Featured Application

This study provides a theoretical basis for permeability evaluation and waterproof performance repair of overlying strata damaged after shallow coal seam group mining.

Abstract

The mining of shallow coal seam groups triggers mine water inrush and ecological environment destruction. Effective groundwater prevention and control requires controlling the compaction and seepage characteristics (CSCs) of broken rock in goaf. In this study, the CSCs of roof lithology and goaf broken rock combinations are experimentally investigated. The results indicate that, for samples with identical gradation, the percentage of void (PV) is minimized in sandstone–mudstone combinations, while PV increases with higher coal content. Initial compaction of composite samples is primarily governed by soft rock re-crushing, whereas the stable compaction stage is determined by the initial PV. Under low axial stress, the CSCs of lithological combination samples exhibit instability, with the mudstone layer reducing flow velocity by approximately 36% under equivalent compaction and seepage conditions. Particle migration, leading to the blockage of the seepage section, is an important cause of the decrease in permeability. Based on experimental findings, a stress–void–seepage coupling model is established to describe the compaction–seepage behavior of lithologic combination broken rock in shallow goafs.

1. Introduction

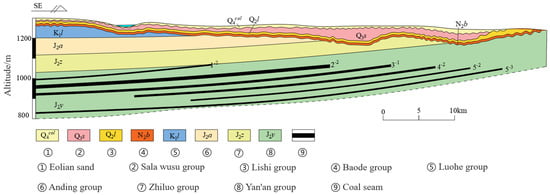

The mining of shallow coal seams severely disrupts groundwater equilibrium, adversely impacting the mining area’s ecology and increasing mine water inflow [1,2,3,4]. In China, coal resources and water resources exhibit an inverse spatial distribution. Due to policy-driven development, western regions have emerged as the primary coal-producing areas. As illustrated in Figure 1, the typical geological characteristics of shallow buried coal seam groups include multi-seam intervals, argillaceous soft rock layers, and sandy hard rock structures [5]. These regions face water scarcity and ecological fragility, exacerbated by high-intensity coal mining [6,7]. In 2023, the five major western coal bases accounted for over 80% of national coal production. The expansion of large-scale mining operations and soaring coal output have significantly increased goaf areas. After a mining fracture destroys the aquifer, groundwater migrates to the goaf [8,9,10].

Figure 1.

Distribution of the main coal seams and overlying strata structures in the Ordos coal-accumulating basin [5].

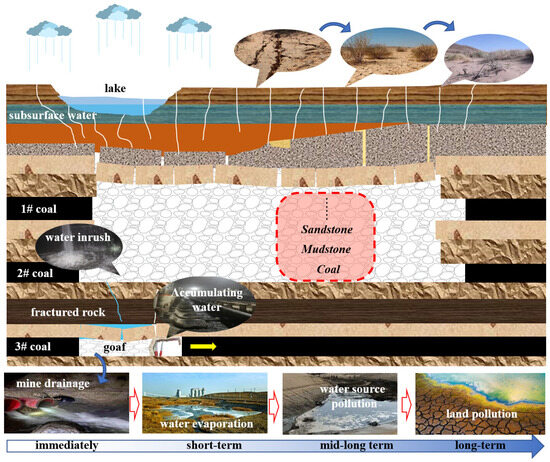

To prevent water inrush accidents, extensive groundwater drainage is implemented, leading to several critical issues (Figure 2): (a) Declining ecological water levels cause vegetation degradation [1,11]; (b) Over recent decades, large volumes of discharged mine water have primarily evaporated, leaving behind heavy metals and solutes that contaminate both water and soil [12]; (c) Current regulations prohibit mine water discharge due to water quality and balance concerns, while treatment costs remain prohibitively high [13,14]; (d) Concealed water sources, when connected by mining-induced fractures, often trigger large-scale casualties [15]. Aquifers are particularly vulnerable to mining-induced fractures following shallow coal seam extraction [16,17]. The seepage characteristics of compacted broken rock in goaf areas are crucial for evaluating the permeability of repeatedly mined overburden, which is essential for ensuring mining safety.

Figure 2.

Water and environment problems caused by shallow coal seam group mining.

Numerous compaction–seepage experiments on broken rock have significantly enhanced our understanding of nonlinear seepage behavior. By integrating mechanical testing systems with water pressure control systems, researchers can analyze the seepage characteristics of broken rock under various compaction conditions. The displacement control method proves effective for establishing theoretical models of broken rock compaction–seepage under different compaction levels, while the load control method is more suitable for investigating compaction–seepage characteristics (CSCs) under specific engineering conditions [18]. Current research has examined CSCs related to lithology, particle size, and mixed-particle-size samples, with particular attention to complex phenomena such as particle migration, erosion of weakly cemented minerals, and water–rock mixed flow [19,20,21,22]. However, in underground coal mining engineering, the roof—as a critical surrounding rock zone—typically consists of multiple lithological combinations. While studies have established CSCs for single lithology samples, research on the CSCs of combined lithologies in goaf areas remains relatively limited.

The hardness, lithology, and structural composition of roof strata are fundamentally linked to key strata control elements, including mine pressure manifestation, bolt support design, non-pillar mining techniques, and coal pillar width determination [23,24,25]. These geological parameters, along with roof structure characteristics and the thickness ratio between bedrock and overburden layers, serve as critical criteria for water resource protection zoning in mining areas [26].

