A Measurement-Driven Method for the Simultaneous Solution of AX = YB in the Implementation of Simulated Robotic Production Systems

Abstract

1. Introduction

- (a)

- The robot’s internal direct three-point measurement method—frequently inaccessible due to reference positions being out of reach.

- (b)

- The indirect measurement method using one of the AX = BY solutions.

- (c)

- Geometrical estimation of the robot world coordinate frame with aligned UCS in the measurement system.

- (a)

- Utilizing the robot’s internal TCP measurement function;

- (b)

- Direct numerical import of CAD data from modeling software;

- (c)

- Tool measurement performed at the manufacturer’s site prior to mounting on the flange.

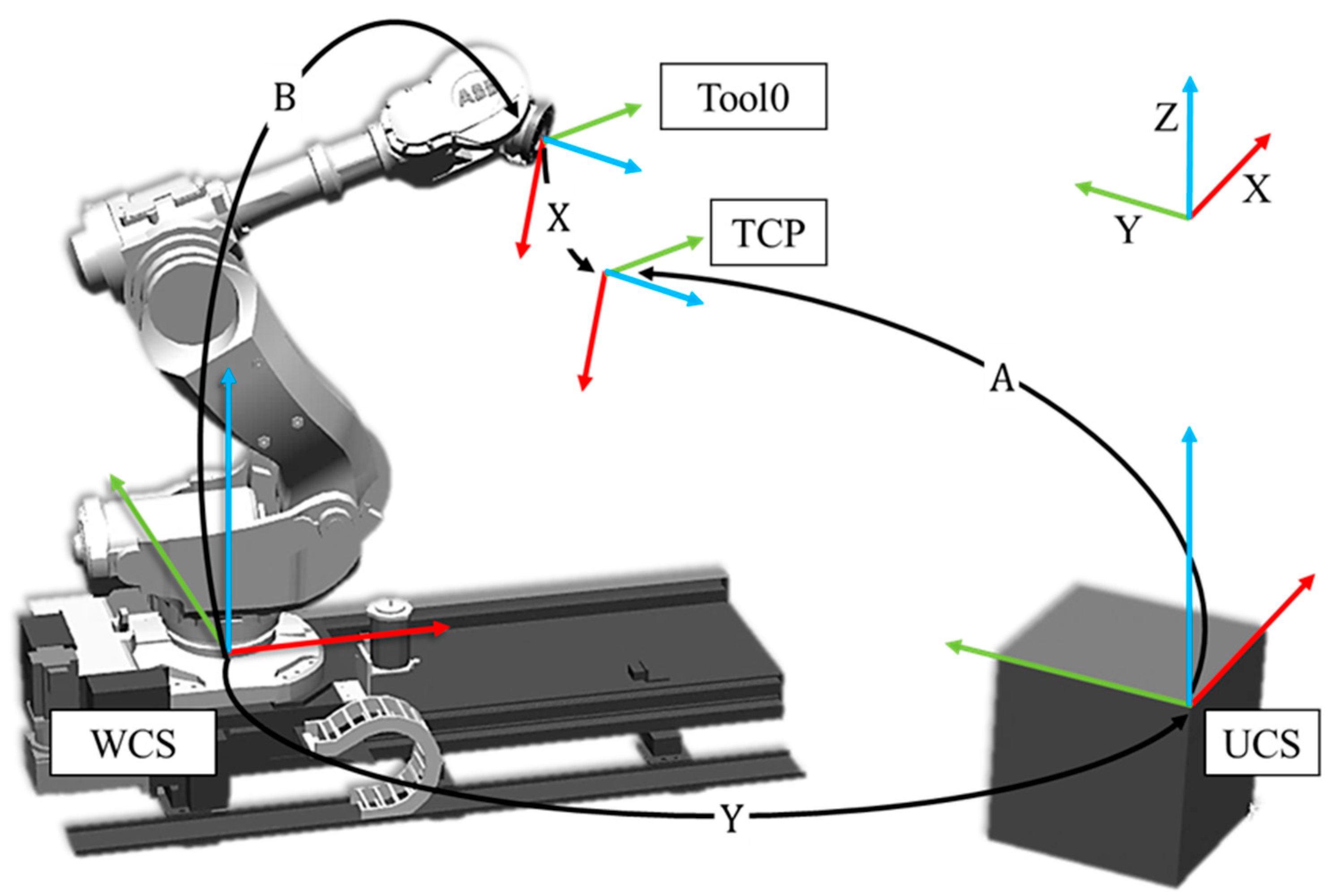

- X represents the unknown transformation from the robot’s flange to the TCP (TCP translation);

- B is the known robot joint transformation computed from Denavit–Hartenberg (D-H) parameters [9];

- Y is the transformation from the WORLD coordinate system to the BASE (or UCS);

- A is the measured TCP position in the local UCS, often obtained from an external measurement system.

