Study on Skid Resistance of Asphalt Pavements Under Macroscopic and Microscopic Texture Features: A Review of the State of the Art

Abstract

1. Introduction

2. Research on Anti-Skid Mechanisms of Asphalt Pavement

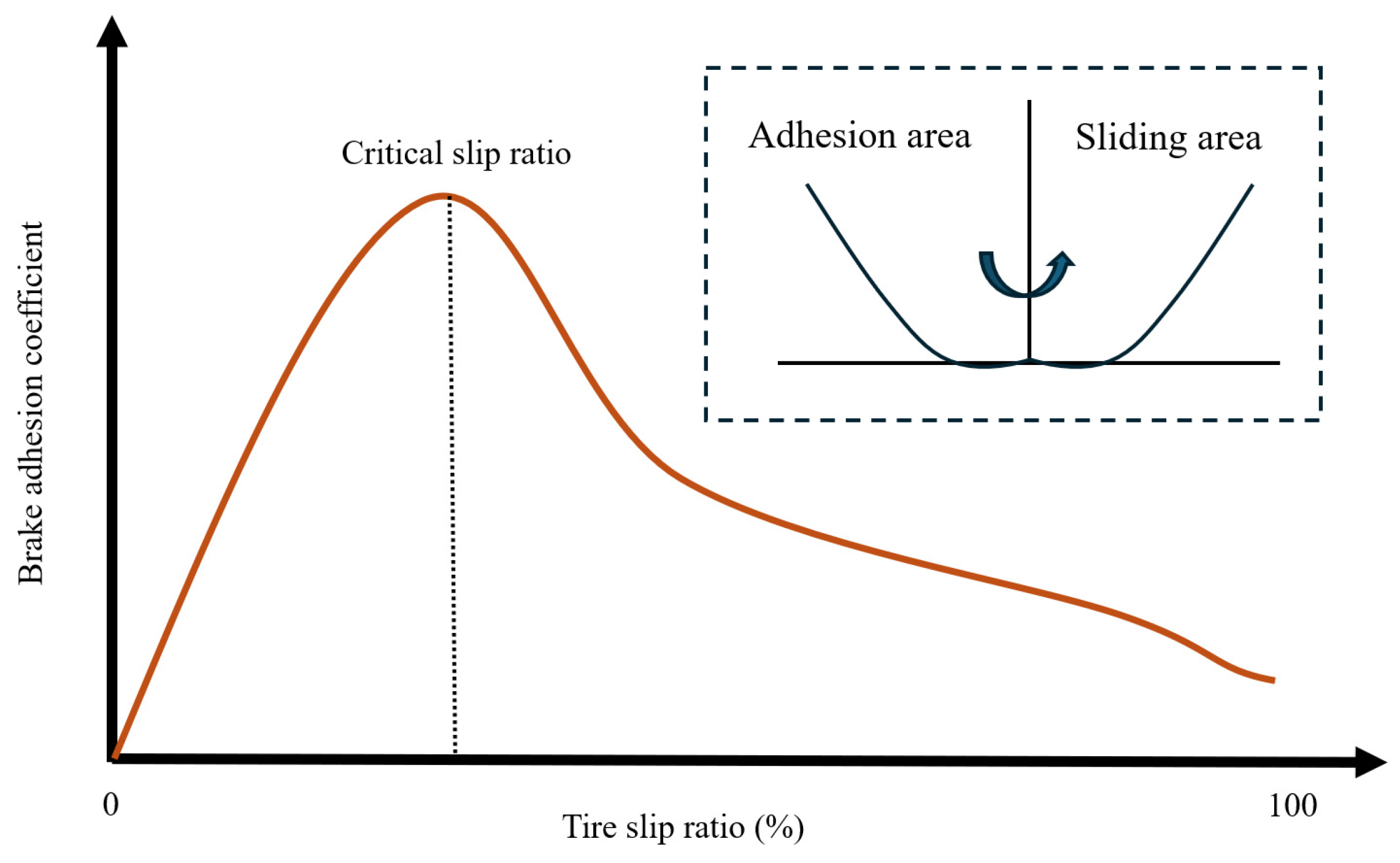

2.1. Mechanical Mechanism Between Tyres and Road Surfaces

2.1.1. Van Der Waals Forces Between Tyres and Road Surfaces

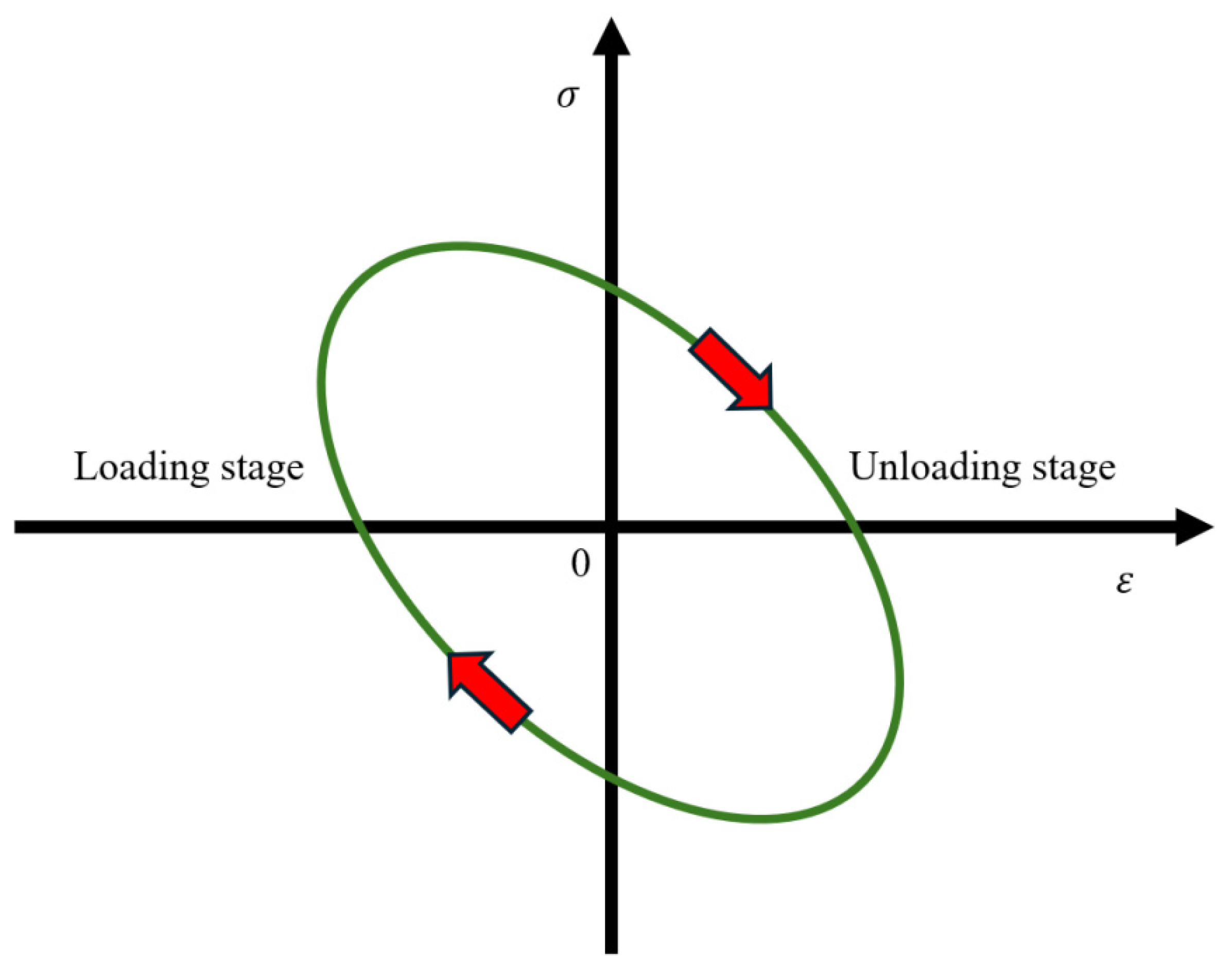

2.1.2. Adhesion Between Tyre and Road Surface

2.1.3. Microcutting of Small-Sized Microconvex Bodies on Pavements

- Van der Waals force action between tyre and pavement.

- Adhesion between tyre and pavement.

- Microcutting action of small-sized microconvex bodies on the pavement.

