Empirical Study on Failure Prediction of Rotating Biological Contactors Available for Landfill Site Operators: Scoring Analysis Based on 17-Year Daily Inspection Reports

Abstract

1. Introduction

2. Materials and Methods

2.1. Overview of Landfill Site

2.2. Leachate Treatment Facility

2.3. Contents of Inspection Logs

2.4. Summary of Inspection Logs

3. Results and Discussion

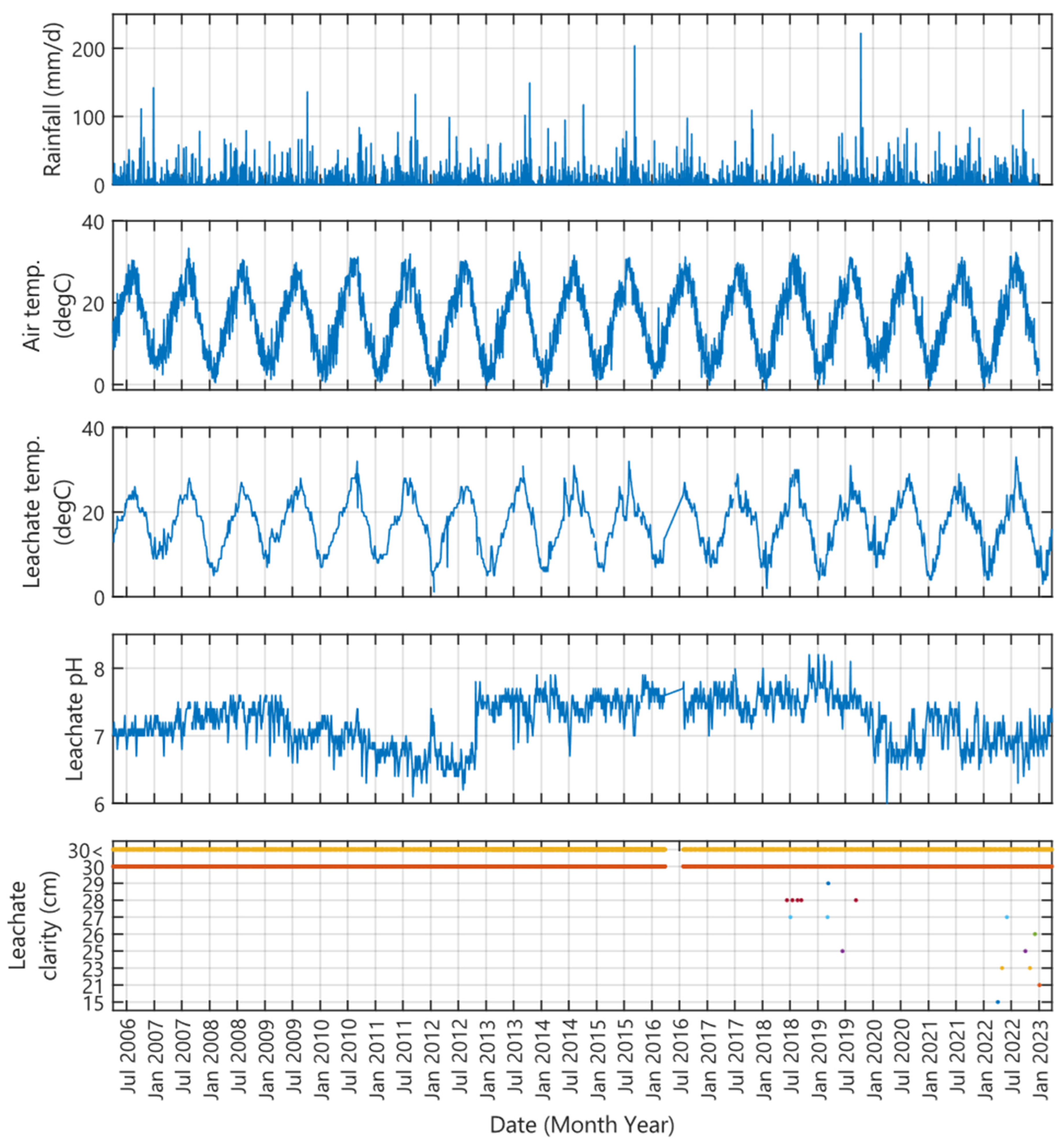

