Abstract

The increasing demands for the reliability of modern industrial equipment and structures necessitate advanced techniques for design, monitoring, and analysis. This review article presents the latest research advancements in the application of machine learning techniques to vibration and acoustic signal analysis from 2015 to 2024. A total of 96 peer-reviewed scientific publications were examined, selected using a systematic Scopus-based search. The main research areas include processes such as modeling and design, health management, condition monitoring, non-destructive testing, damage detection, and diagnostics. In the context of these processes, a review of machine learning techniques was conducted, including convolutional neural networks (CNNs), recurrent neural networks (RNNs), long short-term memory (LSTM), autoencoders, support vector machines (SVMs), decision trees (DTs), nearest neighbor search (NNS), K-means clustering, and random forests. These techniques were applied across a wide range of engineering domains, including civil infrastructure, transportation systems, energy installations, and rotating machinery. Additionally, this article analyzes contributions from different countries, highlighting temporal and methodological trends in this field. The findings indicate a clear shift towards deep learning-based methods and multisensor data fusion, accompanied by increasing use of automatic feature extraction and interest in transfer learning, few-shot learning, and unsupervised approaches. This review aims to provide a comprehensive understanding of the current state and future directions of machine learning applications in vibration and acoustics, outlining the field’s evolution and identifying its key research challenges and innovation trajectories.

1. Introduction

In recent years, a dynamic increase in interest in the application of machine learning (ML) to vibroacoustic data analysis has been observed []. This trend results from the growing need for effective condition monitoring of machines, infrastructure, and industrial systems. Although traditional methods based on vibration and acoustic analysis are still widely used, they face several limitations under conditions of high operational variability, signal nonlinearity, and the presence of noise. In such cases, ML becomes a key tool, enabling the automation of pattern detection, damage classification, and degradation prediction, even when dealing with complex and multidimensional data [,].

Vibrational and acoustic signals have long been the foundation of machine and structural diagnostics—covering a wide range of elements, from bearings and gearboxes to bridges and concrete structures []. In the past, methods such as Fast Fourier Transform (FFT), band-pass filtering, envelope analysis, and wavelet transform were applied. Today, convolutional neural networks (CNNs), long short-term memory networks (LSTMs), autoencoders, and classical ML algorithms such as support vector machines (SVMs), k-nearest neighbors (kNNs), random forest (RF), and K-means clustering come to the forefront [,].

An example of machine learning application can be found in a study on the diagnostics of Electrical Submersible Pumps (ESPs), where raw time-domain data from vibration sensors were used as input for a convolutional neural network, eliminating the need for manual feature extraction. Another study classified vibration signal spectra in the form of images, which were then processed using support vector machines (SVMs), artificial neural networks (ANNs), and the k-nearest neighbors (kNNs) algorithm, achieving high diagnostic accuracy for fans []. Bahrami and his team [] successfully applied a convolutional neural network (CNN) architecture to classify acoustic signals from road surfaces (dry and wet), obtaining an accuracy of 96.36%.

Significant progress has also been observed in data fusion methods and multisensor systems []. Increasingly, vibration signals are analyzed alongside current, acoustic, or optical signals, enhancing the reliability of machine learning classifiers. Such approaches are gaining importance in the context of Industry 4.0, where data from Supervisory Control and Data Acquisition (SCADA) systems can be enriched with real-time physical measurements [,].

ML plays a key role throughout the analytical pipeline: from feature extraction (e.g., Principal Component Analysis (PCA) and Mel-Frequency Cepstral Coefficients (MFCCs)), through feature selection (e.g., Fisher Score), to classification or regression. In the context of sequential data, which is particularly important in time-series failure analysis, models such as long short-term memory (LSTM) and recurrent neural networks (RNNs) are used, as they can identify damage evolution patterns over time. Despite the achievements, many challenges remain to be addressed. The most important include the following [,]:

- Lack of standardized test datasets that would allow for the comparability of results;

- Difficulties in obtaining labeled data under real-world conditions, which is often costly and time-consuming;

- The need to develop models that are robust to noise and variability in environmental conditions.

In response to these challenges, increasing attention is being directed toward unsupervised learning methods (such as autoencoders and clustering), transfer learning, and few-shot learning [,]. The synergy between machine learning and vibration and acoustic analysis is gaining importance and becoming one of the most promising research areas in diagnostic engineering. Numerous studies confirm the effectiveness of machine learning methods in both laboratory and industrial applications from wind turbine monitoring and crack detection in composite materials to the diagnostics of railway components [,]. Among these approaches, particular attention has been given to long short-term memory (LSTM) networks, a type of recurrent neural network designed to effectively model sequential data with long-range dependencies. Their ability to process noisy and complex time-series information makes them highly suitable for tasks such as structural health monitoring, where predicting stress and deformation based on limited sensor data is critical [].

In the following sections of this review, we will focus on the classification of available methods, case study analyses, and the identification of research gaps. It should be emphasized that vibrational phenomena are ubiquitous and accompany almost every aspect of human technical activity from vibrations in buildings and engineering infrastructure, through industrial machinery and vehicles, to such seemingly minor everyday elements as child car seats [,]. This review seeks to address the following research questions:

- Which families of machine learning algorithms currently dominate applications in vibration and acoustic signal analysis?

- What performance metrics (e.g., accuracy, F1-score) are most commonly reported, and how have they evolved over the past decade?

- Which diagnostic tasks—such as condition monitoring, health management, or damage detection—are most frequently targeted in these studies?

- Have there been observable shifts in methodological approaches, including types of input data, evaluation strategies, or engineering domains, between 2015 and 2024?

In each of these fields, vibration analysis serves not only as a diagnostic tool but also as a basis for evaluating comfort, safety, and operational reliability. In the case of large structures such as bridges or buildings, vibration measurements allow for the detection of structural damage and the assessment of its impact on stability. In transport and mechanical devices, they enable early fault detection, which can prevent failures. Even in such precise applications as child seat design, vibrations play a significant role influencing the comfort of the small passenger and safety during travel.

The aim of this review article is to provide a comprehensive overview of the current state of knowledge regarding the application of machine learning methods to the analysis of vibration and acoustic signals in the context of technical diagnostics and the condition monitoring of structures and machines. Special attention will be paid to modern solutions developed over the past decade (2015–2024), including both classical methods such as support vector machines, k-nearest neighbors, and decision trees (DTs), as well as novel deep learning techniques, including convolutional neural networks, long short-term memory, and autoencoders.

Due to the interdisciplinary nature of the subject, applications in various fields of engineering were also analyzed—from heavy industry and transportation infrastructure to energy and defense systems. Particular attention was paid to data integration from multiple sources (data fusion), automatic feature extraction, and unsupervised methods, as well as implementation challenges such as the lack of standardized datasets and the need to operate under varying environmental conditions and signal disturbances.

As part of the review, 96 scientific publications indexed in the Scopus database between 2015 and 2024 were examined, with content containing key phrases related to “vibration”, “acoustics”, and “machine learning”. During the analyzed period, a significant increase in the number of publications in this area was observed, clearly indicating growing interest in both the scientific community and industry regarding the use of artificial intelligence for monitoring and diagnostics. The conducted review also revealed research gaps and potential directions for future studies, including the development of noise-robust methods, few-shot learning, transfer learning, and the creation of open and diverse benchmark datasets. An important direction is also the full integration of machine learning methods with control, maintenance, and asset management systems, aligning with the concept of Industry 4.0.

This review distinguishes itself from previous works by offering the first comprehensive, decade-spanning analysis (2015–2024) focused exclusively on the application of machine learning techniques in the field of vibration and acoustic signal analysis. Several prior review papers have addressed the role of machine learning in engineering diagnostics more broadly. For example, some studies have focused on specific algorithm classes (e.g., deep learning architectures), others on individual industries such as aerospace or automotive, or on narrow diagnostic modalities like bearing fault detection. However, these reviews often lacked a unified decade-spanning synthesis of vibration and acoustic signal applications across sectors. Moreover, few have systematically compared methodological approaches, geographical trends, and algorithm adoption patterns in this domain.

