A Review of Coordinated Control Technology for Chassis of Distributed Drive Electric Vehicles

Abstract

1. Introduction

2. Architectures for Coordinated Control of DDEV Chassis

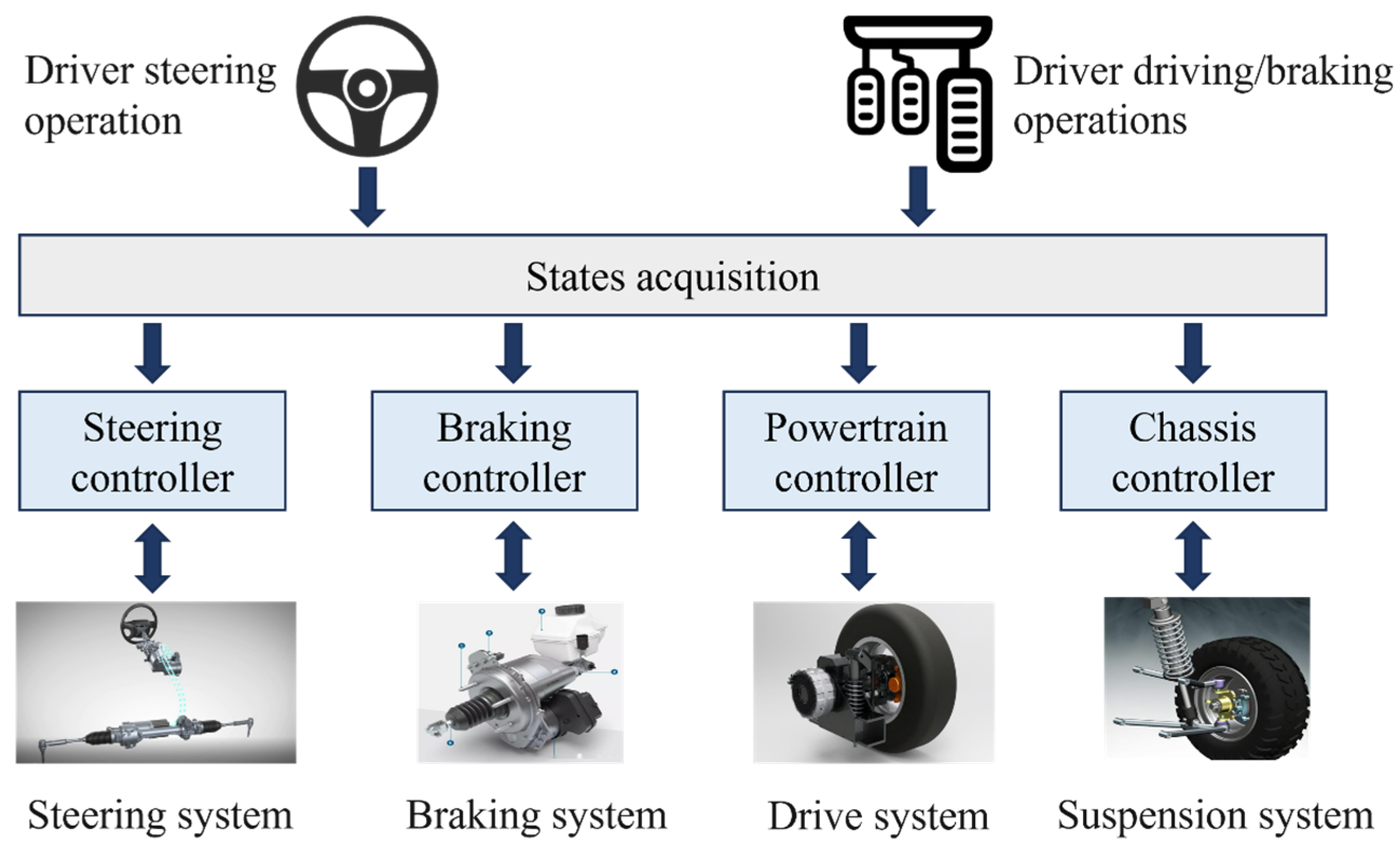

2.1. Decentralized Architecture

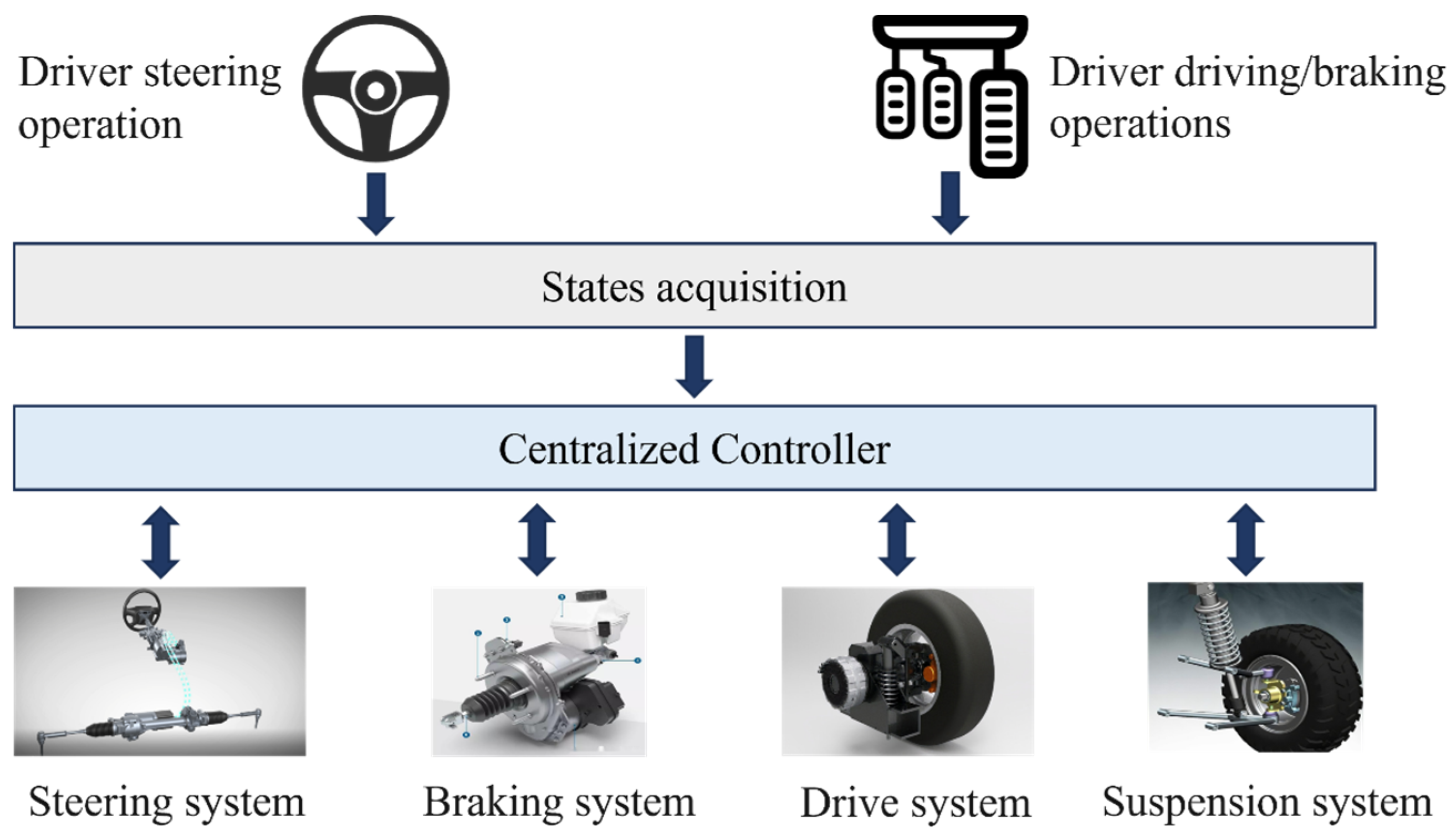

2.2. Centralized Architecture

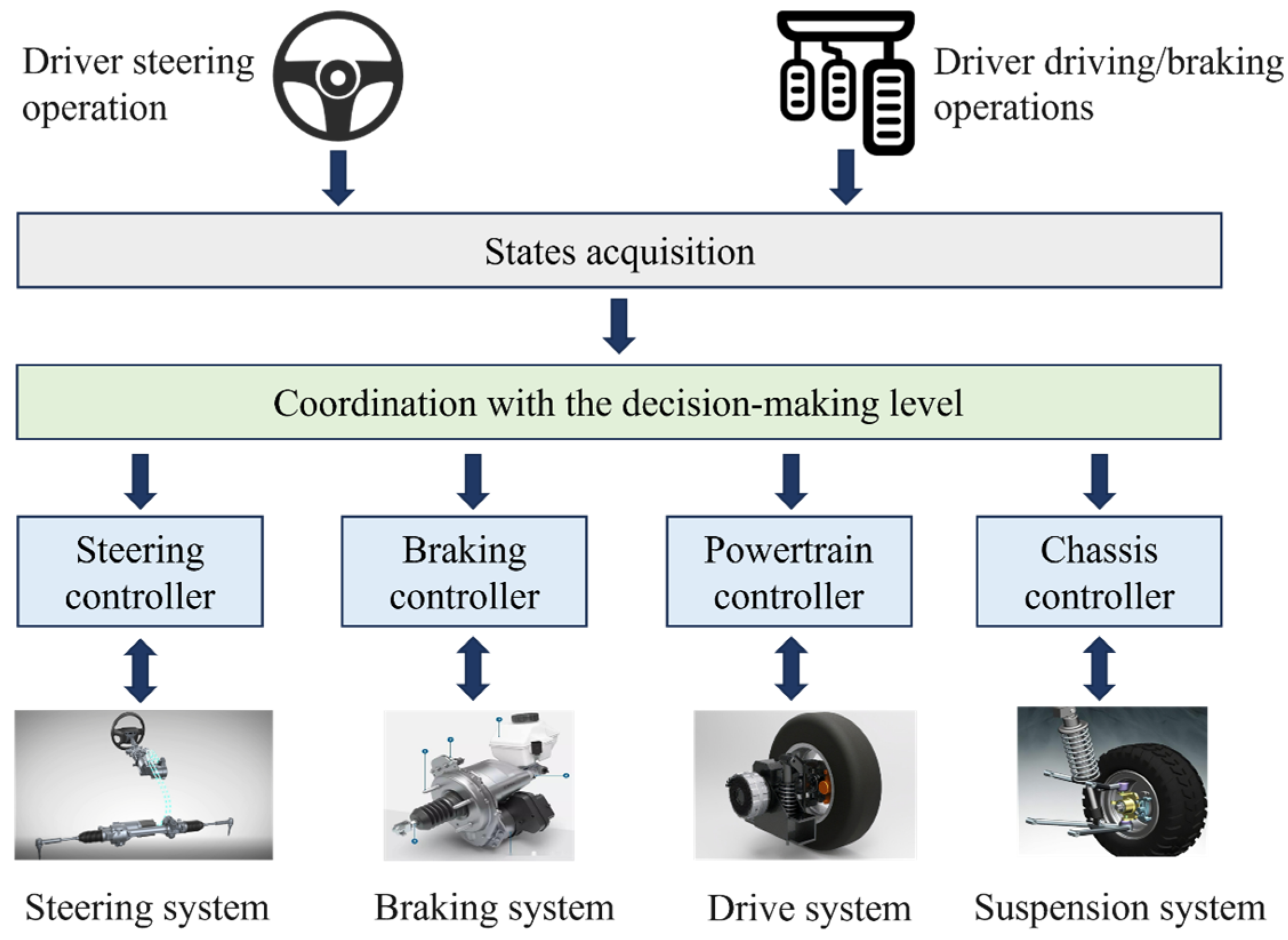

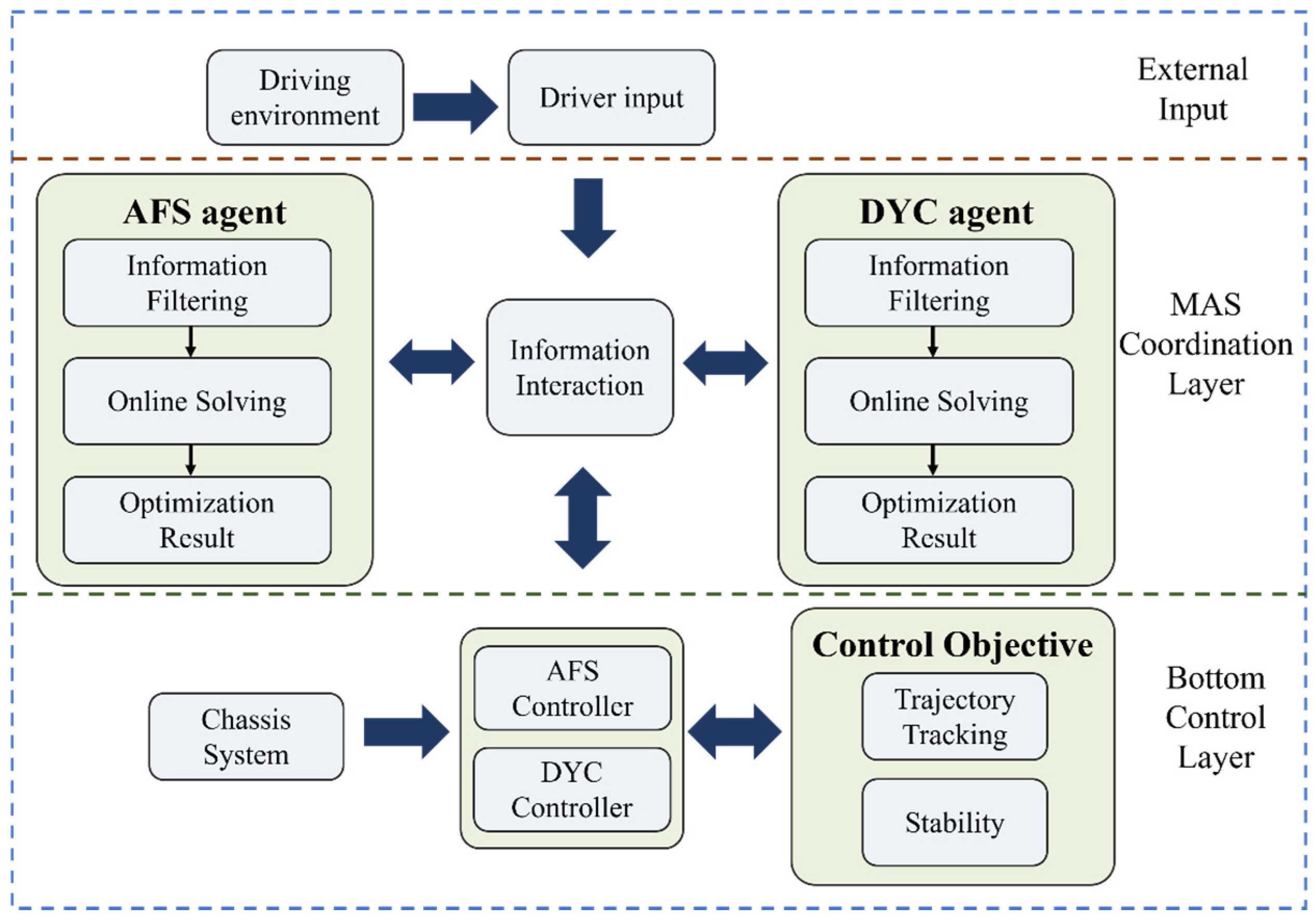

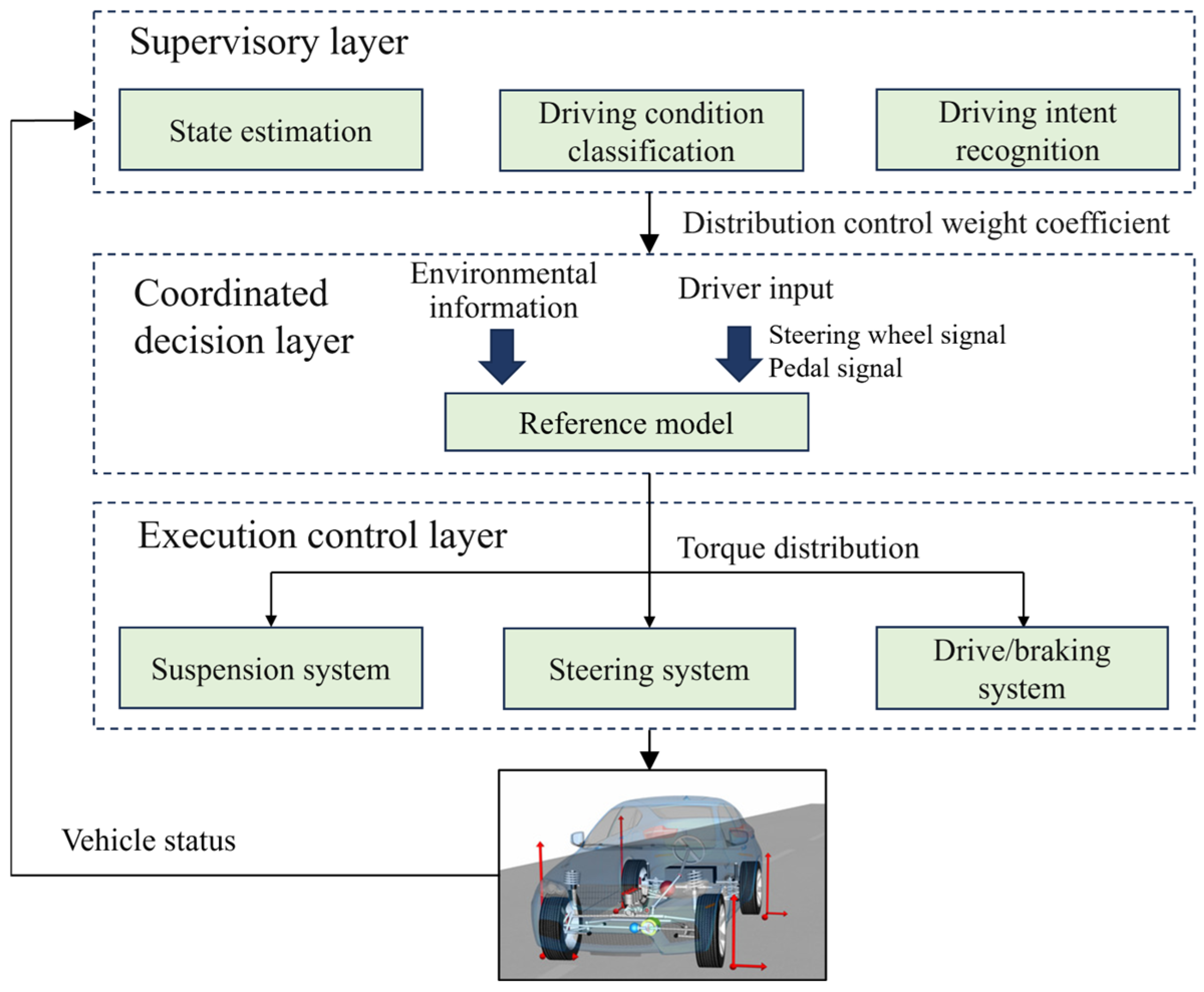

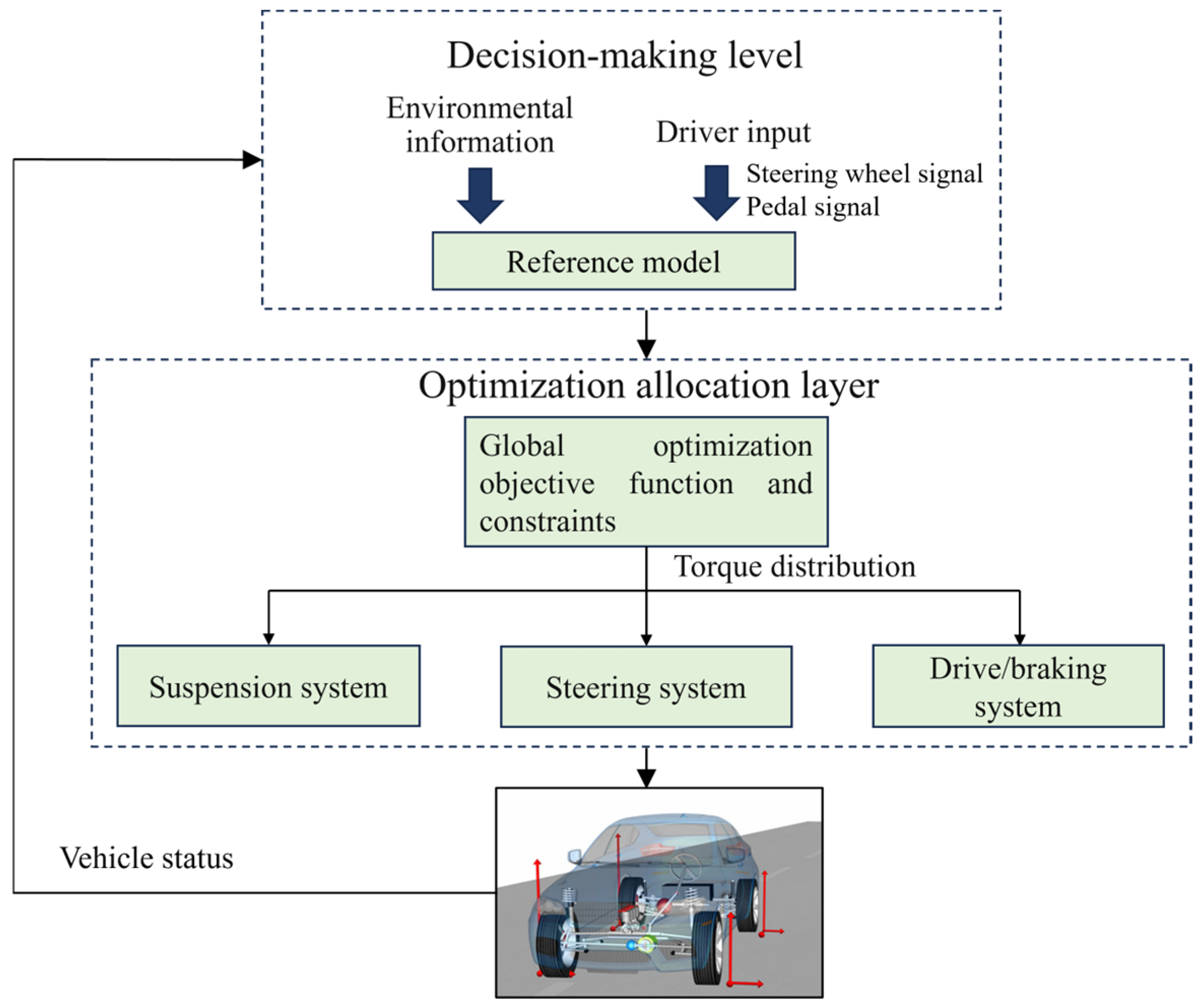

2.3. Hierarchical Architecture

3. Two-Dimensional Coordinated Control Strategies for DDEV Chassis

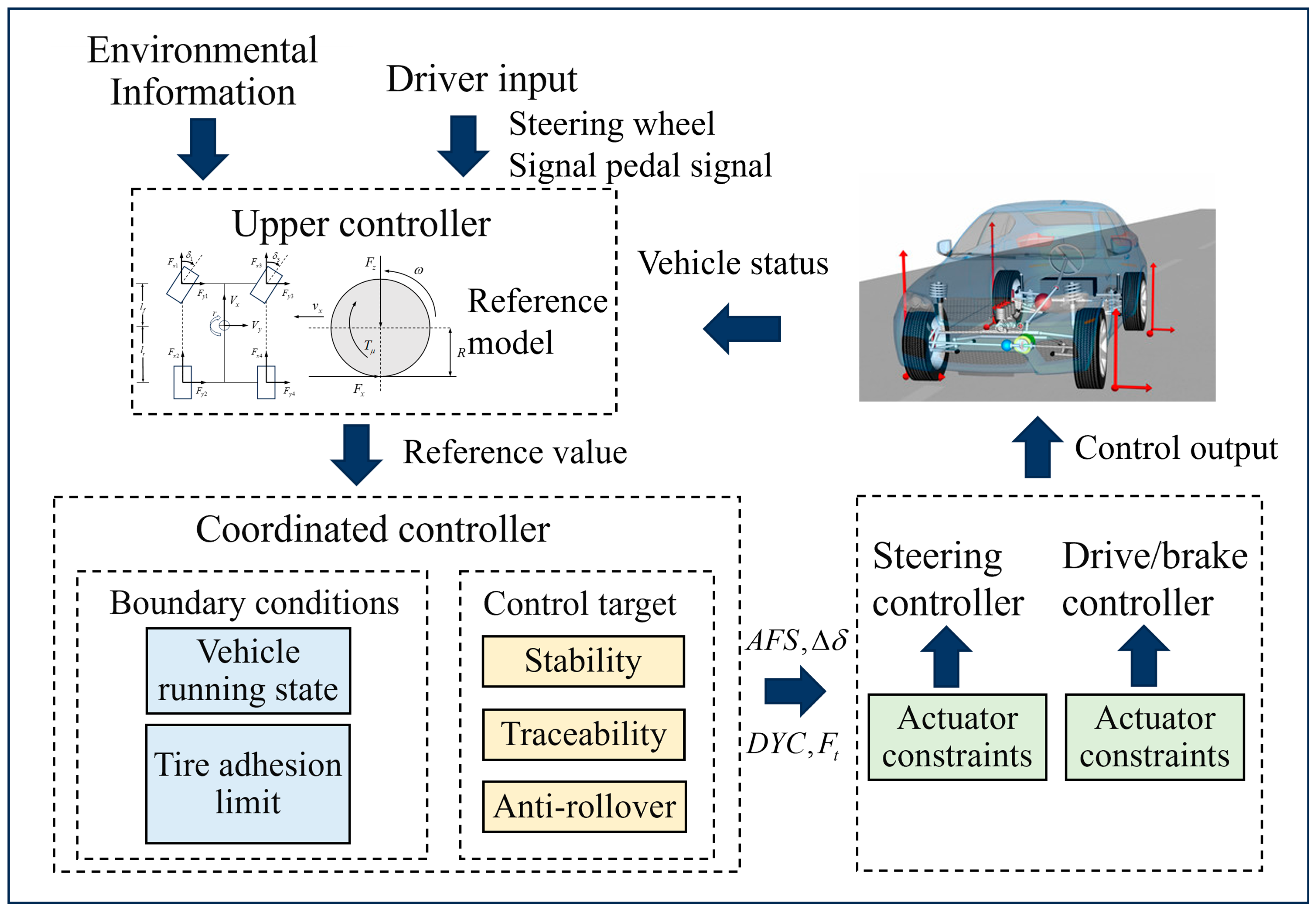

