- Nikjow, M.A.; Liang, L.; Qi, X.; Sepasgozar, S.M.E.; Chileshe, N. Triggers of Delays in International Projects Using Engineering Procurement and Construction Delivery Methods in the Belt and Road Initiative: Case Study of a High-Speed Railway Projects. Sustainability 2021, 13, 9503. [Google Scholar] [CrossRef]

- Welde, M.; Bukkestein, I. Over Time or on Time? A Study of Delays in Large Government Projects. Procedia Comput. Sci. 2021, 196, 772–781. [Google Scholar] [CrossRef]

- Zou, P.X.W.; Zhang, G.; Wang, J. Understanding the Key Risks in Construction Projects in China. Int. J. Proj. Manag. 2007, 25, 601–614. [Google Scholar] [CrossRef]

| Risk ID | Risk Factor | Risk Categories | Reference |

|---|---|---|---|

| R1 | Land acquisition delays | (I) Technical risk | [30,31] |

| R2 | Delay in handover of work land | ||

| R3 | Many utilities are not detected at the start of work. | ||

| R4 | Difficult and limited project road access | ||

| R5 | The project owner’s time-consuming decision-making process | (II) Project owner risk | [30,32,33,34,35] |

| R6 | Delay in issuing work permits | ||

| R7 | Changes in scope of work | ||

| R8 | Inaccuracy in predicting the budget | ||

| R9 | Project delay by the owner | ||

| R10 | Sequencing work activities must be adjusted to train operating patterns (switch over) | (III) Construction risk | [24,32] |

| R11 | Inconsistencies in the order of schedule priorities that can affect project execution | ||

| R12 | Many changes to the design of drawings, specifications, and scope-of-work packages during the project by the project owner/external | (IV) Project design and methods risk | [5,30,32,35,36,37] |

| R13 | Incomplete design from the planner | ||

| R14 | Request for changes in work method/design from clients/external parties during the construction period | ||

| R15 | Design inconsistencies and ambiguity | ||

| R16 | Project complexity (design) | ||

| R17 | Lots of additional work | (V) Contract risk | [32,36,38] |

| R18 | High indirect costs | (VI) Financial risk | [5,30,36] |

| R19 | There are complicated procedures for permitting construction projects from various parties. | (VII) External risks | [5,24,30,32,33,34] |

| R20 | Interfaces, dependencies between phases, and work packages | ||

| R21 | High-risk project location | (VIII) HSE and environmental risks | [24,30,35] |

| R22 | Working on active train tracks |

| No. Activity | Critical Work Activity | Duration (in Days) | Risk ID | Dominant Risk |

|---|---|---|---|---|

| A | Demolition Zone 1 | 50.00 | R10 | Sequencing work activities must be adjusted to train operating patterns (switch over) |

| B | Building Work Zone 1 | 290.00 | R6 | Delay in issuing work permits |

| C | Demolition Zone 2 | 25.00 | R20 | Interfaces, dependencies between phases, and work packages |

| D | Track Work Zone 2 | 122.00 | R22 | Working on active train tracks |

| E | Demolition Zone 3 | 29.00 | R6 | Delay in issuing work permits |

| F | Track Work Zone 3 | 114.00 | R22 | Working on active train tracks |

| G | Demolition Zone 4-Sub A | 44.00 | R6 | Delay in issuing work permits |

| H | Building Work Zone 4-Sub A | 196.00 | R5 | The project owner’s time-consuming decision-making process |

| I | Safety Assessment | 29.00 | R19 | There are complicated procedures for permitting construction projects from various parties. |

| No. Activity | Duration (Days) | Risk ID | Additional Days (Inherent Risk) | PERT (Day) | Theoretical Value (in Days) | Simulation Value (*) (in Days) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P (in Days) | ML (in Days) | O (in Days) | α = 80 | α = 90 | α = 95 | α = 80 | α = 90 | α = 95 | |||||

