1. Introduction

Over the years, humankind has increasingly relied on advanced technologies to enhance production efficiency. Each industrial revolution has introduced transformative tools and paradigms. Industry 1.0, emerging in the 1780s, leveraged steam, water, and fossil fuels to power mechanical production systems [

1]. This was followed by Industry 2.0 in the 1870s, characterized by the widespread adoption of electrical energy, which enabled mass production and assembly lines. The advent of Industry 3.0 in the 1970s saw the integration of electronics and information technology, laying the foundation for automation in manufacturing.

Industry 4.0 represents a continuation and intensification of these technological advances. It is defined by the convergence of artificial intelligence (AI), cloud computing, the Internet of Things (IoT), and cyber–physical systems (CPSs), which together facilitate real-time communication between digital and physical systems [

2]. This integration led to the development of Cyber–Physical Production Systems (CPPSs), where machines collaborate and make decisions autonomously. Skobelev and Borovik [

3] (p. 307) described Industry 4.0 as a means to achieve industrial competitiveness by embedding CPSs into production processes.

Despite its groundbreaking potential, Industry 4.0 has been critiqued for overlooking the human dimension. As Skobelev and Borovik [

3] noted, the transformation it initiated placed excessive focus on technological automation, often disregarding the centrality of human labor. This shortfall catalyzed the evolution toward Industry 5.0, which seeks to rebalance industrial priorities by reintroducing human values into technological systems.

Industry 5.0, as described by Xu et al. [

2] (p. 530), moves beyond economic growth and job creation to promote societal well-being, sustainability, and resilience. This human-centric vision recognizes the essential role of people in intelligent manufacturing ecosystems and aims to harmonize industrial development with social and environmental considerations.

To explore this emerging paradigm, the present study undertakes a systematic bibliometric literature review (LRSB) of the transition from Industry 4.0 to Industry 5.0. Applying the PRISMA 2020 protocol, the analysis examines 53 peer-reviewed sources from the Scopus database. This review focuses on the integration of AI, optimization techniques, and human values, offering insights into how these elements are reshaping the future of industry. Key themes include human–machine collaboration, ethical governance, and the alignment of advanced technologies with sustainability and societal needs.

2. Materials and Research Methods

This study adopts a systematic bibliometric literature review (LRSB) guided by the PRISMA 2020 framework to ensure a transparent, replicable, and unbiased approach to identifying, selecting, and analyzing relevant academic literature. The PRISMA protocol is particularly suited for synthesizing interdisciplinary research, as it mandates detailed reporting and methodological rigor. As noted by Linnenluecke et al. [

4], such systematic reviews minimize bias and enhance scientific validity through structured, replicable, and also synthesized procedures [

5]. Similarly, Haddaway et al. [

6] highlighted PRISMA’s capacity to ensure full transparency in review methods and outcomes.

The LRSB method, as detailed by Rosário et al. [

7] and Rosário [

8], offers a comprehensive and methodical way to map scholarly output in emerging research domains. Unlike traditional literature reviews, an LRSB involves a deliberate selection of studies that directly address the research questions, maintaining a strong emphasis on transparency and methodological rigor.

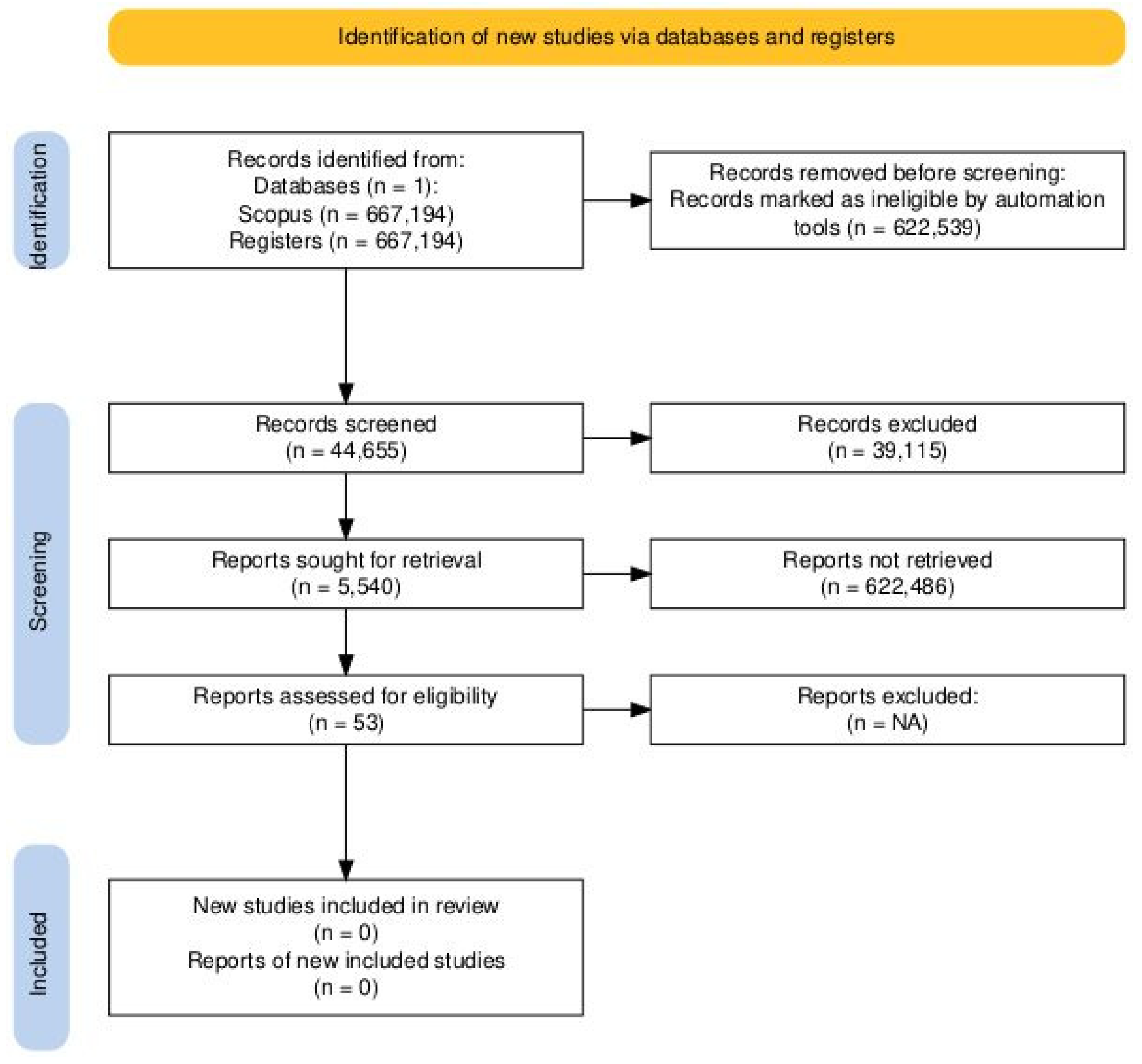

The review process followed a six-step sequence structured into three main phases (

Table 1):

This structured approach ensures a coherent and credible synthesis of knowledge across the domains of artificial intelligence, industrial transformation, and human values.

With respect to the data source and search strategy, the Scopus database was selected as the sole data source due to its extensive academic coverage, rigorous indexing, and advanced analytical tools. Scopus offers citation analysis, keyword mapping, and bibliometric evaluation capabilities, which are crucial for tracing research trajectories and identifying thematic trends. Despite its advantages, relying exclusively on Scopus may introduce limitations, such as the underrepresentation of regional or non-English publications and delayed indexing of recent works—factors acknowledged as potential biases in global research representation.

The literature search was confined to peer-reviewed journal articles, conference papers, and book chapters published up to April 2025, ensuring that the dataset maintained both academic credibility and relevance. The search employed Boolean keyword combinations, beginning with the broad term “artificial intelligence”, which yielded 667,194 results. Subsequent refinements narrowed the focus:

Adding “industry” reduced the results to 44,655 entries;

Including “industry 4.0” identified 5540 documents;

Adding “industry 5.0” yielded 376 entries;

Applying the exact keyword “smart manufacturing” refined the final dataset to 53 peer-reviewed publications (N = 53).

These filters ensured that the literature selected directly aligned with the study’s central themes: artificial intelligence, industrial evolution, and value-driven innovation.

With regard to the inclusion and exclusion criteria, to maintain focus and rigor, only works that explored the application of artificial intelligence within industrial and smart manufacturing contexts were included. Studies that lacked direct relevance to AI or failed to address the Industry 4.0–5.0 transition were excluded. This filtering process emphasized thematic alignment and methodological soundness, while ensuring that the final dataset addressed the study’s core research objectives. Further screening details are summarized in

Table 2, which outlines each stage of keyword refinement and selection criteria.

Regarding the analytical framework, the analysis applied a blend of narrative synthesis and bibliometric techniques, as outlined by Rosário et al. [

7,

8]. This hybrid method facilitated both qualitative interpretation and quantitative mapping of trends, recurring themes, and influential contributions. Bibliometric tools such as VOSviewer version 1.6.18 and Bibliometrix version 4.1.2 were used to visualize keyword co-occurrences, citation networks, and authorship patterns.

Ultimately, the selected 53 publications—comprising 25 conference papers, 23 journal articles, and 5 book chapters—formed the empirical basis of this review. These sources were examined for methodological quality, relevance to AI and human values, and alignment with the emerging paradigm of Industry 5.0, as illustrated in

Figure 1:

3. Publication Distribution

This section presents an overview of the publication patterns identified through the bibliometric review. The analysis focused on peer-reviewed literature related to the thematic core of the study—AI, optimization, and human values in the transition from Industry 4.0 to Industry 5.0—covering documents published up to April 2025.

