Performance Prediction and Optimization of High-Plasticity Clay Lime–Cement Stabilization Based on Principal Component Analysis and Principal Component Regression

Abstract

1. Introduction

2. Materials and Method

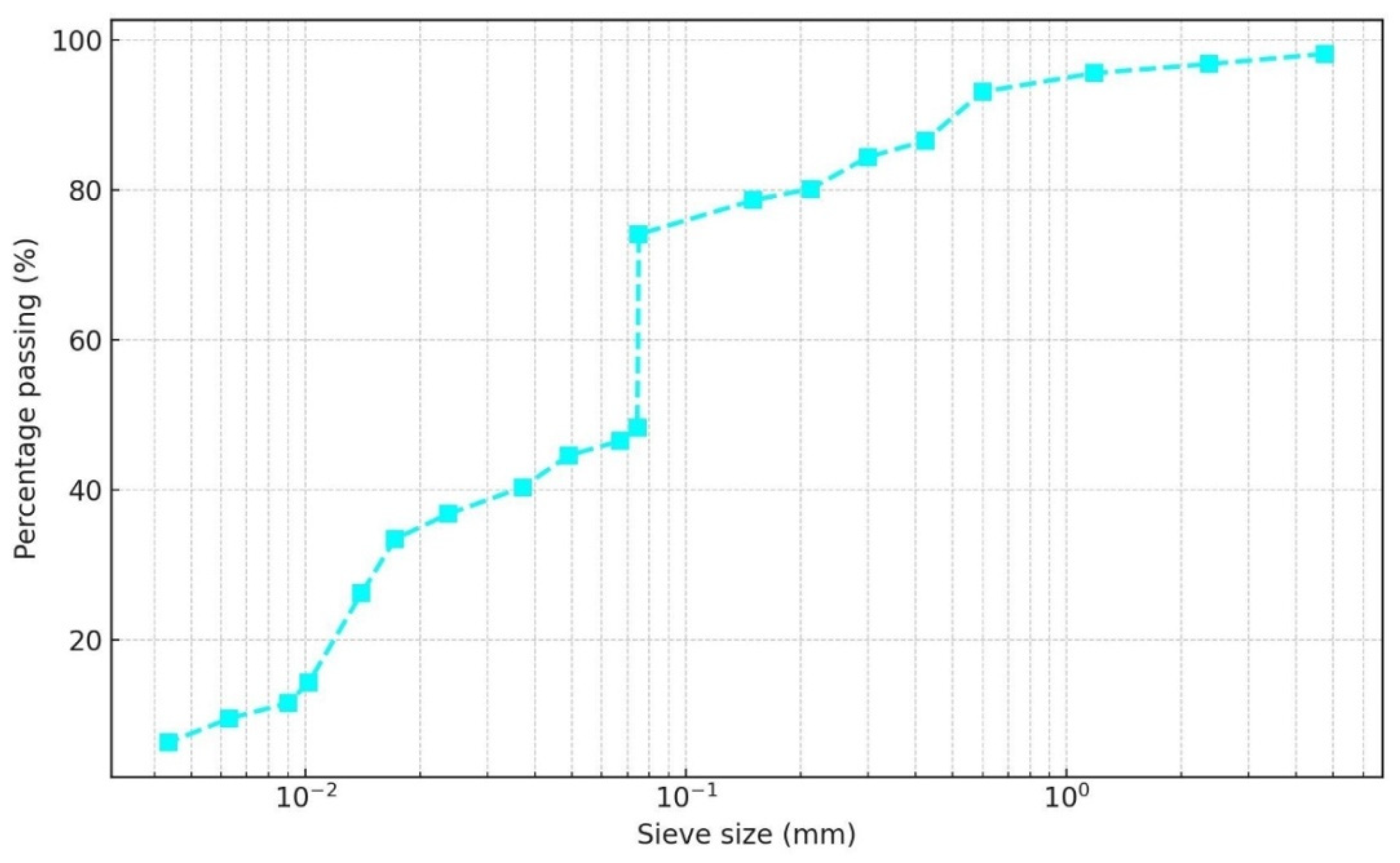

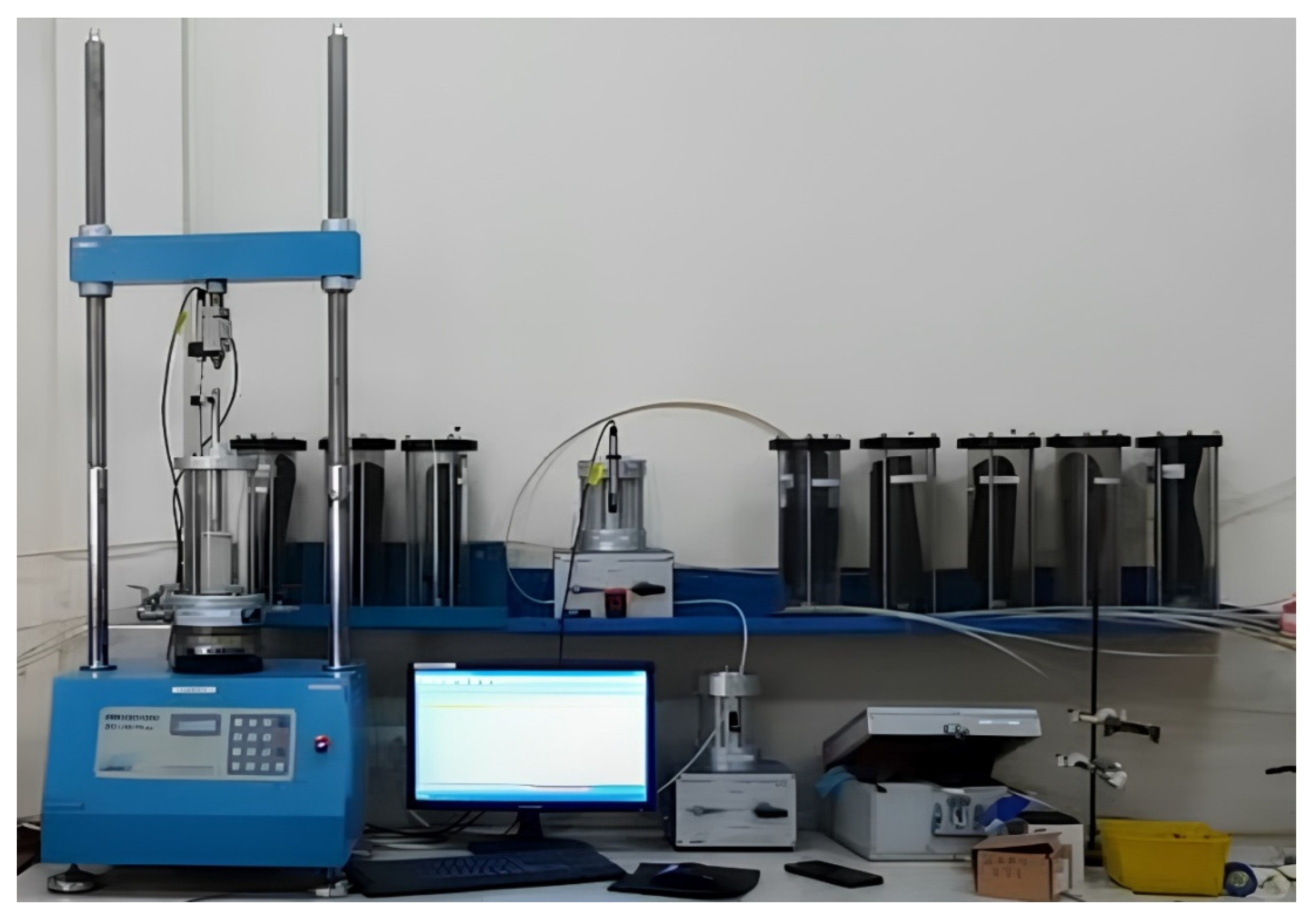

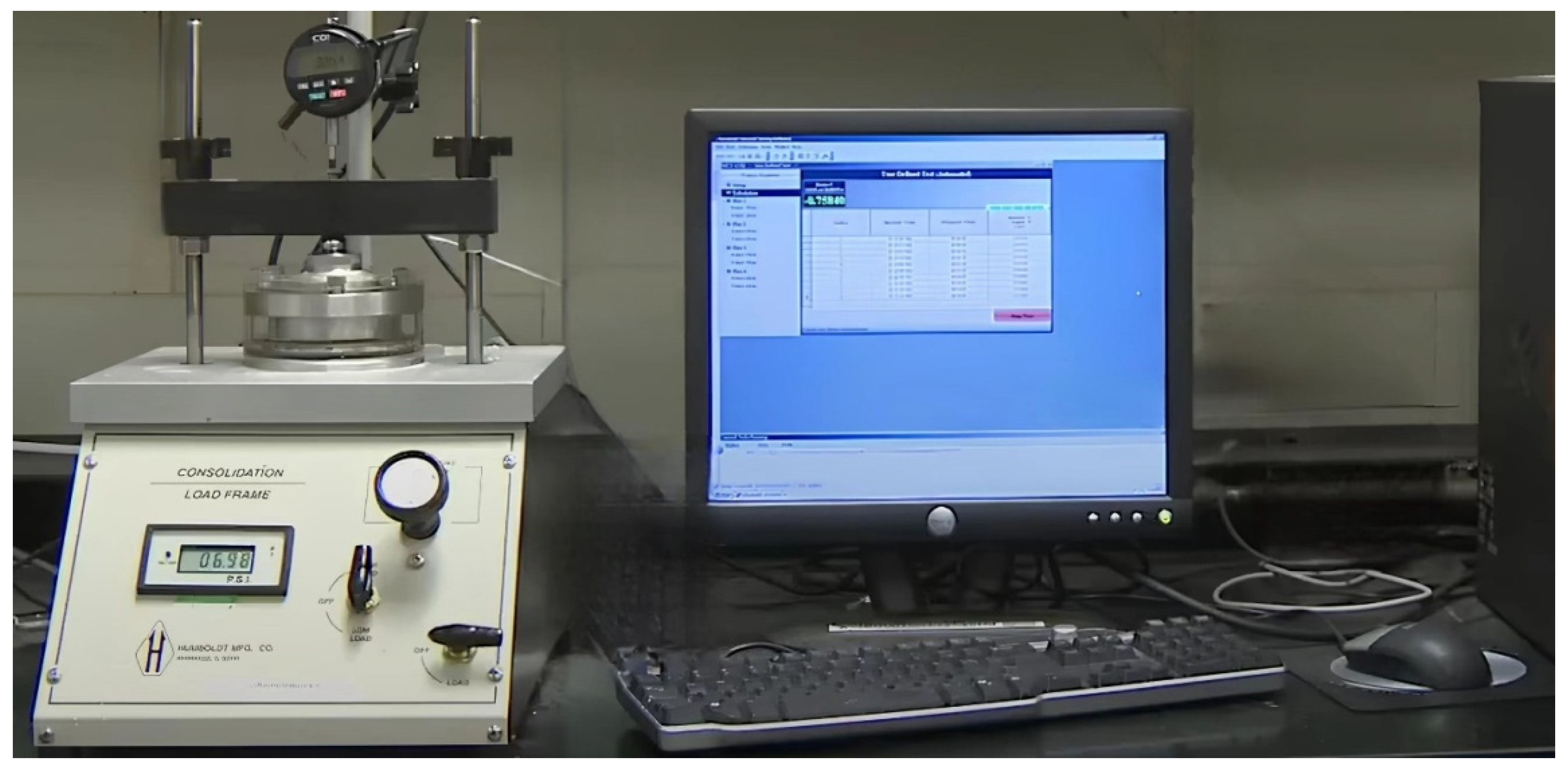

2.1. Specimen Preparation

Method of the Test

2.2. Principal Component Regression (PCR) Method

2.2.1. Data Preprocessing

2.2.2. Standardization

2.2.3. Principal Component Analysis (PCA)

2.2.4. Eigenvalue Decomposition

2.2.5. Principal Components (PC)

2.2.6. Principal Component Regression (PCR)

2.3. Sensitivity Analysis via Principal Component Regression

2.4. Causality Analysis Using Principal Component Regression

3. Consolidation Properties

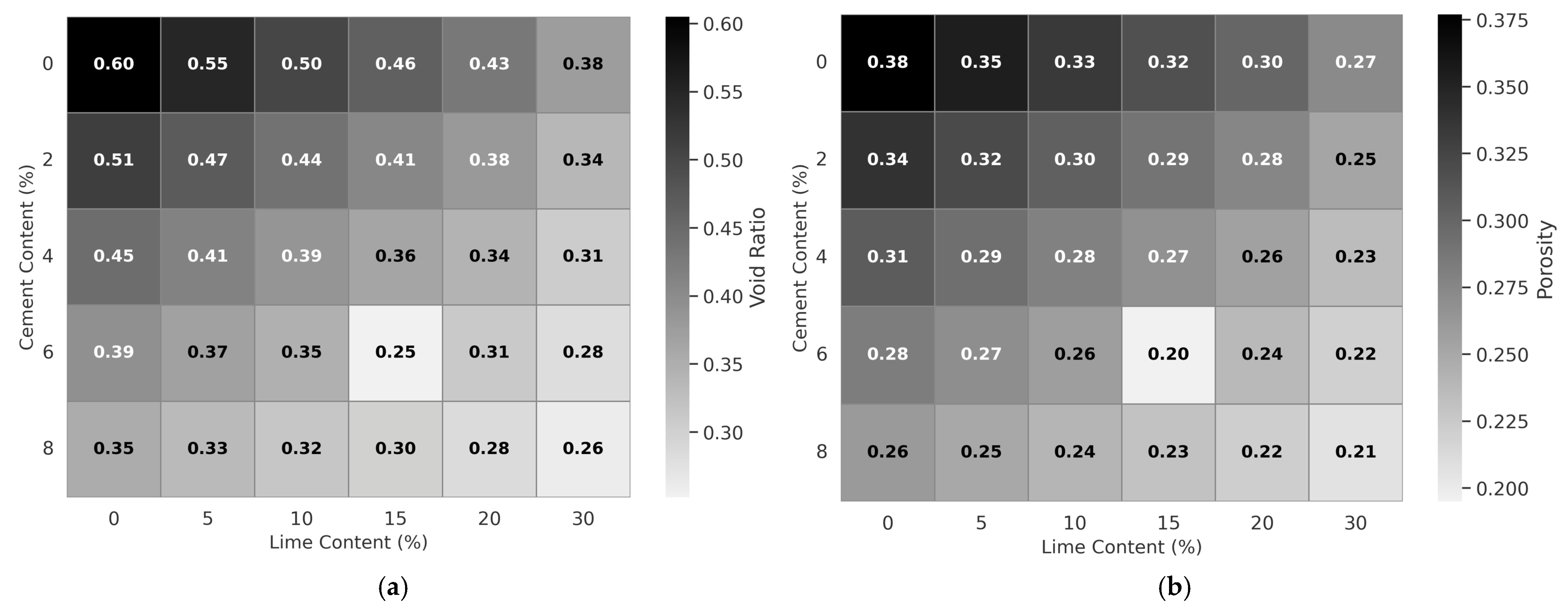