This paper addresses that gap by providing a focused, decade-long analysis of 96 publications (2015–2024) that specifically apply machine learning to vibration and acoustic diagnostics across diverse engineering systems. While earlier reviews have either addressed broader diagnostic methods or focused on single aspects (e.g., specific algorithms or industrial sectors), this article presents an in-depth, multidimensional synthesis of 96 publications drawn from a targeted and methodologically rigorous Scopus-based selection. By categorizing research according to algorithm types, application domains (such as condition monitoring, damage detection, and non-destructive testing), and methodological approaches, this review not only maps the technological evolution in this field but also highlights research gaps and emerging trends. Furthermore, it includes a unique statistical analysis of temporal and geographical publication trends, providing valuable insights into the global landscape of machine learning-driven vibroacoustic diagnostics.

This paper is organized as follows: Section 2 describes the document selection criteria and review methodology. Section 3 provides a thematic synthesis of the analyzed studies according to application domains and machine learning techniques. Section 4 presents a quantitative and bibliometric analysis. Section 5 outlines key challenges and future directions, and Section 6 concludes the review with final insights.

2. Materials and Methods

This article is a systematic literature review on the application of machine learning in the analysis of vibration and acoustic signals in the context of condition monitoring and diagnostics of machines and engineering structures. The aim was to collect, organize, and analyze research findings from the past ten years (2015–2024), using both classical methods and advanced deep learning techniques, in the context of real-world engineering applications. Data management was conducted using PostgreSQL 16.2 (PostgreSQL Global Development Group, Berkeley, CA, USA). All data processing, model development, and analysis were performed in Python 3.12.2 (Python Software Foundation, Wilmington, DE, USA).

2.1. Search and Select Documents

To identify scientific publications on the application of machine learning in the analysis of vibration and acoustic signals, the authors employed a systematic analytical approach. The process involved formulating and executing a query in Scopus, processing and classifying bibliographic data, and analyzing content based on defined thematic and methodological criteria. The selection of articles was carried out using a rational query logic aimed at narrowing the results to technical documents relevant to practical applications of machine learning methods in engineering. The search was conducted using a query that included the following components:

TITLE (vibration OR acoustics) AND TITLE-ABS-KEY (“machine learning”)

The results were limited to publications from the years 2015–2024, published in English, and at the final stage of publication. To narrow the thematic scope, only works containing selected machine learning techniques in the keywords were included, such as Convolutional Neural Networks, Recurrent Neural Networks, Long Short-Term Memory, Autoencoders, Support Vector Machines, Decision Trees, k-Nearest Neighbors, Random Forests, and K-means Clustering. These nine algorithms also form the basis of the classification framework used throughout the review, ensuring full alignment between the keyword filtering process and the analytical categorization.

Additionally, publications from non-engineering-related fields such as medicine, psychology, social sciences, business, arts, agriculture, chemistry, mathematics, neuroscience, theoretical computer science, earth sciences, environmental sciences, and related areas were excluded from the results. Based on this query, 152 documents were obtained and subsequently underwent a selection process. Publications affiliated with countries outside a selected group of twelve nations were excluded: Brazil, China, Germany, India, Iraq, Italy, Japan, Malaysia, Poland, Republic of Korea, UK, and USA. These twelve countries were selected based on preliminary bibliometric analysis, which showed that they collectively accounted for over 90% of all English-language publications retrieved in the initial Scopus query. By focusing on this group, the review preserves broad geographical diversity while minimizing the risk of excluding influential research. This filtering step ensured relevance without compromising the representativeness of the sample.

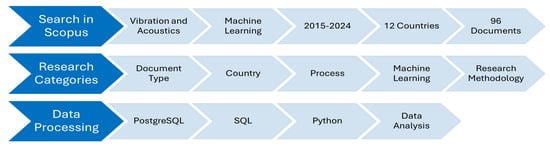

This step allowed for the preservation of geographical diversity while focusing on research-active centers in the field of vibration and acoustic diagnostics. The final number of analyzed publications was 96. The procedure related to data collection and preparation for the article is presented in Figure 1.

Figure 1.

Data collection and preparation workflow.

The collected bibliographic data were imported into a relational PostgreSQL database. The source file included fields such as: “Title”, “Authors”, “Affiliation”, “Year of Publication”, “Document Type”, “Keywords”, “DOI”, “Abstract”, “Citations”, “Publication Stage”, and others. This enabled the structured processing of information and the creation of SQL (Structured Query Language) queries for further aggregation and classification of results. For the purpose of analysis, Python software 3.12.2 was also used along with the following libraries: pandas (for data operations), matplotlib and seaborn (for visualization). The data were prepared in tabular form and categorized according to defined classification criteria.

Although machine learning methods are often categorized based on their learning paradigm such as supervised, unsupervised, or deep learning in this review, a unified classification approach was deliberately chosen. Instead of strictly separating algorithms by architectural depth or formal learning type, methods were grouped in a way that reflects their actual use in vibration and acoustic signal analysis.

This decision stems from the observation that, in engineering applications, the boundaries between classical and deep learning methods are frequently blurred. For instance, in [,], CNNs were used for feature extraction from acoustic emission signals, while classification was performed using a traditional SVM model—a hybrid approach that combines deep and classical techniques. Similarly, [] applied random forest and SVM on multisensor fusion data that had been preprocessed using statistical and spectral transforms, traditionally considered part of feature engineering. In [], an autoencoder typically classified as an unsupervised deep model was used for reconstructing missing acoustic emission data, but the reconstructed outputs were further analyzed using supervised classifiers. Likewise, in [], SVM and kNN were applied to vibration data that had been manually segmented and transformed, but could just as easily serve as inputs to a deep learning model.

Even within a single publication, such as [], deep learning and classical methods coexist. The authors used a DCNN-LSTM hybrid model part of the deep learning family but also compared its performance to traditional baselines like decision trees and kNN.

Given such overlap, a rigid taxonomy based purely on algorithmic structure would have been limiting. The chosen classification reflects how methods are used and combined in practice, with the primary goal being to highlight the diversity of techniques and their diagnostic contributions.

The systematic and rigorous methodology employed in this review is fundamental to the credibility and robustness of its findings. By adhering to a PRISMA-inspired protocol, including a precisely formulated Scopus query, strict temporal and language filters, and a meticulous multi-stage selection process, the review ensures that the analyzed dataset of 96 publications is highly relevant and representative of the field’s advancements. The intentional exclusion of non-engineering domains and the strategic focus on a pre-identified group of twelve research-active countries further refine the scope, preserving broad geographical diversity while concentrating on influential research centers. Moreover, the adoption of a unified classification framework for machine learning algorithms, which acknowledges the practical blurring of boundaries between classical and deep learning techniques in real-world applications, provides a nuanced and accurate basis for comparative analysis, enhancing the analytical depth of the subsequent sections.

To ensure transparency and facilitate reproducibility of this review, it is important to provide representative examples of the actual search strategies employed during the literature selection phase. As part of the document retrieval process, a structured query was formulated and executed in the Scopus database. The primary Scopus query applied was

TITLE (vibration or acoustics) AND TITLE-ABS-KEY (machine PRE/0 learning)

This general query was subsequently refined by adding targeted keywords to narrow the scope specifically to technical applications of selected machine learning methods. An example of the extended version is as follows:

TITLE (vibration or acoustics) AND TITLE-ABS-KEY (machine PRE/0 learning) AND (LIMIT-TO (EXACTKEYWORD,” Convolutional Neural Networks”) OR LIMIT-TO (EXACTKEYWORD,” Recurrent Neural Networks”) OR LIMIT-TO (EXACTKEYWORD,”LSTM”) OR LIMIT-TO (EXACTKEYWORD,” Long Short-term Memory”) OR LIMIT-TO (EXACTKEYWORD,” Autoencoder”) OR LIMIT-TO (EXACTKEYWORD,”SVM”) OR LIMIT-TO (EXACTKEYWORD,” Support Vector Machines”) OR LIMIT-TO (EXACTKEYWORD,” Decision Trees”) OR LIMIT-TO (EXACTKEYWORD,” Nearest Neighbor Search”) OR LIMIT-TO (EXACTKEYWORD,”K-means Clustering”) OR LIMIT-TO (EXACTKEYWORD,” Random Forests”))

These queries were constrained to publications written in English, issued between 2015 and 2024, and finalized at the publication stage. Additional exclusion filters were applied to omit papers outside of engineering-related domains, as discussed earlier in this section.

