1. Introduction

Maintenance 4.0, as an important part of the digital transformation in the textile industry, plays a critical role in increasing the efficiency and sustainability of production processes. Thanks to the integration of technologies such as the Internet of Things (IoT), big data analytics, and artificial intelligence, machine failures can be predicted in advance, and unplanned downtimes are minimized. This both reduces production costs and increases competitiveness by increasing quality. It also contributes to environmental sustainability, with positive effects on energy consumption and resource use. In a sector such as textiles, which requires intensive machine use, Maintenance 4.0 applications offer a strategic advantage in terms of production continuity and business performance.

The concepts of sustainability and digitalization are encountered in the manufacturing industry, as in every field. The optimum use of limited resources has become one of the most fundamental policies of nations, countries, and companies. While businesses develop production and management policies that consider sustainability in terms of environmental and social impacts and sustainability, they are trying to lay the foundations of Industry 4.0 with digitalization [

1,

2]. Industry 4.0 has entered our lives with the application of digital technologies such as the Internet of Things (IoT), cyber–physical systems (CPS), artificial intelligence (AI), virtual reality (VR), augmented reality (AR), and big data analysis (BDA) in the manufacturing sector [

3,

4,

5].

Ensuring the continuity of production activities without interruptions or delays is of critical importance. The advent of Industry 4.0 technologies has necessitated the adoption of innovative approaches to maintenance operations. Maintenance 4.0 aims to enable failure prediction, optimize resource utilization, and establish continuously improving maintenance systems [

6,

7]. Survival in a highly competitive environment is closely linked to the uninterrupted operation of production processes. An effective maintenance policy enables cost-effective production and enhances customer satisfaction without compromising quality or quantity [

8]. Maintenance 4.0 applications—where physical systems are synchronized with the virtual world through the integration of computers and technological devices—are a subset of Industry 4.0. These applications involve automated data collection, data analysis, and intelligent decision-making systems [

1,

9]. In today’s volatile and uncertain market environment, implementing a technically and administratively sound maintenance plan and management strategy is a highly complex process for businesses. Such a long-term strategic plan supports businesses in addressing the economic, environmental, and social dimensions underpinning the principle of sustainability [

10,

11,

12].

The periodic maintenance of machines is a critical factor across all industries. It ensures the optimal functioning of machinery and equipment, minimizes the risk of unexpected downtime and emergency repairs, reduces workplace accident risks, extends the lifespan of assets, and ensures compliance with safety and environmental standards. These goals are achieved through regular inspections, preventive and corrective actions, part replacements, and adjustments [

13,

14]. A substantial contribution to operational excellence can be achieved through the strategic integration of various maintenance approaches, including corrective, preventive, predictive, autonomous maintenance, and focused improvement initiatives. Corrective maintenance refers to the maintenance activities undertaken when a machine, component, equipment, or system experiences a malfunction. Its primary objective is to restore the affected asset to its normal operational condition. As the machine or system ceases to operate, it necessitates immediate intervention, often leading to increased maintenance and downtime-related costs. The affected equipment remains non-operational until the underlying issue is fully resolved [

15]. Preventive maintenance is a planned maintenance strategy carried out at certain intervals to keep machinery and equipment in an optimum working condition in order to prevent failures and to minimize the risk of breakdown time. Corrective actions and precautions are taken by focusing on potential problems before failure occurs. With this maintenance strategy, less idle time is spent, costs are lower, and equipment reliability is increased [

16]. Predictive maintenance is a maintenance strategy based on continuous monitoring of the conditions and performance of equipment and machinery and determining when maintenance is necessary. It is the identification of signs of wear or abnormalities before failures occur using data collected with the help of devices such as oil, vibration analysis, sensors, etc. Predictive maintenance allows for maintenance planning, when necessary, thus avoiding unnecessary interventions. This means preventing unnecessary stops and excessive interventions, thus helping to minimize costs [

17]. Autonomous maintenance is a maintenance strategy that involves machine operators in the process. In this maintenance strategy, operators are directly involved in the maintenance and repair of machines and are responsible for the operation of the equipment. Operators are responsible for the regular cleaning, lubrication, simple adjustments, and maintenance of machines and equipment. It is an approach that increases operational efficiency and reduces machine idle time [

18]. Specific improvement is the creation of a specific improvement strategy by creating multifunctional teams to eliminate chronic machinery and equipment problems and increase performance. It focuses on developing effective solutions that aim to obtain to the root causes of problems. Specific improvement is the activities that create a culture of cooperation within the organization, eliminate chronic problems, and extend equipment life span [

14].

To implement different maintenance policies within the company, some data needs to be collected. For Maintenance 4.0 applications, data collected from multiple data sources, such as sensors and the Internet of Things, are stored in cloud services and analyzed using artificial neural networks. As a result of these analyses, a Maintenance 4.0 policy is developed within the company [

19].

