Integrating Digital Twin Software Solutions with Collaborative Industrial Systems: A Comprehensive Review for Operational Efficiency

Abstract

1. Introduction

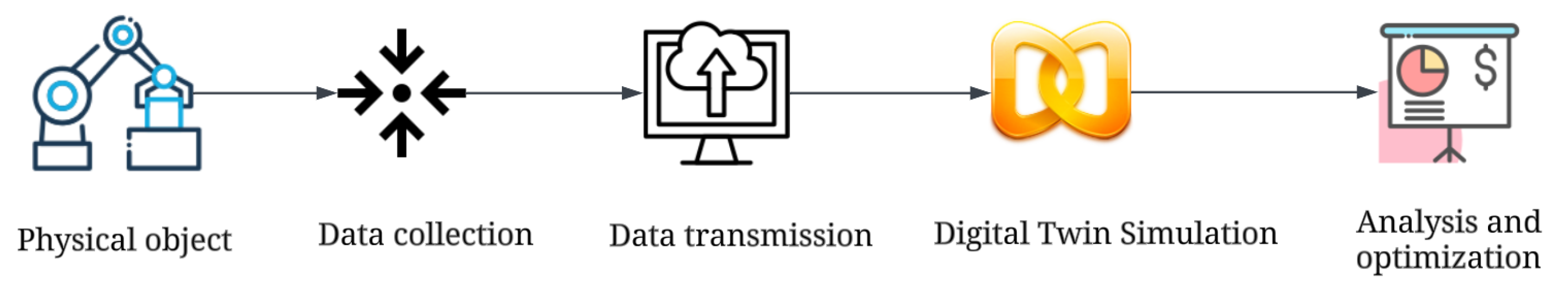

- A DT constitutes a virtual, dynamic portrayal of a physical artifact or system.

- Data is exchanged automatically and bidirectionally between the DT and the corresponding physical system.

- The DT encompasses data across all product lifecycle stages and maintains connections to each phase.

1.1. Research Gaps and Challenges

1.2. Research Questions

- What are the key challenges and opportunities associated with utilizing digital twin software solutions in conjunction with industrial collaborative robotics applications?

- How does the integration of digital twins and collaborative robots contribute to improved operational efficiency, productivity, and decision-making processes?

- What are the implications of the integration of digital twin software solutions with industrial cobot applications for different industries, such as manufacturing, energy, healthcare, and transportation?