2.2. Classification Criteria

All classified publications were subjected to an in-depth content analysis related to all tasks assigned to the respective studies and methodological categories. The classification process was based on information available in publication metadata, such as:

- Title, abstract, keywords, author attribution, and full text of the article when necessary. The first step was to determine the type of document, distinguishing between journal articles, conference papers, and other publications.

- Book chapters, literature reviews, compiled letters, or research data. The second aspect of the classification involved identifying the country of affiliation of the authors. This allowed us to analyze the geographical distribution of the publications and assess research activity across different regions of the world.

Another element was the identification of the machine learning algorithm used in each publication—these were assigned to one or more of the most commonly applied types: CNN, RNN, LSTM, autoencoders, SVM, DT, kNN, K-means clustering, and RFs. The general learning approach also considered the types of signals used, which were analyzed in time, frequency, time-frequency domains, or as multisensor data. For the purpose of this review, machine learning techniques were grouped into three general categories:

- Classical methods, including support vector machines (SVMs), decision trees (DTs), k-nearest neighbors (kNNs), and random forests (RFs), which typically rely on manually engineered features and are known for their interpretability and computational efficiency.

- Deep learning methods, such as convolutional neural networks (CNNs), recurrent neural networks (RNNs), long short-term memory networks (LSTMs), and autoencoders, which are capable of learning hierarchical representations directly from raw data, particularly effective for time-series and time–frequency signal analysis.

- Hybrid approaches, which combine elements from both paradigms. For example, some studies use CNNs to automatically extract features from vibration or acoustic signals, and then apply classical classifiers like SVM or kNN for final classification. These methods aim to balance representational power and model simplicity.

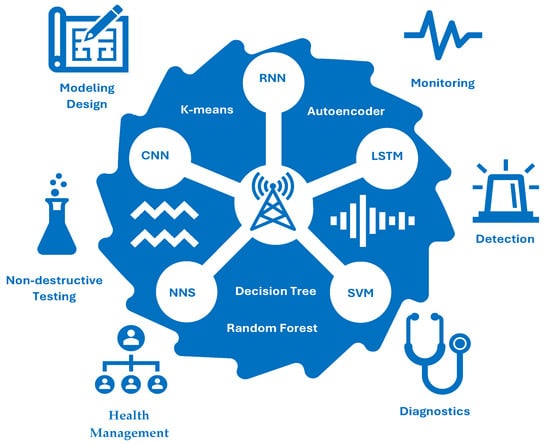

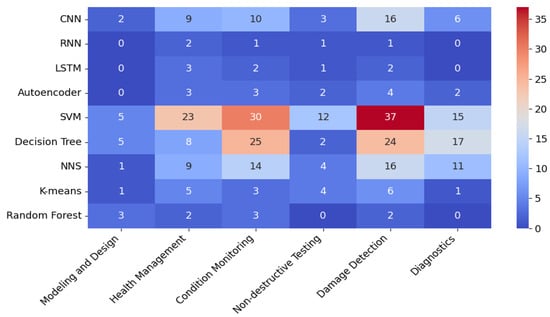

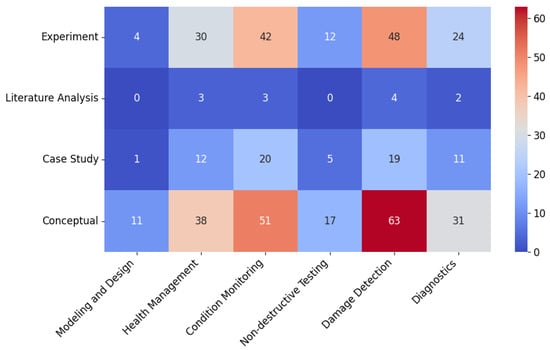

Key classification criteria also included the technical processes in which machine learning was applied. Based on content analysis, the activities presented in the publications were assigned to one or more of six application categories: condition monitoring (e.g., damage detection), diagnostics, health management, non-destructive testing, and modeling and design. In many cases, the publications reflected the multidisciplinary nature of the topics and diverse practical applications, often referring to multiple categories simultaneously. A similar situation applied to the classification of research methodologies, in which the type of conducted research was considered: experimental, case studies, conceptual work (including models and theories), and literature reviews. The relationships between individual algorithms and technical processes are presented in Figure 2.

Figure 2.

Interconnection of systems.

The above diagram visualizes the relationships between ML techniques, placed centrally, and their application contexts, arranged peripherally. The illustration shows typical algorithms such as CNN, SVM, RNN, and LSTM connected with symbolically represented processes such as diagnostics, monitoring, detection, or health management. This figure highlights not only the multidimensional nature of approaches used in the analysis of vibration and acoustic signals, but also their interconnections. For example, convolutional neural networks can be used both in non-destructive testing and in bearing diagnostics, whereas decision trees find application in condition monitoring classification systems or in predictive analysis. The graphical representation of these relationships helps to illustrate the complexity and flexibility of machine learning applications in the field of vibration and acoustic engineering.

Beyond the systematic selection of literature, a key strength of this review’s methodology lies in its pragmatic approach to classifying machine learning techniques and their applications. Instead of adhering to rigid theoretical distinctions between learning paradigms, algorithms were categorized based on their observed utility and common combinations within vibration and acoustic signal analysis. This decision stems from the recognition that, in engineering applications, the boundaries between classical and deep learning methods are frequently blurred, leading to hybrid approaches that leverage the strengths of both. By aligning the classification criteria with real-world technical processes like condition monitoring, damage detection, and health management, this review ensures that its analytical insights are directly relevant and applicable to the practical demands of diagnostic engineering, bridging the gap between theoretical advancements and industrial implementation.

2.3. Data Processing and Analysis

All data were processed using SQL queries, which enabled the creation of reports on the geographical distribution of publications, the most commonly used ML methods, types of applications, and temporal trends. In parallel, a qualitative analysis was conducted through the review of abstracts and—when necessary—full-text articles, in order to accurately assign them to research categories. During the analysis, cases were identified in which publications covered multiple processes simultaneously—for example, diagnostics and condition prediction. In such cases, a multi-level classification was applied, which allowed for the construction of cross-tabulations and comparative analyses. Visualizations presenting the course of the analysis and the relationships between research categories are presented in Section 3.

2.4. Review Protocol and Quality Assessment

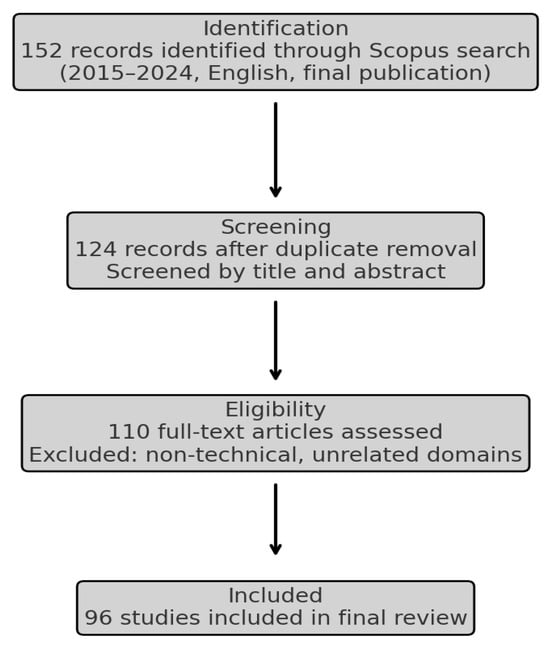

To ensure transparency and reproducibility, this review followed a structured protocol inspired by PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses). The process was organized into four key stages: identification, screening, eligibility, and inclusion. A flow diagram summarizing these steps is provided in Figure 3.

Figure 3.

PRISMA-style flow diagram illustrating the literature selection process, including identification, screening, eligibility assessment, and final inclusion of studies in the review.

In the identification stage, 152 documents were retrieved from the Scopus database using the following query: TITLE (vibration OR acoustics) AND TITLE-ABS-KEY (“machine learning”). The search was limited to publications from 2015 to 2024, written in English, and at the final publication stage. During screening, duplicate entries were removed, and the remaining records were assessed based on title and abstract. Documents were excluded if they did not explicitly apply machine learning techniques to vibration or acoustic signal analysis, or if their focus was unrelated to engineering practice.

Eligibility assessment involved full-text analysis. Papers were included if they met the following criteria:

- The study involved practical or experimental use of ML in vibration or acoustic analysis;

- It contained sufficient methodological detail;

- It was a peer-reviewed article or conference paper;

- It originated from one of twelve selected countries active in this research domain.