3.1. Lateral and Longitudinal Coordinated Control Strategies

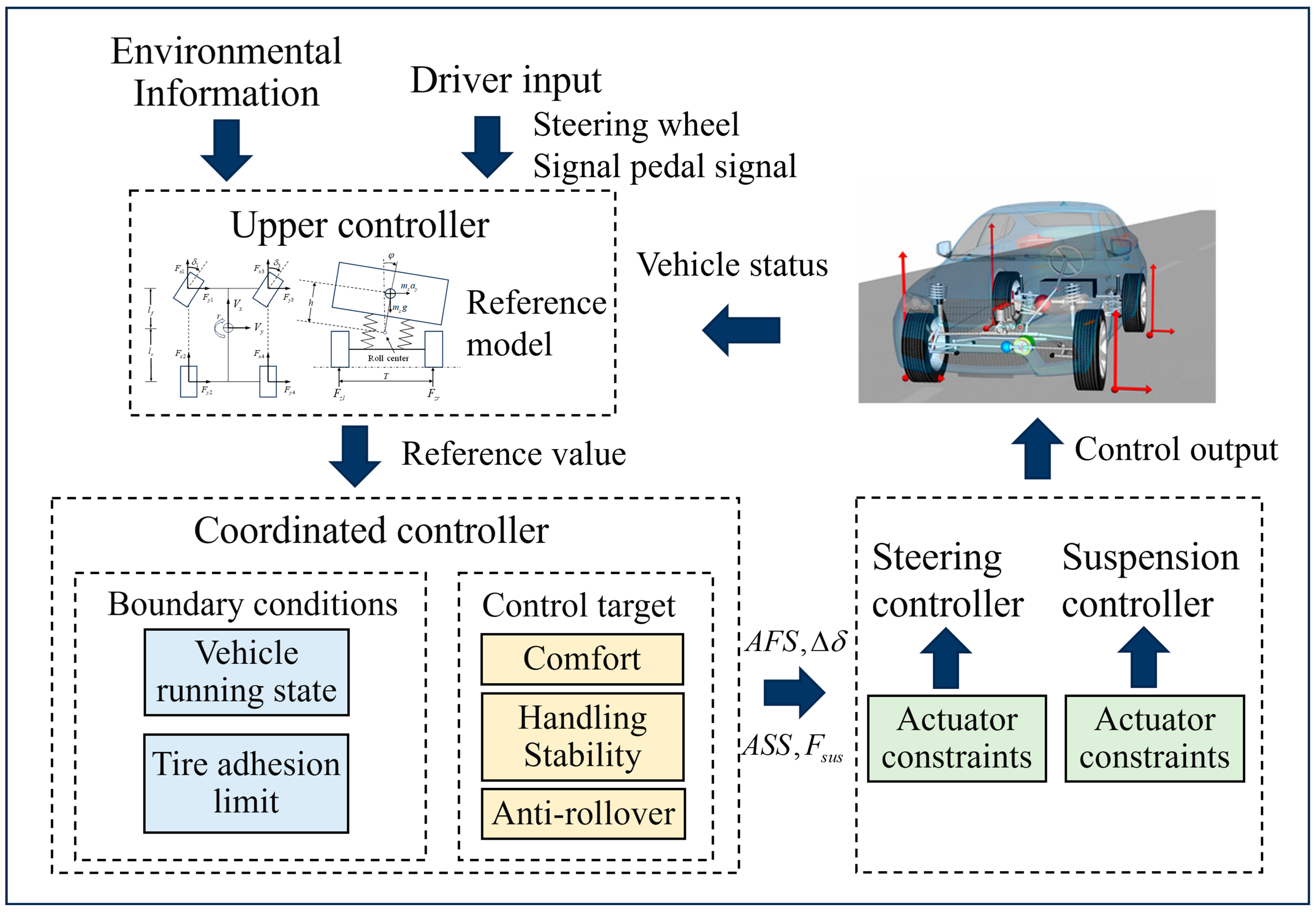

3.2. Lateral and Vertical Coordinated Control Strategies

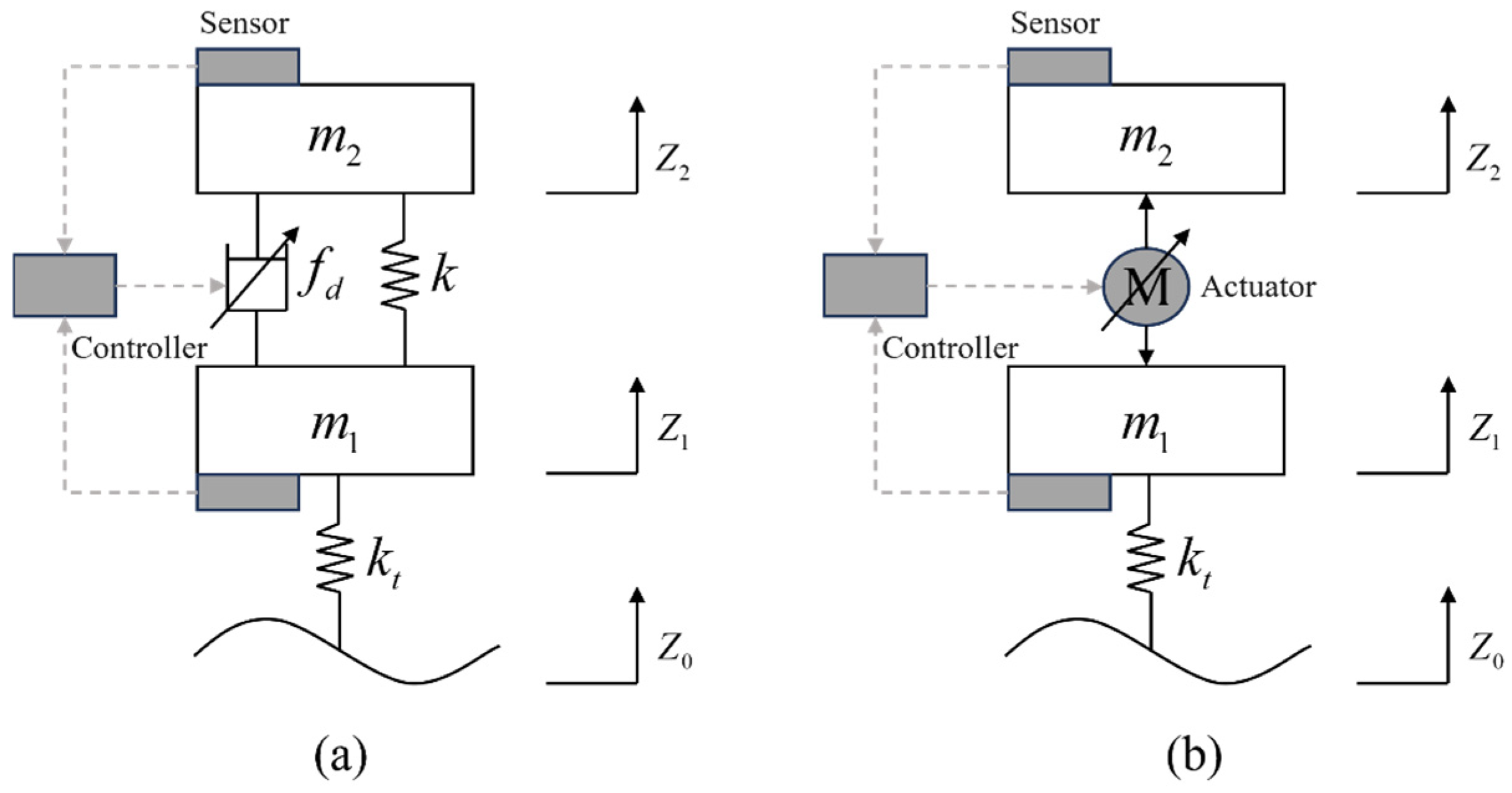

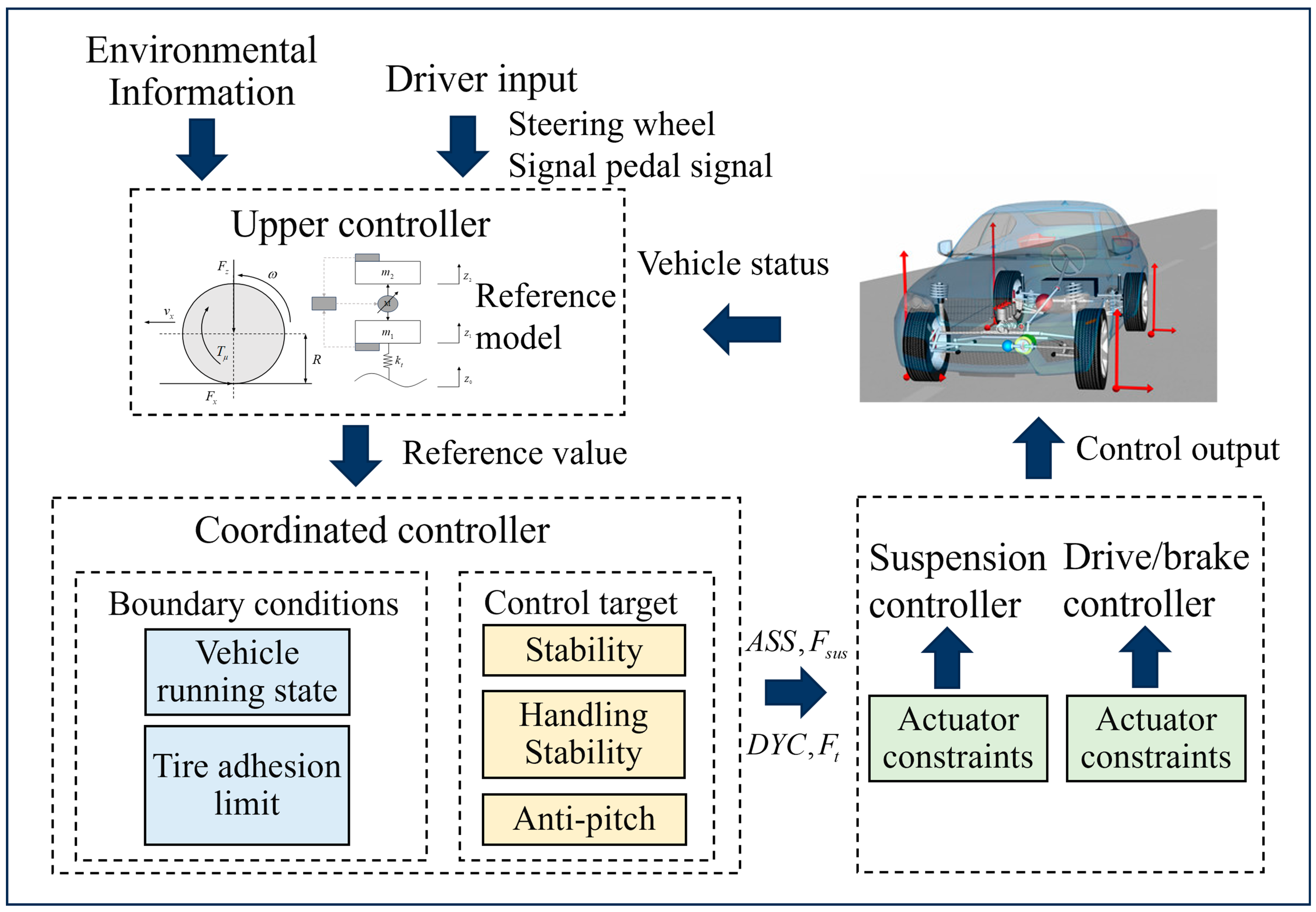

3.3. Longitudinal and Vertical Coordinated Control Strategies

4. Three-Dimensional Coordinated Control Strategies for DDEV Chassis

5. Discussion

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, X.; Chikangaise, P.; Shi, W.; Chen, W.-H.; Yuan, S. Review of Intelligent Sprinkler Irrigation Technologies for Remote Autonomous System. Int. J. Agric. Biol. Eng. 2018, 11, 23–30. [Google Scholar] [CrossRef]