1.3. Structure of the Paper

2. Digital Twin Software Solutions

2.1. General Applications

2.2. Manufacturing Support Applications

3. Methodology

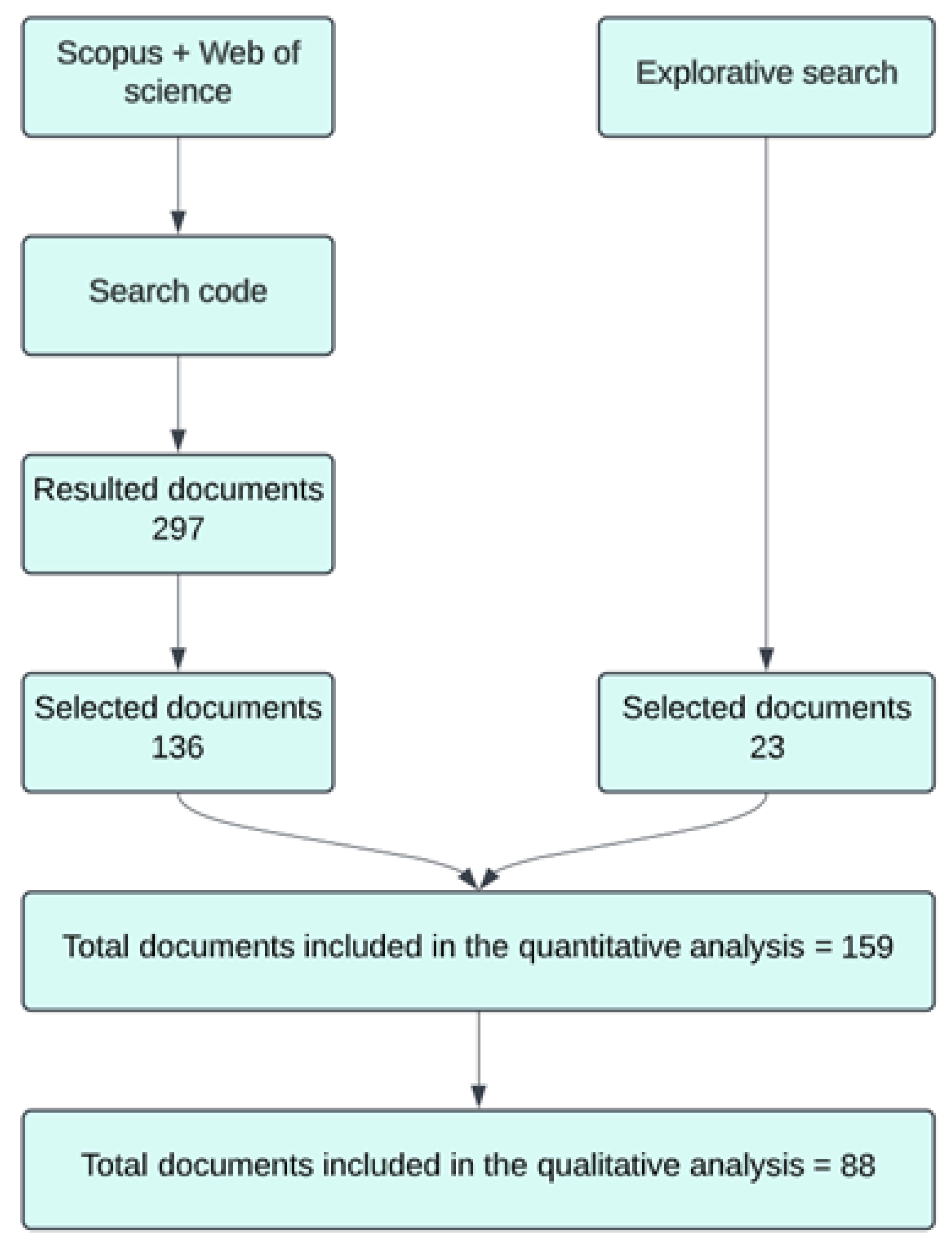

3.1. Databases and Keyword Searching

3.2. Collection and Evaluation of Literature

3.3. Analytical Approach

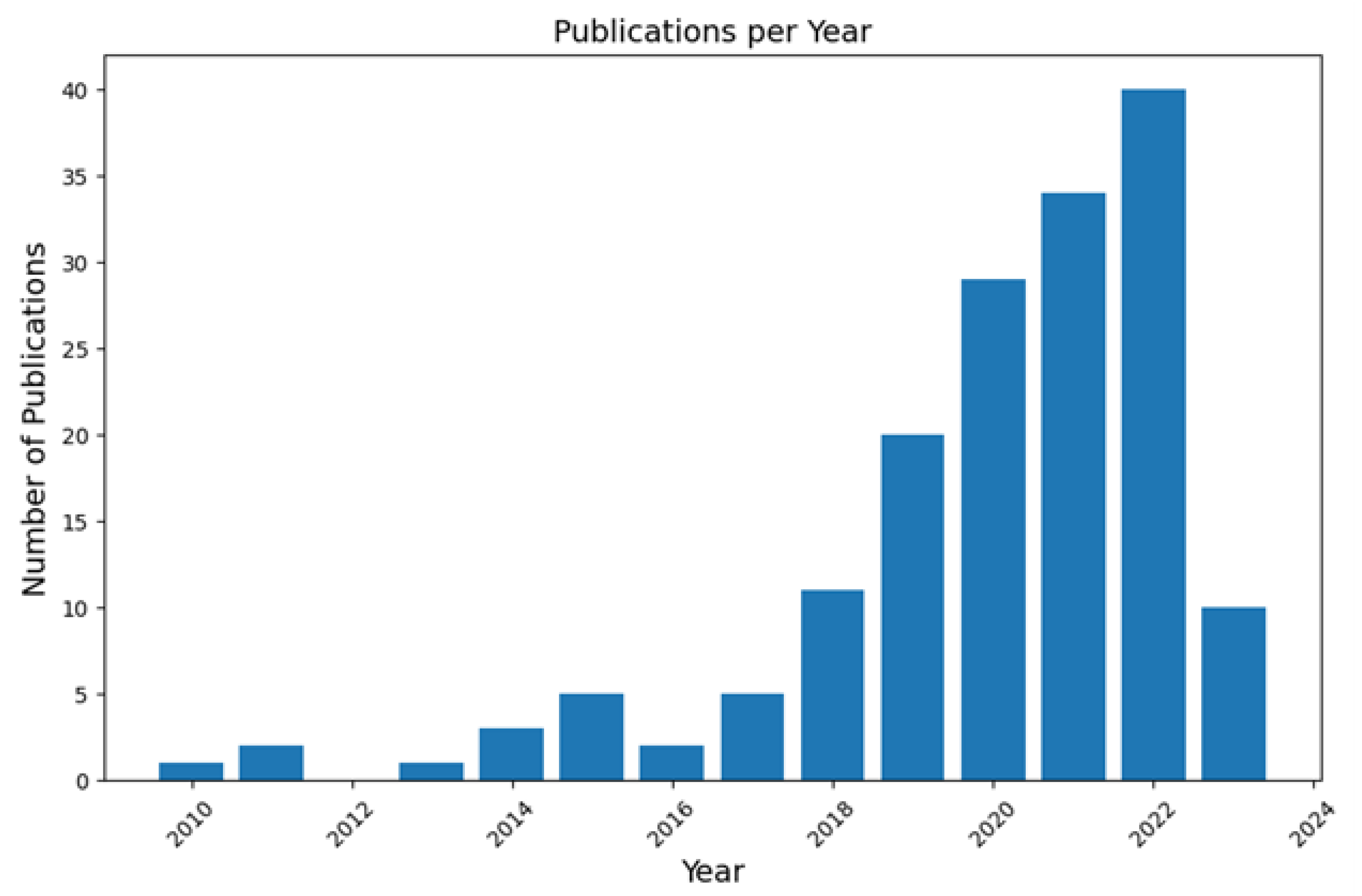

4. Quantitative Analysis

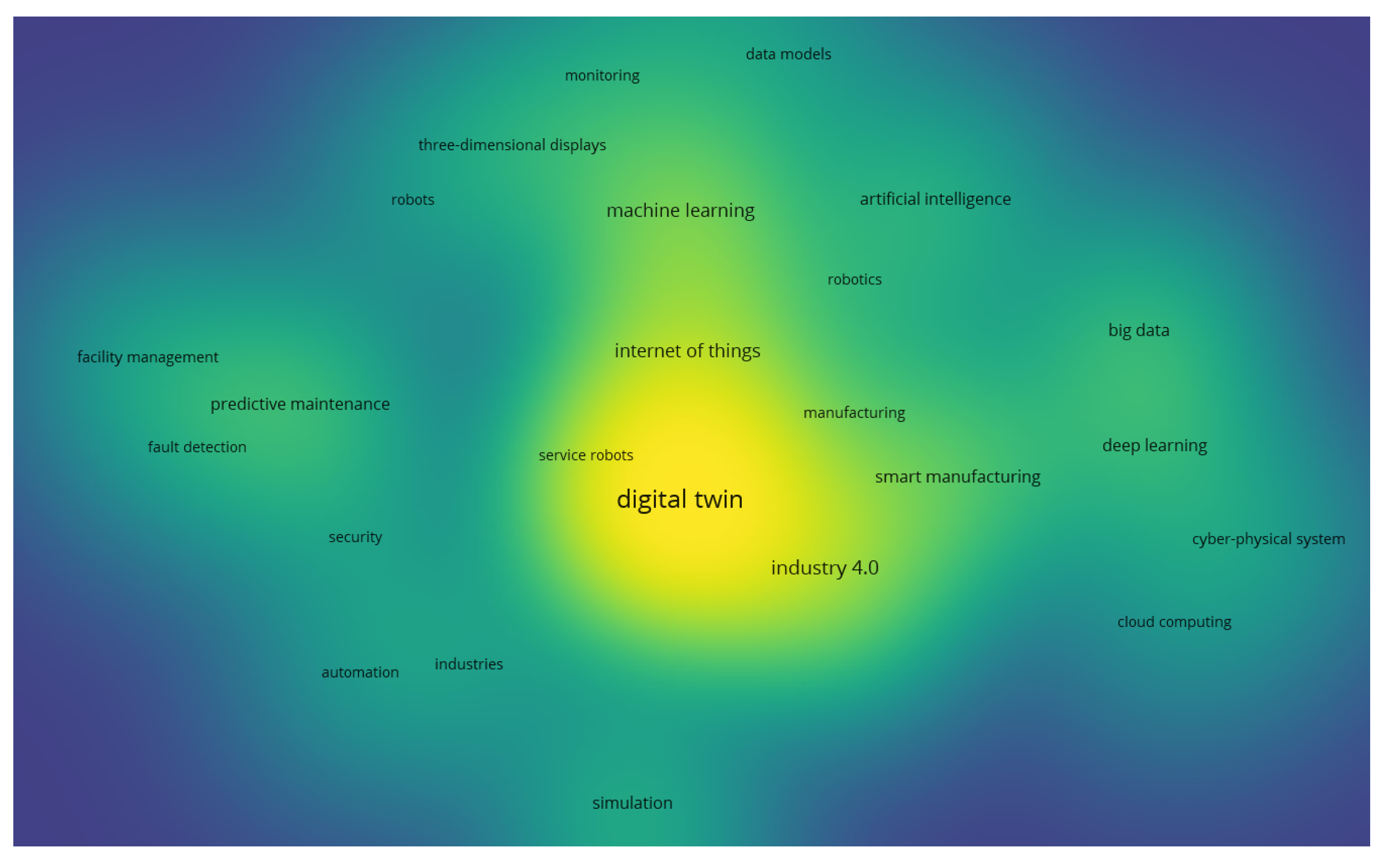

Density Visualization of Keyword Co-Occurrence Analysis

5. Qualitative Analysis

5.1. Automation in Industrial Collaborative Robotics Applications

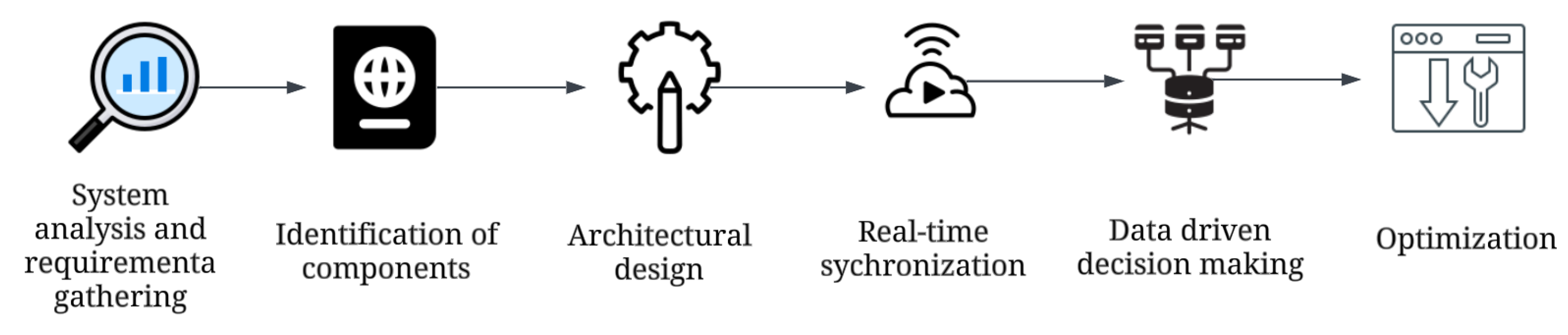

5.2. Design and Implementation of Digital Twin Software Solutions for Collaborative Robots

5.2.1. Communication and Synchronization Mechanisms

5.2.2. Integration of Artificial Intelligence and Machine Learning Algorithms

5.2.3. Challenges and Considerations

5.3. Interoperability and Architectural Design

5.4. Machine Learning in Industrial Collaborative Robotics Applications

5.4.1. Conventional Approaches to Machine Learning Techniques in Industrial Collaborative Robotics Applications

| Algorithm | Description | Example Use Case |

|---|---|---|

| Support Vector Machines (SVM) | A powerful algorithm for classification and regression tasks, known for its ability to handle complex data sets. | [111] |

| Random Forest | An ensemble learning algorithm that combines multiple decision trees to make predictions or classifications. | [112] |

| Naive Bayes | A probabilistic algorithm often used for text classification and other tasks involving discrete data. | [113] |

| k-Nearest Neighbors (k-NN) | Classifies new data points based on their k nearest neighbors, commonly used for pattern recognition. | [114] |

| Neural Networks | Interconnected nodes that mimic biological neural networks, used for classification, regression, and pattern recognition tasks. | [115] |

5.4.2. Deep Learning in Industrial Collaborative Robotics Applications

| Technique | Description | Example Use Case |

|---|---|---|

| Convolutional Neural Networks (CNN) | Well-suited for image and video processing tasks, CNNs excel at object recognition and segmentation. | [119] |

| Recurrent Neural Networks (RNN) | Effective for sequential data processing, RNNs capture temporal dependencies and handle time-series data. | [120] |

| Generative Adversarial Networks (GAN) | GANs consist of two neural networks competing against each other, enabling tasks such as image generation and anomaly detection. | [121] |

| Reinforcement Learning | RL focuses on training agents to make decisions and take actions based on feedback from the environment. It can be utilized for robotic control and optimization tasks. | [122] |

6. Knowledge Gaps and Future Trends

- Innovative Techniques for Efficiency Improvement: To enhance efficiency in cobot applications, innovative techniques such as data management, predictive analysis, and real-time monitoring can be explored. These techniques enable proactive fault detection, performance optimization, and timely decision-making. Further research is needed to develop advanced algorithms and methodologies that can handle complex data sets and extract valuable insights for improved operational efficiency.

- Context Awareness and Data Types: In the context of digital twin-enabled systems, dissonant or even incompatible data types captured by a diverse suite of sensors limit the ability to include context awareness in forecasts. Considering the autonomous characteristics inherent in Digital Twins and their capacity to parse pertinent data for practical utilization, future research should focus on integrating diverse data sources and exploring advanced techniques to incorporate context awareness, such as contextual sensing, adaption, resource discovery, and augmentation [125]. This will enhance the accuracy and reliability of predictions, enabling more effective fault detection and smart management in industrial cobot applications.

