Featured Application

The proposed IMOAHLO algorithm is applied to optimize raw material formulation schemes in rotary hearth furnace operations. By simultaneously balancing elemental content, scheme similarity, continuous operation, and start–stop switching, the algorithm ensures enhanced process stability and optimized material composition. Real-world tests demonstrate its capability to reduce operational fluctuations and maximize resource efficiency, making it a valuable tool for automating complex industrial processes in steelmaking and beyond.

Abstract

This study develops a complex, multivariable optimization framework for raw material formulation in rotary hearth furnaces (RHF), addressing the inherent coupling effects among compositional control, operational stability, and resource efficiency. Based on an in-depth analysis of the multiple constraints that must be balanced in the blending process, this paper constructs a multi-objective optimization mathematical model incorporating elemental content, scheme similarity, a continuous operation time, and start–stop switching. An improved multi-objective adaptive human learning optimization algorithm (IMOAHLO) is proposed, which enhances local optimization through neighborhood search and an adaptive learning mechanism. This approach overcomes the shortcomings of traditional methods that rely on human expertise and are prone to getting trapped in local optima, ensuring the system operates stably over the long term while meeting production demands. Using 100 factual datasets from a steel plant’s RHF production line, comparative experiments between IMOAHLO and three other algorithms show that the proposed method outperforms its counterparts on three evaluation metrics: hypervolume, inverted generational distance, and generational distance. This indicates significant improvements in system stability, reduced operational fluctuations, and optimized elemental content in the blended materials. Furthermore, two practical case studies are presented to demonstrate the optimization results of the proposed algorithm under varying production conditions, proving its flexibility and high performance in multi-objective optimization applications in complex industrial scenarios and highlighting its significant engineering value. Although this work focuses on the RHF blending line in the steel industry, the same framework can be readily extended to other continuous blending processes.

1. Introduction

The steel industry has long been regarded as the foundation of the global industrial system and plays an indispensable role in promoting the development of modern society. As the world’s largest producer and consumer of steel, China contributes approximately 50% of the global steel production [1]. However, the rapid development of the steel industry also faces the dual challenges of environmental pollution and resource waste [2]. The large amounts of waste and pollutants generated during the steel production process significantly impacts the environment. Therefore, effectively recycling the solid waste containing hazardous metallic elements generated during steel production can not only greatly improve resource utilization efficiency but also reduce environmental pollution [3]. The RHF stands out among various technologies for processing iron-containing dust due to its low energy consumption and high metallization rate, and has been widely adopted [4,5].

In the process of treating iron-containing dust with the RHF, the raw material blending system serves as the crucial initial step, ensuring the supply of qualified mixed materials that meet the requirements of the production plan to the subsequent stages of production. The effectiveness of the blending system mainly depends on the formulating blending scheme which is a complex decision-making process influenced by various factors, such as the types of raw materials, elemental composition, bin levels, production schedules, and the operational status of the RHF, etc. Traditional formulation schemes based on manual experience are characterized by a high computational complexity and excessive reliance on individual expertise, making it difficult to achieve a balanced optimization of multiple objectives during the production process, which can easily lead to fluctuations in product quality and declines in production efficiency. The design of the formulation scheme for the blending system is regarded as a multi-objective optimization process, addressed using optimization algorithms to provide decision support for operators. Although traditional optimization algorithms, such as the Newton method, are theoretically well established, they typically rely on precise mathematical models and are prone to becoming trapped in local optima, making them difficult to solve complex multi-objective optimization problems [6]. Heuristic and metaheuristic algorithms are effective solutions for such problems. As a metaheuristic optimization algorithm, the Human Learning Optimization (HLO) algorithm is capable of effectively handling complex problems that are nonlinear, non-differentiable, and non-convex without relying on precise mathematical models [7]. The algorithm seeks optimal solutions by simulating human behaviors during the learning process, including random learning, individual learning, and social learning. With its rapid convergence capability and superior global search performance, HLO has demonstrated its effectiveness in solving multi-objective optimization problems [8]. Therefore, this paper develops an improved multi-objective adaptive HLO algorithm (IMOAHLO) specifically for the formulation scheme optimization problem in RHF blending systems. The primary goal is to ensure a long-term, stable operation of the blending line—minimizing manual interventions—while meeting production requirements for elemental composition and resource utilization.

