Research on the Mechanical Behavior and Rockburst Risk of the Deep-Buried Roadway at the Stratigraphical Boundary of Different Lithologies

Abstract

1. Introduction

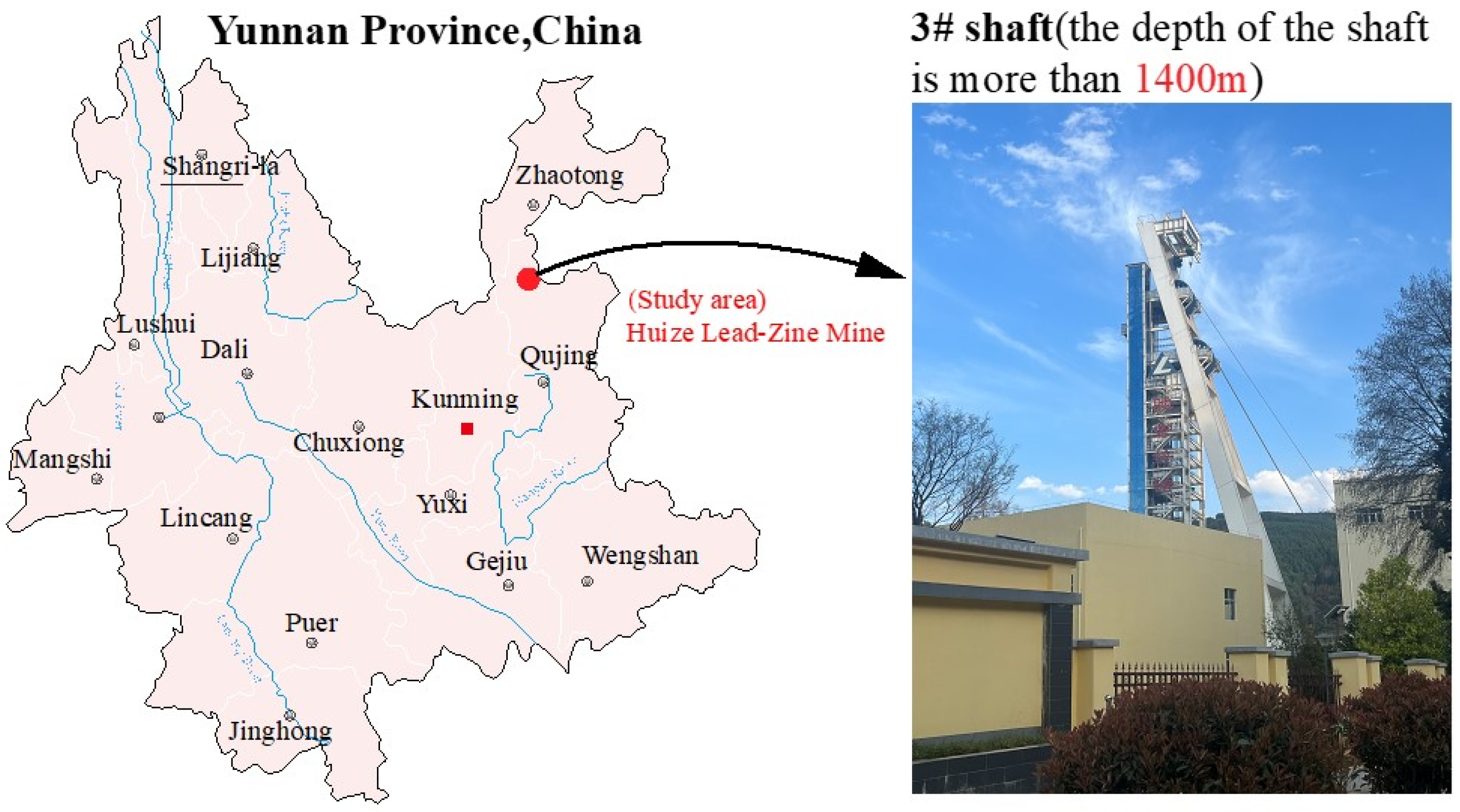

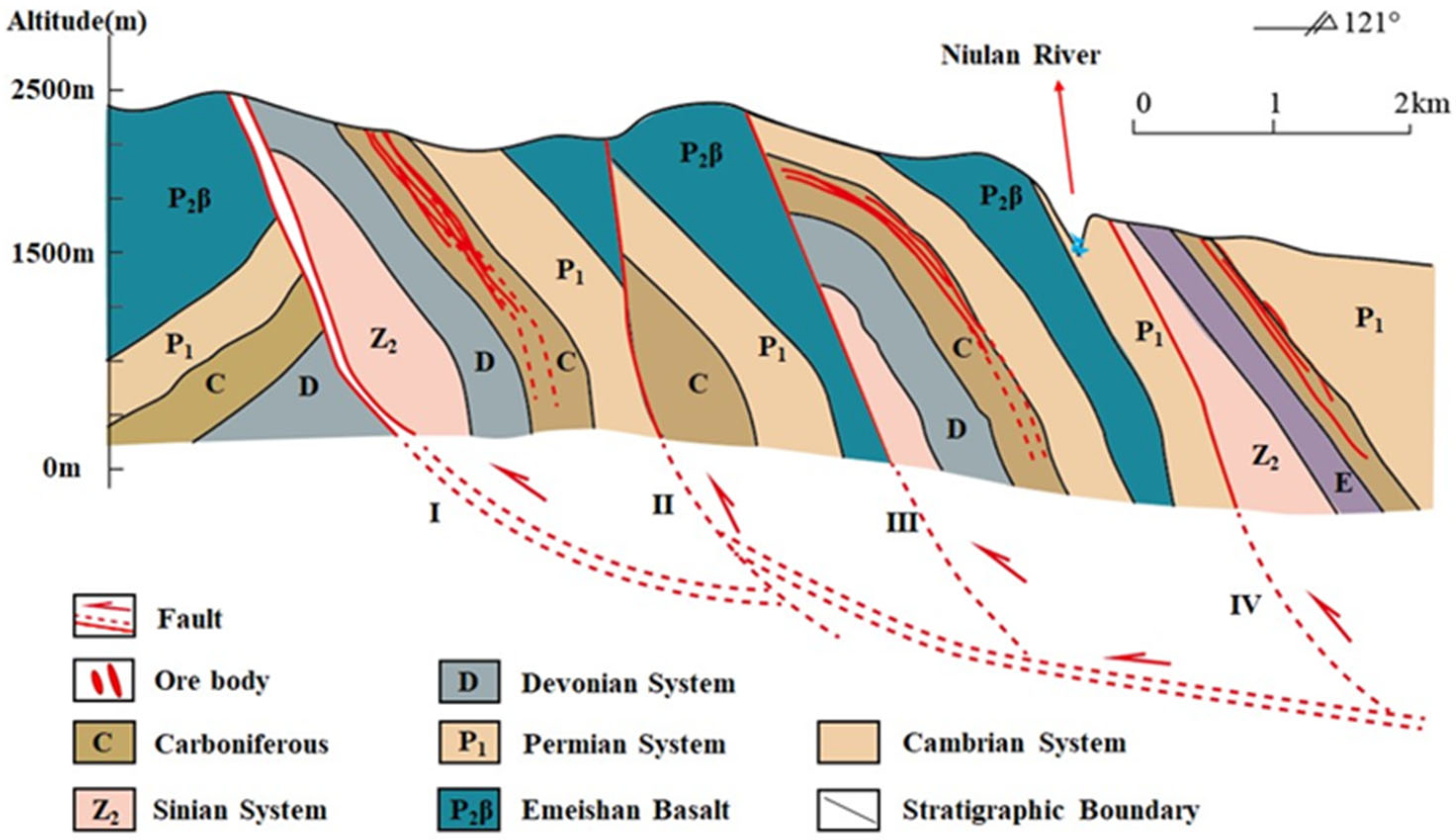

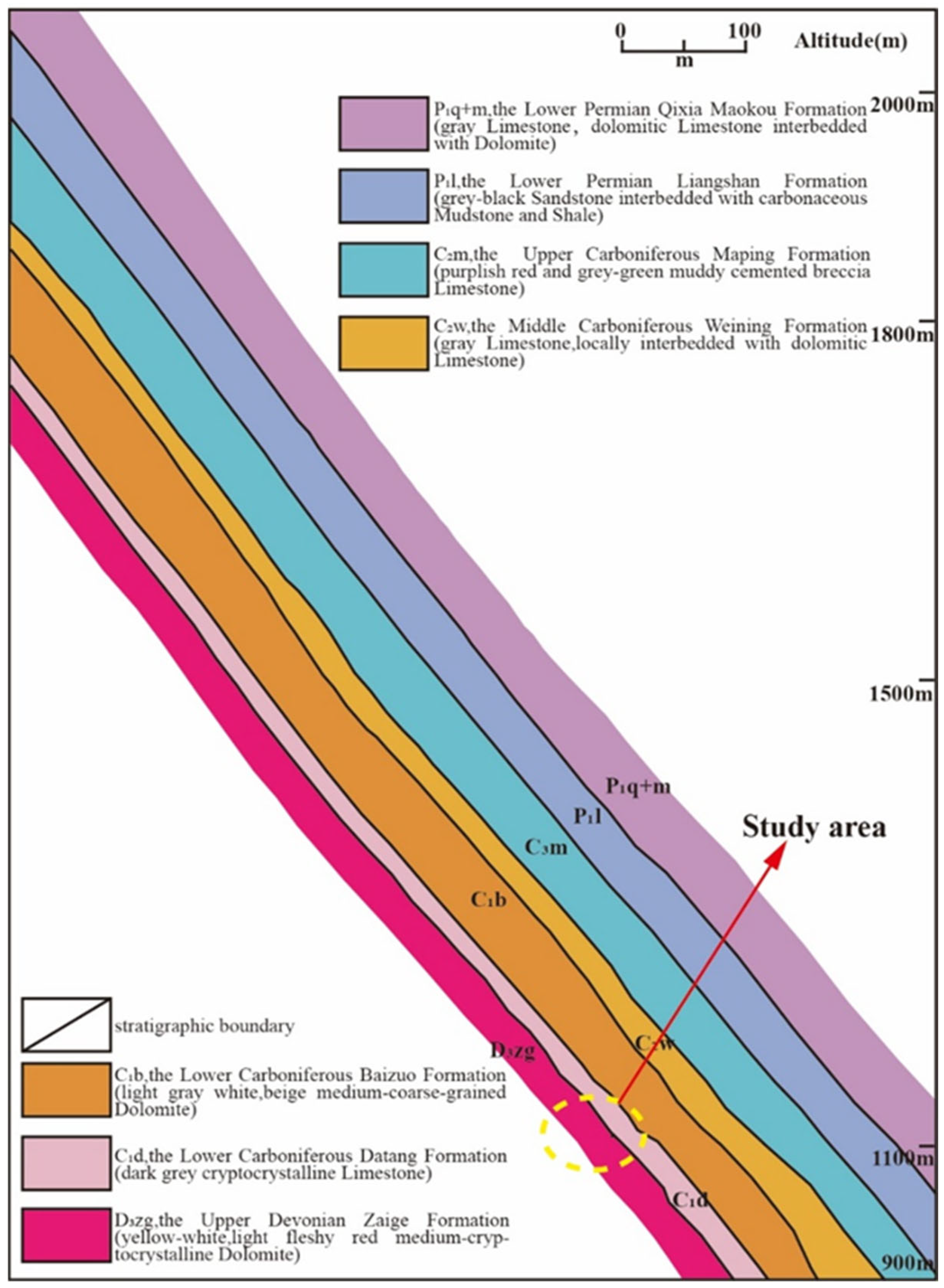

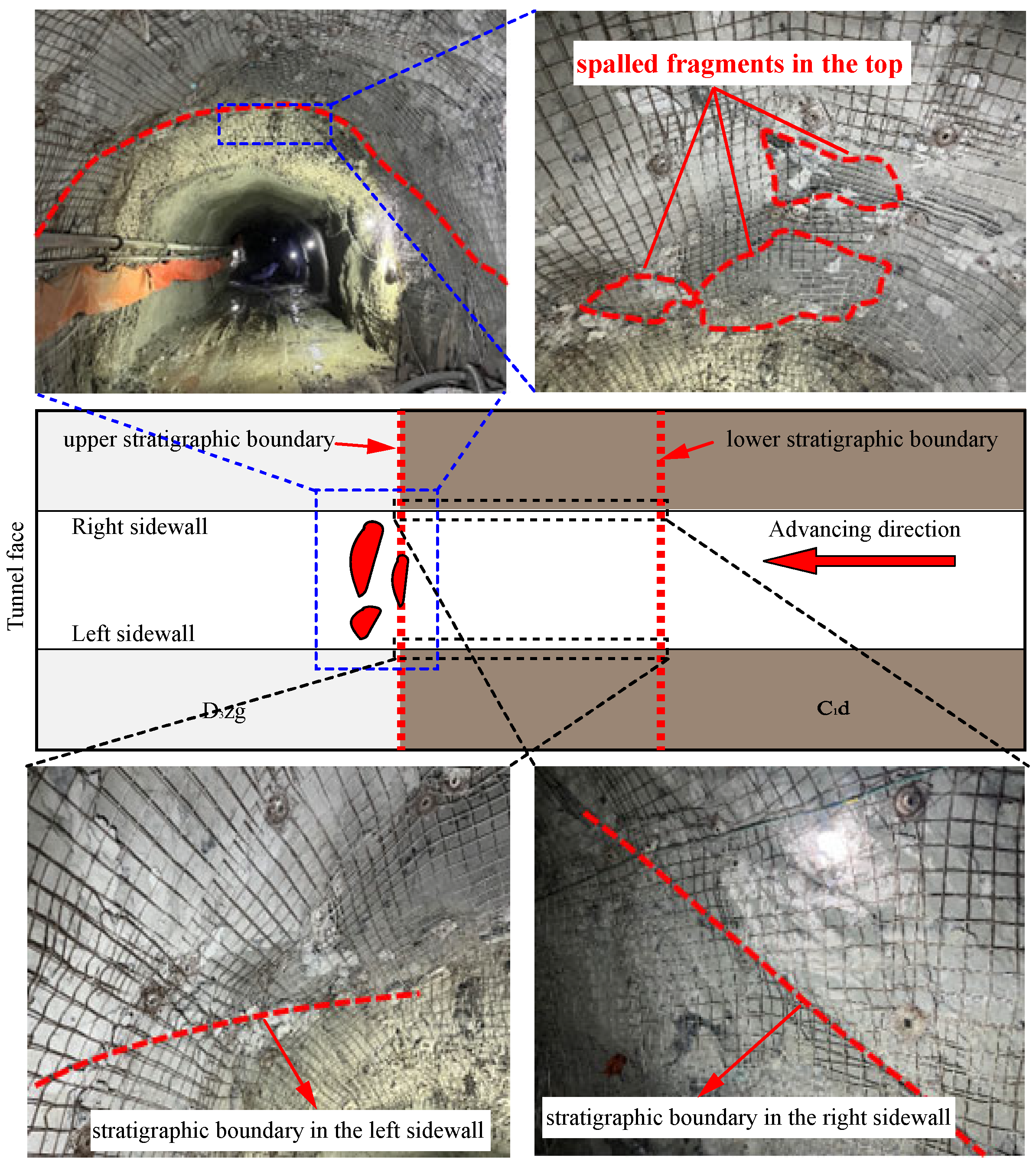

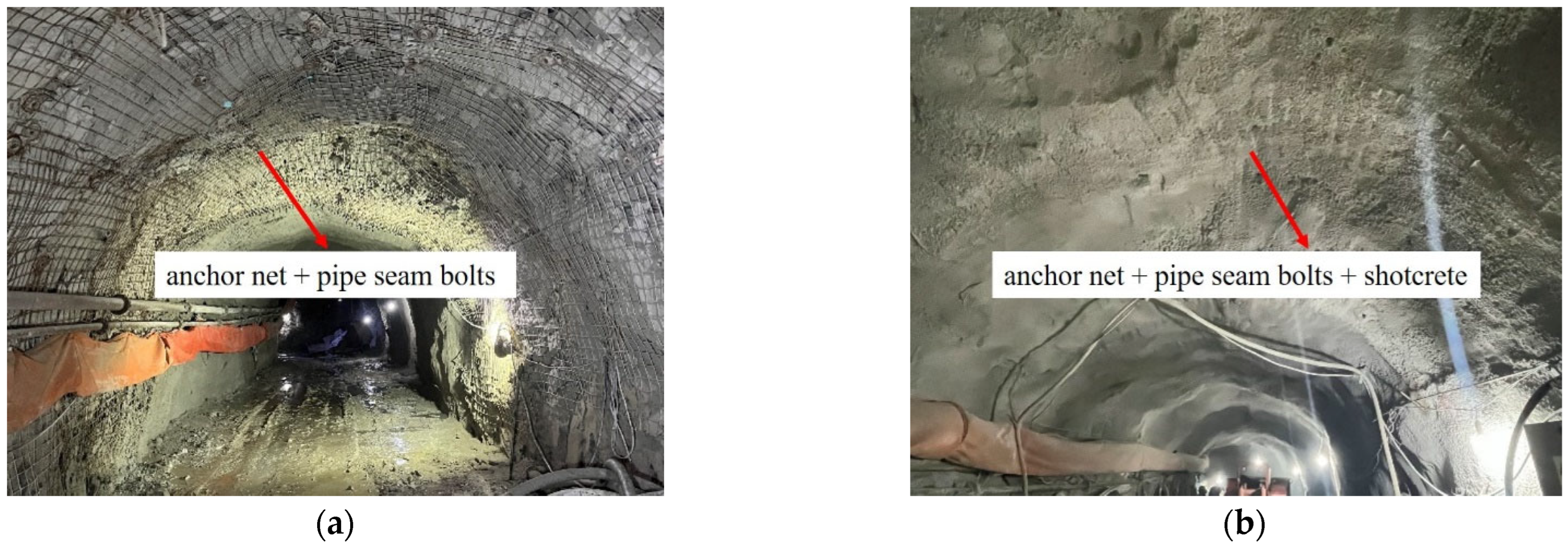

2. Engineering Overview

3. Study on Rockburst Potential Assessment Based on Rock Mechanics Tests

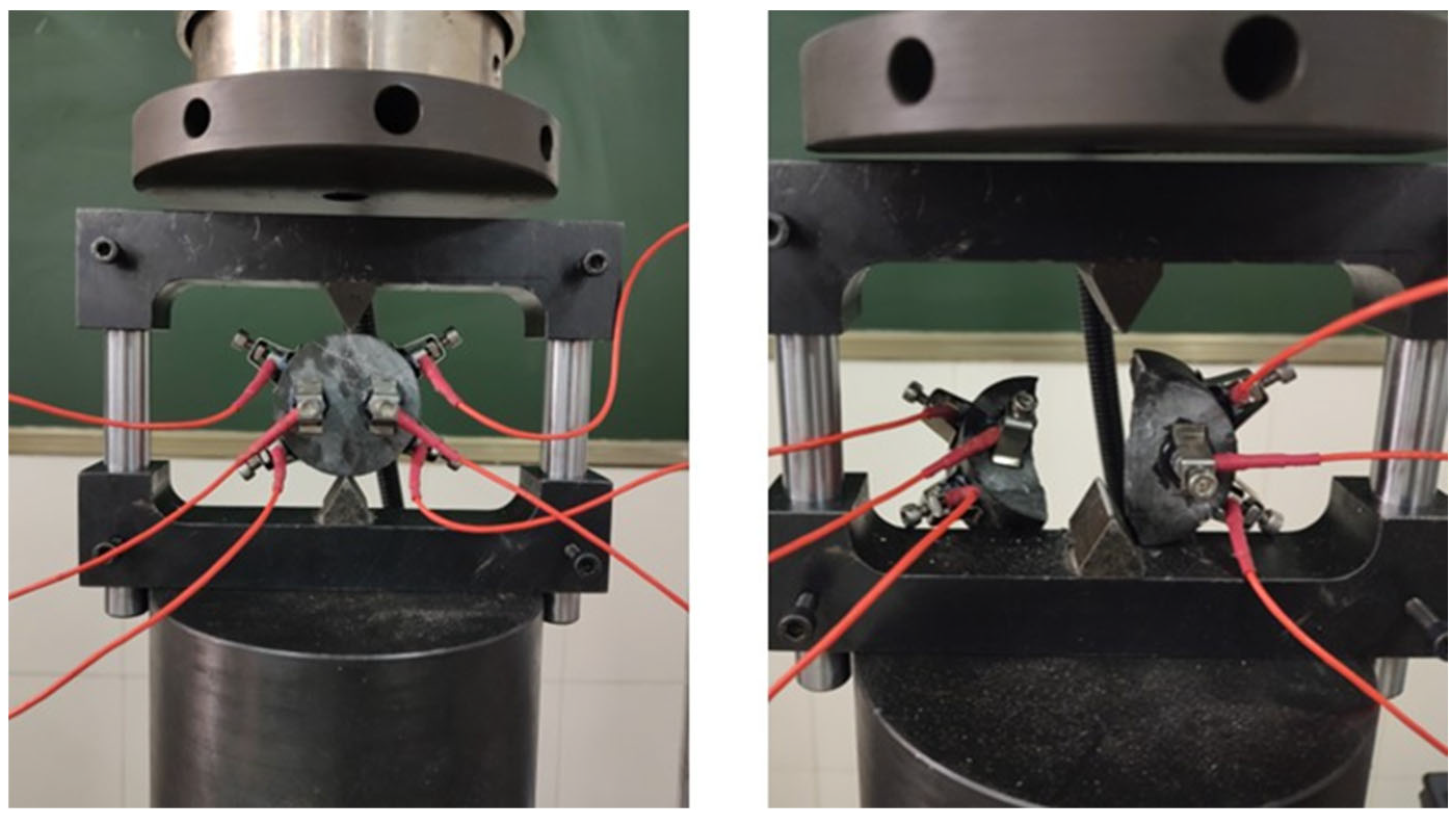

3.1. Study on Basic Mechanical Properties of the Rock