- System-Level Integration: It can be said that the value of a Digital Twin is positively correlated with the level at which it is implemented. The workflow and infrastructure that exist in manufacturing are typically arranged in five levels: station, cell, shop, factory, and enterprise. A “station” refers to a location where a single manufacturing or assembly process is carried out. A “cell” represents a collection of stations that collectively perform a set of processes within a subsystem. A “shop” encompasses a cluster of cells responsible for the manufacturing or assembly of a subsystem. A “factory” comprises a grouping of shops that handle the manufacturing or assembly of an entire system. An “enterprise” is constituted by a collection of factories that contribute a diverse array of complete systems to the market. It is easy to see how quickly the accomplished tasks of humans and machines scale up, which is why operation efficiency is critical. One of the biggest considerations for operational efficiency is knowledge management. Considerations should be made for which level of the manufacturing scheme a digital twin will be implemented. Incorporating components that operate at the system level is crucial for accurate predictions in context-aware smart management and fault detection in industrial cobot applications. Future research should explore the integration of various subsystems, sensors, and data sources to create a holistic view of the collaborative robotic system. This will enable a comprehensive understanding of system behavior and facilitate proactive maintenance, optimization, and decision-making.

- Deep Learning Applications and Challenges: Deep learning techniques offer significant analytical capabilities for processing large data sets and detecting complex problems within collaborative robotic systems. However, to broaden their application, challenges such as high computing complexity and lengthy training times need to be addressed. Further research should focus on developing efficient deep learning algorithms, hardware accelerators, and distributed computing techniques to overcome these challenges and unlock the full potential of deep learning in industrial cobot applications. Furthermore, the dilemma of “black box” AI and ML models can be addressed with Explainable AI (XAI), a subset of AI and ML that supports human trustworthiness and compliance by explaining the reasoning that draws. The inclusion of XAI in Industrial DT applications would authenticate the reasoning for operators in the field. This is particularly useful for risk reduction, ethical consideration, and real-time decision making, when collaborating with operators.

- Reduced Human Involvement in Data Pre-processing and Interpretation: Further research is needed to explore deep learning applications in the context of cobot applications with the aim of reducing the need for human involvement in data pre-processing and interpretation. Automation of these tasks through advanced algorithms and methodologies will streamline the analysis process, accelerate decision-making, and enable real-time responses in industrial collaborative robotic systems.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hosamo, H.H.; Nielsen, H.K.; Alnmr, A.N.; Svennevig, P.R.; Svidt, K. A review of the Digital Twin technology for fault detection in buildings. Front. Built Environ. 2022, 8, 1013196. [Google Scholar] [CrossRef]

- Hosamo, H.H.; Imran, A.; Cardenas-Cartagena, J.; Svennevig, P.R.; Svidt, K.; Nielsen, H.K. A Review of the Digital Twin Technology in the AEC-FM Industry. Adv. Civ. Eng. 2022, 2022, 2185170. [Google Scholar] [CrossRef]

- Sharma, A.; Kosasih, E.; Zhang, J.; Brintrup, A.; Calinescu, A. Digital Twins: State of the art theory and practice, challenges, and open research questions. J. Ind. Inf. Integr. 2022, 30, 100383. [Google Scholar] [CrossRef]

- Khan, S.; Farnsworth, M.; McWilliam, R.; Erkoyuncu, J. On the requirements of digital twin-driven autonomous maintenance. Annu. Rev. Control 2020, 50, 13–28. [Google Scholar] [CrossRef]

