A Framework for Integrating Robotic Process Automation with Artificial Intelligence Applied to Industry 5.0

Abstract

1. Introduction

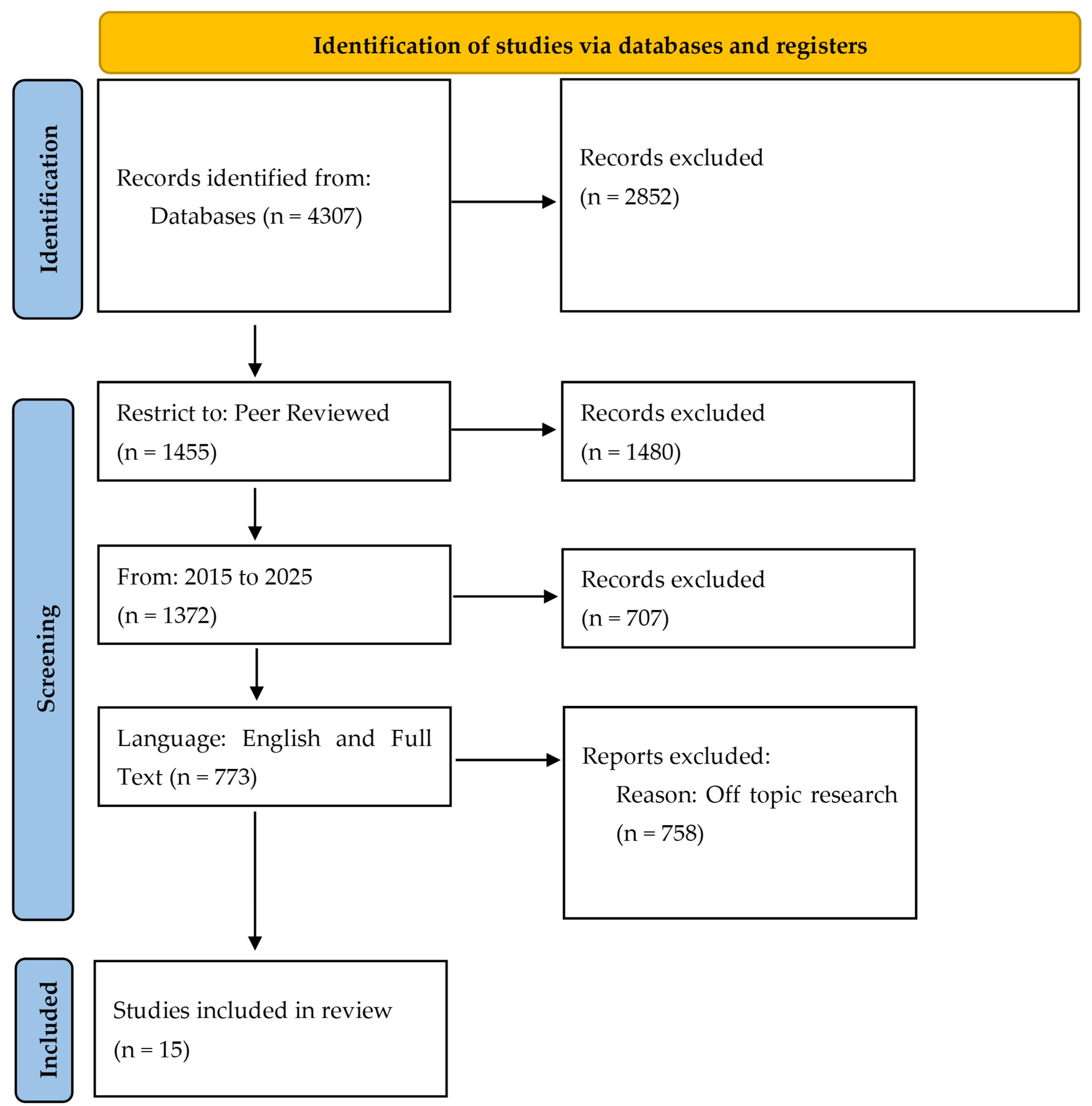

2. Systematic Literature Review

2.1. Method

2.2. Summary and Analysis of Selected Articles

3. Development of the Framework

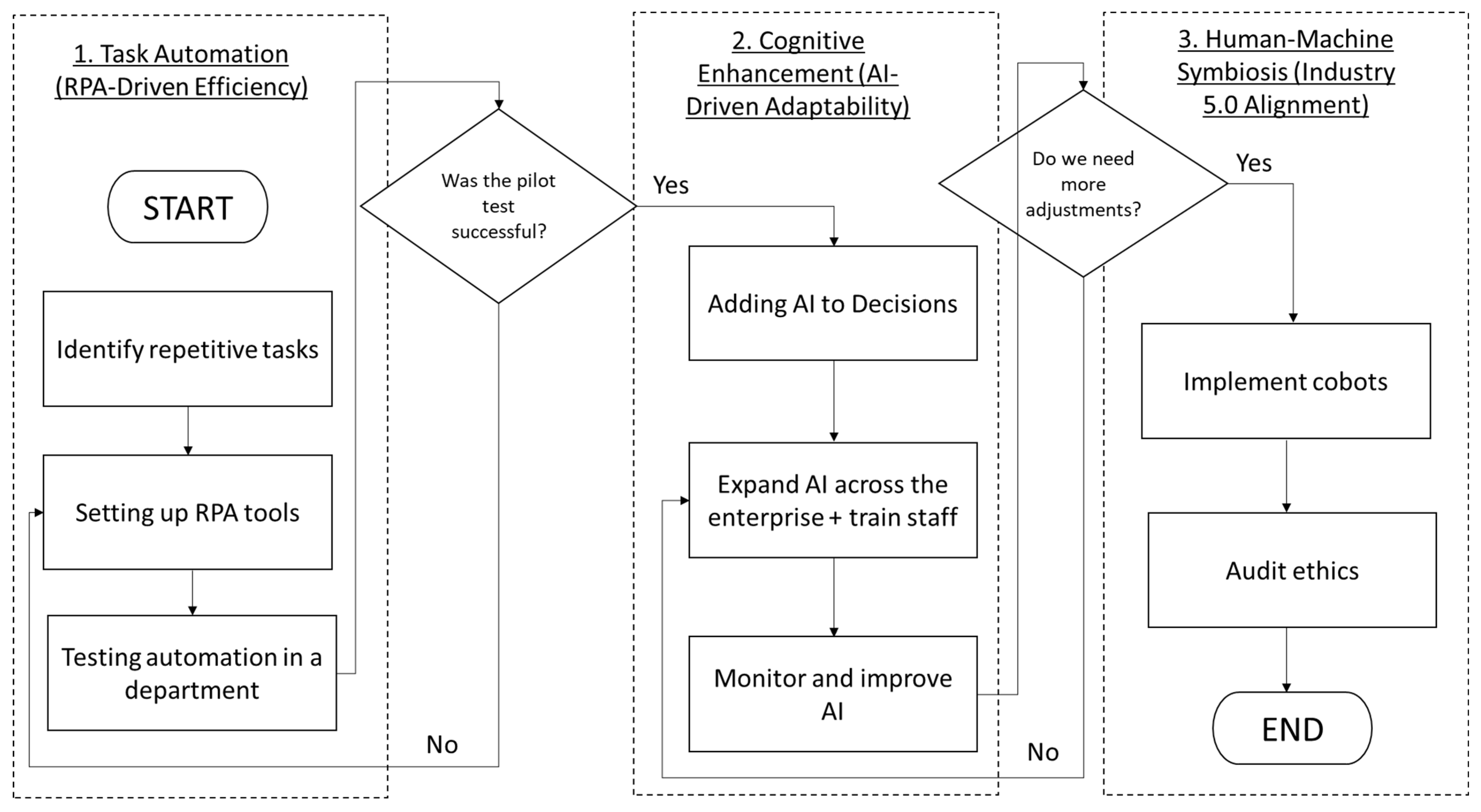

3.1. Framework Proposal

- Task Automation (RPA-Driven Efficiency)—Streamlining repetitive, rule-based processes.

- Cognitive Enhancement (AI-Driven Adaptability)—Enabling predictive and autonomous decision-making.

- Human–Machine Symbiosis (Industry 5.0 Alignment)—Ensuring collaboration, sustainability, and resilience.

