Modeling and Key Parameter Interaction Analysis for Ship Central Cooling Systems

Abstract

1. Introduction

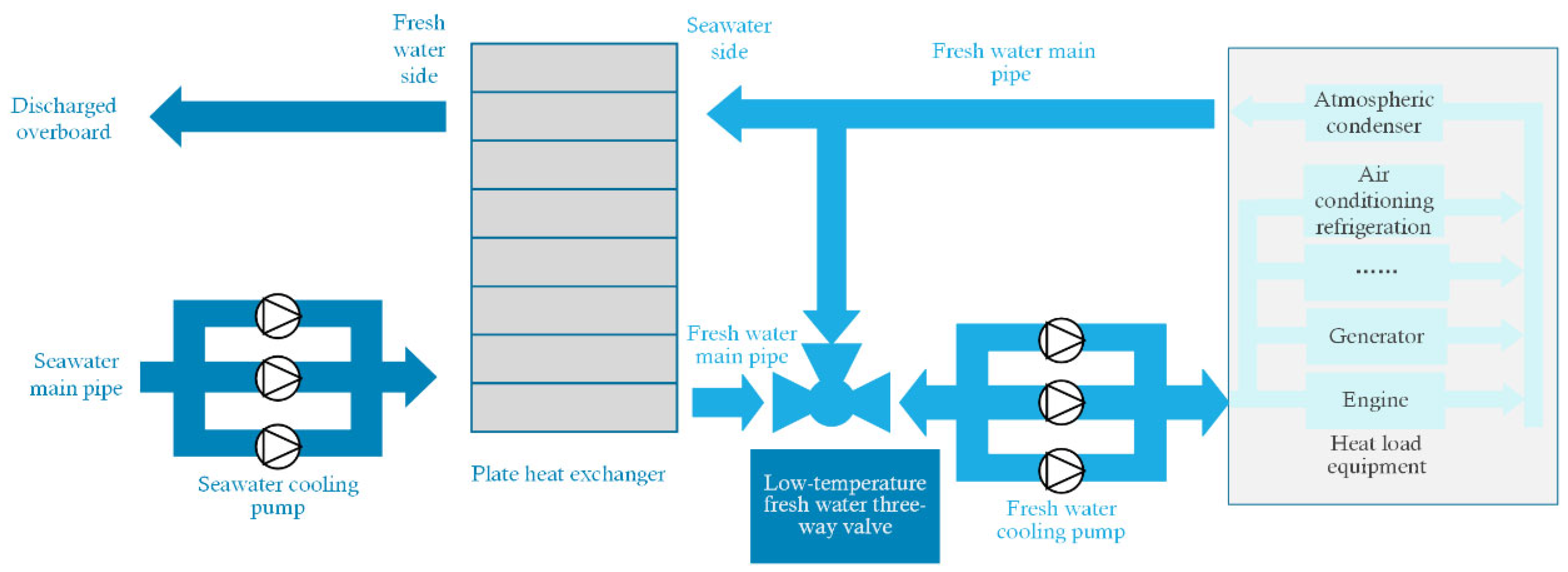

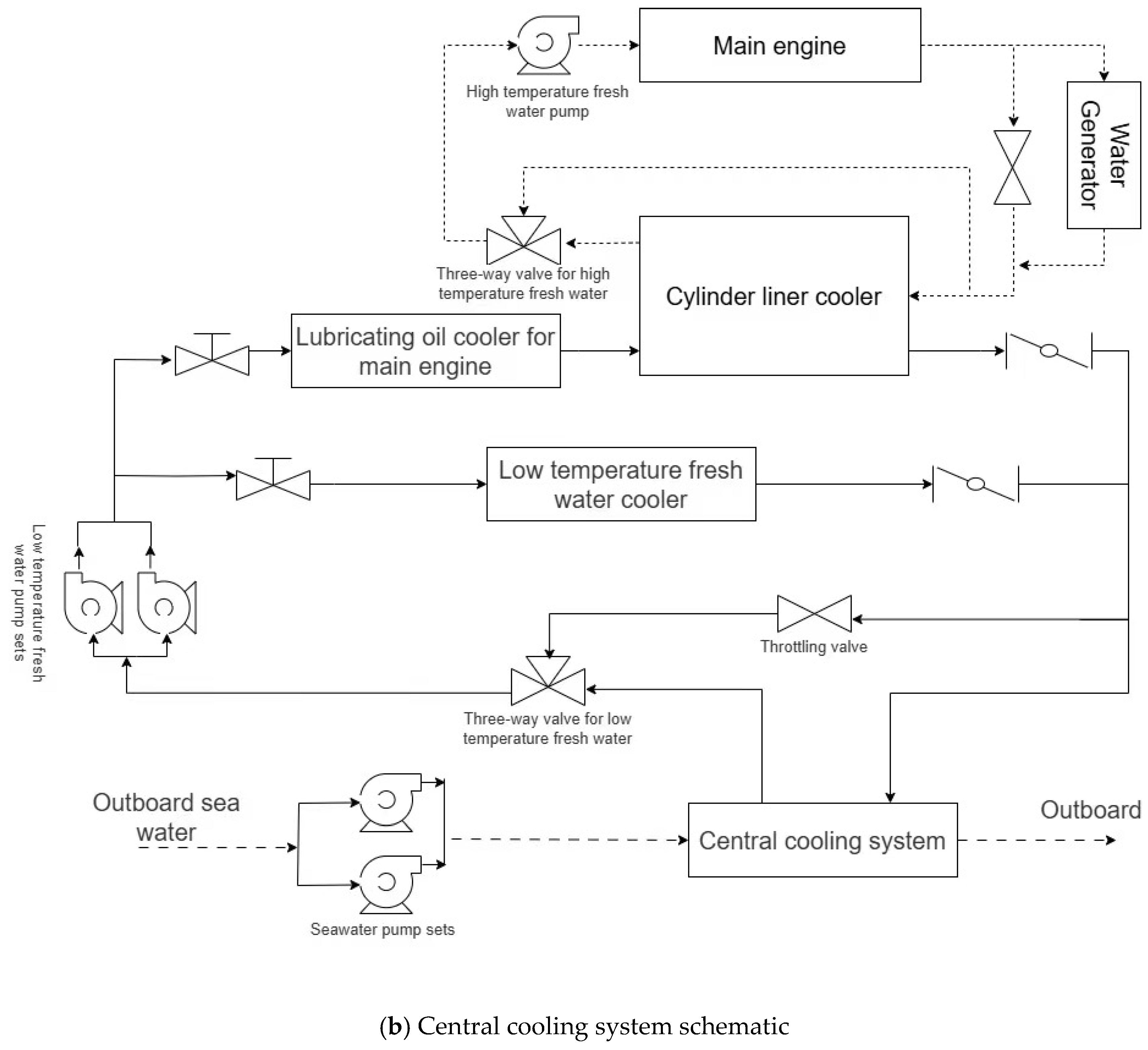

2. Principle of Operation of the Ship Central Cooling System