The final inclusion phase resulted in 96 documents being accepted for in-depth analysis. Publications from non-engineering domains (e.g., psychology, arts, environmental studies) or without clear experimental validation were excluded. It should be clarified that “lack of experimental validation” refers to papers that did not present any concrete application, simulation, or implementation of machine learning in vibration or acoustic diagnostics. Conceptual works or theoretical frameworks were included if they contributed to method development, performance evaluation, or modeling strategies relevant to the domain. Therefore, some non-empirical studies were retained, provided they met the review’s thematic and methodological relevance criteria.

To evaluate the quality of the included works, citation counts were analyzed, along with publication type (journal/conference) and journal ranking (e.g., Q1–Q2). High-quality studies with strong experimental design were prioritized, even if citation counts were modest due to recent publication dates. All selected publications were independently reviewed by two co-authors to ensure relevance, completeness, and methodological clarity. In case of disagreement, consensus was reached through discussion. This structured protocol reinforces the credibility of the review and provides a transparent foundation for the thematic and statistical synthesis presented in the following sections.

To enhance transparency, the 96 publications that were included in the final dataset for systematic review have been clearly marked in the References Section using an asterisk (*). This allows readers to distinguish between the core set of analyzed studies and the supporting or contextual literature.

3. Analysis of the State of the Art

In recent years, machine learning techniques have become essential tools in the analysis of vibration and acoustic signals, enabling more accurate diagnostics, damage detection, and condition monitoring across various engineering applications. This chapter provides a comprehensive overview of developments from 2015 to 2024, focusing on the growing impact of both classical approaches, such as support vector machines and decision trees, and modern deep learning methods, including convolutional neural networks, recurrent neural networks, and long short-term memory networks. Particular attention is given to the application of these techniques in real-world scenarios, addressing challenges such as noise robustness and data variability. Furthermore, this chapter highlights emerging trends, identifies research gaps, and discusses opportunities for future advancements. The next section offers a detailed review of the literature, organized by methodology, application areas, and machine learning algorithms.

3.1. Review from 2015 to 2024

The topic of ball bearing fault diagnosis using artificial neural networks and decision trees was discussed in detail in []. The authors demonstrated the effectiveness of these methods—87% for ANN and 89% for DT, respectively. Articles [,,] presented the use of deep learning and techniques such as principal component analysis and mel-frequency cepstral coefficients in the analysis of spectrogram images and time-series data. These techniques achieved very high diagnostic accuracy, reaching up to 100%. Article [] discussed the integration of accelerometers with SCADA systems and the use of classifiers such as linear discriminant analysis (LDA) and kNNs in industrial machine diagnostics, with particular emphasis on Industry 4.0 solutions.

In the literature [,,,,], various machine learning algorithms appear—DTs, SVMs, RFs, and clustering methods—applied in the diagnostics of large structures, concrete prefabricates, gears, and misalignment in rotating machinery. The effectiveness of these approaches often exceeded 90%.

In [] compares three methods for assessing water pipe degradation: absolute threshold, linear discrimination, and SVM. The highest accuracy was achieved using SVM; however, the threshold method is less complex and effective when physical properties are known. In [], a diagnostic method for hydraulic brake system faults was developed based on vibration signal analysis and machine learning. The combination of histogram features with a fuzzy classifier provided high classification performance.

The proposed Adaptive Chirplet Transform (ACT) and the TFFNet network with an Embedded Feature Pyramid (EFP) in [] enable effective classification of underwater acoustic signals. The method outperformed existing solutions on two real-world datasets. In [], the authors evaluate the potential of using acoustic signals to monitor multiple machines. Time-frequency feature analysis allowed for the differentiation of machining parameters. The best results for predicting cutting depth were obtained using the Fine KNN classifier (62%). In [], the effectiveness of 1D-CNN was evaluated in damage detection based on vibration, using both simulated and field data from a truss bridge. The model achieved an F1-score of 90.58%, outperforming other methods, even with single-channel measurements. In [], the authors presented a method for evaluating tool wear based on acoustic emission signals during Al-SiC composite machining. The best results were obtained using a decision tree, achieving a blade condition prediction error below 6%.

In [], the authors presented a method for damage detection in planar frame joints using statistical features of the vibration signal and SVM. The algorithm effectively classifies the structural condition, confirming its usefulness in structural health monitoring. Article [] introduced a bridge damage detection method using pre-trained CNNs (AlexNet, ResNet) and scalograms from wavelet transforms. An accuracy of 98–100% was achieved, preserving temporal and spatial information at a lower computational cost. In [], an impact-based method combined with machine learning was used for non-destructive evaluation of Shinkansen track slabs. PCA and autoencoders enabled support condition differentiation with over 79% accuracy, supporting long-term railway infrastructure monitoring. In [], the authors presented an early fault detection method for a reciprocating compressor based on vibration signal analysis. The highest effectiveness (99.67%) was achieved using the Lazy K Star classifier and autoregressive features. In [], the authors showed that acoustic emission data can be used to accurately predict friction in steel–steel sliding contacts. The Gaussian process regression (GPR) model on acoustic emission histogram data achieved RMS 0.03 and r = 0.8, enabling remote friction monitoring under variable machine operating conditions. A review of DL methods confirmed the effectiveness of CNN and UPN in structural damage detection. In [], a review of vibration-based damage identification studies in civil engineering structures using Deep Learning (DL) is presented. The paper discusses the effectiveness of DL tools, such as Convolutional Neural Networks (CNNs) and Unsupervised Pretrained Networks (UPNs), in detecting and localizing structural damage directly from raw sensor data. Murakawa et al. [] developed a portable vibration system for concrete diagnostics using SVM (70% accuracy). Hebert et al. [] applied RF to evaluate CTWD distance in the WAAM process based on acoustic signals.

Subsequent publications [,] also addressed the use of CNNs, this time in the context of diagnostics of wind turbine gearboxes, transmission systems, and turning tools, highlighting the high effectiveness of this method. In [], the authors focused on surface roughness prediction during steel milling based on acoustic emission. Both supervised and unsupervised ML algorithms were used, such as kNN, RBF-SVM, RF, K-means, and DBSCAN. The best results were obtained after feature reduction and cross-validation of the models. In article [], the effectiveness of an acoustic camera and CNN in detecting gearbox anomalies was evaluated. Sound images were classified with 95% accuracy, even under noisy operating conditions. The method demonstrated potential as a non-destructive monitoring tool. In [], the authors also examined the use of machine learning (SVM, Naive Bayes, kNN) for fault detection in wind turbine gearboxes based on vibration analysis. The best results were achieved with the Naive Bayes model (95.7%). This method improves turbine reliability and supports the development of renewable energy.

Diagnostics of building structures, road and underwater infrastructure were widely discussed in works [,,,,]. These studies used, among others, acoustic emission analysis, K-means, SVM, and FCBF (Fast Correlation-Based Filter), achieving accuracies close to 100%. Similarly effective were methods used for predicting the wear of cutting tools, valves, brakes, and transmission components, as confirmed by studies [,,,,]. The topics of wind turbine diagnostics, FRP (Fiber-Reinforced Polymer) materials, marine environments, bearings, and asphalt surfaces were addressed in articles [,,,,], where tools such as SVM, PCA, and ReliefF (Relief-Based Feature Selection) were used, reaching accuracies up to 97%.

Studies [,,,,] focused on bearing vibrations, non-contact diagnostics, faults in electric motors, and turbines. Methods such as DAMM + SVM (Dual-Axis Motion Magnification + Support Vector Machine), laser vibration sensors, kNN, and XGBoost (Extreme Gradient Boosting) achieved very high accuracy—up to 99.4%. Equally promising results were obtained in the diagnostics of textile materials, BSP (Bearing Signal Processing), welding stress, and vehicle condition, as discussed in [,,,,].

In studies [,,,,], the use of advanced vibration and acoustic emission techniques in the diagnostics of steel structures, bridges, turbines, and composite materials CFRP (Carbon Fiber-Reinforced Polymer) was analyzed. Scalograms, FRF (Frequency Response Function), PCA, and classifiers such as kNN and SVM once again confirmed their effectiveness. The prediction of bridge stresses, diagnostics of ceramic composites, and data generation were the focus of research [,,].

