Optimization and Application of Drilling Parameters Based on Gas–Solid Coupling Simulation

Abstract

1. Introduction

2. Coupled Gas–Solid Modeling of Gas Extraction

2.1. Physical Model

- (1)

- The coal body is a continuous, homogeneous medium, ignoring the inhomogeneity of the microscopic pore structure;

- (2)

- The deformation of the coal body is much smaller than its geometric size, ignoring its plastic deformation and large deformation;

- (3)

- The mechanical properties of the coal rock body are isotropic, ignoring the anisotropic characteristics of joints and fissures;

- (4)

- Only gas flow is considered, ignoring the influence of water or other fluids;

- (5)

- Gas seepage in the coal body conforms to Darcy’s law, and gas diffusion conforms to Fick’s law;

- (6)

- The temperature is constant during gas flow.

2.2. Mathematical Model

2.2.1. Gas Diffusion Control Equation

2.2.2. Equation of Control for Gas Seepage

2.2.3. Coal Body Deformation Control Equation

3. Numerical Simulation

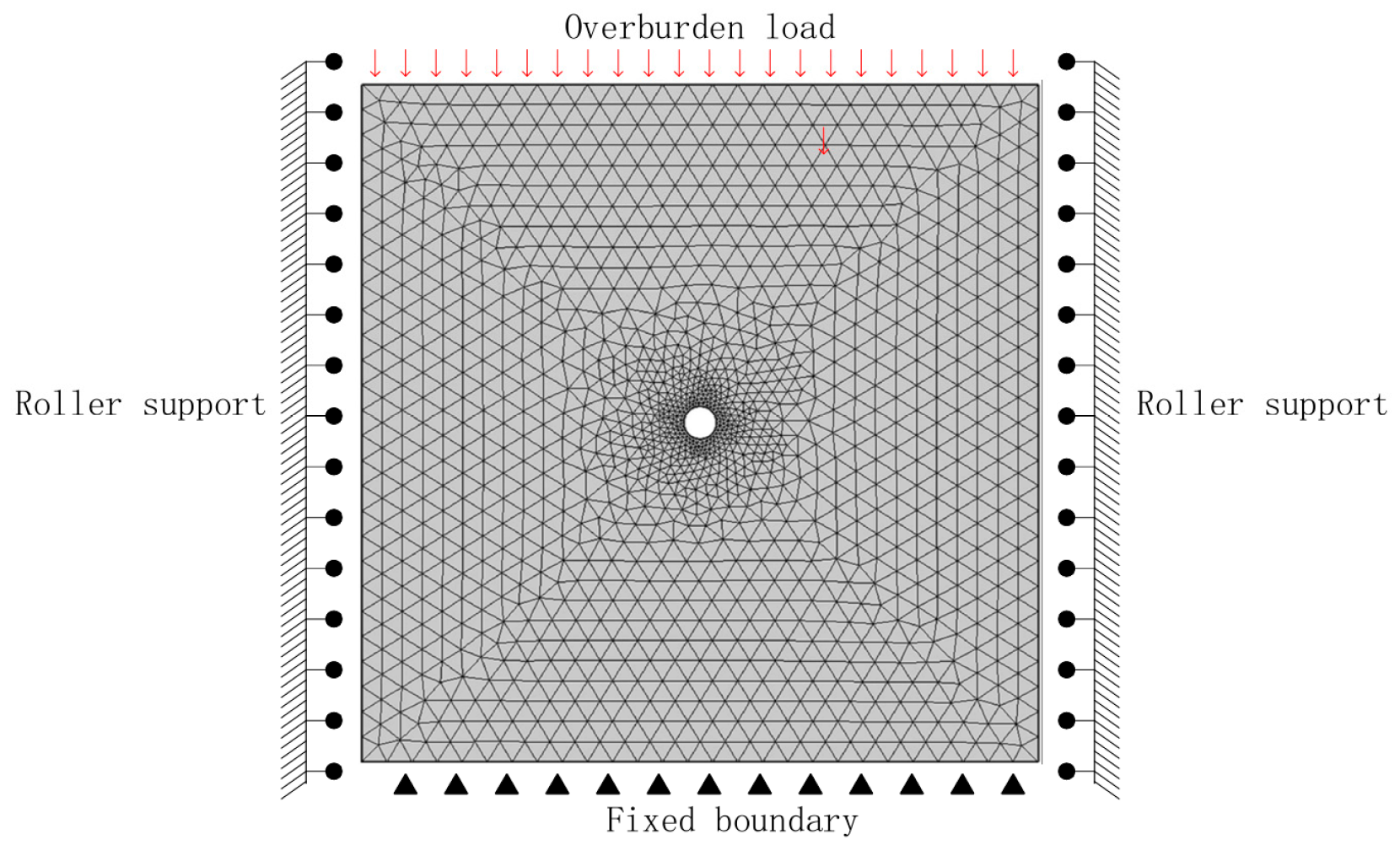

3.1. Geometric Modeling and Boundary Conditions

3.2. Numerical Simulation Parameter Setting