3.2. Framework Features

3.2.1. RPA’s Role: Structured Automation for Efficiency

3.2.2. AI’s Role: Cognitive Augmentation for Adaptability

3.2.3. Industry 5.0 Integration: Human-Centric Automation

3.2.4. Implementation Roadmap

3.3. Framework Validation and Expected Outcomes

4. Analysis and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Leng, J.; Zhu, X.; Huang, Z.; Li, X.; Zheng, P.; Zhou, X.; Mourtzis, D.; Wang, B.; Qi, Q.; Shao, H.; et al. Unlocking the power of industrial artificial intelligence towards Industry 5.0: Insights, pathways, and challenges. J. Manuf. Syst. 2024, 73, 349–363. [Google Scholar] [CrossRef]

- Afrin, S.; Roksana, S.; Akram, R. AI-Enhanced Robotic Process Automation: A Review of Intelligent Automation Innovations. IEEE Access 2025, 13, 173–197. [Google Scholar] [CrossRef]

- Flechsig, C.; Anslinger, F.; Lasch, R. Robotic Process Automation in purchasing and supply management: A multiple case study on potentials, barriers, and implementation. J. Purch. Supply Manag. 2021, 28, 100718. [Google Scholar] [CrossRef]

- Yazdani, A.; Costa, S.; Kroon, B. Artificial intelligence: Friend or foe? Aust. N. Z. J. Obstet. Gynaecol. 2023, 63, 127–130. [Google Scholar] [CrossRef]

- Singh, S. Integrating Hyper-Automation with RPA and AI for End-to-End Business Process Optimization. Darpan Int. Res. Anal. 2024, 12, 199–211. [Google Scholar] [CrossRef]

- Jha, N.; Prashar, D.; Nagpal, A. Combinando Inteligência Artificial com Automação de Processos Robóticos—Uma Abordagem de Automação Inteligente. In Aprendizado Profundo e Big Data para Transporte Inteligente; Ahmed, K.R., Hassanien, A.E., Eds.; Estudos em Inteligência Computacional; Springer: Cham, Switzerland, 2021; Volume 945. [Google Scholar] [CrossRef]

- van der Aalst, W.M.P.; Bichler, M.; Heinzl, A. Robotic Process Automation. Bus. Inf. Syst. Eng. 2018, 60, 269–272. [Google Scholar] [CrossRef]

- Syed, R.; Suriadi, S.; Adams, M.; Bandara, W.; Leemans, S.J.J.; Ouyang, C.; ter Hofstede, A.H.M.; van de Weerd, I.; Wynn, M.T.; Reijers, H.A. Robotic Process Automation: Contemporary Themes and Challenges. Comput. Ind. 2020, 115, 103162. [Google Scholar] [CrossRef]

- Geyer-Klingeberg, J.; Nakladal, J.; Baldauf, F.; Veit, F. Process Mining and Robotic Process Automation: A Perfect Match. Lect. Notes Bus. Inf. Process. 2020, 393, 41–53. [Google Scholar] [CrossRef]

- Ribeiro, J.; Lima, R.; Eckhardt, T.; Paiva, S. Robotic Process Automation and Artificial Intelligence in Industry 4.0—A Literature review. Procedia Comput. Sci. 2021, 181, 51–58. [Google Scholar] [CrossRef]

- Wamba-Taguimdje, S.-L.; Fosso Wamba, S.; Kala Kamdjoug, J.R.; Tchatchouang Wanko, C.E. Influence of Artificial Intelligence (AI) on Firm Performance: The Business Value of AI-Based Transformation Projects. Bus. Process Manag. J. 2020, 26, 1893–1924. [Google Scholar] [CrossRef]

- Mourtzis, D.; Tsoubou, S.; Angelopoulos, J. Otimização da confiabilidade de células robóticas com base em gêmeos digitais e manutenção preditiva. Electronics 2023, 12, 1999. [Google Scholar] [CrossRef]

- Agostinelli, S.; Marrella, A.; Mecella, M. Towards Intelligent Robotic Process Automation for BPMers. arXiv 2021, arXiv:2001.00804. [Google Scholar] [CrossRef]

- Jiménez-Ramírez, A.; Reijers, H.A.; Barba, I.; Del Valle, C. A Method to Improve the Early Stages of the Robotic Process Automation Lifecycle. Lect. Notes Bus. Inf. Process. 2021, 406, 3–18. [Google Scholar] [CrossRef]

- Kokina, J.; Blanchette, S. Early Evidence of Digital Labor in Accounting: Innovation with Robotic Process Automation. Int. J. Account. Inf. Syst. 2019, 35, 100431. [Google Scholar] [CrossRef]

