Damping Rates of Anti-Vibration Gloves Made of Different Materials

Abstract

1. Introduction

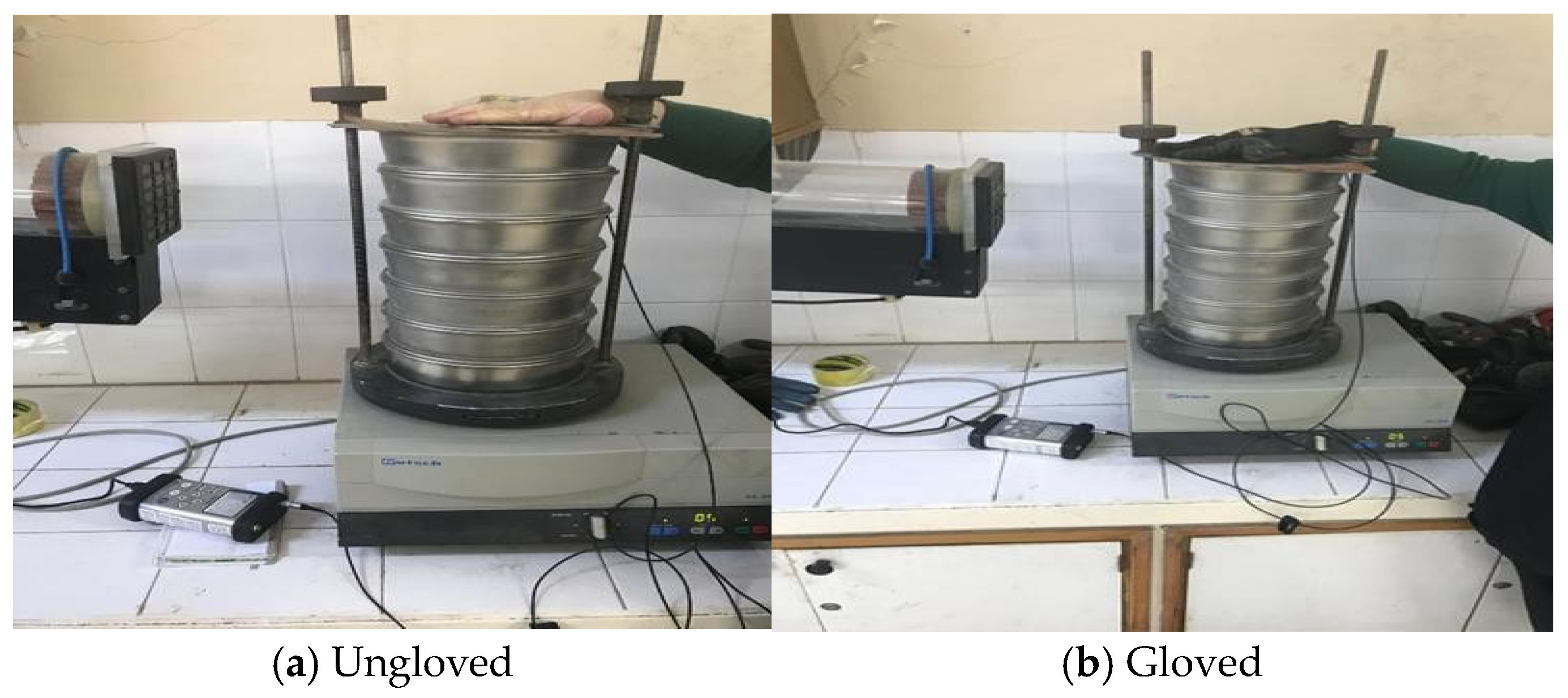

2. Materials and Methods

| No. | Appearance of Gloves | Features of Gloves | |

|---|---|---|---|

| 1 |  |  | Palm is made of 5 mm CHLOROPRENE RUBBER. |

| 2 |  |  | Palm is made of CHLOROPRENE RUBBER. A 6 mm anti-vibration thicken pad provides protection against vibration. |