3.1. Relationship with Leachate Water Quality

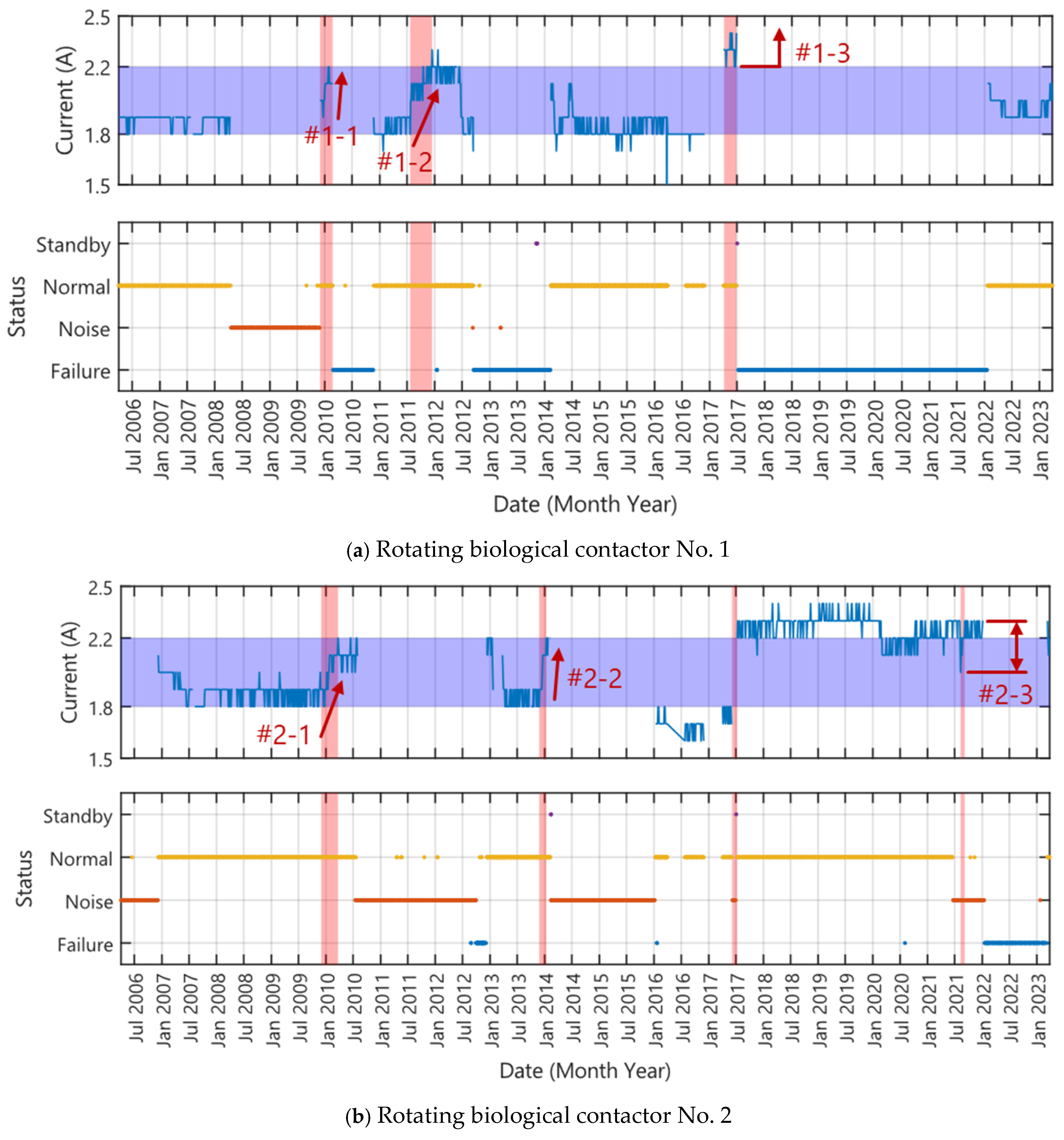

3.2. Characteristic Indicators of RBC Failure

- (1)

- Normal operation is associated with a defined current range;

- (2)

- A sharp rise in current tends to precede the onset of abnormal noise;

- (3)

- Failure is preceded by sustained current fluctuations with increasing amplitude following the appearance of abnormal noise.