Coal measure strata can be classified into three primary types based on mineral composition and mechanical properties, mudstone, sandstone, and coal seams, each exhibiting distinct functional behaviors during mining operations [27,28]. In the Ordos Basin, where coal seams predominantly originate from fluvial-lacustrine deposits, mudstone typically interbeds with coal layers [29]. The naturally low permeability of mudstone makes it an effective aquiclude. Within goaf areas, roof strata typically comprise multiple layers including immediate roofs and false roofs in the caving zone, while sandstone generally forms structural layers that function as main roofs and key strata, governing periodic mine pressure behavior [30,31].

Coal seams primarily serve as mining targets but may also occur as immediate or false roofs that collapse into the goaf during the working face advancing. Importantly, roof structure significantly influences the permeability evolution characteristics of compacted broken rock in goaf areas [32,33,34]. While single-lithology studies indicate that fractured mudstone in shallow coal-bearing strata shows the greatest potential for waterproof recovery [18], actual caving zones in shallow coal seam goafs typically contain vertically mixed lithological combinations (Figure 2). This complex arrangement necessitates focused research on the seepage characteristics of compacted broken roof materials with combined lithologies.

This study investigates the water-resisting recovery characteristics of compacted lithological combinations in broken roof strata within shallow coal seam goafs. Using Shaping Coal Mine as a representative case study of typical shallow coal seam groups, we conducted experiments to analyze the compaction–seepage characteristics (CSCs) of lithologically combined broken rocks under shallow buried stress conditions. The Forchheimer theory was employed to model the seepage behavior of compacted broken rock. To quantify water-resisting capacity recovery, we introduced a void sensitivity index for characterizing permeability evolution during rock compaction. Based on experimental results, we developed a comprehensive permeability analysis model for combined lithology broken rock in shallow goafs. Furthermore, this study establishes a compaction-permeability analytical model specifically for caved rock strata in shallow mining conditions.

2. Engineering Background

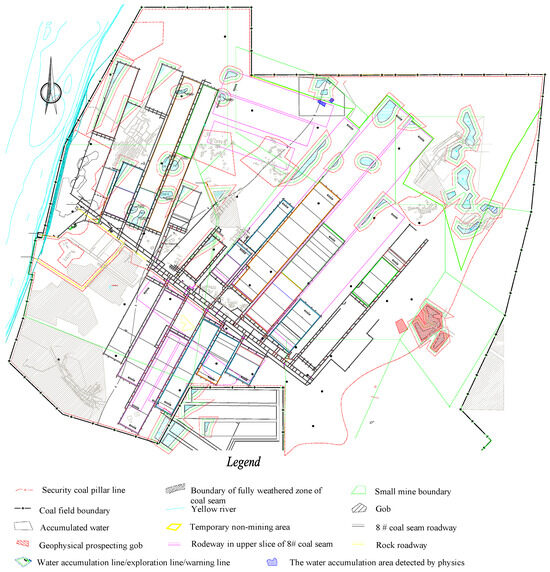

Shaping Coal Mine of Shanxi Jinshen Energy Co., Ltd. is located in Hequ County, Shanxi Province, China. The approved production capacity of the mine is 8.00 Mt/a. The mining area borders the Yellow River and represents typical shallow coal seam group mining conditions. As a model integrated resource mine, Shaping Coal Mine extracts coal seams 8 #~13 #, with overlying goafs of varying configurations—predominantly room-and-pillar and longwall mining systems. These upper goafs, containing significant water accumulation, pose potential hazards such as concealed water bodies that may impact safe and efficient extraction of underlying coal seams. Figure 3 illustrates the spatial distribution of these upper goafs and their water accumulation characteristics.

Figure 3.

Distribution of upper goaf and detection of water accumulation in Shaping Coal Mine.

In arid mining regions, water resource conservation and roof water management during downward coal seam group extraction have emerged as critical challenges for achieving sustainable and safe mining operations. Current high-intensity longwall mining practices inevitably lead to water resource depletion during extraction. Nevertheless, the restoration of water-resisting capacity through goaf compaction in the caving zone fundamentally determines the extent of roof water drainage required.

The roof structure of Shaping Coal Mine is shown in Table 1. Following collapse and subsequent compaction in the goaf, the roof strata undergo secondary fragmentation, exhibiting distinct grading characteristics [18]. Furthermore, according to the structural characteristics of the roof, there are different types of broken rock combinations in the goaf.

Table 1.

The roof structure of Shaping Coal Mine.

This study investigates the CSCs of typical lithological combinations in shallow coal seam goafs. Rock samples were prepared to simulate shallow coal seam conditions, with loading stages designed based on the self-weight stress environment characteristic of shallow goafs. Using lithological combination as the primary control variable, we conducted systematic experiments to measure permeability evolution in composite broken rock samples under varying compaction states. This research aims to elucidate how roof lithology combinations influence the restoration of water-resisting capacity in shallow coal seam goafs.

3. Experiment

The compaction–seepage experiments employed an experimental system, methodology, and procedures consistent with those described in [18]. The key factor in the experimental scheme, namely the shallow buried lithology combination, is the focus of attention.