- Li, H.; Geng, W.; Hassan, M.M.; Zuo, M.; Wei, W.; Wu, X.; Ouyang, Q.; Chen, Q. Rapid Detection of Chloramphenicol in Food Using SERS Flexible Sensor Coupled Artificial Intelligent Tools. Food Control 2021, 128, 108186. [Google Scholar] [CrossRef]

- Bo, W.; Xiaoxue, D.; Yana, W.; Hanping, M. Multi-Machine Collaboration Realization Conditions and Precise and Efficient Production Mode of Intelligent Agricultural Machinery. Int. J. Agric. Biol. Eng. 2024, 17, 27–36. [Google Scholar] [CrossRef]

- Li, Y.; Xu, L.; Lv, L.; Shi, Y.; Yu, X. Study on Modeling Method of a Multi-Parameter Control System for Threshing and Cleaning Devices in the Grain Combine Harvester. Agriculture 2022, 12, 1483. [Google Scholar] [CrossRef]

- Zhang, Z.; Lu, Y.; Zhao, Y.; Pan, Q.; Jin, K.; Xu, G.; Hu, Y. TS-YOLO: An All-Day and Lightweight Tea Canopy Shoots Detection Model. Agronomy 2023, 13, 1411. [Google Scholar] [CrossRef]

- Zhai, X.; Li, Z.; Zhang, J.; Shi, J.; Zou, X.; Huang, X.; Zhang, D.; Sun, Y.; Yang, Z.; Holmes, M.; et al. Natural Biomaterial-Based Edible and pH-Sensitive Films Combined with Electrochemical Writing for Intelligent Food Packaging. J. Agric. Food Chem. 2018, 66, 12836–12846. [Google Scholar] [CrossRef]