3.2. Assessment of Rockburst Potential Based on Rock Mechanics Test Results

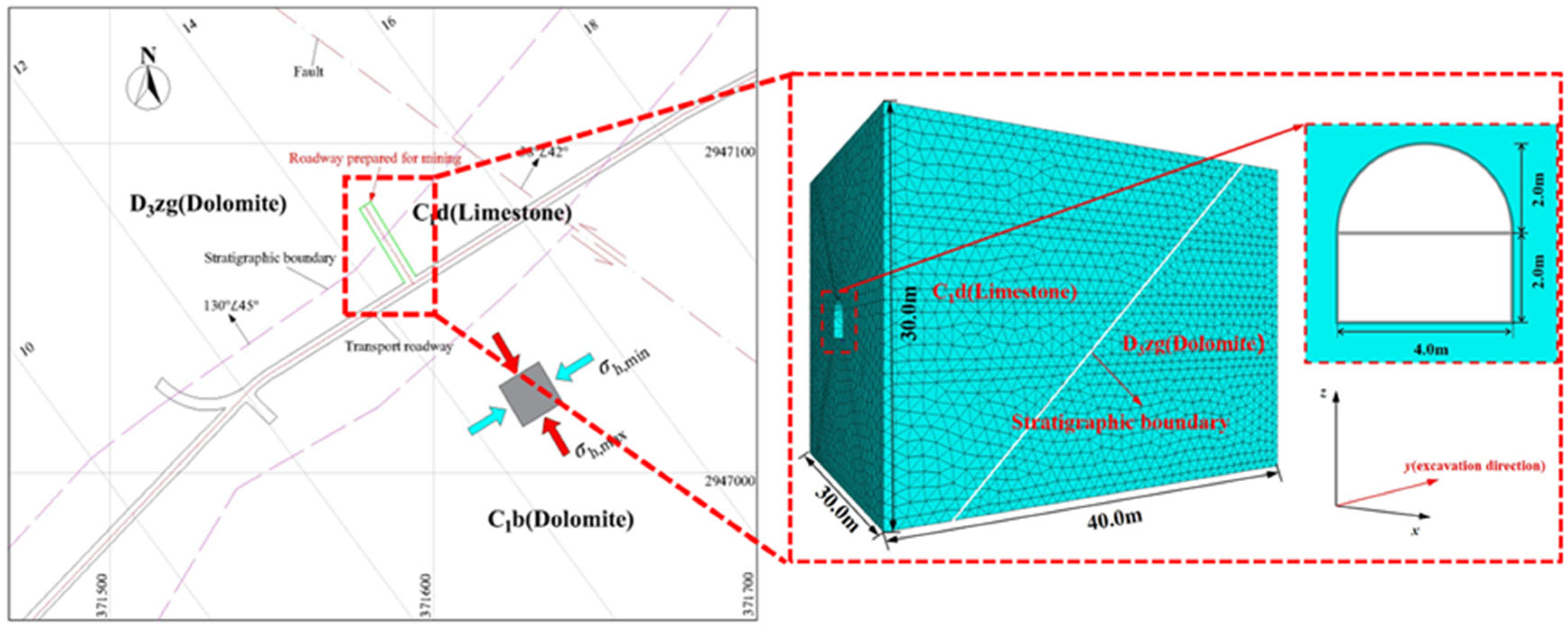

4. Geomechanics Modelling Establishment of Different Lithologies

4.1. Construction of Geometric Models

4.2. Numerical Model Parameter Matching

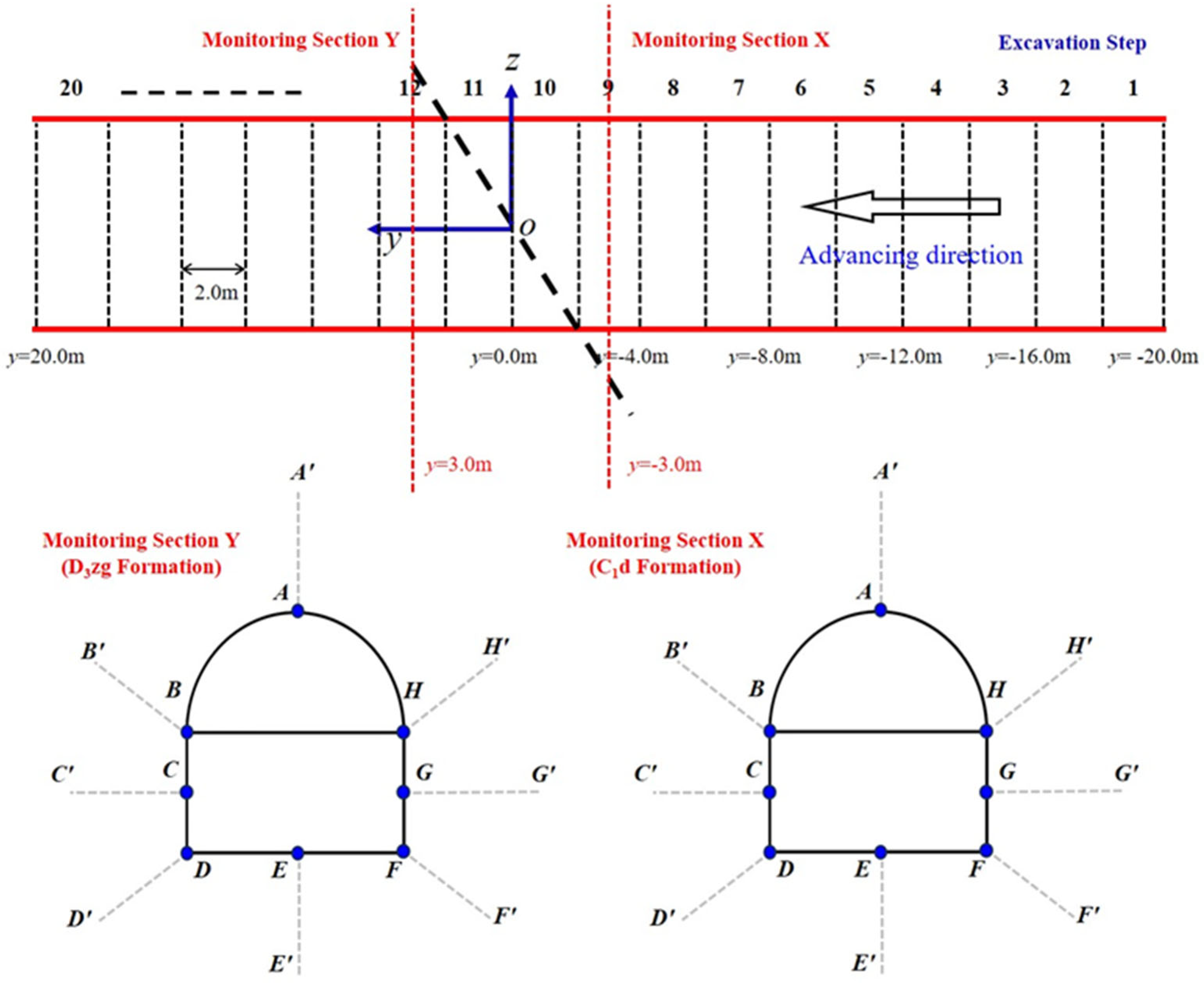

4.3. Boundary Conditions and Monitoring Scheme

5. Analysis and Discussion of Numerical Simulation Results

5.1. Study on Mechanical Behavior Characteristics of the Surrounding Rock at Stratigraphic Boundary

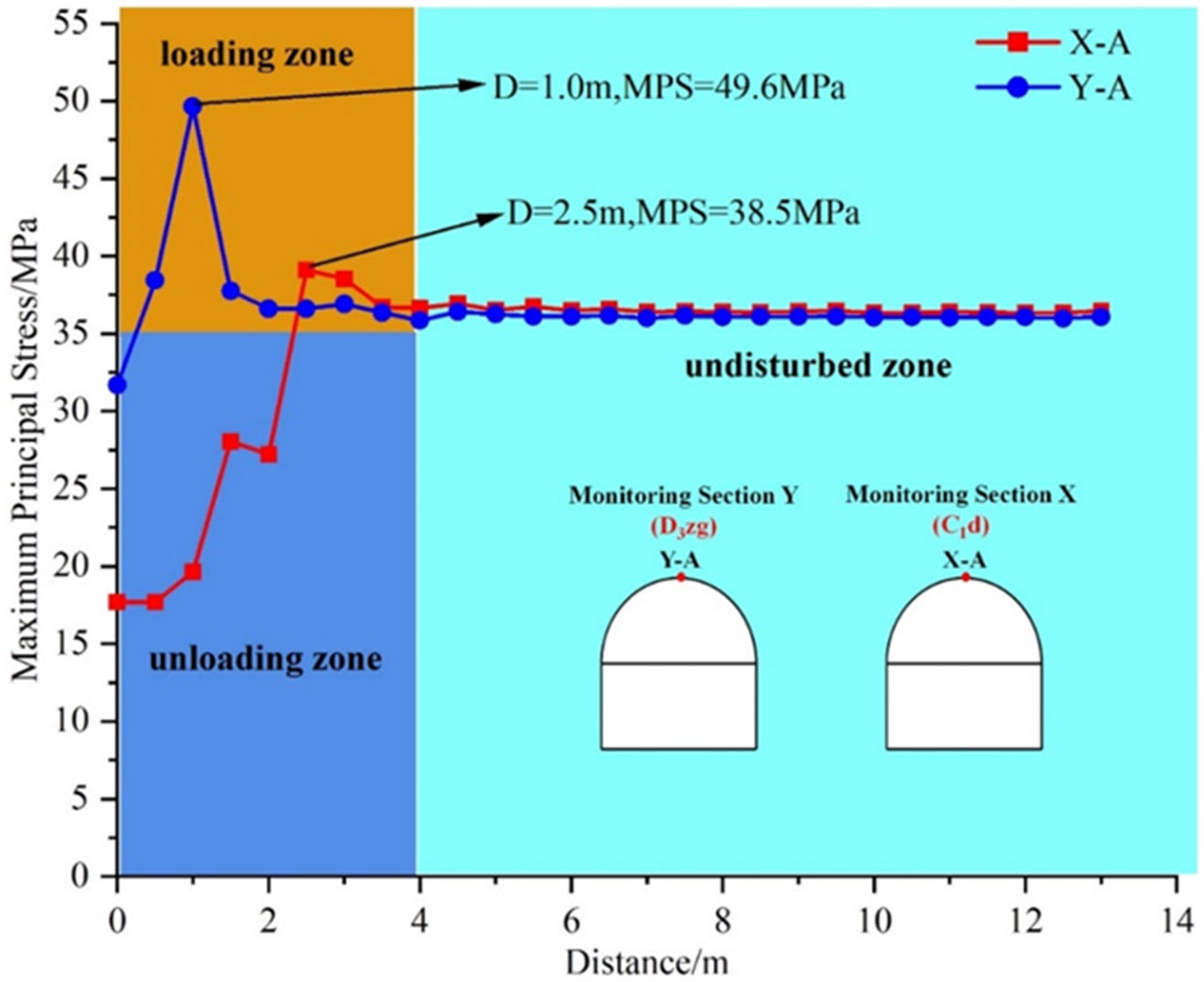