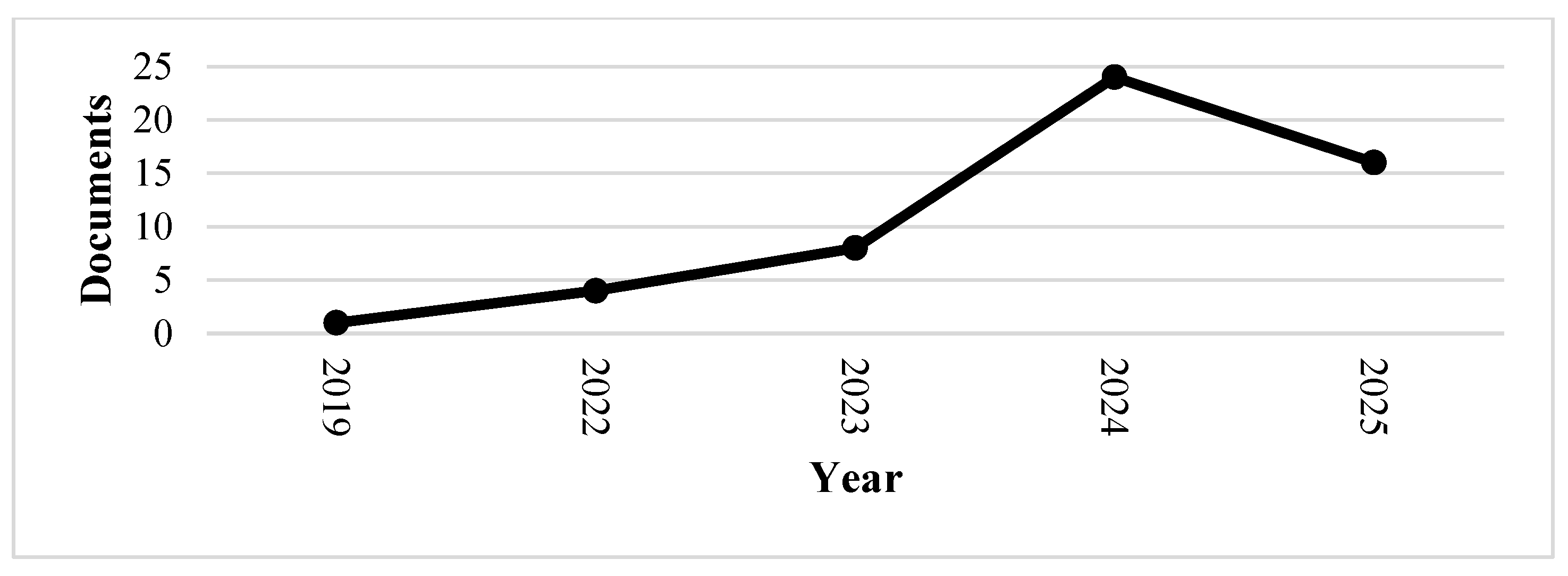

3.1. Temporal Distribution

A notable surge in academic interest occurred between 2022 and 2024, with 2024 recording the highest volume of publications (24 documents). This sharp rise reflects increasing attention to AI-driven industrial transformation and the emerging discourse around human-centered innovation (

Figure 2). The apparent drop in 2025 is attributed to the review cutoff date in April, not a decline in research output.

3.2. Source Journals

The documents analyzed were published across a wide array of academic outlets, reflecting the interdisciplinary nature of the topic. The most represented journals include:

Procedia Computer Science (5 publications);

IFAC PapersOnLine (4);

Springer Series in Reliability Engineering (3);

Applied Sciences—Switzerland (3);

Other journals and conference proceedings each contributed 1–2 publications, illustrating a dispersed but growing research base.

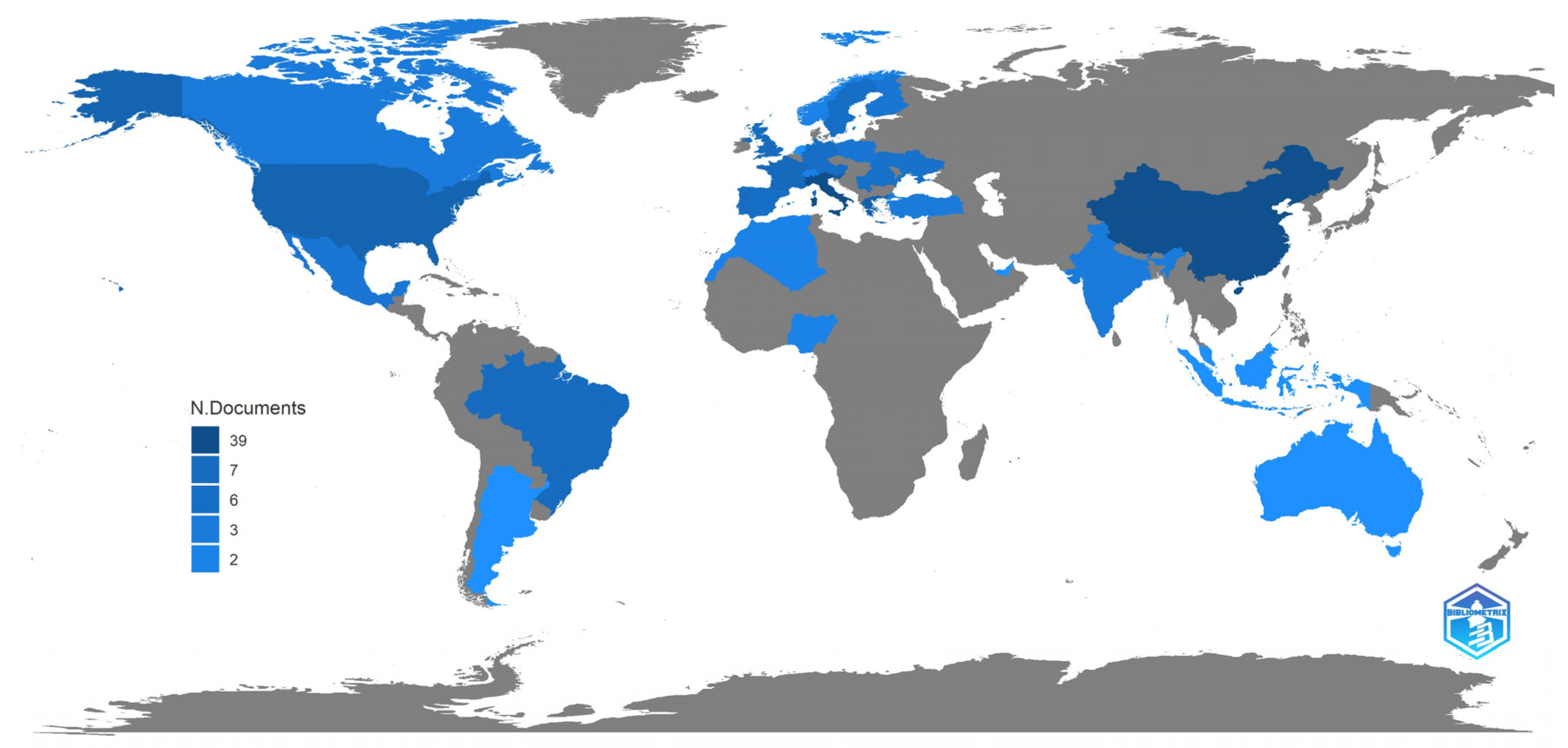

3.3. Geographic Distribution

The global nature of this research field is evident in the diverse country representation. As shown in

Figure 3 and

Table 3, leading contributors include:

The active participation of both developed nations and emerging economies like Brazil highlights the strategic importance of this research area, as industries and institutions worldwide increasingly adopt intelligent technologies.

This widespread engagement reflects an international push toward intelligent, sustainable industrial systems, with both developed and emerging economies actively contributing.

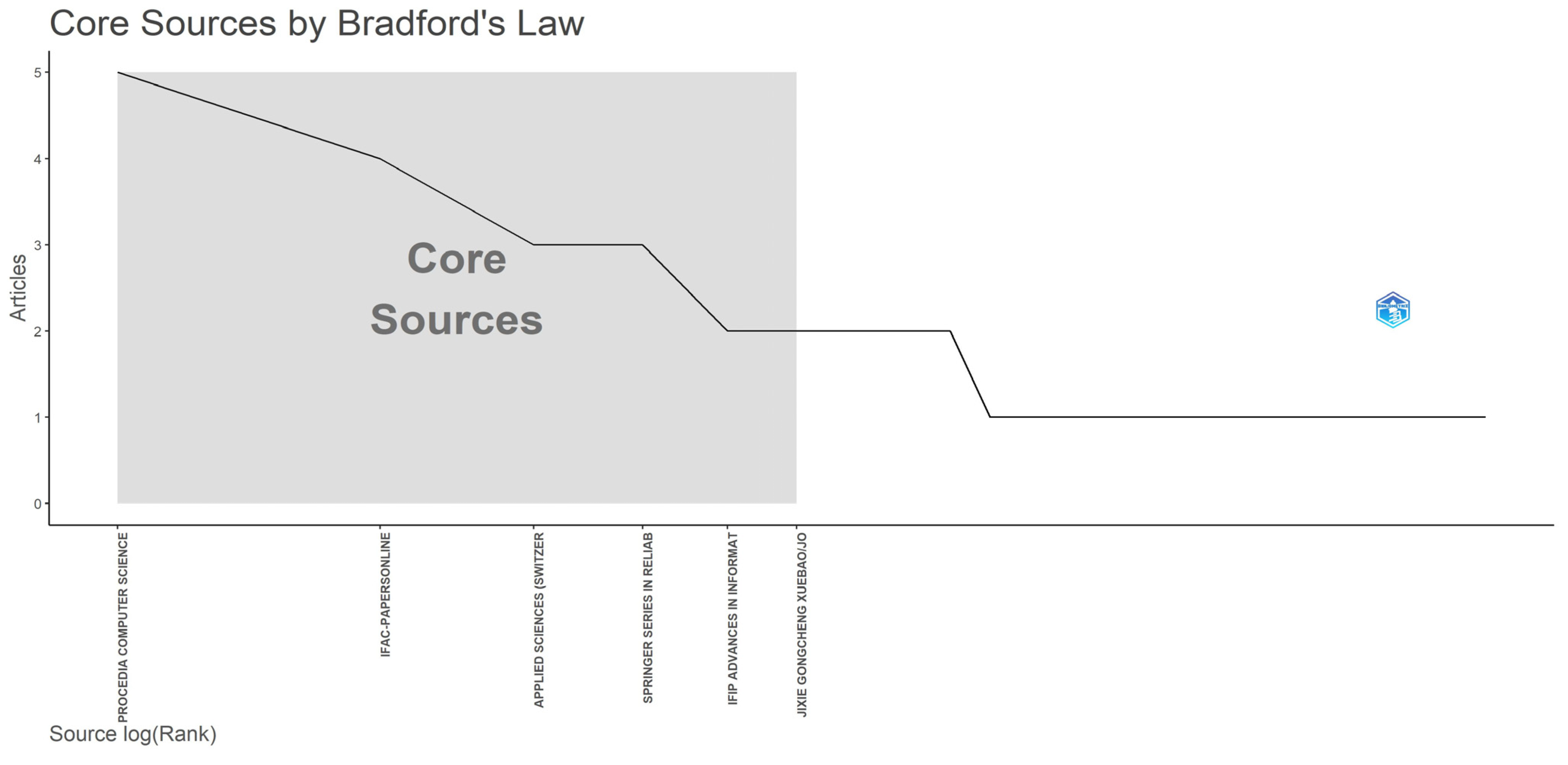

3.4. Core Sources and Citation Trends

Applying Bradford’s law, six journals emerged as core sources, accounting for 11% of the total literature. These publications act as intellectual hubs, facilitating early discourse and influencing subsequent research directions (

Figure 4,

Table 4). Although it is an empirical method, mostly through observation and focused on quantity rather than quality, Bradford’s law is useful in mapping research productivity and dissemination patterns, while enabling quantitative analysis of literature distribution and aiding in identifying core journals, in which most relevant articles are published [

7].