3.1. Effects of Lime–Cement Stabilization on the Void Ratio and Porosity of the Clay Soil

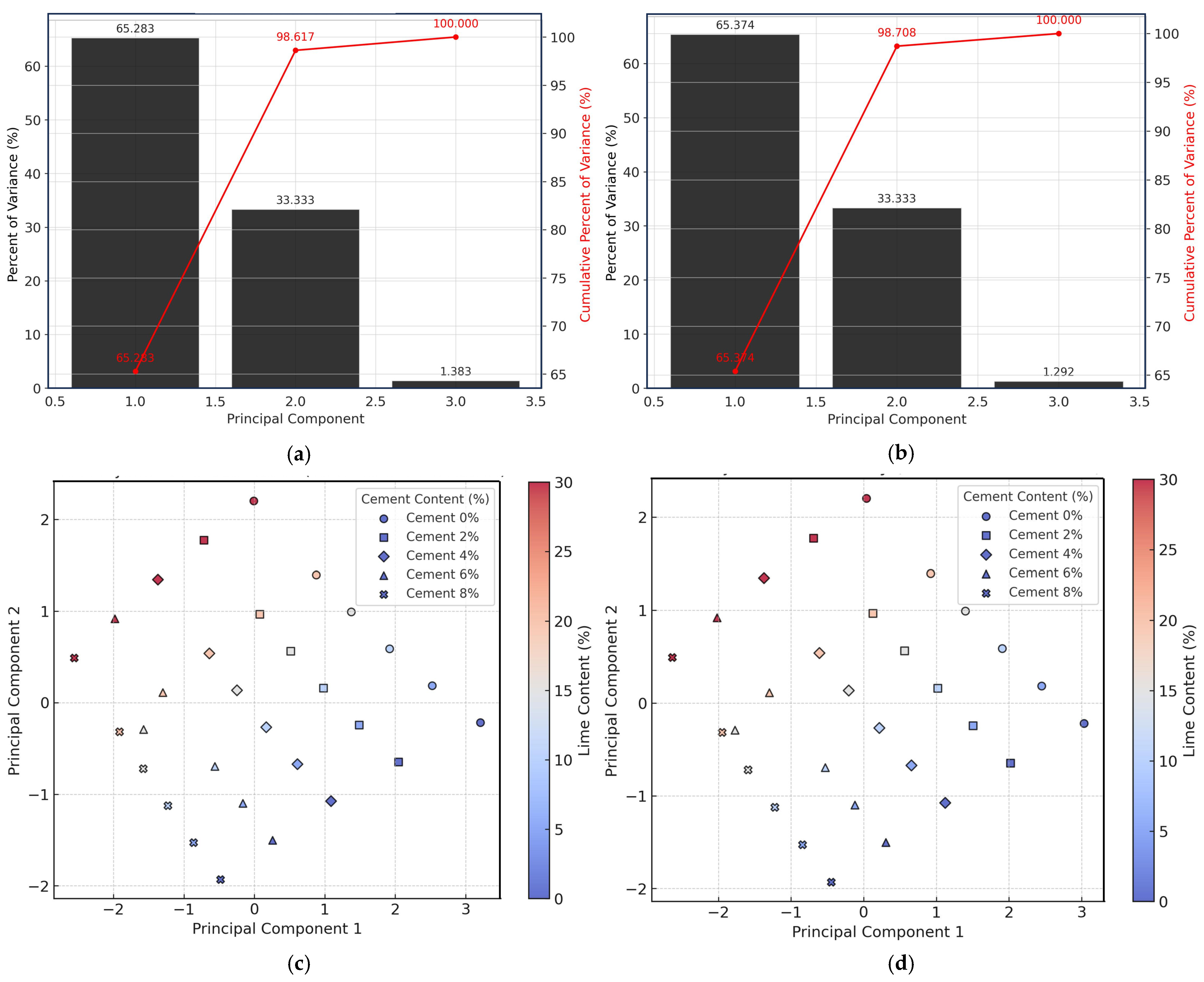

3.2. Principal Component Analysis of Soil Stabilization Effects on Void Ratio and Porosity

3.3. Effects of Lime–Cement Stabilization on the Preconsolidation Stress of the Clay Soil

3.4. Principal Component Analysis of Pre-Consolidation Stress in Stabilized Soil

3.5. Effects of Lime–Cement Stabilization on the Compression Index of the Clay Soil

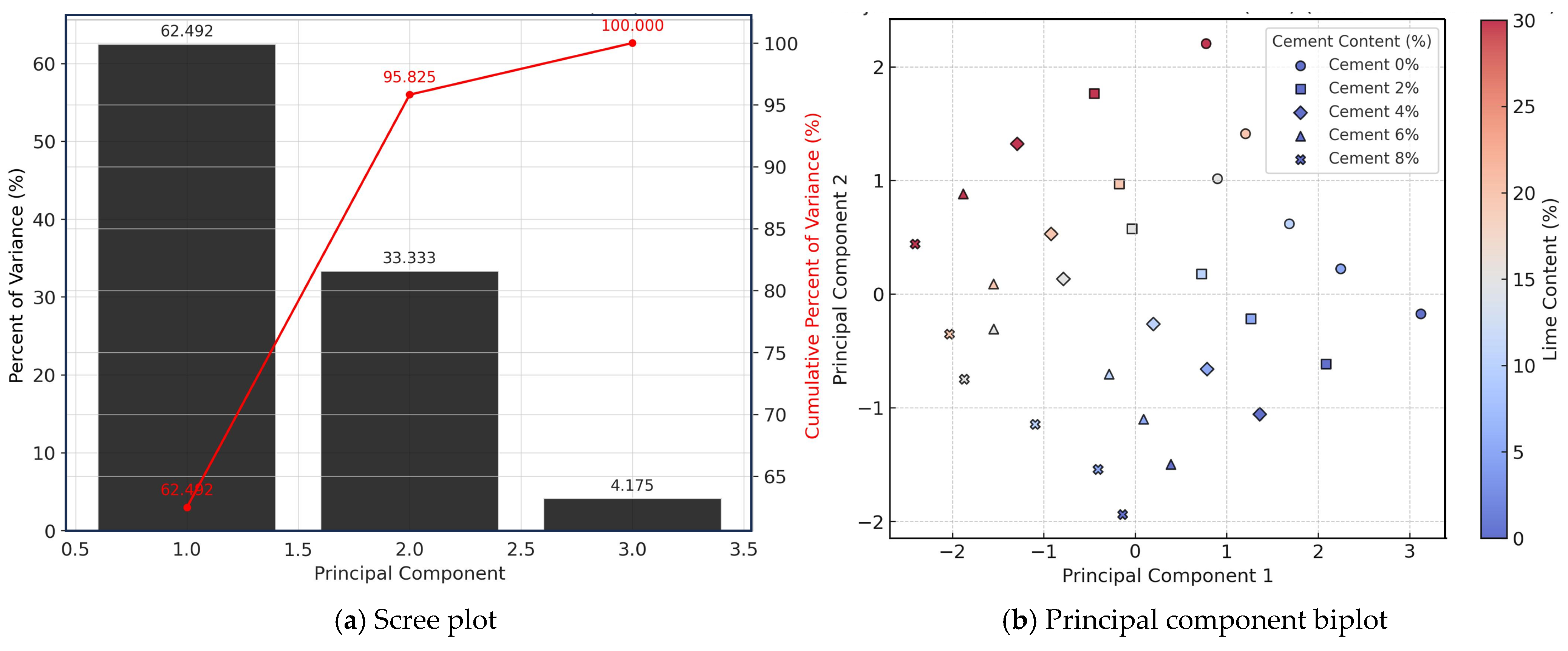

3.6. Principal Component Analysis of Compression Index in Stabilized Soil

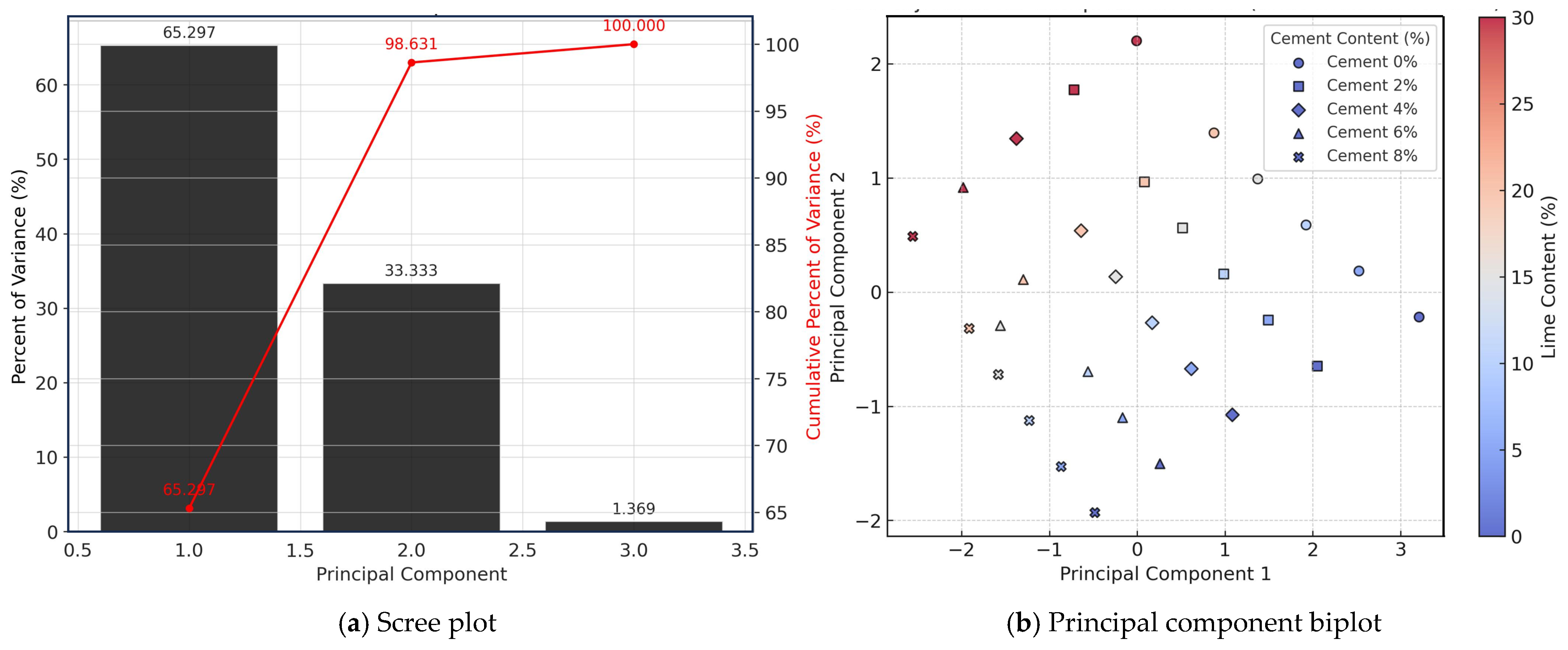

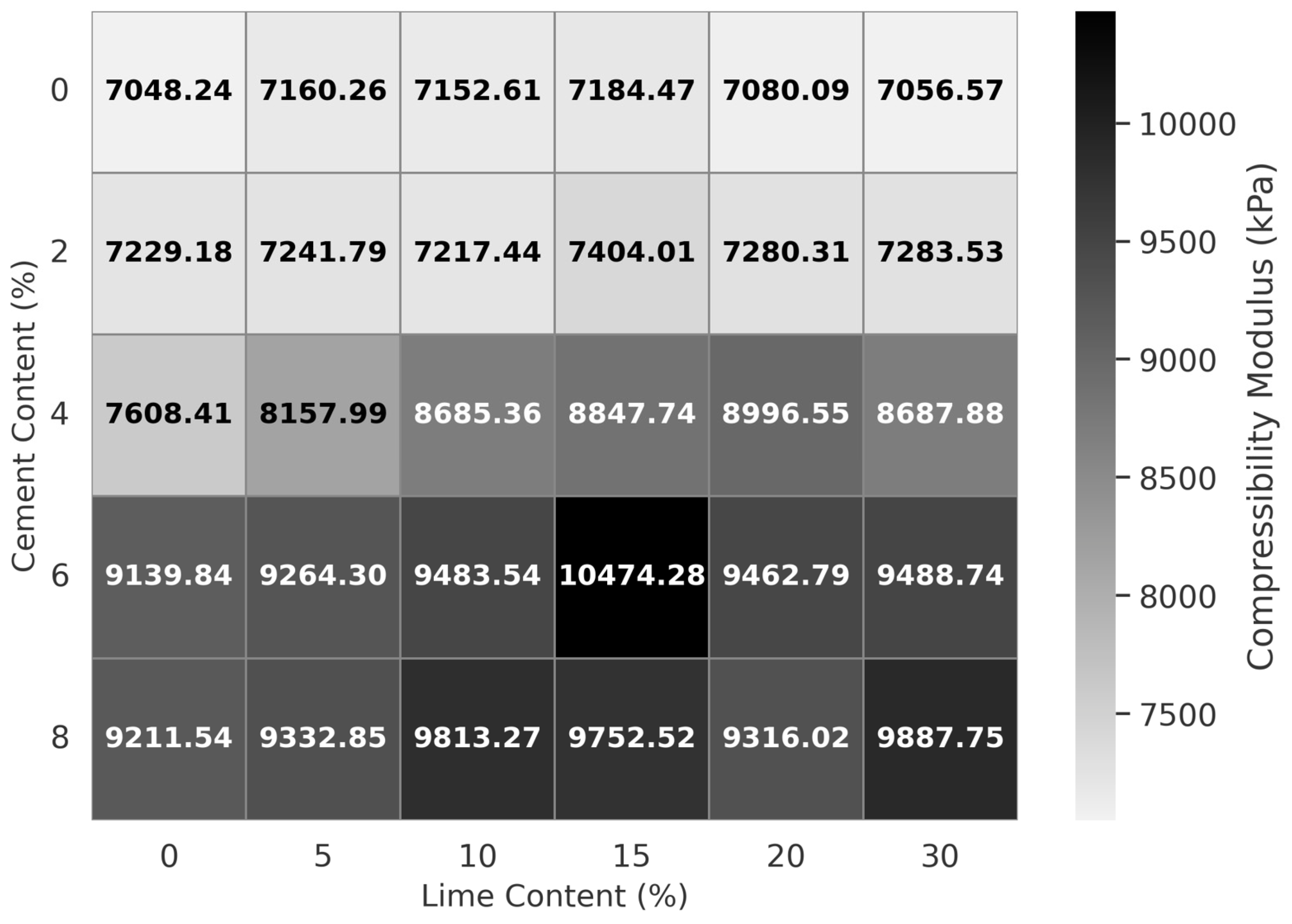

3.7. Effects of Lime–Cement Stabilization on the Compressibility Modulus of the Clay Soil

3.8. Principal Component Analysis of Compressibility Modulus in Stabilized Soil