| 3 |  |  | There is an 8 mm special anti-vibration pad in the area extending from the palm to the fingertips. |

| 4 |  |  | A 7 mm FOAM LATEX RUBBER coating on the palm reduces impacts, shocks, and vibrations. |

| 5 |  |  | A 7 mm full-length palm padding (35% POLYURETHANE) reduces vibration and palm impact. |

| 6 |  |  | An 8 mm full-length palm padding (29% POLYURETHANE) reduces vibration and palm impact. |

| 7 |  |  | A 6 mm full-length palm padding (37% POLYURETHANE) reduces vibration and palm impact. |

| 8 |  |  | A 5 mm vibration damping layer is coated with a POLYMER. |

| 9 |  |  | There is a 5 mm SBR FILLER (Rubber Filler) on each finger and palm. |

| 10 |  |  | There is 2.5 mm CHLOROPRENE (NEOPRENE) padding in the palm. |

| 11 |  |  | There is soft 6 mm GEL FOAM padding in the thumb, index finger, and palm area. |

| 12 |  |  | The palm is covered with 3 mm of LATEX FOAM. |

3. Results and Discussion

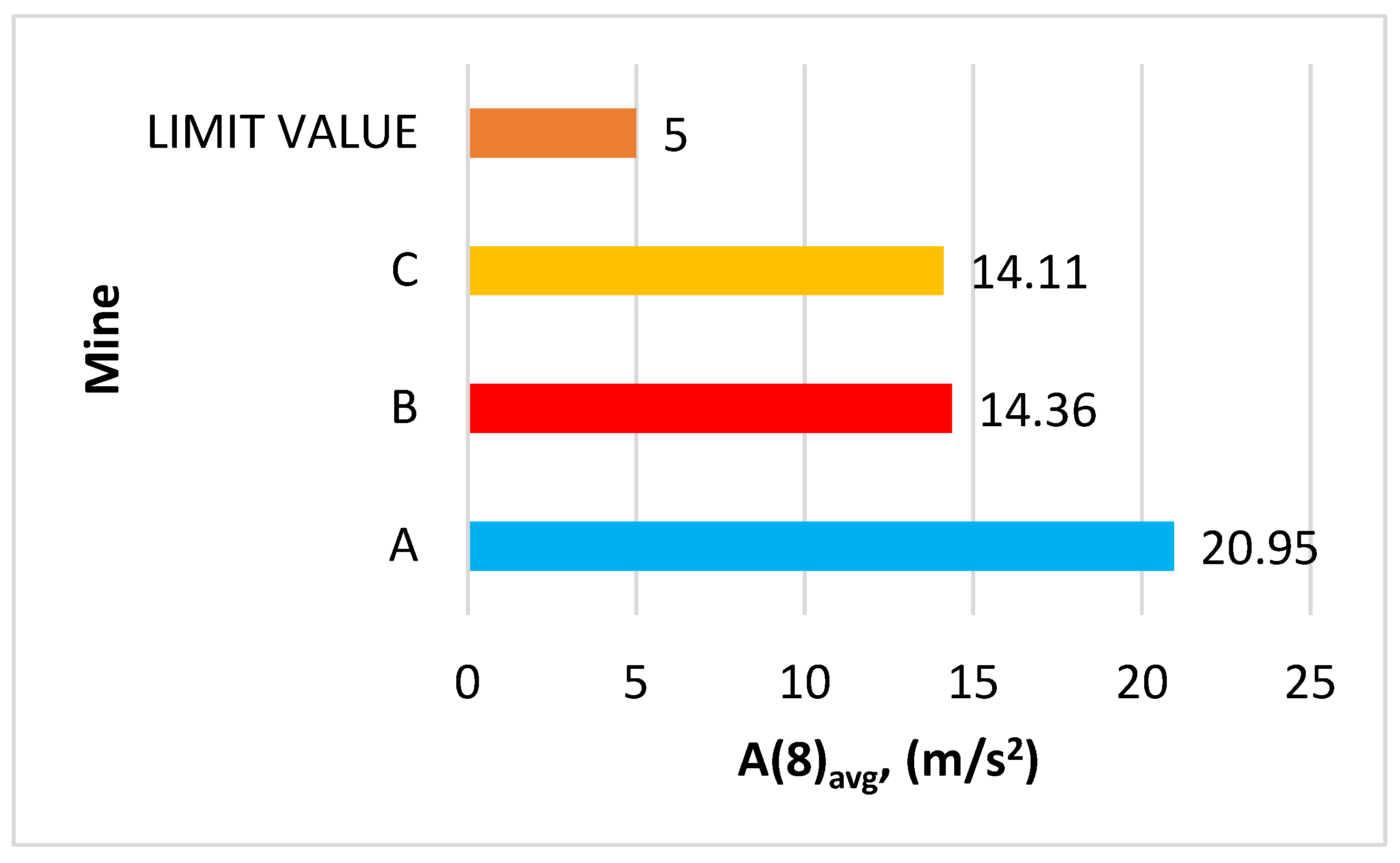

3.1. Results of Field Measurements

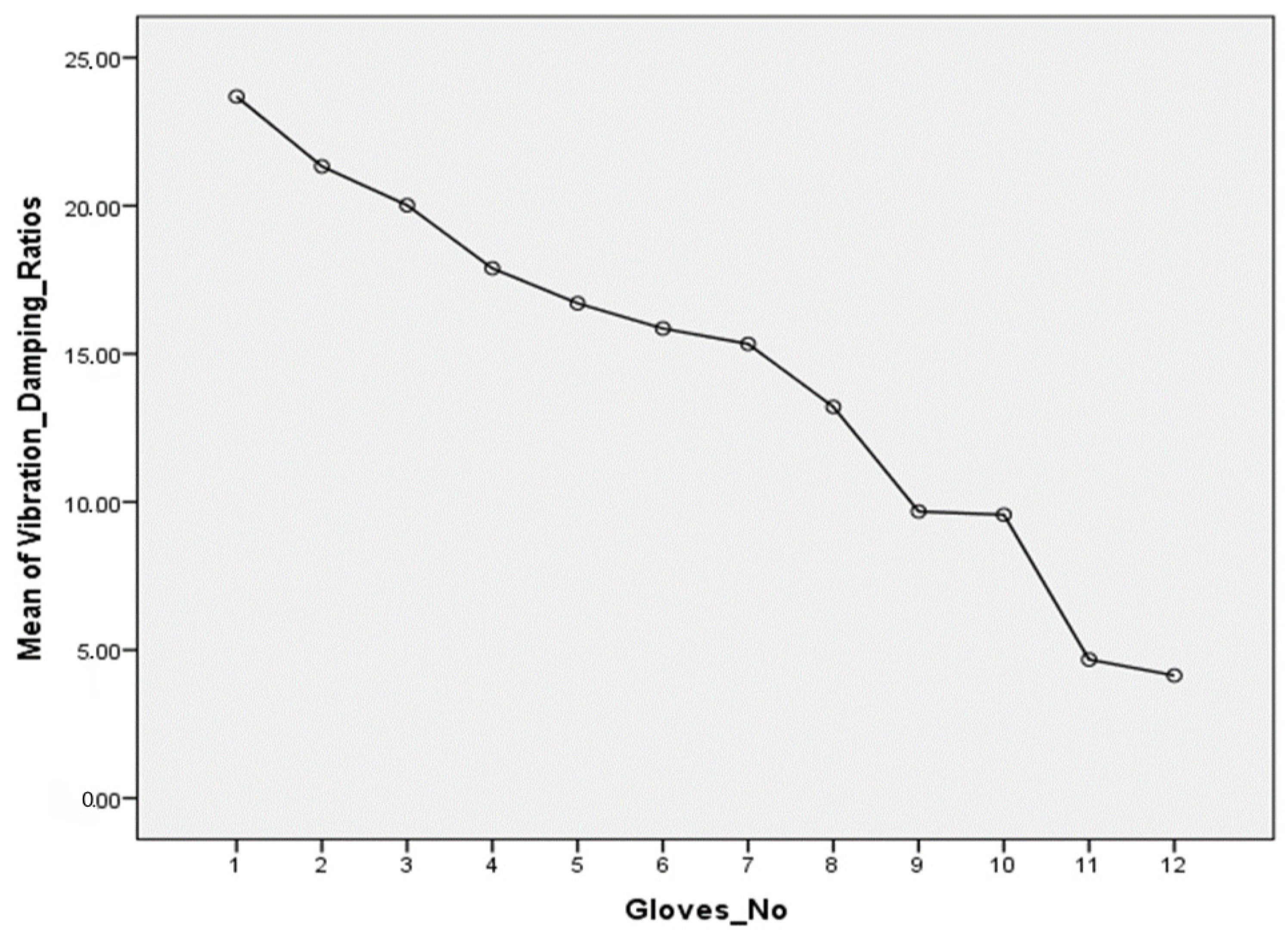

3.2. Results of Laboratory Measurements

3.3. Statistical Evaluation of the Measurement Results