3.1. Experimental System

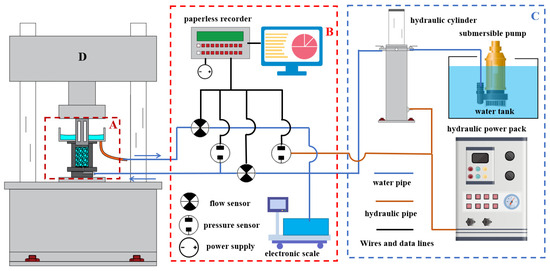

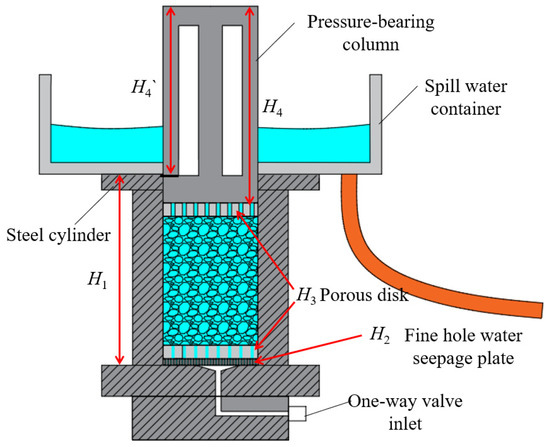

The experimental system used in the broken rock compaction–seepage test is shown in Figure 4. The compaction–seepage experimental device is shown in Figure 5.

Figure 4.

Compaction–seepage experimental system. A is the seepage device, B is the data acquisition system, C is the seepage water pressure control system, and D is the loading system.

Figure 5.

Compaction–seepage experimental device.

3.2. Experimental Scheme

Considering both the dimensions of the seepage device and rock density, the combined lithology broken rock samples were prepared by mass according to volume similarity principles. During testing, constant loading was maintained to achieve stable axial stress conditions. The seepage water pressure was systematically varied across 4~5 discrete values within the 0~1 MPa range, with flow rate measurements recorded only after achieving steady-state seepage conditions.

Based on typical lithological combinations found in sedimentary rock strata, we conducted compaction–seepage experiments on various broken rock lithology assemblages. This study quantitatively analyzes the seepage characteristics of three distinct lithological combinations during compaction to identify the most effective permeability-reducing configuration and its governing factors. The experimental scheme is shown in Table 2, and the η of each sample is 0.5. To accurately explore the complex CSC of the combined lithology, the gradient of axial compression loading is adjusted to 1 MPa, and the water pressure is applied in the same way as the article [18].

Table 2.

Experimental scheme of compaction and seepage for different lithological broken rock combinations.

3.3. Sample

Rock samples with different lithologies were taken from the roof of Shaping Coal Mine in Shanxi Province, China. According to the experimental requirements, the maximum particle size does not exceed 1/5 of the cylinder diameter, and the broken rock samples of the three kinds of lithology are broken to the particle size range of 0~20 mm. After screening, a 1 L measuring cup is used to weigh and measure the crushing expansion coefficient of the equal-volume broken rock in each particle size range, and the average value is taken after 6 random sampling measurements. The test results of bulking coefficient Kp and initial porosity φ0 in different particle size ranges of the three lithological samples are presented in Table 3.

Table 3.

The Kp and φ0 of rock samples with different particle sizes for three kinds of lithology.

The different states of broken rock in goaf are quantitatively described by the Taibo continuous gradation formula [21].

where M is the mass of the broken rock less than the diameter d, Mt is the total mass of the rock sample, D is the particle size of the largest block in the broken rock, and η is the Taibo gradation index.

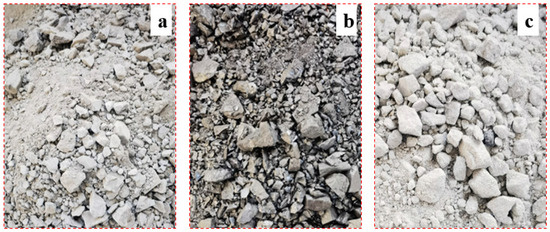

It can be seen from the Taibo gradation formula that the preparation of continuously graded rock samples is independent of the density of rock samples and is only related to the mass ratio of broken rock in each particle size range. The prepared η = 0.5 sample is shown in Figure 6.

Figure 6.

Rock sample: (a) mudstone; (b) coal; (c) sandstone.

4. Results

4.1. Characteristics of Voids

Using crushed rock samples with a consistent porosity (η) of 0.5, we systematically analyzed the void characteristics and bulking behavior across different lithological combination layers (Table 4). The results reveal that mudstone and sandstone exhibit comparable pore volumes (PV), with average values of 33% (PV) and 1.50 (bulking coefficient). In contrast, coal samples demonstrated significantly higher porosity, showing an average PV of 43% and bulking coefficient of 1.76.

Table 4.

The bulking characteristics of combined lithologic samples.

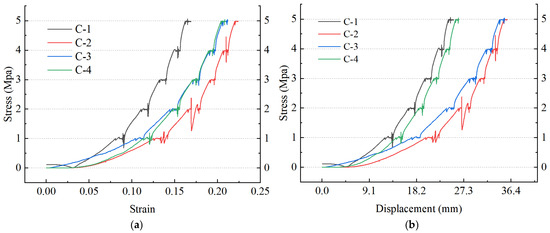

4.2. Compaction Characteristics

In the compaction seepage experiment of lithological combination samples, the axial stress was 0–5 MPa, and 1 MPa was used as the graded loading gradient to test the seepage characteristics under 0 MPa, 1 MPa, 2 MPa, 3 MPa, 4 MPa, and 5 MPa axial stress. The ‘stress-displacement’ and ‘stress-strain’ recorded during the whole compaction seepage experiment are shown in Figure 7. The results show that the axial compression of 2 MPa is the dividing line. When the axial compression is less than 2 MPa, the order of strain from large to small under the same axial compression is C-2 > C-4 > C-3 > C-1. When the axial compression is greater than 2 MPa, the order of strain from large to small under the same axial compression is C-2 > C-4 ≈ C-3 > C-1. In the C-1 case, the stress decreased and then increased. The compaction curves of C-4 and C-3 are close to the same compaction characteristics after 2 MPa axial compression. Creep phenomenon is common under five-stage axial compression in the range of 1~5 MPa. The seepage water pressure of the C-3 has the least influence on the pulse of the load under constant load.