3. Calculation Model

3.1. Mathematical Model

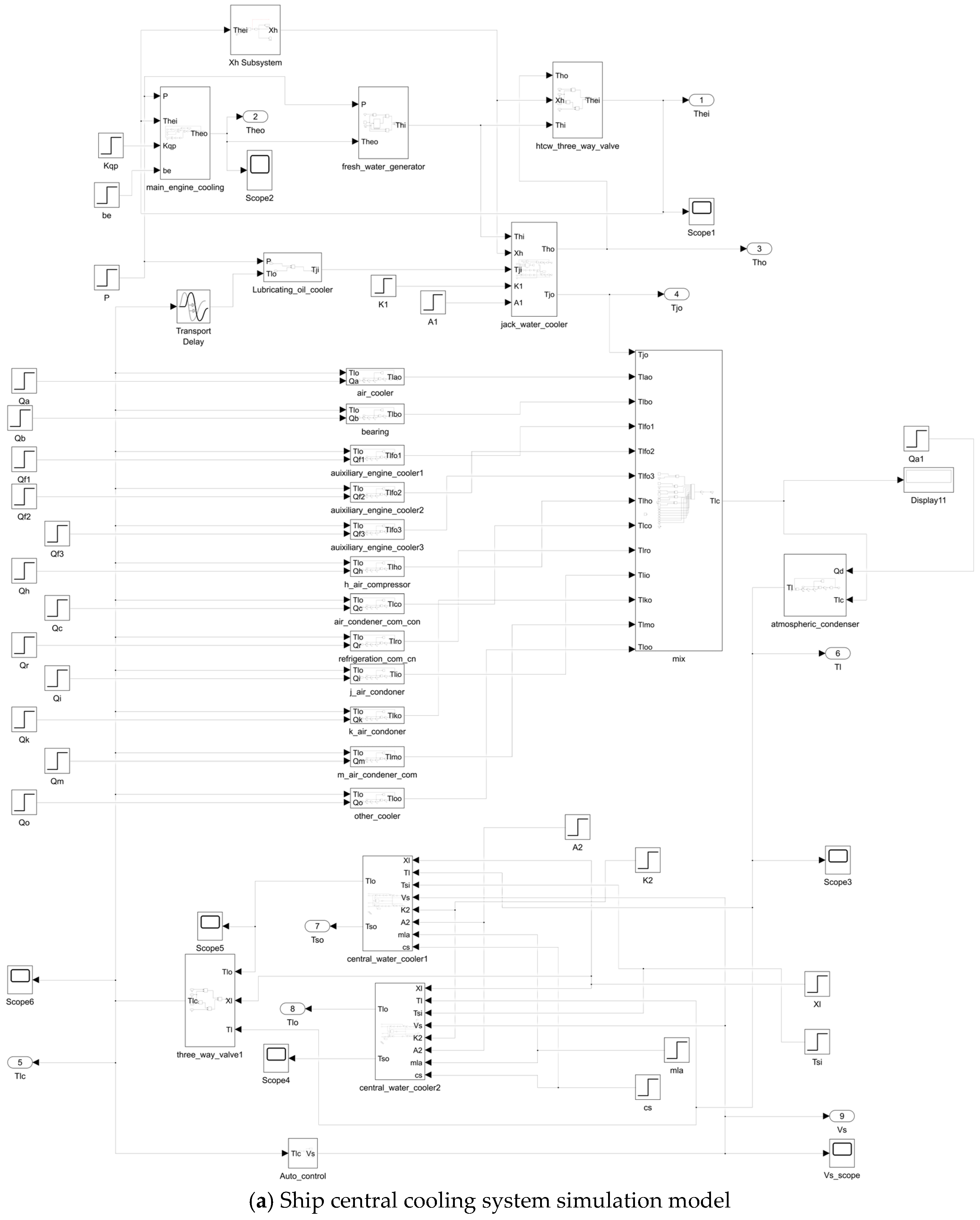

3.2. Establishment of the Simulation Model

3.3. Simulation Model Validation

4. Development of the Response Surface Model

4.1. Selection of Design Variables

