Remote Real-Time Monitoring and Control of Small Wind Turbines Using Open-Source Hardware and Software

Abstract

1. Introduction

1.1. State of the Art

1.2. Work Contributions

- Development of a complete open-source control and communication system based on Arduino®, Raspberry Pi®, and a WebSocket–MATLAB® interface;

- Implementation of a custom Printed Circuit Board (PCB) for real-time measurement of voltage, current, and wind speed in SWTs;

- Full experimental validation of the proposed platform on a functional prototype, with all components integrated and tested;

- The use of open-source hardware, standard communication protocols, and detailed experimental descriptions ensures high reproducibility of the entire platform.

1.3. Paper Organization

2. Theoretical Framework

2.1. Wind Turbine and Generator

2.2. Rectifier

2.3. DC–DC Boost Converter and Operation Point

- Follow the MPPT trajectory by imposing the optimal voltage corresponding to the best tip–speed ratio, or;

- Apply Power Curtailment, intentionally limiting output to match grid demands or storage constraints.

2.4. Battery Energy Storage System

- State of Charge (SOC): indicates the instantaneous energy level relative to the battery’s nominal capacity. It is calculated as:where is the nominal capacity of the battery, and and are the respective charge and discharge currents over time ;

- State of Health (SOH): reflects the battery’s ability to retain capacity compared to its nominal value and is defined as:where is the currently available maximum capacity.