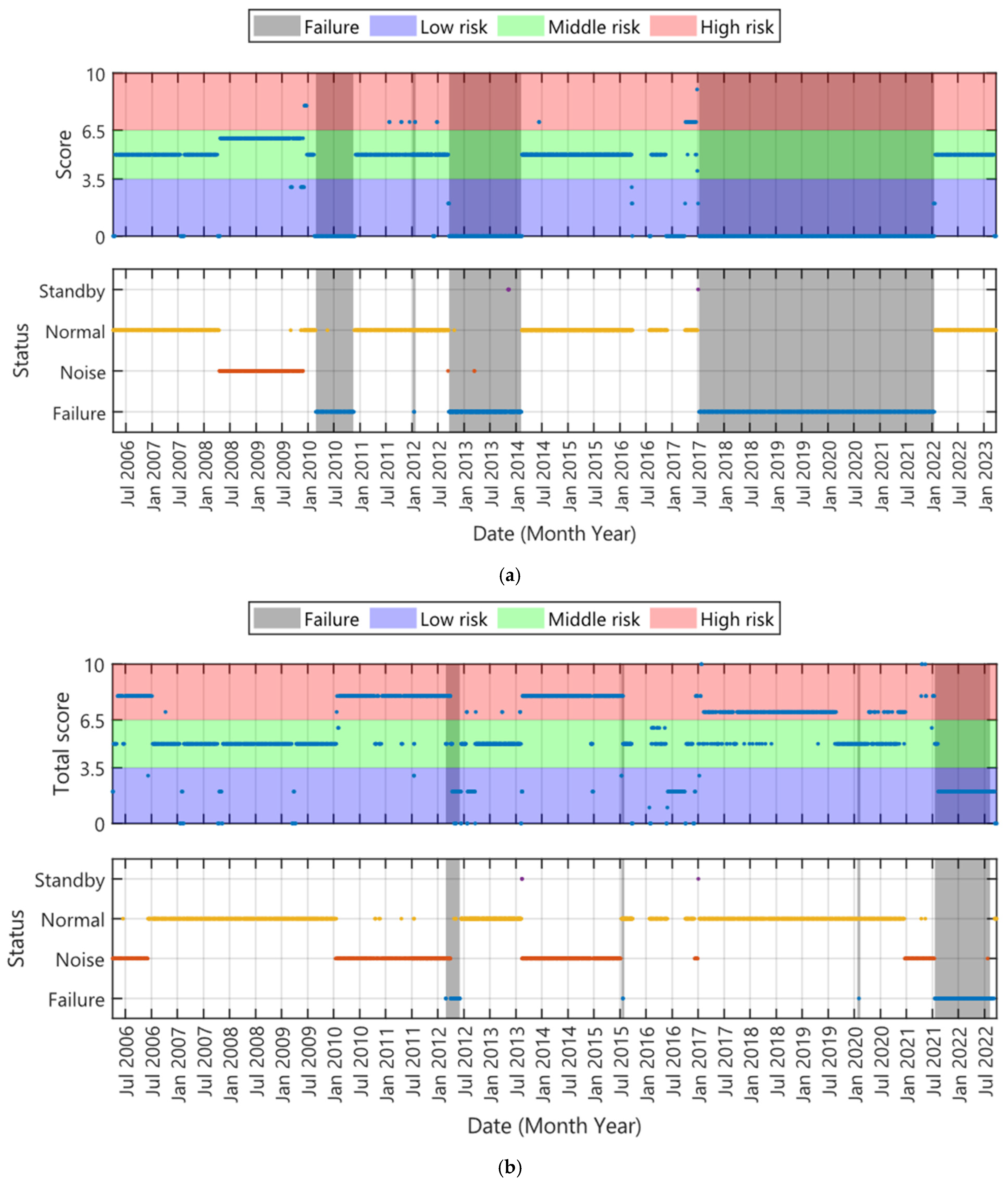

3.3. Failure Prediction Scoring Model

3.4. Applicability

4. Conclusions

- The scoring model constructed by artificial intelligence proved effective for predicting failures in cases where abnormal noise persisted over an extended period.

- In contrast, for failure cases that occurred without abnormal noise, the application of a revised scoring model that accounted for sudden increases in current improved the accuracy of early fault detection.