4. Conclusions and Recommendations

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zeyrek, S. Vibration. Occupational Health and Safety. Specialization Thesis, Ministry of Labor and Social Security General Directorate of Occupational Health and Safety, Ankara, Turkey, 2009. Available online: https://www.csgb.gov.tr/Media/guon31qb/serapzeyrek.pdf (accessed on 2 June 2025).

- Fritz, M. Description of the Relationship Between the Forces Acting in the Lumbar Spine and Whole Body Vibrations By Means of Transfer Functions. Clin. Biomech. 2000, 15, 234–240. [Google Scholar] [CrossRef] [PubMed]

- Erdem, B.; Doğan, T.; Özgen, Z. Measurement and Evaluation of Hand-Arm Vibration Exposure Sourced From Some Power Tools in Mining Workplaces. Mining 2016, 55, 23–44. [Google Scholar]

- Arıtan, A.E.; Tümer, M. Investigation of Hand-Arm Vibration Exposure in the Use of Pneumatic Hammer in the Natural Stone Quarries. Çukurova Univ. J. Fac. Eng. Archit. 2018, 33, 57–66. [Google Scholar]

- Youakim, S. Hand-Arm Vibration Syndrome. BC Med. J. 2009, 51, 10. [Google Scholar]

- Xu, X.; Yuan, Z.; Gong, M.; He, L.; Wang, R.; Wang, J.; Yang, Q.; Wang, S. Occupational Hazards Survey Among Coal Workers Using Hand-Held Vibrating Tools in a Northern China Coal Mine. Int. J. Ind. Ergon. 2017, 62, 21–26. [Google Scholar] [CrossRef]

- Arıtan, A.E.; Memiş, Z. Investigation of Vibration Exposure of Natural Stone Operators Working in The Field. In Proceedings of the International Symposium on Occupational Health and Safety in Mining 2019, Adana, Turkey, October 3–4 2019; pp. 485–492. [Google Scholar]

- Nyantumbu, B.; Barber, C.M.; Ross, M.; Curran, A.D.; Fishwick, D.; Dias, B.; Kgalamono, S.; Phillips, J.I. Hand–Arm Vibration Syndrome in South African Gold Miners. Occup. Med. 2006, 57, 25–29. [Google Scholar] [CrossRef] [PubMed]

- Erol, İ. Investigation of Noise and Vibration Exposure of Underground Coal Mining Machinery Operators. Çukurova Univ. J. Fac. Eng. Archit. 2022, 37, 55–65. [Google Scholar]

- Oddo, R.; Loyau, T.; Boileau, P.E.; Champoux, Y. Design of a Suspended Handle to Attenuate Rock Drill Hand-Arm Vibration: Model Development and Validation. J. Sound Vib. 2003, 275, 623–640. [Google Scholar] [CrossRef]