- Reduction of implementation steps—simplifying the deployment of simulation-based robot programs by minimizing the number of required measurement procedures.

- Shortened commissioning time—enabling more efficient integration of executable programs onto real robotic systems.

- Robot-specific accuracy—allowing for the best-fitting calibration solution to be directly tailored to each individually measured robot, improving positional precision.

- Scalability in multi-robot setups—increasing the efficiency of calibration processes in production cells involving multiple robots operating on a shared tooling station.

2. Comparative Evaluation of UCS and TCP Estimation Methods

2.1. Overview of the Compared Methods

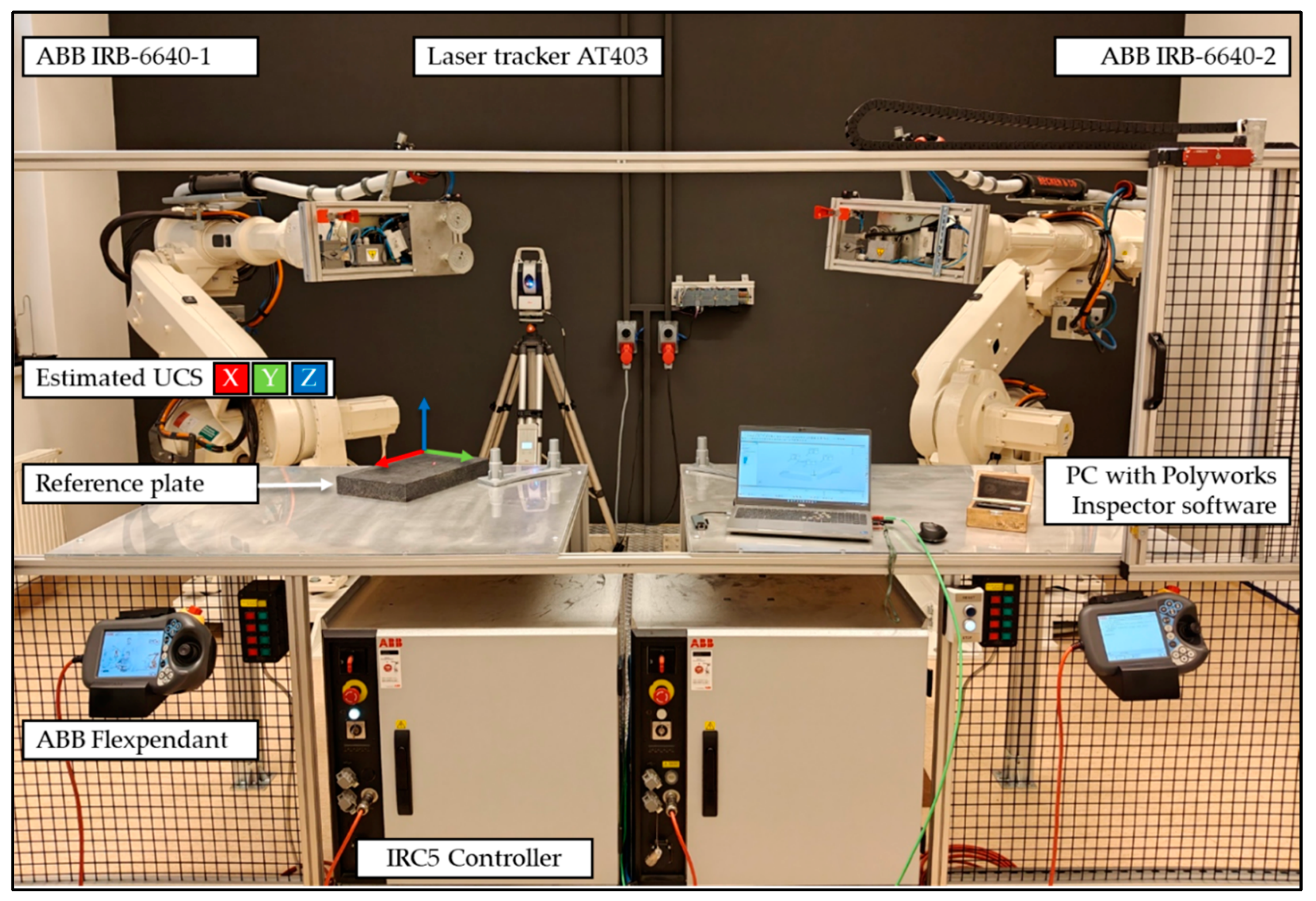

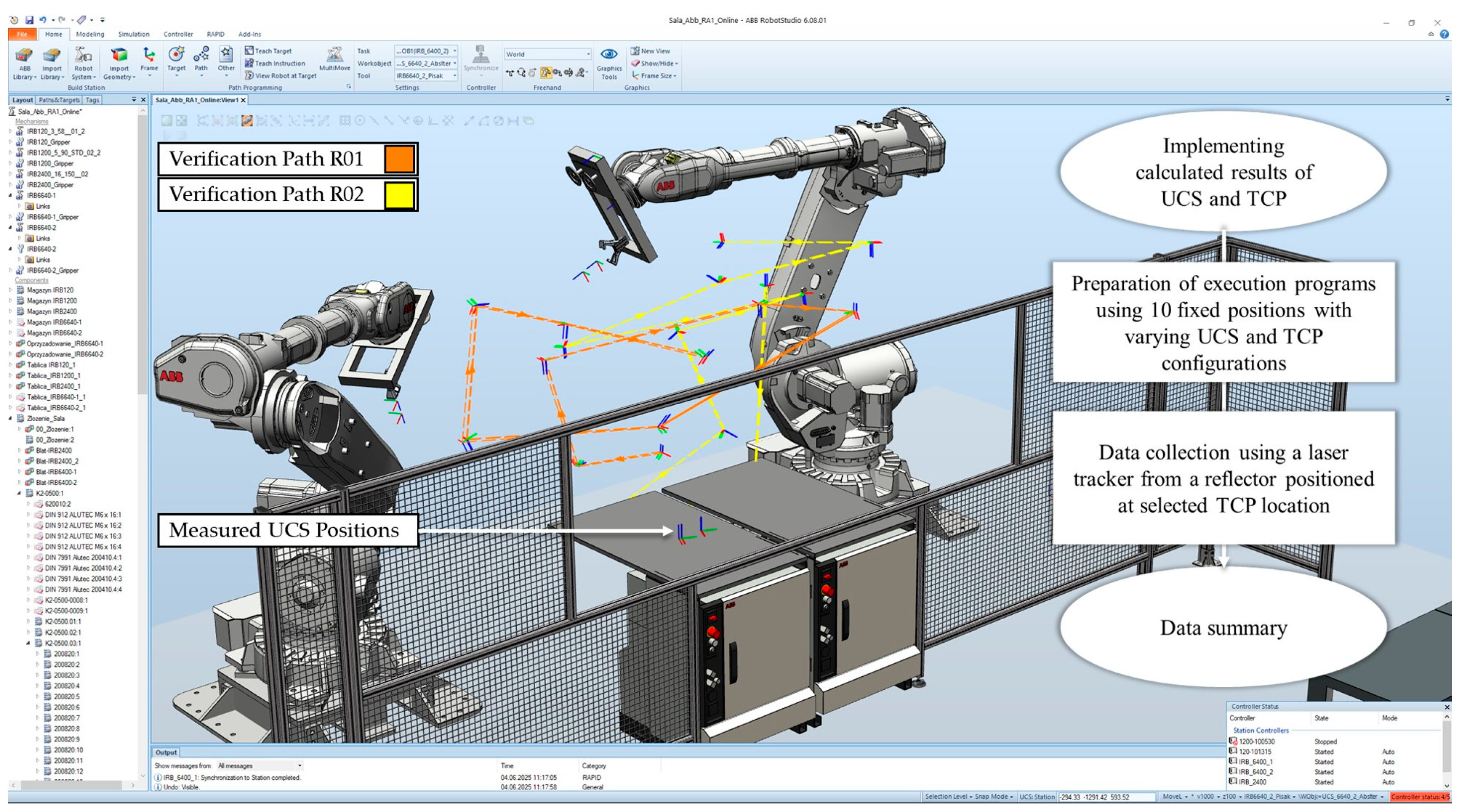

2.2. Experimental Setup for UCS and TCP Estimation Evaluation

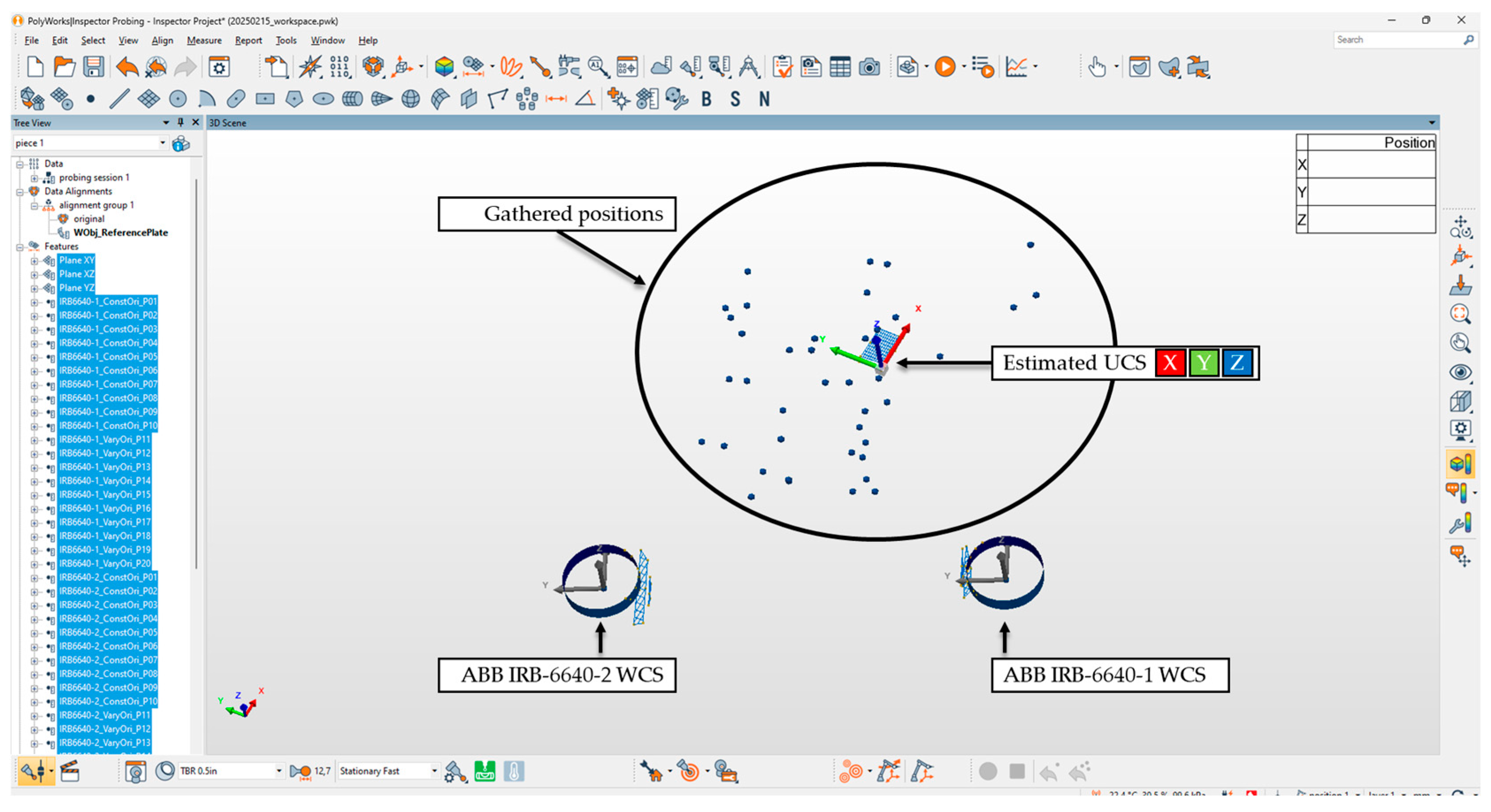

2.3. Data Recording Process

3. Iterative Estimation of Coordinate Transformation and TCP Translation

4. Comparative Validation Based on Measurement Data

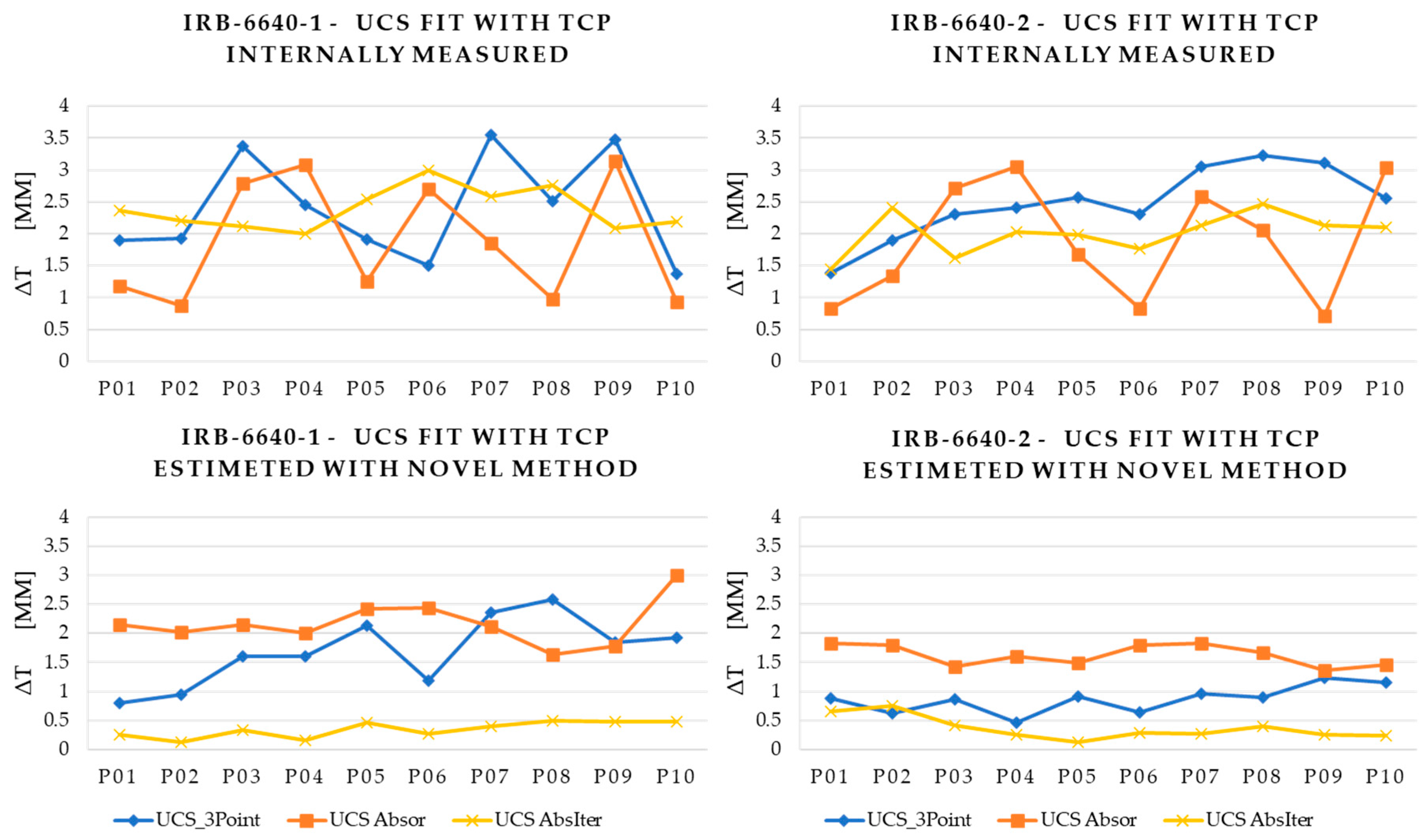

- Robot internal method (3Point)—Method A: UCS defined using the robot’s internal three-point procedure.

- Absolute orientation solution (Absor)—Method B: UCS estimated using the absolute-orientation-based algorithm, with a predefined TCP.

- Geometrical estimation—Method C: UCS defined from geometrical referencing of the robot base and surrounding fixture.

- Proposed algorithm (AbsIter)—Novel Method D: UCS and TCP jointly estimated using the proposed method with additional robot orientations.

5. Summary and Conclusions

- Accuracy improvement: The proposed method (M4) consistently achieved the lowest average translational errors, with mean ΔT values of 0.345 mm (R01) and 0.364 mm (R02) when paired with its own TCP estimation. In comparison, the commonly used internal three-point method (M1) resulted in average errors of 2.399 mm (R01) and 2.483 mm (R02), while the absolute orientation method (M2) showed errors of 1.878 mm (R01) and 1.886 mm (R02). Even when those methods were enhanced with the proposed TCP, their errors remained significantly higher than those achieved by the full M4 approach. This represents an accuracy improvement of over 80% in translational error reduction relative to standard industrial techniques, confirming that joint optimization of UCS and TCP yields superior positional precision.

- Stability across configurations: The proposed algorithm maintained robust performance across varying robot poses and tool orientations, showing low variance in ΔT across all ten test points. It outperformed or matched the absolute orientation method (M2), which showed average ΔT values of 1.88 mm (R01) and 1.89 mm (R02).