3. Measurement, Control, and Communication Architecture

3.1. Custom-Designed Hardware Components

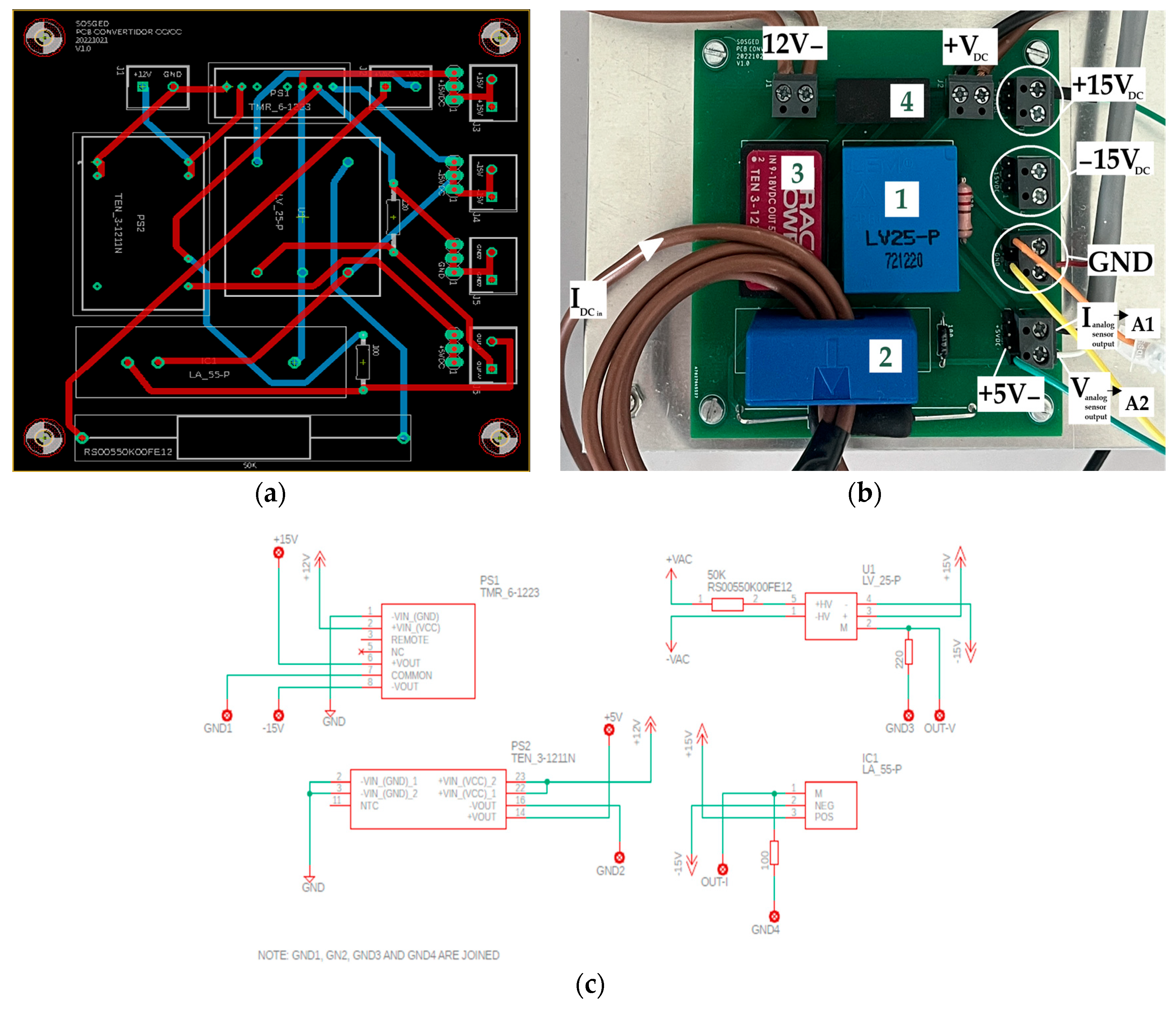

3.1.1. Voltage and Current Measurement Board

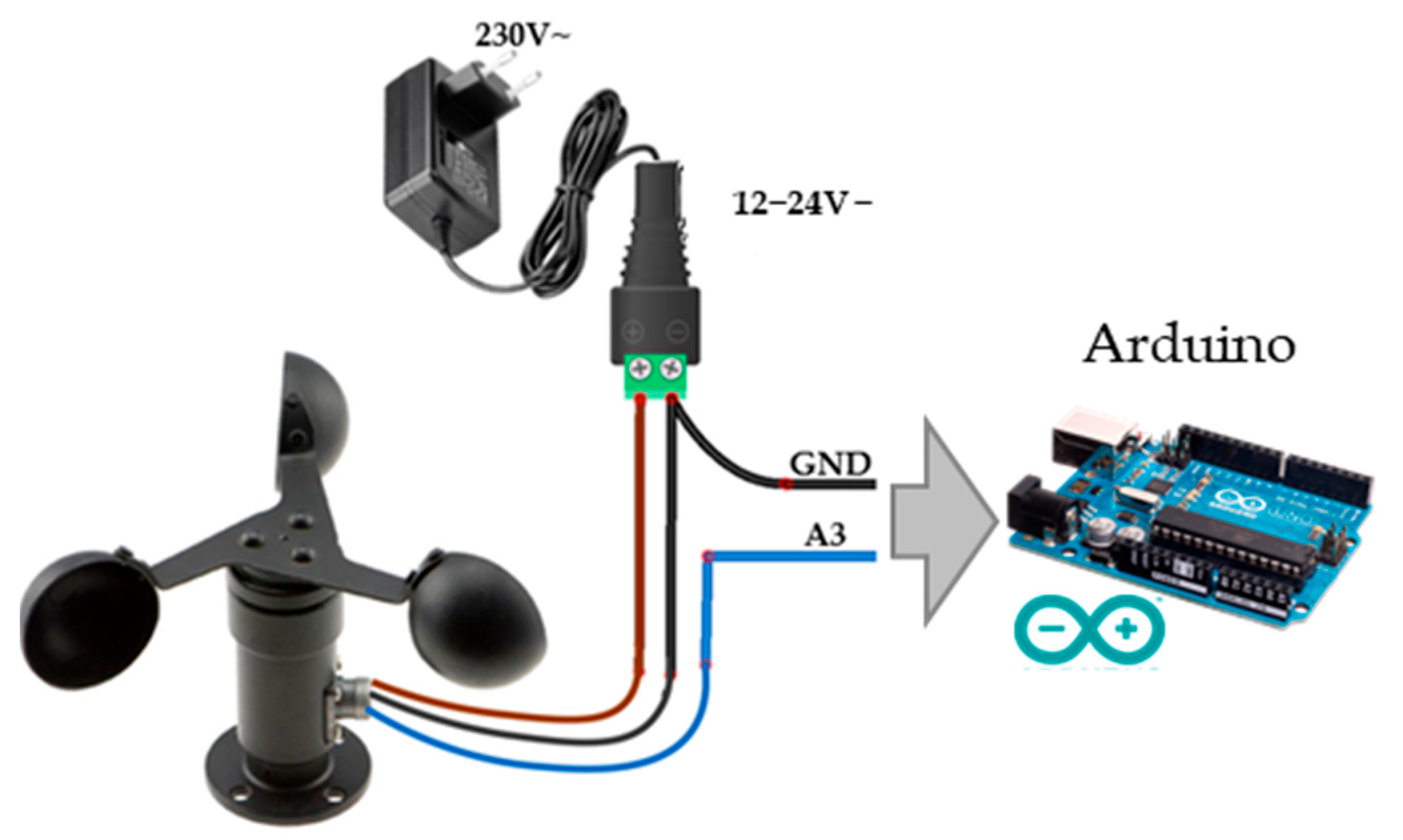

3.1.2. Wind Speed Measurement

- is the measured analog voltage;

- is the offset voltage under no-wind conditions (e.g., 0.054 V);

- is the maximum output voltage of the sensor (5 V);

- is the sensor’s maximum wind speed range (32.4 m/s).

3.2. Software and Communication

3.2.1. Measurement and Data Acquisition Layer: Arduino®

- A start delimiter (0x02) to indicate the beginning of a new message;

- A sequence of encoded sensor readings in hexadecimal format;

- A checksum value for basic error detection; and

- An end delimiter (0x03) to mark the end of the transmission.

3.2.2. Communication and Data Management Layer: Raspberry Pi®

- Data Acquisition Server—process1.py

- Control Command Server—process2.py

- Process Management—maestro.py

| Algorithm 1: Pseudocode—Process Management and Communication Logic | ||

| maestro.py (Process Manager) ---------------------- Define list of subprocesses: [process1.py, process2.py] For each process in list: -Create a new worker process -Assign target: run process as Python script Start all worker processes in parallel Wait for processes to run continuously (blocking) | process1.py (Measurement Data Server) ------------------------------- Initialize UART port (9600 bps, timeout 2.5 s) Start WebSocket server on port 8081 On client connection: Loop indefinitely: -Read up to 32 bytes from UART buffer -If more data is available: -Read remaining bytes (in waiting) -Concatenate full message -Send raw data to client via WebSocket -Wait for client acknowledgment before next cycle | process2.py (Control Command Server) ------------------------------- Start WebSocket server on port 8080 On client connection: Loop indefinitely: -Wait for command from client via WebSocket -Convert string command to ASCII bytes -Open UART port (9600 bps) -Send command to Arduino® -Send confirmation back to client |