While this work is grounded in the steel industry’s RHF blending context, the proposed modeling and algorithmic framework have a broader applicability. The same framework can be readily extended to other continuous blending processes, such as middling coal proportioning in thermal power plants, as well as blending optimization in copper, iron, and other metallurgical industries, thereby offering a significant engineering value across various manufacturing and energy-conversion sectors. In these fields, operators also seek to balance product quality, energy efficiency, and uninterrupted operation, making IMOAHLO a valuable decision-support tool.

The main contributions of this paper are summarized as follows:

- (1)

- A mathematical model was constructed based on a comprehensive consideration of the multiple constraints that need to be balanced in production, modeling a formulation scheme as a complex multi-objective optimization problem. This model addresses the core requirements of the RHF blending process and fills the gap in systematic modeling within this field.

- (2)

- An IMOAHLO algorithm was proposed which integrates neighborhood search and adaptive mechanisms based on the traditional Human Learning Optimization (HLO) algorithm, balancing exploration and exploitation efficiency, and enhancing its local search capability as well as adaptability to production constraints.

- (3)

- Experiments based on real-world data from a steel plant demonstrated that the IMOAHLO algorithm significantly outperforms three other optimization algorithms across multiple evaluation metrics. It achieves the goal of optimizing the element content in blended materials, improves production stability, and reduces the frequency of manual intervention, thereby indicating the algorithm’s intelligent decision-making capability in industrial application scenarios.

The rest of the paper is organized as follows: Section 2 introduces the current state of research on formulation strategy in the blending system and the development of the HLO algorithm. Section 3 describes the mathematical model for the formulation scheme optimization. Section 4 provides the proposed algorithm. Section 5 gives the extensive experiments and comparisons based on real-world cases. Finally, Section 6 concludes the paper.

2. Literature Review

Blending is an essential step in many industries [6,9,10,11,12,13]. By determining an appropriate proportion, the optimized formulation strategy plays a crucial role in mitigating fluctuations in raw material supply, improving product quality, and reducing costs [10]. However, the primary challenge in optimizing formulation strategy lies in uncertainty, particularly the uncertainty of raw materials and their composition [6]. In recent years, scholars have proposed an increasing number of intelligent optimization algorithms, such as Genetic Algorithms [14], Particle Swarm Optimization (PSO) [15], and Human Learning Optimization (HLO) [7], etc. These optimization algorithms address these challenges with their excellent heuristic search capabilities and ability to find satisfactory solutions within a short time.