Further studies [,,] addressed the impact of vibrations on operators, detection of road shocks, and structural monitoring. Diagnostics of brake systems and laser welds were presented in [,,,]. Articles [,,,,] discussed the diagnostics of machine components, while [,,,,] focused on bolted joints, transformers, and acoustic waves.

Studies [,,,,] dealt with monitoring of cutting tools and autonomous underwater vehicles (AUVs). Diagnostics of engines and gearboxes were presented in [,,,,], while the following publications [,,,,] described pipelines and cutting tools. Works [,,,,] addressed the topics of biometrics and wind turbine diagnostics, while [,] focused on vibration analysis of induction motors and gear transmissions.

The comprehensive review of studies from 2015 to 2024 unequivocally demonstrates the profound impact of machine learning on vibroacoustic diagnostics, marking a significant maturation of the field. Across a diverse spectrum of applications—ranging from the intricate fault diagnosis of ball bearings and industrial fans to the large-scale structural health monitoring of bridges and wind turbines—ML techniques consistently achieve remarkably high diagnostic accuracies, frequently exceeding 90% and, in several instances, reaching near-perfect classification rates. This widespread success, particularly with the increasing adoption of deep learning architectures such as Convolutional Neural Networks (CNNs) for image-based spectrogram analysis and Recurrent Neural Networks (RNNs) for time-series data, signifies a transition from theoretical exploration to the development of robust, practical solutions capable of addressing complex, real-world engineering challenges.

A critical underlying trend in the field’s evolution is the increasing sophistication of data handling, particularly through multi-sensor data fusion and automatic feature extraction. Studies consistently highlight that integrating information from diverse sources—such as vibration, acoustic, current, and optical signals—significantly enhances the reliability and accuracy of machine learning classifiers, especially in complex fault scenarios. This approach provides a more comprehensive diagnostic picture, mitigating the limitations of single-sensor systems. Concurrently, the proliferation of deep learning methods, notably CNNs and LSTMs, has enabled the automatic extraction of salient features directly from raw data, thereby streamlining the diagnostic pipeline and reducing the reliance on laborious manual feature engineering. These advancements collectively align with the principles of Industry 4.0, facilitating the development of highly reliable, automated, and real-time condition monitoring systems capable of integrating seamlessly with broader industrial digital ecosystems.

3.2. Technical Evaluation and Thoughtful Analysis

The conducted studies show that diagnostic techniques based on ML have significantly improved in effectiveness compared to traditional methods. In many cases, very precise results were obtained, which were numerically confirmed across various industrial and engineering applications. For example, the use of ANNs and DTs enabled the classification of ball bearing faults with accuracies of 87% and 89%, respectively []. In the analysis of spectrogram images, convolutional neural networks achieved over 90% accuracy in identifying fan defects [].

In [], SCADA systems were combined with LDA and kNN methods, enabling effective assessment of cutting blade conditions—the classification accuracy exceeded 90%. In the context of larger structures such as suspension bridges, the use of ML—including clustering and kernel density estimation (KDE)—effectively supported vibration analysis, achieving over 85% accuracy []. Other studies showed that techniques such as K-means++ and k-NN are well-suited for detecting bushing faults at early stages of degradation, with accuracy exceeding 90% [].

In the analysis of gear fatigue cracks, the J48 algorithm (a type of decision tree) achieved 93.3% accuracy, outperforming classical methods []. In water pipe diagnostics, the application of SVM also proved effective—with over 90% correct diagnoses, compared to only around 80% for simple threshold-based methods []. In the automotive sector, methods based on fuzzy logic and histogram analysis of vibration signals outperformed traditional statistical approaches, reaching approximately 85% accuracy [].

Significant benefits were also observed with the use of CNNs in diagnostics of rotating machinery—the effectiveness of these methods was on average 20% higher compared to traditional feature extraction approaches []. Data fusion from multiple sensors further improved results by more than 15%, especially in the case of complex faults [,,]. Automatic feature extraction using deep learning methods contributed to increasing the efficiency of the entire diagnostic process—by as much as 30% [,].

Subsequent studies highlight the need to further improve precision through integration of data from different sources. This may allow for even more accurate detection of coexisting faults—up to 100% accuracy [,]. Validation of these methods in real industrial conditions is also becoming increasingly important, particularly in terms of robustness to environmental noise, which can still reduce accuracy by 5–10% [,,]. Unsupervised and semi-supervised learning methods are gaining importance, as they can reduce the need for labeled data by up to half while maintaining a high level of accuracy [,].

The optimization of ML models for computational efficiency is also becoming a priority—especially in cases where simplicity and performance need to be combined. In such scenarios, classical algorithms like kNN and decision trees can achieve over 95% accuracy [,]. More advanced approaches—such as autoencoders or GANs—can further improve model performance through the generation of synthetic data, resulting in accuracy gains of up to 10–20% [,,].

Therefore, the topic of machine learning in the context of vibroacoustic signal analysis is gaining increasing attention. As system and data complexity grows, so does the demand for effective diagnostic methods capable of handling variable operating conditions, noise, and nonlinearity. Traditional approaches—such as FFT analysis or filtering—have limitations that modern ML techniques effectively overcome by automating anomaly detection, fault diagnosis, and failure prediction.

Section 3 presents a quantitative analysis of scientific publications from 2015 to 2024 that met specific research criteria. This allowed for the identification of key development directions in the field of vibroacoustic diagnostics of machines and structures. Particular attention should be given to algorithms such as SVM, kNN, RF, and modern deep learning techniques (CNN, LSTM, autoencoders), which are increasingly used in the analysis of complex signals and structural systems.

The quantitative evaluation of machine learning applications in vibroacoustic diagnostics reveals not merely incremental improvements but substantial performance gains that fundamentally reshape the capabilities of diagnostic engineering. Deep learning methods, for instance, have demonstrated an average of 20% higher effectiveness compared to traditional feature extraction approaches in complex tasks like rotating machinery diagnostics. Furthermore, the strategic integration of data from multiple sensors consistently yields accuracy improvements exceeding 15%, particularly in the detection of complex, coexisting faults, with some studies achieving near 100% accuracy through such comprehensive data fusion. The efficiency of the diagnostic process itself is significantly enhanced by automatic feature extraction, leading to improvements of up to 30%. These compelling numerical confirmations underscore that machine learning is not just an alternative but a superior paradigm for handling the increasing complexity, noise, and nonlinearity inherent in modern industrial and structural data, thereby setting new benchmarks for diagnostic precision and reliability.

Despite the remarkable accuracy achievements, the practical deployment of machine learning models in real industrial environments continues to face significant challenges, primarily concerning robustness to environmental noise and the pervasive scarcity of labeled data. Studies indicate that environmental noise can still degrade diagnostic accuracy by 5–10%, highlighting the ongoing need for more resilient algorithms. In response to the high cost and time associated with manual data labeling, unsupervised and semi-supervised learning methods are gaining considerable traction, demonstrating their capacity to reduce labeled data requirements by up to half while maintaining high accuracy. Concurrently, the optimization of ML models for computational efficiency remains a priority, especially for real-time, embedded applications where classical algorithms like kNN and decision trees can still achieve over 95% accuracy with lower resource demands. This strategic focus on robustness, data efficiency, and computational practicality is crucial for transitioning advanced ML concepts from research to widespread industrial adoption and scalability.

3.3. Comparative Technical Analysis of Machine Learning Methods

Beyond the general review of applications, a deeper technical comparison of machine learning techniques used in vibration and acoustic signal analysis is essential to understand their practical strengths and trade-offs. The most widely used methods include classical algorithms such as support vector machines (SVMs), decision trees (DTs), and k-nearest neighbors (kNNs), as well as deep learning techniques like convolutional neural networks (CNNs), recurrent neural networks (RNNs), and long short-term memory (LSTM).

From the perspective of computational complexity, classical methods such as SVM and DT offer fast training and low resource consumption, making them suitable for embedded diagnostic systems and real-time applications. However, they often rely on manual feature engineering, which can limit their performance when dealing with complex or noisy datasets.

In contrast, deep learning methods like CNN and LSTM can automatically extract relevant features from raw signals and achieve superior classification accuracy, particularly for time-series and time–frequency data. CNNs have demonstrated over 95% accuracy in image-based spectrogram diagnostics [,], while LSTM networks have been successful in modeling the temporal evolution of damage in bridge structures and rotating machinery [,]. However, these models require significantly more training data and computational resources, which may pose challenges in real-world deployment.