Figure 7.

Compaction characteristics of lithology combination broken rock: (a) stress–strain; (b) stress–displacement.

According to the results, the seepage and compaction characteristics of the combined crushed stone have the following characteristics: the strain of the combined crushed stone within 0~2 MPa axial compression is affected by many factors such as lithological strength, softening characteristics, layered thickness, number of interfaces, accumulation structure, and initial PV. Therefore, the ‘mudstone-coal’ combination condition has the largest deformation during the initial compaction process. From a comprehensive perspective, the compaction characteristics are still dominated by the initial PV, and the order of strain and initial PV in the compacted state is finally consistent. In a non-argillaceous rock combination sample of ‘coal-sandstone’, the contribution rate of seepage water pressure to the external load of broken rock is small.

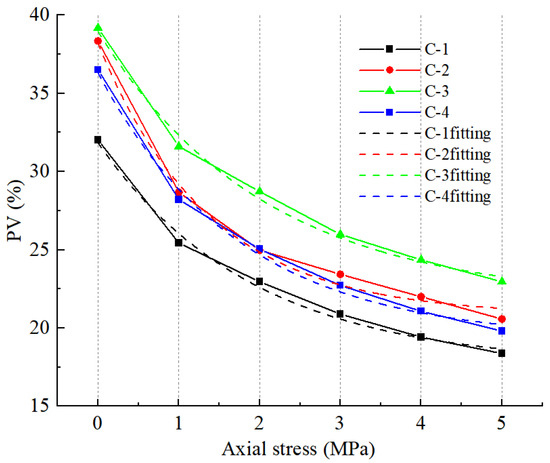

The void and bulking characteristics of each sample under different axial stresses are shown in Figure 8. The compaction characteristic parameters of the four composite samples fitted by Formula (2) are shown in Table 5.

Figure 8.

Characteristics of PV variation during compaction–seepage test process.

Table 5.

Fitting parameters of compaction characteristics of lithological combination broken rock.

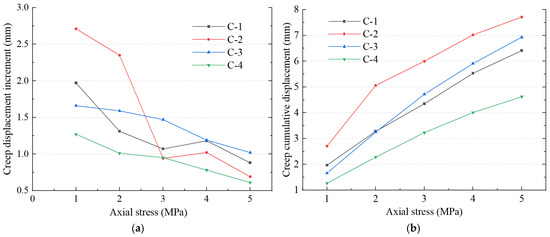

The creep amount of the load-holding stage during the compaction process is shown in Figure 9. From Figure 9a, it can be seen that the overall regularity of the change in creep amount in the same period under fixed axial stress is poor. For C-3 and C-4, the change trend of creep under each axial stress is similar. Combined with the above-mentioned stress–strain law, the compaction characteristics of C-3 and C-4 are similar as a whole. The creep amount of C-2 is greater than that of C-1 in the range of no more than 3 MPa axial compression. After the axial compression is greater than 3 MPa, the creep amount of C-1 and C-2 has the same trend, and the creep amount of C-1 is greater than that of C-2. However, the overall regularity of creep accumulation under each axial stress is good. As shown in Figure 9b, the creep accumulation is sorted into two sections from large to small. No more than 2 MPa: C-2 > C-1 > C-3 > C-4; more than 2 MPa: C-2 > C-3 > C-1 > C-4.

Figure 9.

Creep characteristics of equal duration under different axial stress: (a) creep increment; (b) creep cumulative amount.

The results show that the corresponding lithology combination compaction process has the following characteristics: The addition of thin mudstone in the middle of the sandstone + coal combination condition has little effect on its compaction characteristics. About the 0~3 MPa axial compression range gives priority to crushed coal compaction, while the 3~5 MPa axial compression range is of mudstone-dominant creep characteristics. The creep amount of the combined compaction process of low-strength coal and mudstone broken rock is the largest.

4.3. Seepage Characteristics

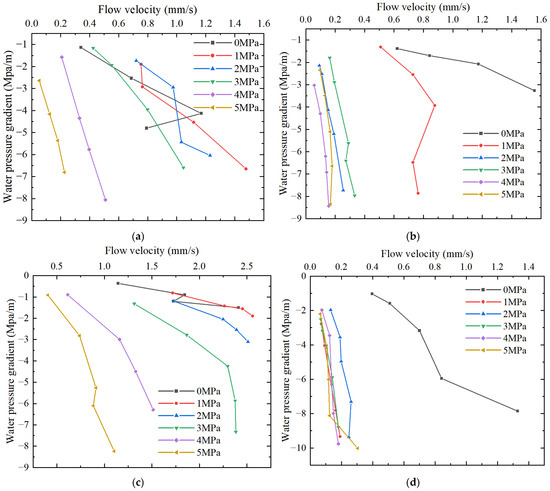

Compaction seepage experiments were carried out on four samples with different lithological combinations. The seepage characteristics under different axial stress are shown in Figure 10.

Figure 10.

Compaction seepage characteristics of lithology combination samples: (a) C-1; (b) C-2; (c) C-3; (d) C-4.