- Jose, A.; Shrivastava, S. Evolution of Electrical Vehicles, Battery State Estimation, and Future Research Directions: A Critical Review. IEEE Access 2024, 12, 158627–158646. [Google Scholar] [CrossRef]

- Fesli, U.; Ozdemir, M.B. Electric Vehicles: A Comprehensive Review of Technologies, Integration, Adoption, and Optimization. IEEE Access 2024, 12, 140908–140931. [Google Scholar] [CrossRef]

- Hu, Z.; Mehrjardi, R.T.; Ehsani, M. On the Lifetime Emissions of Conventional, Hybrid, Plug-in Hybrid and Electric Vehicles. IEEE Trans. Ind. Applicat. 2024, 60, 3502–3511. [Google Scholar] [CrossRef]

- Yu, Y.; Hao, S.; Guo, S.; Tang, Z.; Chen, S. Motor Torque Distribution Strategy for Different Tillage Modes of Agricultural Electric Tractors. Agriculture 2022, 12, 1373. [Google Scholar] [CrossRef]

- Jiangyi, H.; Fan, W. Design and Testing of a Small Orchard Tractor Driven by a Power Battery. Eng. Agríc. 2023, 43, e20220195. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, S.; Zhao, X.; Zheng, Z. Path Tracking and Handling Stability Coordinated Control of 4WS and DYC for Distributed In-Wheel Motor Drive Electric Vehicle Under Extreme Conditions. IEEE Trans. Veh. Technol. 2024, 73, 18402–18417. [Google Scholar] [CrossRef]

- Feng, Z.; Zhao, S.; Gao, W.; Zhang, Y.; Fei, L. Study on a Novel In-Wheel Motor Driving System Driven by Two Permanent Magnet Synchronous Disc Motors. IEEE Trans. Veh. Technol. 2023, 72, 5922–5933. [Google Scholar] [CrossRef]

- Dong, H.; Xi, J. Model Predictive Longitudinal Motion Control for the Unmanned Ground Vehicle with a Trajectory Tracking Model. IEEE Trans. Veh. Technol. 2022, 71, 1397–1410. [Google Scholar] [CrossRef]

- Azzaghdam, E.T.; Alankus, O.B. Longitudinal Control of Autonomous Vehicles Consisting Power-Train with Non-Linear Characteristics. IEEE Trans. Intell. Veh. 2022, 7, 133–142. [Google Scholar] [CrossRef]

- Alves, J.A.V.; Chinelato, C.I.G.; Angelico, B.A. Vehicle Lateral Stability Regions for Control Applications. IEEE Access 2022, 10, 87787–87802. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, L.; Liu, S.; Wang, J. Event-Triggered Adaptive Fuzzy Approach-Based Lateral Motion Control for Autonomous Vehicles. IEEE Trans. Intell. Veh. 2024, 9, 1260–1269. [Google Scholar] [CrossRef]

- Xu, H.; Liu, J.; Luo, T.; Yao, Y.; Lv, C. Model-Based Design of an Active Suspension for the Improvement of In-Wheel Motor Drive Electric Vehicle. IEEE Access 2024, 12, 45597–45615. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, L.; Liu, Y.; Wang, J.; Yang, C.; Zhang, J. Motion Posture Control of Corner Module Architecture Intelligent Electric Vehicle on Deep-Potholed Roads. IEEE/ASME Trans. Mechatron. 2024, 29, 4480–4491. [Google Scholar] [CrossRef]

- Zhao, H.; Chen, W.; Zhao, J.; Zhang, Y.; Chen, H. Modular Integrated Longitudinal, Lateral, and Vertical Vehicle Stability Control for Distributed Electric Vehicles. IEEE Trans. Veh. Technol. 2019, 68, 1327–1338. [Google Scholar] [CrossRef]

- Wang, Z.; Ding, X.; Zhang, L. Chassis Coordinated Control for Full X-by-Wire Four-Wheel-Independent-Drive Electric Vehicles. IEEE Trans. Veh. Technol. 2023, 72, 4394–4410. [Google Scholar] [CrossRef]

- Skrickij, V.; Kojis, P.; Šabanovič, E.; Shyrokau, B.; Ivanov, V. Review of Integrated Chassis Control Techniques for Automated Ground Vehicles. Sensors 2024, 24, 600. [Google Scholar] [CrossRef] [PubMed]

- Yu, F.; Li, D.-F.; Crolla, D.A. Integrated Vehicle Dynamics Control—State-of-the Art Review. In Proceedings of the 2008 IEEE Vehicle Power and Propulsion Conference, Harbin, China, 3–5 September 2008; IEEE: New York, NY, USA, 2008; pp. 1–6. [Google Scholar]

- Yang, S.; Zhai, C.; Gao, Y.; Dou, H.; Zhao, X.; He, Y.; Wang, X. Planting Uniformity Performance of Motor-Driven Maize Precision Seeding Systems. Int. J. Agric. Biol. Eng. 2022, 15, 101–108. [Google Scholar] [CrossRef]

- Xu, S.; Li, J.; Zhang, X.; Song, J.; Zeng, X. Research on Composite Braking Control Strategy of Four-Wheel-Drive Electric Vehicles with Multiple Motors Based on Braking Energy Recovery Optimization. IEEE Access 2023, 11, 110151–110163. [Google Scholar] [CrossRef]

- Tong, X.; Wang, Y.; Guan, Y.; Tian, S.; Wu, T. Layered Control Strategy of Brake-by-Wire Based on Residual Collision Time. J. Jiangsu Univ. (Nat. Sci. Ed.) 2025, 46, 28–35. [Google Scholar] [CrossRef]

- Fu, X.; Xiao, S.; Xu, C. Parallel Compound Braking Strategy of Vehicle Driven by Wheel Motor. J. Jiangsu Univ. (Nat. Sci. Ed.) 2025, 46, 9–17. [Google Scholar] [CrossRef]

- Tang, Z.; Zhang, H.; Li, H.; Li, Y.; Ding, Z.; Chen, J. Developments of Crawler Steering Gearbox for Combine Harvester Straight Forward and Steering in Situ. Int. J. Agric. Biol. Eng. 2020, 13, 120–126. [Google Scholar] [CrossRef]

- Luo, Y.; Wei, L.; Xu, L.; Zhang, Q.; Liu, J.; Cai, Q.; Zhang, W. Stereo-Vision-Based Multi-Crop Harvesting Edge Detection for Precise Automatic Steering of Combine Harvester. Biosyst. Eng. 2022, 215, 115–128. [Google Scholar] [CrossRef]

- Chen, T.; Xu, L.; Ahn, H.S.; Lu, E.; Liu, Y.; Xu, R. Evaluation of Headland Turning Types of Adjacent Parallel Paths for Combine Harvesters. Biosyst. Eng. 2023, 233, 93–113. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, H.; Zhang, D.; Shen, Y.; Wang, Z. Path Tracking and Anti-Rollover Control of High Gap Four-Wheel Independent Drive Sprayer. J. Jiangsu Univ. (Nat. Sci. Ed.) 2023, 44, 657–664. [Google Scholar] [CrossRef]

- Li, J.; Nie, Z.; Chen, Y.; Ge, D.; Li, M. Development of Boom Posture Adjustment and Control System for Wide Spray Boom. Agriculture 2023, 13, 2162. [Google Scholar] [CrossRef]

- Chen, S.; Zhou, Y.; Tang, Z.; Lu, S. Modal Vibration Response of Rice Combine Harvester Frame under Multi-Source Excitation. Biosyst. Eng. 2020, 194, 177–195. [Google Scholar] [CrossRef]

- Xu, L.; Chai, X.; Gao, Z.; Li, Y.; Wang, Y. Experimental Study on Driver Seat Vibration Characteristics of Crawler-Type Combine Harvester. Int. J. Agric. Biol. Eng. 2019, 12, 90–97. [Google Scholar] [CrossRef]

- Xue, W.; Zhang, C. Variable Universe Fuzzy PID Control for Vehicle Active Suspension Based on Genetic Algorithm. J. Jiangsu Univ. (Nat. Sci. Ed.) 2024, 45, 8–15. [Google Scholar] [CrossRef]

- Vivas-Lopez, C.A.; Tudon-Martinez, J.C.; Hernandez-Alcantara, D.; Morales-Menendez, R. Global Chassis Control System Using Suspension, Steering, and Braking Subsystems. Math. Probl. Eng. 2015, 2015, 263424. [Google Scholar] [CrossRef]

- Zhao, H.; Lu, X.; Chen, H.; Liu, Q.; Gao, B. Coordinated Attitude Control of Longitudinal, Lateral and Vertical Tyre Forces for Electric Vehicles Based on Model Predictive Control. IEEE Trans. Veh. Technol. 2022, 71, 2550–2559. [Google Scholar] [CrossRef]

- Shi, X.; Wang, H.; Chen, L.; Sun, X.; Yang, C.; Cai, Y. Robust Path Tracking Control of Distributed Driving Six-Wheel Steering Commercial Vehicle Based on Coupled Active Disturbance Rejection. IEEE Trans. Veh. Technol. 2023, 72, 13940–13952. [Google Scholar] [CrossRef]

- Mazzilli, V. Integrated Chassis Control: Classification, Analysis and Future Trends. Annu. Rev. Control 2021, 51, 172–205. [Google Scholar] [CrossRef]

- Tang, C.; Khajepour, A. Wheel Modules with Distributed Controllers: A Multi-Agent Approach to Vehicular Control. IEEE Trans. Veh. Technol. 2020, 69, 10879–10888. [Google Scholar] [CrossRef]

- Schilke, N.A.; Fruechte, R.D.; Boustany, N.M.; Karmel, A.M.; Repa, B.S.; Rillings, J.H. Integrated Vehicle Control. In Proceedings of the International Congress on Transportation Electronics, San Francisco, CA, USA, 1–3 May 1989; IEEE: Dearborn, MI, USA, 1988; pp. 97–106. [Google Scholar]