2.2. Factors Affecting the Skid Resistance of Asphalt Pavements

2.2.1. Influence of Aggregate Properties on Skid Resistance of Asphalt Pavements

2.2.2. Influence of Gradation Type of Mix on Skid Resistance of Asphalt Pavements

2.2.3. Influence of Asphalt Binder on the Skid Resistance of Pavements

3. Methods for the Characterisation and Evaluation of the Skid Resistance of Asphalt Pavements

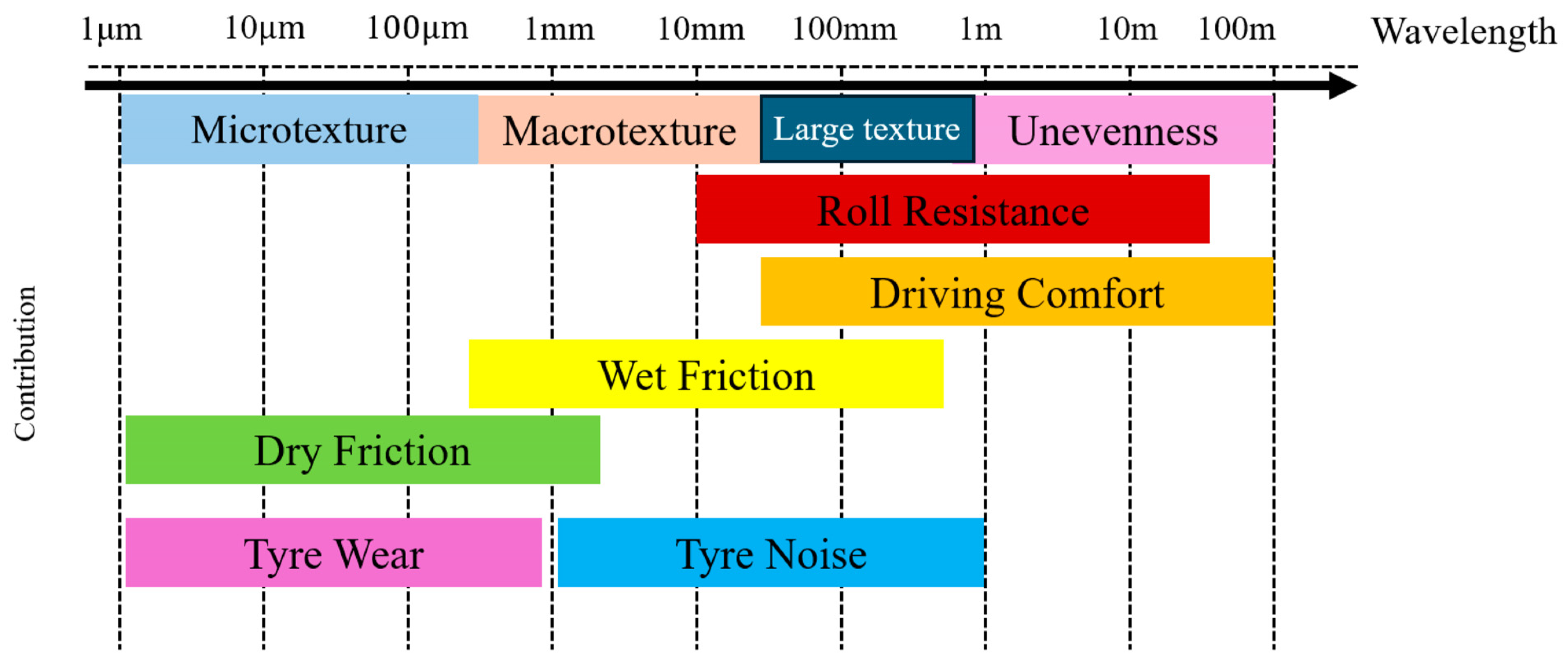

3.1. Characterisation Methods for Asphalt Pavement Macro- and Microtextures

3.2. Pavement Macro- and Microtexture Measurement Methods

3.2.1. Pavement Texture Measurement Methods

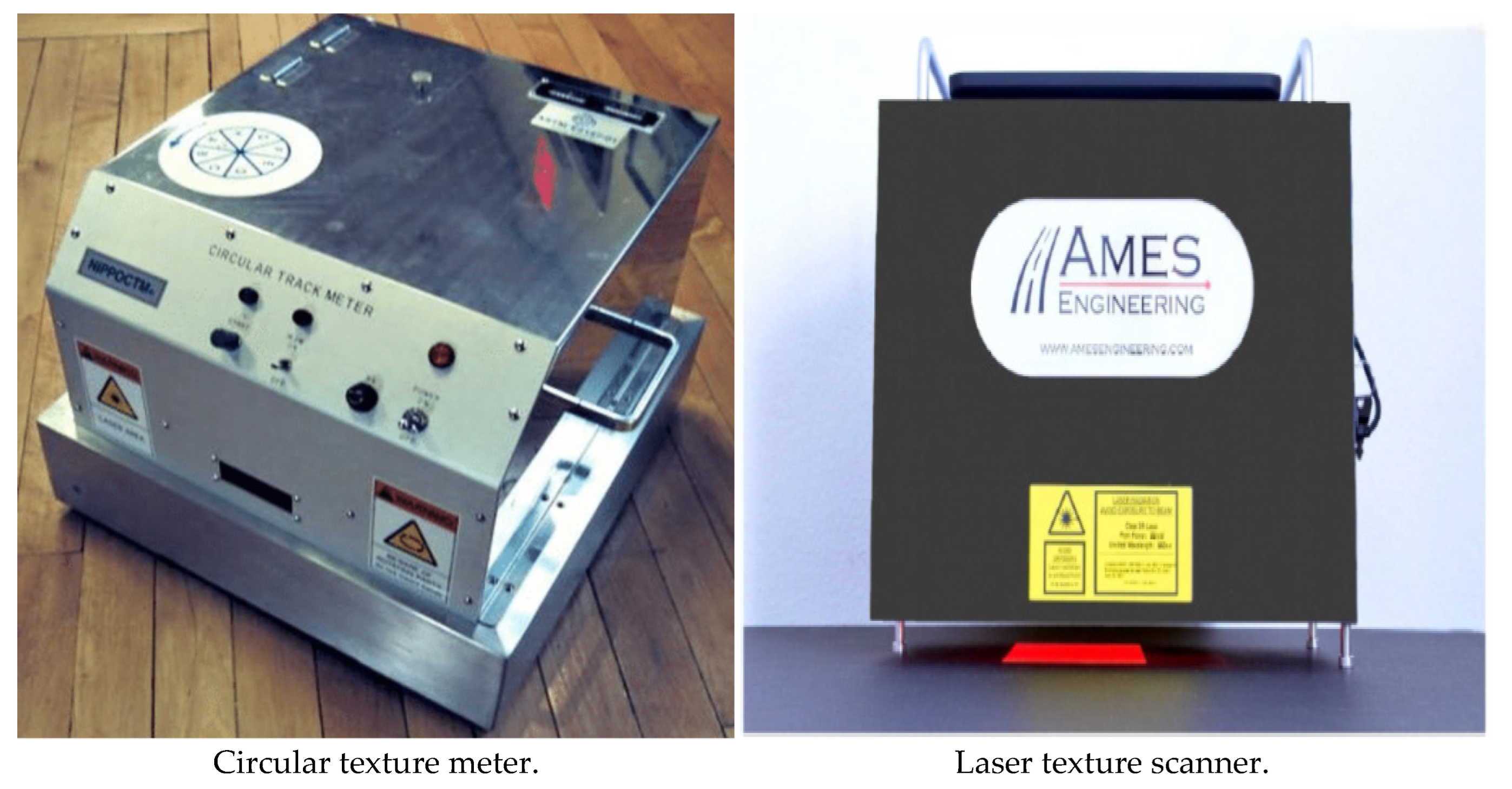

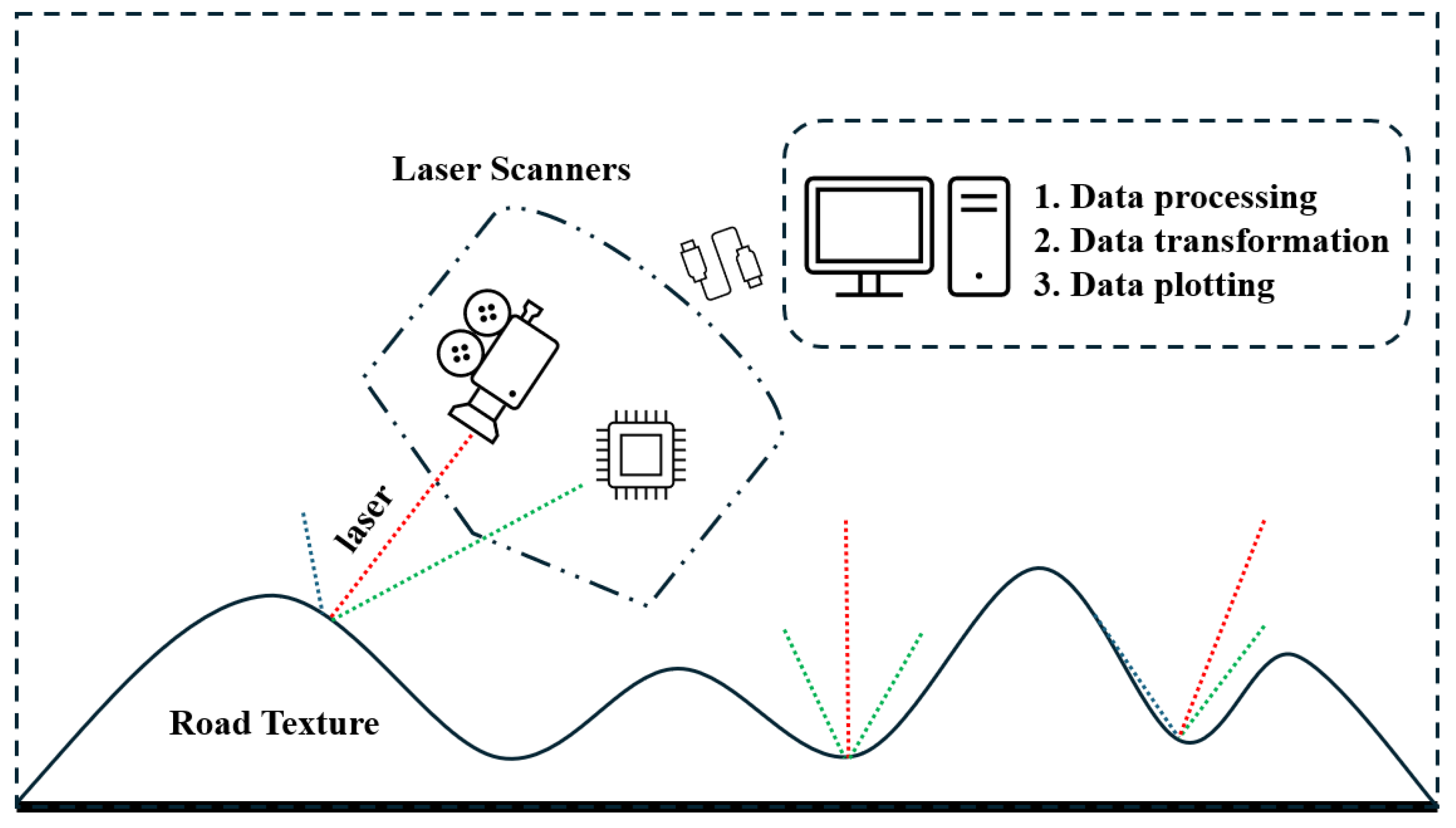

- (1)

- Laser scanning measurement method

- (2)

- Image processing methods

- (3)