- Limitations of geometric estimation: The geometric estimation approach (M3) demonstrated the poorest results, with translational errors as high as 18.05 mm in some positions and significant instability across measurement series. These errors stem from misalignment in WCS estimation, particularly in rotation, which is not detectable during measurement but emerges only after offline computation. This approach is not recommended as it depends directly on the quality of the robot’s structural elements, which may be inconsistent.

- Impact of TCP estimation: In all evaluated methods, replacing the robot’s internally defined TCP with the one estimated by the proposed algorithm led to substantial improvements. For example, using internal TCP with the three-point method yielded a mean ΔT of 2.40 mm (R01) and 2.48 mm (R02), while integrating the proposed TCP reduced errors to 1.70 mm and below.

- Industrial applicability: The novel method does not rely on external TCP estimations or measurements and therefore offers a robust, repeatable, and flexible alternative for integrating simulated programs into real robot systems, especially in scenarios where direct robot control access is limited.

- Setup efficiency: This approach to UCS determination can significantly shorten the setup time, especially in multi-robot workstations. This efficiency increase is achieved through a single calibration of the measurement system and a one-time alignment with the workstation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tanz, L.; Daub, R. Automated Commissioning of Offline-Generated Robot Programs. Procedia CIRP 2022, 107, 810–814. [Google Scholar] [CrossRef]

- Szulc, W.A.; Czop, P. The Effectiveness of a Robotic Workstation Simulation Implementation in the Automotive Industry Using a Closed-Form Solution of the Absolute Orientation Problem. Robotics 2024, 13, 161. [Google Scholar] [CrossRef]

- Wang, P.; Wang, Z.; Duan, J.; Miao, Y.; Tian, W. Review of the Development Status of Low-Code Programming Software for Robots. Digit. Eng. 2025, 4, 100039. [Google Scholar] [CrossRef]

- Asif, S.; Bueno, M.; Ferreira, P.; Anandan, P.; Zhang, Z.; Yao, Y.; Ragunathan, G.; Tinkler, L.; Sotoodeh-Bahraini, M.; Lohse, N.; et al. Rapid and Automated Configuration of Robot Manufacturing Cells. Robot. Comput. Integr. Manuf. 2025, 92, 102862. [Google Scholar] [CrossRef]

- Janssen, C.; Falk, B.; Schmitt, R. Efficient Commissioning Processes for the Automotive Final Assembly. Key Eng. Mater. 2014, 613, 288–295. [Google Scholar] [CrossRef]

- Gan, Y.; Dai, X. Base Frame Calibration for Coordinated Industrial Robots. Rob. Auton. Syst. 2011, 59, 563–570. [Google Scholar] [CrossRef]

- Bilancia, P.; Schmidt, J.; Raffaeli, R.; Peruzzini, M.; Pellicciari, M. An Overview of Industrial Robots Control and Programming Approaches. Appl. Sci. 2023, 13, 2582. [Google Scholar] [CrossRef]

- Sanneman, L.; Fourie, C.; Shah, J.A. The State of Industrial Robotics: Emerging Technologies, Challenges, and Key Research Directions. Found. Trends Robot. 2021, 8, 225–306. [Google Scholar] [CrossRef]

- Siciliano, B.; Khatib, O. Springer Handbook of Robotics; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 9783319325521. [Google Scholar]

- Dornaika, F.; Horaud, R. Simultaneous Robot-World and Hand-Eye Calibration. IEEE Trans. Robot. Autom. 1998, 14, 617–622. [Google Scholar] [CrossRef]

- Shah, M. Solving the Robot-World/Hand-Eye Calibration Problem Using the Kronecker Product. J. Mech. Robot. 2013, 5, 031007. [Google Scholar] [CrossRef]

- Strobl, K.H.; Hirzinger, G. Optimal Hand-Eye Calibration. In Proceedings of the International Conference on intelligent Robots and Systems, Beijing, China, 9–15 October 2006; pp. 4647–4653. [Google Scholar]

- Zhang, W.; Ma, X.; Cui, L.; Chen, Q. 3 Points Calibration Method of Part Coordinates for Arc Welding Robot. In Proceedings of the Intelligent Robotics and Applications: First International Conference, ICIRA 2008, Wuhan, China, 15–17 October 2008; Springer: Berlin/Heidelberg, Germany, 2008; Volume 5314. [Google Scholar]

- Horn, B.K.P. Closed-Form Solution of Absolute Orientation Using Unit Quaternions. J. Opt. Soc. Am. A 1986, 4, 629–642. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, F.; Qu, X.; Shi, X. A Rapid Coordinate Transformation Method Applied in Industrial Robot Calibration Based on Characteristic Line Coincidence. Sensors 2016, 16, 239. [Google Scholar] [CrossRef] [PubMed]