- The revised scoring model enabled the numerical evaluation of high-risk conditions by tracking cumulative changes in current before failures occurred. For the rotating disc devices targeted in this study, a method for quantitative predictive maintenance was successfully demonstrated using simple monitoring indicators such as abnormal noise and current.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RBC | rotating biological contactor |

References

- Amorim, C.L.; Duque, A.F.; Afonso, C.M.M.; Castro, P.M.L. Bioaugmentation for treating transient 4-fluorocinnamic acid shock loads in a rotating biological contactor. Bioresour. Technol. 2013, 144, 554–562. [Google Scholar] [CrossRef] [PubMed]

- Brazil, B.L. Performance and operation of a rotating biological contactor in a tilapia recirculating aquaculture system. Aquac. Eng. 2006, 34, 261–274. [Google Scholar] [CrossRef]

- Brenner, R.C.; Heidam, J.A.; Opatken, E.J.; Petraske, A.C., Jr. Design Information on Rotating Biological Contactors; EPA-600/2-84-106; U. S. EPA: Washington, DC, USA, 1984. [Google Scholar]

- Mba, D. Mechanical evolution of the rotating biological contactor into the 21st century. Proc. Inst. Mech. Eng. Part E-J. Process Mech. Eng. 2003, 217, 189–219. [Google Scholar] [CrossRef]

- Nilling, J.J.; Deka, M.; Prasad, S.; Tungi, S.; Bharti, A. Performance evaluation of laboratory scale RBC to treat wastewater from hostels. Int. J. Innov. Res. Sci. Eng. Technol. 2007, 3, 168–175. [Google Scholar]

- Popa, M.; Ungureanu, N.; Vladut, V. Applications of rotating biological contactors in wastewater treatment. Cadastre Ser. 2019, 49, 136–145. [Google Scholar]

- Rana, S.; Gupta, N.; Rana, R.S. Removal of organic pollutant with the use of rotating biological contactor. Mater. Today Proc. 2018, 5, 4218–4224. [Google Scholar] [CrossRef]

- Tonde, M.R.; Mali, J.R.; Patil, S.B. Study of rotating biological contactors (RBCs) for wastewater treatment process. Int. J. Creat. Res. Thoughts 2017, 82, 621–623. [Google Scholar]

- EPA. Review of Current RBC Performance and Design Procedures; EPA/600/S2-85/033; U. S. EPA: Washington, DC, USA, 1985. [Google Scholar]

- Márqueza, P.; Gutiérreza, M.C.; Toledoa, M.; Alhamab, J.; Michánb, C.; Martína, M.A. Activated sludge process versus rotating biological contactors in WWTPs: Evaluating the influence of operation and sludge bacterial content on their odor impact. Process Saf. Environ. Prot. 2022, 160, 775–785. [Google Scholar] [CrossRef]

- Castillo, E.; Vergara, M.; Moreno, Y. Landfill leachate treatment using a rotating biological contactor and an upward-flow anaerobic sludge bed reactor. Waste Manag. 2007, 27, 720–726. [Google Scholar] [CrossRef]

- Imtinan, S.I.F.; Purwanto, P.; Yulianto, B. The biological treatment method for landfill leachate. Proc. E3S Web Conf. 2020, 202, 06006. [Google Scholar] [CrossRef]

- Kulikowska, D.; Józwiak, T.; Kuczajowska-Zadrozna, M.; Pokój, T.; Gusiatin, Z. Efficiency of nitrification and organics removal from municipal landfill leachate in the rotating biological contactor (RBC). Desalination Water Treat. 2011, 33, 125–131. [Google Scholar] [CrossRef]

- Varma, A.L.; Prasad, M.K. Treatment of synthetic leachate by rotating biological contactor: A review. Int. J. Res. Appl. Sci. Eng. Technol. 2019, 7, 993–997. [Google Scholar] [CrossRef]

- Coetzee, G.; Malandra, L.; Wolfaardt, G.M.; Viljoen-Bloom, M. Dynamics of a microbial biofilm in a rotating biological contactor for the treatment of winery effluent. Water SA 2024, 30, 407–412. [Google Scholar] [CrossRef][Green Version]

- Ghawi, A.H.; Kris, J. Use of a rotating biological contactor for appropriate technology wastewater treatment. Slovak J. Civ. Eng. 2009, 3, 1–8. [Google Scholar]

- Hassard, F.; Biddle, J.; Cartmell, E.; Jefferson, B.; Tyrrel, S.; Stephenson, T. Rotating biological contactors for wastewater treatment—A review. Process Saf. Environ. Prot. 2015, 94, 285–306. [Google Scholar] [CrossRef]