- Huang, F.; Vasarhelyi, M.A. Applying Robotic Process Automation (RPA) in Auditing: A Framework. Int. J. Account. Inf. Syst. 2022, 45, 100571. [Google Scholar] [CrossRef]

- Bongomin, O.; Yemane, A.; Kembabazi, B.; Malanda, C.; Chikonkolo Mwape, M.; Sheron Mpofu, N.; Tigalana, D. Industry 5.0: The Potential for Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2023, 125, 3081–3099. [Google Scholar] [CrossRef]

- Longo, F.; Padovano, A.; Umbrello, S. Value-Oriented and Ethical Technology Engineering in Industry 5.0: A Human-Centric Perspective for the Design of the Factory of the Future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, X.; Cao, X.; Huang, C.; Liu, E.; Qian, S.; Liu, X.; Wu, Y.; Dong, F.; Qiu, C.-W.; et al. Artificial Intelligence: A Powerful Paradigm for Scientific Research. Innovation 2021, 2, 100179. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Artificial Intelligence Applications for Industry 5.0: A Literature-Based Study. Int. J. Intell. Netw. 2023, 4, 26–38. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Fathi, M. Industry 5.0 and Its Applications in Orthopedics. J. Clin. Orthop. Trauma 2022, 34, 102017. [Google Scholar] [CrossRef]

- Kaasinen, E.; Anttila, A.-H.; Heikkilä, P.; Laarni, J.; Koskinen, H.; Väätänen, A. Smooth and Resilient Human–Machine Teamwork as an Industry 5.0 Design Challenge. Sustainability 2022, 14, 2773. [Google Scholar] [CrossRef]

- Akter, S.; McCarthy, G.; Sajib, S.; Michael, K.; Dwivedi, Y.K.; D’Ambra, J.; Shen, K.N. Algorithmic Bias in Data-Driven Innovation in the Age of AI. Int. J. Inf. Manag. 2021, 60, 102387. [Google Scholar] [CrossRef]

- Dwivedi, Y.K.; Hughes, L.; Ismagilova, E.; Aarts, G.; Coombs, C.; Crick, T.; Duan, Y.; Dwivedi, R.; Edwards, J.; Eirug, A.; et al. Artificial Intelligence (AI): Multidisciplinary Perspectives on Emerging Challenges, Opportunities, and Agenda for Research, Practice and Policy. Int. J. Inf. Manag. 2021, 57, 101994. [Google Scholar] [CrossRef]

- Renda, A.; Schwaag Serger, S.; Tataj, D.; Morlet, A.; Isaksen, J.; Martins, F.; Røtnes, R.; Klenert, D.; Torre, A.; Compañó, R.; et al. Industry 5.0, a Transformative Vision for Europe: Governing Systemic Transformations Towards a Sustainable Industry. Eur. Comm. 2022, 1, 1–112. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Mubarak, M.F.; Mubarik, M.; Rejeb, A.; Nilashi, M. Identifying Industry 5.0 Contributions to Sustainable Development: A Strategy Roadmap for Delivering Sustainability Values. Sustain. Prod. Consum. 2022, 33, 716–737. [Google Scholar] [CrossRef]

- Femmer, H. Assisted Requirements Engineering—What Will Remain in the Hands of the Future Requirements Engineer? (Invited Keynote). In Software Quality: Future Perspectives on Software Engineering Quality. SWQD 2021; Winkler, D., Biffl, S., Mendez, D., Wimmer, M., Bergsmann, J., Eds.; Lecture Notes in Business Information Processing; Springer: Cham, Switzerland, 2021; Volume 404. [Google Scholar] [CrossRef]

- Klammer, C.; Wetzlmaier, T.; Pfeiffer, M.; Steiner, T.; Konnerth, M. Testing Autogenerated OPC UA NodeSet Models for Product Variants in Industry. In Software Quality: Future Perspectives on Software Engineering Quality. SWQD 2021; Winkler, D., Biffl, S., Mendez, D., Wimmer, M., Bergsmann, J., Eds.; Lecture Notes in Business Information Processing; Springer: Cham, Switzerland, 2021; Volume 404. [Google Scholar] [CrossRef]