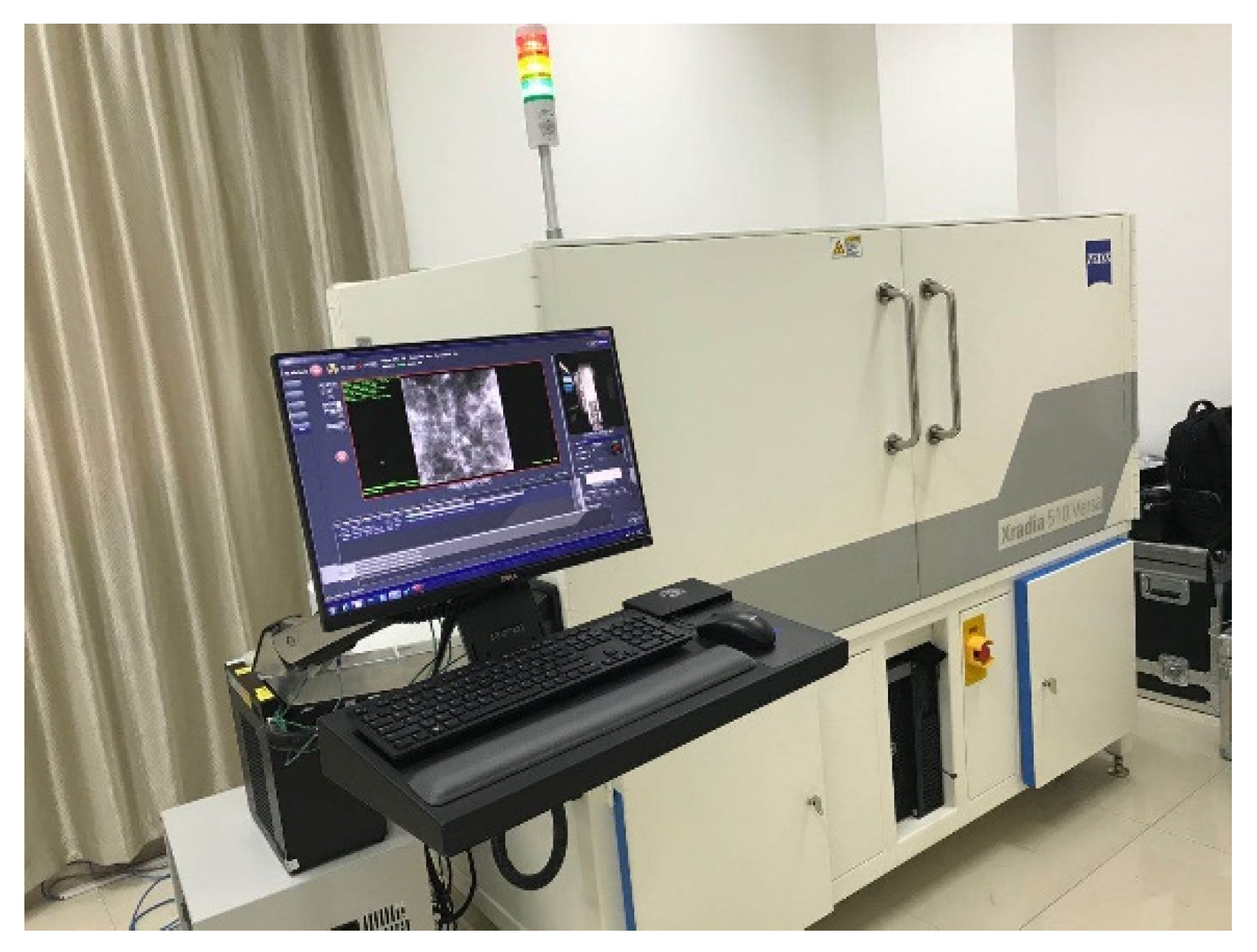

- CT scanning method

- (4)

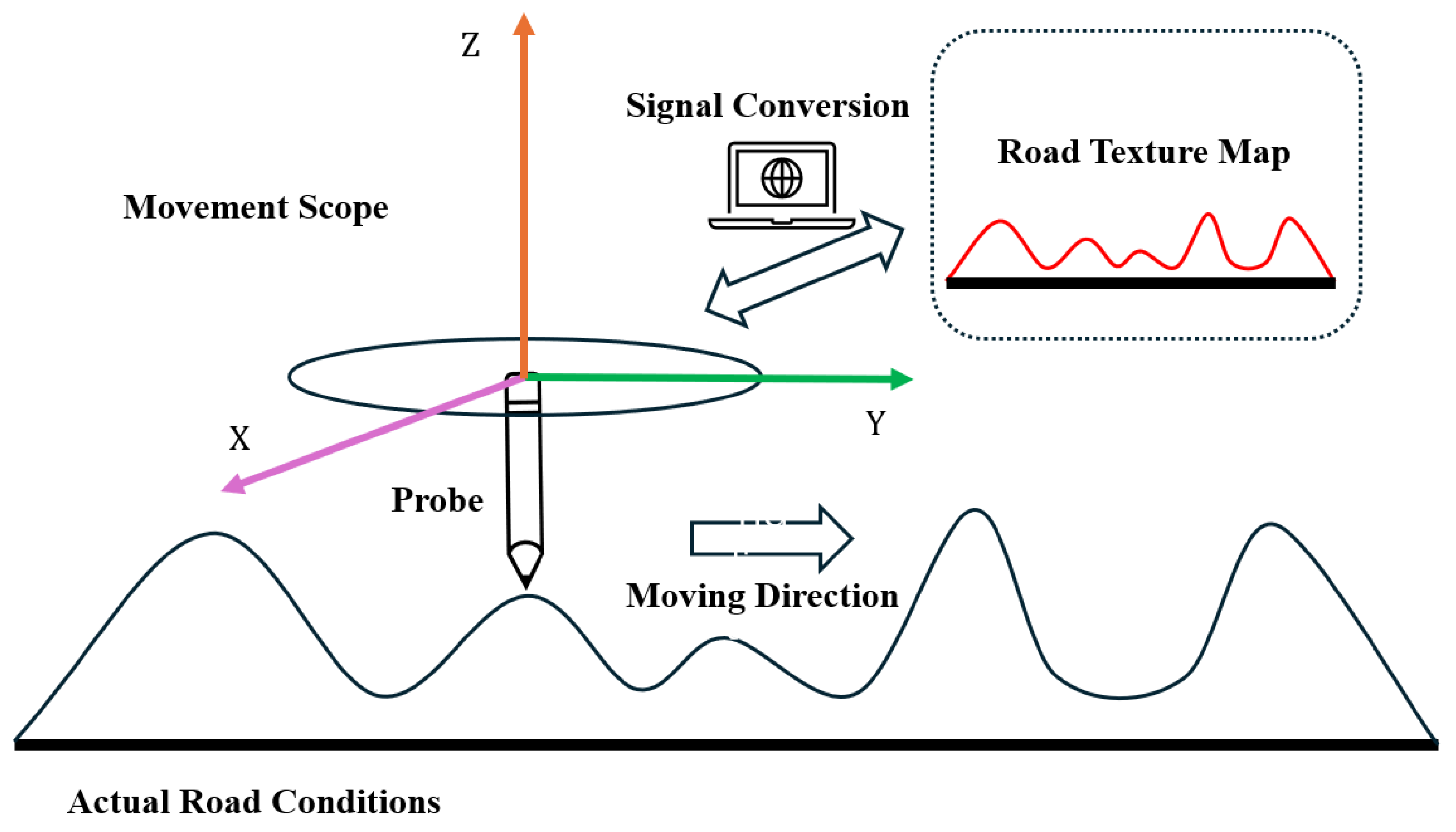

- Mechanical stylus method

- (5)

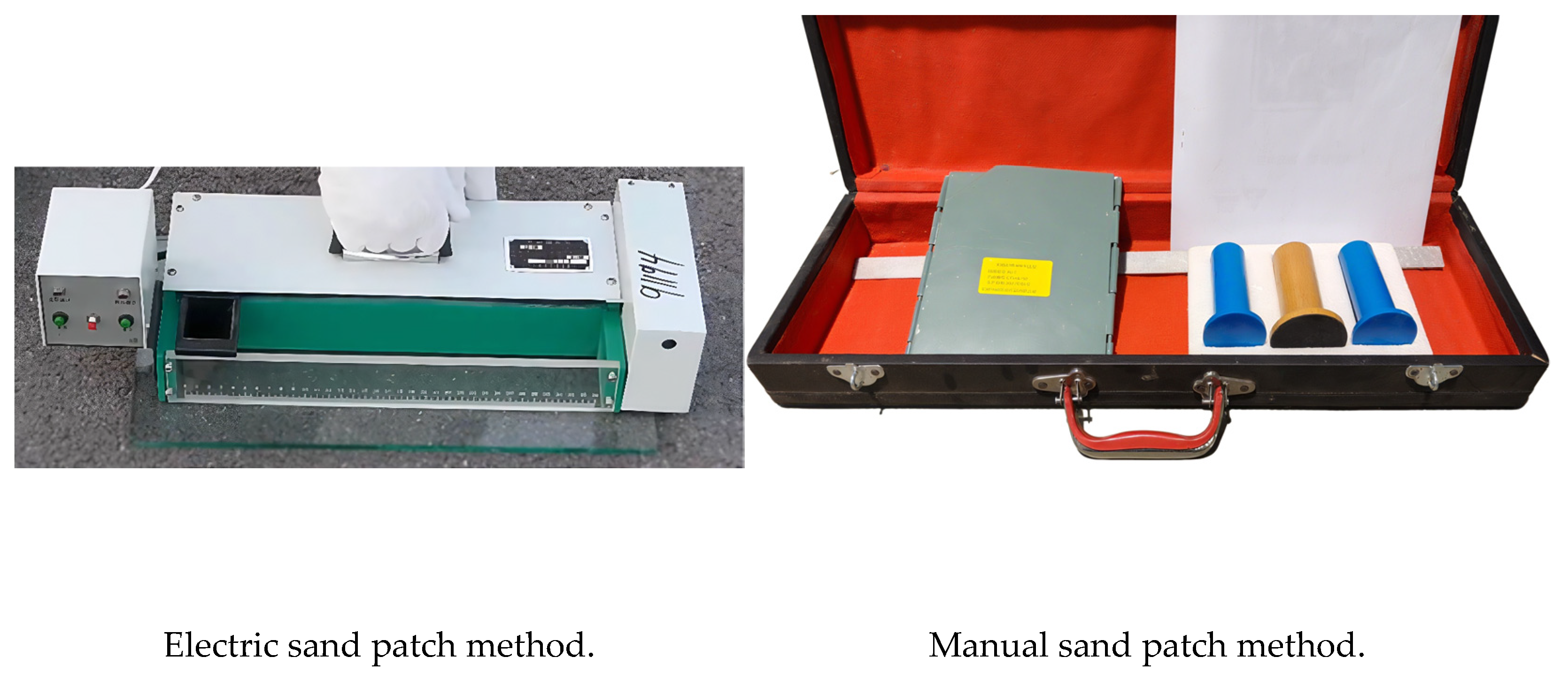

- Sand patch method (SPM)