The results show that the seepage characteristics of C-1 change from unstable to stable in the range of 2–3 MPa. Subsequently, for the convenience of narration, the axial compression interval in which the seepage characteristics change from unstable to stable is called seepage stabilized axial compression (SSAC). In the axial compression range of 3~5 MPa, the permeability decreases by one order of magnitude for each 1 MPa increase, the flow rate decreases sharply, and the nonlinear seepage characteristics are stable. The SSAC of C-2 is 1~2 MPa, and the flow velocity decreases sharply under the axial stress of 1 MPa, and then the decrease of flow velocity becomes smaller. The SSAC of C-3 is 0~1 MPa. In the axial compression range of 3~5 MPa, the flow velocity decreases obviously with the increase of 1 MPa, and the flow velocity tends to be stable with the increase in water pressure gradient. The flow velocity of C-4 decreased sharply after axial compression loading. With the gradual compaction, the flow velocity changed little and fluctuated in a small range. In the case of various lithological combinations, the flow velocity of sandstone and coal composite specimens under the same axial stress is the largest. The remaining samples have mudstone combinations, and the variation range of flow velocity is close.

The permeability and non-Darcy factor are obtained by fitting, and then the changes in k and β under different φd are analyzed as shown in Table 6. The results of compaction–seepage process show that: For C-1, φd is decreased by 13.65%, k increases first and then decreases, and the absolute value of β increases monotonously. For C-2, φd decreased by 17.78% during the compaction and seepage process, k experienced two ‘decrease-increase’ fluctuations, and the absolute value of β increases monotonously. For C-3, φd decreases by 16.21%, k has two ‘increase-decrease’ fluctuation changes, and the absolute value of β increases monotonously. For C-4, φd decreased by 16.70%, k had three ‘decrease-increase’ fluctuations, and β had two ‘increase-decrease’ fluctuations.

Table 6.

Fitting results of non-Darcy seepage characteristics.

The experimental results show that the seepage characteristics of the combined rock samples under low axial stress are unstable, and the curves of water pressure gradient and flow velocity show tortuous characteristics. The flow velocity of the combined samples with mudstone is small, and the flow velocity does not exceed 1.6 mm/s. The flow velocity of the combined samples without mudstone is larger, and the flow velocity exceeds 2.5 mm/s. Under the same axial stress and water pressure gradient, the flow velocity of mudstone can be reduced by about 36%. The change trend and change times of CSC of lithology combination are related to the order and number of interfaces of lithology combination.

5. Discussions

This paper analyzes the lithological combination characteristics in shallow buried goaf areas. Step-loading and steady-state seepage experiments were conducted to investigate the seepage behavior under different compaction states. The variations in compaction stress, porosity, and permeability were determined. Furthermore, the correlation between the experimental findings and the engineering conditions of shallow coal seam group mining requires further discussion.

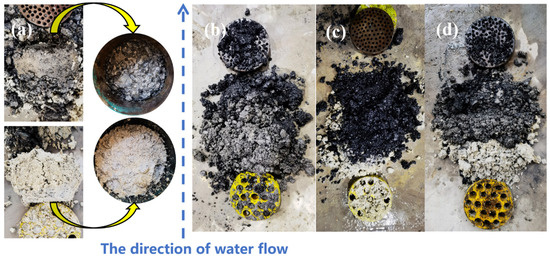

5.1. Sample Characteristics After Compaction Seepage

After the test, the sample experiencing compaction seepage was extruded from the seepage device (see Figure 11). By observing the characteristics of the samples, it is found that the ‘sandstone + mudstone’ combination sample is divided into two sections of cementation. The cementation at the interface is poor, and separation occurs after extrusion. The graded sandstone is broken obviously, and the coarse pore permeable plate is filled. The surface of the graded mudstone is compacted and broken, and the sandstone particles are distributed between the broken rock, indicating that the sandstone is broken and migrated to the mudstone layer with the water flow.

Figure 11.

The samples obtained after the compaction seepage experiment of the lithology combination broken rock: (a) C-1; (b) C-2; (c) C-3; (d) C-4.

On the whole, the combined samples with coal are not cemented, and the particle migration occurs in the compaction and seepage process of graded mudstone and sandstone, which is blocked in the sample in front of the seepage path. Based on this, it is speculated that re-crushing mainly occurs in broken coal seams during compaction. The reasons include the low strength of coal samples, softening in water, and sharp broken particles, which are prone to stress concentration. The migration of particles blocking the seepage section is an important reason for the decrease in permeability. Water–sand mixed flow and mud migration are typical seepage erosion phenomena, and the permeability decreases during the migration across the interface. In the corresponding engineering site, the permeability reduction at the interface of the broken rock combination can promote the formation of a stable relatively impermeable layer in the goaf. An important reason for the permeability instability caused by re-mining is that the interface of the broken rock combination is destroyed again. Mud and fine sand migrate with groundwater, and water inrush, sand inrush, and mud inrush occur in the mining space. Due to the influence of lithologic combination, the management process of coal seam goaf needs to focus on the water accumulation in goaf, the compaction permeability of broken coal and rock, and the conduction state of interlayer strata during repeated mining. It is a necessary measure to drain the water in the goaf of the roof before mining, and the permeability evaluation after repeated mining is of great significance for the storage and migration of groundwater.