- Al-Ali, A.R.; Gupta, R.; Zaman Batool, T.; Landolsi, T.; Aloul, F.; Al Nabulsi, A. Digital Twin Conceptual Model within the Context of Internet of Things. Future Internet 2020, 12, 163. [Google Scholar] [CrossRef]

- Schluse, M.; Priggemeyer, M.; Atorf, L.; Rossmann, J. Experimentable Digital Twins—Streamlining Simulation-Based Systems Engineering for Industry 4.0. IEEE Trans. Ind. Inform. 2018, 14, 1722–1731. [Google Scholar] [CrossRef]

- Gelernter, D. Mirror Worlds: Or the Day Software Puts the Universe in a Shoebox...How It Will Happen and What It Will Mean; Oxford University Press: Oxford, UK, 1991. [Google Scholar]

- Grieves, M. Digital twin: Manufacturing excellence through virtual factory replication. White Pap. 2014, 1, 1–7. [Google Scholar]

- Rajamurugu, N.; Karthik, M. Introduction, History, and Concept of Digital Twin. In Digital Twin Technology: Fundamentals and Applications; Wiley: Hoboken, NJ, USA, 2022; pp. 19–32. [Google Scholar]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Springer: Cham, Switzerland, 2017; pp. 85–113. [Google Scholar]

- Trauer, J.; Schweigert-Recksiek, S.; Engel, C.; Spreitzer, K.; Zimmermann, M. What is a digital twin?—Definitions and insights from an industrial case study in technical product development. Des. Soc. DESIGN Conf. 2020, 1, 757–766. [Google Scholar] [CrossRef]

- Madni, A.M.; Madni, C.C.; Lucero, S.D. Leveraging digital twin technology in model-based systems engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef]

- Popa, L.; Berdich, A.; Groza, B. CarTwin—Development of a digital twin for a real-world in-vehicle CAN network. Appl. Sci. 2022, 13, 445. [Google Scholar] [CrossRef]

- Hosamo, H.H.; Svennevig, P.R.; Svidt, K.; Han, D.; Nielsen, H.K. A Digital Twin predictive maintenance framework of air handling units based on automatic fault detection and diagnostics. Energy Build. 2022, 261, 111988. [Google Scholar] [CrossRef]

- Guerra-Zubiaga, D.; dos Santos, M.C.; Voicu, R.C.; Richards, G.; Gosnell, S.; Barbosa, G.F. A digital twin approach to support a multi-task industrial robot operation using design of experiments. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 516. [Google Scholar] [CrossRef]

- Malik, A.A.; Brem, A. Digital twins for collaborative robots: A case study in human-robot interaction. Robot. Comput.-Integr. Manuf. 2021, 68, 102092. [Google Scholar] [CrossRef]

- Matheson, E.; Minto, R.; Zampieri, E.G.; Faccio, M.; Rosati, G. Human–robot collaboration in manufacturing applications: A review. Robotics 2019, 8, 100. [Google Scholar] [CrossRef]

- Avila, E.A.; Chapa, D.P.; Arenas, I.D.; Hurtado, C.V. A Digital Twin implementation for Mobile and collaborative robot scenarios for teaching robotics based on Robot Operating System. In Proceedings of the 2022 IEEE Global Engineering Education Conference (EDUCON), Tunis, Tunisia, 28–31 March 2022; pp. 559–564. [Google Scholar]

- Guerra-Zubiaga, D.; Kuts, V.; Mahmood, K.; Bondar, A.; Nasajpour-Esfahani, N.; Otto, T. An approach to develop a digital twin for industry 4.0 systems: Manufacturing automation case studies. Int. J. Comput. Integr. Manuf. 2021, 34, 933–949. [Google Scholar] [CrossRef]

- Holmes, D.; Papathanasaki, M.; Maglaras, L.; Ferrag, M.A.; Nepal, S.; Janicke, H. Digital twins and cyber security–solution or challenge? In Proceedings of the 2021 6th South-East Europe Design Automation, Computer Engineering, Computer Networks and Social Media Conference (SEEDA-CECNSM), Preveza, Greece, 24–26 September 2021; pp. 1–8. [Google Scholar]

- Lim, K.Y.H.; Zheng, P.; Chen, C.H. A state-of-the-art survey of Digital Twin: Techniques, engineering product lifecycle management and business innovation perspectives. J. Intell. Manuf. 2020, 31, 1313–1337. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Van Dinter, R.; Tekinerdogan, B.; Catal, C. Predictive maintenance using digital twins: A systematic literature review. Inf. Softw. Technol. 2022, 151, 107008. [Google Scholar] [CrossRef]

- Norambuena, N.; Ortega, J.; Muñoz-La Rivera, F.; Covarrubias, M.; Valín Rivera, J.L.; Ramírez, E.; Ketterer, C.I.G. Integrating Digital Twins of Engineering Labs into Multi-User Virtual Reality Environments. Appl. Sci. 2025, 15, 3819. [Google Scholar] [CrossRef]

- Nambiar, S.; Jonsson, M.; Tarkian, M. Automation in Unstructured Production Environments Using Isaac Sim: A Flexible Framework for Dynamic Robot Adaptability. Procedia CIRP 2024, 130, 837–846. [Google Scholar] [CrossRef]

- Zhou, Z.; Song, J.; Xie, X.; Shu, Z.; Ma, L.; Liu, D.; Yin, J.; See, S. Towards building AI-CPS with NVIDIA Isaac Sim: An industrial benchmark and case study for robotics manipulation. In Proceedings of the 46th International Conference on Software Engineering: Software Engineering in Practice, Lisbon, Portugal, 14–20 April 2024; pp. 263–274. [Google Scholar]

- Yu, W.; Patros, P.; Young, B.; Klinac, E.; Walmsley, T.G. Energy digital twin technology for industrial energy management: Classification, challenges and future. Renew. Sustain. Energy Rev. 2022, 161, 112407. [Google Scholar] [CrossRef]

- Onile, A.E.; Machlev, R.; Petlenkov, E.; Levron, Y.; Belikov, J. Uses of the digital twins concept for energy services, intelligent recommendation systems, and demand side management: A review. Energy Rep. 2021, 7, 997–1015. [Google Scholar] [CrossRef]

- Laubenbacher, R.; Mehrad, B.; Shmulevich, I.; Trayanova, N. Digital twins in medicine. Nat. Comput. Sci. 2024, 4, 184–191. [Google Scholar] [CrossRef]

- Chakshu, N.K.; Sazonov, I.; Nithiarasu, P. Towards enabling a cardiovascular digital twin for human systemic circulation using inverse analysis. Biomech. Model. Mechanobiol. 2021, 20, 449–465. [Google Scholar] [CrossRef]

- Ahmadi-Assalemi, G.; Al-Khateeb, H.; Maple, C.; Epiphaniou, G.; Alhaboby, Z.A.; Alkaabi, S.; Alhaboby, D. Digital twins for precision healthcare. In Cyber Defence in the Age of AI, Smart Societies and Augmented Humanity; Springer: Cham, Switzerland, 2020; pp. 133–158. [Google Scholar]

- Qian, C.; Liu, X.; Ripley, C.; Qian, M.; Liang, F.; Yu, W. Digital twin—Cyber replica of physical things: Architecture, applications and future research directions. Future Internet 2022, 14, 64. [Google Scholar] [CrossRef]