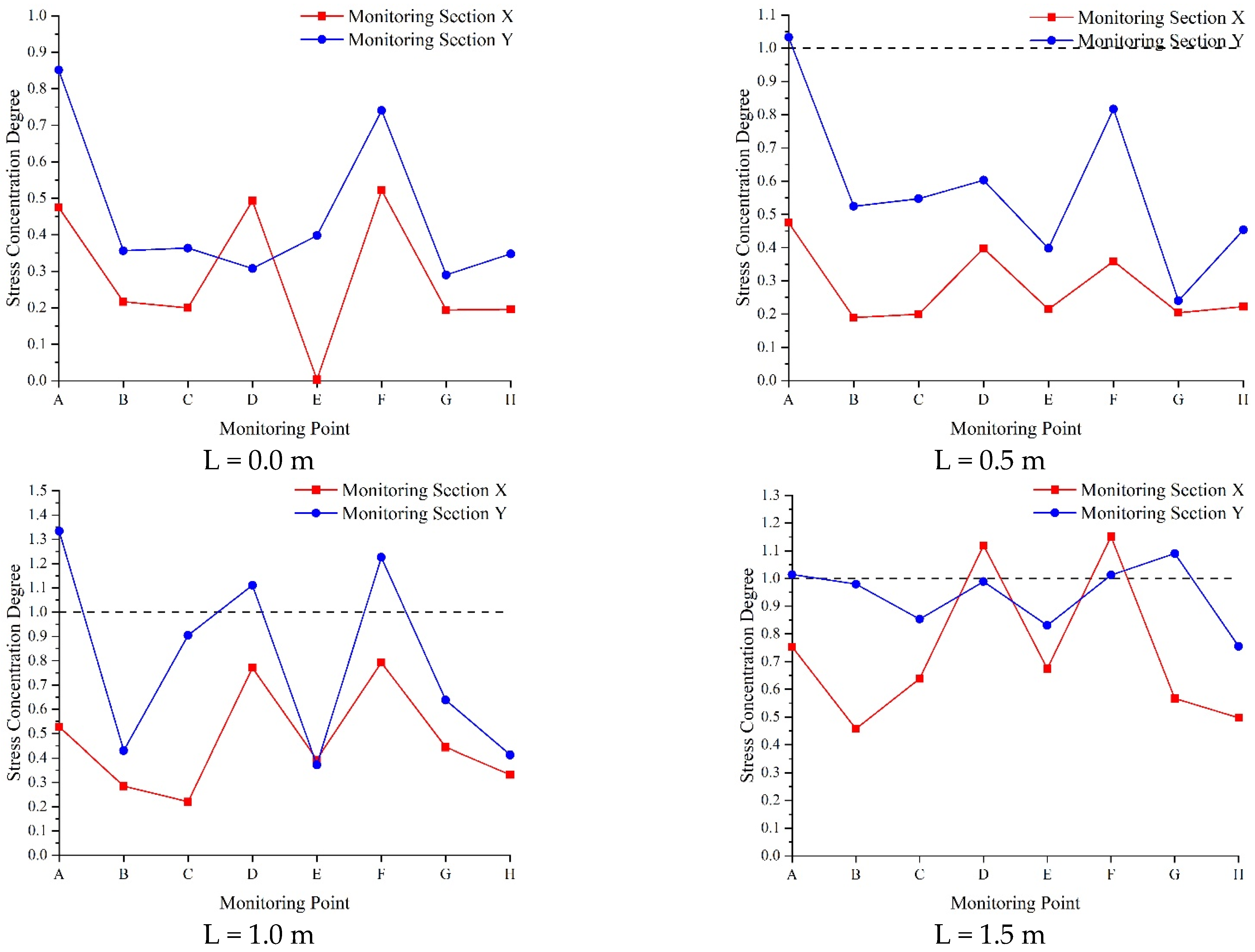

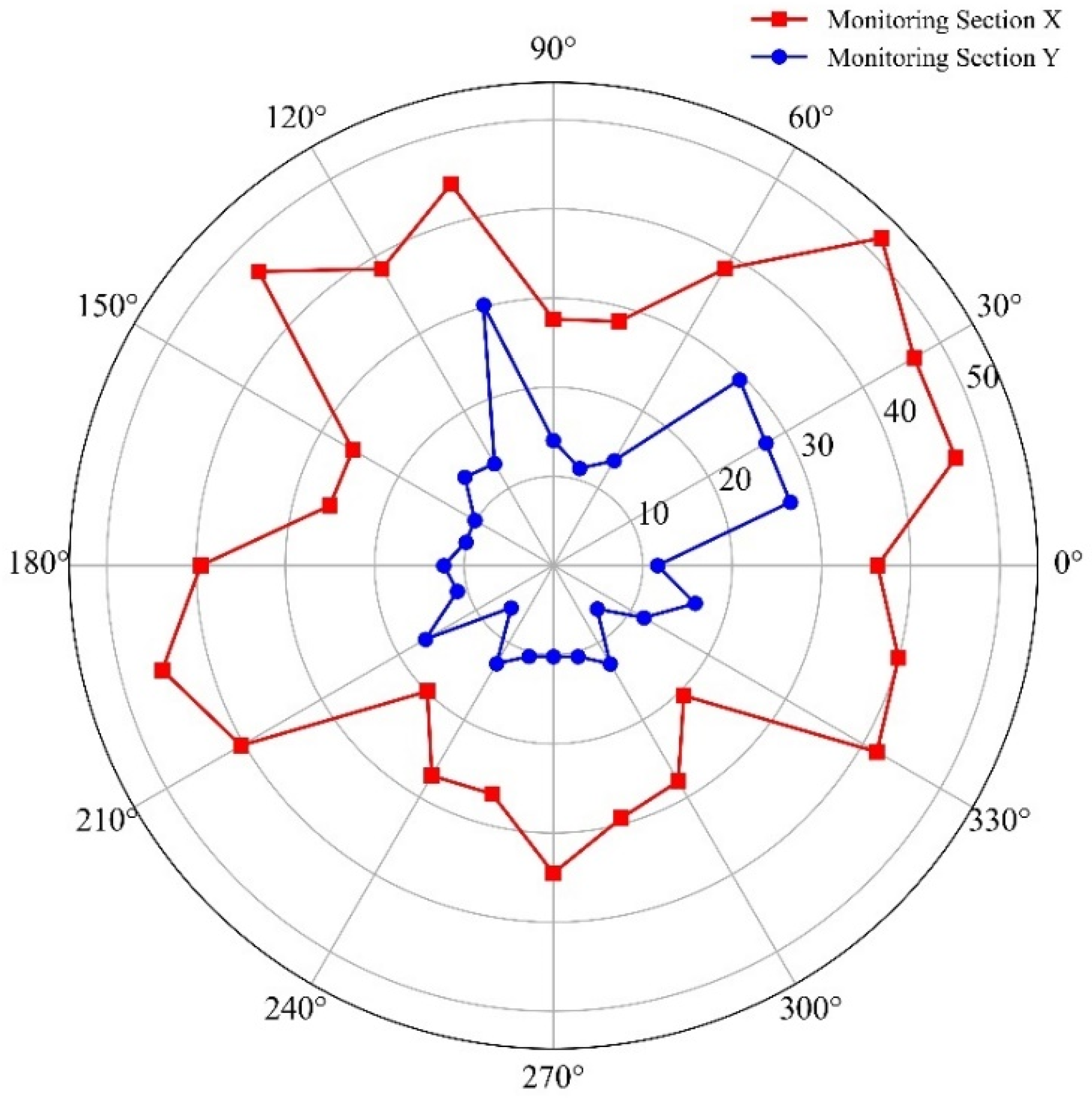

5.1.1. Study on the Distribution Characteristics and Evolution Law of the Stress Field

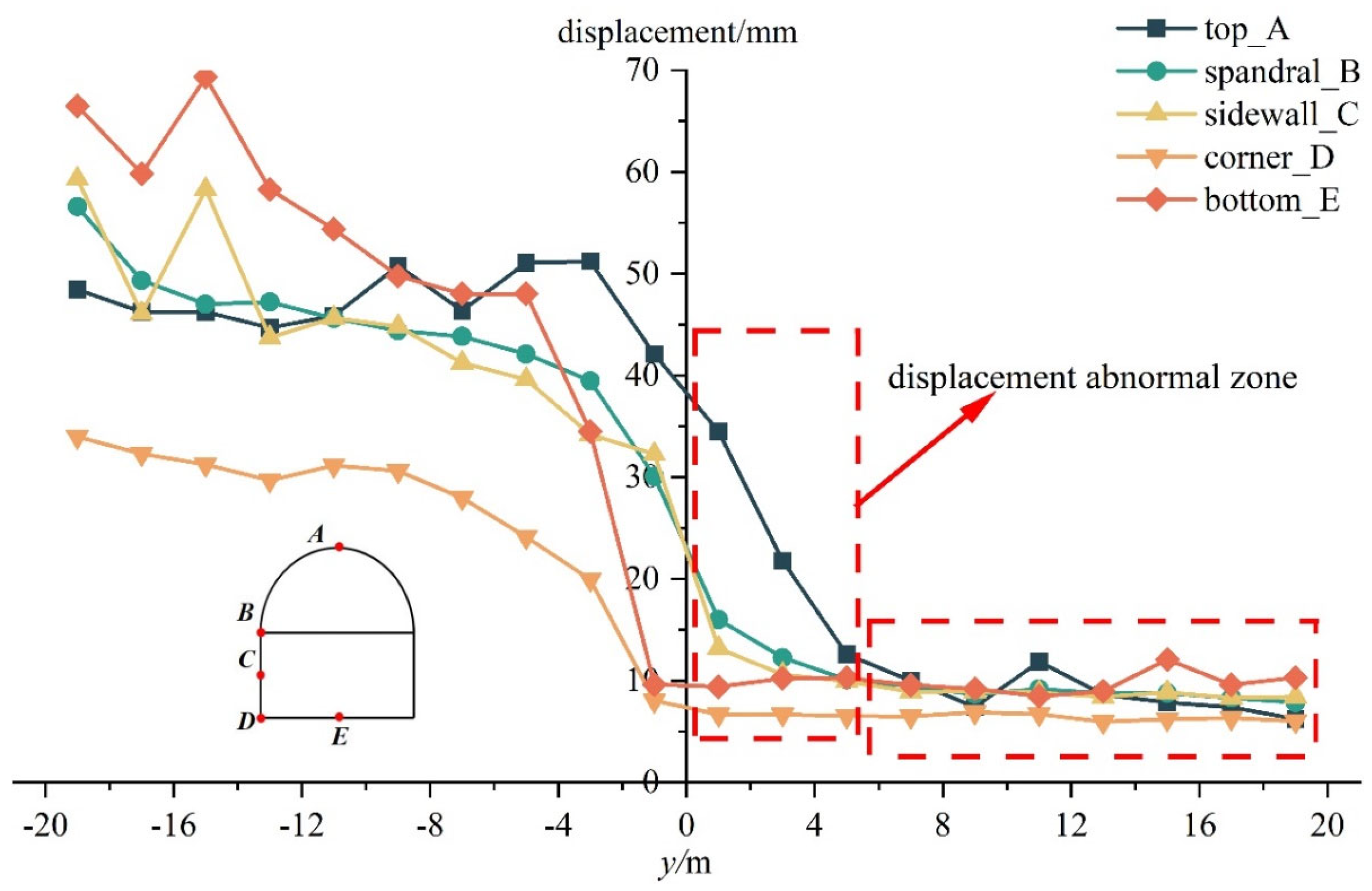

5.1.2. Study on the Distribution Characteristics and Evolution Law of Displacement Field

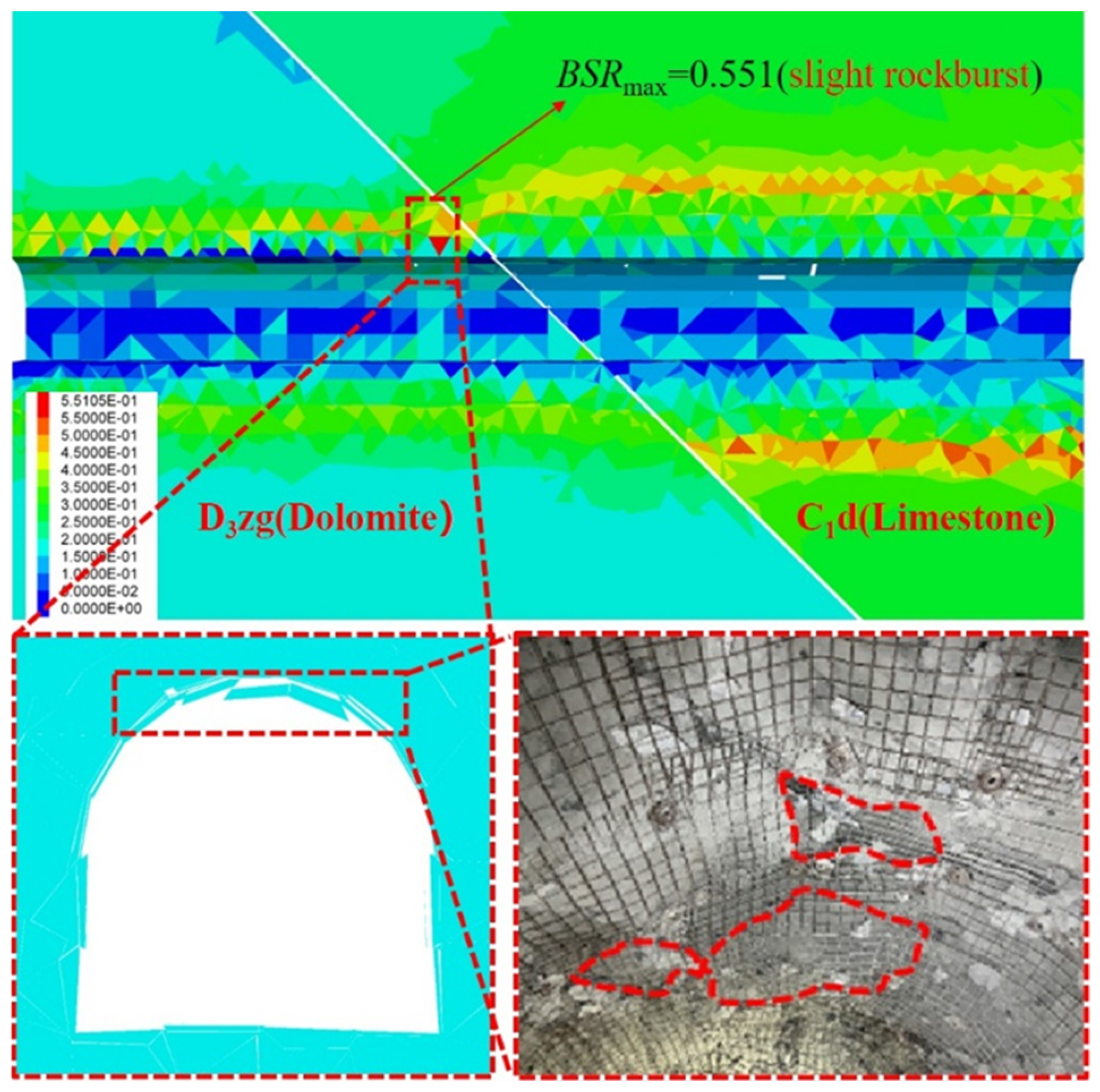

5.2. Analysis of Rockburst Risk Assessment for the Deep-Buried Roadway Crossing Stratigraphic Boundary

6. Conclusions

- (1)