4. Strength Properties

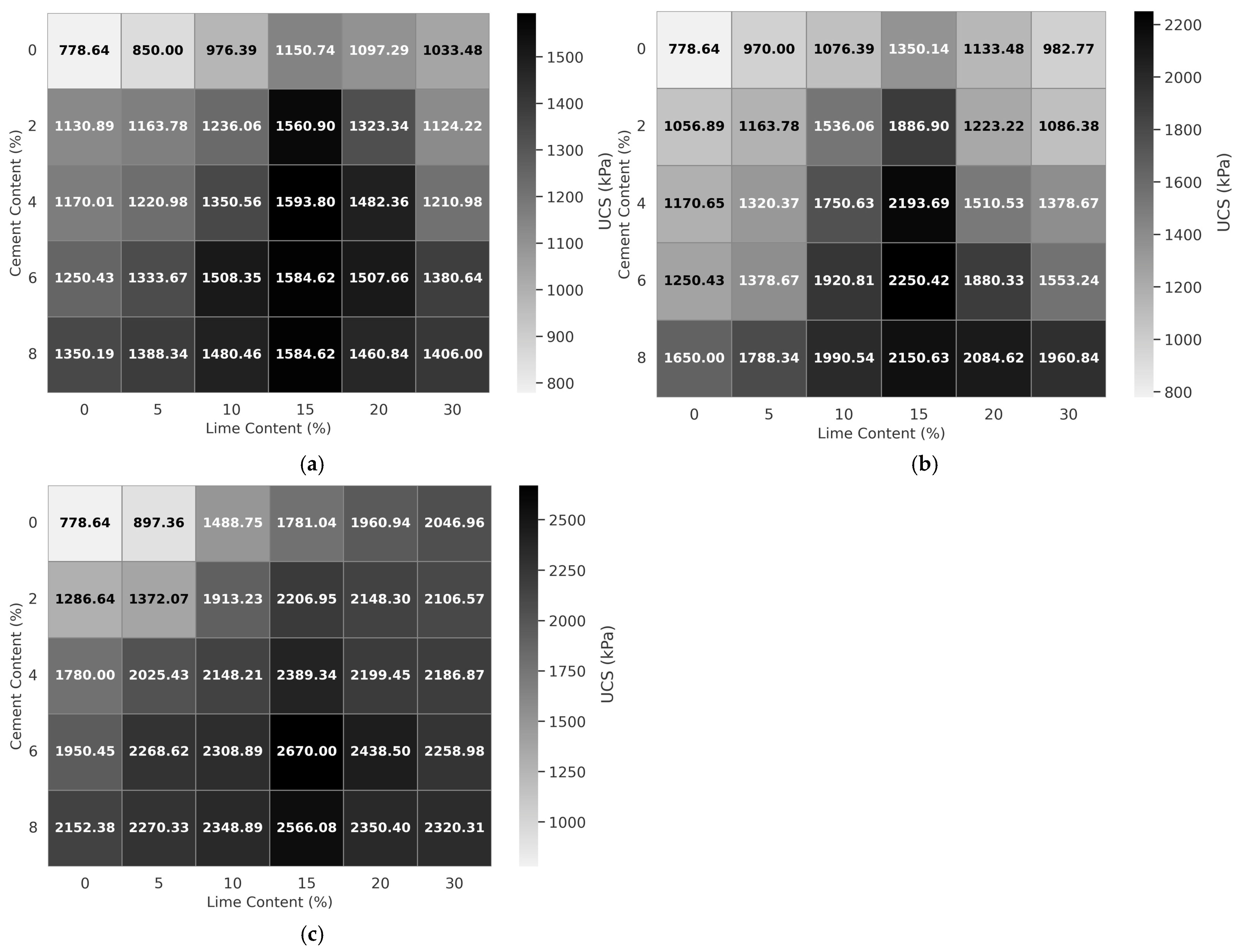

4.1. Unconfined Compressive Strength of Lime–Cement Stabilized Clay Soil

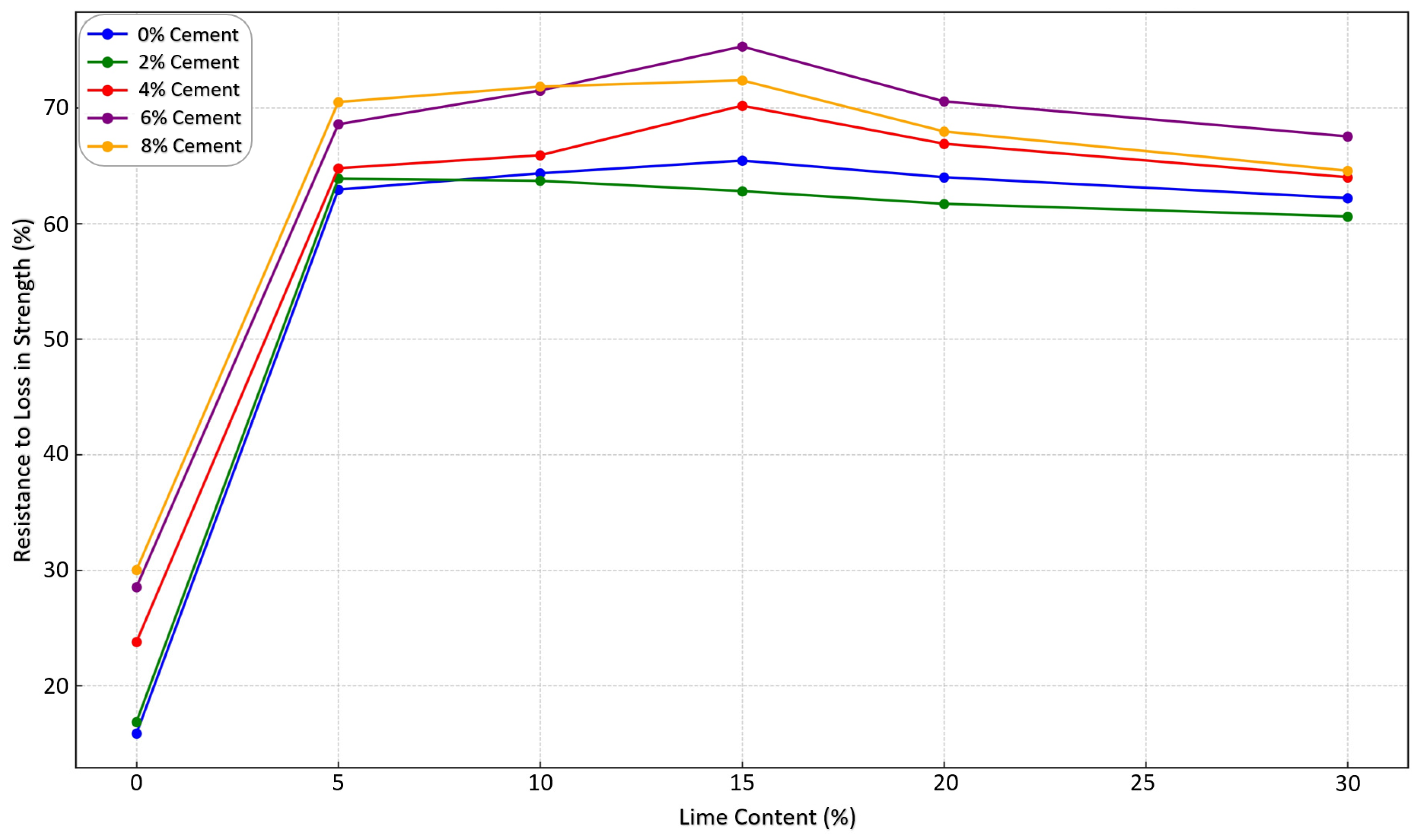

4.2. Effects of Lime–Cement Stabilization on the Resistance to Loss in Strength of the Clay Soil

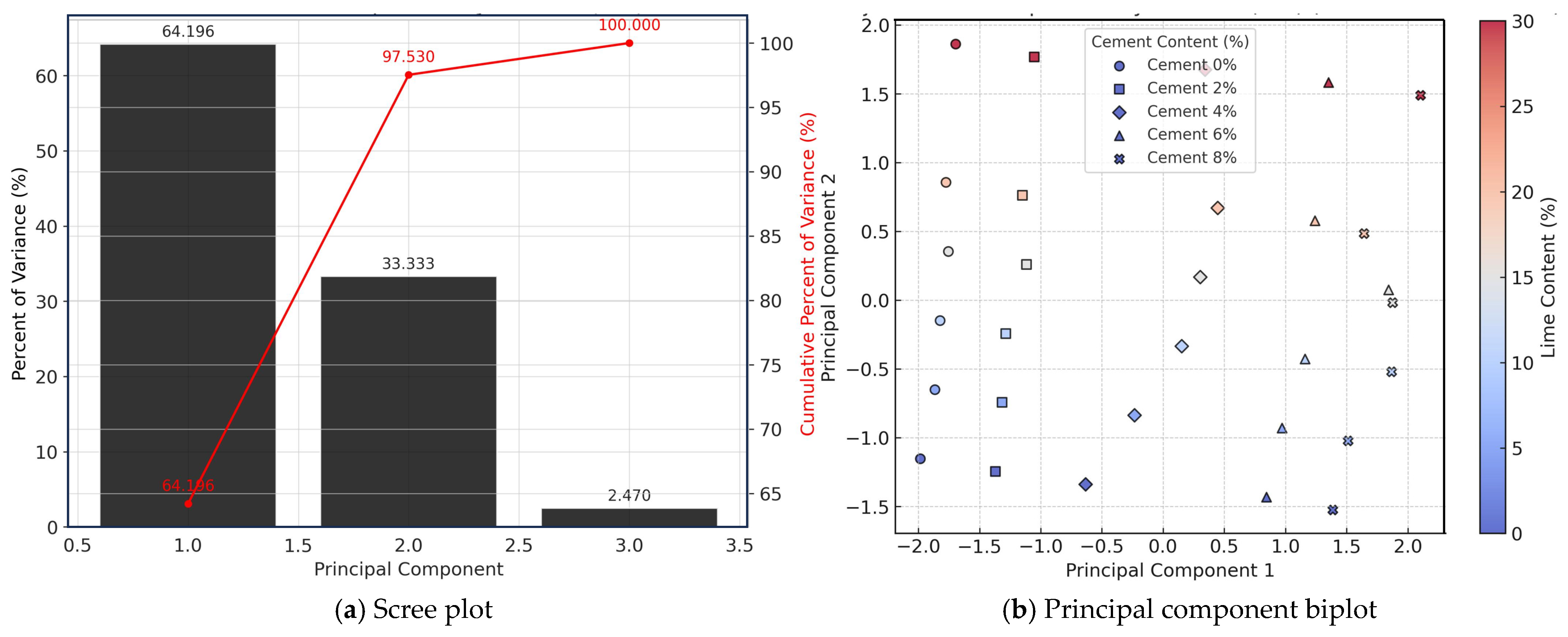

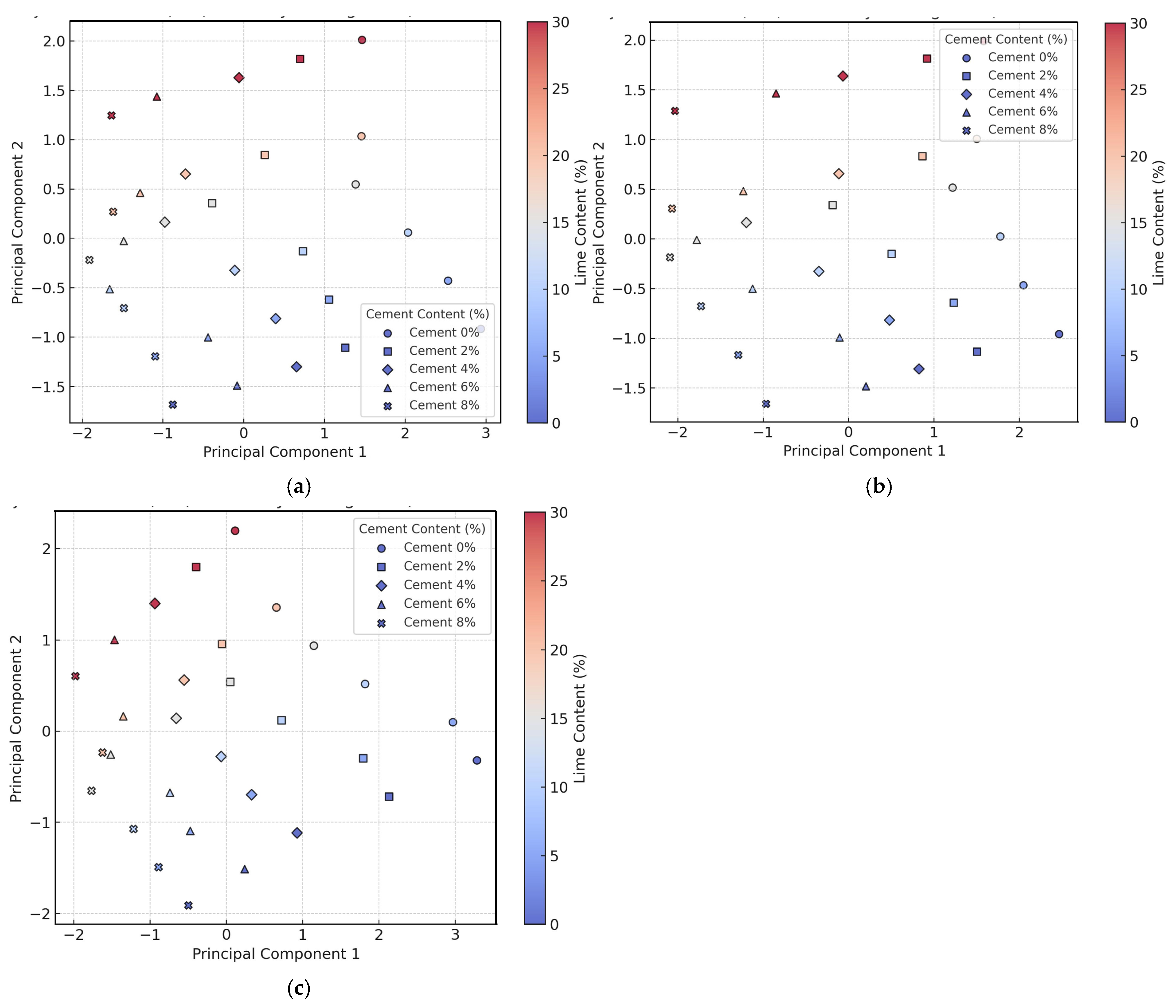

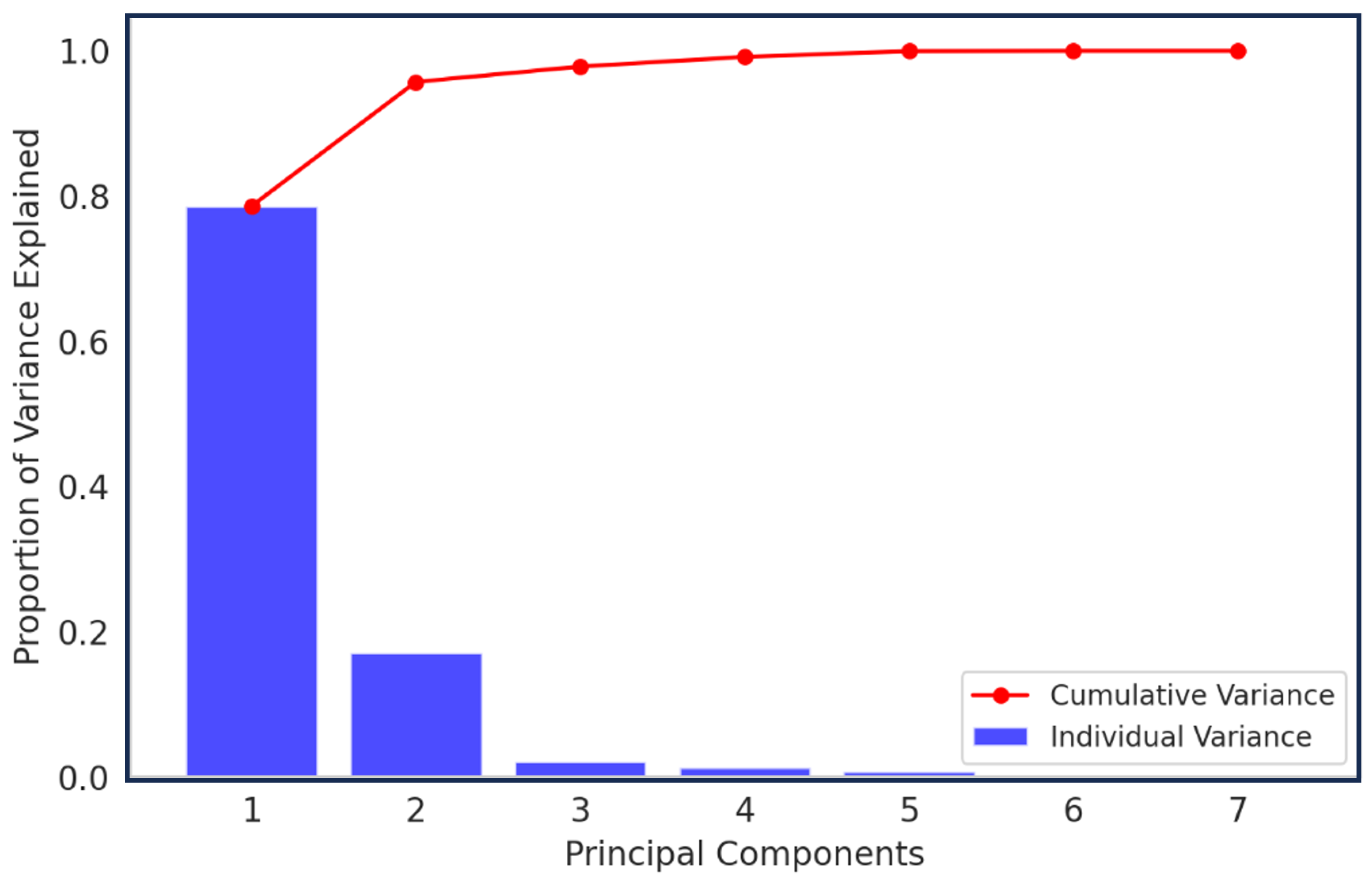

4.3. Principal Component Analysis of UCS in Stabilized Soil

5. Principal Component Regression Analysis

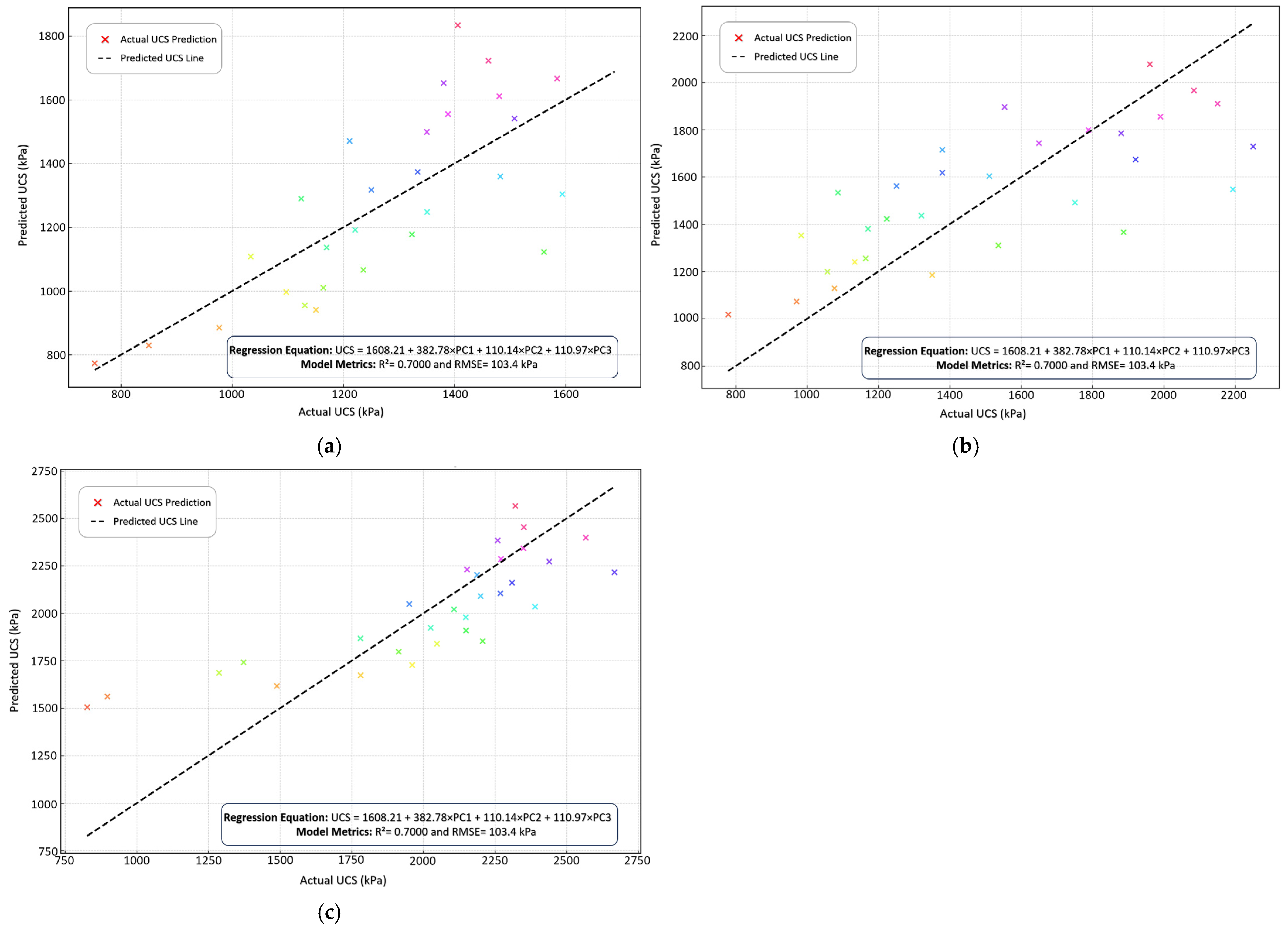

5.1. Effects of Lime–Cement Stabilization on the Principal Component Regression (PCR) in the Strength of the Clay Soil

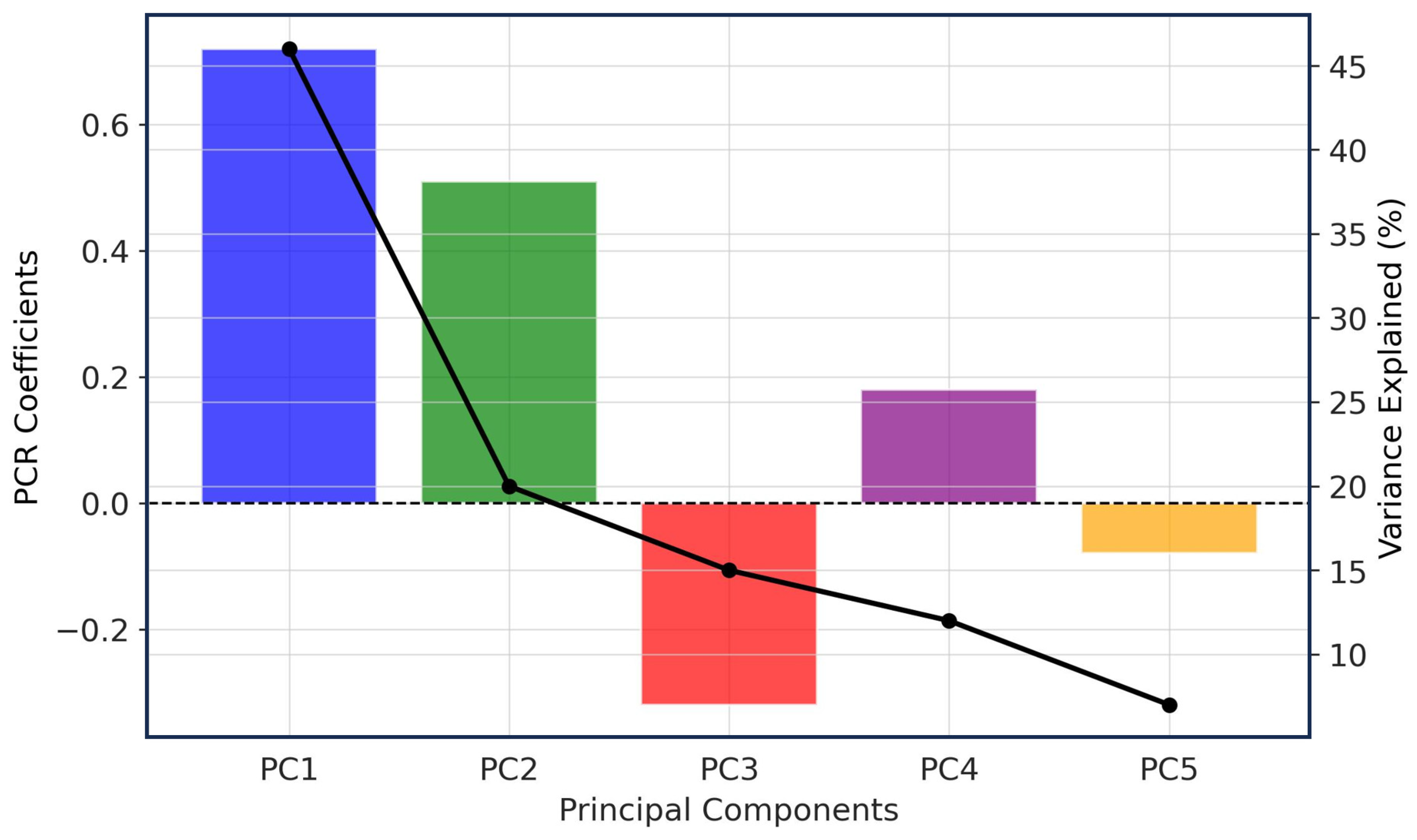

5.2. Analysis of Principal Component Through Sensitivity Analysis for Unconfined Compressive Strength