- Nor, A.A.; Mohd, I.G.; Musli, N.Y. Hand Arm Vibration and Personnel Noise Exposure Characteristics of Hand Held Grass Cutter Machines. In Proceedings of the 21st International Congress on Sound and Vibration, Beijing China, 13–17 July 2014; pp. 1–8. [Google Scholar]

- Brown, A.P. The Effects of Anti-Vibration Gloves On Vibration Induced Disorders: A Case Study. J. Hand Ther. 1990, 3, 94–100. [Google Scholar] [CrossRef]

- Jetzer, T.; Haydon, P.; Reynolds, D.D. Effective Intervention with Ergonomics, Antivibration Gloves, And Medical Surveillance To Minimize Hand-Arm Vibration Hazards in The Workplace. J. Occup. Environ. Med. 2003, 45, 1312–1317. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.G.; McDowell, T.W.; Welcome, D.E.; Wu, J.Z.; Rakheja, S. Analysis of Anti-Vibration Gloves Mechanism and Evaluation Methods. J. Sound Vib. 2008, 321, 435–453. [Google Scholar] [CrossRef]

- ISO 10819; Mechanical Vibration and Shock—Hand–Arm Vibration—Measurement and Evaluation of the Vibration Transmissibility of Gloves at the Palm of the Hand. ISO: Geneva, Switzerland, 2013.

- SET Machine. Technical Specifications of Machines. 2025. Available online: https://www.setmakina.com/en/tigeryt24 (accessed on 2 June 2025).

- TS EN ISO 5349-1; Turkish Standards, Mechanical Vibration–Measurement and Evaluation of Hand-Transmitted Vibration to Which Persons Are Exposed–Part 1: General Rules. TSE: Ankara, Turkey, 2005.

- TS EN ISO 5349-2; Turkish Standards, Mechanical Vibration—Measurement and Evaluation of Human Exposure to Hand-Transmitted Vibration—Part 2: Practical Guidance for Measurement at the Workplace. TSE: Ankara, Turkey, 2015.

- Amazon.de. 2024. Available online: https://www.amazon.de/s?k=anti+vibRAT%C4%B0ON+GLOVES (accessed on 2 June 2025).

- TUR-2013-R-107868; Regulation on the Protection of Workers from Vibration-Related Risk. Ministry of Labor and Social Security (MLSS): Ankara, Turkey, 2013.

- O’Boyle, M.; Griffin, M.J. Predicting the Effects of Push Force on the Transmission of Vibration Through Glove Materials to the Palm of the Hand. In Proceedings of the 10th International Conference on Hand-Arm Vibration, Las Vegas, NV, USA, 7–11 June 2004. [Google Scholar]

- Laszlo, H.E.; Griffin, M.J. The Transmission of Vibration Through Gloves: Effects of Push Force, Vibration Magnitude and Inter-Subject Variability. Ergonomics 2011, 54, 488–496. [Google Scholar] [CrossRef] [PubMed]

| Air Consumption at 6 Bar | 60 I/s |

|---|---|

| Air Hose Diameter | 8 mm |

| Water Pipe Diameter | 5 mm |

| Impact Rate | ≥31 Hz |

| Hole Diameter | 34–42 mm |

| Sank Size | 22 × 108 |

| Piston Stroke | 70 mm |

| Working Pressure | 6 Bar |

| Weight | 24 kg |

| Glove No. | Average Values of the Vibration Exposure A Mine A(8)avg, (m/s2) | Vibration Damping Rate (%) | Average Values of the Vibration Exposure B Mine A(8)avg, (m/s2) | Vibration Damping Rate (%) | Average Values of the Vibration Exposure C Mine A(8)avg, (m/s2) | Vibration Damping Rate (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| Ungloved | Gloved | Ungloved | Gloved | Ungloved | Gloved | ||||