4.2. Principle and Modeling of Response Surface Methodology

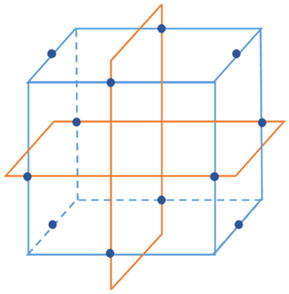

4.3. Box–Behnken Experimental Design

4.4. Establishment of the Response Prediction Model

5. Results and Analysis

5.1. Analysis of Variance for the Model

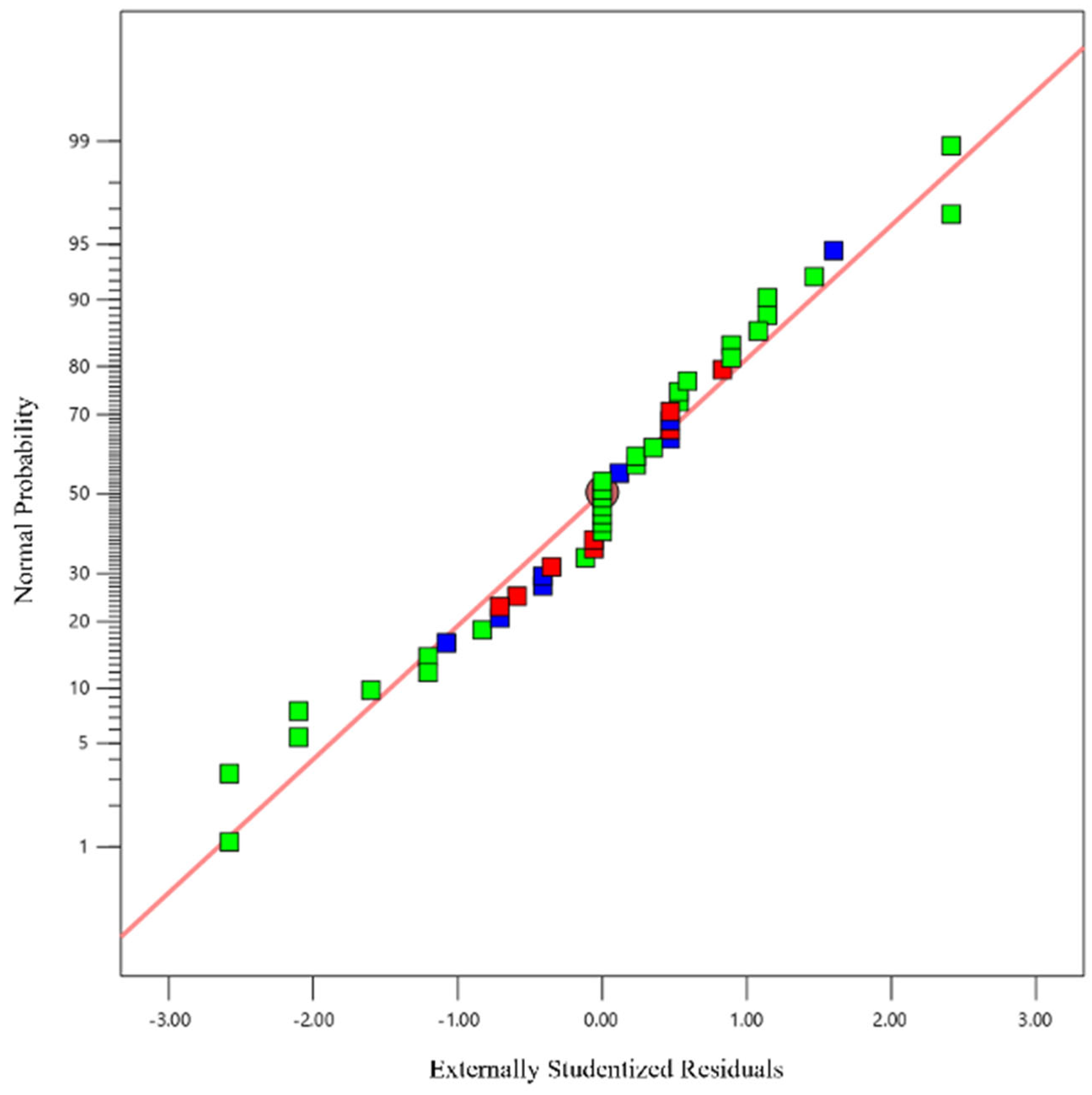

5.2. Model Evaluation

5.3. Prediction Model Validation

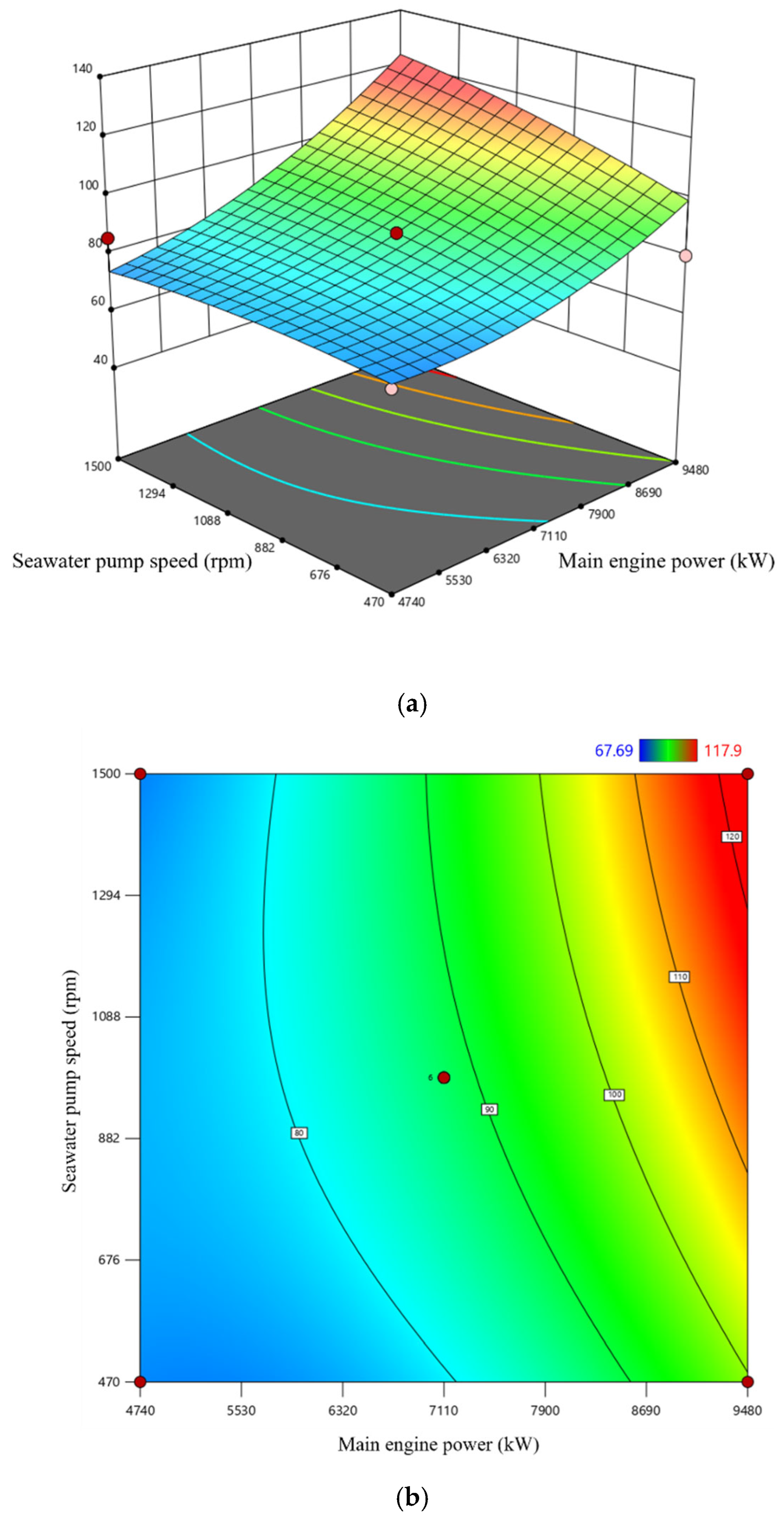

5.4. Analysis of Key Parameter Sensitivity and Interaction

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jimenez, V.J.; Kim, H.; Munim, Z.H. A review of ship energy efficiency research and directions towards emission reduction in the maritime industry. J. Clean. Prod. 2022, 366, 132888. [Google Scholar] [CrossRef]