In the case, citation analysis reveals robust scholarly engagement. The most cited work, “Industry 5.0 and Human-Robot Co-working”, has accumulated 504 citations, highlighting its centrality to the field. This study, published in Procedia Computer Science, explores organizational and human factors in collaborative robotics. These data are displayed in detail in

Table 4:

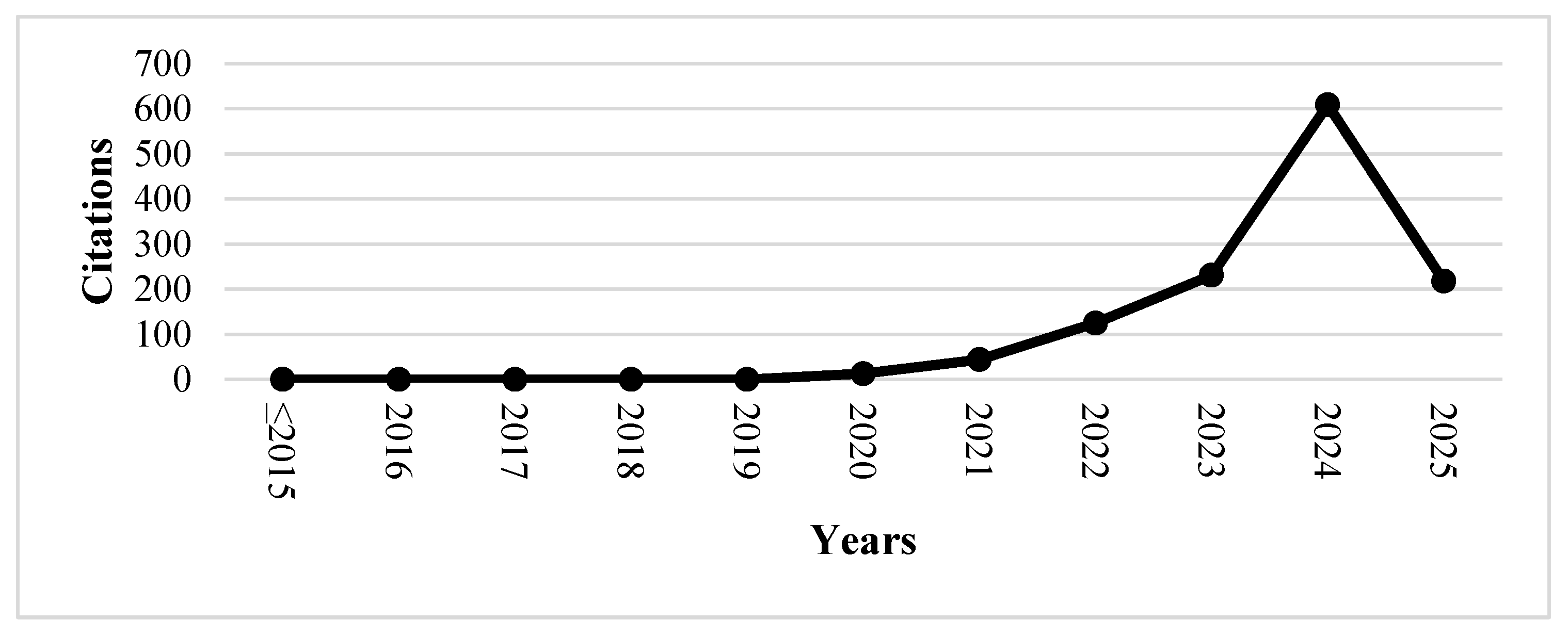

Across all documents analyzed, the total citations amounted to 1240, with 25 publications achieving at least 10 citations (

Appendix A). The h-index for the reviewed corpus stands at 25, underscoring both the quality and impact of the selected works. Citation trends from ≤2015 to 2025 (

Figure 5) show a strong upward trajectory, with an R

2 value of 0.52, indicating a consistent rise in academic relevance.

3.5. Disciplinary Breadth

The reviewed documents span multiple subject areas, reflecting the interdisciplinary scope of Industry 4.0–5.0 research:

Engineering (37 documents);

Computer Science (34);

Mathematics (10);

Decision Sciences, Business, Management & Accounting (6 each);

Physics, Energy, Environmental Science, Medicine, Arts & Humanities (2–4 each).

This thematic diversity reinforces the integration of technical, social, and ethical dimensions in the ongoing industrial transition.