Compared to traditional methods, the use of linguistic assessments in the fuzzy approach enhances its reliability by better capturing the nuances of expert judgment. Among various fuzzy techniques, the Pythagorean Fuzzy method yields more precise and sensitive results, which contributes to its growing preference in contemporary decision-making applications. Moreover, its inclusion among recent methodological advancements reinforces its suitability for addressing complex evaluation problems.

Importantly, this method incorporates the three fundamental components of uncertainty: membership, non-membership, and hesitation degrees. To improve the realism and robustness of the hesitation measurement, it calculates hesitation by squaring the membership and non-membership values. This enhances the reliability of the derived scores and strengthens the overall score function, allowing for more accurate interpretations of expert opinions.

Additionally, the method supports more dependable sensitivity analysis by offering a solid mathematical foundation for evaluating the stability of results under varying expert weights. Its straightforward implementation, even in problems involving numerous criteria, further contributes to its selection. The combination of analytical rigor and practical simplicity makes the Pythagorean Fuzzy SWARA method both a reliable and user-friendly tool for multi-criteria decision-making.

Although businesses believe that Maintenance 4.0 applications are necessary and beneficial, it is obvious that the implementation rates of these policies are very low. Some barriers are encountered during the implementation of these policies. This study particularly addresses the barriers encountered in Maintenance 4.0 applications in the textile industry, which is the one of the largest industries in Turkey [

20]. The main reason for choosing the textile industry is that it is a labor-intensive industry. The fact that workers are not highly qualified and that workers are fatigued due to long working hours increases the potential for workers to make mistakes, which inevitably results in damage to machines. In the second part of this study, a literature review was conducted on the subject, while in the third part, the identified barriers and the method used were introduced. In the fourth part, its application was performed in textile factories operating in Istanbul, and in the fifth part, the results obtained from the application were evaluated. In the final part, the difficulties encountered in this study and the potential for future studies were discussed.

2. Literature Review

In this section, many studies conducted in the literature within the scope of Maintenance 4.0 and the method used are summarized.

According to the search results made with the keywords “Maintenance 4.0” and “barriers” in the Web of Science database on 4 May 2025, four articles were found. Naik and Kirkire conducted a study to identify the barriers to the implementation of Maintenance 4.0 in manufacturing industries, categorize these identified barriers, rank the barriers according to their priorities, and suggest the digital technologies required to overcome these barriers [

1]. James and his colleagues also conducted a study to identify and analyze the challenges faced in implementing the Maintenance 4.0 concept in industries. They collected the opinions of academics and industry experts through a survey study. As a result of their study, “technician skill challenges”, “cybersecurity challenges”, and “IoT application challenges” were determined to be the primary challenges [

13]. El Kihel and his colleagues have worked to create a methodology for the implementation of Maintenance 4.0 with the data obtained as a result of digitalization and digitization. The main purpose of this methodology is to minimize downtime, optimize energy consumption, and increase the utilization rate and life of machines. As a result of this methodology, difficult workloads and risks are reduced by technologies, such as the digitalization of maintenance documents (procedures, risk prevention, machine history) and the rapid detection of machine failures [

19]. In their study conducted in 2024, Samadhiya and his colleagues provided the integration of Industry 4.0 to ensure sustainability in total productive maintenance applications. It aimed to determine and prioritize the main drivers of total productive maintenance. As a result, it was determined that Industry 4.0 came first among the main drivers, followed by senior management support and the formal Industry 4.0 adoption program [

21].