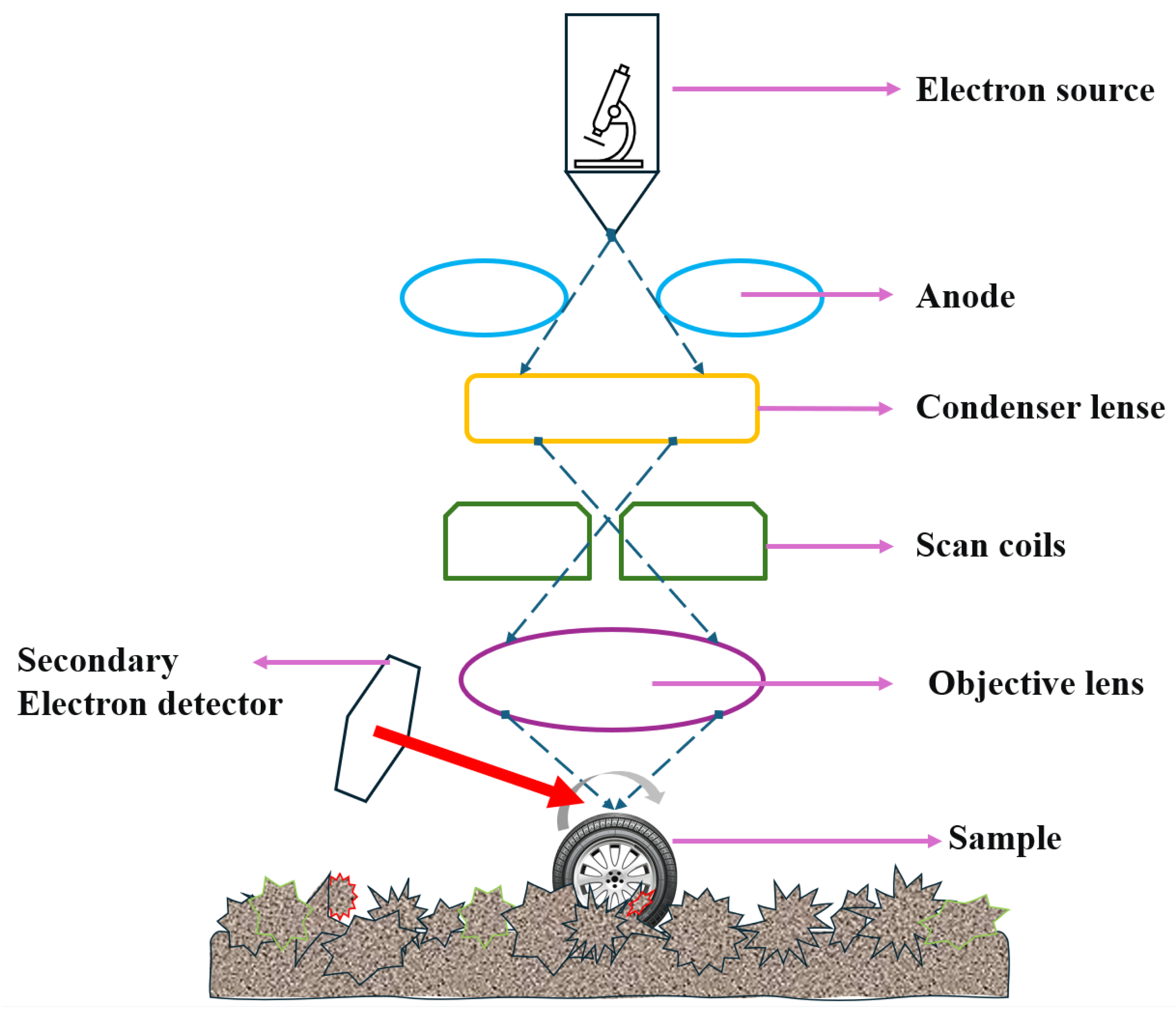

3.2.2. Measurement of Pavement Microtexture

- (1)

- Laser measurement method

- (2)