Analysis of Principal Component Loadings in Soil Stabilization

5.3. Principal Component Regression Sensitivity Analysis for Unconfined Compressive Strength

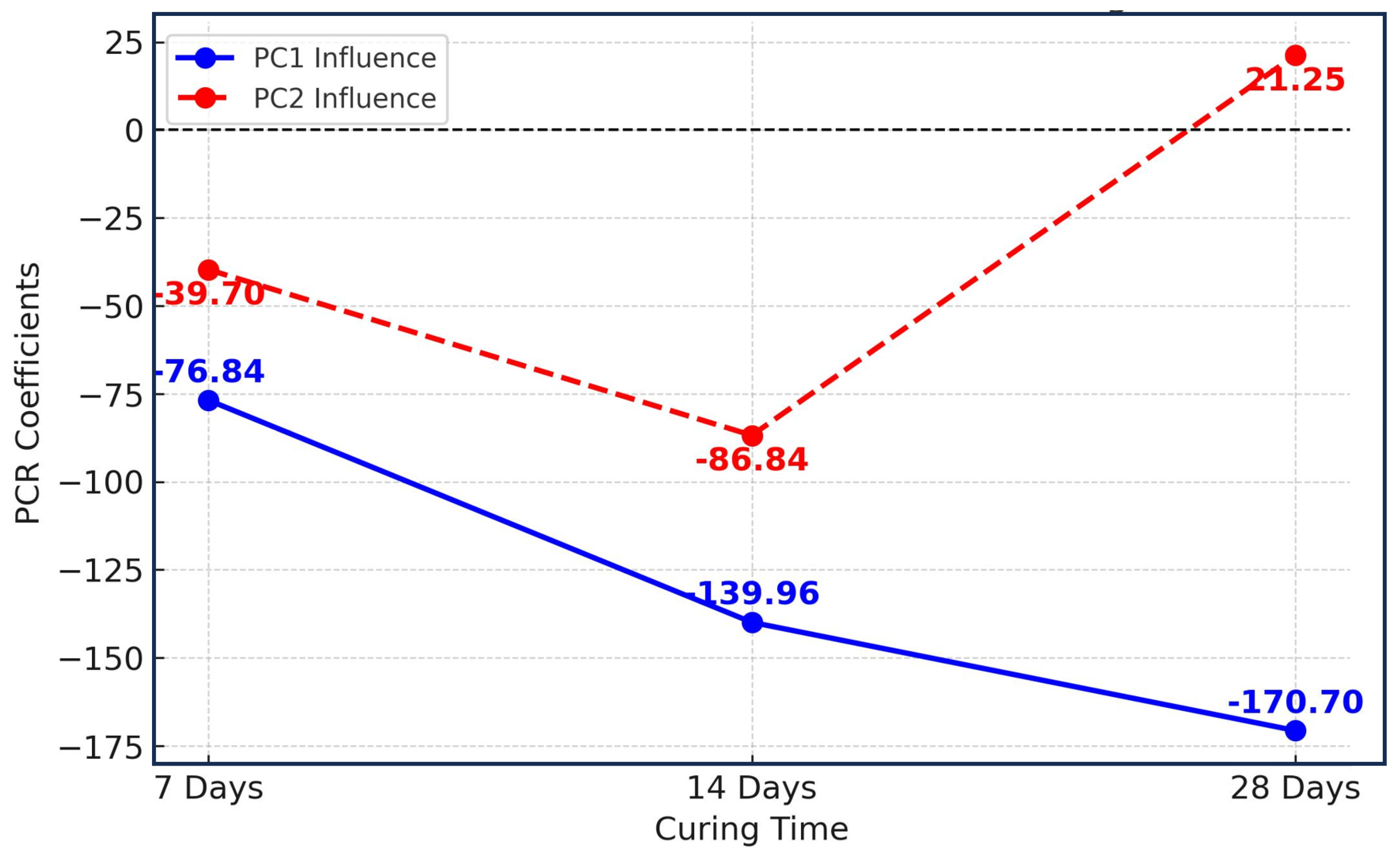

5.4. Causality Analysis Using Principal Component Regression (PCR)

6. Conclusions

- The combination of 6% cement and 15% lime (by dry soil weight) yielded maximum improvements: UCS increased by 222.5% to 2670 kPa at 28 days, void ratio decreased by 58% to 0.25, porosity decreased by 49.5% to 0.19, pre-consolidation stress increased by 206% to 1088.92 kPa, and the compression index decreased by 58% to 0.20, and the compressibility modulus increased by 16% to 10,474.28 kPa compared to untreated soil (779 kPa UCS, 0.60 void ratio, 0.38 porosity, 355.63 kPa preconsolidation stress, 0.48 compression index, and 7048 kPa compressibility modulus).