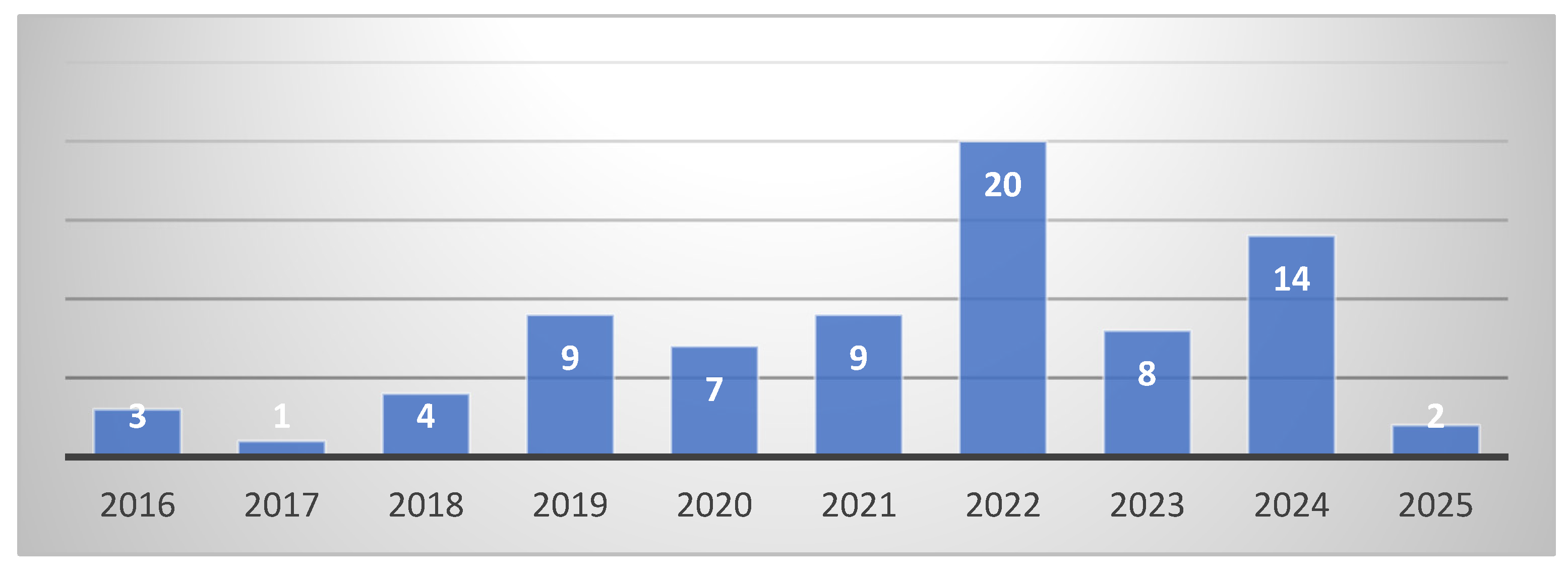

Since very few articles were reached because of the determined keywords, the word barrier was removed from the keywords, and a new search was conducted only for the keyword Maintenance 4.0. 77 studies were conducted on Maintenance 4.0 between 2016 and 2025. The distribution of publications by year is given in

Figure 1. Of these publications, 40 are articles, 3 are early access, 1 is a book chapter, 32 are proceeding papers, 8 are review articles and 1 is editorial material.

Benhamza Hlihel and his colleagues developed a Maintenance 4.0 competency model that can be applied to all sectors in their study conducted in 2024. The Maintenance 4.0 competency model has three hierarchical levels: managers, engineers, and technicians. The determined competencies are organized according to four categories: technical, personal, social, and methodological. As a result of the study, basic competencies were determined for Maintenance 4.0 stakeholders [

23].

In a study conducted on the railway industry, data on the operating conditions of a high-speed bogie were collected and analyzed using Industry 4.0 tools. The data collected allowed for the creation of indicators corresponding to abnormalities in a train’s behavior [

24]. In their study, Di Nardo and his colleagues developed a fixed maintenance program using Industry 4.0 tools such as artificial intelligence, machine learning, big data analytics, the Internet of Things, and predictive analytics. This research contributes to the development of the Maintenance 4.0 concept by closing the gap between theory and practice [

25]. Another study investigated the integration of Maintenance 4.0 in heating, ventilation, and air conditioning (HVAC) systems. With the help of tools such as artificial intelligence and the Internet of Things, it identified the obstacles and difficulties encountered in Maintenance 4.0 applications in HVAC systems [

26]. In a study conducted in 2020, smart and sustainable maintenance was addressed from three different perspectives. The first of these is the historical perspective, which addresses the evolution of the maintenance approach. The second is the development perspective, which provides historical perspectives on maintenance data and data-driven maintenance technology. The last is the maintenance technology perspective, which addresses the dimensions of sustainable development and potential opportunities together [

27]. In a study conducted on the chemical fertilizer industry, the Best Worst Method and Proximity Index Value methods were used in the selection of predictive maintenance suppliers to digitalize predictive maintenance. The weights of the supplier criteria determined by a literature review were calculated with BWM, and the final ranking of the suppliers was based on the overall proximity values obtained using the PIV method [

28].

Although there are studies on Maintenance 4.0 applications, it is obvious that the subject is still new and not sufficiently studied. It is important to develop and implement models for Maintenance 4.0 applications, especially for different industries.

It is important to determine the barriers that may be encountered in Maintenance 4.0 applications in businesses and their importance levels. At this point, businesses faced with the decision-making process should analyze which criteria they will focus on and how they will propose a solution to these criteria. Human beings are in a decision-making process at every step of their lives. Sometimes they make efforts to determine the right choices by using instinctive and sometimes scientific methods. Multi-criteria decision-making (MCDM) problems and solution methods are also among the subjects that researchers often work on. Fuzzy sets are also used to eliminate the uncertainties experienced especially in the decision-making process.