4. Analysis of Numerical Simulation Results

4.1. Analysis of the Effect of Negative Extraction Pressure on Gas Pressure

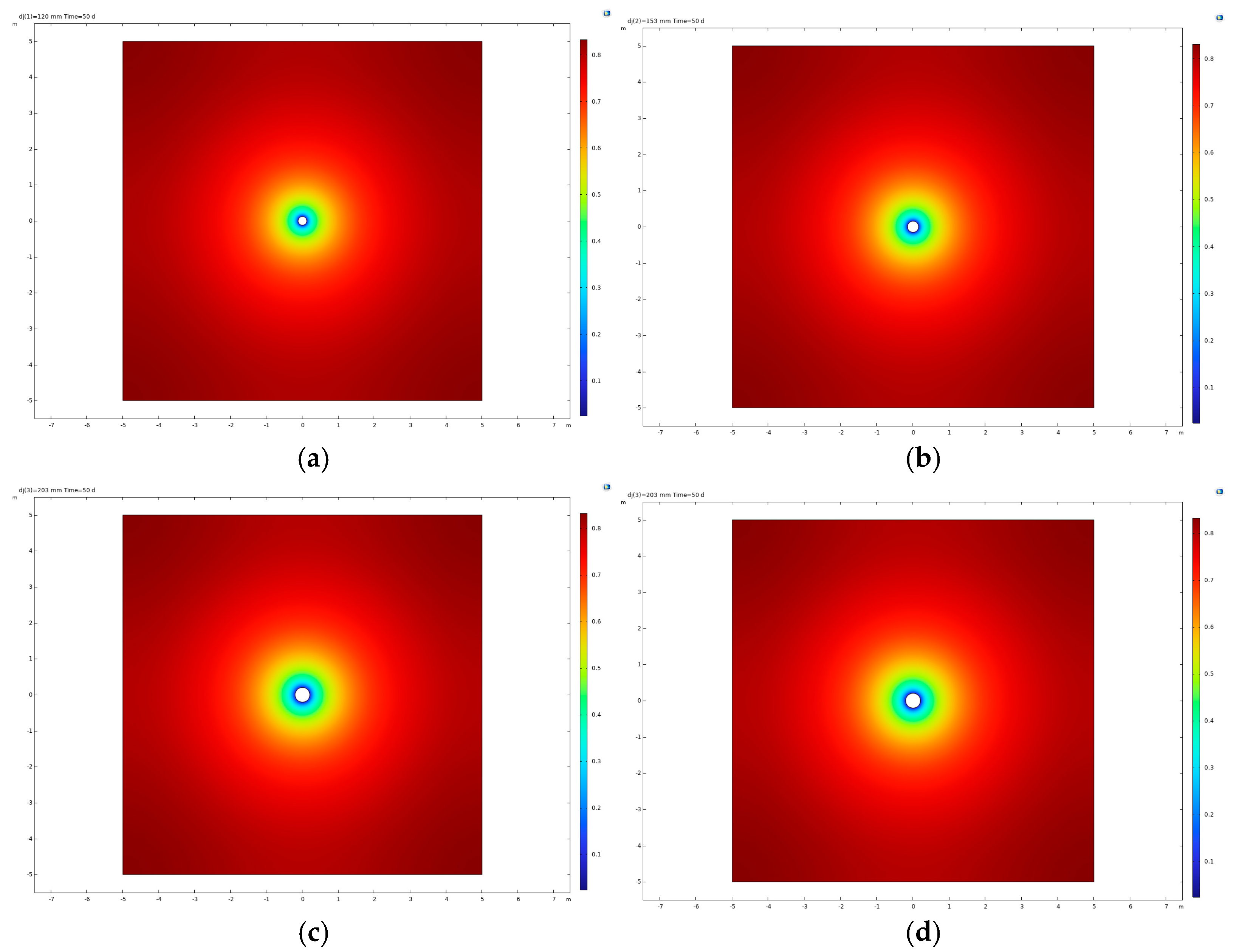

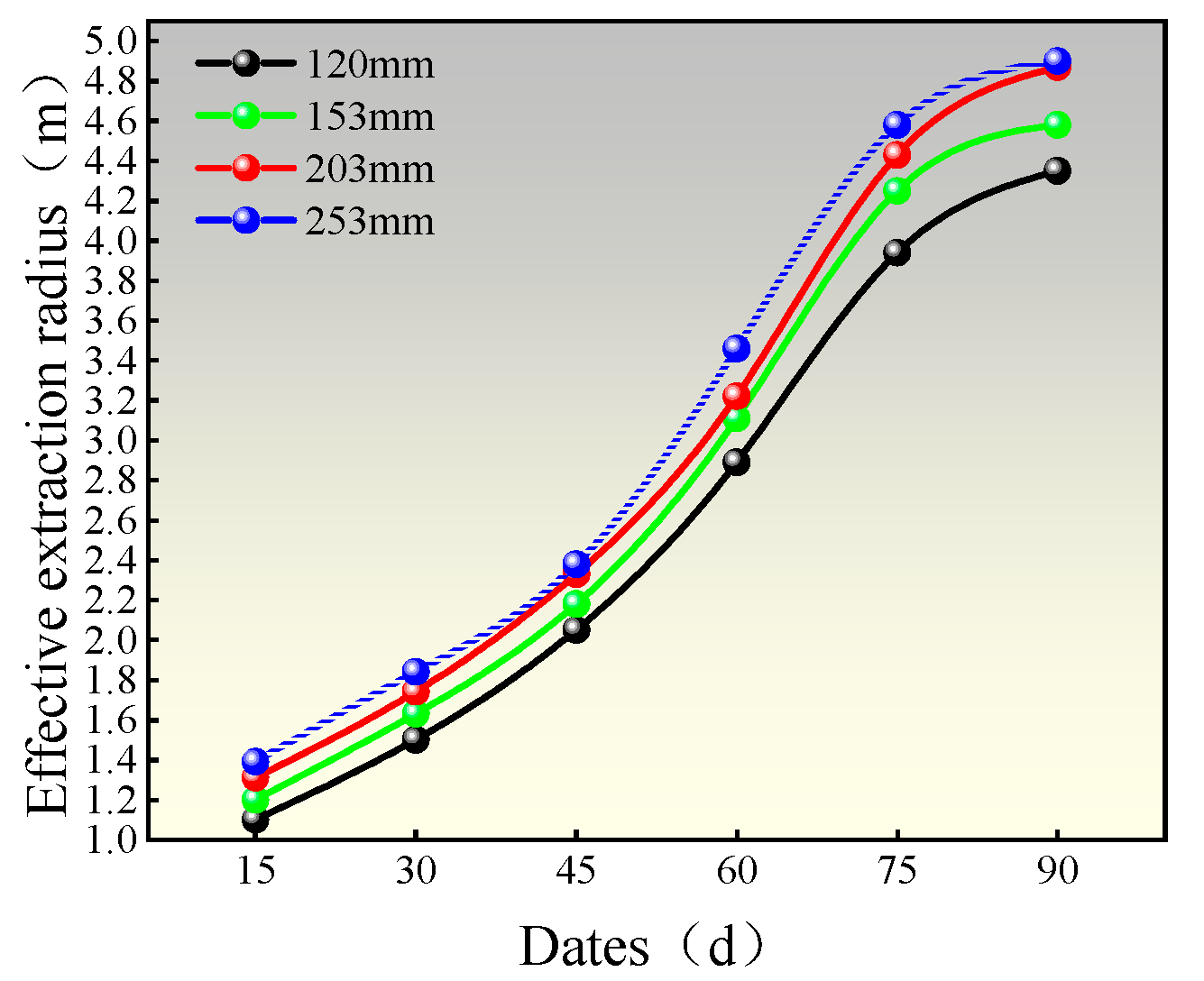

4.2. Analysis of the Effect of Borehole Diameter on Gas Pressure

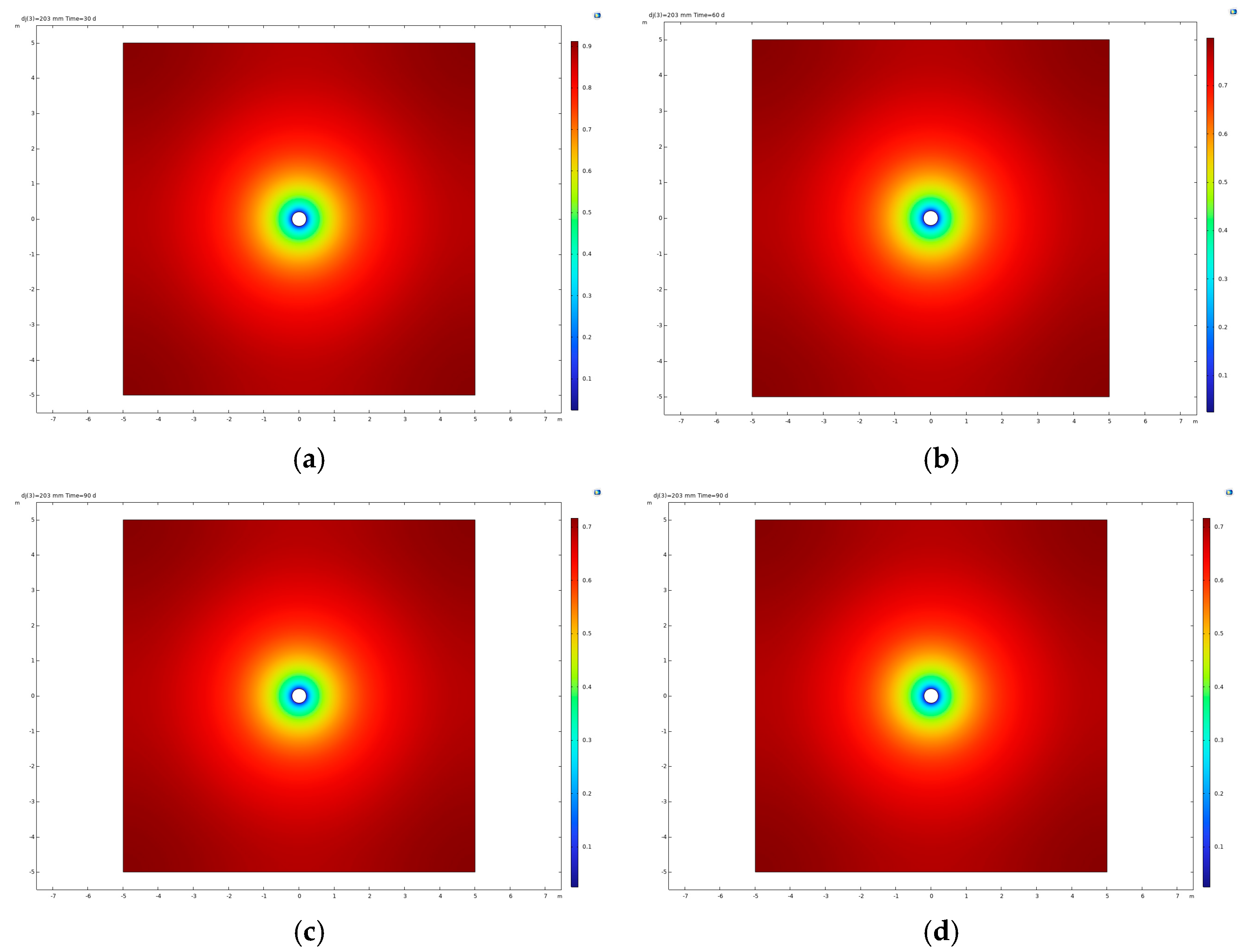

4.3. Analysis of the Effect of Extraction Time on Gas Pressure

5. Engineering Practice

5.1. Mine Overview and Drill Layout

5.2. Analysis of Pumping Effects and Technological Advantages

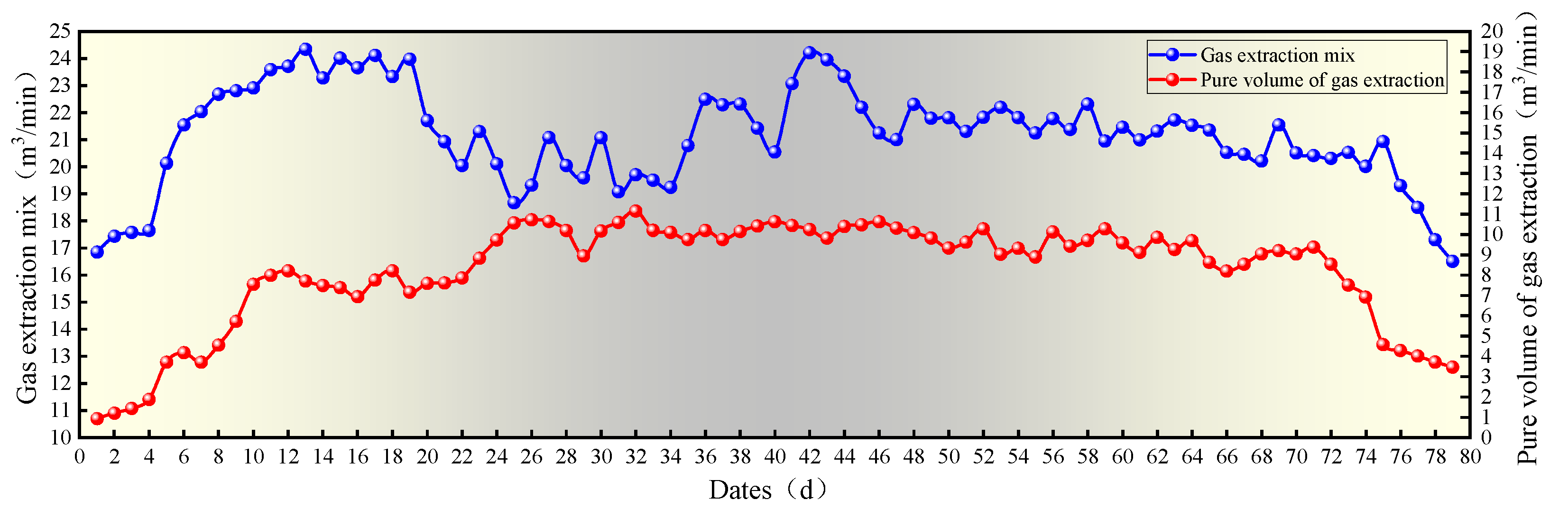

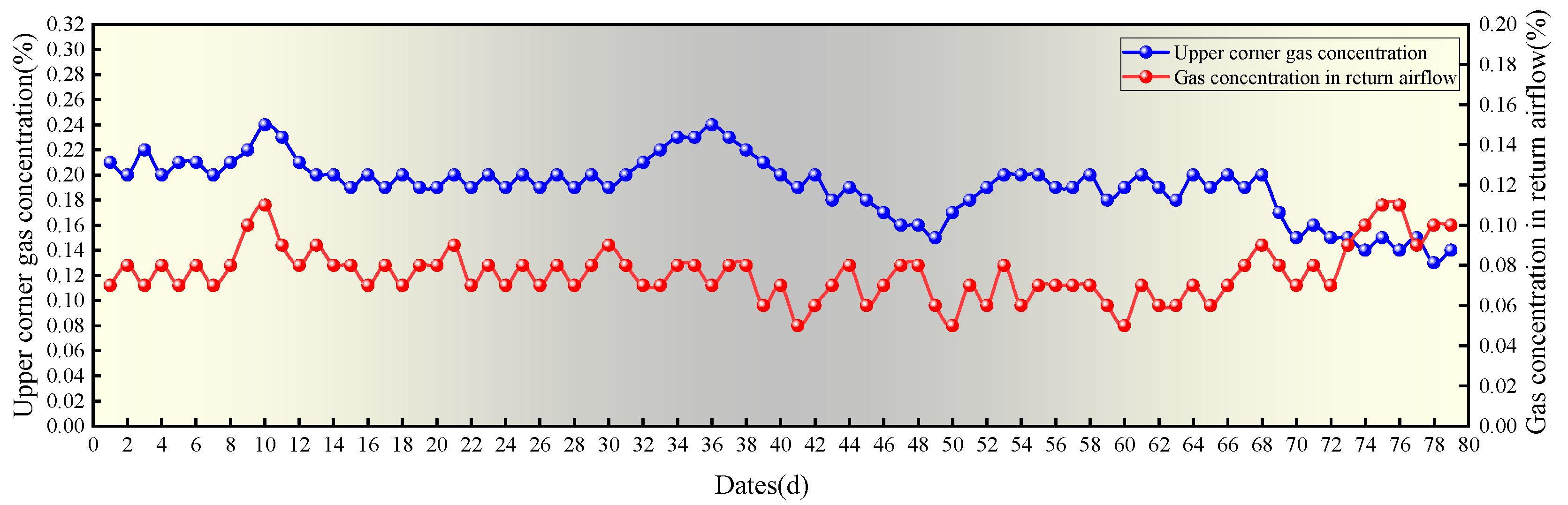