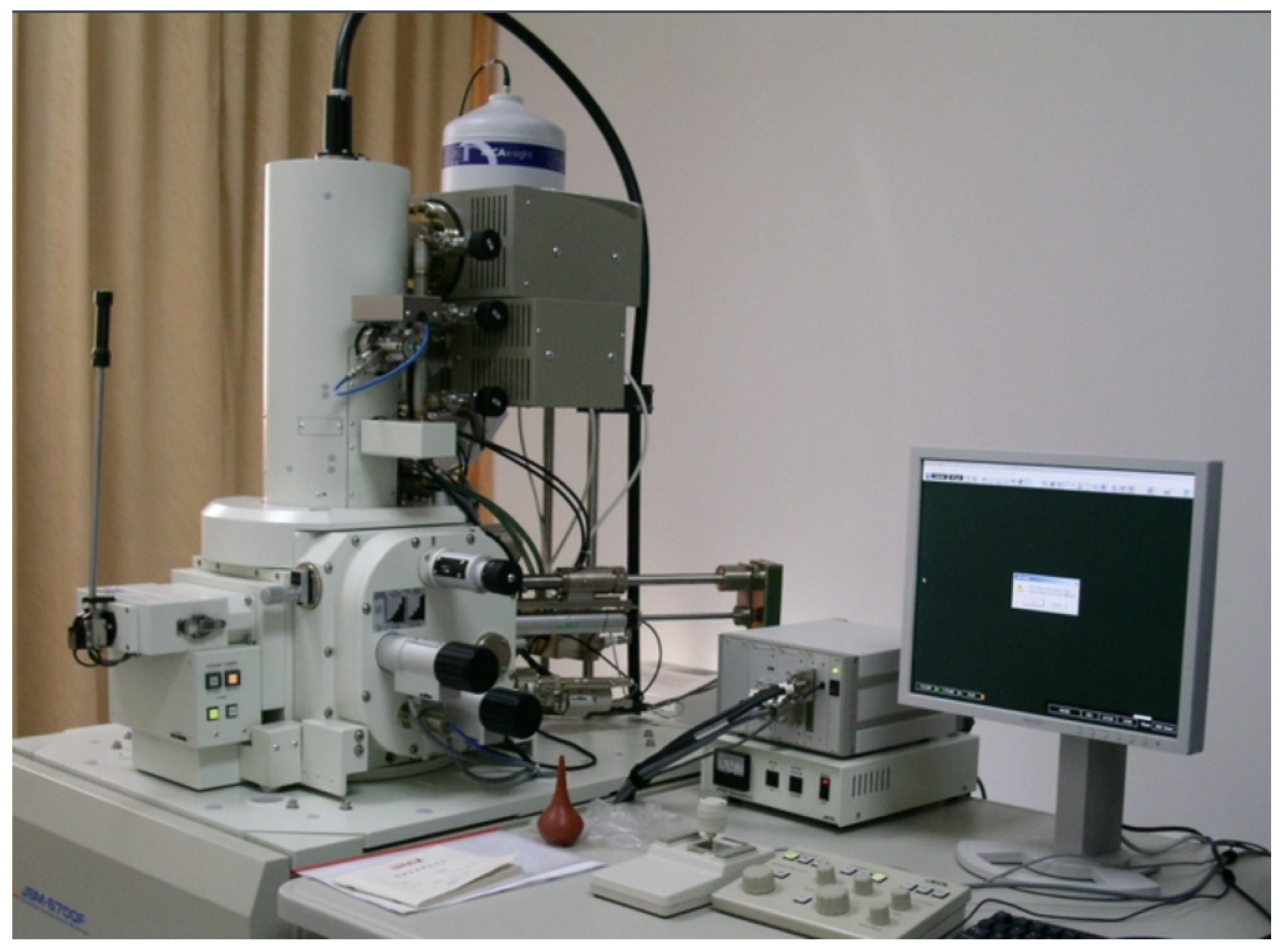

- Direct microscopic observation method

3.3. Traditional Skid Resistance Testing Methods and Indicators for Asphalt Pavements

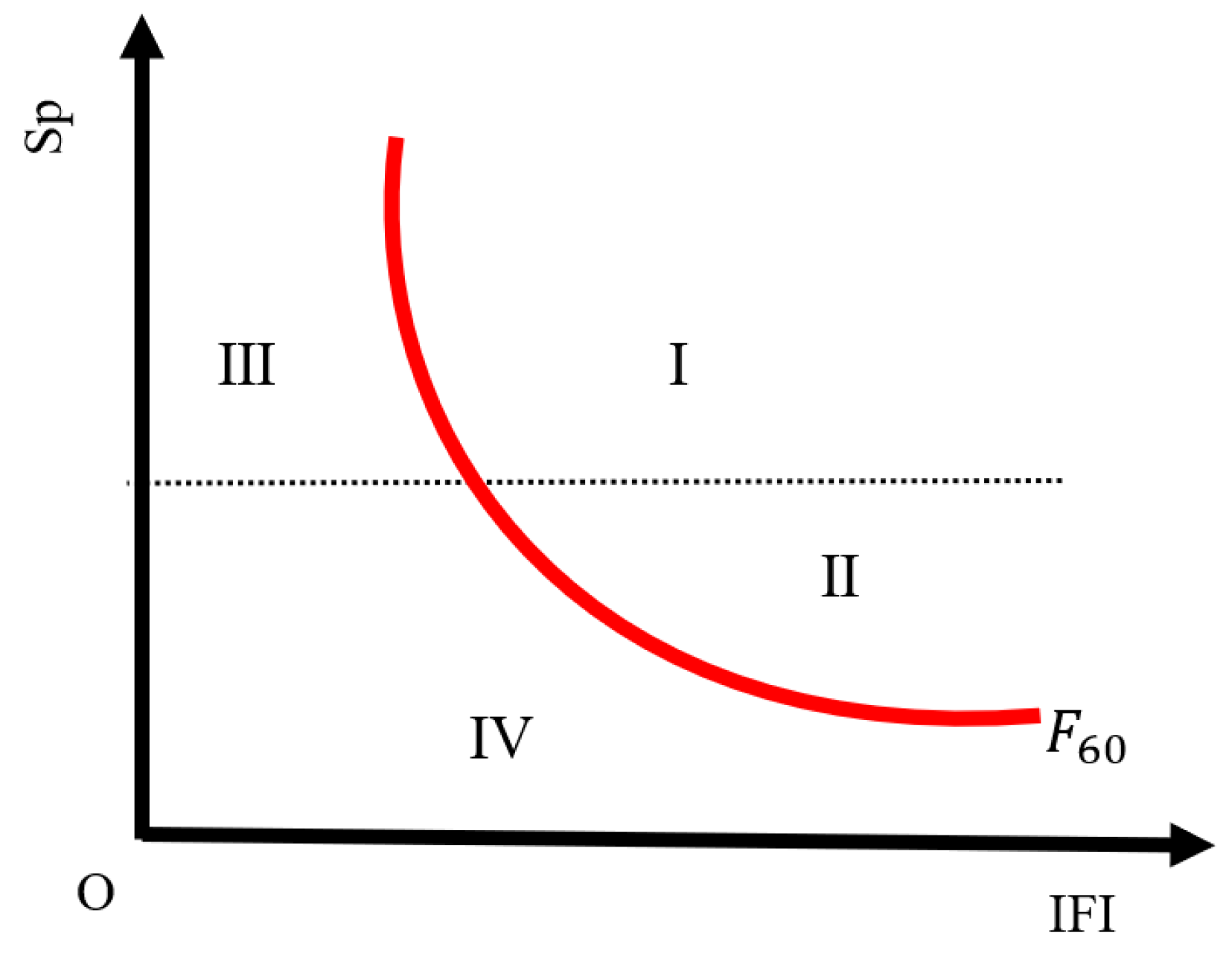

3.4. Asphalt Pavement Skid Resistance Evaluation Model

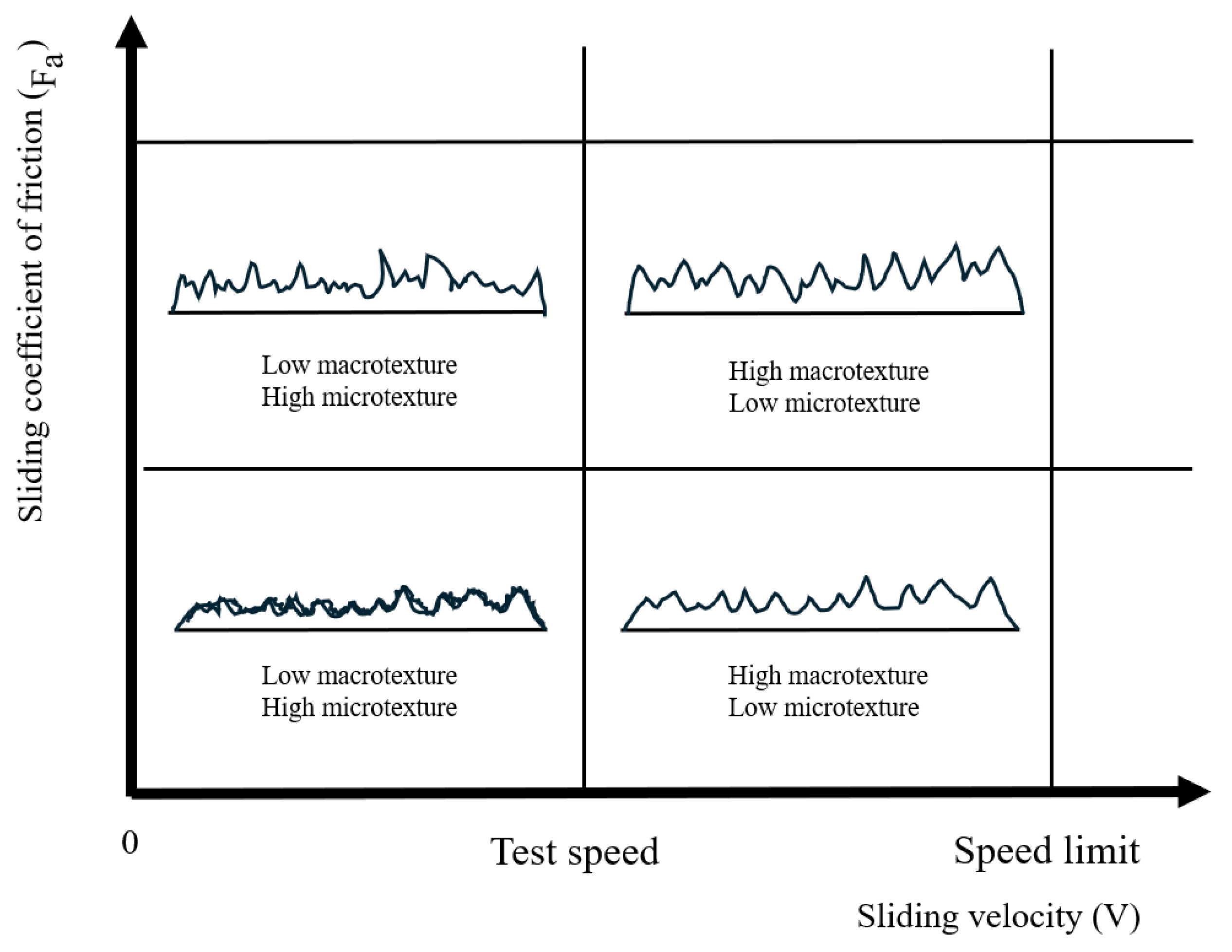

4. Study of the Relationship Between Pavement Macroscopic and Microscopic Texture Characteristics and Skid Resistance Performance

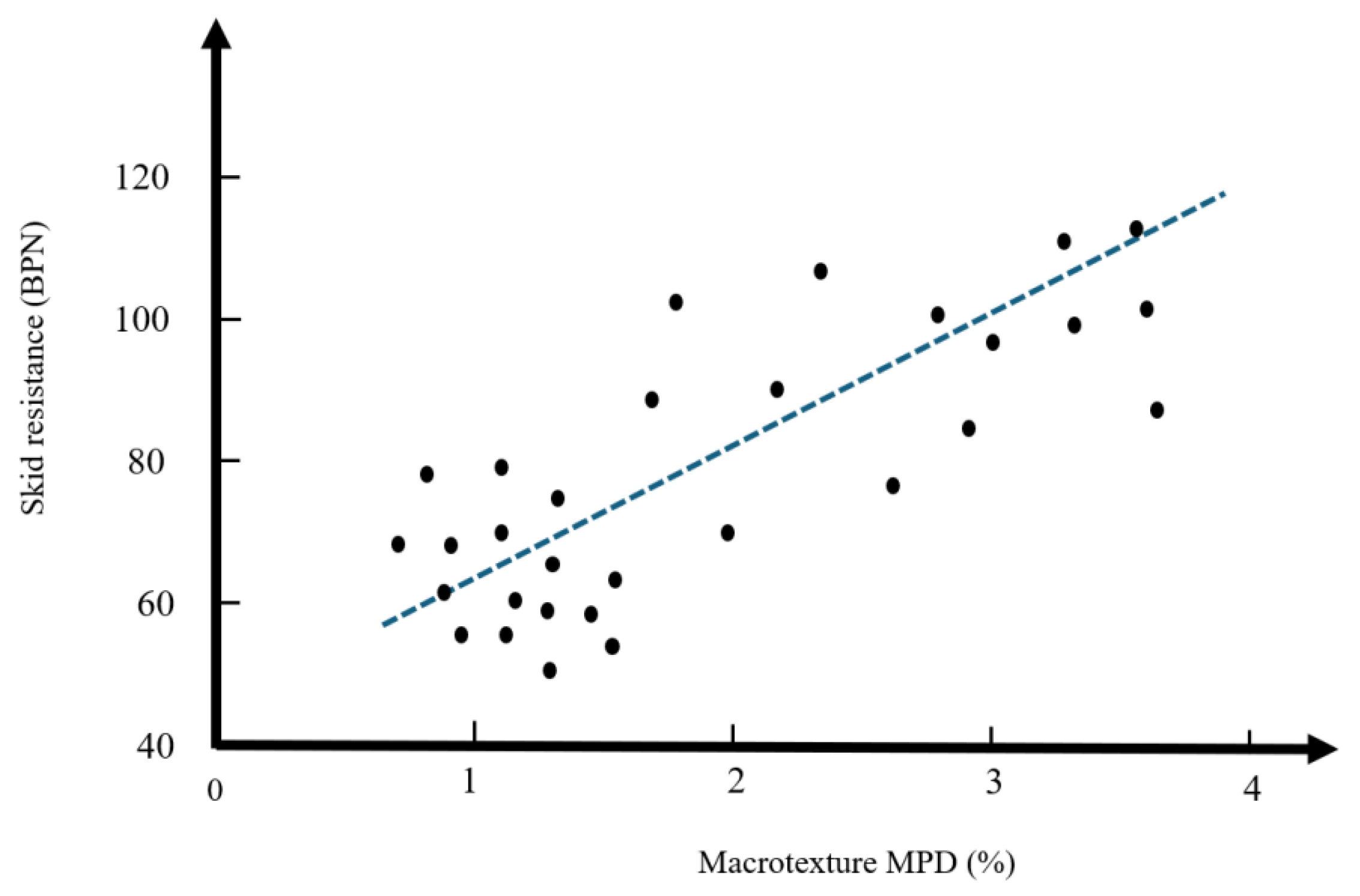

4.1. Effect of Macrotexture on Skid Resistance of Asphalt Pavements

4.1.1. Dry Pavement

4.1.2. Wet Pavement

4.2. Effect of Microtexture on Skid Resistance of Asphalt Pavements

4.2.1. Dry Pavement

4.2.2. Wet Pavement

5. Conclusions and Future Work

- The skid resistance of asphalt pavements is significantly influenced by the type and quality of the aggregate in the asphalt mix and the grading type of the asphalt mix. While different HMA classifications often exhibit similar texture characteristics, the relationships between aggregate properties and grading design and the endogenous mechanisms of macroscopic and microscopic texture refinement for mix differentiation have not been thoroughly investigated.

- In terms of pavement skid resistance measurement methods, there remains a significant gap between laboratory testing and field testing. It is necessary to optimise pavement skid resistance testing technology to bridge this gap between laboratory and actual engineering tests and to establish a quantitative relationship between pavement texture characteristics and skid resistance.

- Based on the various random uncertainty parameters in actual engineering, the macro- and microtexture evolution behaviour of pavement under the service conditions of the entire environmental domain has not yet been fully elucidated. It is necessary to investigate the long-term skid resistance attenuation characteristics of different pavement types throughout their life cycles and to integrate these uncertainty factors with pavement skid resistance to develop a unified real-time skid resistance evaluation model for asphalt pavements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jamroz, K.; Budzyński, M.; Romanowska, A.; Żukowska, J.; Oskarbski, J.; Kustra, W. Experiences and Challenges in Fatality Reduction on Polish Roads. Sustainability 2019, 11, 959. [Google Scholar] [CrossRef]

- Chu, L.; Cui, X.; Fwa, T.F. Evaluation of Skid Resistance of Grooved Pavements. In Proceedings of the International Conference on Maintenance and Rehabilitation of Pavements, Guimarães, Portugal, 24–26 July 2024. [Google Scholar]

- Tan, Y.; Li, J.; Xu, H.; Li, Z.; Wang, H. The mechanisms, evaluation and estimation of anti-skid performance of snowy and icy pavement: A review. J. Road Eng. 2023, 3, 229–238. [Google Scholar] [CrossRef]

- Liu, X.; Luo, H.; Chen, C.; Zhu, L.; Chen, S.; Ma, T.; Huang, X. A technical survey on mechanism and influence factors for asphalt pavement skid-resistance. Friction 2024, 12, 845–868. [Google Scholar] [CrossRef]

- Dunford, A. Friction and the Texture of Aggregate Particles Used in the Road Surface Course. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2013. [Google Scholar]