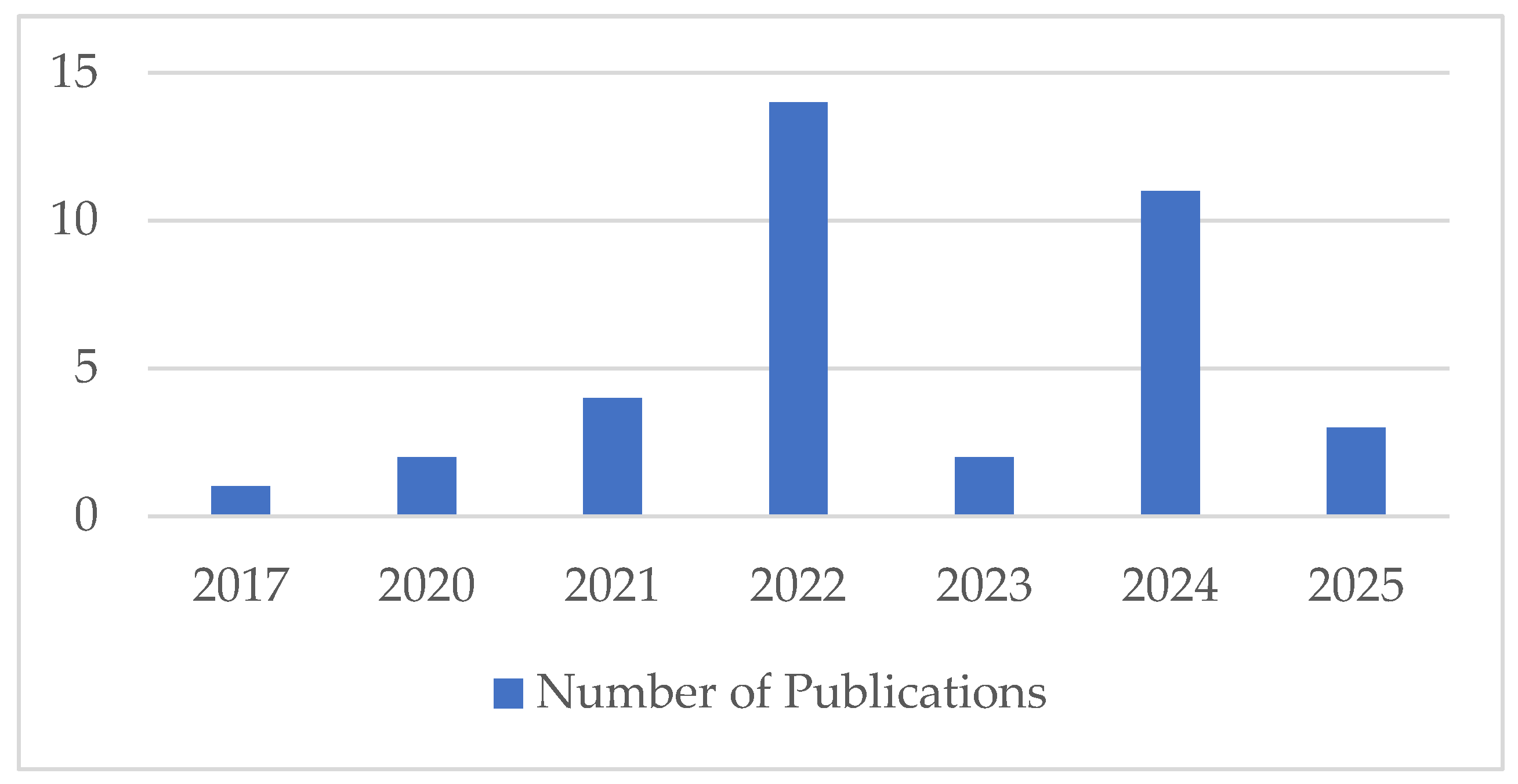

There are many methods developed to determine the criteria by which a decision will be made in decision-making problems and the relative importance levels of these criteria. One of these methods is the SWARA method. As a result of the search made with the keywords “SWARA” and “Pythagorean” in the Web of Science database on 10 May 2025, 39 studies were found. All of these studies are articles published in different scientific journals. The distribution of publications obtained according to these keywords by year is shown in

Figure 2.