- Guo, J.; Dai, Z.; Liu, M.; Xie, Z.; Jiang, Y.; Yang, H.; Xie, D. Distributed Drive Electric Vehicle Handling Stability Coordination Control Framework Based on Adaptive Model Predictive Control. Sensors 2024, 24, 4811. [Google Scholar] [CrossRef]

- Lee, K.; Seol, J. Development of Integrated Chassis Control of Semi-Active Suspension with Differential Brake for Vehicle Lateral Stability. World Electr. Veh. J. 2025, 16, 91. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, L.; Cai, Y.; Sun, X.; Wang, H. Adaptive Coordinated Control Strategy for Autonomous Vehicles Based on Four-Wheel Steering. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2025, 239, 548–563. [Google Scholar] [CrossRef]

- Gordon, T.; Howell, M.; Brandao, F. Integrated Control Methodologies for Road Vehicles. Veh. Syst. Dyn. 2003, 40, 157–190. [Google Scholar] [CrossRef]

- Chokor, A.; Talj, R.; Doumiati, M.; Hamdan, A.; Charara, A. A Comparison between a Centralised Multilayer LPV/∞ and a Decentralised Multilayer Sliding Mode Control Architectures for Vehicle’s Global Chassis Control. Int. J. Control 2022, 95, 303–318. [Google Scholar] [CrossRef]

- Liang, J.; Lu, Y.; Yin, G.; Fang, Z.; Zhuang, W.; Ren, Y.; Xu, L.; Li, Y. A Distributed Integrated Control Architecture of AFS and DYC Based on MAS for Distributed Drive Electric Vehicles. IEEE Trans. Veh. Technol. 2021, 70, 5565–5577. [Google Scholar] [CrossRef]

- Fan, X.; Chen, M.; Huang, Z.; Yu, X. A Review of Integrated Control Technologies for Four In-Wheel Motor Drive Electric Vehicle Chassis. J Braz. Soc. Mech. Sci. Eng. 2025, 47, 89. [Google Scholar] [CrossRef]

- Li, Z.; Chen, H.; Liu, H.; Wang, P.; Gong, X. Integrated Longitudinal and Lateral Vehicle Stability Control for Extreme Conditions with Safety Dynamic Requirements Analysis. IEEE Trans. Intell. Transport. Syst. 2022, 23, 19285–19298. [Google Scholar] [CrossRef]

- Cui, L.; Chakraborty, S.; Ozbay, K.; Jiang, Z.-P. Data-Driven Combined Longitudinal and Lateral Control for the Car Following Problem. IEEE Trans. Contr. Syst. Technol. 2025, 33, 991–1005. [Google Scholar] [CrossRef]

- Shi, X.; Wang, H.; Cai, Y.; Sun, X.; Chen, L.; Yang, C. Two-Stage Auxiliary Drifting Path Tracking Control for Distributed Driving Three-Axle Commercial Vehicles. ISA Trans. 2024, 153, 404–419. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, L.; Wang, C.; Wang, M.; Cao, D.; Wang, Z. Integrated Decision Making and Motion Control for Autonomous Emergency Avoidance Based on Driving Primitives Transition. IEEE Trans. Veh. Technol. 2023, 72, 4207–4221. [Google Scholar] [CrossRef]

- Yim, S.; Choi, J.; Yi, K. Coordinated Control of Hybrid 4WD Vehicles for Enhanced Maneuverability and Lateral Stability. IEEE Trans. Veh. Technol. 2012, 61, 1946–1950. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, C.; Guo, D.; Liu, Z.; Zhou, Z.; Wang, Z. Coordinated Steering Control Combining DDAS and AFS for the Front-Wheel-Independent- Drive Electric Vehicles. IEEE Trans. Transp. Electrific. 2024, 10, 6295–6308. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; Zhao, W. A Human-Vehicle Game Stability Control Strategy Considering Drivers’ Steering Characteristics. IEEE Trans. Intell. Transport. Syst. 2021, 22, 7306–7316. [Google Scholar] [CrossRef]

- Cao, W.; Zhu, Z.; Nan, J.; Zhang, X.; Zou, Y.; Cui, Y. Combined LKA and DYC Control for Electric Vehicle with a Domain-Centralized E/E Architecture Based on Software-Defined Networking. IEEE Trans. Transp. Electrific. 2024, 10, 5439–5450. [Google Scholar] [CrossRef]

- Tavernini, D.; Vacca, F.; Metzler, M.; Savitski, D.; Ivanov, V.; Gruber, P.; Hartavi, A.E.; Dhaens, M.; Sorniotti, A. An Explicit Nonlinear Model Predictive ABS Controller for Electro-Hydraulic Braking Systems. IEEE Trans. Ind. Electron. 2020, 67, 3990–4001. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, L.; Zhang, J.; Liu, X.; Wang, J. Traction Control for Electric Vehicles with Dual-Mode Coupling Drive System on Split Ramps. IEEE Trans. Transp. Electrific. 2024, 10, 2632–2642. [Google Scholar] [CrossRef]

- Hajiloo, R.; Khajepour, A.; Kasaiezadeh, A.; Chen, S.-K.; Litkouhi, B. A Model Predictive Control of Electronic Limited Slip Differential and Differential Braking for Improving Vehicle Yaw Stability. IEEE Trans. Control Syst. Technol. 2023, 31, 797–808. [Google Scholar] [CrossRef]

- Xu, T.; Fan, W.; Sun, Y.; Ji, X.; Liu, Y. Differential Steering Control Based on CNF and ADRC Techniques for Distributed-Drive Articulated Heavy Vehicles. IEEE Trans. Veh. Technol. 2024, 73, 6429–6442. [Google Scholar] [CrossRef]

- Yang, X.; Wang, Z.; Peng, W. Coordinated Control of AFS and DYC for Vehicle Handling and Stability Based on Optimal Guaranteed Cost Theory. Veh. Syst. Dyn. 2009, 47, 57–79. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Zhang, Z.; Li, T. Robust Adaptive Backstepping Sliding Mode Attitude Control of Quadrotor UAV Based on RBF Network. J. Jiangsu Univ. (Nat. Sci. Ed.) 2025, 46, 36–42. [Google Scholar] [CrossRef]

- Huang, Y.; Zhuang, D. Vehicle Longitudinal Control Based on Disturbance Observer and Terminal Sliding Mode. J. Jiangsu Univ. (Nat. Sci. Ed.) 2024, 45, 513–520. [Google Scholar] [CrossRef]

- Ataei, M.; Khajepour, A.; Jeon, S. Model Predictive Control for Integrated Lateral Stability, Traction/Braking Control, and Rollover Prevention of Electric Vehicles. Veh. Syst. Dyn. 2020, 58, 49–73. [Google Scholar] [CrossRef]

- Guo, P.; Yu, L. Trajectory Tracking Control of Driverless Vehicle Based on Road Adaptive Model Predictive Control. J. Jiangsu Univ. (Nat. Sci. Ed.) 2023, 44, 270–275. [Google Scholar] [CrossRef]

- Liu, W.; Khajepour, A.; He, H.; Wang, H.; Huang, Y. Integrated Torque Vectoring Control for a Three-Axle Electric Bus Based on Holistic Cornering Control Method. IEEE Trans. Veh. Technol. 2018, 67, 2921–2933. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, J.; Li, Z.; Li, S.; Ding, H. Multi-Agent-Based Coordinated Control of ABS and AFS for Distributed Drive Electric Vehicles. Energies 2022, 15, 1919. [Google Scholar] [CrossRef]

- Chen, W.; Shi, Z. Consensus Algorithm of Apron Multi-Agent Networks Based on Self-Triggered Impulsive Pinning Control. J. Jiangsu Univ. (Nat. Sci. Ed.) 2023, 44, 194–199. [Google Scholar] [CrossRef]

- Lu, E.; Xue, J.; Chen, T.; Jiang, S. Robust Trajectory Tracking Control of an Autonomous Tractor-Trailer Considering Model Parameter Uncertainties and Disturbances. Agriculture 2023, 13, 869. [Google Scholar] [CrossRef]

- Liu, H.; Yan, S.; Shen, Y.; Li, C.; Zhang, Y.; Hussain, F. Model Predictive Control System Based on Direct Yaw Moment Control for 4WID Self-Steering Agriculture Vehicle. Int. J. Agric. Biol. Eng. 2021, 14, 175–181. [Google Scholar] [CrossRef]

- Zhou, H.; Jia, F.; Jing, H.; Liu, Z.; Guvenc, L. Coordinated Longitudinal and Lateral Motion Control for Four Wheel Independent Motor-Drive Electric Vehicle. IEEE Trans. Veh. Technol. 2018, 67, 3782–3790. [Google Scholar] [CrossRef]

- Li, Y.; Cai, Y.; Sun, X.; Chen, L.; Lian, Y. Distributed Cooperative Control of Autonomous Vehicle Chassis Based on Multiagent Theory. IEEE Trans. Transp. Electrific. 2025, 11, 5324–5336. [Google Scholar] [CrossRef]

- Gheisarnejad, M.; Mirzavand, G.; Ardeshiri, R.R.; Andresen, B.; Khooban, M.H. Adaptive Speed Control of Electric Vehicles Based on Multi-Agent Fuzzy Q-Learning. IEEE Trans. Emerg. Top. Comput. Intell. 2023, 7, 102–110. [Google Scholar] [CrossRef]

- Liang, J.; Li, Y.; Yin, G.; Xu, L.; Lu, Y.; Feng, J.; Shen, T.; Cai, G. A MAS-Based Hierarchical Architecture for the Cooperation Control of Connected and Automated Vehicles. IEEE Trans. Veh. Technol. 2023, 72, 1559–1573. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, J.; Li, Z.; Xu, N.; Ding, H.; Zhang, Z.; Guo, K.; Xu, H. Coordinated Optimal Control of AFS and DYC for Four-Wheel Independent Drive Electric Vehicles Based on MAS Model. Sensors 2023, 23, 3505. [Google Scholar] [CrossRef]

- Cai, Y.; Li, Y.; Lian, Y.; Chen, L.; Zhong, Y.; Sun, X.; Yuan, C. Cooperative Control of Coupled Multiagent System of Autonomous Vehicle Chassis Based on Co-DMPC. IEEE Trans. Transp. Electrific. 2025, 11, 1875–1890. [Google Scholar] [CrossRef]