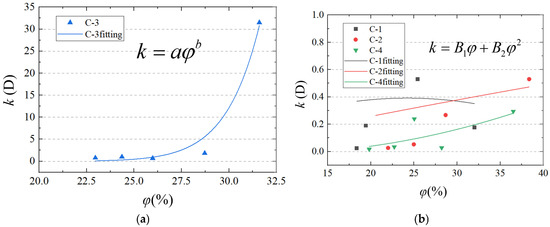

5.2. Permeability Analysis Model

To obtain the φ-k relationship of the broken rock compaction process, the φ-k curve is fitted. According to the characteristics of the experimental data, the combined samples without mudstone are fitted by exponential fitting and the combined samples with mudstone are fitted by a quadratic function. The fitting curve is shown in Figure 12, and the parameter results are shown in Table 7.

Figure 12.

φ-k fitting curve of broken rock in lithology combination: (a) no mudstone; (b) contains mudstone.

Table 7.

Compaction seepage φ-k curve fitting results of broken rock.

The compaction characteristics of broken rock have been obtained in Section 4.2. Combining Formula (2) and the φ-k model in Figure 12, respectively, the σ-φ-k analysis model of the compaction process of lithologic combination broken rock can be obtained in Formulas (3) and (4).

It should be noted that the fitting degree of the φ-k relationship of the combined samples containing mudstone is low and there is volatility. In the case of overburden permeability assessment serving water inrush prevention, it is necessary to consider the discreteness and increase the safety factor.

5.3. PV Sensitivity of Permeability

The permeability of the collapsed rock mass is mainly determined by the voids and the void structure. The low porosity of the mudstone layer in the lithology combination sample is the main reason for the low permeability of the combination sample. To analyze the permeability variation characteristics of compacted rock mass, the PV sensitivity parameter of permeability change (Dg) is adopted.

where ks is initial permeability, ke is compacted permeabilities, φs is initial PV, and φe is compacted PV.

In Table 8, the Dg of the combined samples is not more than 20. The Dg of the sample containing mudstone combination is significantly smaller than that of the C-3. The φs and φe of the C-3 samples are the largest. In addition, the combination of sandstone and coal lacks the plugging effect of mud, which together leads to the C-3 exhibiting significantly higher Dg values compared to other samples.

Table 8.

Permeability void sensitivity analysis results of compaction process.

The low ks and Dg jointly indicate that the mudstone and sandstone combination has the best water-proof recovery ability, followed by the sandstone + mudstone + coal combination and the mudstone + coal. To reduce the loss of water resources in overlying strata and eliminate the risk of water inrush in lower coal seam mining, the caving coal seam in goaf should be reinforced and anti-seepage treated to ensure that the goaf of overlying strata has a water-proof function. The value of ks indicates that the permeability of the combined samples containing mudstone is significantly lower under the uncompacted state, and ks is related to φs, showing a consistent order of magnitude. The combination of different lithology shows that, under the condition of compacted, that is, under the condition of self-weight stress recovery, the permeability of the combined samples containing mudstone is similar and the water resistance performance is better. The permeability and porosity of the composite samples containing coal are larger. Therefore, the existence of residual coal in goaf is not conducive to the recovery of compaction and water insulation performance in goaf.

The results of Figure 7 and Figure 8 show that one of the important reasons for the fastest recovery of sandstone and mudstone combined compaction is that the initial porosity of the compaction process is the lowest and the porosity under different loading levels is always the smallest. The minimum Dg of C-1 sample shows that the sandstone and mudstone combination sample has the characteristics of low permeability and small reduction in permeability during compaction.

5.4. Future Work

The migration of particulate matter and argillaceous material obstructs voids along the seepage path, leading to reduced permeability in the vertical composite unit. This phenomenon provides valuable insights for artificial aquifuge design. It is planned to enhance the erosion of upper broken rock in the goaf through environmental induction, such as temperature and PH, to realize the gap sealing of the lower broken rock and reduce the leakage of water resources after coal mining.

At engineering sites, the critical mudstone layer in the goaf is affected by mining. As the gradation of broken rock away from the roof gradually becomes larger, the CSC of mudstone with different gradations need to be further analyzed. In addition, the upper goaf in the mining process of coal seam group will experience mining influence many times, and the influence of caving and re-compaction on the permeability of broken rock in goaf needs to be explored.

6. Conclusions

This study demonstrates that roof structure plays a critical role in water-resisting capacity restoration in shallow coal seam goafs. Our experimental results confirm that roof lithological composition represents a fundamental engineering–geological control factor. Through systematic investigation of compaction–seepage characteristics (CSCs) for four distinct lithological combinations in shallow mining conditions, we establish the following key findings:

- (1)

- In the shallow buried stress range, the compaction characteristics of broken rock in goaf are affected by many factors, such as lithology, strength, softening characteristics, layered thickness, number of interfaces, accumulation structure, and initial porosity.

- (2)

- The seepage characteristics of lithologic combination samples under low axial stress are unstable, and the curves of water pressure gradient and flow velocity show tortuous characteristics. The change trend and change times of CSC of lithology combination are related to the order and number of interfaces of lithology combination.

- (3)

- The contribution for restoration of water-proofing function of the rock sample compaction of the combination lithology from high to low is mudstone, sandstone, and coal. Although the strength of coal and mudstone is low, the softening effect of mudstone by water is stronger. The coal compaction process mainly breaks and seals the large pores, and the mudstone also has the advantage of cement sealing the small pores.

- (4)

- The ‘stress-void-seepage’ analysis model of compaction seepage of lithologic combination broken rock considering compaction and re-breaking is established, and the permeability PV sensitivity index is analyzed. The restoration of the water-proofing function of mudstone and sandstone combined compaction is the most obvious.