- A single principal component (PC1) explained the vast majority of variance in key consolidation parameters: 90.33% for void ratio, 98.32% for porosity, 99.32% for pre-consolidation stress, 99.75% for compression index, and 99.89% for compressibility modulus. This overwhelmingly indicates that the combined lime and cement stabilizer content is the primary driver of microstructural modification and densification, with secondary factors contributing minimally.

- The PCR model achieved an R2 of 0.700 and an RMSE of 103.4 kPa for UCS prediction. The PCR causality model showed marked improvement in predictive accuracy with curing time, with R2 increasing from 0.687 at 7 days to 0.830 at 28 days, while RMSE decreased from 11.2 kPa to 7.8 kPa. Sensitivity analysis identified soil compressibility characteristics (PC1: void ratio, porosity, compression index) as the dominant influence on UCS (46% variance explained, β = −170.70 at 28 days), with its negative effect intensifying progressively from β = −76.84 at 7 days to β = −170.70 at 28 days, confirming that reduced compressibility is the primary causal mechanism for strength gain.

- The most significant UCS gain occurred between 7 and 14 days under optimal stabilization (15% lime, 6% cement), increasing by 40.4% (1584.62 kPa to 2250.42 kPa), compared to only an 18.5% increase from 14 to 28 days (2250.42 kPa to 2670 kPa). Concurrently, the PCR model’s explanatory power (R2) improved from 68.7% at 7 days to 83.0% at 28 days, indicating that soil-stabilizer interactions become more deterministic and predictable with extended curing.