- Aouadj, N.; Hartani, K.; Fatiha, M. New Integrated Vehicle Dynamics Control System Based on the Coordination of Active Front Steering, Direct Yaw Control, and Electric Differential for Improvements in Vehicle Handling and Stability. SAE Int. J. Veh. Dyn. Stab. NVH 2020, 4, 119–133. [Google Scholar] [CrossRef]

- Yakub, F.; Mori, Y. Enhancing Path Following Control Performance of Autonomous Ground Vehicle through Coordinated Approach under Disturbance Effect. IEEJ Trans. Electron. Inf. Syst. 2015, 135, 102–110. [Google Scholar] [CrossRef]

- Ding, N.; Taheri, S. An Adaptive Integrated Algorithm for Active Front Steering and Direct Yaw Moment Control Based on Direct Lyapunov Method. Veh. Syst. Dyn. 2010, 48, 1193–1213. [Google Scholar] [CrossRef]

- Di Cairano, S.; Tseng, H.E.; Bernardini, D.; Bemporad, A. Vehicle Yaw Stability Control by Coordinated Active Front Steering and Differential Braking in the Tire Sideslip Angles Domain. IEEE Trans. Control Syst. Technol. 2013, 21, 1236–1248. [Google Scholar] [CrossRef]

- Qiao, Y.; Chen, X.; Yin, D. Coordinated Control for the Trajectory Tracking of Four-Wheel Independent Drive–Four-Wheel Independent Steering Electric Vehicles Based on the Extension Dynamic Stability Domain. Actuators 2024, 13, 77. [Google Scholar] [CrossRef]

- Vignati, M.; Sabbioni, E. A Cooperative Control Strategy for Yaw Rate and Sideslip Angle Control Combining Torque Vectoring with Rear Wheel Steering. Veh. Syst. Dyn. 2022, 60, 1668–1701. [Google Scholar] [CrossRef]

- Lelkó, A.; Németh, B.; Gáspár, P. Reinforcement Learning-Based Robust Vehicle Control for Autonomous Vehicle Trajectory Tracking. Eng. Proc. 2024, 79, 30. [Google Scholar]

- Yang, S.; Geng, C. A Longitudinal/Lateral Coupled Neural Network Model Predictive Controller for Path Tracking of Self-Driving Vehicle. IEEE Access 2023, 11, 117121–117136. [Google Scholar] [CrossRef]

- Shen, X.; Yu, F. Investigation on Integrated Vehicle Chassis Control Based on Vertical and Lateral Tyre Behaviour Correlativity. Veh. Syst. Dyn. 2006, 44, 506–519. [Google Scholar] [CrossRef]

- Liang, J.; Lu, Y.; Pi, D.; Yin, G.; Zhuang, W.; Wang, F.; Feng, J.; Zhou, C. A Decentralized Cooperative Control Framework for Active Steering and Active Suspension: Multi-Agent Approach. IEEE Trans. Transp. Electrific. 2022, 8, 1414–1429. [Google Scholar] [CrossRef]

- Li, Y.; Cai, Y.; Sun, X.; Wang, H.; Chen, L.; Lian, Y.; Dong, Z. Distributed Modeling and Scenario-Driven Extension Hybrid-DMPC Coordinated Control of Autonomous Vehicle Chassis. IEEE Trans. Intell. Transport. Syst. 2025, 26, 7186–7196. [Google Scholar] [CrossRef]

- Cheng, S.; Li, L.; Liu, C.-Z.; Wu, X.; Fang, S.-N.; Yong, J.-W. Robust LMI-Based H-Infinite Controller Integrating AFS and DYC of Autonomous Vehicles with Parametric Uncertainties. IEEE Trans. Syst. Man Cybern. Syst. 2021, 51, 6901–6910. [Google Scholar] [CrossRef]

- Chang, X.-H.; Liu, Y. Quantized Output Feedback Control of AFS for Electric Vehicles with Transmission Delay and Data Dropouts. IEEE Trans. Intell. Transport. Syst. 2022, 23, 16026–16037. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, L.; Wang, R.; Xu, X.; Shen, Y.; Liu, Y. Modeling and Test on Height Adjustment System of Electrically-Controlled Air Suspension for Agricultural Vehicles. Int. J. Agric. Biol. Eng. 2016, 9, 40–47. [Google Scholar]

- Cui, L.; Mao, H.; Xue, X.; Ding, S.; Qiao, B. Design Optimization and Test for a Pendulum Suspension of the Crop Sprayer Boom in Dynamic Conditions Based on a Six DOF Motion Simulator. Int. J. Agric. Biol. Eng. 2018, 11, 76–85. [Google Scholar] [CrossRef]

- Cui, L.; Xue, X.; Le, F.; Mao, H.; Ding, S. Design and Experiment of Electro Hydraulic Active Suspension for Controlling the Rolling Motion of Spray Boom. Int. J. Agric. Biol. Eng. 2019, 12, 72–81. [Google Scholar] [CrossRef]

- Wu, J.; Zhou, H.; Liu, Z.; Gu, M. Ride Comfort Optimization via Speed Planning and Preview Semi-Active Suspension Control for Autonomous Vehicles on Uneven Roads. IEEE Trans. Veh. Technol. 2020, 69, 8343–8355. [Google Scholar] [CrossRef]

- Liu, C.; Chen, L.; Yang, X.; Zhang, X.; Yang, Y. General Theory of Skyhook Control and Its Application to Semi-Active Suspension Control Strategy Design. IEEE Access 2019, 7, 101552–101560. [Google Scholar] [CrossRef]

- Canale, M.; Milanese, M.; Novara, C. Semi-Active Suspension Control Using “Fast” Model-Predictive Techniques. IEEE Trans. Control Syst. Technol. 2006, 14, 1034–1046. [Google Scholar] [CrossRef]

- Qin, W.; Liu, F.; Yin, H.; Huang, J. Constraint-Based Adaptive Robust Control for Active Suspension Systems Under the Sky-Hook Model. IEEE Trans. Ind. Electron. 2022, 69, 5152–5164. [Google Scholar] [CrossRef]

- Jin, X.; Wang, J.; He, X.; Yan, Z.; Xu, L.; Wei, C.; Yin, G. Improving Vibration Performance of Electric Vehicles Based on In-Wheel Motor-Active Suspension System via Robust Finite Frequency Control. IEEE Trans. Intell. Transport. Syst. 2023, 24, 1631–1643. [Google Scholar] [CrossRef]

- Manna, S.; Mani, G.; Ghildiyal, S.; Stonier, A.A.; Peter, G.; Ganji, V.; Murugesan, S. Ant Colony Optimization Tuned Closed-Loop Optimal Control Intended for Vehicle Active Suspension System. IEEE Access 2022, 10, 53735–53745. [Google Scholar] [CrossRef]

- Li, J.; Shang, Z.; Li, R.; Cui, B. Adaptive Sliding Mode Path Tracking Control of Unmanned Rice Transplanter. Agriculture 2022, 12, 1225. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Z.; Ding, S.; Xia, J.; Xing, G. Adaptive Disturbance Observer-Based Fixed Time Nonsingular Terminal Sliding Mode Control for Path-Tracking of Unmanned Agricultural Tractors. Biosyst. Eng. 2024, 246, 96–109. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, K.; Ding, R.; Jiang, Y.; Jiang, Y. A Novel Hydraulic Interconnection Design and Sliding Mode Synchronization Control of Leveling System for Crawler Work Machine. Agriculture 2025, 15, 137. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, C.; Li, H.; Xia, H. Design and Evaluation of a Control System for the Fertigation Device. J. ASABE 2022, 65, 1293–1302. [Google Scholar] [CrossRef]

- Chen, J.; Ning, X.; Li, Y.; Yang, G.; Wu, P.; Chen, S. A Fuzzy Control Strategy for the Forward Speed of a Combine Harvester Based on KDD. Appl. Eng. Agric. 2017, 33, 15–22. [Google Scholar] [CrossRef]

- Chen, H.; Gong, M.-D.; Zhao, D.-X.; Liu, W.-B.; Jia, G.-Y. Coordination Control of Multi-Axis Steering and Active Suspension System for High-Mobility Emergency Rescue Vehicles. Mathematics 2022, 10, 3562. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Xiao, F.; Lin, Z.; Deng, C. Coordinated Control of Active Suspension and DYC for Four-Wheel Independent Drive Electric Vehicles Based on Stability. Appl. Sci. 2022, 12, 11768. [Google Scholar] [CrossRef]

- March, C.; Shim, T. Integrated Control of Suspension and Front Steering to Enhance Vehicle Handling. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2007, 221, 377–391. [Google Scholar] [CrossRef]

- Xiao, F.; Hu, J.; Jia, M.; Zhu, P.; Deng, C. A Novel Integrated Control Framework of AFS, ASS, and DYC Based on Ideal Roll Angle to Improve Vehicle Stability. Adv. Eng. Inform. 2022, 54, 101764. [Google Scholar] [CrossRef]

- Xu, F.; Zhou, C.; Liu, X.; Wang, J. GRNN Inverse System Based Decoupling Control Strategy for Active Front Steering and Hydro-Pneumatic Suspension Systems of Emergency Rescue Vehicle. Mech. Syst. Signal Process. 2022, 167, 108595. [Google Scholar] [CrossRef]

- Qin, Y.; Zhao, Z.; Wang, Z.; Li, G. Study of Longitudinal–Vertical Dynamics for In-Wheel Motor-Driven Electric Vehicles. Automot. Innov. 2021, 4, 227–237. [Google Scholar] [CrossRef]

- Bayar, K. Shortening the Braking Distance of a Passenger Car through Coordinated Control of Brakes and Active Suspension. Mühendis Ve Makina 2021, 62, 372–394. [Google Scholar] [CrossRef]

- Valdivieso-Soto, A.; Galluzzi, R.; Tramacere, E.; Cespi, R.; Castellanos Molina, L.M. Lyapunov-Based Pitch Control for Electric Vehicles Using In-Wheel Motors. Vehicles 2025, 7, 37. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, Y.; Hu, M.; Yang, Z.; Fu, C. Longitudinal–Vertical Comprehensive Control for Four-Wheel Drive Pure Electric Vehicle Considering Energy Recovery and Ride Comfort. Energy 2021, 236, 121417. [Google Scholar] [CrossRef]