- Based on the results of the rock mechanics laboratory tests, and combined with the brittleness index and the maximum stored elastic strain energy index criteria, it was found that the D3zg formation (dolomite) is prone to slight to moderate rockburst, while the C1d formation (limestone) is prone to slight rockburst. From the perspective of internal causative factors, both formations possess rockburst potential.

- (2)

- Differences in the distribution characteristics of the surrounding rock stress field were observed when the roadway crossed different formations. In the C1d formation, the stress release zone is larger, the stress concentration zone is located farther from the excavation surface, and the degree of stress accumulation is relatively low. In contrast, in the D3zg formation, the stress release zone is smaller, the stress concentration zone is closer to the excavation surface, and the degree of stress accumulation is relatively high. Additionally, when the roadway crosses the stratigraphic boundary, an abnormal stress zone forms in the lower plate (the relatively harder formation), primarily concentrated near the vault. This stress abnormal zone provides favorable external conditions for energy accumulation, thus increasing the likelihood of rockburst disasters.

- (3)

- The surrounding rock displacement is significantly affected by lithological differences, particularly in formations with a low elastic modulus. Furthermore, the displacement in the high-modulus rock near the stratigraphic boundary is greater than in other locations within the same formation. This may be attributed to the larger displacement of the lower-modulus rock squeezing the harder rock, a phenomenon particularly evident near the vault.

- (4)