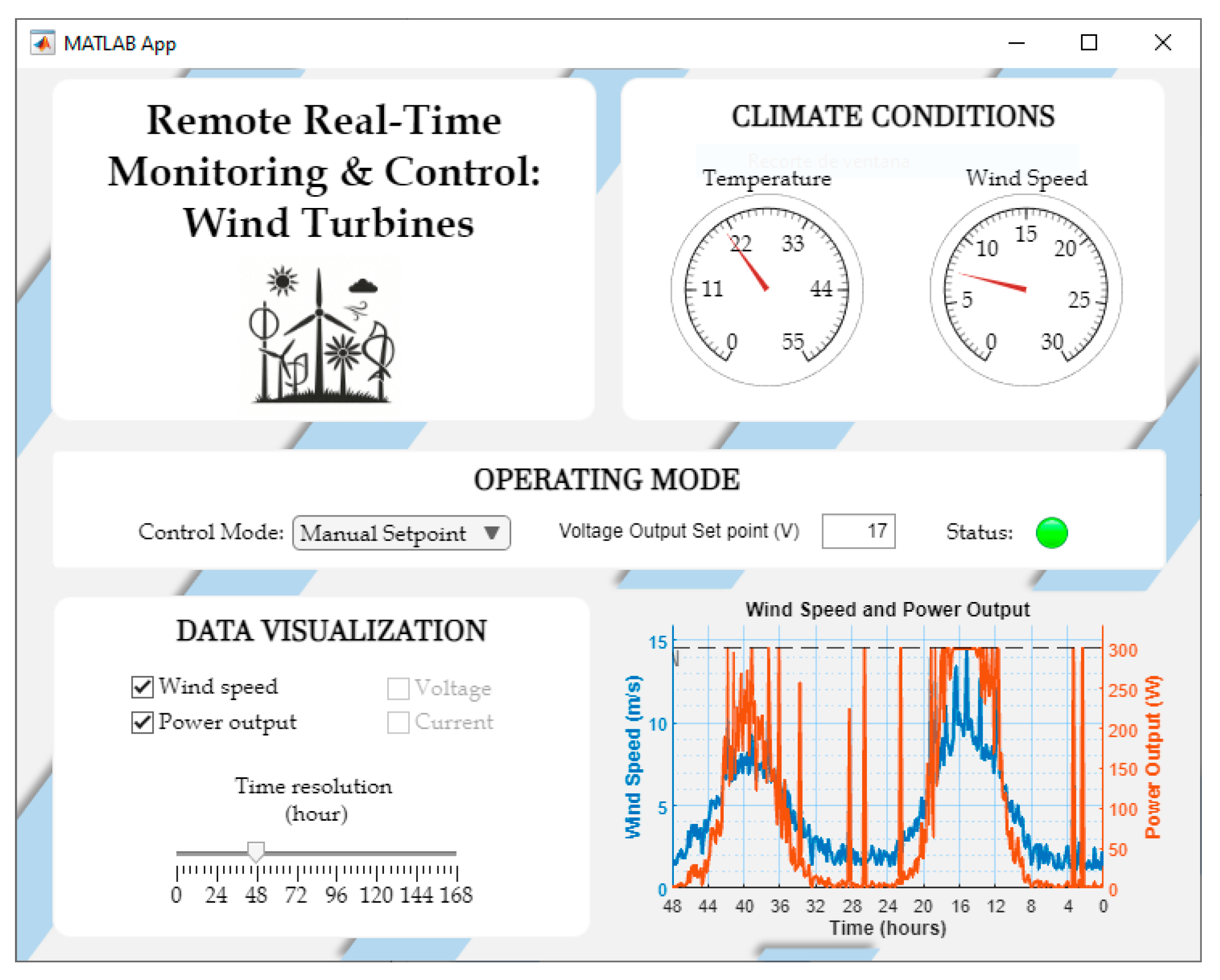

3.2.3. Supervisory Control and Monitoring Layer: MATLAB® App

- One to receive real-time measurement data (port 8081);

- Another to send control commands (port 8080).

| Algorithm 2: Pseudocode—MATLAB® App WebSocket Communication Logic |

| Initialize WebSocket connection to the Raspberry Pi at IP ”XXX.XXX.X.XXX" with port 8081 for receiving data from the DC–DC converter. Initialize WebSocket connection to the Raspberry Pi at IP “XXX.XXX.X.XXX” with port 8080 for sending control commands to the converter. Periodically check for incoming data from the converter via WebSocket: - If data is received: - Parse the incoming data frame to identify and extract key parameters. - Convert raw sensor data into physical units using predefined scaling factors. - Update the app with real-time values: power, current, temperature, voltage, and wind speed. On user command, send control signals to the converter via WebSocket: - Switch the operating mode (MPPT or Power Curtailment) and send corresponding control commands. - If Power Curtailment is selected, send power reserve settings to the converter. Ensure periodic update of operational parameters and maintain communication integrity between the system and the converter by continuously processing data every few seconds. |

3.2.4. System Data Flow

- The Arduino® continuously acquires voltage, current, and wind speed measurements, structuring the information into UART frames and transmitting them to the Raspberry Pi® via serial communication;

- Upon receiving the UART data, the Raspberry Pi® parses the frames, formats the content into JavaScript Object Notation structures, and broadcasts it through a WebSocket server (port 8081), enabling real-time data availability to external clients;

- The MATLAB® app, acting as a WebSocket client, subscribes to the data stream, dynamically updates the graphical user interface, and enables the operator to send control commands based on system conditions;

- Commands sent by the user are transmitted from the MATLAB® app to the Raspberry Pi® via WebSocket (port 8080), which are then forwarded through UART to the Arduino®. These commands trigger control actions such as modifying the PWM signal to the boost converter or toggling operating modes.