In 2024, Pandey and Khurana used the hybrid SWARA–COmplex Proportional Assessment (COPRAS) method based on Pythagorean fuzzy numbers. In the study, solutions were developed to determine the risks encountered in Industry 4.0 applications and to reduce these risks. To determine the importance levels of the identified risks, the SWARA method based on Pythagorean fuzzy numbers was used, and after determining the weights of the risks, the solution suggestions developed using the COPRAS method based on Pythagorean fuzzy numbers were ranked [

30]. Rani et al. addressed the solar panel selection problem and used the SWARA-VlseKriterijumska Optimizcija i Kaompromisno Resenje (VIKOR) method based on Pythagorean fuzzy numbers to solve the problem. While the SWARA method was used to determine the subjective weights of the evaluation criteria, the VIKOR method was preferred to rank the alternatives [

31]. Another use of MCDM methods in different fields is in the evaluation of smart city waste management techniques. In a study conducted in India, the objective and subjective weights of the criteria to be used in the evaluation of smart city waste management techniques were determined using the MEthod based on the Removal Effects of Criteria (MEREC)–SWARA method based on Pythagorean fuzzy numbers. The Additive Ratio Assessment (ARAS) method was used in the ranking of alternatives [

32]. Studies on the subject are summarized in

Table 1.

4. Determination of Barriers in the Textile Industry

Initially, experts with relevant experience in Maintenance 4.0 were selected to participate in the evaluation process. Preference was given to individuals with demonstrable expertise in the field. A summary profile of these experts is presented in

Table 1.

Subsequently, a comprehensive literature review was carried out, supported by preliminary expert insights, to identify the criteria to be included in the study. The barriers associated with Maintenance 4.0 were determined based on this dual input from both the literature and expert opinions.

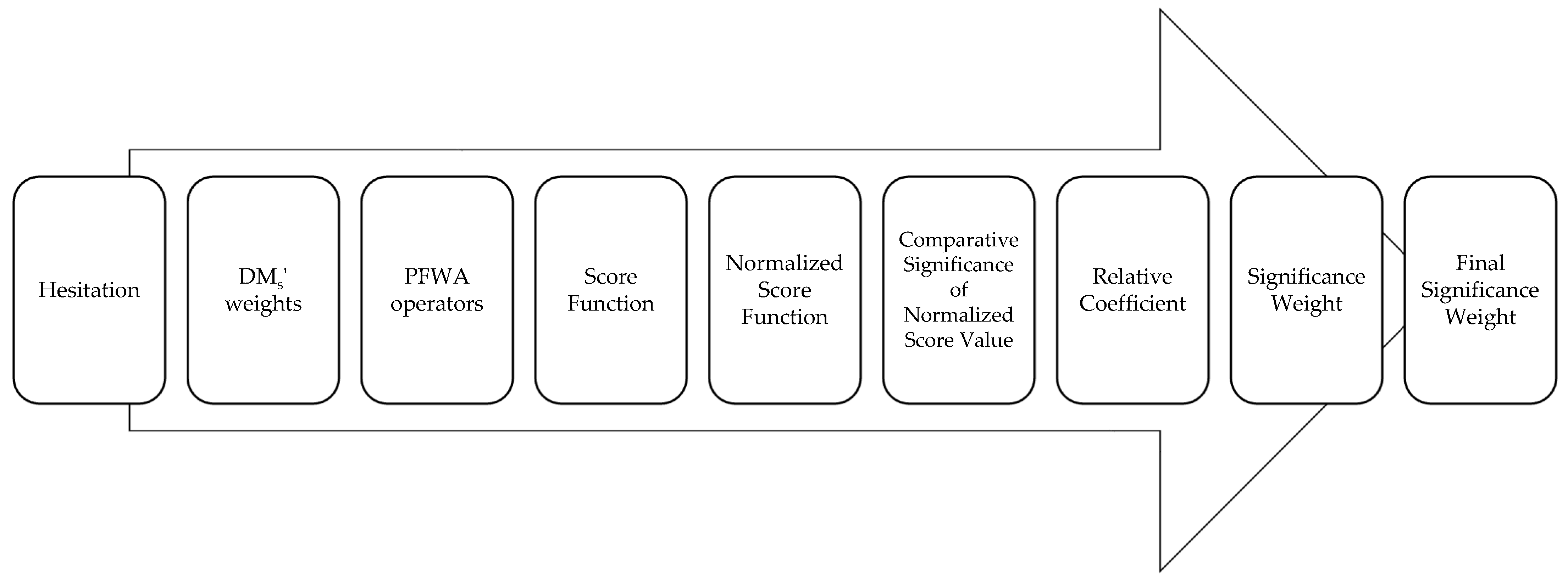

In the third phase, the Pythagorean Fuzzy SWARA method, which is capable of addressing the dimensions of truth, falsity, and indeterminacy independently, was employed. Following this, the linguistic variables used for the evaluations were clearly defined.

Decision-makers then assessed the criteria using these predefined linguistic terms. Drawing on their expertise and professional judgment, they evaluated the importance and impact of each criterion. This linguistic-based approach facilitates the standardization and comparability of inherently subjective assessments. To enhance the robustness of the analysis and reduce bias, additional validation techniques, such as sensitivity analysis, were employed to ensure the reliability of the assigned weights.

Next, individual evaluations were aggregated based on expert-specific weightings and then were subsequently transformed into a single representative value using normalization procedures.