- Saini, S.K. Modeling and experimentation for novel aerofoil embedded mesh disk-based partially submerged rotating reactor. Chem. Eng. J. Adv. 2022, 12, 100382. [Google Scholar] [CrossRef]

- Cheng, H.; Li, W.; Gong, Z.; Wen, C.; Zhang, C.; Lu, X. Treatment performance and characteristics of biofilm carriers in an aerobic waterwheel-driven rotating biological contactor. Water 2025, 17, 356. [Google Scholar] [CrossRef]

- Irfan, M.; Waqas, S.; Arshad, U.; Khan, J.A.; Legutko, S.; Kruszelnicka, I.; Kramarczyk, D.G.; Rahman, S.; Skrzypczak, A. Response surface methodology and ANN modelling of membrane rotating biological contactors for wastewater treatment. Materials 2022, 15, 1932. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Huda, N.; Harun, N.Y.; Nordin, N.; Shamsuddin, N.; Wibisono, Y.; Khan, A.L.; Roslan, J. Membrane filtration as post-treatment of rotating biological contactor for wastewater treatment. Sustainability 2021, 13, 7287. [Google Scholar] [CrossRef]

- Yan, Z.; Pei, Z. Light enables partial nitrification and algal-bacterial consortium in rotating biological contactors performance and microbial community. Sustainability 2024, 16, 5538. [Google Scholar] [CrossRef]

- Cheng, L.; Deng, G.; Zhang, C.; Yang, Y.; Abdelfattah, A.; Eltawab, R.; Jia, H. Enhanced low-energy chemical oxygen demand (COD) removal in aeration-free conditions through pulse-rotating bio-contactors enriched with glycogen-accumulating organisms. Water 2024, 16, 1417. [Google Scholar] [CrossRef]

- Ucar, A.; Karakose, M.; Kirimça, N. Artificial Intelligence for Predictive Maintenance Applications: Key Components, Trustworthiness, and Future Trends. Appl. Sci. 2024, 14, 898. [Google Scholar] [CrossRef]

- Waqas, S.; Harun, N.Y.; Sambudi, N.S.; Bilad, M.R.; Abioye, K.J.; Ali, A.; Abdulrahman, A. A Review of Rotating Biological Contactors for Wastewater Treatment. Water 2023, 15, 1913. [Google Scholar] [CrossRef]