| A | 50.00 | R10 | 720.00 | 700.00 | 680.00 | 700.00 | 706.94 | 710.13 | 712.44 | 706.94 | 710.13 | 712.43 | |

| B | 290.00 | R6 | 45.00 | 30.00 | 30.00 | 32.50 | 34.13 | 35.53 | 36.76 | 34.13 | 35.53 | 36.76 | |

| C | 25.00 | R20 | 45.00 | 30.00 | 30.00 | 32.50 | 34.13 | 35.53 | 36.76 | 34.13 | 35.53 | 36.76 | |

| D | 122.00 | R22 | 40.00 | 35.00 | 30.00 | 35.00 | 36.73 | 37.53 | 38.11 | 36.73 | 37.53 | 38.11 | |

| E | 29.00 | R6 | 45.00 | 35.00 | 30.00 | 35.83 | 37.78 | 38.31 | 39.67 | 37.78 | 38.31 | 39.67 | |

| F | 114.00 | R22 | 45.00 | 35.00 | 30.00 | 35.83 | 38.31 | 39.67 | 40.70 | 38.31 | 39.67 | 40.70 | |

| G | 44.00 | R6 | 45.00 | 35.00 | 30.00 | 35.83 | 37.78 | 38.31 | 39.67 | 37.78 | 38.31 | 39.67 | |

| H | 196.00 | R5 | 50.00 | 40.00 | 30.00 | 40.00 | 43.47 | 45.07 | 46.21 | 43.47 | 45.07 | 46.21 | |

| I | 29.00 | R19 | 45.00 | 35.00 | 25.00 | 35.00 | 38.47 | 40.07 | 41.21 | 38.47 | 40.07 | 41.21 | |

| Ʃ (day) | 899.00 | 982.50 | 1007.73 | 1020.16 | 1031.52 | 1007.73 | 1020.16 | 1031.52 | |||||

| Ʃ (Month) | 29.97 | 32.75 | 33.59 | 34.01 | 34.38 | 33.59 | 34.01 | 34.38 | |||||

| No. | Schedule Model | Duration (in Days) 1 | Completion Time (Pre-Risk Mitigation) | Comparison with Initial Duration (%) |

|---|---|---|---|---|

| 1 | Initial contract | 674.00 days | 30 September 2021 | - |

| 2 | PERT value | 1555.66 days | 16 April 2024 | 130.81% |

| 3 | Theoretical value (confidence level 80%) | 1575.70 days | 6 May 2024 | 133.78% |

| 4 | Theoretical value (confidence level 90%) | 1584.78 days | 15 May 2024 | 135.13% |

| 5 | Theoretical value (confidence level 95%) | 1592.33 days | 23 May 2024 | 136.25% |

| 6 | Simulation value (confidence level 80%) | 1575.70 days | 6 May 2024 | 133.78% |

| 7 | Simulation value (confidence level 90%) | 1584.78 days | 15 May 2024 | 135.13% |

| 8 | Simulation value (confidence level 95%) | 1592.33 days | 23 May 2024 | 136.25% |

| No. Activity | Duration (Days) | Risk ID | Additional Days (Residual Risk) | PERT (Day) | Theoretical Value | Simulation Value (*) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P (in Days) | ML (in Days) | O (in Days) | α = 80 | α = 90 | α = 95 | α = 80 | α = 90 | α = 95 | ||||

| A | 50.00 | R10 | 550.00 | 500.00 | 470.00 | 503.33 | 516.80 | 523.85 | 529.15 | 516.80 | 523.85 | 529.15 |

| B | 290.00 | R6 | 30.00 | 25.00 | 20.00 | 25.00 | 26.73 | 27.53 | 28.11 | 26.73 | 27.53 | 28.11 |

| C | 25.00 | R20 | 35.00 | 25.00 | 20.00 | 25.83 | 28.31 | 29.67 | 30.70 | 28.31 | 29.67 | 30.70 |

| D | 122.00 | R22 | 30.00 | 25.00 | 25.00 | 25.83 | 26.38 | 26.84 | 27.25 | 26.38 | 26.84 | 27.25 |

| E | 29.00 | R6 | 35.00 | 25.00 | 20.00 | 25.83 | 28.31 | 29.67 | 30.70 | 28.31 | 29.67 | 30.70 |

| F | 114.00 | R22 | 40.00 | 35.00 | 30.00 | 35.00 | 36.73 | 37.53 | 38.11 | 36.73 | 37.53 | 38.11 |

| G | 44.00 | R6 | 35.00 | 25.00 | 25.00 | 26.67 | 27.75 | 28.70 | 29.51 | 27.75 | 28.70 | 29.51 |

| H | 196.00 | R5 | 40.00 | 30.00 | 25.00 | 30.83 | 33.31 | 34.67 | 35.70 | 33.31 | 34.67 | 35.70 |

| I | 29.00 | R19 | 30.00 | 25.00 | 20.00 | 25.00 | 26.73 | 27.53 | 28.11 | 26.73 | 27.53 | 28.11 |

| Ʃ (day) | 899.00 | 723.33 | 751.07 | 765.99 | 777.33 | 751.07 | 765.99 | 777.33 | ||||

| Ʃ (Month) | 29.97 | 24.11 | 25.03 | 25.53 | 25.91 | 25.03 | 25.53 | 25.91 | ||||

| No. | Schedule Model | Duration (in Days) 1 | Completion Time (Post-Risk Mitigation) | Comparison with Initial Duration (%) |