- Schwarz, C.; Wang, Z. The role of digital twins in connected and automated vehicles. IEEE Intell. Transp. Syst. Mag. 2022, 14, 41–51. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, W. Application framework of digital twin-driven product smart manufacturing system: A case study of aeroengine blade manufacturing. Int. J. Adv. Robot. Syst. 2019, 16, 1729881419880663. [Google Scholar] [CrossRef]

- Matania, O.; Bechhoefer, E.; Bortman, J. Digital twin of a gear root crack prognosis. Sensors 2023, 23, 9883. [Google Scholar] [CrossRef]

- Zorchenko, N.; Tyupina, T.; Parshutin, M. Technologies used by General Electric to create digital twins for energy industry. Power Technol. Eng. 2024, 58, 521–526. [Google Scholar] [CrossRef]

- Xia, K.; Sacco, C.; Kirkpatrick, M.; Saidy, C.; Nguyen, L.; Kircaliali, A.; Harik, R. A digital twin to train deep reinforcement learning agent for smart manufacturing plants: Environment, interfaces and intelligence. J. Manuf. Syst. 2021, 58, 210–230. [Google Scholar] [CrossRef]

- Agalianos, K.; Ponis, S.; Aretoulaki, E.; Plakas, G.; Efthymiou, O. Discrete event simulation and digital twins: Review and challenges for logistics. Procedia Manuf. 2020, 51, 1636–1641. [Google Scholar] [CrossRef]

- Saavedra Sueldo, C.; Perez Colo, I.; De Paula, M.; Villar, S.A.; Acosta, G.G. ROS-based architecture for fast digital twin development of smart manufacturing robotized systems. Ann. Oper. Res. 2023, 322, 75–99. [Google Scholar] [CrossRef]

- Magrin, C.E.; Del Conte, G.; Todt, E. Creating a digital twin as an open source learning tool for mobile robotics. In Proceedings of the 2021 Latin American Robotics Symposium (LARS), 2021 Brazilian Symposium on Robotics (SBR), and 2021 Workshop on Robotics in Education (WRE), Natal, Brazil, 11–15 October 2021; pp. 13–18. [Google Scholar]

- Pedraza López, A. Evaluación de Implementación Utilizando iTwin. js Para la Integración de Gemelos Digitales en el Puerto de Buenaventura. Master’s Thesis, Universidad de Los Andes, Bogota, Colombia, 2022. [Google Scholar]

- Bécue, A.; Maia, E.; Feeken, L.; Borchers, P.; Praça, I. A new concept of digital twin supporting optimization and resilience of factories of the future. Appl. Sci. 2020, 10, 4482. [Google Scholar] [CrossRef]

- Nava-Téllez, I.A.; Elias-Espinosa, M.C.; Escamilla, E.B.; Saavedra, A.H. Digital twins and virtual reality as means for teaching industrial robotics: A case study. In Proceedings of the 2023 11th International Conference on Information and Education Technology (ICIET), Fujisawa, Japan, 18–20 March 2023; pp. 29–33. [Google Scholar]

- Jin, X.; Dong, H.; Yao, X. Research on the integrated application of digital twin technology in the field of automobile welding. In Proceedings of the International Conference on Advanced Manufacturing Technology and Manufacturing Systems (ICAMTMS 2022), Shijiazhuang, China, 30 August 2022; Volume 12309, pp. 38–42. [Google Scholar]

- Kherbache, M.; Maimour, M.; Rondeau, E. Digital twin network for the IIoT using eclipse ditto and hono. IFAC-PapersOnLine 2022, 55, 37–42. [Google Scholar] [CrossRef]

- Martins, A.; Costelha, H.; Neves, C. Supporting the design, commissioning and supervision of smart factory components through their digital twin. In Proceedings of the 2020 IEEE International Conference on Autonomous Robot Systems and Competitions (ICARSC), Ponta Delgada, Portugal, 15–17 April 2020; pp. 114–119. [Google Scholar]

- Arnarson, H.; Solvang, B.; Shu, B. The application of open access middleware for cooperation among heterogeneous manufacturing systems. In Proceedings of the 2020 3rd International Symposium on Small-Scale Intelligent Manufacturing Systems (SIMS), Gjovik, Norway, 10–12 June 2020; pp. 1–6. [Google Scholar]

- Sørensen, J.V.; Ma, Z.; Jørgensen, B.N. Potentials of game engines for wind power digital twin development: An investigation of the Unreal Engine. Energy Inform. 2022, 5, 39. [Google Scholar] [CrossRef]

- Lin, X.; Kundu, L.; Dick, C.; Obiodu, E.; Mostak, T.; Flaxman, M. 6G digital twin networks: From theory to practice. IEEE Commun. Mag. 2023, 61, 72–78. [Google Scholar] [CrossRef]

- Wang, Z.; Han, K.; Tiwari, P. Digital twin simulation of connected and automated vehicles with the unity game engine. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI), Beijing, China, 15 July–15 August 2021; pp. 1–4. [Google Scholar]

- Mattila, J.; Ala-Laurinaho, R.; Autiosalo, J.; Salminen, P.; Tammi, K. Using digital twin documents to control a smart factory: Simulation approach with ROS, gazebo, and Twinbase. Machines 2022, 10, 225. [Google Scholar] [CrossRef]

- Tøttrup, M.F.; Hu, E.C.; Kramer, B.A.; Macedo, H.D.; Esterle, L. Using INTO-CPS Tools in the Development of a Digital Twin for the F1TENTH Race Car. In Proceedings of the International Conference on Software Engineering and Formal Methods, Berlin, Germany, 26–29 September 2022; Springer: Cham, Switzerland, 2022; pp. 200–209. [Google Scholar]

- Al-Geddawy, T. A digital twin creation method for an opensource low-cost changeable learning factory. Procedia Manuf. 2020, 51, 1799–1805. [Google Scholar] [CrossRef]

- Ngo, D.; Guerra-Zubiaga, D.A.; González-Badillo, G.; Vatankhah Barenji, R. Towards a digital twin for cloud manufacturing: Case study. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Pittsburgh, PA, USA, 9–15 November 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018; Volume 52019, p. V002T02A072. [Google Scholar]

- Perry, L.; Guerra-Zubiaga, D.A.; Richards, G.; Abidoye, C.; Hantouli, F. Optimizing a manufacturing pick-and-place operation on a robotic arm using a digital twin. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, New Orleans, LO, USA, 29 October–2 November 2023; American Society of Mechanical Engineers: New York, NY, USA, 2023; Volume 87608, p. V003T03A077. [Google Scholar]

- Zhang, Q.; Zhang, X.; Xu, W.; Liu, A.; Zhou, Z.; Pham, D.T. Modeling of digital twin workshop based on perception data. In Proceedings of the Intelligent Robotics and Applications: 10th International Conference, ICIRA 2017, Wuhan, China, 16–18 August 2017; Proceedings, Part III 10. Springer: Cham, Switzerland, 2017; pp. 3–14. [Google Scholar]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Pires, F.; Ahmad, B.; Moreira, A.P.; Leitão, P. Digital twin based what-if simulation for energy management. In Proceedings of the 2021 4th IEEE International Conference on Industrial Cyber-Physical Systems (ICPS), Victoria, BC, Canada, 10–12 May 2021; pp. 309–314. [Google Scholar]

- Arnarson, H. Digital Twin Simulation with Visual Components. Master’s Thesis, UiT Norges Arktiske Universitet, Tromsø, Norway, 2019. [Google Scholar]

- Keith, D.; Suparna Pal, R.M.K.Y. Contextual Digital Twin Runtime Environment. U.S. Patent 11 119 799, 7 November 2017. [Google Scholar]

- GE Vernova Is the Pioneer of Digital Twin Technology. Available online: https://www.gevernova.com/software/innovation/digital-twin-technology (accessed on 29 May 2025).