- (5)

- In the engineering site, the permeability reduction at the interface of the broken rock combination can promote the formation of a stable water-proof rock layer in the goaf.

Author Contributions

Conceptualization, methodology, funding acquisition, writing—original draft preparation, writing—review and editing, K.M. and S.T.; validation, review, and editing, W.L.; formal analysis and visualization, J.L.; validation, investigation and data curation, J.T., H.Z. and J.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Jiangsu Funding Program for Excellent Postdoctoral Talent, (Nos. 2024ZB531) and the National Natural Science Foundation of China (Nos. 51874281).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

Thank Wang Dapeng and Liu Xuewen engineers in Shanxi Jinshen Shaping Coal Mining Co., Ltd. for their help in obtaining materials used for experiments.

Conflicts of Interest

Author Jinhu Tian was employed by Shaanxi Energy Fengjiata Mining Operation Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Feng, H.B.; Duan, Y.; Zhou, J.W.; Su, D.H.; Li, R.; Xiong, R.M. Effects of groundwater level decline on soil-vegetation system in semiarid grassland influenced by coal mining. Land Degrad. Dev. 2024, 35, 2297–2312. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.; Zhang, J.; Bai, H. A state-of-the-art review on rock seepage mechanism of water inrush disaster in coal mines. Int. J. Coal Sci. Technol. 2022, 9, 50. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Sun, Q.; Wang, Y.B. Evolution Laws of Water-Flowing Fracture Zone and Mine Pressure in Mining Shallow-Buried, Hard, and Extra-Thick Coal Seams. Appl. Sci. 2024, 14, 2915. [Google Scholar] [CrossRef]

- Song, S.J.; Ruan, H.; Wei, J.B.; Niu, R.L.; Cheng, X.; Chen, B.D. The Influence of the Key Characteristics of Overburden Rock Structure on the Development Height of Water-Conducting Fracture in Yushenfu Coal Mine Area, China. Appl. Sci. 2024, 14, 10537. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, H.; Jin, D. Discussion on roof water loss control method of coal seam based on pre-splitting grouting reformation(P-G). Coal Geol. Explor. 2021, 49, 159–167. [Google Scholar]

- Zeng, Y.F.; Wu, Q.; Mei, A.S.; Wang, L.; Yin, W.B.; Yang, L.; Zhao, D.; Meng, S.H.; Gao, H.F. Hydrogeochemical process and coal mining-motivated effect on the hydrochemistry for the groundwater system in mining area of Western China. J. Geochem. Explor. 2024, 263, 107516. [Google Scholar] [CrossRef]

- Chi, M.B.; Zhang, D.S.; Zhao, Q.; Yu, W.; Liang, S.S. Determining the scale of coal mining in an ecologically fragile mining area under the constraint of water resources carrying capacity. J. Environ. Manag. 2021, 279, 111621. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, X.J.; Han, P.H.; Bai, Q.S.; Chen, J.H. Failure analysis of residual coal pillar under the coupling of mining stress and water immersion in the goaf underground water reservoir. Environ. Earth Sci. 2023, 82, 309. [Google Scholar] [CrossRef]

- Wang, Q.Q.; Li, W.P.; Li, T.; Li, X.Q.; Liu, S.L. Goaf water storage and utilization in arid regions of northwest China: A case study of Shennan coal mine district. J. Clean. Prod. 2018, 202, 33–44. [Google Scholar] [CrossRef]

- Li, P.; Ma, L.Q.; Wu, Y.; Zhang, L.Q.; Hao, Y. Concurrent Mining During Construction and Water-Filling of a Goaf Groundwater Reservoir in a Coal Mine. Mine Water Environ. 2018, 37, 763–773. [Google Scholar] [CrossRef]

- Yang, Z.; Li, W.P.; Li, X.Q.; He, J.H. Quantitative analysis of the relationship between vegetation and groundwater buried depth: A case study of a coal mine district in Western China. Ecol. Indic. 2019, 102, 770–782. [Google Scholar] [CrossRef]

- Wei, X.X.; Xu, N.Z.; Chen, L.; Chen, J.G.; Li, J. Occurrence, mobility, and potential risk of uranium in an abandoned stone coal mine of Jiangxi Province, China. Environ. Earth Sci. 2024, 83, 531. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, Q. Mine Water Treatment, Resource Utilization and Prospects in Coal Mining Areas of Western China. Mine Water Environ. 2024, 43, 210–230. [Google Scholar] [CrossRef]

- Gao, P.H.; Wang, Y.T.; Zhang, Z.H.; Cao, Y.R.; Liu, Z.; Zhang, D.H. The general methods of mine water treatment in China. Des. Water Treat. 2020, 202, 183–205. [Google Scholar] [CrossRef]

- Bringemeier, D. Inrush and Mine Inundation-A Real Threat to Australian Coal Mines? In Proceedings of the International-Mine-Water-Association Symposium (IMWA 2012), Bunbury, Australia, 29 September–4 October 2012; Edith Cowan University: Bunbury, Australia, 2012; pp. 25–29. [Google Scholar]

- Wu, Z.P.; Liang, Y.P.; Miao, K.J.; Li, Q.G.; Liu, S.C.; Ran, Q.C.; Sun, W.J.; Yin, H.L.; Ma, Y. Damage Law and Reasonable Width of Coal Pillar under Gully Area: Linking Fractal Characteristics of Coal Pillar Fractures to Their Stability. Fractal Fract. 2024, 8, 407. [Google Scholar] [CrossRef]