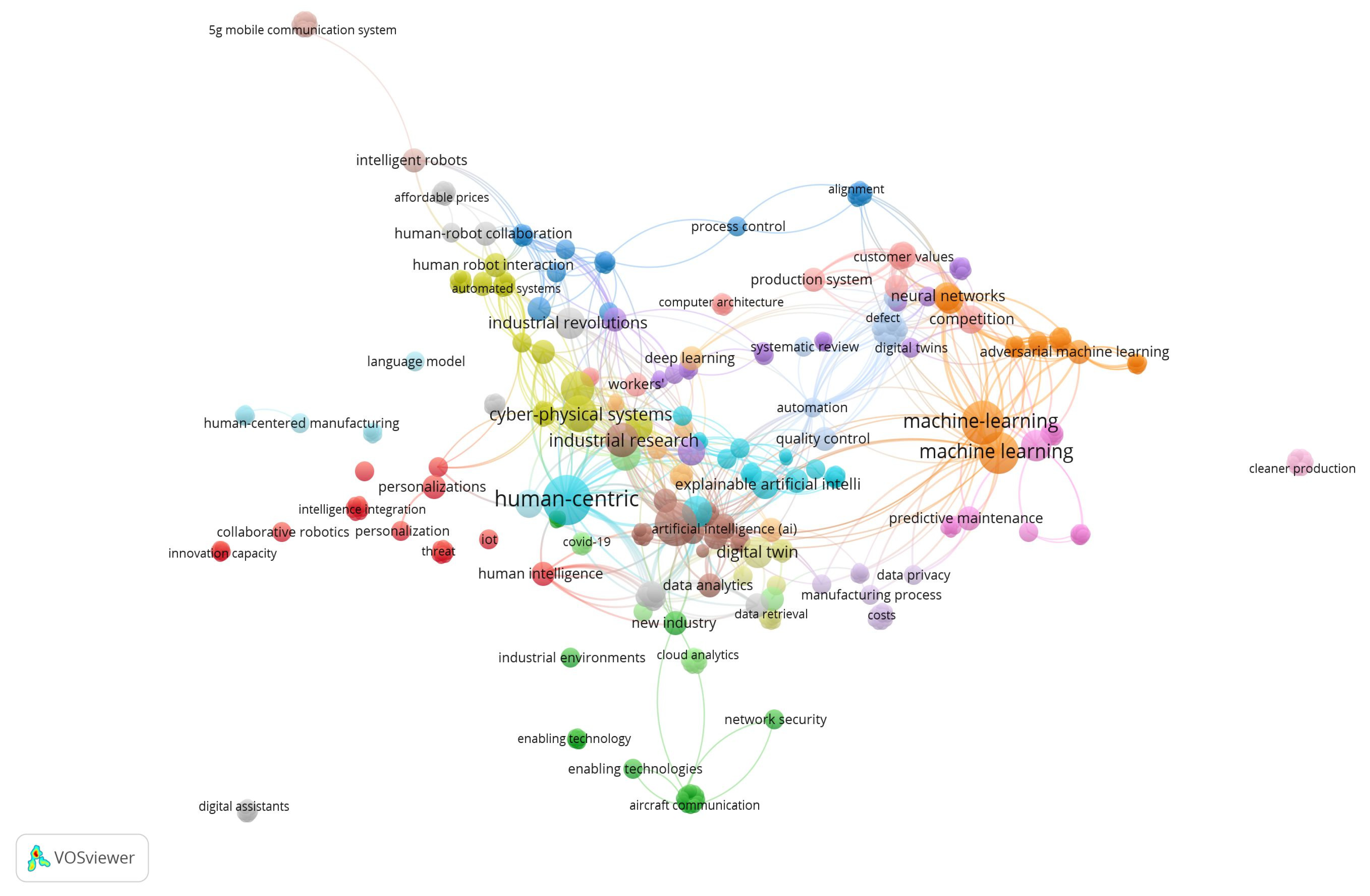

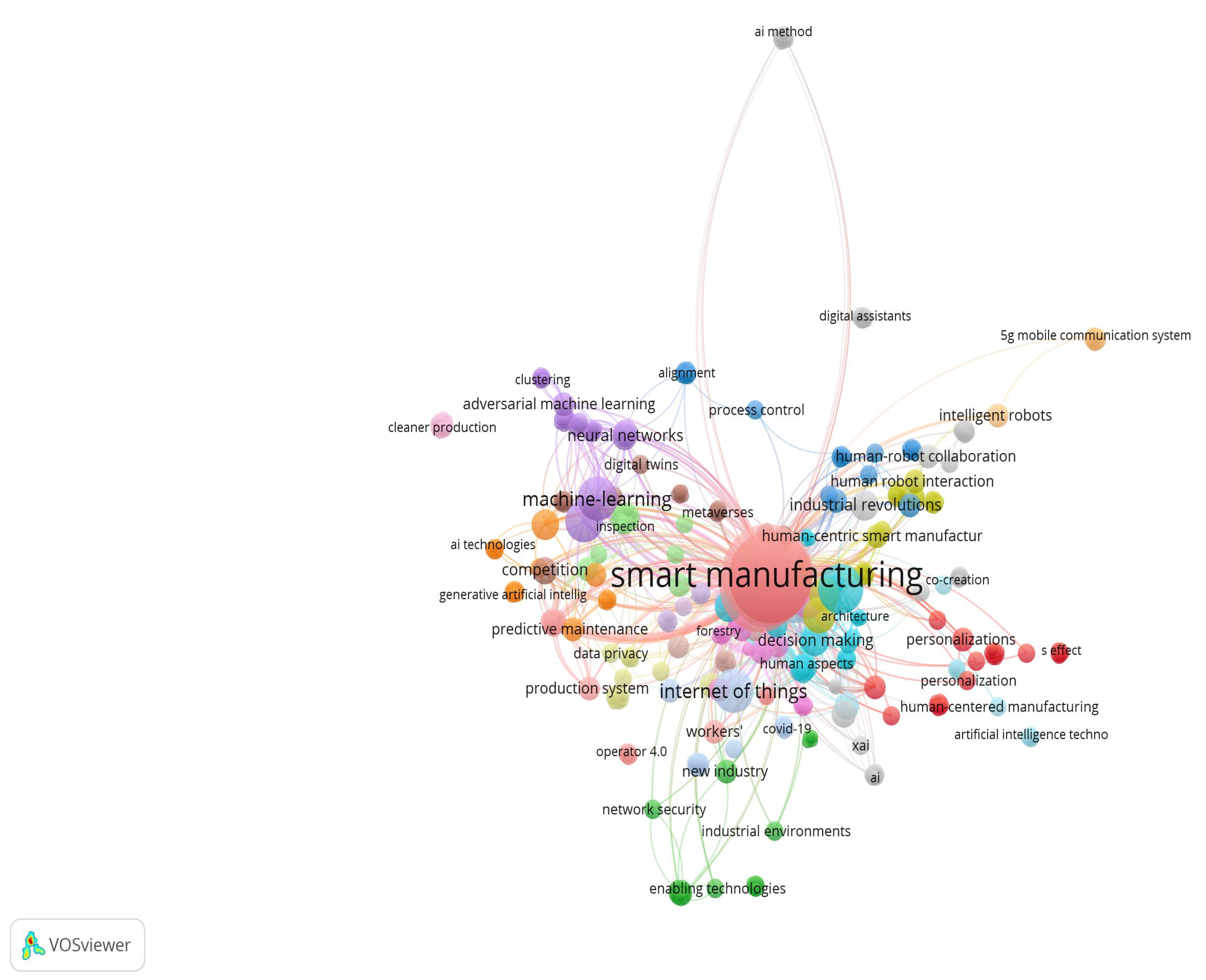

The bibliometric analysis, conducted using VOSviewer and Bibliometrix software, mapped the research landscape around the keywords “AI, Optimization, and Human Values” within the context of Industry 4.0 and 5.0.

Figure 6,

Figure 7,

Figure 8,

Figure 9 and

Figure 10 offer complementary visualizations that reveal the structural and thematic dynamics of the field.

Figure 6 illustrates a keyword co-occurrence network, emphasizing the centrality of terms like artificial intelligence, Industry 4.0, Industry 5.0, and smart manufacturing. The clustering reveals how discussions remain largely grounded in technology-centric frameworks, with limited conceptual engagement beyond the industrial application layer. This concentration suggests a dominant focus on operational and implementation concerns, potentially overshadowing human-centric or regulatory considerations.

Figure 6.

Network of all keywords.

Figure 6.

Network of all keywords.

Figure 7, a three-field plot (authors, cited references, and keywords), clarifies the intellectual foundation of the field. A small number of authors and sources are repeatedly linked to key terms, suggesting a tightly interconnected scholarly community. However, the limited thematic variety within the high-frequency keywords points to a narrow conceptual bandwidth, underscoring the need for broader interdisciplinary integration.

Figure 7.

Three-field plot analysis (AU = authors, CR = references, DE = authors keywords).

Figure 7.

Three-field plot analysis (AU = authors, CR = references, DE = authors keywords).

The Sankey diagram, as Xiao et al. [

9] described, provides a clear way to trace the flow and development of major topics throughout the analysis. It further reinforces this by showing unidirectional flows from pivotal terms like Industry 5.0 and smart manufacturing, which lack outgoing connections. This pattern implies that while these themes dominate discourse, they are not sufficiently influencing or branching into emerging subfields, indicating a potential stagnation in thematic diversification [

8].

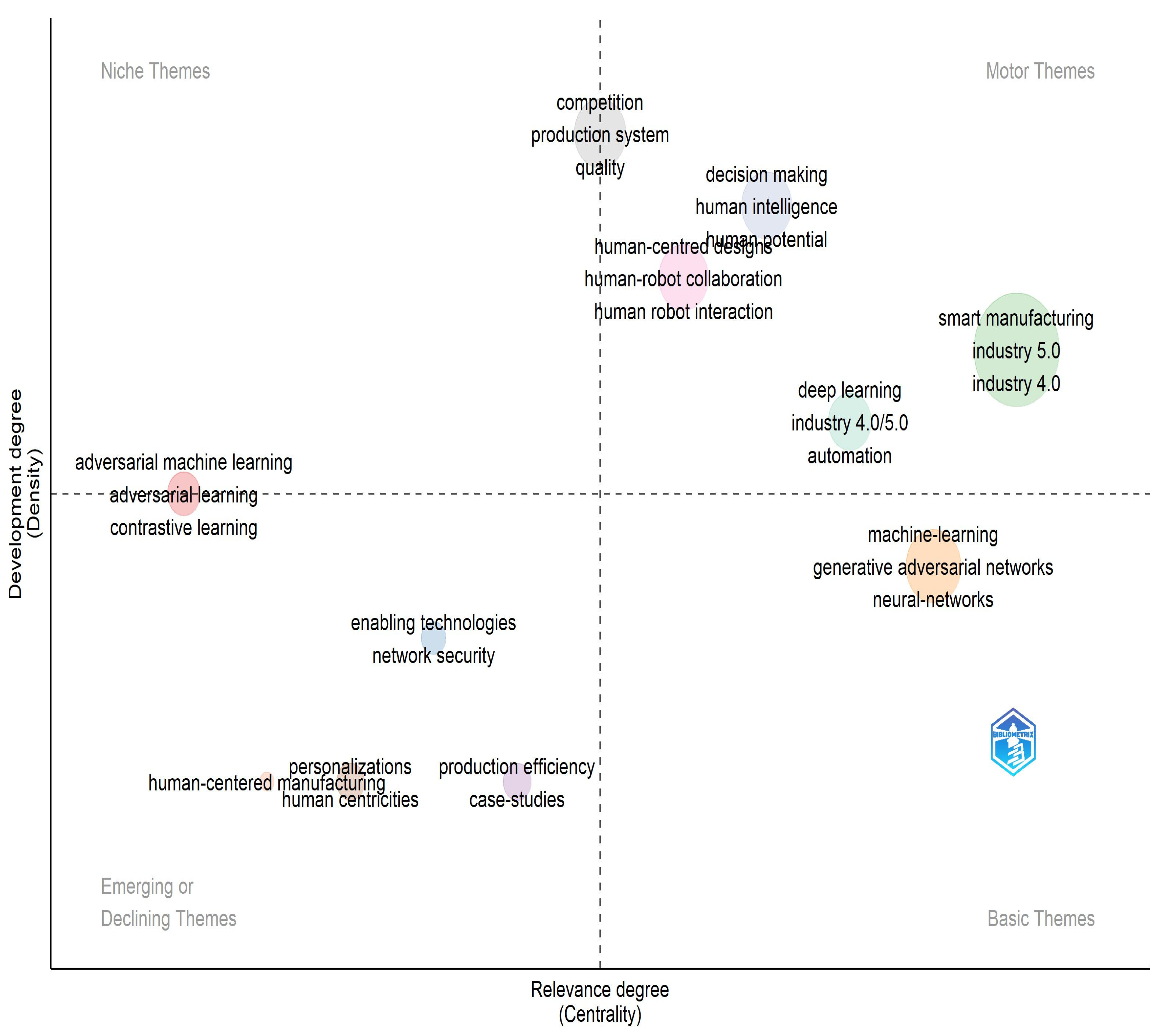

Figure 8, the thematic map, positions research clusters based on centrality and density. Core themes in the upper-right quadrant, such as AI and smart manufacturing, are both well-developed and influential. In contrast, emerging yet underdeveloped areas—network security, enabling technologies, and production efficiency—occupy the lower-left quadrant, signaling future research opportunities. The presence of highly specialized but isolated topics in the upper-left quadrant—e.g., inventory control and customer service—reflects fragmented efforts that could benefit from stronger integration into central research currents.

Figure 8.

Network of linked keywords.

Figure 8.

Network of linked keywords.

Figure 9 offers a closer look at the thematic evolution. The prominence of machine learning, generative adversarial networks, and neural networks as basic themes reflects an entrenched reliance on data-driven methodologies. However, their clustering away from human-centric concepts like human intelligence and human-robot interaction—which appear in more strategic, developmental positions—suggests a gap between technical advancements and human-centered design principles.

Figure 9.

Thematic map analysis.

Figure 9.

Thematic map analysis.

Figure 10, the co-citation network, highlights a well-established core of frequently cited studies that reinforce dominant paradigms in AI and industrial evolution. The dense central structure indicates a mature field, though the presence of peripheral nodes hints at niche but potentially transformative areas awaiting deeper exploration.

Figure 10.

Network of co-citation.

Figure 10.

Network of co-citation.