Autoencoders and unsupervised clustering (e.g., K-means) are increasingly used in scenarios where labeled data are scarce. They are effective in anomaly detection and noise filtering but typically lack interpretability and require careful tuning to avoid false positives.

In terms of robustness to noise and environmental variability, studies have shown that CNNs and hybrid models combining multiple sensors (vibration, acoustic, current) can achieve accuracy gains of up to 15–20% compared to single-sensor SVM-based classifiers [,,]. Additionally, ensemble methods such as random forests and gradient boosting machines (e.g., XGBoost) provide resilience against overfitting and offer built-in feature importance metrics.

Ultimately, the choice of method depends on the specific application constraints—real-time responsiveness, explainability, sensor types, data volume, and operational variability. Table 1 summarizes key characteristics of selected machine learning methods in the context of vibration and acoustic diagnostics.

Table 1.

Technical characteristics of selected ML methods applied to vibroacoustic signal analysis.

A nuanced understanding of the technical characteristics of various machine learning methods is paramount for their effective application in vibroacoustic diagnostics, as the choice often involves a fundamental trade-off between interpretability, computational efficiency, and raw performance. Classical algorithms, including Support Vector Machines (SVMs), Decision Trees (DTs), and k-Nearest Neighbors (kNNs), are favored for their low computational overhead and inherent interpretability, making them suitable for embedded diagnostic systems and real-time applications where resources are constrained. However, their reliance on meticulous manual feature engineering can limit their efficacy when dealing with complex or noisy datasets. Conversely, deep learning architectures like Convolutional Neural Networks (CNNs) and Long Short-Term Memory (LSTM) networks excel in automatically extracting hierarchical representations directly from raw signals, achieving superior accuracy—often exceeding 95% for image-based diagnostics—and demonstrating high robustness to noise. Nevertheless, these models demand significantly larger training datasets and greater computational resources, posing challenges for deployment in resource-limited environments. This inherent dichotomy necessitates a context-dependent selection strategy, aligning the chosen method with specific application constraints such as real-time responsiveness, the need for model explainability, available data volume, and operational variability.

In light of the distinct trade-offs between classical and deep learning approaches, hybrid and ensemble methodologies are increasingly being adopted as a pragmatic strategy to leverage the strengths of different machine learning paradigms. Hybrid models, for instance, often combine the automatic feature extraction capabilities of deep learning networks—such as CNNs for processing time-frequency representations—with the classification efficiency and interpretability of classical algorithms like SVM or kNN. This synergistic integration has been shown to yield substantial accuracy gains, particularly when fusing data from multiple sensor types (e.g., vibration, acoustic, current), improving performance by 15–20% over single-sensor, single-algorithm approaches. Similarly, ensemble methods, including Random Forests and Extreme Gradient Boosting (XGBoost), enhance model robustness by aggregating predictions from multiple base learners, thereby mitigating overfitting and providing valuable insights through built-in feature importance metrics. These advanced architectural choices reflect a growing sophistication in model design, aimed at achieving optimal performance, resilience, and practical utility in complex vibroacoustic diagnostic scenarios.

The accuracy ranges reported in Table 1 are based on the minimum and maximum values found across the individual studies included in this review.

3.4. Case-Based Applications in Structural Health Monitoring and Vibration Diagnostics

Machine learning techniques have found widespread and impactful applications in structural health monitoring (SHM) and vibration-based diagnostics. These applications often involve large-scale systems, missing data, multisensor integration, and complex time-series behaviors—all of which present challenges well-suited to modern ML models. In [], a hybrid DCNN-LSTM model was used to predict strain in railway bridge elements subjected to dynamic loads. The approach effectively combined spatial and temporal feature extraction, achieving high accuracy in forecasting stress evolution—a critical need in long-span bridge monitoring. In [], pretrained CNN models (AlexNet, ResNet) were applied to wavelet scalograms derived from vibration signals, allowing for the accurate detection of damage in bridge structures. The method achieved classification accuracy up to 100%, without requiring manual feature engineering, and proved effective in identifying structural degradation. In [], a 1D-CNN was employed to detect faults in truss bridges using both simulated and field data. The model achieved an F1-score exceeding 90%, even with single-sensor input, demonstrating that deep learning can provide robust fault detection in sparse-sensor environments.

Missing data, a common issue in SHM systems, was addressed in [] using autoencoders to recover incomplete acoustic emission signals in reinforced concrete monitoring. The reconstruction accuracy exceeded 90%, ensuring continuity in damage evaluation and enhancing long-term monitoring reliability. In [], vibration, current, and temperature data were combined and analyzed using ML models such as SVM and random forest. The multisensor fusion approach improved fault detection accuracy by over 15% compared to single-sensor systems, illustrating the value of data integration in SHM applications. Tool wear monitoring using acoustic emission was investigated in [], where CNNs were used to extract time–frequency features, followed by SVM-based classification. The model achieved over 94% accuracy in predicting surface roughness during steel milling, offering an interpretable and high-performance solution. In [], various ML models (SVM, kNN, decision trees) were compared for diagnosing wind turbine gearbox faults based on vibration analysis. SVM provided the best results, with classification accuracy exceeding 95%, making it suitable for condition-based maintenance strategies.

A fuzzy classifier was developed in [] for identifying hydraulic brake system faults. By using histogram-derived features from vibration signals, the classifier effectively differentiated between fault types, even under overlapping signal conditions.

These studies demonstrate the practical effectiveness of both classical and deep learning models in a variety of SHM scenarios—from infrastructure monitoring to rotating machinery diagnostics. The growing diversity of applications confirms that machine learning is not only a promising research direction but also a critical enabler of real-time, autonomous diagnostic systems.

The detailed case studies presented in this review underscore machine learning’s transformative capacity to address the unique complexities inherent in Structural Health Monitoring (SHM) and vibration-based diagnostics. These applications frequently involve large-scale systems, the challenge of missing or incomplete data, the need for robust multi-sensor integration, and the analysis of intricate temporal behaviors. ML models, particularly deep learning architectures, have proven exceptionally adept at navigating these obstacles. For instance, autoencoders effectively recover missing acoustic emission signals in reinforced concrete, ensuring data continuity for damage evaluation. Similarly, hybrid DCNN-LSTM models accurately predict strain evolution in railway bridges, capturing critical temporal dependencies. The consistent improvement in fault detection accuracy—often exceeding 15%—achieved through the fusion of diverse sensor data (vibration, acoustic, current) further exemplifies ML’s ability to synthesize disparate information for a more comprehensive and precise assessment of system health. These successes demonstrate that ML is not merely a diagnostic tool but a critical enabler for overcoming the inherent challenges of real-world SHM, paving the way for more resilient and intelligent monitoring systems.

The diverse range of successful applications, from infrastructure monitoring to rotating machinery diagnostics, solidifies machine learning’s pivotal role in advancing condition-based maintenance and autonomous diagnostic systems. For example, SVM models have achieved over 95% accuracy in diagnosing wind turbine gearbox faults based on vibration analysis, making them highly suitable for proactive maintenance strategies. The effective identification of hydraulic brake system faults using fuzzy classifiers and histogram features from vibration signals further illustrates ML’s versatility across different mechanical systems. This broad applicability, coupled with the demonstrated high performance in real-world scenarios, confirms that machine learning is transitioning from a promising research direction to a critical enabling technology. It is actively moving the field of technical diagnostics closer to a paradigm of predictive and proactive asset management, where early fault detection and degradation forecasting become standard operational practices.

3.5. Key Observations by Category: Methods, Diagnostic Applications, and Research Methodology

A noticeable evolution in approaches to vibroacoustic signal analysis using machine learning is evident in the literature review. In the initial period, classical methods such as support vector machines (SVMs), decision trees, or kNNs dominated, used mainly for diagnostics of rotating machinery components and simple mechanical systems [,,]. In recent years, deep neural networks (CNNs, LSTM, autoencoders) have gained increasing significance, enabling automatic feature extraction and raw data processing—particularly in the analysis of complex structures, multisensor systems, and cases with limited access to labeled data [,,,].