5.2.1. Analysis of Extraction Effects

5.2.2. Comparison of Technical Advantages

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, Y.; Liu, X.; Wang, S.; Ge, Y. Energy relations between China and the countries along the Belt and Road: An analysis of the distribution of energy resources and interdependence relationships. Renew. Sustain. Energy Rev. 2019, 107, 133–144. [Google Scholar] [CrossRef]

- Bilgen, S. Structure and environmental impact of global energy consumption. Renew. Sustain. Energy Rev. 2014, 38, 890–902. [Google Scholar] [CrossRef]

- Chen, S.; Tang, D.; Tao, S.; Xu, H.; Zhao, J.; Fu, H.; Ren, P. In-situ stress, stress-dependent permeability, pore pressure and gas-bearing system in multiple coal seams in the Panguan area, western Guizhou, China. J. Nat. Gas Sci. Eng. 2018, 49, 110–122. [Google Scholar] [CrossRef]

- Wang, X.; Tian, C.; Wang, Q.; Shi, Z.; Sun, Y.; Wang, K. Study on influencing factors and prevention measures of coal-rock-gas compound dynamic disaster in deep coal mine mining. Sci. Rep. 2025, 15, 2080. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, T.; Lin, B. Multi-field coupling theory and research progress of methane extraction in deep coal seams: A review. J. Nat. Gas Sci. Eng. 2022, 107, 104796. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, S.; Ma, X.; Wu, Z.; Zhang, W.; Shao, H. Study of the destruction of ventilation systems in coal mines due to gas explosions. Powder Technol. 2015, 286, 401–411. [Google Scholar] [CrossRef]

- Duan, H.; Wang, Y.; Xiao, Q.; Wang, J.; Peng, D. Gas extraction technology and application of near horizontal high directional drilling. Energy Rep. 2022, 8, 1326–1333. [Google Scholar] [CrossRef]