4. Experimental Setup

4.1. Wind Turbine

4.2. Power Electronics

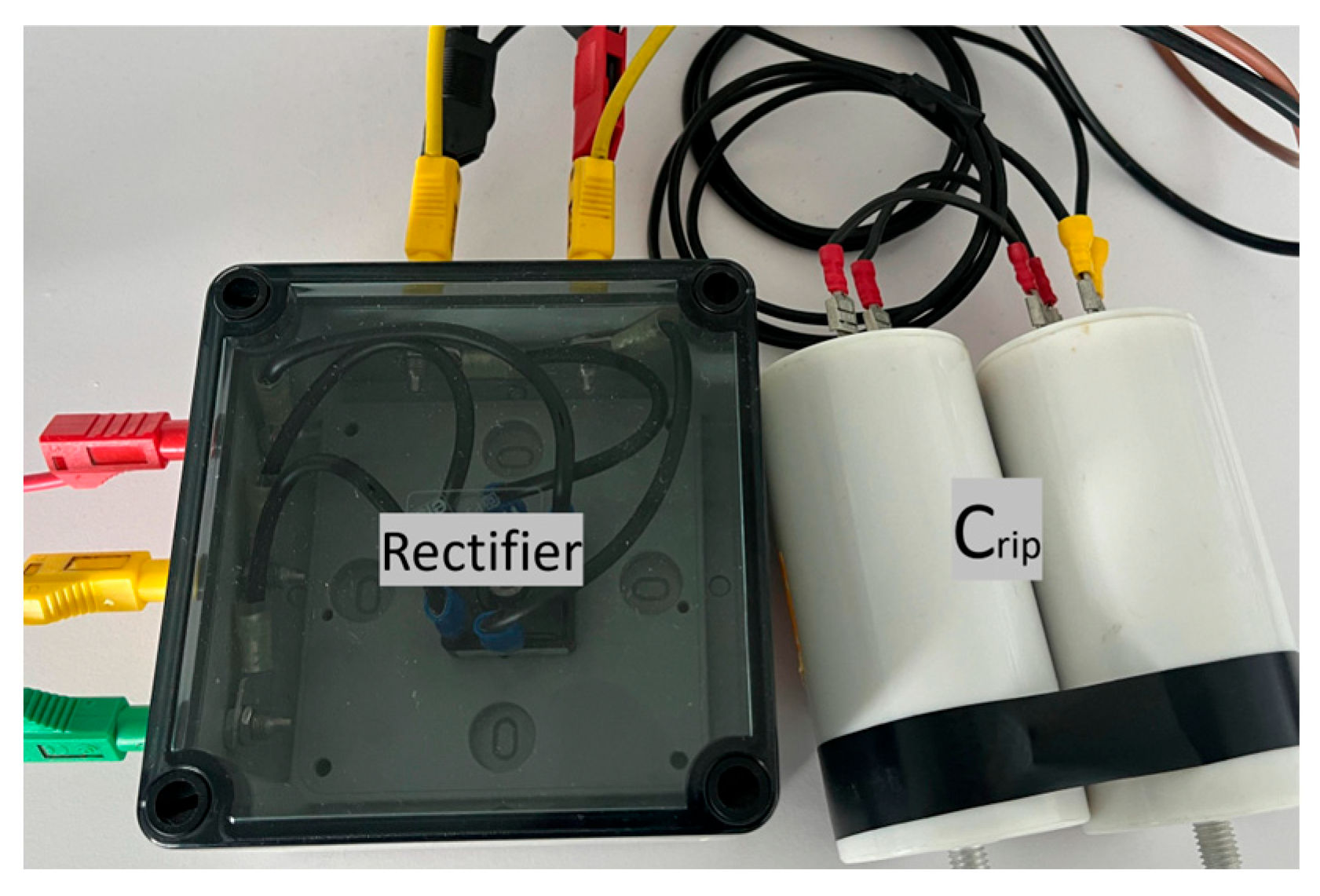

4.2.1. AC–DC Rectification and Filtering

4.2.2. DC–DC Boost Converter

4.3. Battery

4.4. System Overview

- Oscilloscope: to visualize PWM signal, coil current, and switching transients on the IGBT gate;

- Watt meters and multimeters: to monitor generated power and verify measurement accuracy;

- Tachometer and frequency meter: to evaluate generator shaft speed and electrical frequency, enabling rotor characterization.