An increase in the importance of data integration from various sources—such as vibration, acoustic, current, or temperature signals—can also be observed, which increases the robustness of classifiers to interference and improves diagnostic effectiveness [,,,]. More and more often, ML is becoming an element of broader predictive systems and diagnostic platforms consistent with the Industry 4.0 concept [,]. Future directions of development include the miniaturization of models, development of algorithms capable of learning from small datasets, and standardization of evaluation methods, which may contribute to their wider implementation in industrial practice [,,].

3.5.1. Machine Learning Techniques

In the period 2015–2019, classical methods dominated, such as support vector machines (SVMs), decision trees (DTs), or kNNs, which achieved high effectiveness with low data and computational requirements. For example, SVM achieved over 90% accuracy in bearing diagnostics [], gearbox systems [], and bridge structures []. In the analysis of compressor condition, the Lazy K Star classifier with autoregressive features achieved 99.67% accuracy [].

Since 2020, a clear increase in the use of deep learning methods has been observed—including convolutional neural networks (CNNs), recurrent neural networks (RNNs), long short-term memory (LSTM), and autoencoders. CNNs allowed up to 100% accuracy in bridge diagnostics based on wavelet scalograms [] and effectively classified acoustic images of gearboxes under noise conditions []. LSTM proved successful in stress prediction in bridge structures [], and autoencoders enabled the reconstruction of missing acoustic emission data [].

Hybrid approaches are increasingly appearing in research, e.g., DCNNs + LSTM for dynamic load estimation [], CNNs with classification using SVMs [], or combinations of autoencoders with PCA []. These models enable automatic feature extraction and classification accuracy improvement by 15–20% compared to single algorithms [,].

It should be emphasized that the future belongs to lightweight deep network architectures, transfer models, and energy-efficient solutions ready for integration with edge systems and embedded controllers (Edge AI). Wider use of generative models (e.g., GANs) is also to be expected for synthesizing training data in environments with limited labeled data.

3.5.2. Diagnostic Application Areas

The most common application of machine learning was damage detection (89.6% of the analyzed publications), followed by condition monitoring and technical health diagnostics of systems. Damage in engineering structures was detected using CNNs (ResNet50)—such as in the case of bridge trusses [] or bridges using wavelets [], where effectiveness reached 90–100%.

In condition monitoring, data from various sensors (vibration, acoustics, temperature, SCADA) were effectively integrated. In [], LDA and kNN classified blade conditions in industrial cutting systems, while [] used PCA and autoencoders to assess the support condition of Shinkansen tracks. In the context of rotating devices, CNN models increased fault recognition effectiveness by more than 20% compared to classical techniques [].

In non-destructive testing, applications in concrete, steel, and composites dominated. For example, [] examined acoustic emission in concrete using autoencoders, and [] compared the effectiveness of several methods (SVMs, kNNs, trees) in diagnosing wind turbine gearboxes. Meanwhile, [] demonstrated the high effectiveness of fuzzy logic in diagnosing brake systems—even with overlapping signals.

It should be noted that the area of diagnostic applications will shift toward predictive regression models allowing for Remaining Useful Life (RUL) estimation and integration with maintenance and asset management systems. A rapidly developing trend will be personalized diagnostics—adapted to a variable usage profile and local environmental conditions.

3.5.3. Research Methodologies

Among the analyzed works, experimental studies with real measurement data, e.g., from vibration, acoustic, optical, or electrical systems, prevailed. The paper [] tested acoustic emission in various machines, achieving the best results in cutting depth prediction using the Fine kNN classifier. In [], random forest (RF) was used in diagnosing WAAM welding joints by analyzing sound signals with high accuracy.

Conceptual studies introduced new network architectures or atypical learning strategies, e.g., TFFNet in [] for underwater signal classification, outperforming classical methods on real datasets. Meanwhile, case studies demonstrated the effectiveness of ML models in real conditions, e.g., tool wear assessment [], engine and gearbox diagnostics [], or industrial pipeline monitoring [].

In the future, balancing theoretical and practical research will be key. An increase in the number of validated benchmarks and open datasets is expected, which will allow for result replicability and objective model comparisons. At the same time, the importance of field studies in variable conditions will grow, with emphasis on model robustness to interference and data loss.

4. Results and Discussion

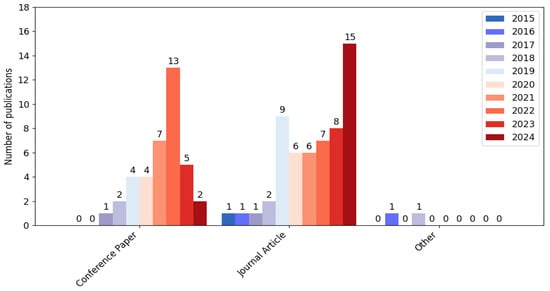

Table 2 presents a review of scientific publications from the years 2015–2019 and 2020–2024 that focused on the application of ML methods in vibroacoustic signal analysis—particularly in the context of diagnostics of machinery, infrastructure, and industrial systems. In the first of these periods, 23 publications were identified, while in the subsequent five years the number rose to 73. In total, 96 studies were analyzed, over three-quarters (76%) of which were published in the latter period. This clearly demonstrates the growing interest in this subject area. In terms of document types, journal articles dominated—totaling 56 papers, which accounts for more than half of the entire dataset (58%). Conference papers appeared 38 times (39.6%), while only two publications (2%) were classified as “other”. Statistical analysis indicates that the change in the distribution of document types over time is significant (χ2 = 7.02; p = 0.029). This may suggest that conferences have gained importance in recent years as a platform for sharing research findings. A statistically significant relationship was found between the type of document and the time period. This indicates that the distribution of publication formats changed over time—in particular, conference papers became markedly more prevalent in the 2020–2024 period. This trend may reflect the growing pace of research dissemination and the expansion of ML topics in conference venues.

Table 2.

Publications by year in all categories.

Looking at specific machine learning methods, support vector machines were by far the most frequently used—appearing in 42 publications, which is nearly 44% of all cases. The next most common were general-purpose neural networks (NNs) and CNNs used in 18 and 17 studies, respectively. Notably, 16 out of the 17 CNN-related publications come from the 2020–2024 period, illustrating the sharp increase in interest in this technique. Overall analysis of ML methods confirmed significant shifts in their popularity over time (χ2 = 16.43; p = 0.036), reflecting evolving technological trends in research. A significant shift was also observed in the types of machine learning methods employed. Specifically, deep learning models such as CNN and NNS became substantially more common in the recent period, replacing earlier dominance of classical techniques like SVMs and decision trees. This shift likely reflects broader adoption of neural architectures, availability of computing resources, and increasing dataset complexity. Regarding areas of application, the most frequently addressed topic was damage detection—present in as many as 86 publications (almost 90%). Condition monitoring appeared in 76% of the studies, and health management in just over half (54%). Less attention was given to system design (11%) and non-destructive testing methods (23%). Although the numerical data suggest a clear predominance of certain topics, the statistical test did not confirm significant temporal differences (χ2 = 0.48; p = 0.992). No statistically significant association was detected between application domain and time period. This means that the focus areas—such as damage detection, condition monitoring, and health management—remained consistent across the decade, regardless of the ML methods used. This suggests a stable research interest in key diagnostic challenges.

In terms of research methodology, conceptual studies were dominant—as many as 70 out of 96 publications (73%) were theoretical in nature. Experiments appeared in more than half of the cases (55%), and case studies were present in one in four publications. Literature reviews were relatively rare. In this case, as well, no significant changes were observed in the structure of research approaches between the two periods (χ2 = 2.46; p = 0.482), which may suggest that the distribution of methods remains relatively stable despite the increase in the number of studies. There was no significant difference in the distribution of research methodologies over time. Experimental, conceptual, and case study-based approaches were used with similar frequency in both periods, indicating a sustained methodological balance in how research was conducted and reported.

Figure 4 presents a comparison of the number of publications from the periods 2015–2019 and 2020–2024, broken down by document type. It is clearly visible that the number of publications increased significantly in all categories during the more recent period. The largest growth pertains to journal articles (“Journal Article”), which rose from 14 to 42. This increase may indicate a growing formalization and maturity of research in this field. A substantial rise was also observed in conference papers (“Conference Paper”)—from 7 to 31. This may suggest increased activity within the scientific community and a growing number of research findings being presented at international forums. In contrast, publications classified as “Other” appeared only in the years 2015–2019 and were not present in the later period, which may indicate a shift away from less formal forms of presenting results. The overall trend suggests a dynamic development of the topic related to the application of machine learning methods in vibroacoustic signal analysis, particularly after 2020. The increased number of publications in peer-reviewed journals and at conferences confirms the growing interest of the research community and the maturation of this research domain.