|---|---|---|---|---|

| 1 | Initial contract | 674.00 days | 30 September 2021 | - |

| 2 | PERT value | 1319.82 days | 24 August 2023 | 95.82% |

| 3 | Theoretical value (confidence level 80%) | 1342.26 days | 16 September 2023 | 99.15% |

| 4 | Theoretical value (confidence level 90%) | 1345.10 days | 28 September 2023 | 99.57% |

| 5 | Theoretical value (confidence level 95%) | 1363.02 days | 7 October 2023 | 102.23% |

| 6 | Simulation value (confidence level 80%) | 1342.26 days | 16 September 2023 | 99.15% |

| 7 | Simulation value (confidence level 90%) | 1354.10 days | 28 September 2023 | 100.91% |

| 8 | Simulation value (confidence level 95%) | 1363.02 days | 7 October 2023 | 102.23% |

| Act. | Duration (Days) | Risk ID | Risk Causes | Code | Additional Days (Inherent Risk) | Code | Preventive Actions | Code | Risk Response (Inherent) | ||

| P (in Days) | ML (in Days) | O (in Days) | |||||||||

| A | 50.00 | R10 | Land acquisition | C1 | 720.00 | 700.00 | 680.00 | IR1 | Creating a land acquisition mitigation plan | PA1 | Mitigate |

| Interface, dependencies between packages | C2 | Create integration of work stages together | PA2 | Transfer | |||||||

| Many design changes | C3 | Check all DED drawings before starting work. | PA3 | Mitigate | |||||||

| B | 290.00 | R6 | Poor communication between parties | C4 | 45.00 | 30.00 | 30.00 | IR2 | Creating a communication management plan | PA4 | Mitigate |

| Complicated bureaucracy | C5 | Prepare a licensing flowchart | PA5 | Accept | |||||||

| Licensing is complicated by various parties | C6 | Developing a licensing plan strategy | PA6 | Mitigate | |||||||

| C | 25.00 | R20 | Waiting for other work packages to complete | C7 | 45.00 | 30.00 | 30.00 | IR3 | Make a joint planning schedule | PA7 | Transfer |

| D | 122.00 | R22 | Limited job access | C8 | 40.00 | 35.00 | 30.00 | IR4 | Create the right working method | PA8 | Mitigate |

| High-risk project location | C9 | Creating an HSE work plan | PA9 | Mitigate | |||||||

| Work during the window time | C10 | Socialization to passengers | PA10 | Accept | |||||||

| E | 29.00 | R6 | Inadequate communication among parties | C11 | 45.00 | 35.00 | 30.00 | IR5 | Creating a communication management plan | PA11 | Mitigate |

| Complicated bureaucracy | C12 | Prepare a licensing flowchart | PA12 | Accept | |||||||

| Licensing is complicated by various parties | C13 | Developing a licensing plan strategy | PA13 | Mitigate | |||||||

| F | 114.00 | R22 | Limited job access | C14 | 45.00 | 35.00 | 30.00 | IR6 | Create the right working method | PA14 | Mitigate |

| High-risk project location | C15 | Creating an HSE work plan | PA15 | Mitigate | |||||||

| Work during the window time | C16 | Socialization to passengers | PA16 | Accept | |||||||

| G | 44.00 | R6 | Inadequate communication among parties | C17 | 45.00 | 35.00 | 30.00 | IR7 | Creating a communication management plan | PA17 | Mitigate |

| Complicated bureaucracy | C18 | Prepare a licensing flowchart | PA18 | Accept | |||||||

| Licensing is complicated by various parties | C19 | Developing a licensing plan strategy | PA19 | Mitigate | |||||||

| H | 196.00 | R5 | Poor communication between parties | C20 | 50.00 | 40.00 | 30.00 | IR8 | Creating a communication management plan | PA20 | Mitigate |

| Complicated bureaucracy | C21 | Creating a communication flowchart | PA21 | Accept | |||||||

| Project owner’s inconsistency in schedule priority order | C22 | Develop a plan for the method and appropriate stages of work | PA22 | Mitigate | |||||||

| I | 29.00 | R19 | Complicated bureaucracy | C23 | 45.00 | 35.00 | 25.00 | IR9 | Creating a communication flowchart | PA23 | Accept |

| Incomplete administrative files | C24 | Create a document monitoring plan | PA24 | Mitigate | |||||||

| Poor communication between parties | C25 | Creating a communication management plan | PA25 | Mitigate | |||||||

| Act. | Duration (Days) | Risk ID | Risk Effect | Code | Additional Days (Residual Risk) | Code | Corrective Action | Code | Risk Response (Residual) | ||