- Resistance to strength loss, evaluated after 7 days of soaking following 7 days of curing compared to 14-day cured strength, increased substantially from only 9% for untreated soil to 76% for soil stabilized with the optimal combination (15% lime, 6% cement). This demonstrates the effectiveness of the formed cementitious bonds (C-S-H, C-A-H gels) in creating a water-resistant soil matrix with enhanced long-term performance under adverse environmental conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, J.; Xie, H.; Li, C.; Liu, Y. Deep Learning-Based Reconstruction of 3D Morphology of Geomaterial Particles from Single-View 2D Images. Materials 2024, 17, 5100. [Google Scholar] [CrossRef] [PubMed]

- Arias-Jaramillo, Y.P.; Gómez-Cano, D.; Carvajal, G.I.; Hidalgo, C.A.; Muñoz, F. Evaluation of the Effect of Binary Fly Ash-Lime Mixture on the Bearing Capacity of Natural Soils: A Comparison with Two Conventional Stabilizers Lime and Portland Cement. Materials 2023, 16, 3996. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, A.; Idris, A.; Umar, I.; Lin, H.; Shehu, H. Enhanced bearing capacity prediction using hybrid tree-based ensemble learning with advanced meta-heuristic optimization. Eng. Res. Express 2025, 7, 015113. [Google Scholar] [CrossRef]

- Umar, I.; Abubakar, S.; Lin, H.; Hassan, J. Metakaolin as a soil stabilizing admixture: A comprehensive analysis of California bearing ratio and consolidation behavior using experimental and machine learning approaches. Earth Sci. Inform. 2025, 18, 200. [Google Scholar] [CrossRef]

- Elhaik, E. Principal Component Analyses (PCA)-based findings in population genetic studies are highly biased and must be reevaluated. Sci. Rep. 2022, 12, 14683. [Google Scholar] [CrossRef]

- Anowar, F.; Sadaoui, S.; Selim, B. Conceptual and empirical comparison of dimensionality reduction algorithms (PCA, KPCA, LDA, MDS, SVD, LLE, ISOMAP, LE, ICA, t-SNE). Comput. Sci. Rev. 2021, 40, 100378. [Google Scholar] [CrossRef]

- Pan, J.; Lin, H.; Wu, J.; Zeng, L. An innovative GWO-BiLSTM model for predicting the advance rates of double-line subway shield tunneling with TBM. Arch. Civ. Mech. Eng. 2025, 25, 163. [Google Scholar] [CrossRef]

- Panchbhai, K.G.; Lanjewar, M.G.; Naik, A.V. Modified MobileNet with leaky ReLU and LSTM with balancing technique to classify the soil types. Earth Sci. Inform. 2024, 18, 77. [Google Scholar] [CrossRef]

- Malashin, I.; Tynchenko, V.; Gantimurov, A.; Nelyub, V.; Borodulin, A. Applications of Long Short-Term Memory (LSTM) Networks in Polymeric Sciences: A Review. Polymers 2024, 16, 2607. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Moghal, A.A.B.; Ebid, A.; Rehman, A.U.; Hanandeh, S.; Priyan, V. Estimating the strength of soil stabilized with cement and lime at optimal compaction using ensemble-based multiple machine learning. Sci. Rep. 2024, 14, 15308. [Google Scholar] [CrossRef]

- Ahmed, S.A.K.; Vakili, A.H.; Keskin, I.; Onur, M.I. A state-of-the-art review on the dynamic characteristics of untreated and treated soils by traditional, recycled, and sustainable stabilizers. Transp. Geotech. 2024, 49, 101430. [Google Scholar] [CrossRef]

- Liu, H.; Su, H.; Sun, L.; Dias-Da-Costa, D. State-of-the-art review on the use of AI-enhanced computational mechanics in geotechnical engineering. Artif. Intell. Rev. 2024, 57, 196. [Google Scholar] [CrossRef]

- Jeremiah, J.J.; Abbey, S.J.; Booth, C.A.; Kashyap, A. Results of Application of Artificial Neural Networks in Predicting Geo-Mechanical Properties of Stabilised Clays—A Review. Geotechnics 2021, 1, 147–171. [Google Scholar] [CrossRef]

- Umar, I.H.; Firat, M.E.O. A Study on Uniaxial Compressive Strength and Ultrasonic Non-Destructive Analysis of Fine-Grained Soil in Seasonally Frozen Regions. Turk. J. Sci. Technol. 2022, 17, 267–277. [Google Scholar] [CrossRef]

- Baldovino, J.d.J.A.; Palma Calabokis, O.; Saba, M. From Bibliometric Analysis to Experimental Validation: Bibliometric and Literature Review of Four Cementing Agents in Soil Stabilization with Experimental Focus on Xanthan Gum. Sustainability 2024, 16, 5363. [Google Scholar] [CrossRef]

- ASTM D24872018; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM: West Conshohocken, PA, USA, 2018; pp. 125–133.

- ASTM D422-632018; Standard Test Method for Particle-Size Analysis of Soils. ASTM: West Conshohocken, PA, USA, 2018.

- ASTM D4318-002018; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM: West Conshohocken, PA, USA, 2018.

- ASTM D8542023; Standard Test Methods for Specific Gravity of Soil Solids by the Water Displacement Method. ASTM: West Conshohocken, PA, USA, 2023.

- ASTM D2166-062010; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM: West Conshohocken, PA, USA, 2010.

- ASTM D2435M-11(2020); Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM D698-122021; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D7263-212021; Standard Test Methods for Laboratory Determination of Density and Unit Weight of Soil Specimens. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D2216-192019; Standard Test Methods for Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass. ASTM: West Conshohocken, PA, USA, 2019.

- Tang, T.M.; Allen, G.I. Integrated Principal Components Analysis. J. Mach. Learn. Res. 2021, 22, 1–71. [Google Scholar]

- Perrin, T.V.E.; Roustant, O.; Rohmer, J.; Alata, O.; Naulin, J.; Idier, D.; Pedreros, R.; Moncoulon, D.; Tinard, P. Functional principal component analysis for global sensitivity analysis of model with spatial output. Reliab. Eng. Syst. Saf. 2021, 211, 107522. [Google Scholar] [CrossRef]

- Umar, I.H.; Lin, H.; Ibrahim, A.S. Laboratory Testing and Analysis of Clay Soil Stabilization Using Waste Marble Powder. Appl. Sci. 2023, 13, 9274. [Google Scholar] [CrossRef]

- Lee, G.; Sim, E.; Yoon, Y.; Lee, K. Probabilistic orthogonal-signal-corrected principal component analysis. Knowl.-Based Syst. 2023, 268, 110473. [Google Scholar] [CrossRef]

- Greenacre, M.; Groenen, P.J.F.; Hastie, T.; D’Enza, A.I.; Markos, A.; Tuzhilina, E. Principal component analysis. Nat. Rev. Methods Prim. 2022, 2, 100. [Google Scholar] [CrossRef]

- Ji, Y.; Fu, J.; Lu, Y.; Liu, B. Three-dimensional-based global drought projection under global warming tendency. Atmos. Res. 2023, 291, 106812. [Google Scholar] [CrossRef]

- Iliyas, S.; Idris, A.; Umar, I.H.; Lin, H.; Muhammad, A.; Xie, L. Experiment and Analysis of Variance for Stabilizing Fine-Grained Soils with Cement and Sawdust Ash as Liner Materials. Materials 2024, 17, 2397. [Google Scholar] [CrossRef]

- Laouidji, Z.; Boutlikht, M.; Douadi, A.; Hebbache, K.; Atiki, E.; Belebchouche, C.; Moretti, L.; Czarnecki, S. Exploring the Effect of Lime and Cement Ratios on the Mechanical Properties of Clay Bricks Made from Different Types of Soils. Buildings 2025, 15, 631. [Google Scholar] [CrossRef]

- Parhizkar, A.; Nazarpour, A.; Khayat, N. Investigation of geotechnical and microstructure characteristics of gypsum soil using ground granulated blast-furnace slag (GGBS), fly ash, and lime. Constr. Build. Mater. 2024, 418, 135358. [Google Scholar] [CrossRef]

- Qureshi, L.A.; Ali, B.; Ali, A. Combined effects of supplementary cementitious materials (silica fume, GGBS, fly ash and rice husk ash) and steel fiber on the hardened properties of recycled aggregate concrete. Constr. Build. Mater. 2020, 263, 120636. [Google Scholar] [CrossRef]

- Khan, S.U.; Nuruddin, M.F.; Ayub, T.; Shafiq, N. Effects of different mineral admixtures on the properties of fresh concrete. Sci. World J. 2014, 2014, 986567. [Google Scholar] [CrossRef]

- Banu, S.A.; Attom, M.F. Effect of Curing Time on Lime-Stabilized Sandy Soil against Internal Erosion. Geosciences 2023, 13, 102. [Google Scholar] [CrossRef]

- Boukhatem, G.; Bencheikh, M.; Benzerara, M.; Anas, S.M.; Sabri, M.M.; Najm, H.M. Optimizing properties of clayey soil using lime and waste marble powder: A sustainable approach for engineering applications. Front. Mater. 2024, 11, 1392875. [Google Scholar] [CrossRef]

- Hasan, H.; Dang, L.; Khabbaz, H.; Fatahi, B. Swelling pressure and consolidation of soft clay stabilized with bagasse ash and lime. In Proceedings of the 10th International Conference on the Bearing Capacity of Roads, Railways and Airfields (BCRRA 2017), Athens, Greece, 28–30 June 2017; pp. 1069–1075. [Google Scholar]

- Abu Talib, M.K.; Yasufuku, N.; Ishikura, R. Effects of sugarcane bagasse ash (SCBA) on the strength and compressibility of cement stabilized peat. Lowl. Technol. Int. 2015, 17, 73–82. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, W.; Fan, W.; Liu, D. The effect of polyvinyl alcohol solution with a high degree of alcoholysis on the expansion and cracking behaviour of quicklime-treated soil in earthen sites. Bull. Eng. Geol. Environ. 2021, 80, 4159–4170. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, W.; Han, N.; Cai, T.; Du, Y. Feasibility of Polyvinyl Alcohol-Treated Soil in a Mud State as the Anti-Weathering Material for Earthen Sites. Int. J. Arch. Heritage 2021, 17, 486–499. [Google Scholar] [CrossRef]

- Oshioname, E.A.; Paul, Y.; Mustapha, A.; Abdullahi, A.-A. Consolidation Characteristics of Lateritic Soil Treated with Rice Husk Ash. Malays. J. Civ. Eng. 2022, 34, 19–28. [Google Scholar] [CrossRef]

- Mohamed, A.A.M.S.; Yuan, J.; Al-Ajamee, M.; Dong, Y.; Ren, Y.; Hakuzweyezu, T. Improvement of expansive soil characteristics stabilized with sawdust ash, high calcium fly ash and cement. Case Stud. Constr. Mater. 2023, 18, e01894. [Google Scholar] [CrossRef]

- Khankhaje, E.; Jang, H.; Kim, J.; Rafieizonooz, M. Utilizing rice husk ash as cement replacement in pervious concrete: A review. Dev. Built Environ. 2025, 22, 100675. [Google Scholar] [CrossRef]

- Anvar, A.; Said, S.; Kadir, U.; Ilkhom, K. Some Peculiarities of the Process of Preparing the Zeolites Containing Breeds in a Ball Mill. Int. J. Recent Technol. Eng. 2019, 8, 7695–7698. [Google Scholar] [CrossRef]

- Lone, I.J.; Joia, P.S. Soil Stabilization of Black Cotton Soil Using Lime and Wood Ash. Int. Res. J. Eng. Technol. 2022, 9, 1111–1117. [Google Scholar]

- Olaiya, B.C.; Lawan, M.M.; Olonade, K.A. Utilization of sawdust composites in construction—A review. SN Appl. Sci. 2023, 5, 140. [Google Scholar] [CrossRef]