- Wang, K.; Wang, J.; Huang, L.; Yuan, Y.; Wu, G.; Xing, H. A comprehensive review on the prediction of ship energy consumption and pollution gas emissions. Ocean Eng. 2022, 266, 112826. [Google Scholar] [CrossRef]

- Fan, A.; Yan, J.; Xiong, Y.; Shu, Y.; Fan, X.; Wang, Y.; He, Y.; Chen, J. Characteristics of real-world ship energy consumption and emissions based on onboard testing. Mar. Pollut. Bull. 2023, 194, 115411. [Google Scholar] [CrossRef] [PubMed]

- Jeon, T.-Y.; Jung, B.-G. A Study of PI Controller Tuning Methods Using the Internal Model Control Guide for a Ship Central Cooling System as a Multi-Input, Single-Output System. J. Mar. Sci. Eng. 2023, 11, 2025. [Google Scholar] [CrossRef]

- Kocak, G.; Durmusoglu, Y. Energy efficiency analysis of a ship’s central cooling system using variable speed pump. J. Mar. Eng. Technol. 2018, 17, 43–51. [Google Scholar] [CrossRef]

- Jeon, T.Y.; Lee, Y.C. Energy saving in ship central cooling systems: IMC-Tuned PID with feedforward control. J. Mar. Sci. Eng. 2025, 13, 510. [Google Scholar] [CrossRef]

- Su, C.L.; Chung, W.L.; Yu, K.T. An energy-savings evaluation method for variable-frequency-drive applications on ship central cooling systems. IEEE Trans. Ind. Appl. 2014, 50, 1286–1294. [Google Scholar] [CrossRef]

- Jeon, T.-Y.; Lee, C.-M.; Hur, J.-J. A study on the control solution of ship’s central fresh water-cooling system for efficient energy control based on merchant training ship. J. Mar. Sci. Eng. 2022, 10, 679. [Google Scholar] [CrossRef]

- Pariotis, E.; Zannis, T.; Katsanis, J.S. An integrated approach for the assessment of central cooling retrofit using variable speed drive pump in marine applications. J. Mar. Sci. Eng. 2019, 7, 253. [Google Scholar] [CrossRef]

- Yimchoy, S.; Supatti, U. An energy-savings evaluation method for variable-frequency-drive applications on water pump systems. In Proceedings of the 2021 24th International Conference on Electrical Machines and Systems (ICEMS), Gyeongju, Republic of Korea, 31 October–3 November 2021; pp. 603–608. [Google Scholar] [CrossRef]

- Lee, C.M.; Jeon, T.-Y.; Jung, B.-G.; Lee, Y.-C. Design of energy saving controllers for central cooling water systems. J. Mar. Sci. Eng. 2021, 9, 513. [Google Scholar] [CrossRef]

- Dere, C.; Deniz, C. Load optimization of central cooling system pumps of a container ship for the slow steaming conditions to enhance the energy efficiency. J. Clean. Prod. 2019, 222, 206–217. [Google Scholar] [CrossRef]

- Theotokatos, G.; Sfakianakis, K.; Vassalos, D. Investigation of ship cooling system operation for improving energy efficiency. J. Mar. Sci. Technol. 2017, 22, 38–50. [Google Scholar] [CrossRef]

- Meyers, W.T. Design, Analysis and Modeling of a Modular Navy Integrated Power and Energy Corridor Cooling System; Massachusetts Institute of Technology: Cambridge, MA, USA, 2024. [Google Scholar]

- Wang, J.; Zhao, F.; Sun, L.; Hou, Y.; Chen, N. Research on the energy savings of ships’ water cooling pump motors based on direct torque control. Processes 2023, 11, 1938. [Google Scholar] [CrossRef]

- Chi, G.; Hu, S.; Yang, Y.; Chen, T. Response surface methodology with prediction uncertainty: A multi-objective optimisation approach. Chem. Eng. Res. Des. 2012, 90, 1235–1244. [Google Scholar] [CrossRef]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef] [PubMed]