- Omniverse Digital Twins. Available online: https://docs.omniverse.nvidia.com/digital-twins/latest/index.html (accessed on 29 May 2025).

- Gong, X.; Sui, L.; Morton, J.; Brennan, M.A.; Brennan, C.S. Investigation of nutritional and functional effects of rice bran protein hydrolysates by using Preferred Reporting Items for Systematic Reviews and Meta-Analysis (PRISMA) guidelines: A review. Trends Food Sci. Technol. 2021, 110, 798–811. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Visualizing bibliometric networks. In Measuring Scholarly Impact: Methods and Practice; Springer: Cham, Switzerland, 2014; pp. 285–320. [Google Scholar]

- Van Eck, N.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2009, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Wallin, J.A. Bibliometric methods: Pitfalls and possibilities. Basic Clin. Pharmacol. Toxicol. 2005, 97, 261–275. [Google Scholar] [CrossRef]

- Radhakrishnan, S.; Erbis, S.; Isaacs, J.A.; Kamarthi, S. Novel keyword co-occurrence network-based methods to foster systematic reviews of scientific literature. PLoS ONE 2017, 12, e0172778. [Google Scholar]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Zhuang, C.; Liu, J.; Xiong, H. Digital twin-based smart production management and control framework for the complex product assembly shop-floor. Int. J. Adv. Manuf. Technol. 2018, 96, 1149–1163. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, S.; Cheng, H. An application framework of digital twin and its case study. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1141–1153. [Google Scholar] [CrossRef]

- Aheleroff, S.; Xu, X.; Zhong, R.Y.; Lu, Y. Digital Twin as a Service (DTaaS) in Industry 4.0: An Architecture Reference Model. Adv. Eng. Inform. 2021, 47. [Google Scholar] [CrossRef]

- Schou, C.; Andersen, R.S.; Chrysostomou, D.; Bøgh, S.; Madsen, O. Skill-based instruction of collaborative robots in industrial settings. Robot. Comput.-Integr. Manuf. 2018, 53, 72–80. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Substantial capabilities of robotics in enhancing industry 4.0 implementation. Cogn. Robot. 2021, 1, 58–75. [Google Scholar] [CrossRef]

- Pires, F.; Cachada, A.; Barbosa, J.; Moreira, A.P.; Leitão, P. Digital twin in industry 4.0: Technologies, applications and challenges. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; Volume 1, pp. 721–726. [Google Scholar]

- Melesse, T.Y.; Di Pasquale, V.; Riemma, S. Digital Twin models in industrial operations: State-of-the-art and future research directions. IET Collab. Intell. Manuf. 2021, 3, 37–47. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, H.; Yang, G.; Li, X.; Yang, H. Human digital twin (HDT) driven human-cyber-physical systems: Key technologies and applications. Chin. J. Mech. Eng. 2022, 35, 11. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Kevin, I.; Wang, K.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput.-Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Alexopoulos, K.; Nikolakis, N.; Chryssolouris, G. Digital twin-driven supervised machine learning for the development of artificial intelligence applications in manufacturing. Int. J. Comput. Integr. Manuf. 2020, 33, 429–439. [Google Scholar] [CrossRef]

- Liang, C.J.; McGee, W.; Menassa, C.C.; Kamat, V.R. Real-time state synchronization between physical construction robots and process-level digital twins. Constr. Robot. 2022, 6, 57–73. [Google Scholar] [CrossRef]

- Douthwaite, J.A.; Lesage, B.; Gleirscher, M.; Calinescu, R.; Aitken, J.M.; Alexander, R.; Law, J. A modular digital twinning framework for safety assurance of collaborative robotics. Front. Robot. AI 2021, 8, 758099. [Google Scholar] [CrossRef] [PubMed]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Enabling flexible manufacturing system (FMS) through the applications of industry 4.0 technologies. Internet Things Cyber-Phys. Syst. 2022, 2, 49–62. [Google Scholar] [CrossRef]

- Ramasubramanian, A.K.; Mathew, R.; Kelly, M.; Hargaden, V.; Papakostas, N. Digital twin for human–robot collaboration in manufacturing: Review and outlook. Appl. Sci. 2022, 12, 4811. [Google Scholar] [CrossRef]

- Profanter, S.; Tekat, A.; Dorofeev, K.; Rickert, M.; Knoll, A. OPC UA versus ROS, DDS, and MQTT: Performance evaluation of industry 4.0 protocols. In Proceedings of the 2019 IEEE International Conference on Industrial Technology (ICIT), Melbourne, VIC, Australia, 13–15 February 2019; pp. 955–962. [Google Scholar]

- Proos, D.P.; Carlsson, N. Performance comparison of messaging protocols and serialization formats for digital twins in IoV. In Proceedings of the 2020 IFIP Networking Conference (Networking), Paris, France, 22–26 June 2020; pp. 10–18. [Google Scholar]

- Duong, T.Q.; Van Huynh, D.; Khosravirad, S.R.; Sharma, V.; Dobre, O.A.; Shin, H. From digital twin to metaverse: The role of 6G ultra-reliable and low-latency communications with multi-tier computing. IEEE Wirel. Commun. 2023, 30, 140–146. [Google Scholar] [CrossRef]

- Gonga, A.; Landsiedel, O.; Johansson, M. MobiSense: Power-efficient micro-mobility in wireless sensor networks. In Proceedings of the 2011 International Conference on Distributed Computing in Sensor Systems and Workshops (DCOSS), Barcelona, Spain, 27–29 June 2011; pp. 1–8. [Google Scholar]

- Scott, K.; Refaei, T.; Trivedi, N.; Trinh, J.; Macker, J.P. Robust communications for disconnected, intermittent, low-bandwidth (DIL) environments. In Proceedings of the 2011—MILCOM 2011 Military Communications Conference, Baltimore, MD, USA, 7–10 November 2011; pp. 1009–1014. [Google Scholar]

- Soret, B.; Mogensen, P.; Pedersen, K.I.; Aguayo-Torres, M.C. Fundamental tradeoffs among reliability, latency and throughput in cellular networks. In Proceedings of the 2014 IEEE Globecom Workshops (GC Wkshps), Austin, TX, USA, 8–12 December 2014; pp. 1391–1396. [Google Scholar]

- Laaki, H.; Miche, Y.; Tammi, K. Prototyping a digital twin for real time remote control over mobile networks: Application of remote surgery. IEEE Access 2019, 7, 20325–20336. [Google Scholar] [CrossRef]

- Mykoniatis, K.; Harris, G.A. A digital twin emulator of a modular production system using a data-driven hybrid modeling and simulation approach. J. Intell. Manuf. 2021, 32, 1899–1911. [Google Scholar] [CrossRef]

- Calandra, D.; Pratticò, F.G.; Cannavò, A.; Casetti, C.; Lamberti, F. Digital twin-and extended reality-based telepresence for collaborative robot programming in the 6G perspective. Digit. Commun. Netw. 2024, 10, 315–327. [Google Scholar] [CrossRef]