| Operating | Standby | |||||

|---|---|---|---|---|---|---|

| Normal | Noise | Normal | Noise | Failure | Total Events | |

| Blower No. 1 | 1015 | 0 | 968 | 0 | 0 | 1983 |

| Blower No. 2 | 1047 | 0 | 935 | 1 | 0 | 1983 |

| Filtration pump No. 1 | 549 | 0 | 14 | 107 | 1308 | 1978 |

| Filtration pump No. 2 | 1428 | 0 | 8 | 26 | 513 | 1975 |

| Sludge scraper | 1983 | 0 | 0 | 0 | 0 | 1983 |

| Sludge dewatering machine | 1983 | 0 | 0 | 0 | 0 | 1983 |

| Caustic soda injection pump | 1983 | 0 | 0 | 0 | 0 | 1983 |

| Sulfuric acid injection pump | 1983 | 0 | 0 | 0 | 0 | 1983 |

| Phosphoric acid injection pump | 1983 | 0 | 0 | 0 | 0 | 1983 |

| Dewatering agent injection pump | 1981 | 0 | 0 | 0 | 0 | 1981 |

| Miscellaneous wastewater pump | 1975 | 0 | 0 | 0 | 8 | 1983 |

| Sludge feed pump | 1983 | 0 | 0 | 0 | 0 | 1983 |

| Groundwater pump | 1981 | 0 | 0 | 0 | 0 | 1981 |

| Adjustment tank pump No. 1 | 946 | 0 | 1036 | 0 | 0 | 1982 |

| Adjustment tank pump No. 2 | 1097 | 0 | 881 | 0 | 0 | 1978 |

| Leachate water pump No. 1 | 1977 | 0 | 6 | 0 | 0 | 1983 |

| Leachate water pump No. 2 | 1974 | 0 | 9 | 0 | 0 | 1983 |

| Backwash blower No. 1 | 1981 | 0 | 2 | 0 | 0 | 1983 |

| Backwash blower No. 2 | 1981 | 0 | 2 | 0 | 0 | 1983 |

| Blower No. 1 | 1015 | 0 | 968 | 0 | 0 | 1983 |

| Blower No. 2 | 1047 | 0 | 935 | 1 | 0 | 1983 |

| Rotating disk device No. 1 | 1086 | 3 | 5 | 154 | 767 | 2015 |

| Rotating disk device No. 2 | 1091 | 428 | 3 | 343 | 150 | 2015 |

| Checking | Cleaning | Calibration | Total Events | |

| pH meter for neutralization tank | 1995 | 33 | 7 | 1996 |

| pH meter for flocculation mixing tank | 1993 | 34 | 6 | 1994 |

| Indicator | Description | Weight |

| (a) Abnormal noise frequency score | Number of abnormal noise occurrences in the past 30 days | +3 points if 3 or more times |

| (b) Peak current score | Maximum current exceeds 2.3 A | +2 points |

| (c) Current fluctuation score | Standard deviation exceeds 0.1 A | +2 points |

| (d) Abnormally low current | Minimum current is less than or equal to 1.6 A | +1 point |

| (e) Duration of abnormal period | Number of consecutive days with abnormal noise | +3 points if 1 week or more |

| (f) Sudden rise in current | Number of consecutive days with rising power consumption | +5 points if 2 week or more |

| Score Range | Risk Level | Recommended Action |

| 0–3 points | Low | No issues; normal operation |

| 4–7 points | Middle | Perform inspection as planned |

| 7 points or more | High | Prompt inspection and consideration of backup unit startup |

| Factors Affecting High Score | Time From the Last Alert | |||||||||

| RBC No. | Date | Score | (a) | (b) | (c) | (d) | (e) | (f) | Periods Giving High Score | (High Score) to the Failure |

| 1 | 25 February 2025 | 8 points | 3 | 5 | 7–21 December 2009 | 66 days after | ||||

| 16 January 2012 | 7 points | 2 | 5 | 25 July 2011, 17 October 2011, 15 December 2011 | 32 days after | |||||

| 18 September 2012 | 7 points | 2 | 5 | 25 June 2012 | 85 days after | |||||

| 10 July 2017 | 7 points | 2 | 5 | 6 April–19 June 2017 | 21 days after | |||||

| 2 | 27 August 2012 | 8 points | 3 | 2 | 3 | 26 July 2010–23 August 2012 | 4 days after | |||

| 21 January 2016 | 8 points | 3 | 2 | 3 | 17 February 2014–4 January 2016 | 17 days after | ||||

| 3 August 2020 | 7 points | 2 | 5 | 10 August 2017–24 February 2020 | 161 days after | |||||

| 17 January 2022 | 7 points | 2 | 5 | 12 October 2020–24 June 2021 | 207 days after | |||||

| 8 points | 3 | 2 | 3 | 18 October–11 November 2021 | 67 days after | |||||

| 10 points | 3 | 2 | 5 | 15 November 2021–13 January 2022 | 4 days after | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ishimori, H.; Isobe, Y.; Ishigaki, T.; Yamada, M. Empirical Study on Failure Prediction of Rotating Biological Contactors Available for Landfill Site Operators: Scoring Analysis Based on 17-Year Daily Inspection Reports. Appl. Sci. 2025, 15, 6950. https://doi.org/10.3390/app15136950

Ishimori H, Isobe Y, Ishigaki T, Yamada M. Empirical Study on Failure Prediction of Rotating Biological Contactors Available for Landfill Site Operators: Scoring Analysis Based on 17-Year Daily Inspection Reports. Applied Sciences. 2025; 15(13):6950. https://doi.org/10.3390/app15136950

Chicago/Turabian StyleIshimori, Hiroyuki, Yugo Isobe, Tomonori Ishigaki, and Masato Yamada. 2025. "Empirical Study on Failure Prediction of Rotating Biological Contactors Available for Landfill Site Operators: Scoring Analysis Based on 17-Year Daily Inspection Reports" Applied Sciences 15, no. 13: 6950. https://doi.org/10.3390/app15136950

APA StyleIshimori, H., Isobe, Y., Ishigaki, T., & Yamada, M. (2025). Empirical Study on Failure Prediction of Rotating Biological Contactors Available for Landfill Site Operators: Scoring Analysis Based on 17-Year Daily Inspection Reports. Applied Sciences, 15(13), 6950. https://doi.org/10.3390/app15136950