| 1 | 20.95 | 16.14 | 22.96 | 14.36 | 11.30 | 21.31 | 14.11 | 10.33 | 26.79 |

| 2 | 16.78 | 19.90 | 11.58 | 19.36 | 10.62 | 24.73 | |||

| 3 | 16.83 | 19.67 | 11.96 | 16.71 | 10.77 | 23.67 | |||

| 4 | 17.86 | 14.75 | 12.07 | 15.95 | 10.87 | 22.96 | |||

| 5 | 18.12 | 13.51 | 12.34 | 14.07 | 10.93 | 22.54 | |||

| 6 | 18.24 | 12.94 | 12.42 | 13.51 | 11.13 | 21.12 | |||

| 7 | 18.27 | 12.79 | 12.44 | 13.37 | 11.31 | 19.84 | |||

| 8 | 18.88 | 9.88 | 12.54 | 12.67 | 11.70 | 17.08 | |||

| 9 | 19.18 | 8.45 | 12.88 | 10.31 | 12.66 | 10.28 | |||

| 10 | 19.19 | 8.40 | 12.89 | 10.24 | 12.69 | 10.06 | |||

| 11 | 20.06 | 4.25 | 13.79 | 3.97 | 13.29 | 5.81 | |||

| 12 | 20.13 | 3.91 | 13.84 | 3.62 | 13.42 | 4.89 | |||

| Glove No. | Average Values of the Vibration Exposure A(8)avg, (m/s2) | Vibration Damping Rate (%) | |

|---|---|---|---|

| Ungloved | Gloved | ||

| 1 | 0.74 | 0.41 | 44.59 |

| 2 | 0.44 | 40.54 | |

| 3 | 0.45 | 39.19 | |

| 4 | 0.46 | 37.84 | |

| 5 | 0.47 | 36.49 | |

| 6 | 0.48 | 35.14 | |

| 7 | 0.49 | 33.78 | |

| 8 | 0.50 | 32.43 | |

| 9 | 0.52 | 29.73 | |

| 10 | 0.53 | 28.38 | |

| 11 | 0.54 | 27.03 | |

| 12 | 0.57 | 22.97 | |

| Statistic | Std. Error | ||

|---|---|---|---|

| Mean | 14.34 | 1.11 | |

| 95% Confidence Interval for the Mean | Lower Bound | 12.09 | |

| Upper Bound | 16.59 | ||

| 5% Trimmed Mean | 14.29 | ||

| Median | 13.51 | ||

| Variance | 44.38 | ||

| Std. Deviation | 6.66 | ||

| Minimum | 3.62 | ||

| Maximum | 26.79 | ||

| Range | 23.17 | ||

| Interquartile Range | 9.96 | ||

| Skewness | 0.02 | 0.39 | |

| Kurtosis | −1.02 | 0.77 | |

| Kolmogorov–Smirnov a | Shapiro–Wilk | |||||

|---|---|---|---|---|---|---|

| Statistic | df | p-Value | Statistic | df | Sig. | |

| Vibration Damping Ratios | 0.11 | 36 | 0.20 * | 0.96 | 36 | 0.18 |

| No. | N | Mean | Std. Deviation | Std. Error | 95% Confidence Interval for the Mean | Minimum | Maximum | |