- Veza, I.; Spraggon, M.; Fattah, I.R.; Idris, M. Response surface methodology (RSM) for optimizing engine performance and emissions fueled with biofuel: Review of RSM for sustainability energy transition. Results Eng. 2023, 18, 101213. [Google Scholar] [CrossRef]

- Chen, W. Research on Cascade Control Modeling and Simulation for Ship Central Cooling Systems; Shanghai Jiao Tong University: Shanghai, China, 2012. [Google Scholar]

- Mäkelä, M. Experimental design and response surface methodology in energy applications: A tutorial review. Energy Convers. Manag. 2017, 151, 630–640. [Google Scholar] [CrossRef]

- Szpisják-Gulyás, N.; Al-Tayawi, A.N.; Horváth, Z.H.; László, Z.; Kertész, S.; Hodúr, C. Methods for experimental design, central composite design and the Box–Behnken design, to optimise operational parameters: A review. Acta Aliment. 2023, 52, 521–537. [Google Scholar] [CrossRef]

| Parameter Category (Quantity/Unit) | Parameter Name | Design Value |

|---|---|---|

| Seawater Pump Set (2) | Single Seawater Pump Flow Rate | 320 m3/h |

| Single Seawater Pump Head | 25 m | |

| Single Seawater Pump Power | 37 kW | |

| Seawater Pump Speed | 1760 rpm | |

| Low-Temperature Freshwater Pump Set (2) | Single Low-Temperature Freshwater Pump Flow Rate | 180 m3/h |

| Single Low-Temperature Freshwater Pump Head | 25 m | |

| Single Low-Temperature Freshwater Pump Power | 22 kW | |

| Low-Temperature Freshwater Pump Speed | 1760 rpm | |

| High-Temperature Freshwater Pump (1) | High-Temperature Freshwater Pump Flow Rate | 640 m3/h |

| High-Temperature Freshwater Pump Head | 25 m | |

| High-Temperature Freshwater Pump Power | 74 kW | |

| High-Temperature Freshwater Pump Speed | 1760 rpm | |

| Plate Heat Exchanger (2) | Central Cooler Heat Transfer Area | 200 m2 |

| Main Engine (1) | Main Engine Power | 9480 kW |

| Main Engine Cooling Water Flow Rate | 120 m3/h | |

| Auxiliary (2) | Single Auxiliary Machine Power | 660 kW |

| Auxiliary Cooling Water Flow Rate | 120 m3/h | |

| System Heat Load | Total Heat Load of High-Temperature Freshwater Circuit | 1910 kW |

| Total Heat Load of Low-Temperature Freshwater Circuit | 4490 kW | |

| System Design | Seawater Temperature | 32 °C |

| Freshwater Temperature | 36 °C | |

| Main Engine Jacket Water Cooler Inlet Temperature | 80 °C | |

| Main Engine Jacket Water Cooler Outlet Temperature | 65 °C | |

| Low-Temperature Freshwater Three-Way Valve Outlet Temperature | 36 °C |

| Parameter | High-Temperature Freshwater to Main Engine Inlet Temperature | Main Engine Jacket Cooler Inlet Temperature | Low-Temperature Freshwater Three-Way Valve Outlet Temperature |

|---|---|---|---|

| Design Value | 65 °C | 80 °C | 36 °C |

| Simulation Value | 65.8 °C | 78.5 °C | 36.3 °C |

| Relative Error | 1.23% | 1.88% | 0.83% |

| Independent Variable | Symbol | Level | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| Main Engine Power/kW | X1 | 4740 | 7110 | 9480 |

| Seawater Temperature/°C | X2 | 20 | 26 | 32 |

| Seawater Pump Speed/rpm | X3 | 470 | 985 | 1500 |

| Three-way Valve Opening | X4 | 20% | 50% | 80% |

| Low-Temperature Fresh Water Flow Rate/m3/s | X5 | 0.12 | 0.15 | 0.18 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 7647.29 | 20 | 382.36 | 10.94 | <0.0001 |