5. In-Lab System Test

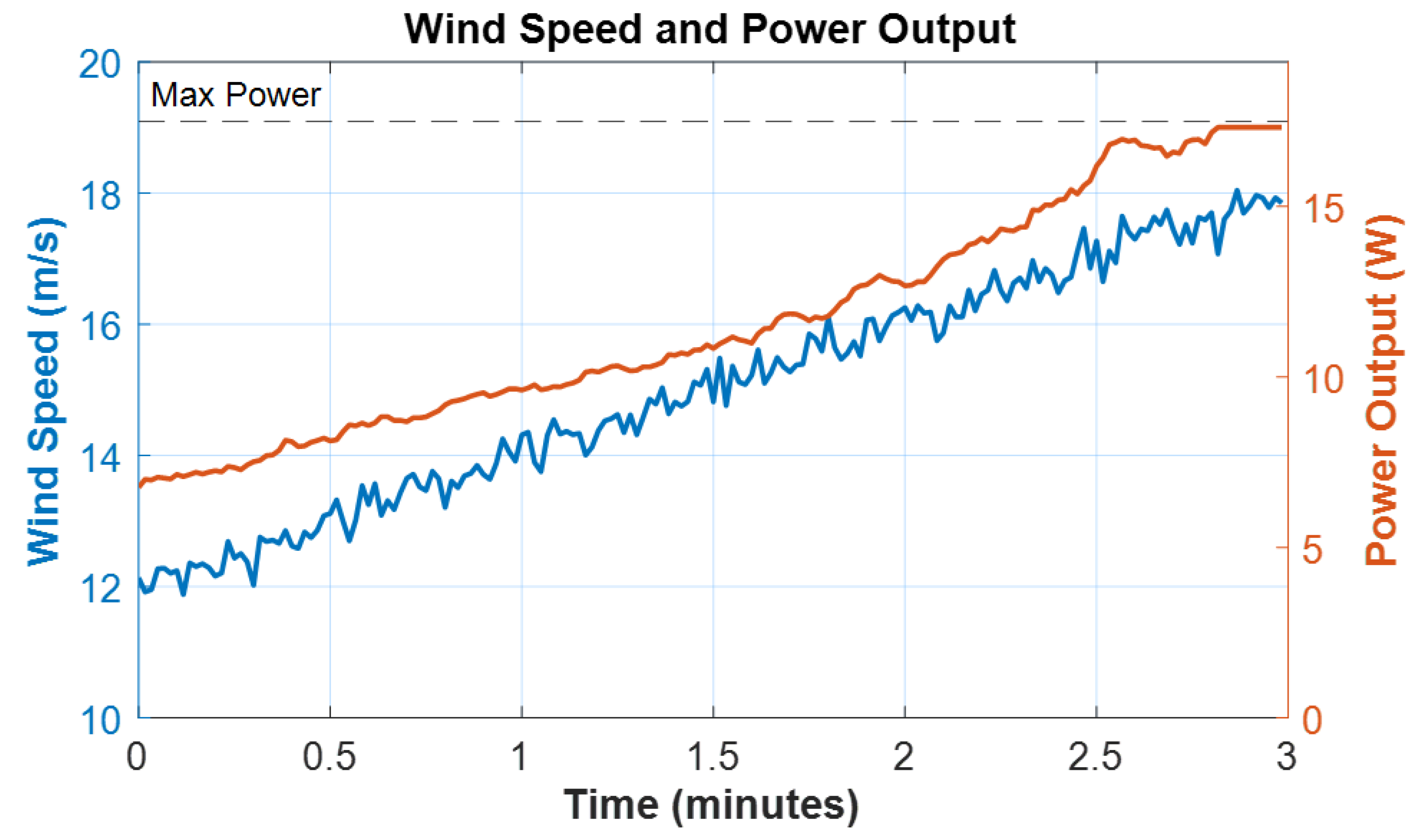

5.1. MPPT Operation

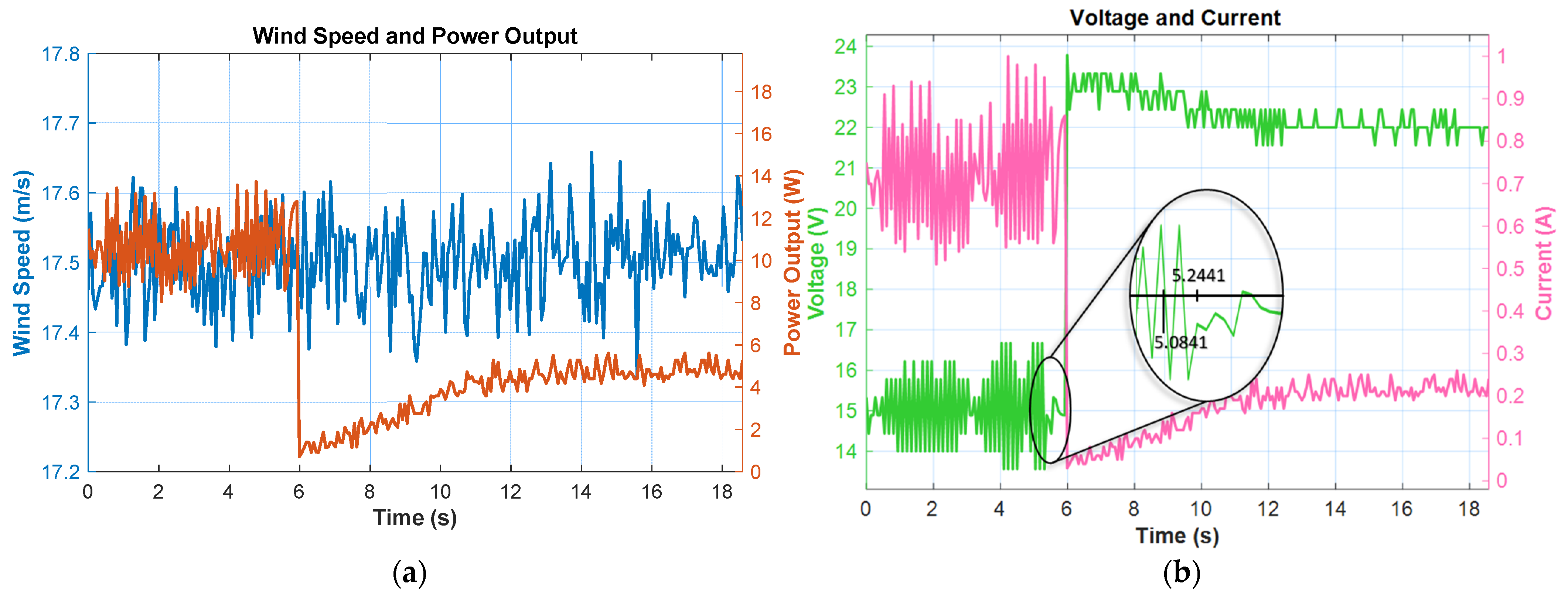

5.2. Variable Power Reference Operation

5.3. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lau, H.C.; Tsai, S.C. Global Decarbonization: Current Status and What It Will Take to Achieve Net Zero by 2050. Energies 2023, 16, 7800. [Google Scholar] [CrossRef]

- Pepermans, G.; Driesen, J.; Haeseldonckx, D.; Belmans, R.; D’haeseleer, W. Distributed Generation: Definition, Benefits and Issues. Energy Policy 2005, 33, 787–798. [Google Scholar] [CrossRef]

- Lopez-Garcia, D.A.; Torreglosa, J.P.; Vera, D. A Decentralized P2P Control Scheme for Trading Accurate Energy Fragments in the Power Grid. Int. J. Electr. Power Energy Syst. 2019, 110, 271–282. [Google Scholar] [CrossRef]

- Renewable Energy Directive. Available online: https://energy.ec.europa.eu/topics/renewable-energy/renewable-energy-directive-targets-and-rules/renewable-energy-directive_en (accessed on 1 May 2025).