Finally, the deneutrosophication process was conducted to translate the neutrosophic evaluations into crisp numerical values. The overall methodological framework of the study is depicted in

Figure 3.

Subsequently, the crisp values were obtained. The score function was calculated and then normalized. To determine the comparative significance of each score value, the normalized score function values were subtracted sequentially, meaning each value from the one that follows it. To find the relative coefficient, 1 was added to each comparative significance score. Finally, the significant and final significant weight values were calculated in sequence.

Maintenance 4.0 is an increasingly critical topic in today’s industrial landscape. However, as a relatively new concept, it brings certain challenges and ambiguities. Therefore, this study aims to highlight these barriers and determine their significance levels. It is believed that identifying these significance values will contribute to more meaningful and effective management of the related issues.

The assessments were applied by DM

s in the Maintenance 4.0. DM

s is illustrated in

Table 5. Considerable time was required both to identify suitable individuals for the evaluation and to ensure the completion of their assessments. Additionally, processing their inputs in the methodological framework was time-consuming. To enhance the reliability of the study, five DM

s were consulted during the application of fuzzy methods. The DM

s involved in this study are presented in

Table 5.

The general roles of the experts within the company are presented in

Table 6.

The textile sector was deliberately chosen for this study due to its exceptionally high level of human capital and its relevance as a dynamic and complex industry. This focus allows for in-depth, context-specific insights and provides a robust environment to test the proposed framework. The textile sector is particularly labor-intensive and employs a large number of workers. In addition to the high number of employees, the generally low level of qualifications among workers contributes to frequent errors. These errors often lead to both product- and machine-related problems. For this reason, the textile sector was selected for this study. A company utilizing advanced technology was chosen to conduct the research.

The aim of this study was to examine Maintenance 4.0 barriers within this sector and to demonstrate the feasibility of integrating Maintenance 4.0 strategies with Industry 4.0 technologies. Bursa, home to one of Turkey’s largest organized industrial zones, holds significant prominence in the textile industry and serves as a leading hub in this field. The sector was selected with the intention of setting a precedent for other industries and encouraging digital transformation and maintenance initiatives across different segments of the textile industry.

Since consultancy and training activities had previously been conducted with the DMs, their respective areas of expertise were already known. To enhance the efficiency of the study, the opinions of five DMs were collected. Five DMs currently working in the textile sector in Bursa participated in the study. Professionals with experience in both maintenance practices and technological implementation were purposefully chosen. The interviews were conducted face-to-face, and pairwise comparisons were performed using linguistic variables. Linguistic terms were utilized to enhance the clarity and precision of the assessments.

The methodology was explained with examples to ensure a clear understanding of the process. The scales and criteria used for evaluation were also introduced in detail. Additionally, a sensitivity analysis was introduced to verify the reliability of the weight assignments given to the DMs.

The primary objective of this study was to prioritize criteria through the use of the Pythagorean Fuzzy SWARA method.

This approach, recognized in the contemporary literature for its effectiveness, had not yet been applied to analyze Maintenance 4.0 barriers. It was selected for its robustness and ability to yield reliable, nuanced insights. The evaluations were carried out based on the linguistic scale provided in

Table 4. The implementation calculations of this study are demonstrated in

Figure 4.

The hesitation degree for Case 1 is calculated using Equation (3), as demonstrated in

Table 7. First, the decision-makers were evaluated in Equation (5), as shown in

Table 3. The evaluation table of the five decision-makers is presented in

Table 7. Once the hesitation values are determined, the importance weights of the DM

s are computed using Equation (6).

Subsequently, the linguistic evaluations of the decision-makers are presented in

Table 8, based on the linguistic scale provided in

Table 4.

The calculation of the criteria weights using Equations (3)–(12) is shown in

Table 9.

Based on the linguistic evaluation results provided in

Table 8 for the criteria, the PFWA value is calculated using Equation (7). Subsequently, the score function is computed using Equation (9). This score function value is then normalized using Equation (5) to obtain the normalized score function. Following this, the comparative significance of the normalized score value (

) is determined. The relative coefficient (

) is calculated using Equation (10), while the significance weight (

) is obtained using Equation (11). Finally, the final significant weight (

) is computed using Equation (12).

The weights of the main and sub-criteria are presented in

Table 10.