- Oniga, E.; Asachi, G.; Păun, C.D.; Oniga, V.E.; Dragomir, I. Three-Dimensional Transformation of Coordinate Systems Using Nonlinear Analysis–Procrustes Algorithm. Int. J. Eng. Sci. Emerg. Technol. 2017, 6, 355–363. [Google Scholar] [CrossRef]

- Kim, S.; Kim, M. Rotation Representations and Their Conversions. IEEE Access 2023, 11, 6682–6699. [Google Scholar] [CrossRef]

- Tabb, A.; Ahmad Yousef, K.M. Solving the Robot-World Hand-Eye(s) Calibration Problem with Iterative Methods. Mach. Vis. Appl. 2017, 28, 569–590. [Google Scholar] [CrossRef]

- Li, H.; Ma, Q.; Wang, T.; Chirikjian, G.S. Simultaneous Hand-Eye and Robot-World Calibration by Solving the AX = YB Problem Without Correspondence. IEEE Robot. Autom. Lett. 2016, 1, 145–152. [Google Scholar] [CrossRef]

- Wang, Y.; Song, H.; Du, Y.; Qiu, J.; Zhang, A. A Complete Analytical Solution to Hand-Eye Calibration Using Quaternions and Eigenvector-Eigenvalue Identity. J. Intell. Robot. Syst. Theory Appl. 2023, 109, 54. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiao, G.; Song, G.; Song, A.; Wen, X. Experimental Analysis on the Effectiveness of Kinematic Error Compensation Methods for Serial Industrial Robots. Math. Probl. Eng. 2021, 2021, 8086389. [Google Scholar] [CrossRef]

- Li, W.; Dong, M.; Lu, N.; Lou, X.; Sun, P. Simultaneous Robot–World and Hand–Eye Calibration without a Calibration Object. Sensors 2018, 18, 3949. [Google Scholar] [CrossRef]

- Pan, J.; Fu, Z.; Yue, H.; Lei, X.; Li, M.; Chen, X. Toward Simultaneous Coordinate Calibrations of AX=YB Problem by the LMI-SDP Optimization. IEEE Trans. Autom. Sci. Eng. 2023, 20, 2445–2453. [Google Scholar] [CrossRef]

- Ali, I.; Suominen, O.; Gotchev, A.; Morales, E.R. Methods for Simultaneous Robot-World-Hand–Eye Calibration: A Comparative Study. Sensors 2019, 19, 2837. [Google Scholar] [CrossRef]

| IRB 6640-R01 | X [mm] | Y [mm] | Z [mm] | Q0 | Q1 | Q2 | Q3 |

|---|---|---|---|---|---|---|---|

| UCS_3point | 1629.190 | 1071.970 | 915.263 | 0.974142 | 0.001790 | 0.001257 | −0.225926 |

| UCS_AbsOri_withTCP | 1632.170 | 1070.160 | 917.030 | 0.974113 | 0.000780 | 0.001124 | −0.226058 |

| UCS_Geometrical | 1632.265 | 1052.513 | 918.997 | 0.973929 | 0.004281 | 0.003842 | −0.226782 |

| UCS_AbsIter | 1629.342 | 1074.242 | 915.302 | 0.974272 | 0.000858 | 0.001591 | −0.225369 |

| TCP_AbsIter | −178.748 | 7.301 | 76.210 | 1.000000 | 0.000000 | 0.000000 | 0.000000 |

| TCP_Internal | −179.206 | 7.533 | 71.334 | 1.000000 | 0.000000 | 0.000000 | 0.000000 |

| IRB 6640-R02 | |||||||

| UCS_3point | 1616.480 | −2494.640 | 914.222 | 0.974081 | 0.001109 | −0.000078 | −0.226198 |

| UCS_AbsOri_withTCP | 1618.838 | −2492.048 | 914.041 | 0.974106 | 0.000684 | 0.000748 | −0.226091 |

| UCS_Geometrical | 1612.251 | −2486.860 | 22.398 | 0.973748 | −0.000803 | 0.002966 | −0.227607 |

| UCS_AbsIter | 1616.328 | −2495.413 | 913.986 | 0.974088 | 0.000633 | 0.000703 | −0.226167 |

| TCP_AbsIter | −349.873 | 75.604 | 23.609 | 1.000000 | 0.000000 | 0.000000 | 0.000000 |

| TCP_Internal | −345.739 | 75.405 | 23.877 | 1.000000 | 0.000000 | 0.000000 | 0.000000 |