- Purg, D.; Braček Lalić, A. Introduction. In Hidden Champions in Dynamically Changing Societies; Braček Lalić, A., Purg, D., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Braček Lalić, A.; Berberović, D. Research Methodology. In Hidden Champions in Dynamically Changing Societies; Braček Lalić, A., Purg, D., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Purg, D.; Walravens, A. Hidden Champions: Leadership Success Factors. In Hidden Champions in Dynamically Changing Societies; Braček Lalić, A., Purg, D., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Berberović, D.; Kožo, A.; Činjarević, M. Hidden Champions: Common Lessons Learned on the Path to Success. In Hidden Champions in Dynamically Changing Societies; Braček Lalić, A., Purg, D., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Lee, J.; Davari, H.; Singh, J.; Pandhare, V. Industrial Artificial Intelligence for Industry 4.0-Based Manufacturing Systems. Manuf. Lett. 2018, 18, 20–23. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, X.; Wang, L. Smart Manufacturing Process and System Automation—A Critical Review of the Standards and Envisioned Scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0: Towards a Sustainable, Human-Centric and Resilient European Industry; European Commission: Brussels, Belgium, 2021. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 5.0 and Human-Robot Co-Working. Procedia CIRP 2021, 104, 1035–1040. [Google Scholar] [CrossRef]

- European Commission. Horizon Europe Strategic Plan 2021–2024; Publications Office of the EU: Luxembourg, 2021. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M. Digital Transformation of Manufacturing Small and Medium Enterprises: A Maturity Model for Leveraging Industry 4.0. J. Manuf. Technol. Manag. 2021, 32, 1033–1056. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature Review of Industry 4.0 and Related Technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- de Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Foropon, C.; Godinho Filho, M. When Titans Meet—Can Industry 4.0 Revolutionise the Environmentally Sustainable Manufacturing Wave? Technol. Forecast. Soc. Change 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Cook, D.; Guyatt, G.; McDonald, R.; McDonald, J.; Morris, A.; Munn, A.; Niven, D.; Sibbald, W.; Stevens, R.; Whelan, T. Central venous catheter replacement strategies: A systematic review of the literature. Crit. Care Med. 1997, 25, 1417–1424. [Google Scholar] [CrossRef]

- Eriksen, M.; Frandsen, T. The impact of patient, intervention, comparison, outcome (PICO) as a search strategy tool on literature search quality: A systematic review. J. Med. Libr. Assoc. 2018, 106, 420–431. [Google Scholar] [CrossRef] [PubMed]

- Maddikunta, P.K.R.; Pham, Q.-V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Akundi, A.; Euresti, D.; Luna, S.; Ankobiah, W.; Lopes, A.; Edinbarough, I. State of Industry 5.0—Analysis and Identification of Current Research Trends. Appl. Syst. Innov. 2022, 5, 27. [Google Scholar] [CrossRef]

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0: Prospect and retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

- Žižić, M.; Mladineo, M.; Gjeldum, N.; Celent, L. From Industry 4.0 towards Industry 5.0: A Review and Analysis of Paradigm Shift for the People, Organization and Technology. Energies 2022, 15, 5221. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Tseng, M.; Grybauskas, A.; Stefanini, A.; Amran, A. Behind the definition of Industry 5.0: A systematic review of technologies, principles, components, and values. J. Ind. Prod. Eng. 2023, 40, 432–447. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. A Literature Review of the Challenges and Opportunities of the Transition from Industry 4.0 to Society 5.0. Energies 2022, 15, 6276. [Google Scholar] [CrossRef]

- Introna, V.; Santolamazza, A.; Cesarotti, V. Integrating Industry 4.0 and 5.0 Innovations for Enhanced Energy Management Systems. Energies 2024, 17, 1222. [Google Scholar] [CrossRef]

- Özdemir, V.; Hekim, N. Birth of Industry 5.0: Making Sense of Big Data with Artificial Intelligence, “The Internet of Things” and Next-Generation Technology Policy. OMICS J. Integr. Biol. 2018, 22, 65–76. [Google Scholar] [CrossRef] [PubMed]

- Rovzanec, J.; Novalija, I.; Zajec, P.; Kenda, K.; Tavakoli, H.; Suh, S.; Veliou, E.; Papamartzivanos, D.; Giannetsos, T.; Menesidou, S.; et al. Human-centric artificial intelligence architecture for industry 5.0 applications. Int. J. Prod. Res. 2022, 61, 6847–6872. [Google Scholar] [CrossRef]