Figure 4.

Summary of the number of publications from 2015–2019 and 2020–2024, broken down by document type.

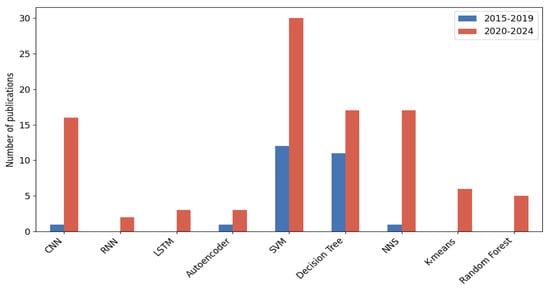

Figure 5 presents a comparison of the number of publications from 2015–2019 and 2020–2024, categorized by the machine learning methods used. The comparison clearly shows that, in recent years, the use of nearly all analyzed methods has increased significantly. SVM stands out in particular, having already been one of the most frequently used methods in the first period (12 publications), with the number increasing to 30 in 2020–2024. This confirms its established position in vibroacoustic diagnostics. Also noteworthy is the sharp rise in interest in deep learning methods. For CNNs, the number of publications rose from 1 to 16, while for NNSs it increased from 1 to 17. This surge indicates growing popularity of more advanced techniques, especially in the context of analyzing complex signals and diagnostic images.

Figure 5.

Comparison of the number of publications from 2015–2019 and 2020–2024 by machine learning methods applied.

Decision trees also saw growth, increasing from 11 to 17 publications. Autoencoders appeared three times in the recent period, compared to just once between 2015 and 2019. Methods such as K-means and RF had not been recorded previously, but appeared in six and five publications, respectively, in the last five years, which may suggest their relatively recent adoption in this field.

Sequential methods such as RNN and LSTM also emerged only after 2020—although their numbers are still low (two publications using RNN, three using LSTM), their presence may indicate the beginning of exploration of these techniques for time-series signal processing. The chart demonstrates not only a significant increase in the number of publications, but also a growing diversity of ML methods being applied. This clearly indicates a dynamic development of research in vibroacoustic diagnostics using machine learning, particularly after 2020, and growing interest in next-generation algorithms.

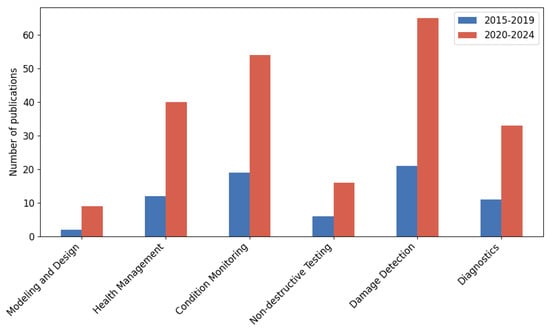

Figure 6 presents a comparison of the number of publications from 2015–2019 and 2020–2024, grouped according to the main application areas of machine learning methods in vibroacoustic signal analysis. In all categories, there is a clear increase in the number of studies in the more recent period, confirming growing interest in the practical aspects of technical diagnostics. The most frequently addressed topic was damage detection—the number of publications increased from 21 to 65, representing the largest growth among all analyzed areas. This highlights the critical importance of this issue in the context of technical system reliability.

Figure 6.

Comparison of the number of publications from 2015–2019 and 2020–2024, grouped by the main areas of application of machine learning methods in the analysis of vibroacoustic signals.

The second most discussed topic was condition monitoring—here, the number of publications increased from 19 to 54, which also confirms the growing need for continuous oversight of machine and equipment operation. A significant increase was also observed in the category of health management—from 12 to 40 publications—which may indicate greater emphasis on preventive approaches and long-term maintenance planning.

Areas such as diagnostics and non-destructive testing are also developing dynamically—the number of studies increased from 11 to 33 and from 6 to 16, respectively. Although the absolute numbers are lower than in the leading categories, the clear growth confirms their increasing role in the research landscape.

The fewest publications concerned the area of modeling and design, where the number of studies increased from two to nine. Nevertheless, even here a positive development trend can be observed. The data from the chart clearly indicate that, after 2020, research on the application of ML in vibroacoustic signal analysis has increasingly focused on practical applications. The greatest attention is directed toward those areas that have a direct impact on the safety, reliability, and efficiency of industrial systems—primarily damage detection and condition monitoring.

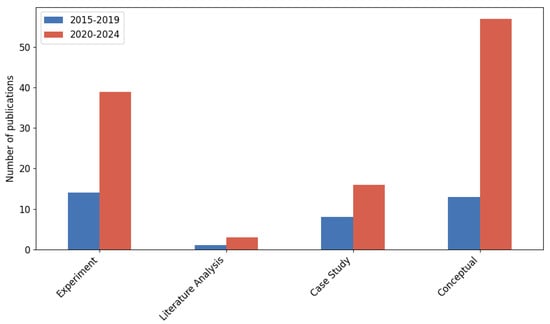

Figure 7 presents a comparison of the number of publications from 2015–2019 and 2020–2024 according to the applied research methodology. The data clearly show a significant increase in scientific activity across all analyzed categories in recent years. The highest number of studies concerned conceptual research—the number of publications in this category rose from 13 to as many as 57. Such a substantial increase indicates the intensive development of theoretical foundations related to the application of machine learning in vibroacoustic signal analysis. The high number of publications in this category may suggest that researchers are focusing on developing new models, data structures, and analytical frameworks that will serve as the basis for future practical applications.

Figure 7.

Comparison of the number of publications from 2015–2019 and 2020–2024 according to the research methodology used.

A notable increase was also observed in experimental research—from 14 to 39 studies. This may indicate a transition from concept formulation to practical testing, both in laboratory and industrial conditions. Such a trend suggests the maturation of the entire field and a growing emphasis on validating models in real-world scenarios. Case studies also gained importance—the number of publications in this category doubled, rising from 8 to 16. This shows that more and more research is based on concrete, real-life examples that help to better understand the application of ML algorithms in engineering practice.

The fewest studies were recorded in the category of literature analysis—here, the increase was modest, from one to three publications. Although still a marginal part of the total, the presence of this category indicates that systematic literature reviews are beginning to appear in this field as well. The chart clearly shows the dominance of conceptual research but also a gradual increase in interest in experiments and practical applications. This can be interpreted as a sign of the field’s maturation—from theory development, through model validation, to implementation in real technical environments. The growing methodological diversity indicates an increasingly comprehensive approach to exploring the topic of machine learning in technical diagnostics.

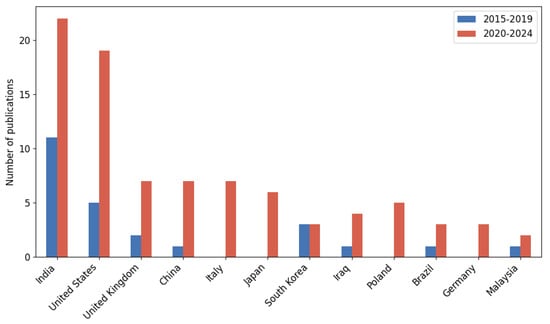

Analyzing the data from Figure 8 and Table 3, it is clearly evident that interest in the topic of machine learning in the context of vibroacoustic signal analysis has significantly increased in recent years. In most countries, the number of publications from 2020–2024 was much higher than in 2015–2019—both in terms of total output and growth rate. The most spectacular increase was recorded in the United States, where the number of publications rose from 5 to 19. In India, which had already been an active research hub in this area, the number of publications doubled—from 11 to 22. In the United Kingdom, the number of studies increased from two to seven, and in China, from one to seven. This is a clear signal that these countries are not only maintaining but also strengthening their presence in this research domain.

Figure 8.

Comparison of the number of publications from 2015–2019 and 2020–2024 by country.

Table 3.

Publications by year in different countries.

New publications also appeared from countries such as Italy, Japan, Poland, and Germany. Notably, these countries had no publications in 2015–2019, but in the following five years each contributed between three and seven papers. This suggests that the topic of ML in technical diagnostics is attracting attention from researchers in an increasingly international context.