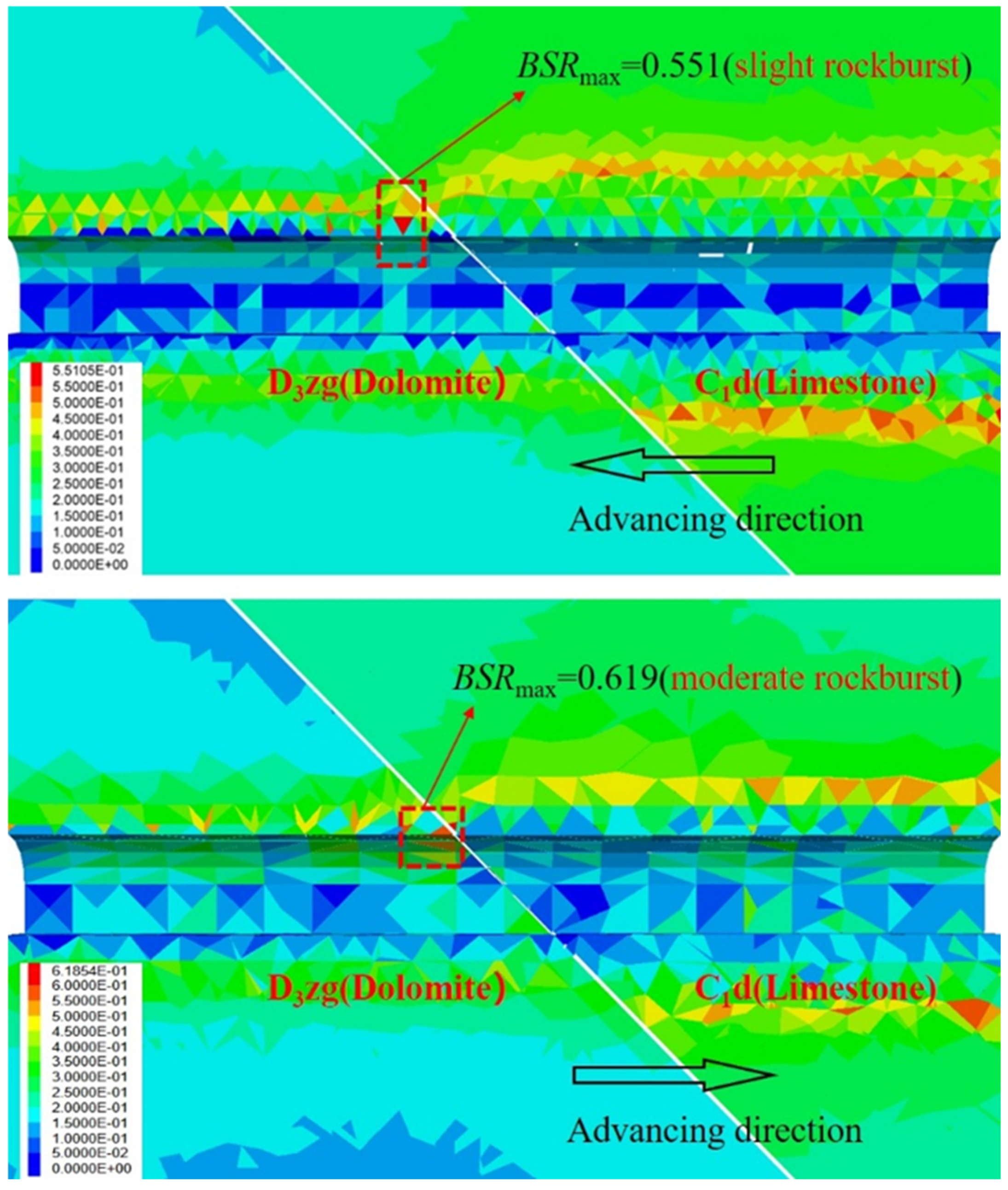

- When the roadway is located in the C1d formation, larger BSR values are distributed farther from the excavation surface. In the D3zg formation, larger BSR values appear closer to the excavation face, indicating a higher rockburst risk in the D3zg formation compared to the C1d formation. In the scenario where the roadway is excavated from the C1d formation to the D3zg formation, the BSR index peaks near the arch top adjacent to the stratigraphic boundary (close to the D3zg formation), reaching a maximum of 0.551, which corresponds to a slight rockburst risk. However, when the excavation direction is reversed (from D3zg to C1d), the BSR index peaks at 0.619, indicating a moderate rockburst risk, which is higher in magnitude. These simulation results demonstrate that the direction of roadway excavation affects the level of rockburst risk, especially when crossing multi-stratigraphic tectonic zones with differing lithologies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, M.; Cheng, T.; Qiao, Y.; Li, H. A review of rockburst: Experiments, theories, and simulations. J. Rock Mech. Geotech. Eng. 2023, 15, 1312–1353. [Google Scholar] [CrossRef]

- Su, G.; Li, P.; Xu, H.; Liu, X. A two-step method for predicting rockburst using sound signals. Acta Geotech. 2023, 19, 273–303. [Google Scholar] [CrossRef]

- Feng, X.T.; Xiao, Y.X.; Feng, G.L.; Yao, Z.B.; Chen, B.R.; Yang, C.X.; Su, G.S. Study on the development process of rockbursts. Chin. J. Rock Mech. Eng. 2019, 38, 649–673. [Google Scholar]

- Yu, Q. Study on Rockburst Nucleation Process and Early Warning Method of Deep-Buried Tnnels. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2016. [Google Scholar]

- Jiang, F.F.; Zhou, H.; Liu, C.; Sheng, J. Progress, prediction and prevention of rockbursts in underground metal mines. Chin. J. Rock Mech. Eng. 2019, 38, 956–972. [Google Scholar]

- Askaripour, M.; Saeidi, A.; Rouleau, A.; Mercier-Langevin, P. Rockburst in underground excavations: A review of mechanism, classification, and prediction methods. Undergr. Space 2022, 7, 577–607. [Google Scholar] [CrossRef]

- Li, P.; Chen, B.; Zhou, Y.; Xiao, Y.; Feng, G.; Zhu, G. Research progress of rockburst prediction and early warning in hard rock underground engineering. J. China Coal Soc. 2019, 44, 447–465. [Google Scholar]

- Wang, J.; Apel, D.B.; Pu, Y.; Hall, R.; Wei, C.; Sepehri, M. Numerical modeling for rockbursts: A state-of-the-art review. J. Rock Mech. Geotech. Eng. 2021, 13, 457–478. [Google Scholar] [CrossRef]

- Zhou, J.; Li, X.; Mitri, H.S. Evaluation method of rockburst: State-of-the-art literature review. Tunn. Undergr. Space Technol. 2018, 81, 632–659. [Google Scholar] [CrossRef]

- Liang, W.Z.; Zhao, G.Y. A review of long-term and short-term rockburst risk evaluations in deep hard rock. Chin. J. Rock Mech. Eng. 2022, 41, 19–39. [Google Scholar]

- Kusui, A.; Villaescusa, E.; Funatsu, T. Mechanical behaviour of scaled-down unsupported tunnel walls in hard rock under high stress. Tunn. Undergr. Space Technol. 2016, 60, 30–40. [Google Scholar] [CrossRef]

- Zhang, C.Q.; Zhou, H.; Feng, X.T. An Index for Estimating the Stability of Brittle Surrounding Rock Mass: FAI and its Engineering Application. Rock Mech. Rock Eng. 2011, 44, 401–414. [Google Scholar] [CrossRef]

- Zhang, C.Q.; Feng, X.T.; Zhou, H.; Qiu, S.L.; Wu, W.P. Rockmass damage development following two extremely intense rockbursts in deep tunnels at Jinping II hydropower station, southwestern China. Bull. Eng. Geol. Environ. 2013, 72, 237–247. [Google Scholar] [CrossRef]

- Wang, Z.; Dou, L.; Li, J.; Kang, K.; Feng, L. Numerical investigation of damage risks of roadway surrounding rocks under oblique incident dynamic loads. Shock. Vib. 2017, 2017, 6298372. [Google Scholar] [CrossRef]

- Guo, C.B.; Zhang, Y.S.; Jiang, L.W.; Sun, D.S.; Xiong, T.Y.; Du, Y.B.; Zheng, G. Research on rockburst mechanism and profile suitability of deep-buried tunnel in fold structure body. Chin. J. Rock Mech. Eng. 2012, 31, 2758–2766. [Google Scholar]

- Yang, J.; Chen, W.; Tan, X.; Yang, D. Analytical estimation of stress distribution in interbedded layers and its implication to rockburst in strong layer. Tunn. Undergr. Space Technol. 2017, 81, 289–295. [Google Scholar] [CrossRef]

- Cai, M.F. Prediction and prevention of rockburst in metal mines—A case study of Sanshandao gold mine. J. Rock Mech. Geotech. Eng. 2016, 8, 204–211. [Google Scholar] [CrossRef]

- Cai, M.F.; Ji, D.; Guo, Q.F. Study of rockburst prediction based on in-situ stress measurement and theory of energy accumulation caused by mining disturbance. Chin. J. Rock Mech. Eng. 2013, 32, 1973–1980. [Google Scholar]

- Sepehri, M. Finite Element Analysis Model for Determination of In-Situ and Mining Induced Stresses as a Function of Two different Mining Methods Used at Diavik Diamond Mine. Ph.D. Thesis, University of Alberta, Edmonton, AL, Canada, 2016. [Google Scholar]

- Sepehri, M.; Apel, D.B.; Adeeb, S.; Leveille, P.; Hall, R.A. Evaluation of mining-induced energy and rockburst prediction at a diamond mine in Canada using a full 3D elastoplastic finite element model. Eng. Geol. 2020, 266, 105457. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, C.; Wu, F.; Li, X.; Glowacz, A. Rockburst Characteristics and Mechanisms during Steeply Inclined Thin Veins Mining: A Case Study in Zhazixi Antimony Mine, China. Shock. Vib. 2018, 2018, 1–16. [Google Scholar] [CrossRef]

- Wang, J.-A.; Park, H.D. Comprehensive prediction of rockburst based on analysis of strain energy in rocks. Tunn. Undergr. Space Technol. 2001, 16, 49–57. [Google Scholar] [CrossRef]

- Weng, L.; Huang, L.; Taheri, A.; Li, X. Rockburst characteristics and numerical simulation based on a strain energy density index: A case study of a roadway in Linglong gold mine, China. Tunn. Undergr. Space Technol. 2017, 69, 223–232. [Google Scholar] [CrossRef]