- The European Green Deal—European Commission. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 1 May 2025).

- Donadel, C.B.; Fardin, J.F.; Encarnacao, L.F. Distributed Generation Units as Ancillary Services Providers in a Pre Smart Grid Environment. Int. J. Emerg. Electr. Power Syst. 2017, 18, 20170021. [Google Scholar] [CrossRef]

- Madureira, A.G.; Pecas Lopes, J.A. Ancillary Services Market Framework for Voltage Control in Distribution Networks with Microgrids. Electr. Power Syst. Res. 2012, 86, 1–7. [Google Scholar] [CrossRef]

- Rezaei, N.; Kalantar, M. Smart Microgrid Hierarchical Frequency Control Ancillary Service Provision Based on Virtual Inertia Concept: An Integrated Demand Response and Droop Controlled Distributed Generation Framework. Energy Conv. Manag. 2015, 92, 287–301. [Google Scholar] [CrossRef]

- Faria, P.; Soares, T.; Vale, Z.; Morais, H. Distributed Generation and Demand Response Dispatch for a Virtual Power Player Energy and Reserve Provision. Renew. Energy 2014, 66, 686–695. [Google Scholar] [CrossRef]

- Aourir, J.; Locment, F. Limited Power Point Tracking for a Small-Scale Wind Turbine Intended to Be Integrated in a DC Microgrid. Appl. Sci. 2020, 10, 8030. [Google Scholar] [CrossRef]

- Lyu, X.; Subotić, I.; Groß, D. Unified Grid-Forming Control of PMSG Wind Turbines for Fast Frequency Response and MPPT. arXiv 2022, arXiv:2207.09536. [Google Scholar]

- Chalise, S.; Atia, H.; Poudel, B.; Tonkoski, R. Impact of Active Power Curtailment of Wind Turbines Connected to Residential Feeders for Overvoltage Prevention. In Proceedings of the 2016 IEEE Power and Energy Society General Meeting (PESGM), Boston, MA, USA, 17–21 July 2016; pp. 471–479. [Google Scholar]

- Sánchez-Herrera, R.; Mejías, A.; Márquez, M.A.; Andújar, J.M. A Fully Integrated Open Solution for the Remote Operation of Pilot Plants. IEEE Trans. Ind. Inform. 2019, 15, 3943–3951. [Google Scholar] [CrossRef]

- Bradney, D.; Evans, S.; Chu, M.; Clausen, P. A Low-Cost, High-Speed, Multi-Channel Arduino-Based Data Acquisition System for Wind Turbine Systems. Wind. Eng. 2020, 44, 509–518. [Google Scholar] [CrossRef]

- Chaudhari, K.G. Windmill Monitoring System Using Internet of Things with Raspberry Pi. Int. J. Adv. Res. Electr. Electron. Instrum. Eng. 2019, 8, 482–485. [Google Scholar] [CrossRef]

- Ermeey, A.K.; Taib, M.M.; Nasran, A.R.; Yushafizee, Y.M. A Vertical Wind Turbine Monitoring System Using Commercial Online Digital Dashboard. Int. J. Electr. Comput. Eng. (IJECE) 2020, 10, 5131–5138. [Google Scholar] [CrossRef]

- Pereira, R.I.S.; Dupont, I.M.; Carvalho, P.C.M.; Jucá, S.C.S. IoT Embedded Linux System Based on Raspberry Pi Applied to Real-Time Cloud Monitoring of a Decentralized Photovoltaic Plant. Measurement 2018, 114, 286–297. [Google Scholar] [CrossRef]

- Sánchez-Herrera, M.R.; Márquez, M.; de la Torre, L. Secure and Private Internet of Things for Industry, Training, and Homes: A Communications Solution for Connected Devices. IEEE Ind. Electron. Mag. 2023, 17, 14–21. [Google Scholar] [CrossRef]

- Sasikala, G.; Chandra, Y.P.S.; Siva, N.; Vinesh, A.S. Wind Turbine Fault Monitoring System Using MQTT. J. Phys. Conf. Ser. 2021, 2040, 012002. [Google Scholar] [CrossRef]

- Zhao, D.; Shao, D.; Wang, T.; Cui, L. Time-Frequency Self-Similarity Enhancement Network and Its Application in Wind Turbines Fault Analysis. Adv. Eng. Inform. 2025, 65, 103322. [Google Scholar] [CrossRef]

- Zhao, D.; Shao, D.; Cui, L. CTNet: A Data-Driven Time-Frequency Technique for Wind Turbines Fault Diagnosis under Time-Varying Speeds. ISA Trans. 2024, 154, 335–351. [Google Scholar] [CrossRef]

- Wiens, M.; Steindl, G.; Tubeuf, C.; Birkelbach, F.; Burfeind, J.; Meyer, T. DigiWind-An Open-Source Digital Twin Framework for Wind Energy Systems. IEEE Access 2024, 12, 84046–84063. [Google Scholar] [CrossRef]