- Wang, F.; Ren, T.; Tu, S.; Hungerford, F.; Aziz, N. Implementation of underground longhole directional drilling technology for greenhouse gas mitigation in Chinese coal mines. Int. J. Greenh. Gas Control. 2012, 11, 290–303. [Google Scholar] [CrossRef]

- Yang, F.; Li, P.; Su, W.; Zhang, J.; Wang, L.; Guo, T.; Wang, S. Study on reasonable gas extraction radius based on multi-index and multi-method. Energy Rep. 2022, 8, 287–294. [Google Scholar] [CrossRef]

- Xu, H.; Qin, Y.; Wu, F.; Zhang, F.; Liu, W.; Liu, J.; Guo, M. Numerical modeling of gas extraction from coal seam combined with a dual-porosity model: Finite difference solution and multi-factor analysis. Fuel 2022, 313, 122687. [Google Scholar] [CrossRef]

- Yang, W.; Mengtang, X.; Dezhong, K.; Yuqi, S.; Fei, L. Optimization of drilling parameters for coal seam gas extraction considering fluid-solid coupling and field application. Energy Sci. Eng. 2024, 12, 657–669. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, H. Optimization of Drilling Parameters in Influence Area of Gas-Solid Interaction during Parallel Drilling Hole. Processes 2023, 11, 2371. [Google Scholar] [CrossRef]

- Yan, J.; Zhang, M.; Zhang, W.; Kang, Q. Simulation Study on the Characteristics of Gas Extraction from Coal Seams Based on the Superposition Effect and Hole Placement Method. Sustainability 2023, 15, 8409. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, J.; Ranjith, P.G.; Liang, X.; Wang, S. Investigation of the influence of gas fracturing on fracturing characteristics of coal mass and gas extraction efficiency based on a multi-physical field model. J. Pet. Sci. Eng. 2021, 206, 109018. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, J.; Wei, M.; Elsworth, D. Coal permeability maps under the influence of multiple coupled processes. Int. J. Coal Geol. 2018, 187, 71–82. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, H.; Huang, J.; Zhang, R.; Wang, S.; Hong, Y.; Yang, Y. Influence of coal deformation on the Knudsen number of gas flow in coal seams. Energy 2021, 233, 121161. [Google Scholar] [CrossRef]

- Shang, Y.; Wu, G.; Kong, D.; Wang, Y.; Li, F. Research on Influencing Factors of Effective Gas Extraction Radius in Coal Mine Based on Multiple Linear Regression. Adv. Mater. Sci. Eng. 2022, 2022, 3013647. [Google Scholar] [CrossRef]

- Li, J.; Li, B. Modeling of anisotropic coal permeability under the effects of matrix-fracture interaction. J. Nat. Gas Sci. Eng. 2021, 93, 104022. [Google Scholar] [CrossRef]

- Hatami, M.; Bayless, D.; Sarvestani, A. A model forstress-dependenceof apparent permeability in nanopores of shale gas reservoirs. AIChE J. 2020, 66, e16541. [Google Scholar] [CrossRef]

- Javadpour, F. Nanopores and Apparent Permeability of Gas Flow in Mudrocks (Shales and Siltstone). J. Can. Pet. Technol. 2009, 48, 16–21. [Google Scholar] [CrossRef]

- Qin, Y.; Li, Y.; Zhao, Y.; Xu, H.; Liu, H.; Zhao, J.; Xu, J. Study on gas transport behavior in coal matrix based on free gas density gradient diffusion: Comparison with fick model. Gas Sci. Eng. 2023, 111, 204914. [Google Scholar] [CrossRef]

- Cao, P.; Liu, J.; Leong, Y.-K. A fully coupled multiscale shale deformation-gas transport model for the evaluation of shale gas extraction. Fuel 2016, 178, 103–117. [Google Scholar] [CrossRef]

- Nian, F.; Ju, F.; Zheng, C.; Wu, H.; Cheng, X. Effects of Coal Permeability Anisotropy on Gas Extraction Performance. Processes 2023, 11, 1408. [Google Scholar] [CrossRef]