- Seghir, N.T.; Mellas, M.; Sadowski, Ł.; Żak, A. Effects of marble powder on the properties of the air-cured blended cement paste. J. Clean. Prod. 2018, 183, 858–868. [Google Scholar] [CrossRef]

- Alyamaç, K.; Aydin, A. Concrete properties containing fine aggregate marble powder. KSCE J. Civ. Eng. 2015, 19, 2208–2216. [Google Scholar] [CrossRef]

- Ramzi, S.; Hajiloo, H. The Effects of Supplementary Cementitious Materials (SCMs) on the Residual Mechanical Properties of Concrete after Exposure to High Temperatures—Review. Buildings 2023, 13, 103. [Google Scholar] [CrossRef]

- Umar, I.H.; Muhammad, A.; Ahmad, A.; Yusif, M.A.; Yusuf, A. Suitability of Geotechnical Properties of Bentonite-Bagasse Ash Mixtures Stabilized Lateritic Soil as Barrier in Engineered Waste Landfills. In Proceedings of the 7th International Student Symposium, Samsun, Turkey, 1–3 October 2021; Ondokuz Mayiz University: Samsun, Turkey, 2021. [Google Scholar]

- Güllü, H.; Yetim, M.; Güllü, E. On the rheological, fresh and strength effects of using nano-silica added geopolymer grout for grouting columns. Eur. J. Environ. Civ. Eng. 2023, 28, 1183–1207. [Google Scholar] [CrossRef]

- Güllü, H.; Yetim, M.E.; Güllü, E.B. Effect of using nano-silica on the rheological, fresh and strength characteristics of cement-based grout for grouting columns. J. Build. Eng. 2023, 76, 107100. [Google Scholar] [CrossRef]

- Thomas, G.; Kodi, R. Strengthening of cement blended soft clay with nano-silica particles. Geomech. Eng. 2020, 20, 505–516. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Karimiazar, J.; Teshnizi, E.S.; Arjmandzadeh, R.; Bahmani, S.H. Effect of Nano-Additives on the Strength and Durability Characteristics of Marl. Minerals 2021, 11, 1119. [Google Scholar] [CrossRef]

- Bayat, M. Nanomaterials in Geotechnical Engineering: A Comprehensive Review on Soil Improvement Techniques. Civ. Eng. Infrastruct. J. 2025. [Google Scholar] [CrossRef]

- Uddin, M.N.; Hossain, M.T.; Mahmud, N.; Alam, S.; Jobaer; Mahedi, S.I.; Ali, A. Research and applications of nanoclays: A review. SPE Polym. 2024, 5, 507–535. [Google Scholar] [CrossRef]

- Changizi, F.; Haddad, A. Application of Nano Materials in Improving Geotechnical Properties of Soils: A Review Study. J. Rehabil. Civ. Eng. 2023, 11, 138–158. [Google Scholar] [CrossRef]

- Turan, C.; Javadi, A.A.; Vinai, R. Effects of Class C and Class F Fly Ash on Mechanical and Microstructural Behavior of Clay Soil—A Comparative Study. Materials 2022, 15, 1845. [Google Scholar] [CrossRef]

- Magara, D.; She, H. A Systematic Review of the Effects of Soil Stabilization on Soil Mechanical Properties: A Comparative Study of Fly Ash, Cement and Lime. Open Access Libr. J. 2024, 11, 1–19. [Google Scholar] [CrossRef]

- Ramanujam, I.V.R.; Reddy, K.R.; Ramana, N.V. Evaluation of Pozzolanic activity and lime reactivity of fly ash, GGBS, mica powder and pumice as binders. E3S Web Conf. 2024, 529, 01008. [Google Scholar] [CrossRef]

- Darsi, B.P.; Molugaram, K.; Madiraju, S.V.H. Subgrade Black Cotton Soil Stabilization Using Ground Granulated Blast-Furnace Slag (GGBS) and Lime, an Inorganic Mineral. Environ. Sci. Proc. 2021, 6, 15. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part B Eng. 2018, 164, 179–190. [Google Scholar] [CrossRef]

- Phoon, K.-K.; Cao, Z.-J.; Ji, J.; Leung, Y.F.; Najjar, S.; Shuku, T.; Tang, C.; Yin, Z.-Y.; Ikumasa, Y.; Ching, J. Geotechnical uncertainty, modeling, and decision making. Soils Found. 2022, 62, 101189. [Google Scholar] [CrossRef]

- Efaw, C.M.; Wu, Q.; Gao, N.; Zhang, Y.; Zhu, H.; Gering, K.; Hurley, M.F.; Xiong, H.; Hu, E.; Cao, X.; et al. Localized high-concentration electrolytes get more localized through micelle-like structures. Nat. Mater. 2023, 22, 1531–1539. [Google Scholar] [CrossRef]

- Khanmohammadi, M.; Sadrara, M. Application of principal component analysis–multivariate adaptive regression splines for the determination of surface area in zeolites. J. Chemom. 2022, 37, e3431. [Google Scholar] [CrossRef]

- Sala, L.T.; Nwaogazie, I.L.; Ugbebor, J.N.; Inyang, U.J.; Onofeghara, C.O.; Fowode, K.V.; Ozobu, C.O.; Eyenike, N. Application of Sensitivity & Principal Component Analyses for Modelling of Safety Parameters for Oil & Gas Companies in Niger Delta. Asian J. Probab. Stat. 2025, 27, 97–111. [Google Scholar] [CrossRef]

- Sharbaf, M.A.M.J.; Abedini, M.J. Implementation of supervised principal component analysis for global sensitivity analysis of models with correlated inputs. Stoch. Environ. Res. Risk Assess. 2022, 36, 2789–2818. [Google Scholar] [CrossRef] [PubMed]

- Suvarnapathaki, S. Use of Principal Component Analysis in Regression Problem. Int. J. Res. Anal. Rev. 2023, 10, 125–135. [Google Scholar] [CrossRef]

- Kawano, S.; Fujisawa, H.; Takada, T.; Shiroishi, T. Sparse principal component regression for generalized linear models. Comput. Stat. Data Anal. 2018, 124, 180–196. [Google Scholar] [CrossRef]

| Property | Soil | Lime | Cement |

|---|---|---|---|

| General Properties | |||

| Color | Brown | White | – |

| Specific Gravity | 2.53 | 2.36 | 3.13 |

| pH | 5.31 | 12.1 | 13 |

| Composition/Gradation | |||

| Gravel/Sand/Silt + Clay (%) | 0/25.9/74.1 | – | – |

| Dominant Clay Mineral | Montmorillonite | – | – |

| Engineering Properties | |||

| Liquid Limit/Plastic Limit/Plasticity Index/Linear Shrinkage/Free Swelling (%) | 66/24/42/18.52/71.1 | – | – |

| Optimum Moisture (%)/Max Dry Density (kN/m3) | 21/16.7 | – | – |

| UCS (kPa) | 0.779 | – | 29.1 (3 days) |

| CBR (unsoaked, %) | 8.2 | – | – |

| Material-Specific Properties | |||

| USCS Classification | CH | – | – |

| Melting point/Boiling point (°C) | – | 2547/2894 | – |

| Fineness (µm) | – | 368 | 362 |

| Setting Time (min) | – | – | 33.4 (Initial)/242 (Final) |

| Bulk Density (kg/m3) | – | 555 | 1101 |

| Soundness (mm) | – | – | 0.38 |

| Chemical Constituent | Composition of Cement (%) | Composition of Lime (%) |

|---|---|---|

| SiO2 | 19.3 | 3.5 |

| Al2O3 | 3.67 | 1.25 |

| Fe2O3 | 3.44 | 1.14 |

| Na2O | 0.26 | |

| K2O | 0.78 | 0.09 |

| CaO | 62.62 | 50.5 |

| TiO2 | 0.597 | |

| PbO | 0 | |

| MgO | 3.39 | 1.21 |

| SO3 | 3.21 | |

| SrO2 | - | |

| P2O5 | 0.0897 | |

| NiO2 | - | |

| MnO | 0.237 | 0.05 |

| ZnO | - | |

| CuO | - | |

| Cr2O3 | - | |

| BaO | 0 | |

| Cl | 0.03 | |

| LOI | 2.38 | 42.32 |

| Principal Component | Regression Coefficient | Variance Contribution (%) | Sensitivity Ranking |

|---|---|---|---|

| PC1 (soil compressibility) | 0.72 | 46% | High Sensitivity |

| PC2 (modulus vs. pre-consolidation stress) | 0.51 | 20% | Moderate Sensitivity |

| PC3 (pre-consolidation stress) | −0.32 | 15% | Low Sensitivity |

| PC4 (porosity and compression index) | 0.18 | 12% | Minor Impact |

| PC5 (void ratio and compression index) | −0.08 | 7% | Negligible Impact |

| Curing Time | R2 (Model Fit) | Significant Principal Components (p < 0.05) | Most Influential Factor |

|---|---|---|---|

| 7 Days | 0.687 (68.7%) | PC1 (−76.84, p < 0.001) | Soil Compressibility and Porosity |

| 14 Days | 0.688 (68.8%) | PC1 (−139.96, p < 0.001) | Porosity and Stiffness |

| 28 Days | 0.830 (83.0%) | PC1 (−170.70, p < 0.001) | Soil Strength and Compaction |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Umar, I.H.; Tarauni, Z.A.; Bello, A.B.; Lin, H.; Hassan, J.I.; Cao, R. Performance Prediction and Optimization of High-Plasticity Clay Lime–Cement Stabilization Based on Principal Component Analysis and Principal Component Regression. Appl. Sci. 2025, 15, 7150. https://doi.org/10.3390/app15137150

Umar IH, Tarauni ZA, Bello AB, Lin H, Hassan JI, Cao R. Performance Prediction and Optimization of High-Plasticity Clay Lime–Cement Stabilization Based on Principal Component Analysis and Principal Component Regression. Applied Sciences. 2025; 15(13):7150. https://doi.org/10.3390/app15137150

Chicago/Turabian StyleUmar, Ibrahim Haruna, Zaharaddeen Ali Tarauni, Abdullahi Balarabe Bello, Hang Lin, Jubril Izge Hassan, and Rihong Cao. 2025. "Performance Prediction and Optimization of High-Plasticity Clay Lime–Cement Stabilization Based on Principal Component Analysis and Principal Component Regression" Applied Sciences 15, no. 13: 7150. https://doi.org/10.3390/app15137150

APA StyleUmar, I. H., Tarauni, Z. A., Bello, A. B., Lin, H., Hassan, J. I., & Cao, R. (2025). Performance Prediction and Optimization of High-Plasticity Clay Lime–Cement Stabilization Based on Principal Component Analysis and Principal Component Regression. Applied Sciences, 15(13), 7150. https://doi.org/10.3390/app15137150