| P (in Days) | ML (in Days) | O (in Days) | |||||||||

| A | 50.00 | R10 | Delay in work time | E1 | 550.00 | 500.00 | 470.00 | RR1 | Coordinate with parties to accelerate land acquisition | CA1 | Transfer |

| Changes to the implementation drawing | E2 | Conduct joint meetings between packages to integrate drawings | CA2 | Transfer | |||||||

| Changes in the scope of work | E3 | Conduct design reviews with experts | CA3 | Mitigate | |||||||

| B | 290.00 | R6 | Work is hampered | E4 | 30.00 | 25.00 | 20.00 | RR2 | communicate well with all parties | CA4 | Accept |

| Delay in work time | E5 | Write officially regarding any problems | CA5 | Transfer | |||||||

| Administrative approval is delayed | E6 | Complete the necessary administration | CA6 | Mitigate | |||||||

| C | 25.00 | R20 | Delay in completion time | E7 | 35.00 | 25.00 | 20.00 | RR3 | Hold regular meetings together | CA7 | Transfer |

| D | 122.00 | R22 | The safety of passengers, workers, and train operations is disrupted | E8 | 30.00 | 25.00 | 25.00 | RR4 | Create a mutually agreed standard operating procedure (SOP) | CA8 | Mitigate |

| Delay in work time | E9 | Conducting socialization of labor hazards | CA9 | Transfer | |||||||

| Increase in overtime costs for manpower | E10 | Make monitoring of work activities | CA10 | Mitigate | |||||||

| E | 29.00 | R6 | Work is hampered | E11 | 35.00 | 25.00 | 20.00 | RR5 | Communicate well with all parties | CA11 | Accept |

| Delay in work time | E12 | Write officially regarding any problems | CA12 | Transfer | |||||||

| Administrative approval is delayed | E13 | Complete the necessary administration | CA13 | Mitigate | |||||||

| F | 114.00 | R22 | The safety of passengers, workers, and train operations is disrupted | E14 | 40.00 | 35.00 | 30.00 | RR6 | Create a mutually agreed standard operating procedure (SOP) | CA14 | Mitigate |

| Delay in work time | E15 | Conducting socialization of labor hazards | CA15 | Transfer | |||||||

| Increase in overtime costs for manpower | E16 | Make monitoring of work activities | CA16 | Mitigate | |||||||

| G | 44.00 | R6 | Work is hampered | E17 | 35.00 | 25.00 | 25.00 | RR7 | Communicate well with all parties | CA17 | Accept |

| Delay in work time | E18 | Write officially regarding any problems | CA18 | Transfer | |||||||

| Administrative approval is delayed | E19 | Complete the necessary administration | CA19 | Mitigate | |||||||

| H | 196.00 | R5 | Delay in issuing work permits | E20 | 40.00 | 30.00 | 25.00 | RR8 | Write officially regarding any problems | CA20 | Transfer |

| Lots of work reworked | E21 | Monitor any changes in scope | CA21 | Mitigate | |||||||

| Cost increase | E22 | Submitting a claim for a fee increase | CA22 | Transfer | |||||||

| I | 29.00 | R19 | Delay in handover of work | E23 | 30.00 | 25.00 | 20.00 | RR9 | Conduct a joint planning meeting | CA23 | Transfer |

| Delay in administrative approval | E24 | Complete the necessary administration | CA24 | Accept | |||||||

| Delay in issuing safety assessment permits | E25 | Immediately follow up on the safety assessment test findings | CA25 | Accept | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ichsan, M.; Isvara, W.; Karim, S. Monte Carlo Simulation for Enhancing the Schedule Completion Forecast of Jakarta Central Railway Station Construction Project. Appl. Sci. 2025, 15, 7464. https://doi.org/10.3390/app15137464

Ichsan M, Isvara W, Karim S. Monte Carlo Simulation for Enhancing the Schedule Completion Forecast of Jakarta Central Railway Station Construction Project. Applied Sciences. 2025; 15(13):7464. https://doi.org/10.3390/app15137464

Chicago/Turabian StyleIchsan, Mohammad, Wisnu Isvara, and Syaeful Karim. 2025. "Monte Carlo Simulation for Enhancing the Schedule Completion Forecast of Jakarta Central Railway Station Construction Project" Applied Sciences 15, no. 13: 7464. https://doi.org/10.3390/app15137464

APA StyleIchsan, M., Isvara, W., & Karim, S. (2025). Monte Carlo Simulation for Enhancing the Schedule Completion Forecast of Jakarta Central Railway Station Construction Project. Applied Sciences, 15(13), 7464. https://doi.org/10.3390/app15137464