- Miao, K.J.; Tu, S.H.; Tu, H.S.; Liu, X.; Li, W.L.; Zhao, H.B.; Tang, L.; Ma, J.Y.; Li, Y. Research on Fractal Evolution Characteristics and Safe Mining Technology of Overburden Fissures under Gully Water Body. Fractal Fract. 2022, 6, 486. [Google Scholar] [CrossRef]

- Miao, K.J.; Tu, S.H.; Wang, Y.Y.; Li, J.H.; Zhao, H.B.; Guo, B.H. Utilization of broken rock in shallow gobs for mitigating mining-induced water inrush disaster risks and environmental damage: Experimental study and permeability model. Sci. Total Environ. 2023, 903, 166812. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.; Li, Q.; Wu, J.; Zhong, W.; Huang, Z. Water–rock two-phase flow model for water inrush and instability of fault rocks during mine tunnelling. Int. J. Coal Sci. Technol. 2023, 10, 77. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.Y.; Zhang, J.X. Solid grain migration on hydraulic properties of fault rocks in underground mining tunnel: Radial seepage experiments and verification of permeability prediction. Tunn. Undergr. Space Technol. 2022, 126, 104525. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.Y.; Li, X.B.; Li, Z.H.; Zhou, Z.L.; Li, T.B. Effects of seepage-induced erosion on nonlinear hydraulic properties of broken red sandstones. Tunn. Undergr. Space Technol. 2019, 91, 102993. [Google Scholar] [CrossRef]

- Zhang, B.Y.; He, Q.Y.; Lin, Z.B.; Li, Z.H. Experimental study on the flow behaviour of water-sand mixtures in fractured rock specimens. Int. J. Min. Sci. Technol. 2021, 31, 377–385. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Abbas, T.; Xu, X.B. Application of coal mine roof rating in Chinese coal mines. Int. J. Min. Sci. Technol. 2018, 28, 491–497. [Google Scholar] [CrossRef]

- Brook, M.; Hebblewhite, B.; Mitra, R. Coal mine roof rating (CMRR), rock mass rating (RMR) and strata control: Carborough Downs Mine, Bowen Basin, Australia. Int. J. Min. Sci. Technol. 2020, 30, 225–234. [Google Scholar] [CrossRef]

- Zhu, D.F.; Yu, B.B.; Wang, D.Y.; Zhang, Y.J. Fusion of finite element and machine learning methods to predict rock shear strength parameters. J. Geophys. Eng. 2024, 21, 1183–1193. [Google Scholar] [CrossRef]

- Liu, S.L.; Li, W.P. Zoning and management of phreatic water resource conservation impacted by underground coal mining: A case study in arid and semiarid areas. J. Clean. Prod. 2019, 224, 677–685. [Google Scholar] [CrossRef]

- Xiong, J.; Wu, J.J.; Liu, J.J.; Li, B.; Liu, X.J.; Liang, L.X. Mechanical Properties of Different Lithological Rocks: A Case Study of the Coal Measure Strata in the Eastern Margin of Ordos Basin, China. Geofluids 2022, 2022, 1356735. [Google Scholar]

- Wu, W.D.; Wang, T.C.; Bai, J.B.; Liu, J.H.; Wang, X.Y.; Xu, H.Y.; Feng, G.R. Failure Characteristics and Cooperative Control Strategies for Gob-Side Entry Driving near an Advancing Working Face: A Case Study. Processes 2024, 12, 1398. [Google Scholar] [CrossRef]

- Wang, X.M.; Wang, X.M.; Pan, S.D.; Yang, Q.; Hou, S.H.; Jiao, Y.Q.; Zhang, W.M. Occurrence of analcime in the middle Jurassic coal from the Dongsheng Coalfield, northeastern Ordos Basin, China. Int. J. Coal Geol. 2018, 196, 126–138. [Google Scholar] [CrossRef]

- Miao, K.J.; Wang, D.P.; Tu, S.H.; Tu, H.S.; Zhu, D.F.; Liu, X.W.; Li, W.L.; Tang, L. The Principle and Practice of Strong Mine Pressure Control in the Initial Mining and Caving Stages under Multiple Key Strata. Sustainability 2022, 14, 5772. [Google Scholar] [CrossRef]

- Li, W.L.; Tu, S.A.; Tu, H.S.; Liu, X.; Miao, K.J.; Zhao, H.B.; Ma, J.Y.; Tang, L.; Li, Y. A New Method to Assess Thick, Hard Roof-Induced Rock Burst Risk Based on Mining Speed Effect on Key Energy Strata. Sustainability 2022, 14, 15054. [Google Scholar] [CrossRef]

- Li, H.J.; Chen, Q.T.; Shu, Z.Y.; Li, L.; Zhang, Y.C. On prevention and mechanism of bed separation water inrush for thick coal seams: A case study in China. Environ. Earth Sci. 2018, 77, 759. [Google Scholar] [CrossRef]

- Zhu, L.; Yao, Q.L.; Xia, Z.; Xu, Q.; Yu, L.Q.; Li, X.H. Prevention of water and mud inrush in longwall top coal cave mining under shallow buried thin bedrock. Bull. Eng. Geol. Environ. 2022, 81, 355. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, J.X.; Li, M.; Zhou, N. Experimental evaluation of physical, mechanical, and permeability parameters of key aquiclude strata in a typical mining area of China. J. Clean. Prod. 2020, 267, 122109. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).