- Meng, X.; Kong, L.; Ding, R.; Liu, W.; Wang, R. Research on Active Suspension Control Based on Vehicle Speed Control Under Transient Pavement Excitation. World Electr. Veh. J. 2025, 16, 232. [Google Scholar] [CrossRef]

- Wang, W.-Y.; Chen, M.-C.; Su, S.-F. Hierarchical T—S Fuzzy-Neural Control of Anti-Lock Braking System and Active Suspension in a Vehicle. Automatica 2012, 48, 1698–1706. [Google Scholar] [CrossRef]

- Wang, H.; Hu, Y.; Pi, D.; Wang, J.; Wang, W.; Yan, Y.; Zhao, J.; Wong, P.K.; Xue, P.; Tao, S. Research on Longitudinal-Vertical Coordinated Recovery Drive Control for Corner-Modular Distributed Drive Vehicles. IEEE Trans. Transp. Electrific. 2025, 11, 7979–7990. [Google Scholar] [CrossRef]

- Huang, C.; Hong, J.; Bei, S.; Li, B. Coordinated Control of Vehicle Chassis Energy Flow and Dynamics Based on Hierarchical Hierarchy. Dyn. Syst. Appl. 2021, 30, 700–717. [Google Scholar] [CrossRef]

- Zhao, J.; Wong, P.K.; Ma, X.; Xie, Z. Chassis Integrated Control for Active Suspension, Active Front Steering and Direct Yaw Moment Systems Using Hierarchical Strategy. Veh. Syst. Dyn. 2017, 55, 72–103. [Google Scholar] [CrossRef]

- Chen, J.; Liu, Y.; Liu, R.; Xiao, F.; Huang, J. Integrated Control of Braking-Yaw-Roll Stability under Steering-Braking Conditions. Sci. Rep. 2023, 13, 21110. [Google Scholar] [CrossRef]

- Fergani, S.; Sename, O.; Dugard, L. An Integrated Vehicle Dynamic Controller. IEEE Trans. Veh. Technol. 2016, 65, 1880–1889. [Google Scholar] [CrossRef]

- Zhao, S.; Wu, X.; Lu, H. Adaptive Mode-Switching Coordinated Control Based on Stability Domain for Longitudinal-Lateral-Vertical Decoupling X-By-Wire Electric Vehicles. In Proceedings of the 2024 IEEE Vehicle Power and Propulsion Conference (VPPC), Washington, DC, USA, 7–10 October 2024; IEEE: New York, NY, USA, 2024; pp. 1–7. [Google Scholar]

- Chen, X.; Wang, M.; Wang, W. Unified Chassis Control of Electric Vehicles Considering Wheel Vertical Vibrations. Sensors 2021, 21, 3931. [Google Scholar] [CrossRef]

- Zhao, W.; Yang, Z.; Wang, C. Multi-Objective Optimization of Chassis Integrated System for Electric Wheel Vehicle. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 7–17. [Google Scholar] [CrossRef]

- Jia, J.; Yue, Y.; Sun, A.; Liu, X. Coordinated Control Strategy for Longitudinal, Lateral, and Vertical Motions of Distributed Electric Vehicles Based on Model Predictive Control. In Proceedings of the WCX SAE World Congress Experience, Detroit, MI, USA, 1 April 2025; p. 8300. [Google Scholar]

| Architecture | Decentralized | Centralized | Hierarchical |

|---|---|---|---|

| Features [39] | Each subsystem controlled independently | Single central controller coordinates all subsystems | Multi-layer structure: high-level decision-making, mid-level coordination/distribution, low-level execution |

| Advantages [39,45] | Simple development, aligns with existing supplier models, easy to debug | Easy to achieve global optimization, effectively avoids conflicts | Balances optimization and decoupling, good, modularity, high flexibility, good scalability |

| Disadvantages [39,45] | Difficult to achieve true coordination, prone to conflicts | High computational load, complex development, high risk of single-point failure | Relatively complex design, inter-layer coordination is key |

| Coordinated control capability [46,47] | Weak, difficult to leverage DDEV advantages | Strong, theoretically capable of achieving optimal coordination | Strong, achieved through mid-level coordination and control distribution |

| Fault tolerance capability [48] | Relies on the fault tolerance of individual subsystems | Controller failure has a significant impact | Fault tolerance strategies can be designed at different levels, good redundancy |

| Development complexity [39] | Low | High | Medium to high |

| DDEV applicability [48] | Limited, difficult to fully utilize over-actuation characteristics | Theoretically suitable, but practical implementation is challenging | Very suitable |

| Coordinated Subsystem | Applied Control Algorithm | Achieved Control Effect | Refs |

|---|---|---|---|

| AFS, DYC | Sliding mode backstepping control | Improves vehicle handling and stability and enhances speed tracking performance | [77] |

| AFS, DYC | MPC coordinated with a proportional–integral controller | Exhibits better path tracking performance than standalone AFS under high-speed maneuvering conditions and eliminates effects of crosswind | [78] |

| AFS, DYC | Adaptive control based on the Lyapunov method, with an adaptive law for variations in cornering stiffness | Significantly enhances vehicle stability during emergency obstacle avoidance maneuvers under various road conditions | [79] |

| AFS, differential braking | MPC | Improves yaw stability control, achieves faster convergence, reduces impact on longitudinal dynamics | [80] |

| DYC, ARS, 4WID/4WIS | Expert PID, MPC, SMC | Improves trajectory tracking performance, enhances handling stability and economy | [81] |

| Torque vectoring (TV), rear wheel steering (RWS) | Parallel PI controller, extended Kalman filter | Increases maximum lateral acceleration, increases entry speed for double lane-change maneuvers, and reduces driver workload | [82] |

| Longitudinal control (reference speed), lateral control (steering angle) | Reinforcement learning control, robust control (H∞) | Achieves high-quality trajectory tracking, enables various driving styles, and limits trajectory tracking error | [83] |

| Longitudinal control (reference speed), lateral control (steering angle) | MPC, recurrent neural network | Provides more accurate vehicle state prediction and significantly enhances accuracy and stability of path tracking, especially in challenging high-speed scenarios | [84] |

| Coordinated Subsystem | Applied Control Algorithm | Achieved Control Effect | Refs |

|---|---|---|---|

| SAS, differential braking | Hierarchical control architecture, SMC used for upper-level controller’s desired yaw and roll moment calculation | Enhances the vehicle’s lateral stability while maintaining a good roll performance | [43] |

| AFS, ASS, DYC | MPC, tire force allocation algorithm | Significantly improves the vehicle’s path tracking performance and driving stability under different road adhesion coefficients | [107] |

| Multi-axle steering system, ASS | Dual linear quadratic regulator (DLQR) | Improves the handling stability and ride comfort of the vehicle | [104] |

| AFS, hydro-pneumatic suspension (HPS) | GRNN, PID control | Accurately tracks the desired yaw rate and roll angle, improves vehicle handling stability | [108] |

| AFS, ASS | MAS, MDMPC | Significantly improves the vehicle’s lateral stability, ride comfort, and roll safety during path tracking | [86] |

| Coordinated Subsystem | Applied Control Algorithm | Achieved Control Effect | Refs |

|---|---|---|---|

| ASS, braking system | MPC | Improves ride comfort during braking | [112] |

| ASS, longitudinal speed control | Fuzzy logic control, MPC | Improves vehicle smoothness and stability when passing over impacted roads | [113] |

| ABS, ASS | Fuzzy neural control | Shortens braking time and braking distance, maintain stability | [114] |

| Distributed drive system, ASS | MPC, SMC, EKF | Significantly improves vehicle’s extrication ability and driving stability on low-adhesion roads | [115] |

| Braking system, ASS | Fuzzy coordinated control | Improves composite braking performance | [116] |

| Coordinated Subsystem | Applied Control Algorithm | Achieved Control Effect | Refs |

|---|---|---|---|

| Differential steering, differential braking, ASS | Particle swarm optimization (PSO) | Improves driving comfort and steering stability | [122] |

| ASS, AFS, DYC | Adaptive fuzzy control | Improves the vehicle’s lateral stability and vertical performance | [117] |

| Braking force control, yaw stability control, roll stability control | NMPC, switching control | Effectively prevents rollover, ensures braking safety and yaw stability | [118] |

| SAS, active steering, and electromechanical braking actuators | LPV/H∞ robust control | Improves the vehicle’s dynamic behavior | [119] |

| SBW, ASS, 4WID | Adaptive switching control | Enhances vehicle performance in terms of handling stability, comfort, safety, and economy | [120] |

| AFS, DYC, ASS and Anti-Skid Control | MPC | Effectively improves the vehicle’s ride comfort and enhances its maneuverability and stability under various driving conditions | [123] |

| Drive system, steering system, ASS | NSMC | Enhances driving safety, handling stability, ride comfort, and road-following capability | [20] |

| Four In-Wheel Drive (4IWD), 4-Wheel Independent Steering (4WIS), ASS | H∞ robust controller | Improves tire contact stability | [121] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Cai, Y.; Sun, X.; Wang, H.; Chen, L.; Chen, T.; Yuan, C. A Review of Coordinated Control Technology for Chassis of Distributed Drive Electric Vehicles. Appl. Sci. 2025, 15, 7175. https://doi.org/10.3390/app15137175

Zhang Y, Cai Y, Sun X, Wang H, Chen L, Chen T, Yuan C. A Review of Coordinated Control Technology for Chassis of Distributed Drive Electric Vehicles. Applied Sciences. 2025; 15(13):7175. https://doi.org/10.3390/app15137175

Chicago/Turabian StyleZhang, Yuhang, Yingfeng Cai, Xiaoqiang Sun, Hai Wang, Long Chen, Te Chen, and Chaochun Yuan. 2025. "A Review of Coordinated Control Technology for Chassis of Distributed Drive Electric Vehicles" Applied Sciences 15, no. 13: 7175. https://doi.org/10.3390/app15137175

APA StyleZhang, Y., Cai, Y., Sun, X., Wang, H., Chen, L., Chen, T., & Yuan, C. (2025). A Review of Coordinated Control Technology for Chassis of Distributed Drive Electric Vehicles. Applied Sciences, 15(13), 7175. https://doi.org/10.3390/app15137175