- Zhang, J.; Yang, S.; Li, S.; Lu, Y.; Ding, H. Influence of vehicle-road coupled vibration on tire adhesion based on nonlinear foundation. Appl. Math. Mech. 2021, 42, 607–624. [Google Scholar] [CrossRef]

- Kummer, H.W.; Meyer, W.E. The Penn State Road Friction Tester as Adapted to Routine Measurement of Pavement Skid Resistance; Highway Research Board: Washington, DC, USA, 1963. [Google Scholar]

- Zheng, B.; Tang, J.; Chen, J.; Zhao, R.; Huang, X. Investigation of Adhesion Properties of Tire—Asphalt Pavement Interface Considering Hydrodynamic Lubrication Action of Water Film on Road Surface. Materials 2022, 15, 4173. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Wang, R.; Zhou, H.; Wang, G. Estimation of the Friction Behaviour of Rubber on Wet Rough Road, and Its Application to Tyre Wet Skid Resistance, Using Numerical Simulation. Symmetry 2022, 14, 2541. [Google Scholar] [CrossRef]

- Zhao, L.; Zhao, H.; Cai, J. Tire-pavement friction modeling considering pavement texture and water film. Int. J. Transp. Sci. Technol. 2024, 14, 99–109. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Wang, Z.; Jing, H.; Yang, B. Investigations on Adhesion Characteristics between High-Content Rubberized Asphalt and Aggregates. Polymers 2022, 14, 5474. [Google Scholar] [CrossRef]

- Chen, D.; Wu, J.; Wang, Y.; Su, B.; Liu, Y. High-speed tribology behaviors of aircraft tire tread rubber in contact with pavement. Wear 2021, 486–487, 204071. [Google Scholar] [CrossRef]

- Ban, I.; Bonari, J.; Paggi, M. A computational framework for evaluating tire-asphalt hysteretic friction including pavement roughness. arXiv 2025, arXiv:2504.01511. [Google Scholar]

- Zhu, S.; Liu, X.; Cao, Q.; Huang, X. Numerical Study of Tire Hydroplaning Based on Power Spectrum of Asphalt Pavement and Kinetic Friction Coefficient. Adv. Mater. Sci. Eng. 2017, 2017, 5843061. [Google Scholar] [CrossRef]

- Ivanov, V.; Augsburg, K. Assessment of tire contact properties by nondestructive analysis. Part 1. The contact length in the region of adhesion at slow rolling velocities. J. Frict. Wear 2008, 29, 362–368. [Google Scholar] [CrossRef]

- Khan, M.R.; Mao, S.; Deebani, W.; Elsiddieg, A.M. Numerical analysis of heat transfer and friction drag relating to the effect of Joule heating, viscous dissipation and heat generation/absorption in aligned MHD slip flow of a nanofluid. Int. Commun. Heat Mass Transf. 2022, 131, 105843. [Google Scholar] [CrossRef]

- Srirangam, S.K. Numerical Simulation of Tire-Pavement Interaction. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2015. [Google Scholar]

- Wagner, P.; Wriggers, P.; Veltmaat, L.; Clasen, H.; Prange, C.; Wies, B. Numerical multiscale modelling and experimental validation of low speed rubber friction on rough road surfaces including hysteretic and adhesive effects. Tribol. Int. 2017, 111, 243–253. [Google Scholar] [CrossRef]

- Widodo, E.; Suhami, H.; Firdaus, R.; Mulyadi; Fahruddin, A.R. The Rubber Compound Combination to Strenghthen Tire Valve of 80/90 R-14. IOP Conf. Ser. Mater. Sci. Eng. 2020, 874, 012030. [Google Scholar] [CrossRef]

- Chen, S.; Liu, X.; Luo, H.; Yu, J.; Chen, F.; Zhang, Y.; Ma, T.; Huang, X. A state-of-the-art review of asphalt pavement surface texture and its measurement techniques. J. Road Eng. 2022, 2, 156–180. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, X.; Huang, Q.; Liu, X.; Zhou, Z.; Xing, S. Investigation into the Synergistic Effects of Sediment Concentration and Particle Size on the Friction and Wear Properties of Nitrile Butadiene Rubber. J. Mar. Sci. Eng. 2024, 13, 33. [Google Scholar] [CrossRef]

- Huang, X.; Zheng, B. Research Status and Progress for Skid Resistance Performance of Asphalt Pavements. China J. Highw. Transp. 2019, 32, 32–49. [Google Scholar]

- Zhang, C.; Zeng, L.; Wang, H.; Qu, X. The impact of coarse aggregate mineral compositions on skid resistance performance of asphalt pavement: A comprehensive study. PLoS ONE 2024, 19, e0308721. [Google Scholar] [CrossRef]

- Masad, E.; Rezaei, A.; Chowdhury, A.; Harris, P. Predicting Asphalt Mixture Skid Resistance Based on Aggregate Characteristics; Federal Highway Administration (FHWA): Washington, DC, USA, 2009. [Google Scholar]

- Zhan, Y.; Luo, Z.; Lin, X.; Nie, Z.; Deng, Q.; Qiu, Y.; Wang, T. Pavement preventive maintenance decision-making for high antiwear and optimized skid resistance performance. Constr. Build. Mater. 2023, 400, 132757. [Google Scholar] [CrossRef]

- Lei, J.; Zheng, N.; Bi, J.; Zhao, F.; Wang, Y.; Yang, J. Research on the evolution law of aggregate micro-texture during long-term wearing of asphalt pavement. Constr. Build. Mater. 2024, 444, 137846. [Google Scholar] [CrossRef]

- Lei, J.; Zheng, N.; Chen, X.; Bi, J.; Wu, X. Research on the relationship between anti-skid performance and various aggregate micro texture based on laser scanning confocal microscope. Constr. Build. Mater. 2022, 316, 125984. [Google Scholar] [CrossRef]

- He, Y.; Fan, Z.; Yang, X.; Wang, D.; Zhao, Z.; Lu, G.; Lv, S. Study on the influence of tire polishing on surface texture durability and skid resistance deterioration of asphalt pavement. Wear 2024, 556, 205518. [Google Scholar] [CrossRef]

- Ji, J.; Jiang, T.; Ren, W.; Dong, Y.; Hou, Y.; Li, H. Precise characterization of macro-texture and its correlation with anti-skidding performance of pavement. J. Test. Eval. 2022, 50, 1934–1946. [Google Scholar] [CrossRef]

- Jin, C.; Han, X.; Wu, J.; Ge, D.; Dong, M.; Li, S.; Yang, X. Influence investigation of morphological and distributional properties of surficial aggregates on skid resistance of asphalt pavement. Constr. Build. Mater. 2024, 457, 139394. [Google Scholar] [CrossRef]

- Hall, J.W.; Smith, K.L.; Titus-Glover, L.; Wambold, J.C.; Yager, T.J.; Rado, Z. Guide for Pavement Friction; NCHRP Web Document; Transportation Research Board: Washington, DC, USA, 2009. [Google Scholar]

- Dong, Y.; Wang, Z.; Ren, W.; Jiang, T.; Hou, Y.; Zhang, Y. Influence of morphological characteristics of coarse aggregates on skid resistance of asphalt pavement. Materials 2023, 16, 4926. [Google Scholar] [CrossRef]

- Tan, T.; Fan, Z.; Xing, C.; Tan, Y.; Oeser, M. Evaluation of Geometric Characteristics of Fine Aggregate and Its Impact on Viscoelastic Property of Asphalt Mortar. Appl. Sci. 2019, 10, 130. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, X.; Yu, J.; Wang, Y. Impact of contact stress distribution on skid resistance of asphalt pavements. Constr. Build. Mater. 2017, 133, 330–339. [Google Scholar] [CrossRef]

- Huang, B.T.; Tian, W.P.; Li, J.C.; Cui, E. Fractal Method Based on Quantitative Evaluation of Asphalt Pavement Anti-Slide Performance. China J. Highw. Transp. 2008, 21, 12–17. [Google Scholar]

- Yun, D.; Tang, C.; Gao, J.; Ran, M.; Zhou, X. Effect of asphalt mixture gradation characteristics on long-term skid resistance under high temperature and heavy load. Constr. Build. Mater. 2024, 441, 137386. [Google Scholar] [CrossRef]

- Hou, Y.; Huang, Y.; Sun, F.; Guo, M. Fractal Analysis on Asphalt Mixture Using a Two-Dimensional Imaging Technique. Adv. Mater. Sci. Eng. 2016, 2016, 8931295. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, H.; Yu, T.; Wu, G.; Jia, M. Influence of void content on noise reduction characteristics of different asphalt mixtures using meso-structural analysis. Constr. Build. Mater. 2022, 325, 126806. [Google Scholar] [CrossRef]

- Wei-Feng, W.; Xin-Ping, Y.; Wang-Xin, X.; Xiu-Min, C. Approach of multifractal feature description and recognition for pavement texture. J. Traffic Transp. Eng. 2013, 13, 15–21. [Google Scholar]

- Hallin, J.P.; Sadasivam, S.; Mallela, J.; Hein, D.K.; Darter, M.I.; Von Quintus, H.L. Guide for Pavement-Type Selection; NCHRP Report; Transportation Research Board: Washington, DC, USA, 2011. [Google Scholar]

- Yu, M.; Kong, Y.; Wu, C.; Xu, X.; Li, S.; Chen, H.; Kong, L. The Effect of Pavement Texture on the Performance of Skid Resistance of Asphalt Pavement Based on the Hilbert-Huang Transform. Arab. J. Sci. Eng. 2021, 46, 11459–11470. [Google Scholar] [CrossRef]

- Zhang, Y.L. Skid resistance regularity of different grades bituminous mixture. J. Xi’an Highw. Univ. 2003, 7–10. [Google Scholar]

- Li, W.; Han, S.; Huang, Q. Performance of Noise Reduction and Skid Resistance of Durable Granular Ultra-Thin Layer Asphalt Pavement. Materials 2020, 13, 4260. [Google Scholar] [CrossRef]

- He-Qi, L.; Zhi-Qiang, L. Study of Skid Resistance Technology for Asphalt Pavement. J. Guangdong Univ. Technol. 2004, 303, 124411. [Google Scholar] [CrossRef]

- Chaoqing, Q. Study on Factors Influencing Skid Resistance of Asphalt Pavement Abroad. Urban Roads Bridges Flood Control 2019. [Google Scholar]

- Zhi-Feng, Z.; Qing-Cai, W.; Hua-Ting, L.I.; Jin-Liang, Q.; Xiao-Hong, Z.; Jian-Ming, G.; Amp, B. Influence of Ultra Fine Powdered Rubber on the Properties of Different Rubber. Tire Ind. 2015. [Google Scholar]