- Vairavasundaram, I.; Ramu, S.K.; Stephenraj, J.P.; D, O.P.; Irudayaraj, G.C.R. IoT Based Monitoring System for DFIG Based Wind Turbines under Voltage Dips. E-Prime-Adv. Electr. Eng. Electron. Energy 2024, 9, 100690. [Google Scholar] [CrossRef]

- Alam, M.; Kumar, K.; Verma, S.; Dutta, V. Renewable Sources Based DC Microgrid Using Hydrogen Energy Storage: Modelling and Experimental Analysis. Sustain. Energy Technol. Assess. 2020, 42, 100840. [Google Scholar] [CrossRef]

- Gómez-Ruiz, G.; Sánchez-Herrera, R.; Clavijo-Camacho, J.; Cano, J.M.; Ruiz-Rodríguez, F.J.; Andújar, J.M. A Versatile Platform for PV System Integration into Microgrids. Electronics 2024, 13, 3995. [Google Scholar] [CrossRef]

- Deowan, M.d.E.; Nuhel, A.K.; Sazid, M.M.; Meghla, R.T.; Haider, I.; Hazari, M.d.R. Design and Analysis of IoT-Based Adaptive Microgrid System Including Renewable Energy Sources for Decentralized Zones. In Proceedings of the 2023 3rd International Conference on Robotics, Electrical and Signal Processing Techniques (ICREST), Dhaka, Bangladesh, 7–8 January 2023; pp. 84–89. [Google Scholar]

- Cabrera, M.H.; Gómez, A.B.; Torres, C.J.; Morales, A.S.; Ramírez, A.G. Integration of Industrial Power Quality Analyzer and Open Source Hardware and Software Solution for Microgrids Monitoring. In Proceedings of the 2019 IEEE CHILEAN Conference on Electrical, Electronics Engineering, Information and Communication Technologies (CHILECON), Valparaiso, Chile, 13–27 November 2019; pp. 1–6. [Google Scholar]

- Truong, D.-N.; Thi, M.-S.N.; Ngo, V.-T.; Hoang, A.-Q. Development of the Monitoring Program for an Integrated Small-Scale Wind and Solar Systems Based on IoT Technology. J. Sci. Technol. Issue Inf. Commun. Technol. 2021, 19, 26–31. [Google Scholar] [CrossRef]

- Wang, J.; Li, D.; Lv, X.; Meng, X.; Zhang, J.; Ma, T.; Pei, W.; Xiao, H. Two-Stage Energy Management Strategies of Sustainable Wind-PV-Hydrogen-Storage Microgrid Based on Receding Horizon Optimization. Energies 2022, 15, 2861. [Google Scholar] [CrossRef]

- Li, S.; Patnaik, S.; Li, J. IoT-Based Technologies for Wind Energy Microgrids Management and Control. Electronics 2023, 12, 1540. [Google Scholar] [CrossRef]

- Yang, F.; Wang, D. IoT-Enabled Intelligent Fault Detection and Rectifier Optimization in Wind Power Generators. Alex. Eng. J. 2025, 116, 129–140. [Google Scholar] [CrossRef]

- Senanayaka, J.S.L.; Karimi, H.R.; Robbersmyr, K.G. A Novel Soft-Stall Power Control for a Small Wind Turbine. In Proceedings of the 2017 IEEE 26th International Symposium on Industrial Electronics (ISIE), Edinburgh, UK, 19–21 June 2017; pp. 940–945. [Google Scholar]

- Hameed, Z.; Vatn, J.; Heggset, J. Challenges in the Reliability and Maintainability Data Collection for Offshore Wind Turbines. Renew. Energy 2011, 36, 2154–2165. [Google Scholar] [CrossRef]

- Escudero-Quintero, C.; Guzman-Rodriguez, J.P.; Villegas-Ceballos, J.P.; Henao-Bravo, E.E.; Gonzalez-Montoya, D. Flexible Hardware for Teaching and Research in Renewable Energy and Off-Grid Microgrids. HardwareX 2025, 22, e00636. [Google Scholar] [CrossRef]

- Cano, J.M.; Martin, A.D.; Herrera, R.S.; Vazquez, J.R.; Ruiz-Rodriguez, F.J. Grid-Connected PV Systems Controlled by Sliding via Wireless Communication. Energies 2021, 14, 1931. [Google Scholar] [CrossRef]

- Clavijo-Camacho, J.; Gomez-Ruiz, G.; Ruiz-Rodriguez, F.J.; Sanchez-Herrera, R. A Modular IGBT Power Stack − Based and Open Hardware Framework for Small Wind Turbines Assessment. Sustain. Energy Technol. Assess. 2024, 66, 103804. [Google Scholar] [CrossRef]

- UNE-EN 61400-25-1:2007; Wind Turbines—Part 25-1: Communications for Monitoring and Control of Wind Power Plants—Overall Description and Principles. AENOR Spanish Association for Standardization (AENOR): Madrid, Spain, 2007.

- LV 25-P | LV25 | Closed Loop Hall Effect. Available online: https://www.lem.com/en/product-list/lv-25p (accessed on 2 May 2025).

- LA 55-P | LA55 | Closed Loop Hall Effect. Available online: https://www.lem.com/en/product-list/la-55p (accessed on 2 May 2025).

- Komarizadehasl, S.; Lozano, F.; Antonio Lozano-Galant, J.; Ramos, G.; Turmo, J. Low-Cost Wireless Structural Health Monitoring of Bridges. Sensors 2022, 22, 5725. [Google Scholar] [CrossRef] [PubMed]

- Python 3.13 Documentation. Available online: https://docs.python.org/3/ (accessed on 13 June 2025).

- GNU Octave. Available online: https://octave.org/index (accessed on 14 June 2025).

- jebej/MatlabWebSocket. Available online: https://es.mathworks.com/matlabcentral/fileexchange/50040-jebej-matlabwebsocket (accessed on 3 May 2025).