Kumano et al. modeled the formulation process as a constrained scheduling problem, adopting a hybrid model combining PSO and linear programming to overcome its inherent nonlinearity and optimize raw material operations in steel production [16]. However, this method still needs manual modification and takes two minutes to solve. Zi et al. proposed a multi-objective simulated annealing algorithm that enhanced the exploration of Pareto optimal solutions by introducing a decision space search strategy, thereby addressing the evaluation issues of coke quality and coal blending costs in complex coking-coal blending processes [17]. This study considered the cost, ash content, and sulfur content at the same time, but simplified the proportion range of each raw material. Hu et al. developed a coal quality prediction model based on a PSO-enhanced feedforward neural network to tackle the issues of inaccurate coal quality calculations and overly simplistic coal formulation schemes in thermal power plants. This model does not consider any constraints, so it is difficult to apply in the actual scene [18]. Wu et al. proposed a multi-metal multi-objective hybrid model optimization method that uses the Artificial Bee Colony algorithm to minimize grade fluctuation, mining transportation costs, and production capacity constraints, significantly improving the recovery rates of tungsten, molybdenum, and bismuth [19]. The model reduces the multi-objective problem to a single-objective one by assigning predefined weights to the three objectives, thereby simplifying the computation; however, such a weighted-sum approach may fail to capture the full Pareto front and can bias solutions toward certain objectives. Chen et al. implemented a closed-loop dynamic optimization of formulation parameters in the zinc smelting process using a variational Bayesian approach [20]. The model combines variable Bayesian, expert rules, and chance constrained programming, and achieves an increase in the compliance rate compared with manual mixing. Wang et al. modeled the copper smelting process as a single objective function problem and obtained raw material formulation schemes using an improved PSO algorithm to assist decision-making [21]. For the multi-objective ore formulation problem involving ores of different grades, Chen et al. suggested that, in addition to profit, the stability of the mixed product should also be considered. An improved GA based on non-dominated sorting was adopted to obtain satisfactory solutions [22]. Li et al. introduced a coal formulation optimization framework for coal-fired power plants by establishing a mathematical model aimed at cost minimization and employing a novel multi-strategy fusion multi-objective particle swarm optimization method, which achieved high-quality Pareto distributions under different weight combinations and significantly improved both economic and environmental benefits [23]. Although numerous algorithms have been successfully applied to coal blending, coking, and nonferrous ore blending, their process models and constraint sets differ significantly from those required for RHF operations. In particular, most of the existing work focuses on minimizing economic costs or optimizing the metallurgical grade, but rarely addresses the RHF specific need to account for current inventory levels in order to reduce the frequency of blend ratio changes. They also overlook strict downstream compositional requirements and the fact that each raw material can only be adjusted within a fixed usage range.

Although intelligent optimization algorithms have made some progress in solving formulation optimization problems, the optimization of RHF formulation schemes still faces challenges. Traditional formulation schemes based on human experience are usually computationally complex and struggle to balance multiple objectives during production, leading to fluctuations in product quality and reduced production efficiency. In recent years, the Human Learning Optimization (HLO) algorithm, as a novel meta-heuristic algorithm, has demonstrated significant potential in the field of complex engineering optimization. By simulating the mechanisms of random learning, individual learning, and social learning in human learning behavior [7], the algorithm has exhibited advantages in rapid convergence and global search capabilities for solving optimization problems. The research team has continuously improved the HLO framework and Wang et al. introduced a relearning operator to enhance the solving capability for the multidimensional knapsack problem [24]. Ding and Gu proposed the HLO-PSO hybrid algorithm, which integrates particle swarm optimization strategies to enhance adaptability for workshop scheduling problems [25]. At the engineering application level, HLO has seen numerous improved algorithms, such as fuzzy PID optimal control for power plants [26], adaptive hybrid encoding for flame segmentation [27], the optimization of kernel parameters and regularization coefficients for furnace temperature prediction [28], the optimization of support vector regression (SVR) functions for mine blasting operations [29], and the construction of models to simulate the dynamic behavior of ultra-supercritical power plants [30]. These studies not only confirm the strong potential of HLO and its improved algorithms in complex engineering optimization problems, but also demonstrate that its learning mechanism can effectively coordinate the balance among multiple optimization objectives. This unique advantage in solving formulation optimization problems characterized by multi-objective conflicts provides both theoretical support and a technical pathway for the optimization of RHF formulation schemes.

Human Learning Optimization (HLO) has demonstrated significant advantages across numerous industrial applications. By emulating human learning processes, HLO can incorporate the heuristic approaches that engineers use when addressing RHF blending challenges. Compared to other metaheuristic methods, HLO is particularly adept at generating strategies that closely align with real-world operational requirements.