- Khosravy, M.; Gupta, N.; Pasquali, A.; Dey, N.; Crespo, R.; Witkowski, O. Human-Collaborative Artificial Intelligence Along With Social Values in Industry 5.0: A Survey of the State-of-the-Art. IEEE Trans. Cogn. Dev. Syst. 2024, 16, 165–176. [Google Scholar] [CrossRef]

- Pramod, D. Robotic process automation for industry: Adoption status, benefits, challenges and research agenda. Benchmarking Int. J. 2021, 29, 1562–1586. [Google Scholar] [CrossRef]

- Nalgozhina, N.; Razaque, A.; Raissa, U.; Yoo, J. Developing Robotic Process Automation to Efficiently Integrate Long-Term Business Process Management. Technologies 2023, 11, 164. [Google Scholar] [CrossRef]

- Enríquez, J.; Ramirez, A.; Domínguez-Mayo, F.; García-García, J. Robotic Process Automation: A Scientific and Industrial Systematic Mapping Study. IEEE Access 2020, 8, 39113–39129. [Google Scholar] [CrossRef]

- Bhardwaj, V. A Systematic Review of Robotic Process Automation in Business Operations: Contemporary Trends and Insights. J. Intell. Syst. Control 2023, 2, 153–169. [Google Scholar] [CrossRef]

- Anitha, R.; Abinaya, S.; Laavanya, S.; Gayanthika, M. Robotic Process Automation in Artificial Intelligence. Int. J. Innov. Sci. Res. Technol. (IJISRT) 2024, 9, 305–308. [Google Scholar] [CrossRef]

| Research Strings | |

|---|---|

| Group 1 | “Robotic Process Automation” OR “RPA” OR “Automation” OR “Process Automation” OR “Intelligent Automation” OR “Digital Workforce” OR “Robots” OR “Software Robots” OR “Automation Technology” OR “Business Process Automation” OR “BPA” OR “Automated Workflows” OR “Cognitive Automation” OR “AI-driven Automation” OR “Automation Tools” OR “RPA Solutions” OR “Automation Platform” OR “Robotic Automation” OR “Automated Processes” OR “Machine Learning Automation” OR “Hyperautomation” OR “Automation Software” OR “RPA Implementation” OR “Business Efficiency Automation” OR “Automation Deployment” OR “RPA Technology” OR “Digital Transformation with RPA” OR “Intelligent Process Automation” OR “Automated Operations” OR “End-to-End Automation” |

| AND | |

| Group 2 | “Artificial Intelligence” OR “AI” OR “Machine Learning” OR “Deep Learning” OR “Neural Networks” OR “Natural Language Processing” OR “NLP” OR “Computer Vision” OR “AI Algorithms” OR “AI Models” OR “Supervised Learning” OR “Unsupervised Learning” OR “Reinforcement Learning” OR “AI Applications” OR “AI Solutions” OR “Cognitive Computing” OR “AI Automation” OR “AI-driven Insights” OR “AI Robotics” OR “Intelligent Systems” OR “AI for Business” OR “AI in Healthcare” OR “AI in Finance” OR “AI in Manufacturing” OR “AI Technology” OR “Artificial Neural Networks” OR “AI-Powered Systems” OR “Data Science” OR “Predictive Analytics” OR “AI Ethics” OR “AI Governance” OR “AI and Big Data” OR “AI in IoT” OR “AI Chatbots” OR “AI and Automation” OR “AI Research” OR “AI Development” OR “AI Algorithms in Robotics” OR “AI Innovation” OR “AI Integration” |

| AND | |

| Group 3 | “Industry 5.0” OR “Future of Industry” OR “Humans and Machines” OR “Advanced Automation” OR “Artificial Intelligence” OR “Industrial IoT” OR “Collaborative Robotics” OR “Mass Customization” OR “Advanced Manufacturing Technology” OR “Smart Manufacturing” OR “Intelligent Industry” OR “Digital Transformation” OR “Cyber-Physical Systems” OR “Smart Cities” OR “3D Printing Technology” OR “Industrial Sustainability” OR “Circular Economy” OR “Data Intelligence” OR “Industrial Connectivity” OR “Flexible Automation” OR “Adaptive Manufacturing” OR “5G Technology” OR “Connected Industry” OR “Autonomous Systems” OR “Sustainable Production” OR “Human-AI Collaborative Work” OR “Innovation Culture” OR “Sustainable Transformation” OR “Product Customization” |