- Alam, A. Should robots replace teachers? Mobilisation of AI and learning analytics in education. In Proceedings of the 2021 International Conference on Advances in Computing, Communication, and Control (ICAC3), Mumbai, India, 3–4 December 2021; pp. 1–12. [Google Scholar]

- Lăzăroiu, G.; Andronie, M.; Iatagan, M.; Geamănu, M.; Ștefănescu, R.; Dijmărescu, I. Deep learning-assisted smart process planning, robotic wireless sensor networks, and geospatial big data management algorithms in the internet of manufacturing things. ISPRS Int. J. Geo-Inf. 2022, 11, 277. [Google Scholar] [CrossRef]

- Zonta, T.; Da Costa, C.A.; da Rosa Righi, R.; de Lima, M.J.; Da Trindade, E.S.; Li, G.P. Predictive maintenance in the Industry 4.0: A systematic literature review. Comput. Ind. Eng. 2020, 150, 106889. [Google Scholar] [CrossRef]

- Wu, X.; Xiao, L.; Sun, Y.; Zhang, J.; Ma, T.; He, L. A survey of human-in-the-loop for machine learning. Future Gener. Comput. Syst. 2022, 135, 364–381. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital twin: Enabling technologies, challenges and open research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Hu, W.; Wang, C.; Liu, F.; Peng, X.; Sun, P.; Tan, J. A grasps-generation-and-selection convolutional neural network for a digital twin of intelligent robotic grasping. Robot. Comput.-Integr. Manuf. 2022, 77, 102371. [Google Scholar] [CrossRef]

- Qamsane, Y.; Moyne, J.; Toothman, M.; Kovalenko, I.; Balta, E.C.; Faris, J.; Tilbury, D.M.; Barton, K. A methodology to develop and implement digital twin solutions for manufacturing systems. IEEE Access 2021, 9, 44247–44265. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Parekh, H.; Mani, V.; Belhadi, A.; Sharma, R. Digital twin for sustainable manufacturing supply chains: Current trends, future perspectives, and an implementation framework. Technol. Forecast. Soc. Chang. 2022, 176, 121448. [Google Scholar] [CrossRef]

- Jhunjhunwala, P.; Atmojo, U.D.; Vyatkin, V. Applying skill-based engineering using OPC-UA in production system with a digital twin. In Proceedings of the 2021 IEEE 30th International Symposium on Industrial Electronics (ISIE), Kyoto, Japan, 20–23 June 2021; pp. 1–6. [Google Scholar]

- Hunkeler, U.; Truong, H.L.; Stanford-Clark, A. MQTT-S—A publish/subscribe protocol for Wireless Sensor Networks. In Proceedings of the 2008 3rd International Conference on Communication Systems Software and Middleware and Workshops (COMSWARE’08), Bangalore, India, 6–10 January 2008; pp. 791–798. [Google Scholar]

- Mafioletti, D.R.; de Mello, R.C.; Ruffini, M.; Frascolla, V.; Martinello, M.; Ribeiro, M.R. Programmable data planes as the next frontier for networked robotics security: A ROS use case. In Proceedings of the 2021 17th International Conference on Network and Service Management (CNSM), Izmir, Turkey, 25–29 October 2021; pp. 160–165. [Google Scholar]

- Yun, S.; Park, J.H.; Kim, H.S.; Kim, W.T. Importance-aware sdn control mechanism for real-time data distribution services. In Proceedings of the 2018 International Conference on Information and Communication Technology Convergence (ICTC), Jeju, Republic of Korea, 17–19 October 2018; pp. 1113–1118. [Google Scholar]

- Layer, C.A.; Protocol, C.L.L. for the Internet of Things (IoT) and CoAP-IPSEC Security with DTLS. In Digital Twin Technologies and Smart Cities; Springer: Cham, Switzerland, 2019; p. 151. [Google Scholar]

- Jin, T.; Sun, Z.; Li, L.; Zhang, Q.; Zhu, M.; Zhang, Z.; Yuan, G.; Chen, T.; Tian, Y.; Hou, X.; et al. Triboelectric nanogenerator sensors for soft robotics aiming at digital twin applications. Nat. Commun. 2020, 11, 5381. [Google Scholar] [CrossRef]

- Szpytko, J.; Salgado Duarte, Y. A digital twins concept model for integrated maintenance: A case study for crane operation. J. Intell. Manuf. 2021, 32, 1863–1881. [Google Scholar] [CrossRef]

- Angelopoulos, A.; Michailidis, E.T.; Nomikos, N.; Trakadas, P.; Hatziefremidis, A.; Voliotis, S.; Zahariadis, T. Tackling faults in the industry 4.0 era—A survey of machine-learning solutions and key aspects. Sensors 2019, 20, 109. [Google Scholar] [CrossRef] [PubMed]

- Lopes, D.; Coelho, L.; Silva, M.F. Development of a collaborative robotic platform for autonomous auscultation. Appl. Sci. 2023, 13, 1604. [Google Scholar] [CrossRef]

- Lee, H.; Kim, S.D.; Al Amin, M.A.U. Control framework for collaborative robot using imitation learning-based teleoperation from human digital twin to robot digital twin. Mechatronics 2022, 85, 102833. [Google Scholar] [CrossRef]

- Wang, Q.; Jiao, W.; Wang, P.; Zhang, Y. Digital twin for human-robot interactive welding and welder behavior analysis. IEEE/CAA J. Autom. Sin. 2020, 8, 334–343. [Google Scholar] [CrossRef]

- Huang, Z.; Shen, Y.; Li, J.; Fey, M.; Brecher, C. A survey on AI-driven digital twins in industry 4.0: Smart manufacturing and advanced robotics. Sensors 2021, 21, 6340. [Google Scholar] [CrossRef] [PubMed]

- Tellaeche, A.; Kildal, J.; Maurtua, I. A flexible system for gesture based human-robot interaction. Procedia CIRP 2018, 72, 57–62. [Google Scholar] [CrossRef]

- Chen, J.H.; Song, K.T. Collision-free motion planning for human-robot collaborative safety under cartesian constraint. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, QLD, Australia, 21–25 May 2018; pp. 4348–4354. [Google Scholar]

- Czubenko, M.; Kowalczuk, Z. A simple neural network for collision detection of collaborative robots. Sensors 2021, 21, 4235. [Google Scholar] [CrossRef]

- Heo, Y.J.; Kim, D.; Lee, W.; Kim, H.; Park, J.; Chung, W.K. Collision detection for industrial collaborative robots: A deep learning approach. IEEE Robot. Autom. Lett. 2019, 4, 740–746. [Google Scholar] [CrossRef]

- Yu, Y.; Li, M.; Liu, L.; Li, Y.; Wang, J. Clinical big data and deep learning: Applications, challenges, and future outlooks. Big Data Min. Anal. 2019, 2, 288–305. [Google Scholar] [CrossRef]

- Lee, J.; Azamfar, M.; Singh, J.; Siahpour, S. Integration of digital twin and deep learning in cyber-physical systems: Towards smart manufacturing. IET Collab. Intell. Manuf. 2020, 2, 34–36. [Google Scholar] [CrossRef]

- Wang, T.; Li, J.; Deng, Y.; Wang, C.; Snoussi, H.; Tao, F. Digital twin for human-machine interaction with convolutional neural network. Int. J. Comput. Integr. Manuf. 2021, 34, 888–897. [Google Scholar] [CrossRef]