3. The Mathematical Model for RHF Formulation Scheme Optimization

3.1. Material Formulation

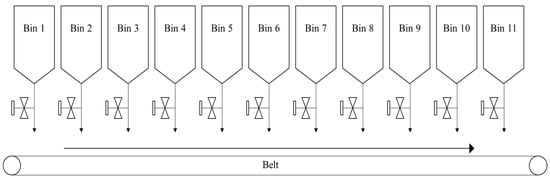

This paper focuses on a RHF production line with an annual output of 250,000 tons in Shanghai Baosteel. The RHF investigated in this study features an internal diameter of 30 m, an effective hearth width of 5 m, and a material bed thickness of approximately 25 mm. The furnace rotates at a speed corresponding to 15 to 40 min per revolution, depending on the operating conditions. The operating temperature is maintained within the range of 1050 °C to 1300 °C. The raw materials from the 12 raw material bins shown in Figure 1 are mixed in a blending system and then conveyed to the pelletizing section, where they are formed into green pellets using a briquetting machine. The green pellets are subsequently dried in a pellet dryer to reduce their moisture content below 2%, and finally transported into the rotary hearth furnace via a belt conveyor.

Figure 1.

A schematic diagram of the rotary hearth furnace blending system.

Bin 1 contains environmental dust, bin 2 contains CDQ carbon powder, bin 3 contains electric-arc furnace dust, bin 4 contains on-site iron dust, bins 5 and 6 contain LT-OG sludge, bins 7 and 8 contain electric-arc furnace OG sludge, bin 9 contains secondary blast furnace dust, bin 10 contains cold rolling sludge, and bin 11 is the recycling bin. Bins 2 to 10 are internal blending bins, containing solid wastes from steel production, which are the target materials for solid waste treatment in the RHF process

At the production site, the material composition in each of the internal blending bins is periodically sampled and chemically analyzed to obtain detailed analytical reports. These reports cover the content of key elements such as carbon, chlorine, zinc, total iron, and ferrous oxide. The elemental composition of the external blending materials, such as the environmental dust bin and the recycling bin, can be approximated by calculating the weighted average of the current internal material compositions and the current formulation scheme. Materials from bins 1 to 11 fall through quantitative feeders and are transported by the conveyor belt to a high-intensity mixer, where they are blended into pellets. Since the RHF blending process involves only the physical blending of raw materials without chemical reactions, the effectiveness of the formulation scheme is determined by the percentage content of materials from each bin, the production plan, and the current status of the production line. In constructing a computationally tractable optimization model, the following simplifying assumptions are adopted. Firstly, the model deliberately omits stochastic factors such as raw material composition variability, pellet breakage probability, and furnace condition disturbances. This intentional simplification facilitates focused the development of the optimization algorithm to generate formulation schemes that satisfy actual production requirements. Secondly, during algorithm execution, it is assumed that these raw material chemical compositions exactly match the measured values and that other physical properties do not affect pellet formation. Finally, materials from Bins 1 to 11 are delivered via quantitative feeders and conveyed by the belt to a high-intensity mixer for homogenization and pelletizing. We assume that all blended materials can be successfully pelletized and that the resulting pellets maintain a sufficient mechanical strength during transportation without significant breakage. Because the RHF blending and pelletizing processes involve only physical mixing without chemical reactions, the effectiveness of the formulation scheme depends solely on the percentage content of materials from each bin, raw material chemical compositions, the production plan, and the real-time production line status.

Based on the above assumptions, the core objectives of the blending process, and the various production constraints, the design of a formulation scheme is considered as a multi-objective optimization problem, with the goal of developing a pellet blending strategy that meets process requirements. The optimization goals include the following four aspects: limiting element content, reducing changes in the formulation scheme, increasing the continuous operation time, and minimizing the start–stop operations of the bins. Below, the multi-objective optimization model for the RHF blending scheme will be described in terms of optimization variables, constraints, and objective functions.

3.2. Optimization Variables

In the proposed multi-objective optimization model, the optimization variables are defined as the percentage of the output material flow from each bin in the RHF production line relative to the total flow, denoted as , and referred to as formulation ratios. The index ranges from 1 to 11, corresponding to the 11 material bins. As mentioned in Section 3.1, bins 2 to 10 are internal blending bins. The core task of the formulation scheme is to determine the output proportion for these bins. The proportion of bin 1 and bin 11 are generally not adjusted during actual production. The proportion of all these 11 bins constitute the RHF formulation scheme :

where to are optimization variables. The set proportion for each optimization variable is defined as a floating-point number between 0 and 1, and is rounded to two decimal places.