| Article | Industry 5.0 (Principles) | RPA | Collaborative AI | Human-Centricity | Technological Integration (I4.0 → I5.0) | Challenges/ Barriers | Practical Applications | Social Values/Sustainability |

|---|---|---|---|---|---|---|---|---|

| [45] | X | X | X | X | X | X | X | |

| [46] | X | X | X | X | ||||

| [47] | X | X | X | X | X | X | X | |

| [48] | X | X | X | X | X | |||

| [49] | X | X | X | X | X | X | X | |

| [50] | X | X | X | X | X | |||

| [51] | X | X | X | X | X | X | ||

| [52] | X | X | ||||||

| [53] | X | X | X | X | X | |||

| [54] | X | X | X | X | X | |||

| [55] | X | X | X | |||||

| [56] | X | X | X | |||||

| [57] | X | X | X | |||||

| [58] | X | X | X | |||||

| [59] | X | X | X |

| 1. Process Assessment and Selection |

| 2. Technology Stack Configuration |

| 3. Pilot Deployment and Validation |

| 4. Full-Scale Integration and Human Augmentation |

| 5. Continuous Optimization and Ethical Governance |

| Feature | Purpose | Industry 5.0 Relevance |

|---|---|---|

| Non-invasive Automation | Executes tasks without modifying legacy systems. | Ensures smooth transition. |

| High Scalability | Deploys multiple bots for parallel task execution. | Supports mass customization. |

| Error Elimination | Reduces human errors in repetitive tasks (e.g., data entry, invoicing). | Enhances operational reliability. |

| Compliance Adherence | Maintains audit trails for regulatory requirements. | Supports ethical transparency. |

| Feature | Purpose | Industry 5.0 Relevance |

|---|---|---|

| Predictive Analytics | Forecasts demand, detects anomalies (e.g., predictive maintenance). | Reduces downtime, improves resilience. |

| Natural Language Processing (NLP) | Enables human–bot interaction (e.g., AI chatbots). | Enhances collaborative interfaces. |

| Computer Vision | Automates quality inspection via image recognition. | Supports precision manufacturing. |

| Adaptive Learning | Self-improving algorithms based on real-time data. | Enables continuous optimization. |

| Stage | Key Actions | Outcome |

|---|---|---|

| 1. Process Assessment | Identify high-impact, rule-based processes for automation. | Priority automation pipeline. |

| 2. Tech Stack Configuration | Select RPA tools (e.g., UiPath, Blue Prism) and AI models (e.g., TensorFlow). | Interoperable system design. |

| 3. Pilot Deployment | Test automation in controlled environments (e.g., finance, logistics). | Proof-of-concept validation. |

| 4. Full-Scale Integration | Expand across departments with human-in-the-loop checks. | Enterprise-wide automation. |

| 5. Continuous Optimization | Monitor performance, refine AI models, ensure ethical compliance. | Sustained efficiency gains. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patrício, L.; Varela, L.; Silveira, Z.; Felgueiras, C.; Pereira, F. A Framework for Integrating Robotic Process Automation with Artificial Intelligence Applied to Industry 5.0. Appl. Sci. 2025, 15, 7402. https://doi.org/10.3390/app15137402

Patrício L, Varela L, Silveira Z, Felgueiras C, Pereira F. A Framework for Integrating Robotic Process Automation with Artificial Intelligence Applied to Industry 5.0. Applied Sciences. 2025; 15(13):7402. https://doi.org/10.3390/app15137402

Chicago/Turabian StylePatrício, Leonel, Leonilde Varela, Zilda Silveira, Carlos Felgueiras, and Filipe Pereira. 2025. "A Framework for Integrating Robotic Process Automation with Artificial Intelligence Applied to Industry 5.0" Applied Sciences 15, no. 13: 7402. https://doi.org/10.3390/app15137402

APA StylePatrício, L., Varela, L., Silveira, Z., Felgueiras, C., & Pereira, F. (2025). A Framework for Integrating Robotic Process Automation with Artificial Intelligence Applied to Industry 5.0. Applied Sciences, 15(13), 7402. https://doi.org/10.3390/app15137402