The final significant weight (

) values presented in

Table 8 have been used to derive the sub-criteria values shown in

Table 9. Based on these values, the importance weights of the corresponding main criteria have also been determined. The findings of this study indicate that Organizational and Managerial is the most critical main criteria. Operational is next in significance, with Technical Competence closely following. Data-Related and Cybersecurity holds the fourth position in the ranking. Conversely, Human Resources and Training and Financial were deemed the least significant among all criteria. These two factors received comparatively lower weightings, with Financial emerging as the least influential overall. The most important criterion highlights the strategic and leadership-related shortcomings of management. It indicates that the organization needs to utilize changes in management practices to effectively prepare for transformation. Operational and technical aspects also stand out with high weightings, emphasizing the importance of process improvement and in establishing a robust technical infrastructure. The “Data-Related and Cybersecurity” dimension points to situations where artificial intelligence and big data are not adequately supported. Therefore, prioritizing the integration of AI and data utilization is essential. Human resources and financial issues are relatively less significant compared to other factors. However, deficiencies in these areas can be addressed through targeted training initiatives and the development of a long-term financial structure.

Among the sub-criteria, the most important one is “Integration challenges between IT and OT systems”, which belongs to the Technical Competence criteria. The second most significant sub-criterion is “Need for organizational restructuring of maintenance-related functions”, under the Organizational and Managerial criteria. The third most important is “Lack of a structured framework specific to Maintenance 4.0 implementation”, which falls under the Operational criteria. The fourth is “Low maturity level of enabling technologies”, also associated with Technical Competence.

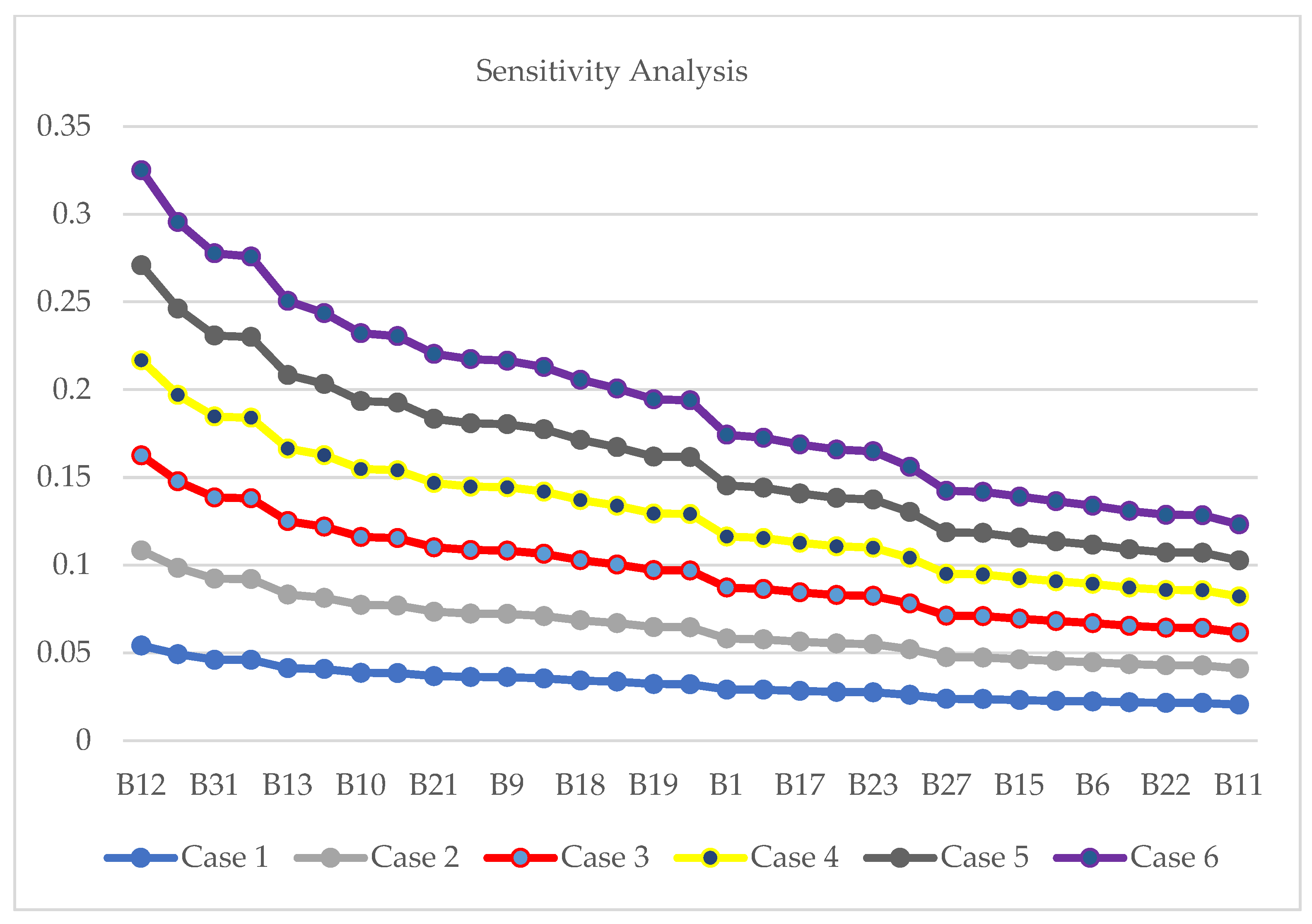

To measure the sensitivity of the results, five additional scenarios were applied. These scenarios are presented in

Table 11. According to these results, the outcomes of the sensitivity analysis are illustrated in

Figure 2. As seen from the results, the expert weightings had little effect on the final outcomes. Even in Case 6, where the expert weight ratios were completely reversed, the results did not change significantly. This highlights an important point regarding the reliability of the evaluation.