| [mm] | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TCP/UCS | (P01) | (P02) | (P03) | (P04) | (P05) | (P06) | (P07) | (P08) | (P09) | (P10) | |

| Internal/3Point | 1.904 | 1.925 | 3.379 | 2.456 | 1.910 | 1.510 | 3.549 | 2.515 | 3.477 | 1.370 | 2.399 |

| Internal/Absor | 1.184 | 0.878 | 2.785 | 3.086 | 1.257 | 2.695 | 1.849 | 0.977 | 3.134 | 0.936 | 1.878 |

| Internal/Geo | 11.694 | 9.458 | 11.960 | 15.701 | 16.339 | 12.457 | 15.698 | 11.437 | 13.257 | 12.947 | 13.095 |

| Internal/AbsIter | 2.364 | 2.202 | 2.114 | 2.001 | 2.545 | 2.991 | 2.583 | 2.756 | 2.091 | 2.192 | 2.384 |

| AbsIter/3Point | 0.796 | 0.944 | 1.598 | 1.597 | 2.132 | 1.177 | 2.353 | 2.584 | 1.847 | 1.921 | 1.695 |

| AbsIter/Absor | 2.154 | 2.024 | 2.157 | 2.010 | 2.417 | 2.443 | 2.115 | 1.641 | 1.778 | 2.993 | 2.173 |

| AbsIter/Geo | 13.376 | 11.747 | 13.789 | 10.191 | 18.052 | 13.071 | 14.792 | 13.536 | 14.355 | 15.180 | 13.809 |

| AbsIter/AbsIter | 0.258 | 0.118 | 0.341 | 0.150 | 0.459 | 0.276 | 0.399 | 0.489 | 0.481 | 0.475 | 0.345 |

| [mm] | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TCP/UCS | (P01) | (P02) | (P03) | (P04) | (P05) | (P06) | (P07) | (P08) | (P09) | (P10) | |

| Internal/3Point | 1.392 | 1.902 | 2.306 | 2.413 | 2.576 | 2.302 | 3.048 | 3.228 | 3.116 | 2.550 | 2.483 |

| Internal/Absor | 0.830 | 1.349 | 2.723 | 3.057 | 1.679 | 0.829 | 2.582 | 2.058 | 0.707 | 3.044 | 1.886 |

| Internal/Geo | 4.146 | 3.202 | 7.690 | 7.731 | 6.243 | 5.566 | 6.957 | 6.788 | 5.591 | 7.750 | 6.166 |

| Internal/AbsIter | 1.443 | 2.402 | 1.616 | 2.032 | 1.993 | 1.759 | 2.133 | 2.475 | 2.132 | 2.104 | 2.009 |

| AbsIter/3Point | 0.882 | 0.624 | 0.865 | 0.454 | 0.907 | 0.633 | 0.965 | 0.891 | 1.229 | 1.154 | 0.874 |

| AbsIter/Absor | 1.825 | 1.802 | 1.423 | 1.596 | 1.490 | 1.800 | 1.820 | 1.670 | 1.361 | 1.452 | 1.624 |

| AbsIter/Geo | 5.766 | 4.787 | 5.876 | 5.798 | 5.630 | 5.991 | 6.525 | 5.573 | 6.111 | 5.907 | 5.796 |

| AbsIter/AbsIter | 0.653 | 0.758 | 0.418 | 0.245 | 0.130 | 0.278 | 0.274 | 0.406 | 0.250 | 0.230 | 0.364 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szulc, W.A.; Czop, P. A Measurement-Driven Method for the Simultaneous Solution of AX = YB in the Implementation of Simulated Robotic Production Systems. Appl. Sci. 2025, 15, 6706. https://doi.org/10.3390/app15126706

Szulc WA, Czop P. A Measurement-Driven Method for the Simultaneous Solution of AX = YB in the Implementation of Simulated Robotic Production Systems. Applied Sciences. 2025; 15(12):6706. https://doi.org/10.3390/app15126706

Chicago/Turabian StyleSzulc, Wojciech Andrzej, and Piotr Czop. 2025. "A Measurement-Driven Method for the Simultaneous Solution of AX = YB in the Implementation of Simulated Robotic Production Systems" Applied Sciences 15, no. 12: 6706. https://doi.org/10.3390/app15126706

APA StyleSzulc, W. A., & Czop, P. (2025). A Measurement-Driven Method for the Simultaneous Solution of AX = YB in the Implementation of Simulated Robotic Production Systems. Applied Sciences, 15(12), 6706. https://doi.org/10.3390/app15126706