- Ahammed, M.A.; Tighe, S.L. Pavement Surface Mixture, Texture, and Skid Resistance: A Factorial Analysis. In Proceedings of the Airfield & Highway Pavements Conference, Seattle, WA, USA, 15–18 October 2008. [Google Scholar]

- Zhi, L.I.; Li, T.; Si-Yu, C. Experimental Study on Skid Resistance Performance and Durability of Granite Asphalt Pavement Anti-skid Layer. Sci. Technol. Eng. 2014. [Google Scholar]

- Li, B.; Xu, O.; Han, S. Fractal characterization of pavement texture and its application in skidding resistance prediction. J. Wuhan Univ. Technol. 2009, 39, 47–56. [Google Scholar]

- Muench, S.T.; Mahoney, J.P.; White, G.C. Pavement Interactive: Pavement Knowledge Transfer with Web 2.0. J. Transp. Eng. 2010, 136, 1165–1172. [Google Scholar] [CrossRef]

- Li, S.; Zhu, K.; Noureldin, S. Evaluation of friction performance of coarse aggregates and hot-mix asphalt pavements. J. Test. Eval. 2007, 35, 571–577. [Google Scholar] [CrossRef]

- Ongel, A.; Lu, Q.; Harvey, J. Frictional properties of asphalt concrete mixes. Proc. Inst. Civ. Eng. -Transp. 2009, 162, 19–26. [Google Scholar] [CrossRef]

- Cross, S.A.; Shitta, H.; Workie, A.; Inestroza, M.C. QC/QA Testing Differences Between Hot Mix Asphalt (HMA) and Warm Mix Asphalt (WMA); Oklahoma Department of Transportation: Oklahoma City, OK, USA, 2013. [Google Scholar]

- Chen, S.; Che, T.; Mohseni, A.; Azari, H.; You, Z. Preliminary study of modified asphalt binders with thermoplastics: The Rheology properties and interfacial adhesion between thermoplastics and asphalt binder. Constr. Build. Mater. 2021, 301, 124373. [Google Scholar] [CrossRef]

- Liu, X.; Li, Z.; Chen, S.; Zhou, Y. Fatigue performance enhancement and high-temperature performance evaluation of asphalt treated base mixture. Constr. Build. Mater. 2021, 305, 124146. [Google Scholar] [CrossRef]

- Remišová, E.; Holešová, N.; Brna, M. Influence of mineral aggregate on asphalt pavement surface properties. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1015, 012072. [Google Scholar] [CrossRef]

- Yu, M.; You, Z.; Wu, G.; Kong, L.; Liu, C.; Gao, J. Measurement and modeling of skid resistance of asphalt pavement: A review. Constr. Build. Mater. 2020, 260, 119878. [Google Scholar] [CrossRef]

- Sun, L.; Wang, Y. Three-dimensional reconstruction of macrotexture and microtexture morphology of pavement surface using six light sources–based photometric stereo with low-rank approximation. J. Comput. Civ. Eng. 2017, 31, 04016054. [Google Scholar] [CrossRef]

- Bitelli, G.; Simone, A.; Girardi, F.; Lantieri, C. Laser Scanning on Road Pavements: A New Approach for Characterizing Surface Texture. Sensors 2012, 12, 9110–9128. [Google Scholar] [CrossRef]

- Wang, T.; Chu, L.; Fwa, T. Improved numerical method for determination of pavement mean texture depth from 3-dimensional digital image. Constr. Build. Mater. 2022, 358, 129447. [Google Scholar] [CrossRef]

- Pourhassan, A.; Gheni, A.A.; ElGawady, M.A. Three-dimensional technique for accurate pavement macrotexture measurement using Surface Volume Parameters. Constr. Build. Mater. 2024, 450, 138630. [Google Scholar] [CrossRef]

- Medeiros, M., Jr.; Babadopulos, L.; Maia, R.; Castelo Branco, V. 3D pavement macrotexture parameters from close range photogrammetry. Int. J. Pavement Eng. 2023, 24, 2020784. [Google Scholar] [CrossRef]

- Lan, Z. Study on Surface Texture Structure and Anti-Skid Performance of Asphalt Pavement Based on Digital Image Technology. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2017. [Google Scholar]

- Taheri-Shakib, J.; Al-Mayah, A. A review of microstructure characterization of asphalt mixtures using computed tomography imaging: Prospects for properties and phase determination. Constr. Build. Mater. 2023, 385, 131419. [Google Scholar] [CrossRef]

- Ning, W.; Zhou, S.; Long, K.; Xie, B.; Ai, C.; Yan, C. Investigation of key morphological parameters of pores in different grades of asphalt mixture based on CT scanning technology. Constr. Build. Mater. 2024, 434, 136770. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M.; Krolczyk, G. Study of surface texture measurement errors. Measurement 2023, 210, 112568. [Google Scholar] [CrossRef]

- Hu, L.; Yun, D.; Gao, J.; Tang, C. Monitoring and optimizing the surface roughness of high friction exposed aggregate cement concrete in exposure process. Constr. Build. Mater. 2020, 230, 117005. [Google Scholar] [CrossRef]

- Sun, F.-Y.; Huang, L.; Wang, L.-B. Molecular dynamics simulation of micro frictional contact characteristics between tires and asphalt pavement. Chin. J. Eng. 2016, 38, 847–852. [Google Scholar]

- Santos, P.M.; Júlio, E.N. A state-of-the-art review on roughness quantification methods for concrete surfaces. Constr. Build. Mater. 2013, 38, 912–923. [Google Scholar] [CrossRef]

- Santos, P.M.D.; Júlio, E.N.B.S. Comparison of Methods for Texture Assessment of Concrete Surfaces. ACI Mater. J. 2010, 107, 433–440. [Google Scholar]

- Gökalp, I.; Uz, V.E.; Saltan, M. Comparative laboratory evaluation of macro texture depth of chip seal samples using sand patch and outflow meter test methods. In Bearing Capacity of Roads, Railways and Airfields; CRC Press: Boca Raton, FL, USA, 2017; pp. 915–920. [Google Scholar]

- Dai, J.; Xu, S.; Song, S. Changes in basalt before and after microwave irradiation based on XRD and SEM. China Sci. Paper 2018, 13, 2781–2783. [Google Scholar]

- Zhang, Y.; Sun, Q.; Geng, J. Microstructural characterization of limestone exposed to heat with XRD, SEM and TG-DSC. Mater. Charact. 2017, 134, 285–295. [Google Scholar] [CrossRef]

- Jiang, B.H.; Yi, Y.U.; Sun, Z.Q.; Gao, X.J.; Shi-Zhang, Y.U. Application of Micro-CT and SEM Technology In-situ Observation of Damage Evolution of C/SiC Composites. In Proceedings of the 2019 Far East NDT New Technology & Application Forum (FENDT), Qingdao, China, 24–27 June 2019. [Google Scholar]

- Guo, F.; Pei, J.; Zhang, J.; Li, R.; Zhou, B.; Chen, Z. Study on the skid resistance of asphalt pavement: A state-of-the-art review and future prospective. Constr. Build. Mater. 2021, 303, 124411. [Google Scholar] [CrossRef]

- Chen, B. Research on Asphalt Pavement Skid Resistance Performance Evaluation Method Based on Tire-Pavement Effective Contact Characteristics. Ph.D. Thesis, South China University of Techology, Guangzhou, China, 2018. [Google Scholar]

- JTG 3450-2019; Field Test Methods of Subgrade and Pavement for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2019.

- Liu, L. Research on Repeatability Calibration of Friction Coefficient of Transverse Force. J. Phys. Conf. Ser. 2022, 2381, 012066. [Google Scholar] [CrossRef]

- Yi-Pei, L.; Pu-Guang, H. Study on asphalt pavement skid resistance evaluation method based on the road surface structural features. Commun. Sci. Technol. Heilongjiang 2016. [Google Scholar]

- ASTM E0524-08R20; Standard Specification for Standard Smooth Tire for Pavement Skid-Resistance Tests. ASTM International: West Conshohocken, PA, USA, 1988.

- Qian, Z.; Xue, Y.; Zhang, L. 3-D textural fractal dimension and skid resistance of asphalt pavement. J. Cent. South Univ. Sci. Technol. 2016, 47, 3590–3596. [Google Scholar]

- Wang, Y. Study on the Relationship Between Sliding Resistance of Asphalt Pavement and Its Surface Rough Characteristics. Ph.D. Thesis, Southeast University Nanjing, Nanjing, China, 2017. [Google Scholar]

- Xiao, W.X.; Zhou, X.L. Research of skid resistance of asphalt pavement based on 3D fractal dimension. J. Highw. Transp. Res. Dev. 2016, 33, 28–32. [Google Scholar]

- Chen, D.; Han, S.; Su, Q.; Han, X. Evaluation indicator of surface texture of asphalt pavement based on skid-resistance and noise reduction performance. J. ZheJiang Univ. (Eng. Sci.) 2017, 51, 896–903. [Google Scholar]

- Chen, W. Evaluation of Skid-Resistance Decay Characteristic of Asphalt Mixture Based on Pressure-Sensitive Film Technology. In Proceedings of the 2020 International Conference on Artificial Intelligence and Electromechanical Automation (AIEA), Tianjin, China, 26–28 June 2020. [Google Scholar]

- Miao, Y.; Cao, D.; Liu, Q. Evaluating the Relationship of Asphalt Pavement Skid Resistance to Slip Speed Using Dynamic Friction Tester Measurements. In Proceedings of the Tenth International Conference of Chinese Transportation Professionals, Beijing, China, 4–8 August 2010; pp. 3678–3685. [Google Scholar]

- Fan, Q.; Chen, C.; Liu, F.; Zheng, H. Analysis on Attenuation Law of Skid Resistance Performance of Asphalt Pavement with Thin Overlay. IOP Conf. Ser. Earth Environ. Sci. 2021, 781, 022100. [Google Scholar] [CrossRef]

- Zhu, H.; Liao, Y. Present Situations of Research on Anti-skid Property of Asphalt Pavement. Highway 2018, 63, 35–46. [Google Scholar]

- Zhao, Z.; Zhang, Z.; Hu, C. Influence of gradation on anti-skidding performance of asphalt pavement. J. Chang. Univ. (Nat. Sci. Ed.) 2005, 25, 6–9. [Google Scholar]

- Shuangquan, J.; Xiaohua, Z. Study on the Attenuation Characteristics of Asphalt Pavement Skid-resistance and the Applicability of Evaluation Index. Energy Conserv. Environ. Prot. Transp. 2018. [Google Scholar]

- Senthilvelan, J.; Izuo, H.; Endo, T.; Ueno, A. Influence of the Unit Content and Grading Distribution of Fine Aggregates on the Long-term Skid Resistance of Concrete Pavement. J. Adv. Concr. Technol. 2024, 22, 431–444. [Google Scholar] [CrossRef]