According to these results, the outcomes of the sensitivity analysis are illustrated in

Figure 5. A sensitivity analysis was conducted to examine how variations in the weights of the decision-makers (DM

s) influence the criteria weights. As observed, only minor changes occurred in the ranking of the criteria. This outcome indicates that the results obtained in Case 1 are robust and reliable. A sensitivity analysis was conducted by altering the importance weights of the decision-makers and applying the Pythagorean Fuzzy SWARA method accordingly. For this purpose, six distinct cases were defined and evaluated.

As seen from the results, the expert weightings had little effect on the final outcomes. Even in Case 6, where the expert weight ratios were completely reversed, the results did not change significantly. This highlights an important point regarding the reliability of the evaluation.

5. Conclusions

With the rapid entrance of Industry 4.0 applications into our lives with cutting-edge technologies, the Maintenance 4.0 paradigm has also become vital for businesses. Maintenance 4.0 does not only aim to detect and prevent failures, but also helps businesses to survive in the face of intense competition by increasing productivity with the effective use of resources. Predictive, smart, proactive, and autonomous maintenance strategies are developed thanks to tools such as artificial intelligence, the Internet of Things, and data analytics used within the scope of Maintenance 4.0 applications. In this way, both equipment availability and reliability are increased, and maintenance costs and production breakdown due to failures are minimized. Therefore, the Maintenance 4.0 paradigm is important for the sustainability of manufacturing enterprises. Although the importance of Maintenance 4.0 is known, it is not very easy to implement them in real life. In this study, the importance of Maintenance 4.0 is emphasized and the barriers encountered are determined. They are defined in line with a comprehensive literature review and expert opinions. The barriers that Maintenance 4.0 applications will encounter in the textile industry, where there is intensive labor use, and the weights of these barriers are determined. The SWARA method, based on Pythagorean fuzzy sets, was used to determine the weights of the barriers.

The results of this study reveal that Organizational and Managerial stands out as the most crucial main criterion. It is followed by Operational, while Technical Competence ranks closely behind in third place. Data-Related and Cybersecurity takes the fourth position in the hierarchy. On the other hand, Human Resources and Training and Financial are identified as the least significant among the main criteria, with Financial having the lowest overall weight.

As for the sub-criteria, the top-ranked is “Integration challenges between IT and OT systems”, which falls under Technical Competence. The next in importance is “Need for organizational restructuring of maintenance-related functions”, categorized under Organizational and Managerial. Ranked third is “Lack of a structured framework specific to Maintenance 4.0 implementation”, belonging to the Operational criteria. The fourth most critical sub-criterion is “Low maturity level of enabling technologies”, also linked to Technical Competence.

This study demonstrates that addressing Maintenance 4.0 requires not only overcoming technological limitations, but also implementing cultural changes within the organization. From a managerial perspective, Maintenance 4.0 should be integrated into the organization’s strategic objectives, which will help promote internal acceptance of the initiative. A more flexible internal structure should be established to support the operations of the maintenance department. For technical barriers, system interfaces should be developed and pilot projects should be conducted to ensure the effective use of data. To overcome data-related barriers, a system that ensures data quality and security must be established. In terms of human resources, training programs and suggestion systems should be implemented to increase employee engagement. As for financial barriers, investments should be planned with a long-term perspective to ensure sustainability and continuity.

The textile sector is limited in terms of both its operational and technological capacities. In this regard, it imposes restrictions on the generalizability of findings compared to other industries. Moreover, differences in workforce structures and organizational cultures are likely to emerge, further limiting the applicability of sector-specific insights. Therefore, incorporating examples from diverse sectors would enable a more comprehensive understanding of the challenges associated with Maintenance 4.0, ultimately leading to more generalizable and robust conclusions.

The most important limitation of this study is the temporal and spatial difficulties experienced in collecting data to determine the barriers and their relative importance levels. In addition, the collection of data only from textile enterprises operating in Turkey may be another limitation. The fact that this study cannot be applied to wider target groups, different countries, and different industry branches may be a barrier. In the future, the same problem can be addressed by determining different barriers for different industries. In addition, different fuzzy sets can be used in solving the problem, and the results can be analyzed with different weighting methods based on the same or different fuzzy sets. Hesitant, Picture, Spherical Neutrosophic, and Fermatean methods can be used in future studies.