- Xu, J.; Jiang, J.; Xu, N.; Liu, Q.; Gao, Y. A new energy index for evaluating the tendency of rockburst and its engineering application. Eng. Geol. 2017, 230, 46–54. [Google Scholar] [CrossRef]

- Zhu, B.; Fan, J.; Shi, X.; Liu, P.; Guo, J. Study on rockburst proneness of deep tunnel under different geo-stress conditions based on DEM. Geotech. Geol. Eng. 2022, 40, 1373–1386. [Google Scholar] [CrossRef]

- Xue, Y.; Cao, Z.; Du, F.; Zhu, L. The influence of the backfilling roadway driving sequence on the rockburst risk of a coal pillar based on an energy density criterion. Sustainability 2018, 10, 2609. [Google Scholar] [CrossRef]

- Luo, P.; Fang, X.; Li, D.; Yu, Y.; Li, H.; Cui, P.; Ma, J. Evaluation of excavation method on point load strength of rocks with poor geological conditions in a deep metal mine. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 90. [Google Scholar] [CrossRef]

- Zhang, C.Q.; Lu, J.J.; Chen, J.; Zhou, H.; Yang, F.J. Discussion on rock burst proneness indexes and their relation. Rock Soil Mech. 2017, 38, 1397–1404. [Google Scholar]

- Xia, Z.Y. Study on Instability Mechanism and Prevention Measure of Extraction Structure in Block Caving Mine. Ph.D. Thesis, University of Science and Technology Beijing, Beijing China, 2021. [Google Scholar]

- Hoek, E.; Diederichs, M.S. Empirical estimation of rock mass modulus. Int. J. Rock Mech. Min. Sci. 2006, 43, 203–215. [Google Scholar] [CrossRef]

- Hoek, E.; Carranza-Torres, C.; Corkum, B. Hoek-Brown failure criterion–2002 Edition. In Proceedings of the Fifth North American Rock Mechanics Symposium, Toronto, ON, Canada, 7–10 July 2002; Volume 1, pp. 267–273. [Google Scholar]

- Gao, Y.H. Study on Determining Representative Elementary Volume of Equivalent Rock Mass and the Mechanical Behavior of Joints. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2015. [Google Scholar]

- Sun, X.; Li, G.; Zhao, C.; Liu, Y.; Miao, C. Investigation of Deep Mine Shaft Stability in Alternating Hard and Soft Rock Strata Using Three-Dimensional Numerical Modeling. Processes 2018, 7, 2. [Google Scholar] [CrossRef]

- Sakhno, I.; Sakhno, S.; Isaienkov, O.; Petrenko, A. Research on influence of stress-strain evolution in immediate floor before and after excavation face on origin floor heave in coal mines roadways. IOP Conf. Ser.: Earth Environ. Sci. 2024, 145, 012026. [Google Scholar] [CrossRef]

- Vennes, I.; Mitri, H. Geomechanical effects of stress shadow created by large-scale destress blasting. J. Rock Mech. Geotech. Eng. 2017, 9, 1085–1093. [Google Scholar] [CrossRef]

- Xu, B.; Xie, H.P.; Tu, Y.J. Numerical simulation of rockburst stress state during excavation of underground powerhouse of pubugou hydropower station. Chin. J. Rock Mech. Eng. 2017, 26, 2894–2900. [Google Scholar]

| Lithology | Sample Number | Diameter (mm) | Height (mm) | Peak Load (kN) | UCS (MPa) | E (GPa) | Poisson |

|---|---|---|---|---|---|---|---|

| Dolomite | BY-1 | 48.50 | 100.10 | 208.10 | 112.46 | 62.10 | 0.42 |

| BY-2 | 48.50 | 100.10 | 164.10 | 88.68 | 56.96 | 0.34 | |

| BY-3 | 48.50 | 99.90 | 126.78 | 68.50 | 54.26 | 0.26 | |

| BY-4 | 48.73 | 99.97 | 213.83 | 114.48 | 62.79 | 0.38 | |

| BY-5 | 48.92 | 99.84 | 187.98 | 99.87 | 59.04 | 0.29 | |

| Average | 96.80 | 59.03 | 0.34 | ||||

| Limestone | HY-1 | 48.70 | 100.00 | 84.33 | 53.59 | 34.47 | 0.40 |

| HY-2 | 48.70 | 100.20 | 96.12 | 59.48 | 41.57 | 0.23 | |

| HY-3 | 48.60 | 100.00 | 139.70 | 78.02 | 39.83 | 0.32 | |

| HY-4 | 48.69 | 100.34 | 164.73 | 60.52 | 37.77 | 0.24 | |

| HY-5 | 47.19 | 100.24 | 178.62 | 55.34 | 32.84 | 0.28 | |

| Average | 61.39 | 37.30 | 0.29 |

| Lithology | Sample Number | Diameter (mm) | Height (mm) | Peak Load (kN) | UTS (MPa) |

|---|---|---|---|---|---|

| Dolomite | BY-6 | 49.90 | 24.70 | 12.12 | 6.26 |

| BY-7 | 49.95 | 25.02 | 9.61 | 4.90 | |

| BY-8 | 49.90 | 24.90 | 8.60 | 4.41 | |

| BY-9 | 50.13 | 24.75 | 12.91 | 6.62 | |

| BY-10 | 48.30 | 24.90 | 13.38 | 7.03 | |

| Average | 5.85 | ||||

| Limestone | HY-6 | 50.02 | 24.81 | 9.83 | 5.04 |

| HY-7 | 47.14 | 25.03 | 10.83 | 5.84 | |

| HY-8 | 49.61 | 25.02 | 10.88 | 5.58 | |

| HY-9 | 49.62 | 24.97 | 11.65 | 5.99 | |

| HY-10 | 48.62 | 24.98 | 7.84 | 4.11 | |

| Average | 5.31 |

| Rockburst Potential Criterion | Lithology | Brittleness Index Criterion | ||

|---|---|---|---|---|

| Expression | Value | Rockburst Classification | ||

| Brittleness index criterion [28] | D3zg | 16.55 | Moderate | |

| C1d | 11.56 | Light | ||

| Maximum stored elastic strain energy index | ||||

| Expression | Value | Rockburst classification | ||

| Energy index criteria [10] | D3zg | 79.37 | Light | |

| C1d | 50.52 | Light | ||

| Lithology | Intact Rock | GSI | Hoek–Brown Parameters | Rock Mass | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| UCS (MPa) | E (GPa) | mi | mb | s | a | D | UCSrm (MPa) | Erm (GPa) | ||

| D3zg | 96.80 | 59.03 | 65 | 12 | 1.754 | 0.0063 | 0.502 | 0.7 | 7.59 | 15.67 |

| C1d | 61.39 | 37.30 | 55 | 10 | 0.844 | 0.0015 | 0.504 | 0.7 | 2.29 | 5.51 |

| Lithology | Block Properties | Contact Properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Density (kg/m3) | K (GPa) | G (GPa) | Cb (MPa) | φb | σbt (MPa) | Kn (GPa /m) | Ks (GPa /m) | Cb (MPa) | φc | σct (MPa) | |

| C1d | 2739 | 4.37 | 2.14 | 2.30 | 25.52 | 0.11 | 239.0 | 95.6 | 0.30 | 25 | 0.10 |

| D3zg | 2729 | 16.32 | 5.85 | 3.77 | 34.79 | 0.35 | 828.3 | 331.3 | 0.95 | 30 | 0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chu, C.; Xia, L.; Wu, S.; Han, S.; Zhang, G. Research on the Mechanical Behavior and Rockburst Risk of the Deep-Buried Roadway at the Stratigraphical Boundary of Different Lithologies. Appl. Sci. 2025, 15, 7026. https://doi.org/10.3390/app15137026

Chu C, Xia L, Wu S, Han S, Zhang G. Research on the Mechanical Behavior and Rockburst Risk of the Deep-Buried Roadway at the Stratigraphical Boundary of Different Lithologies. Applied Sciences. 2025; 15(13):7026. https://doi.org/10.3390/app15137026

Chicago/Turabian StyleChu, Chaoqun, Lei Xia, Shunchuan Wu, Shun Han, and Guang Zhang. 2025. "Research on the Mechanical Behavior and Rockburst Risk of the Deep-Buried Roadway at the Stratigraphical Boundary of Different Lithologies" Applied Sciences 15, no. 13: 7026. https://doi.org/10.3390/app15137026

APA StyleChu, C., Xia, L., Wu, S., Han, S., & Zhang, G. (2025). Research on the Mechanical Behavior and Rockburst Risk of the Deep-Buried Roadway at the Stratigraphical Boundary of Different Lithologies. Applied Sciences, 15(13), 7026. https://doi.org/10.3390/app15137026