- Kassem, E.; Awed, A.; Masad, E.A.; Little, D.N. Development of predictive model for skid loss of asphalt pavements. Transp. Res. Rec. 2013, 2372, 83–96. [Google Scholar] [CrossRef]

- Rajaei, S.; Chatti, K.; Dargazany, R. A Review: Pavement Surface Micro-texture and Its Contribution to Surface Friction. In Proceedings of the Transportation Research Board 96th Annual Meeting, Washington, DC, USA, 8–12 January 2017. [Google Scholar]

- Ejsmont, J.A.; Sommer, S.; Ronowski, G.; Swieczko-Zurek, B. Road texture influence on tyre rolling resistance. Road Mater. Pavement Des. Int. J. 2017, 18, 181–198. [Google Scholar] [CrossRef]

- Serigos, P.; Buddhavarapu, P.; Gorman, G.; Hong, F.; Prozzi, J. The Contribution of Micro- and Macro-Texture to The Skid Resistance of Flexible Pavement; University of Texas at Austin, Center for Transportation Research: Austin, TX, USA, 2016. [Google Scholar]

- Zhu, S.; Ji, X.; Yuan, H.; Li, H.; Xu, X. Long-term skid resistance and prediction model of asphalt pavement by accelerated pavement testing. Constr. Build. Mater. 2023, 375, 131004. [Google Scholar] [CrossRef]

- Kane, M.; Do, M.T.; Cerezo, V.; Rado, Z.; Khelifi, C. Contribution to pavement friction modelling: An introduction of the wetting effect. Int. J. Pavement Eng. 2019, 20, 965–976. [Google Scholar] [CrossRef]

- Yang, G.; Li, Q.J.; Zhan, Y.J.; Wang, K.C.P.; Wang, C. Wavelet based macrotexture analysis for pavement friction prediction. Ksce J. Civ. Eng. 2017, 22, 117–124. [Google Scholar] [CrossRef]

- Deng, Q.; Zhan, Y.; Liu, C.; Qiu, Y.; Zhang, A. Multiscale power spectrum analysis of 3D surface texture for prediction of asphalt pavement friction. Constr. Build. Mater. 2021, 293, 123506. [Google Scholar] [CrossRef]

- Cao, Q.; Liu, X.; Huang, X. Theoretical Analysis of Skid Resistance on Asphalt Pavement Based on Rubber Friction Mechanism. In Proceedings of the 17th COTA International Conference of Transportation Professionals, Beijing, China, 5–8 July 2018. [Google Scholar]

- Lindgren, W. Report of the committee on processes of ore deposition. Econ. Geol. 1928, 23, 591–611. [Google Scholar] [CrossRef]

- Flintsch, G.; Al-Qadi, I.L.; Davis, R.; McGhee, K. Effect of HMA properties on pavement surface characteristics. In Proceedings of the Pavement Evaluation Conference, Roanoke, VA, USA, 21–25 October 2002. [Google Scholar]

- Riahi, E.; Do, M.T.; Kane, M. An energetic approach to model the relationship between tire rolling friction and road surface macrotexture. Surf. Topogr. Metrol. Prop. 2022, 10, 014001. [Google Scholar] [CrossRef]

- Jayme, A.; Al-Qadi, I.L. Thermomechanical coupling of a hyper-viscoelastic truck tire and a pavement layer and its impact on three-dimensional contact stresses. Transp. Res. Rec. 2021, 2675, 359–372. [Google Scholar] [CrossRef]

- Vieira, T.; Sandberg, U.; Erlingsson, S. Rolling Resistance Evaluation of Winter Tires on In-Service Road Surfaces. Tire Sci. Technol. 2021, 49, 78–103. [Google Scholar] [CrossRef]

- Najafi, S.; Flintsch, G.W.; McGhee, K.K. Assessment of operational characteristics of continuous friction measuring equipment (CFME). Int. J. Pavement Eng. 2013, 14, 706–714. [Google Scholar] [CrossRef]

- Liang, Z. The energy equation for rapidly varied steady flow, and its applications. Shuili Xuebao (J. Hydraul. Eng.) 1982, 2, 32–38. [Google Scholar]

- Liu, X.; Cao, Q.; Wang, H.; Chen, J.; Huang, X. Evaluation of vehicle braking performance on wet pavement surface using an integrated tire-vehicle modeling approach. Transp. Res. Rec. 2019, 2673, 295–307. [Google Scholar] [CrossRef]

- Dai, Q. Study on the Influence of Asphalt Pavement Surface Characteristics on Anti Sliding Performance. Master’s Thesis, Southeast University, Nanjing, China, 2007. [Google Scholar]

- Di, Y.; Hu, L.; Sandberg, U.; Tang, C. Skid resistance performance and texture lateral distribution within the lanes of asphalt pavements. J. Traffic Transp. Eng. 2021, 12, 87–107. [Google Scholar]

- Bond, R. The Optimisation of Tyre-Road Friction; University of Birmingham: Birmingham, UK, 1976. [Google Scholar]

- Grigoriadis, K.; Mavros, G.; Knowles, J.; Pezouvanis, A. Experimental investigation of tyre–road friction considering topographical roughness variation and flash temperature. Tribol. Int. 2023, 181, 108294. [Google Scholar] [CrossRef]

- Han, Y.; Lu, Y.; Liu, J.; Zhang, J. Research on tire/road peak friction coefficient estimation considering effective contact characteristics between tire and three-dimensional road surface. Machines 2022, 10, 614. [Google Scholar] [CrossRef]

- Kienle, R.; Ressel, W.; Götz, T.; Weise, M. The influence of road surface texture on the skid resistance under wet conditions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 234, 313–319. [Google Scholar] [CrossRef]

- Cao, P.; Yan, X.; Bai, X.; Yuan, C. Effects of Contaminants on Skid Resistance of Asphalt Pavements. In Proceedings of the International Conference on Traffic & Transportation Studies, Kunming, China, 3–5 August 2010. [Google Scholar]

| Asphalt Mix Type | Texture-Based Mix Category | Classification Details and Friction Characteristics [31] |

| Hot Mix Asphalt | Continuous-graded asphalt mixture | Continuous-graded asphalt mixtures are made of continuous-graded, mutually embedded dense aggregates and asphalt in a hot mixing state; these mixtures form a hot paving state, and their macrotexture depths are generally 0.4–1.2 mm, but their microtextures are similar to open-graded and semi-open-graded asphalt mixtures [50]. |

| Intermittent-graded asphalt mixture | Intermittent-graded asphalt mixtures consist of aggregates that lack one or more grades in the gradation composition and asphalt in the hot mixing and hot paving forming mix; their macrotexture depths are usually greater than 1 mm, and coarse aggregates creating a macrotexture are best, as they provide friction in wet weather and low tyre noise [51]. | |

| Open-graded asphalt mixture | Open-graded asphalt mixtures consist mainly of coarse aggregates, with fewer fine aggregates, and macroscopic texture depth ranges from 1.5 to 3 mm for mixes with residual voids greater than 15 percent after compaction, but the microscopic texture remains similar to that of other types of mixes [52]. | |

| Warm Mix Asphalt | Warm mix asphalt consists of aggregates mixed with asphalt at room temperature to form a mix that is environmentally friendly, with less dust and fumes, and exhibits very few differences between its macrotexture and microtexture compared to HMA pavements, and no significant differences in early skid resistance have been observed [53]. |

| Texture Type | Wavelength (mm) | Amplitude (mm) |

|---|---|---|

| Unevenness | >500 | 1~200 |

| Large texture | 50~500 | 1~50 |

| Macrotexture | 0.5~50 | 0.2~10 |

| Microtexture | <0.5 | 0~0.2 |

| Model Type | Parametric Expression |

| Empirical Formula Model | |

| Y is the slip resistance index or the depth of construction, x is the number of axle loads (10,000), and A and B are regression coefficients. | |

| Penn State Model | |

| F(S) represents the friction factor of the wheel at a slip speed of S; F0, S0 are the characteristic parameters of the test apparatus; F0 is the friction factor at a slip velocity of 0; and S0 is a function that depends on the macroscopic texture of the pavement. | |

| Modified Penn State Model | |

| F10 is the friction factor for a slip velocity of 10 km·h−1, and the rest of the parameters have the same meaning as in the Penn State Model. | |

| Asymptotic Model | |

| A is the attenuation amplitude, B is the attenuation rate, C is the final attenuation value, and x is the number of axial loads. | |

| PIARC Model | |

| is the speed number; is the friction factor corresponding to a slip speed of 60 km·h−1; are the influence coefficients; is the pavement construction parameter (MTD when measured by the sand-laying method, and MPD when measured by the laser method); are the calibration parameters of the instrument is the friction factor at a slip speed of the s friction factor when the slip velocity is s; and IFIis the international friction index. | |

| Pavement Skid Resistance Prediction Model | |

| y is the pendulum value; A is the attenuation rate; X is the cumulative number of axle loads, i.e., 10,000 times; C is the initial value of attenuation related to asphalt mix gradation; and s is the aggregate polishing value. | |

| Friction and Texture Models | |

| is the MPD; Treat is a virtual variable that takes 1 when the cross-section receives an optical texture and 0 otherwise; and ) is the microtexture baseline space parameter. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Zhang, Z.; Wei, J.; Zhang, X.; Wu, W.; Sun, Y.; Wang, G. Study on Skid Resistance of Asphalt Pavements Under Macroscopic and Microscopic Texture Features: A Review of the State of the Art. Appl. Sci. 2025, 15, 6819. https://doi.org/10.3390/app15126819

Chen W, Zhang Z, Wei J, Zhang X, Wu W, Sun Y, Wang G. Study on Skid Resistance of Asphalt Pavements Under Macroscopic and Microscopic Texture Features: A Review of the State of the Art. Applied Sciences. 2025; 15(12):6819. https://doi.org/10.3390/app15126819

Chicago/Turabian StyleChen, Wei, Zhengchao Zhang, Jincheng Wei, Xiaomeng Zhang, Wenjuan Wu, Yuxuan Sun, and Guangyong Wang. 2025. "Study on Skid Resistance of Asphalt Pavements Under Macroscopic and Microscopic Texture Features: A Review of the State of the Art" Applied Sciences 15, no. 12: 6819. https://doi.org/10.3390/app15126819

APA StyleChen, W., Zhang, Z., Wei, J., Zhang, X., Wu, W., Sun, Y., & Wang, G. (2025). Study on Skid Resistance of Asphalt Pavements Under Macroscopic and Microscopic Texture Features: A Review of the State of the Art. Applied Sciences, 15(12), 6819. https://doi.org/10.3390/app15126819