- Shi, Y.; Shen, W.; Wang, L.; Longo, F.; Nicoletti, L.; Padovano, A. A cognitive digital twins framework for human-robot collaboration. Procedia Comput. Sci. 2022, 200, 1867–1874. [Google Scholar] [CrossRef]

- Tuli, T.B.; Kohl, L.; Chala, S.A.; Manns, M.; Ansari, F. Knowledge-based digital twin for predicting interactions in human-robot collaboration. In Proceedings of the 2021 26th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vasteras, Sweden, 7–10 September 2021; pp. 1–8. [Google Scholar]

- Li, C.; Zheng, P.; Li, S.; Pang, Y.; Lee, C.K. AR-assisted digital twin-enabled robot collaborative manufacturing system with human-in-the-loop. Robot. Comput.-Integr. Manuf. 2022, 76, 102321. [Google Scholar] [CrossRef]

- Lee, J.; Davari, H.; Singh, J.; Pandhare, V. Industrial Artificial Intelligence for industry 4.0-based manufacturing systems. Manuf. Lett. 2018, 18, 20–23. [Google Scholar] [CrossRef]

- Hu, J.; Xiao, H.; Ye, Z.; Luo, N.; Zhou, M. Research and Prospects of Digital Twin-Based Fault Diagnosis of Electric Machines. Sensors 2025, 25, 2625. [Google Scholar] [CrossRef]

- Hribernik, K.; Cabri, G.; Mandreoli, F.; Mentzas, G. Autonomous, context-aware, adaptive Digital Twins—State of the art and roadmap. Comput. Ind. 2021, 133, 103508. [Google Scholar] [CrossRef]

| Software Solution | Description | Software Type | Applications | Example Use Case |

|---|---|---|---|---|

| Siemens Process Simulate | Digital manufacturing software | Commercial | Manufacturing | [37] |

| FlexSim | Discrete-event simulation | Commercial | Manufacturing, Logistics, Healthcare | [38] |

| Actin | Universal Robot’s simulation/operating software | Commercial; Research | Aerospace, Manufacturing, Healthcare, Research | [39] |

| CoppeliaSIM | Distributed control architecture-based DT software | Commercial | Robotics Research and Development | [40] |

| iTwin.js | Digital Twin Tool Library | Open-Source | Infrastructure | [41] |

| AnyLogic | Multipurpose simulation modeling software | Commercial | Transportation, Logistics, Manufacturing, Healthcare | [42] |

| RoboDK | Industrial robot simulator and database | Commercial | Industrial Robotics | [43] |

| Dassault DELMIA | Digital manufacturing software | Commercial | Manufacturing | [44] |

| Eclipse | Digital Twin/IoT Framework and Library | Open-Source; Research | Software Development, Standards and Regulations | [45] |

| ABB RobotStudio | ABB industrial robot simulator | Commercial | Industrial Robotics | [46] |

| Visual Components | Offline robot programming software | Commercial | Robotics Research, Industrial Applications | [47] |

| Unreal Engine | Physics-based simulator and development platform | Commercial | Gaming, Animation, Architecture, Automotive | [48] |

| Ansys Twin Builder | Simulation-based Digital Twin software | Commercial | Aerospace, Manufacturing, Robotics Research, Industrial Applications | [46] |

| Simul8 | Digital twin simulation software | Commercial | Logistics, Industrial Applications | [46] |

| NVIDIA Omniverse | Physical AI-Enabled Application Set | Commercial; Research | Manufacturing, Animation, Artificial Intelligence | [49] |

| Unity | Real-time Development Platform | Commercial; Research | Gaming, Animation | [50] |

| Gazebo | Robot Simulator | Open-Source; Research | Robot Development, Design, Education | [51] |

| Into-CPS | Cyber-Physical System Application | Open-Source | Research and Development | [52] |

| Title | Goals | Methods | Findings | No. of Citations | Reference |

|---|---|---|---|---|---|

| Digital twin-driven product design, manufacturing and service with big data | Developed a novel approach to product design, manufacturing, and service utilizing digital twins | Integrated digital data processing in the traditional product development lifecycle | Qualitatively assessed framework performance in three conceptual case studies as successful | 2266 | [68] |

| Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing | Produced an original concept of a digital twin shop-floor (DTS) | Four key components are explored: physical shop-floor, virtual shop-floor, shop-floor service system, and shop-floor digital twin data | Provided an insight into conceptual DTS operation and a framework for further research | 1130 | [69] |

| Digital twin-based smart production management and control framework for the complex product assembly shop-floor | Proposed a system of digital twin-based intelligent production management approach for assembly of complex product | Presented a detailed implementation of the proposed approach for a satellite assembly shop-floor scenario | Successfully illustrated the pragmatic application of the proposed framework in a conceptual satellite assembly shop floor | 601 | [70] |

| An application framework of digital twin and its case study | Created an application framework of DT for product lifecycle management | A DT case study of a welding production line is built and studied using total-elements information perception technology, data storage, data processing, data mapping, and parametric virtual modeling | The proposed system can show 19 types of key data of the production line in real time, limit simulation delay below 1 s, and update a 4 million piece model at more than 50 times per second | 493 | [71] |

| Digital Twin as a Service (DTaaS) in Industry 4.0: An Architecture Reference Model | Designed a holistic reference architecture model for DT-enabled applications | Case study using DTaaS on the virtualization of wetlands to improve maintenance scheduling | Findings indicate that there is a significant relationship between DT capabilities as a service and mass individualization | 462 | [72] |

| Protocol | Description | Example Use Case |

|---|---|---|

| OPC UA (Unified Architecture) | A standard protocol for secure and reliable communication between devices, systems, and applications. | [101] |

| MQTT (Message Queuing Telemetry Transport) | A lightweight publish-subscribe messaging protocol for efficient data exchange. | [102] |

| ROS (Robot Operating System) | A flexible framework for writing robot software, providing libraries and tools for communication and control. | [103] |

| DDS (Data Distribution Service) | A data-centric publish-subscribe communication protocol for real-time and scalable systems. | [104] |

| CoAP (Constrained Application Protocol) | A protocol designed for resource-constrained devices, suitable for IoT and low-power applications. | [105] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guerra-Zubiaga, D.A.; Aksu, M.; Richards, G.; Kuts, V. Integrating Digital Twin Software Solutions with Collaborative Industrial Systems: A Comprehensive Review for Operational Efficiency. Appl. Sci. 2025, 15, 7049. https://doi.org/10.3390/app15137049

Guerra-Zubiaga DA, Aksu M, Richards G, Kuts V. Integrating Digital Twin Software Solutions with Collaborative Industrial Systems: A Comprehensive Review for Operational Efficiency. Applied Sciences. 2025; 15(13):7049. https://doi.org/10.3390/app15137049

Chicago/Turabian StyleGuerra-Zubiaga, David A., Murat Aksu, Gershom Richards, and Vladimir Kuts. 2025. "Integrating Digital Twin Software Solutions with Collaborative Industrial Systems: A Comprehensive Review for Operational Efficiency" Applied Sciences 15, no. 13: 7049. https://doi.org/10.3390/app15137049

APA StyleGuerra-Zubiaga, D. A., Aksu, M., Richards, G., & Kuts, V. (2025). Integrating Digital Twin Software Solutions with Collaborative Industrial Systems: A Comprehensive Review for Operational Efficiency. Applied Sciences, 15(13), 7049. https://doi.org/10.3390/app15137049