The aforementioned visual analyses collectively underscore a field that is technologically robust but conceptually narrow. While AI and smart manufacturing dominate, limited attention to ethics, regulation, and human values creates intellectual blind spots. Future research should aim to bridge this gap by integrating social, philosophical, and interdisciplinary perspectives, broadening the scope beyond technical optimization toward a more holistic vision of Industry 5.0.

4. Theoretical Perspectives

The transition from Industry 4.0 to Industry 5.0 represents more than a technological evolution; it reflects a shift in the underlying theoretical frameworks that guide industrial design, production, and innovation. This section outlines the key conceptual underpinnings of both paradigms, their enabling technologies, and the values shaping their integration.

4.1. Understanding Industry 4.0

Industry 4.0, commonly referred to as the fourth Industrial Revolution, marks the convergence of digital, physical, and biological technologies. Introduced during the 2011 Hannover Fair as part of a German government initiative, it aimed to enhance manufacturing competitiveness through advanced digitalization. However, its conceptual roots trace back to late 20th-century developments in embedded systems and networked communication.

Skobelev and Borovik [

3] (p. 307) described Industry 4.0 as “an umbrella term used to describe a group of connected technological advances that provide a foundation for increased digitization of the business environment”. Similarly, De Souza et al. [

10] (p. 145) emphasized its integration of machines, sensors, and software to enhance prediction, planning, and control.

Key distinctions from previous revolutions comprehend [

11]:

Real-time responsiveness;

Human–machine interaction;

Cyber–physical integration;

Data-driven decision-making.

These advances enabled intelligent, adaptive production systems capable of self-regulation, paving the way for autonomous and interconnected manufacturing ecosystems.

Key Components

Several foundational technologies enable the functionality of Industry 4.0:

Cyber–Physical Systems (CPSs): As the structural backbone of Industry 4.0, CPSs tightly integrate computation, networking, and physical processes through sensors and actuators [

12]. They enable adaptive control, real-time feedback, and self-optimization [

3].

Internet of Things (IoT): IoT connects devices, machines, and systems across industrial environments, enabling continuous data exchange [

2]. When coupled with analytics and AI, it supports predictive maintenance and dynamic process optimization [

13].

Internet of Services (IoS): IoS promotes a shift toward service-based models like product-as-a-service. It leverages Service-Oriented Architecture (SOA) and cloud computing to deliver manufacturing functions on demand [

14].

Smart Factory: Smart factories embody Industry 4.0 principles through flexible, interconnected systems capable of autonomous operation [

15]. They integrate CPSs, IoT, and AI to create self-organizing production environments, enhanced by tools like digital twins and real-time scheduling algorithms [

3,

16,

17].

4.2. Key Technologies in Industry 4.0

Industry 4.0’s impact is driven by the convergence of several transformative technologies:

Industrial Internet of Things (IIoT): IIoT extends IoT capabilities into industrial settings, ensuring low-latency, high-reliability communication between devices and systems [

13,

18].

Additive Manufacturing (3D Printing): This technology supports customization, rapid prototyping, and decentralized production. Integrated with AI and IoT, it offers adaptive process control and reduced waste [

19,

20,

21].

Big Data: Big data analytics transform massive, heterogeneous datasets into actionable insights. Techniques like machine learning and natural language processing support predictive maintenance, inventory optimization, and closed-loop manufacturing [

22,

23,

24].

Artificial Intelligence (AI): AI enables machines to learn, adapt, and make decisions. In manufacturing, it drives process optimization, defect detection, and intelligent automation [

25,

26,

27].

Collaborative Robots (CoBots): Designed to work safely alongside humans, CoBots support hybrid workflows where machines augment human capabilities [

28,

29,

30].

Virtual Reality (VR): VR enhances training, design, and simulation processes. When paired with digital twins and AI, it enables predictive visualization and collaborative design environments [

3,

12].

4.3. Emergence of Industry 5.0

Despite the progress enabled by Industry 4.0, its limitations—particularly in human-centric and ethical dimensions—have become increasingly evident. Industry 5.0 responds to these gaps by re-centering industrial systems around human, societal, and environmental values.

On the one hand, Xu et al. [

2] (p. 530) framed Industry 5.0 as the pursuit of “societal goals beyond jobs and growth”, while the European Commission, on the other hand, emphasizes its regenerative role, integrating people, planet, and prosperity [

31]. It does not reject Industry 4.0 but complements it with a focus on inclusion, resilience, and sustainability [

32,

33].

Zizic et al. [

31] and Alimam et al. [

13] identify the three foundational pillars of Industry 5.0:

Human-centricity: Prioritizing human dignity, creativity, and participation in production processes;

Sustainability: Promoting environmentally responsible practices such as reuse, recycling, and reduced resource consumption;

Resilience: Building flexible systems capable of adapting to disruptions and uncertainties.

4.4. Factors Driving the Shift Toward Industry 5.0

The transition from Industry 4.0 to Industry 5.0 is motivated by a set of interrelated technological, societal, and ethical concerns. While Industry 4.0 advanced automation, data connectivity, and operational efficiency, it often overlooked human welfare, environmental sustainability, and systemic resilience. Industry 5.0 emerges as a necessary evolution—one that seeks to realign industrial innovation with broader societal needs and values. Several key factors underpin this shift:

4.4.1. Human–Machine Collaboration

Unlike the automation-centric ethos of Industry 4.0, Industry 5.0 fosters collaborative interaction between humans and machines. It acknowledges the irreplaceable value of human traits—creativity, empathy, intuition, and ethical judgment—in complex decision-making processes [

34,

35]. Technologies like collaborative robots (CoBots) and AI interfaces are designed to augment, rather than replace, human labor [

30]. These systems support shared workspaces where humans and intelligent machines cooperate dynamically, improving both productivity and worker satisfaction.

4.4.2. Ethical Considerations

The increasing prevalence of AI has raised significant ethical questions, particularly regarding data privacy, algorithmic bias, labor displacement, and transparency [

36,

37]. In response, Industry 5.0 emphasizes ethical governance frameworks, including principles such as fairness, accountability, inclusivity, and explainability [

38,

39]. These values are embedded in the design and deployment of technologies, ensuring alignment with democratic norms and public trust. Ethical foresight is thus reframed as a strategic enabler—not a constraint—in technological development.

4.4.3. Sustainability

As climate concerns intensify, industries are under pressure to adopt environmentally responsible models. Industry 4.0, despite its efficiency gains, often produced carbon-intensive, resource-depleting systems [

40]. Industry 5.0 promotes circular economy practices, optimized resource usage, and carbon-neutral operations through technologies like AI-powered energy management, life cycle assessment tools, and digital twins [

41,

42]. According to Oladeinde and Ojo [

33], this marks a transition from extractive to restorative industrial paradigms, aligning production with global sustainability targets.

4.4.4. Cybersecurity Concerns

As industrial systems become increasingly interconnected, cybersecurity threats—including ransomware, data breaches, and AI-driven attacks—have grown more sophisticated. In 2020 alone, cyberattacks cost the global economy an estimated USD 945 billion [

43]. Industry 5.0 responds by embedding resilient, AI-enhanced security architectures, such as zero-trust models and real-time threat detection mechanisms [

15,

44]. Additionally, it recognizes the human element in cybersecurity, emphasizing awareness, behavior, and ethical responsibility in organizational culture.

4.4.5. Demand for Resilient and Time-Sensitive Systems

Recent disruptions like the COVID-19 pandemic and geopolitical instability have exposed the vulnerabilities of just-in-time global supply chains. Many firms struggled with supplier delays, material shortages, and volatile pricing [

45]. Industry 5.0 emphasizes resilience and temporal adaptability, using edge computing, decentralized AI, and predictive analytics to build systems that can autonomously reconfigure in response to external shocks [

46,

47]. This shift underscores a broader move from optimization toward strength in industrial design.

4.4.6. AI Education and Workforce Preparedness

The widespread adoption of AI in industry demands a digitally literate and adaptable workforce. Industry 5.0 promotes re-skilling and up-skilling through educational initiatives that combine technical training with ethical reasoning and systems thinking [

48,

49]. This human development strategy ensures that technological innovation remains inclusive and empowering, rather than exclusionary. Participatory design and lifelong learning platforms allow workers to meaningfully engage with—and shape—the systems they interact with.

4.4.7. Demand for Co-Creation and Co-Production

Today’s consumers and communities seek greater involvement in the products and services they use. Industry 5.0 responds by embracing co-creation models that allow stakeholders—including customers, employees, and local communities—to actively contribute to innovation [

41]. Using AI tools, open platforms, and digital fabrication, organizations foster participatory processes that reflect diverse needs and values [

50]. This democratization of innovation promotes greater user engagement, product personalization, and social legitimacy.

4.4.8. Advanced Quality Control Requirements

The rising complexity and customization in modern manufacturing necessitate precise and adaptive quality control. Industry 5.0 integrates AI-powered visual inspection, predictive analytics, and real-time monitoring to ensure product excellence across the value chain [

12,

51]. Unlike in earlier models, quality assurance is now a collaborative process, combining machine precision with human insight. This integration not only enhances operational efficiency but also aligns quality standards with ethical and experiential dimensions, such as safety, usability, and sustainability [

49,

52].

4.5. Key Technologies Enabling the Evolution from Industry 4.0 to 5.0

The evolution from Industry 4.0 to Industry 5.0 is not merely defined by technological innovation but by the way these technologies are deployed to align technical performance with human-centric values. The enabling technologies that support this transition fall into three overarching categories: artificial intelligence (AI), optimization tools, and technologies that embed human values into industrial systems.

4.5.1. Artificial Intelligence

AI continues to serve as the cognitive core of modern industry. In Industry 5.0, AI applications are shifting from pure automation to collaborative and creative augmentation, empowering human decision-making and ethical oversight.

Generative AI and Explainable AI (XAI)

Generative AI models (e.g., GPT-based systems, diffusion networks) contribute to design, engineering, and content generation by enabling machines to co-create with humans in real time [

53,

54,

55]. These tools support ideation, rapid prototyping, and personalization.

Meanwhile, Explainable AI (XAI) addresses the black-box nature of complex algorithms by providing interpretable outputs. Das and Rad [

56] emphasized that XAI tools enhance transparency, allowing end-users to trust and understand how decisions are made—an essential element in ethical, human-centered environments [

15,

49].