|---|---|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||||

| 1 | 3 | 23.69 | 2.81 | 1.62 | 16.70 | 30.67 | 21.31 | 26.79 |

| 2 | 3 | 21.33 | 2.96 | 1.71 | 13.98 | 28.67 | 19.36 | 24.73 |

| 3 | 3 | 20.02 | 3.49 | 2.02 | 11.34 | 28.69 | 16.71 | 23.67 |

| 4 | 3 | 17.89 | 4.43 | 2.56 | 6.87 | 28.90 | 14.75 | 22.96 |

| 5 | 3 | 16.71 | 5.06 | 2.92 | 4.14 | 29.27 | 13.51 | 22.54 |

| 6 | 3 | 15.86 | 4.57 | 2.64 | 4.51 | 27.20 | 12.94 | 21.12 |

| 7 | 3 | 15.33 | 3.91 | 2.26 | 5.61 | 25.05 | 12.79 | 19.84 |

| 8 | 3 | 13.21 | 3.63 | 2.09 | 4.19 | 22.23 | 9.88 | 17.08 |

| 9 | 3 | 9.68 | 1.06 | 0.61 | 7.03 | 12.33 | 8.45 | 10.31 |

| 10 | 3 | 9.57 | 1.01 | 0.58 | 7.05 | 12.09 | 8.40 | 10.24 |

| 11 | 3 | 4.68 | 0.99 | 0.57 | 2.21 | 7.14 | 3.97 | 5.81 |

| 12 | 3 | 4.14 | 0.66 | 0.38 | 2.49 | 5.79 | 3.62 | 4.89 |

| Total | 36 | 14.34 | 0.66 | 1.11 | 12.09 | 16.59 | 3.62 | 26.79 |

| Levene Statistic | df1 | df2 | Sig. |

|---|---|---|---|

| 2.70 | 11 | 24 | 0.02 |

| Statistic a | df1 | df2 | Sig. | |

|---|---|---|---|---|

| Welch | 20.41 | 11 | 9.31 | 0.00 |

| Dependent Variable: Vibration Damping Ratios | ||||||

|---|---|---|---|---|---|---|

| (I) Glove-No. | (J) Glove-No. | Mean Difference (I–J) | Std. Error | Sig. | 95% Confidence Interval | |

| Lower Bound | Upper Bound | |||||

| 1 | 9 | 14.00 * | 1.73 | 0.05 | 0.065 | 27.95 |

| 10 | 14.12 * | 1.72 | 0.05 | 0.00 | 28.24 | |

| 11 | 19.01 * | 1.72 | 0.02 | 4.81 | 33.21 | |

| 12 | 19.55 * | 1.67 | 0.03 | 4.12 | 34.97 | |

| 2 | 2.38 | 2.36 | 0.99 | −11.33 | 16.09 | |

| 2 | 11 | 16.65 * | 1.80 | 0.04 | 1.53 | 31.77 |

| 12 | 17.19 * | 1.75 | 0.04 | 0.84 | 33.54 | |

| 9 | 1 | −14.01 * | 1.73 | 0.05 | −27.95 | −0.065 |

| 11 | 5.00 * | 0.84 | 0.05 | 0.11 | 9.89 | |

| 12 | 5.54 * | 0.72 | 0.03 | 0.84 | 10.24 | |

| 10 | 1 | −14.12 * | 1.72 | 0.05 | −28.24 | −0.00 |

| 11 | 4.89 * | 0.82 | 0.04 | 0.13 | 9.64 | |

| 12 | 5.42 * | 0.70 | 0.02 | 0.97 | 9.88 | |

| 11 | 1 | −19.01 * | 1.72 | 0.02 | −33.21 | −4.81 |

| 2 | −16.65 * | 1.80 | 0.04 | −31.77 | −1.53 | |

| 10 | −4.89* | 0.82 | 0.04 | −9.64 | −0.13 | |

| 12 | 1 | −19.55 * | 1.67 | 0.03 | −34.97 | −4.12 |

| 2 | −17.19 * | 1.75 | 0.04 | −33.54 | −0.84 | |

| 9 | −5.54 * | 0.72 | 0.03 | −10.24 | −0.84 | |

| 10 | −5.43 * | 0.70 | 0.02 | −9.88 | −0.97 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Erol, İ. Damping Rates of Anti-Vibration Gloves Made of Different Materials. Appl. Sci. 2025, 15, 6630. https://doi.org/10.3390/app15126630

Erol İ. Damping Rates of Anti-Vibration Gloves Made of Different Materials. Applied Sciences. 2025; 15(12):6630. https://doi.org/10.3390/app15126630

Chicago/Turabian StyleErol, İlknur. 2025. "Damping Rates of Anti-Vibration Gloves Made of Different Materials" Applied Sciences 15, no. 12: 6630. https://doi.org/10.3390/app15126630

APA StyleErol, İ. (2025). Damping Rates of Anti-Vibration Gloves Made of Different Materials. Applied Sciences, 15(12), 6630. https://doi.org/10.3390/app15126630