| X1 | 5581.58 | 1 | 5581.58 | 159.71 | <0.0001 |

| X2 | 326.25 | 1 | 326.25 | 9.34 | 0.0053 |

| X3 | 572.29 | 1 | 572.29 | 16.38 | 0.0004 |

| X4 | 162.31 | 1 | 162.31 | 4.64 | 0.0410 |

| X5 | 27.25 | 1 | 27.25 | 0.7797 | 0.3857 |

| X1 X2 | 57.61 | 1 | 57.61 | 1.65 | 0.2110 |

| X1 X3 | 151.17 | 1 | 151.17 | 4.33 | 0.0480 |

| X1 X4 | 5.22 | 1 | 5.22 | 0.1494 | 0.7024 |

| X1 X5 | 0.6400 | 1 | 0.6400 | 0.0183 | 0.8934 |

| X2 X3 | 4.00 | 1 | 4.00 | 0.1145 | 0.7380 |

| X2 X4 | 5.22 | 1 | 5.22 | 0.1494 | 0.7024 |

| X2 X5 | 9.095 × 10−13 | 1 | 9.095 × 10−13 | 2.602 × 10−14 | 1.0000 |

| X3 X4 | 0.3025 | 1 | 0.3025 | 0.0087 | 0.9266 |

| X3 X5 | 4.45 | 1 | 4.45 | 0.1274 | 0.7241 |

| X4 X5 | 6.81 | 1 | 6.81 | 0.1949 | 0.6626 |

| X12 | 486.20 | 1 | 486.20 | 13.91 | 0.0010 |

| X22 | 8.07 | 1 | 8.07 | 0.2310 | 0.6349 |

| X32 | 52.32 | 1 | 52.32 | 1.50 | 0.2325 |

| X42 | 7.78 | 1 | 7.78 | 0.2225 | 0.6412 |

| X52 | 5.51 | 1 | 5.51 | 0.1576 | 0.6948 |

| Residual | 873.71 | 25 | 34.95 | ||

| Lack of Fit | 306.60 | 20 | 15.33 | 0.1908 | 0.3465 |

| Pure Error | 304.96 | 5 | 60.99 | ||

| Cor Total | 8521.01 | 45 |

| Factor | Result |

|---|---|

| R2 | 0.9688 |

| R2adj | 0.9438 |

| R2pred | 0.8752 |

| X1 (kW) | X2 (°C) | X3 (rpm) | X4 (%) | X5 (m3/s) | Predicted (kW) | Simulation (kW) | Relative Error (%) |

|---|---|---|---|---|---|---|---|

| 4740 | 20 | 470 | 20 | 0.12 | 61.75 | 61.02 | 1.2 |

| 9480 | 32 | 1500 | 80 | 0.18 | 139.27 | 140.52 | 0.9 |

| 7110 | 26 | 985 | 50 | 0.15 | 92.08 | 91.17 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Zhang, P.; Su, P.; Wu, J. Modeling and Key Parameter Interaction Analysis for Ship Central Cooling Systems. Appl. Sci. 2025, 15, 7241. https://doi.org/10.3390/app15137241

Wu X, Zhang P, Su P, Wu J. Modeling and Key Parameter Interaction Analysis for Ship Central Cooling Systems. Applied Sciences. 2025; 15(13):7241. https://doi.org/10.3390/app15137241

Chicago/Turabian StyleWu, Xin, Ping Zhang, Pan Su, and Jiechang Wu. 2025. "Modeling and Key Parameter Interaction Analysis for Ship Central Cooling Systems" Applied Sciences 15, no. 13: 7241. https://doi.org/10.3390/app15137241

APA StyleWu, X., Zhang, P., Su, P., & Wu, J. (2025). Modeling and Key Parameter Interaction Analysis for Ship Central Cooling Systems. Applied Sciences, 15(13), 7241. https://doi.org/10.3390/app15137241