Machine Learning (ML)

ML forms the analytical engine behind many Industry 5.0 systems. Its predictive and adaptive capabilities are applied in areas such as predictive maintenance, energy optimization, and demand forecasting [

21,

28]. Moreover, ML enables responsive systems that adjust in real-time, supporting both operational efficiency and user personalization.

Cyber–Physical Systems (CPSs) and Digital Twins

CPSs and digital twins represent the physical–digital interface essential for smart, adaptive environments. CPSs integrate sensors, actuators, and control systems to create intelligent, context-aware infrastructures [

12]. Digital twins extend these capabilities by simulating physical assets in real time for enhanced diagnostics, scenario testing, and predictive planning [

57,

58]. When paired with AI, they significantly improve resilience and system intelligence.

4.5.2. Optimization Technologies

Optimization tools play a critical role in balancing complex and often competing objectives such as cost, energy use, waste reduction, and production agility.

Multi-Objective Optimization and Edge Computing

Modern industrial challenges require balancing multiple priorities simultaneously. Multi-objective optimization (MOO) algorithms address this by generating optimal trade-offs across competing goals, such as energy efficiency and throughput [

40,

59].

Edge computing, which processes data locally rather than relying solely on cloud infrastructure, enhances real-time responsiveness and reduces latency. Together, MOO and edge computing create systems that are both efficient and highly adaptive [

59,

60].

Life Cycle Assessment (LCA) Models

LCA tools help evaluate the environmental impact of products and processes from cradle to grave. When integrated with AI, they provide real-time insights into resource usage, emissions, and recyclability [

61,

62]. This enables manufacturers to make sustainable choices at every stage of the product life cycle, aligning operations with circular economy principles and global climate targets.

4.5.3. Technologies Emphasizing Human Values

Technologies that prioritize worker well-being, inclusivity, and collaboration are central to Industry 5.0’s ethos. These tools enhance human agency and safety while improving productivity.

Wearable Technologies

Devices such as exoskeletons, smartwatches, and biometric monitors track worker health, posture, fatigue, and exposure to environmental hazards [

20]. These technologies adapt workflows based on individual needs and provide real-time feedback to ensure safety, ergonomics, and productivity [

12,

46].

Human–Robot Collaboration (HRC)

Human–Robot Collaboration (HRC) reframes automation as augmentation—a synergistic partnership that leverages the unique strengths of both humans and robots. Current collaborative robotic systems (CoBots), though more advanced than traditional isolated robotic technologies, are still primarily engineered for task sharing within predefined parameters. They can interpret basic gestures and adjust to environmental changes, but their contextual understanding and adaptability to nuanced human behavior remain limited [

28,

29].

To fully align with a human-centered approach, however, this technology must evolve beyond reactive assistance toward proactive collaboration. This involves developing systems capable of interpreting human intent, emotional cues, and individualized working styles. Rather than merely increasing precision and efficiency, next-generation HRC should prioritize worker autonomy, psychological comfort, and inclusive design—ensuring that robots adapt to humans, not the other way around. While existing systems contribute to job satisfaction and operational flexibility [

19], a truly human-centric model would require robots to support cognitive well-being, foster creative agency, and accommodate diverse abilities and perspectives.

Sensor Technologies

Advanced sensor networks enable the continuous collection of high-resolution data for dynamic control and system refinement. These sensors not only track machine performance and product quality but also monitor worker well-being and environmental conditions, contributing to both efficiency and safety [

51,

59].

Next-Generation Communication Technologies

Technologies such as 5G and beyond offer the ultra-low latency and high bandwidth required for seamless communication among distributed systems, including robotic swarms, smart sensors, and remote operations [

24]. These networks enable real-time synchronization and coordination across geographically dispersed production environments, supporting agile and resilient manufacturing ecosystems [

62].

4.6. Comparative Analysis Between Industry 4.0 and Industry 5.0

Together, the aforementioned technologies represent a shift from automation-driven innovation toward a human-centered, resilient, and ethically grounded industrial paradigm. They enable real-time adaptability, strategic optimization, and values-based design, all of which are hallmarks of Industry 5.0. Likewise, Industry 4.0 and Industry 5.0 represent two consecutive phases in industrial and technological evolution, yet they differ fundamentally in their priorities and philosophical orientation. Understanding their relationship and complementary roles is essential to shaping sustainable and human-centered future development trends.

While Industry 4.0 focus upon digitalization, automation, and real-time data, it integrates cyber–physical systems, the Internet of Things (IoT), artificial intelligence (AI), cloud computing, and robotics into manufacturing and industrial operations/efficiency, Industry 5.0 further relies on human-centric innovation. It extends beyond technological optimization to prioritize human well-being, societal values, and environmental sustainability, whilst emphasizing collaboration between humans and machines rather than replacement, aiming to reintegrate the human into advanced manufacturing in a sustainable way (

Table 5).

The main identified trends might be as follows:

First, while Industry 4.0 streamlined operations, Industry 5.0 asks why and who these optimizations serve, pushing organizations to align with broader ethical and societal goals; it is ensuing a movement away from full automation toward augmented intelligence and collaborative robotics that enhance human capabilities rather than replace them.

Likewise, Industry 5.0 promotes sustainability through circular economy models, building upon the data and efficiency gains of Industry 4.0 to minimize waste and carbon footprints; in other words, AI and machine learning become more embedded and the focus shifts from just “smart systems” to responsible AI, including fairness, transparency, and accountability, paving the way to frameworks that align technological progress with labor rights, digital ethics, and environmental policy.

5. Conclusions

The transition from Industry 4.0 to Industry 5.0 marks a significant reorientation of industrial development from a focus on automation and efficiency to one that integrates technological advancement with human values, sustainability, and resilience. While Industry 4.0 revolutionized manufacturing through technologies such as cyber–physical systems (CPSs), artificial intelligence (AI), and the Internet of Things (IoT), it often fell short in addressing the ethical, environmental, and societal impacts of these innovations [

2,

3].

Industry 5.0 emerges as a complementary evolution—not merely a successor—placing human-centricity, ethical governance, and ecological responsibility at the forefront of industrial systems. It emphasizes co-creation, collaborative intelligence, and the empowerment of human workers rather than their replacement. Enabling technologies such as wearables, collaborative robots (CoBots), life cycle assessment (LCA) models, and explainable AI are being deployed to support more inclusive, transparent, and adaptive systems [

12,

29,

56,

62].

Several key drivers are accelerating this shift, including:

The need for human–machine collaboration that leverages both human judgment and machine precision [

30,

34];

Rising concerns around data ethics, transparency, and accountability [

36,

37,

38,

39];

The global imperative for sustainable and regenerative production models [

31,

40,

41,

42];

Increasing demand for resilient, time-sensitive infrastructures amid geopolitical and pandemic-related disruptions [

45,

46,

47];

The critical role of AI education and workforce reskilling to ensure inclusive digital transformation [

48,

49].

This study contributes to the academic discourse by offering a systematic bibliometric review of 53 peer-reviewed publications that map the intellectual landscape from Industry 4.0 to 5.0. This review identifies the converging technological trends and emerging value-based frameworks shaping the next phase of industrial transformation. It highlights how AI and optimization technologies are evolving beyond efficiency tools to become instruments for ethical reasoning, personalized interaction, and sustainable innovation.

Practically, the findings offer guidance for industry leaders, technology developers, and policymakers seeking to transition toward more equitable and future-ready production systems. The emphasis on co-design, inclusive governance, and strategic workforce development is particularly crucial for ensuring that technological progress enhances—not diminishes—human agency and societal well-being.

However, several avenues remain open for further exploration. Future research should focus on:

Context-specific studies that examine Industry 5.0 implementation across sectors and cultures;

Development of metrics to assess the social, ethical, and environmental impacts of human-centric technologies;

Deeper inquiry into emerging technologies such as quantum AI, bio-digital systems, and synthetic cognition within the Industry 5.0 paradigm.

Ultimately, this review underscores that the success of Industry 5.0 depends not only on technological innovation but also on our collective ability to embed human dignity, sustainability, and resilience into the fabric of industrial systems.

Author Contributions

Conceptualization, A.T.R. and R.J.G.R.; methodology, A.T.R. and R.J.G.R.; software, A.T.R. and R.J.G.R.; validation, A.T.R. and R.J.G.R.; formal analysis, A.T.R. and R.J.G.R.; investigation, A.T.R. and R.J.G.R.; resources, A.T.R. and R.J.G.R.; data curation, A.T.R. and R.J.G.R.; writing—original draft preparation, A.T.R. and R.J.G.R.; writing—review and editing, A.T.R. and R.J.G.R.; visualization, A.T.R. and R.J.G.R.; supervision, A.T.R. and R.J.G.R.; project administration, A.T.R. and R.J.G.R.; funding acquisition, A.T.R. and R.J.G.R. All authors have read and agreed to the published version of the manuscript.

Funding

The first author receives financial support from the Research Unit on Governance, Competitiveness and Public Policies (UIDB/04058/2020) + (UIDP/04058/2020), funded by national funds through FCT—Fundação para a Ciência e a Tecnologia.

Acknowledgments

We would like to express our gratitude to the Editor and the Referees. They offered extremely valuable suggestions or improvements. The authors were supported by the GOYCOPP Research Unit of Universidade de Aveiro and ISEC Lisboa, Higher Institute of Education and Sciences.

Conflicts of Interest

The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Appendix A

Table A1.

Overview of document citations period ≤2015 to 2025.

Table A1.