- Li, W.; Liu, J.; Zeng, J.; Leong, Y.-K.; Elsworth, D.; Tian, J.; Li, L. A fully coupled multidomain and multiphysics model for evaluation of shale gas extraction. Fuel 2020, 278, 118214. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, T.; Guo, X. Research on Gas Extraction Technology of Directional Long Borehole in Ultrathick Coal Seam. Geofluids 2022, 2022, 6957896. [Google Scholar] [CrossRef]

- Liang, S.; Zhang, L.; Ge, D.; Wang, Q. Study on Pressure Relief Effect and Rock Failure Characteristics with Different Borehole Diameters. Shock. Vib. 2021, 2021, 3565344. [Google Scholar] [CrossRef]

| Parameters | Numerical Value | Parameter Unit |

|---|---|---|

| Initial gas pressure of coal seam | 1 × 106 | Pa |

| Initial fracture rate | 0.040 | |

| Initial permeability | 3 × 10−17 | m2 |

| Initial porosity | 0.10 | |

| Klinkenberg factor | 1.44 × 105 | Pa |

| Molecular mass of methane gas | 16 | g/mol |

| Gas state constant | 8.413510 | J/mol/K |

| Seam temperature | 293 | K |

| Methane kinetic viscosity coefficient | 1.08 × 10−5 | mu |

| Langmuir constant (limiting adsorption capacity) | 0.02 | m3/kg |

| Langmuir constant (pressure) | 3.03 | MPa |

| Molar volume of methane at standard conditions | 22.4 | L/mol |

| Apparent density of coal | 1.41 | kg/m3 |

| Poisson’s ratio of coal | 0.3 | GPa |

| Limiting adsorption deformation | 0.005 | |

| Modulus of elasticity of coal matrix | 8200 | MPa |

| Modulus of elasticity of coal | 2800 | MPa |

| Extraction Time | Effective Extraction Radius |

|---|---|

| 30 d | 1.39–1.55 |

| 50 d | 1.96–2.40 |

| 70 d | 2.87–4.38 |

| Drill Hole Number | Hole Diameter/mm | Drilling Depth/m | Distance to the Roof/m | Level Distance to the Lower Gang of the Return Trench/m |

|---|---|---|---|---|

| 1# | 203 | 329 | 39 | 28 |

| 2# | 203 | 333 | 43 | 32 |

| 3# | 203 | 342 | 47 | 36 |

| 4# | 203 | 345 | 51 | 40 |

| Technology Type | Directional High-Level Long Boreholes | High-Level Drainage Galleries |

|---|---|---|

| Roadway section area/m2 | 5.5 | |

| Quantity of work/m | 1349 | 300 |

| Project unit price/CNY | 749.86 | 8000 |

| Total project price/CNY | 1,011,600 | 2,400,000 |

| Amount of gangue/ton | 2733.5 | |

| Gangue treatment cost/CNY | 218,680 | |

| Construction period/d | 15 | 84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, Z.; Yan, G.; Kong, S.; Zong, B.; Liu, H.; Huang, J.; Guo, G. Optimization and Application of Drilling Parameters Based on Gas–Solid Coupling Simulation. Appl. Sci. 2025, 15, 6626. https://doi.org/10.3390/app15126626

Ge Z, Yan G, Kong S, Zong B, Liu H, Huang J, Guo G. Optimization and Application of Drilling Parameters Based on Gas–Solid Coupling Simulation. Applied Sciences. 2025; 15(12):6626. https://doi.org/10.3390/app15126626

Chicago/Turabian StyleGe, Zhiguo, Guochao Yan, Shaoqi Kong, Baodong Zong, Huizhi Liu, Jinjing Huang, and Gaochuan Guo. 2025. "Optimization and Application of Drilling Parameters Based on Gas–Solid Coupling Simulation" Applied Sciences 15, no. 12: 6626. https://doi.org/10.3390/app15126626

APA StyleGe, Z., Yan, G., Kong, S., Zong, B., Liu, H., Huang, J., & Guo, G. (2025). Optimization and Application of Drilling Parameters Based on Gas–Solid Coupling Simulation. Applied Sciences, 15(12), 6626. https://doi.org/10.3390/app15126626