- UNE-EN 61400-25-5:2007; Communications for Monitoring and Control of Wind Power Plants—Conformance Testing. AENOR Spanish Association for Standardization (AENOR): Madrid, Spain, 2007.

| Control/Monitoring Systems | |||||

|---|---|---|---|---|---|

| Criteria | Arduino + Raspberry Pi (WebSocket) + PC (MATLAB App) | Commercial SCADA Systems (e.g., Siemens WinCC, Schneider EcoStruxure, ABB/Emerson) | ZigBee-Based Wireless Control | IoT-Based Solutions (ESP32 + MQTT, Node-RED, ThingsBoard, Blynk) | PLC-Based Traditional Systems |

| Bidirectional Communication | Yes—fully supported via Arduino + Raspberry Pi + MATLAB GUI | Yes—standard SCADA feature for supervisory control | Yes—supported, but mainly low-speed actions | Yes—inherent to MQTT and cloud dashboards | Yes—PLCs offer deterministic bidirectional communication |

| Real-Time Responsiveness | Sub-second (non-deterministic); suitable for supervisory tasks | Moderate (seconds); real-time handled by PLCs, not SCADA | Moderate (100–500 ms); not for fast control loops | Good (<1 s); depends on network/cloud latency | High (ms); hard real-time via scan cycles |

| Protocol Flexibility | High—open source (RS232 y WebSocket) | High—supports industrial protocols (Modbus, OPC UA 1) | Medium—ZigBee only; needs gateway for others | Very High—supports MQTT, HTTP, REST, WebSocket | Medium—limited to industrial fieldbuses/protocols |

| Integration of Customized Logic (MPPT, Curtailment, etc.) | High—Fully programmable (Arduino via MATLAB) | Moderate—Done externally (PLC), limited inside SCADA | Moderate—Possible in MCU nodes but limited use | High—Flexible in both device and cloud layers | High—Fully programmable via IEC languages |

| Ease of Sensor Integration (Modularity) | High—Add sensors easily via Arduino’s analog pins | Moderate—Requires PLC IO config and engineering effort | High—Nodes are plug-and-play in mesh topology | High—Very flexible; dynamic MQTT topics, modular | High—Add IO modules; needs config and programming |

| Open Access and Reprogrammability (for users/developers) | Open-source core; compatible with open/proprietary tools | Limited—Vendor-locked, license-based customization | Good—Open protocol, MCU flexibility | Excellent—Open SDKs, full control of stack | Moderate—Logic modifiable, but closed firmware |

| Target Application Scale | Small—Ideal for 1–5 turbines, microgrids, research | Medium–large—Centralized wind farms and utilities | Small—Suitable for sensor networks or campus setups | Small–medium—Distributed setups, virtual wind farms | Small–medium—Ideal for turbine-level automation |

| Cost and Complexity | Very low cost, moderate DIY complexity | Very high cost, high engineering complexity | Low cost, moderate setup/network complexity | Low–moderate cost, user-friendly interfaces | High cost, moderate programming complexity |

| Component in Figure 3 | Name | Accuracy | Description |

|---|---|---|---|

| 1 | LEM® LV 25-P | ±0.9% (of full scale) | Voltage transducer used to measure the DC bus voltage after rectification. Outputs a scaled analog voltage proportional to the measured DC voltage. |

| 2 | LEM® LA 55-P | ±1.0% (typical, of full scale) | Hall-effect current transducer for non-invasive current measurement. Measures the current flowing through the DC line and provides an analog output. |

| 3 | TRACO POWER TEN 3-1211 | ±1.0% output voltage regulation | Isolated DC–DC converter that provides ±15 V dual supply for the analog sensors. Ensures power isolation between the sensing circuit and the main board. |

| 4 | TRACO POWER YN 06-12D15 | ±2.0% output voltage regulation (typ.) 1 | Dual output power module that delivers regulated ±15 V from a 12 V input, supplying power to the transducers with electrical isolation. |

| 5 | R = 50 kΩ | ±1% | Series resistor connected to the primary side of the LV 25-P for input scaling and current limitation. |

| 6 | R = 220 Ω | ±1% | Converts the output current of the LV 25-P into a proportional voltage signal for analog acquisition. |

| 7 | R = 100 Ω | ±1% | Converts the output current of the LA 55-P into a proportional voltage signal for analog acquisition. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Clavijo-Camacho, J.; Gomez-Ruiz, G.; Sanchez-Herrera, R.; Magro, N. Remote Real-Time Monitoring and Control of Small Wind Turbines Using Open-Source Hardware and Software. Appl. Sci. 2025, 15, 6887. https://doi.org/10.3390/app15126887

Clavijo-Camacho J, Gomez-Ruiz G, Sanchez-Herrera R, Magro N. Remote Real-Time Monitoring and Control of Small Wind Turbines Using Open-Source Hardware and Software. Applied Sciences. 2025; 15(12):6887. https://doi.org/10.3390/app15126887

Chicago/Turabian StyleClavijo-Camacho, Jesus, Gabriel Gomez-Ruiz, Reyes Sanchez-Herrera, and Nicolas Magro. 2025. "Remote Real-Time Monitoring and Control of Small Wind Turbines Using Open-Source Hardware and Software" Applied Sciences 15, no. 12: 6887. https://doi.org/10.3390/app15126887

APA StyleClavijo-Camacho, J., Gomez-Ruiz, G., Sanchez-Herrera, R., & Magro, N. (2025). Remote Real-Time Monitoring and Control of Small Wind Turbines Using Open-Source Hardware and Software. Applied Sciences, 15(12), 6887. https://doi.org/10.3390/app15126887