Overview of document citations period ≤2015 to 2025.

| Documents | | ≤2015 | 2016 | 2017 | 2018 | 2019 | 2021 | 2021 | 2022 | 2023 | 2024 | 2025 | Total |

|---|

| Reviewing human–robot collaboration in manufacturing: Opportunities and challenges in the context of Industry 5.0 | 2025 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 2 |

| Artificial Intelligence of Things Infrastructure for Quality Control in Cast Manufacturing Environments Shedding Light on Industry Changes | 2025 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 3 |

| Industry 4.0 technologies for sustainability within small and medium enterprises: A systematic literature review and future directions | 2024 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 3 | 6 |

| AI’s effect on innovation capacity in the context of Industry 5.0: a scoping review | 2024 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 2 | 4 |

| Toward a Human–Cyber–Physical System for Real-Time Anomaly Detection | 2024 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 2 |

| Human in the AI loop via XAI and active learning for visual inspection | 2024 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 3 |

| Human–machine Collaborative Additive Manufacturing for Industry 5.0 | 2024 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 |

| Digital Twins for Industry 5.0: Unlocking the Human Potential | 2024 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| Exploring the Potential Network Vulnerabilities in the Smart Manufacturing Process of Industry 5.0 via the Use of Machine Learning Methods | 2024 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| Artificial Intelligence in Small and Medium-Sized Enterprises: Requirements and Barriers | 2024 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| Toward human-centered intelligent assistance system in manufacturing: challenges and potentials for operator 5.0 | 2024 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 6 | 4 | 10 |

| Enhancing wisdom manufacturing as industrial metaverse for industry and society 5.0 | 2024 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 11 | 53 | 19 | 83 |

| Towards new-generation human-centric smart manufacturing in Industry 5.0: A systematic review | 2023 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 76 | 38 | 116 |

| Towards Human Digital Twins to enhance workers’ safety and production system resilience | 2023 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 9 | 7 | 16 |

| Digital Triplet Paradigm for Brownfield Development towards Industry 5.0: A Case Study of Intelligent Retrofitting for Oil and Gas Boosting Plant in the Industrial Internet of Things (IIoT) Context | 2023 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 4 |

| Wearable Technology for Smart Manufacturing in Industry 5.0 | 2023 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 8 | 1 | 10 |

| Artificial Intelligence for Smart Manufacturing in Industry 5.0: Methods, Applications, and Challenges | 2023 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 14 | 2 | 19 |

| Explainable Articial Intelligence for Cybersecurity in Smart Manufacturing | 2023 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 3 | 2 | 6 |

| Industry 5.0 and Human-Centered Approach. Bibliometric Review | 2023 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 4 | 0 | 6 |

| Human-centric artificial intelligence architecture for Industry 5.0 applications | 2023 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 13 | 82 | 33 | 129 |

| Enriching Artificial Intelligence Explanations with Knowledge Fragments | 2022 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 3 | 3 | 1 | 10 |

| State of Industry 5.0—Analysis and Identification of Current Research Trends | 2022 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 25 | 63 | 147 | 42 | 277 |

| Industry 5.0: From Manufacturing Industry to Sustainable Society | 2022 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 7 | 5 | 14 |

| Evaluation of AI-Based Digital Assistants in Smart Manufacturing | 2022 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5 | 5 | 2 | 12 |

| Industry 5.0 and Human–Robot Co-working | 2019 | 0 | 0 | 0 | 0 | 0 | 13 | 44 | 96 | 125 | 180 | 46 | 504 |

| | Total | 0 | 0 | 0 | 0 | 0 | 13 | 44 | 125 | 231 | 609 | 218 | 1.24 |

References

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. A Literature Review of the Challenges and Opportunities of the Transition from Industry 4.0 to Society 5.0. Energies 2022, 15, 6276. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Skobelev, P.O.; Borovik, S.Y. On the way from Industry 4.0 to Industry 5.0: From digital manufacturing to digital society. Ind. 4.0 2017, 2, 307–311. [Google Scholar]

- Linnenluecke, M.K.; Marrone, M.; Singh, A.K. Conducting systematic literature reviews and bibliometric analyses. Aust. J. Manag. 2019, 45, 175–194. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Bmj 2021, 372, 71. [Google Scholar] [CrossRef]

- Haddaway, N.R.; Page, M.J.; Pritchard, C.C.; McGuinness, L.A. PRISMA 2020: An R package and Shiny app for producing PRISMA 2020-compliant flow diagrams, with interactivity for optimised digital transparency and Open Synthesis. Campbell Syst. Rev. 2022, 18, e1230. [Google Scholar] [CrossRef]

- Rosário, A.T.; Fernandes, F.; Raimundo, R.G.; Cruz, R.N. Determinants of Nascent Entrepreneurship Development. In Handbook of Research on Nascent Entrepreneurship and Creating New Ventures; Carrizo Moreira, A., Dantas, J., Eds.; IGI Global: Hershey, PA, USA, 2021; pp. 172–193. [Google Scholar] [CrossRef]

- Rosário, A.T. Generative AI and Generative Pre-Trained Transformer Applications: Challenges and Opportunities. In Making Art with Generative AI Tools; Hai-Jew, S., Ed.; IGI Global Scientific Publishing: Hershey, PA, USA, 2024; pp. 45–71. [Google Scholar] [CrossRef]

- Xiao, Q.; Wang, B.; Li, Z.; Zhang, Z.; Xie, K.; Zhou, J.; Lin, K.; Geng, X.; Li, X.; Chen, J. The assembly process and co-occurrence network of soil microbial community driven by cadmium in volcanic ecosystem. Resour. Environ. Sustain. 2024, 17, 100164. [Google Scholar] [CrossRef]

- De Souza, R.O.; Ferenhof, H.A.; Forcellini, F.A. Industry 4.0 and Industry 5.0 from the Lean perspective. Int. J. Manag. Knowl. Learn 2022, 11, 145–155. [Google Scholar] [CrossRef]

- Boursali, A.E.; Benderbal, H.H.; Souier, M. Integrating AI with Lean Manufacturing in the Context of Industry 4.0/5.0: Current Trends and Applications. In IFIP Advances in Information and Communication Technology; Springer Nature: Cham, Switzerland, 2024. [Google Scholar]

- Bajic, B.; Rikalovic, A.; Suzic, N.; Piuri, V. Toward a Human-Cyber-Physical System for Real-Time Anomaly Detection. IEEE Syst. J. 2024, 18, 1308–1319. [Google Scholar] [CrossRef]

- Alimam, H.; Mazzuto, G.; Ciarapica, F.E.; Bevilacqua, M. Digital Triplet Paradigm for Brownfield Development towards Industry 5.0: A Case Study of Intelligent Retrofitting for Oil and Gas Boosting Plant in the Industrial Internet of Things (IIoT) Context. In Proceedings of the 2023 IEEE SmartWorld, Ubiquitous Intelligence and Computing, Autonomous and Trusted Vehicles, Scalable Computing and Communications, Digital Twin, Privacy Computing and Data Security, Metaverse, SmartWorld/UIC/ATC/ScalCom/DigitalTwin/PCDS/Metaverse, Portsmouth, UK, 28–31 August 2023. [Google Scholar]

- Reis, J.Z.; Gonçalves, R.F. The role of internet of services (ios) on industry 4.0 through the service oriented architecture (soa). In Proceedings of the Advances in Production Management Systems. Smart Manufacturing for Industry 4.0: IFIP WG 5.7 International Conference, APMS 2018, Seoul, Republic of Korea, 26–30 August 2018; Springer International Publishing: Cham, Switzerland, 2018; Part II, pp. 20–26. [Google Scholar]

- Bac, T.P.; Ha, D.T.; Tran, K.D.; Tran, K.P. Explainable Articial Intelligence for Cybersecurity in Smart Manufacturing. In Springer Series in Reliability Engineering; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2023; Volume Part F4, pp. 199–223. [Google Scholar] [CrossRef]

- Bousdekis, A.; Mentzas, G.; Apostolou, D.; Wellsandt, S. Evaluation of AI-Based Digital Assistants in Smart Manufacturing. In IFIP Advances in Information and Communication Technology; Springer Nature: Cham, Switzerland, 2022. [Google Scholar]

- Leirmo, T.L. Digital Twins for Industry 5.0: Unlocking the Human Potential. Procedia CIRP 2024, 130, 761–766. [Google Scholar] [CrossRef]

- Boyes, H.; Hallaq, B.; Cunningham, J.; Watson, T. The industrial internet of things (IIoT): An analysis framework. Comput. Ind. 2018, 101, 1–12. [Google Scholar] [CrossRef]

- Jiang, Z.; Xiong, Y.; Wang, B. Human-machine Collaborative Additive Manufacturing for Industry 5.0. J. Mech. Eng. 2024, 60, 238–253. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Tran, K.P. Artificial Intelligence for Smart Manufacturing in Industry 5.0: Methods, Applications, and Challenges. In Springer Series in Reliability Engineering; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2023; Volume Part F4, pp. 5–33. [Google Scholar] [CrossRef]

- Terziyan, V.; Vitko, O. Context-Aware Machine Learning for Smart Manufacturing. Procedia Comput. Sci. 2025, 253, 25–36. [Google Scholar] [CrossRef]

- Huang, L.; Jia, Y. Innovation and development of cultural and creative industries based on big data for industry 5.0. Sci. Program. 2022, 2022, 2490033. [Google Scholar] [CrossRef]

- Akundi, A.; Euresti, D.; Luna, S.; Ankobiah, W.; Lopes, A.; Edinbarough, I. State of Industry 5.0—Analysis and Identification of Current Research Trends. Appl. Syst. Innov. 2022, 5, 27. [Google Scholar] [CrossRef]

- Özdemir, V.; Hekim, N. Birth of industry 5.0: Making sense of big data with artificial intelligence, “the internet of things” and next-generation technology policy. Omics A J. Integr. Biol. 2018, 22, 65–76. [Google Scholar] [CrossRef]

- Abaza, B.F.; Gheorghita, V. Artificial neural network framework for hybrid control and monitoring in turning operations. Appl. Sci. 2025, 15, 3499. [Google Scholar] [CrossRef]

- Bécue, A.; Gama, J.; Brito, P.Q. AI’s effect on innovation capacity in the context of industry 5.0: A scoping review. Artif. Intell. Rev. 2024, 57, 215. [Google Scholar] [CrossRef]

- Grünbichler, R.; Salimbeni, S. Artificial Intelligence in Small and Medium-Sized Enterprises: Requirements and Barriers. In International Symposium on Industrial Engineering and Automation; Lecture Notes in Networks and Systems; Springer Nature: Cham, Switzerland, 2024. [Google Scholar]

- Huang, S.; Chen, J.; Xu, Z.; Yan, Y.; Wang, G. Human-robot Autonomous Collaboration Method of Smart Manufacturing Systems Based on Large Language Model and Machine Vision. J. Mech. Eng. 2025, 61, 130–141. [Google Scholar] [CrossRef]

- Dhanda, M.; Rogers, B.A.; Hall, S.; Dekoninck, E.; Dhokia, V. Reviewing human-robot collaboration in manufacturing: Opportunities and challenges in the context of industry 5.0. Robot. Comput.-Integr. Manuf. 2025, 93, 102937. [Google Scholar] [CrossRef]

- Demir, K.A.; Döven, G.; Sezen, B. Industry 5.0 and Human-Robot Co-working. Procedia Comput. Sci. 2019, 158, 688–695. [Google Scholar] [CrossRef]

- Zizic, M.C.; Mladineo, M.; Gjeldum, N.; Celent, L. From industry 4.0 towards industry 5.0: A review and analysis of paradigm shift for the people, organization and technology. Energies 2022, 15, 5221. [Google Scholar] [CrossRef]

- Iqbal, M.; Lee, C.K.M.; Ren, J.Z. Industry 5.0: From Manufacturing Industry to Sustainable Society. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, Kuala Lumpur, Malaysia, 7–10 December 2022. [Google Scholar]

- Oladeinde, A.H.; Ojo, O.O. Industry 5.0 and Production Planning and Control in Manufacturing Industries. In Proceedings of the International Conference on Science, Engineering and Business for Driving Sustainable Development Goals, SEB4SDG, Omu-Aran, Nigeria, 2–4 April 2024. [Google Scholar]

- Ruiz-de-la-Torre, A.; Rio-Belver, R.M.; Guevara-Ramirez, W.; Merlo, C. Industry 5.0 and Human-Centered Approach. Bibliometric Review. In Lecture Notes on Data Engineering and Communications Technologies; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2023; Volume 160, pp. 402–408. [Google Scholar] [CrossRef]

- Kihel, A.E.; Embarki, S. Harmonizing Human-Centric Collaborative Hybrid Intelligence: A Deep Dive into the Transition from Industry 4.0 to Industry 5.0—A Case Study Experiment. In International Conference on Electronic Engineering and Renewable Energy Systems; Lecture Notes in Electrical Engineering; Springer Nature: Singapore, 2025. [Google Scholar]

- Bechinie, C.; Zafari, S.; Kroeninger, L.; Puthenkalam, J.; Tscheligi, M. Toward human-centered intelligent assistance system in manufacturing: Challenges and potentials for operator 5.0. Procedia Comput. Sci. 2024, 232, 1584–1596. [Google Scholar] [CrossRef]

- Leberruyer, N.; Ahlskog, M.; Bruch, J. Addressing challenges when adopting AI-driven Zero Defect Manufacturing: Insights from industry. Procedia CIRP 2024, 130, 112–119. [Google Scholar] [CrossRef]

- Re Cecconi, F.; Khodabakhshian, A.; Rampini, L. Industry 5.0 in Construction: Towards a More Human-Centric and Ethical AI. In Building Tomorrow: Unleashing the Potential of Artificial Intelligence in Construction; Springer Nature: Cham, Switzerland, 2025; pp. 101–122. [Google Scholar]

- Chen, S.C.; Chen, H.M.; Chen, H.K.; Li, C.L. Multi-Objective Optimization in Industry 5.0: Human-Centric AI Integration for Sustainable and Intelligent Manufacturing. Processes 2024, 12, 2723. [Google Scholar] [CrossRef]

- Hasani, N.; Hosseini, A.; Ashjazadeh, Y.; Diederichs, V.; Ghotb, S.; Riggio, M.; Hansen, E.; Nasir, V. Outlook on human-centred design in industry 5.0: Towards mass customisation, personalisation, co-creation, and co-production. Int. J. Sustain. Eng. 2025, 18, 2486343. [Google Scholar] [CrossRef]

- Santos, A.D.M.; Sant’Anna, Â.M.O. Industry 4.0 technologies for sustainability within small and medium enterprises: A systematic literature review and future directions. J. Clean. Prod. 2024, 467, 143023. [Google Scholar] [CrossRef]

- Cremer, F.; Sheehan, B.; Fortmann, M.; Kia, A.N.; Mullins, M.; Murphy, F.; Materne, S. Cyber risk and cybersecurity: A systematic review of data availability. Geneva Pap. Risk Insur. Issues Pract. 2022, 47, 698–736. [Google Scholar] [CrossRef]

- Shkarupylo, V.; Alsayaydeh, J.A.J.; Yusof, M.F.B.; Oliinyk, A.; Artemchuk, V.; Herawan, S.G. Exploring the Potential Network Vulnerabilities in the Smart Manufacturing Process of Industry 5.0 via the Use of Machine Learning Methods. IEEE Access 2024, 12, 152262–152276. [Google Scholar] [CrossRef]

- Vilko, J.; Hallikas, J. Impact of COVID-19 on logistics sector companies. Int. J. Ind. Eng. Oper. Manag. 2024, 6, 25–42. [Google Scholar] [CrossRef]

- Berti, N.; Finco, S.; Guidolin, M.; Battini, D. Towards Human Digital Twins to enhance workers’ safety and production system resilience. IFAC-PapersOnLine 2023, 56, 11062–11067. [Google Scholar] [CrossRef]

- Agote-Garrido, A.; Martín-Gómez, A.M.; Lama-Ruiz, J.R. Resilience as a Driver of Industrial Manufacturing Systems; Advances in Transdisciplinary Engineering; IOS Press: Amsterdam, The Netherlands, 2024. [Google Scholar] [CrossRef]

- Dehbozorgi, M.H.; Rossi, M.; Terzi, S.; Carminati, L.; Sala, R.; Magni, F.; Pirola, F.; Pozzi, R.; Strozzi, F.; Rossi, T. AI Education for Tomorrow’s Workforce: Leveraging Learning Factories for AI Education and Workforce Preparedness. In Proceedings of the 8th IEEE International Forum on Research and Technologies for Society and Industry Innovation, RTSI, Lecco, Italy, 18–20 September 2024. [Google Scholar]

- Rožanec, J.M.; Montini, E.; Cutrona, V.; Papamartzivanos, D.; Klemencic, T.; Fortuna, B.; Mladenić, D.; Veliou, E.; Giannetsos, T.; Emmanouilidis, C. Human in the AI loop via XAI and active learning for visual inspection. In Artificial Intelligence in Manufacturing: Enabling Intelligent, Flexible and Cost-Effective Production Through AI; Springer Nature: Cham, Switzerland, 2024; pp. 381–406. [Google Scholar] [CrossRef]

- Li, Z.; Ding, Y.; Lei, Y.; Oliveira, F.J.M.S.; Neto, M.J.P.; Kong, M.S.M. Integrating artificial intelligence in industrial design: Evolution, applications, and future prospects. Int. J. Arts Technol. 2024, 15, 139–169. [Google Scholar] [CrossRef]

- Morales Matamoros, O.; Takeo Nava, J.G.; Moreno Escobar, J.J.; Ceballos Chávez, B.A. Artificial Intelligence for Quality Defects in the Automotive Industry: A Systemic Review. Sensors 2025, 25, 1288. [Google Scholar] [CrossRef]

- Rosca, C.M.; Rădulescu, G.; Stancu, A. Artificial Intelligence of Things Infrastructure for Quality Control in Cast Manufacturing Environments Shedding Light on Industry Changes. Appl. Sci. 2025, 15, 2068. [Google Scholar] [CrossRef]

- Boareto, P.A.; Szejka, A.L.; Loures, E.F.R.; Deschamps, F.; Santos, E.A.P. Accelerating Industry 4.0 and 5.0: The Potential of Generative Artificial Intelligence. In International Conference on Innovative Intelligent Industrial Production and Logistics; Communications in Computer and Information Science; Springer Nature: Cham, Switzerland, 2025. [Google Scholar]

- Mikołajewska, E.; Mikołajewski, D.; Mikołajczyk, T.; Paczkowski, T. Generative AI in AI-Based Digital Twins for Fault Diagnosis for Predictive Maintenance in Industry 4.0/5.0. Appl. Sci. 2025, 15, 3166. [Google Scholar] [CrossRef]

- Potthoff, L.; Naussedat, R.; Gunnemann, L. Exploring Generative AI’s Role in Manual Assembly: Application Potentials and Use Concepts. IFAC-PapersOnLine 2024, 130, 194–199. [Google Scholar] [CrossRef]

- Das, A.; Rad, P. Opportunities and challenges in explainable artificial intelligence (xai): A survey. arXiv 2020, arXiv:2006.11371. https://arxiv.org/pdf/2006.11371. [Google Scholar]

- Zhang, H.; Li, Y.; Zhang, S.; Song, L.; Tao, F. Artificial Intelligence-Enhanced Digital Twin Systems Engineering Towards the Industrial Metaverse in the Era of Industry 5.0. Chin. J. Mech. Eng. (Engl. Ed.) 2025, 38, 40. [Google Scholar] [CrossRef]

- Piron, M.; Bovo, E.; Lucchetta, G.; Manzardo, A. Soft-sensors to drive manufacturing toward clean production: LCA based on Digital Twin. J. Clean. Prod. 2025, 498, 145192. [Google Scholar] [CrossRef]

- Terziyan, V.; Tiihonen, T. Digital Cloning as a Self-Adaptive Multicriteria Optimization Process. Procedia Comput. Sci. 2025, 253, 37–48. [Google Scholar] [CrossRef]

- Zhang, J. The application of artificial intelligence technology in human-centered manufacturing in Industry 5.0. Scalable Comput. 2025, 26, 1242–1256. [Google Scholar] [CrossRef]

- Kalem, G.; Kosu, S.; Basaran, M. 5G/6G Technology Capabilities Designed for Secure Edge Network: Smart City Use Cases of Turkcell. In Proceedings of the 2024 6th International Conference on Blockchain Computing and Applications, BCCA, Dubai, United Arab Emirates, 26–29 November 2024. [Google Scholar]

- Turner, C.; Oyekan, J.; Garn, W.; Duggan, C.; Abdou, K. Industry 5.0 and the circular economy: Utilizing LCA with intelligent products. Sustainability 2022, 14, 14847. [Google Scholar] [CrossRef]

- Vacchi, M.; Siligardi, C.; Settembre-Blundo, D. Driving manufacturing companies toward industry 5.0: A strategic framework for process technological sustainability assessment (P-TSA). Sustainability 2024, 16, 695. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).