3.3. Objective Functions

During the process of designing the scheme, it is necessary to comprehensively consider multiple optimization objectives to meet production requirements while achieving an optimal balance between production efficiency and product quality. The objective functions of the multi-objective optimization model are described as follows:

- Element content: The content of each element (C, Cl, and Zn) in the blended pellets, as well as the ratios of the aforementioned elements (C/O and Cl/Zn), needs to be maintained within specific ranges determined by the production plan. This ensures that the final product from the blending system meets specific chemical composition requirements, which is crucial for guaranteeing the performance and quality of the product. The calculation formulas are as follows:where refers to the contents of three elements: C, Cl, and Zn, as well as the ratio of C to O and the ratio of Cl to Zn, is the element content corresponding to the blended material, and and are the upper limit and lower limit of the allowed range, respectively. The fitness function guarantees that the formulation scheme satisfies the process requirements as much as possible within the feasible region. In extreme cases, even if no formulation scheme fully meets the allowable element content range given by Equation (2), the optimization algorithm will prioritize selecting the scheme that is closest to the target range.

- Similarity of the formulation scheme: According to the on-site production experience of RHF, if the difference between the new formulation scheme and the current one is too large, it may lead to instability in material flow on the conveyor belt, thereby causing unpredictable fluctuations and increasing the generation of waste during the recycling process. Therefore, the new formulation scheme similar to the current one are more preferable. The formula to evaluate the similarity between formulation schemes is as follows:where represents the proportion in the original formulation scheme.

- Continuous operation time: After implementing a new formulation scheme, it is necessary to maintain long-duration continuous operation so as to reduce the frequency of switching between schemes and minimize manual interventions. This optimization objective aims to minimize the impact of raw material shortages on the RHF production under the current operating conditions by prioritizing the use of bins with inventory levels, while also providing buffer capacity to address unexpected material supply issues. The formula for calculating the object of continuous operation time is as follows:where is the time required for the remaining material in bin to be depleted, is the remaining material weight in bin , and is the total output flow of all bins in the blending system. The continuous operation time of the formulation scheme is determined by the first bin to be depleted. To facilitate subsequent processing, the negative value is taken to convert this optimization objective into a minimization problem.

- Start–stop switching: Each time a start–stop switching occurs in a bin, the conveyor belt carrying the material becomes unstable. Therefore, when optimizing the formulation scheme, it is essential to minimize start–stop switching to maintain stable operating conditions in the blending system. The calculation formula is as follows:where is the start–stop status indicator for the corresponding bin. When the proportion of a bin changes from 0 to a value greater than 0, it indicates the bin is activated; when the proportion of a bin changes to 0, it indicates the bin is deactivated. In both scenarios, is set to “1” to signify a change in the bin’s operational status. Otherwise, is set to “0” to indicate the bin’s operational status remains unchanged.

3.4. Constraints

This paper requires that the formulation scheme satisfies the following two constraints.

- To ensure the effectiveness of the formulation scheme, the sum of the proportions for the internal bins must equal 1. This constraint guarantees the consistency of the sum of the proportion values in each blending scheme, thereby maintaining balance in the production process, i.e.

- The proportion of each bin needs to be kept within a reasonable range, i.e.where indicates that the bin is not in use, while and are the upper limit and lower limit of the allowed proportion range for the corresponding bin. If exceeds the maximum flow limit , the feeders and belts in the blending system will be unable to output material flow rates beyond this upper limit. Conversely, if falls below the minimum flow limit , the feeders and belts may operate at their lowest flow rate, thereby increasing flow control errors, wasting operational resources, and leading to a decline in production efficiency.

In summary, the multi-objective optimization problem for the RHF formulation scheme addressed in this paper is a continuous multi-objective optimization problem with four optimization objectives and two constraints, which is formulated as the following minimization problem:

4. IMOAHLO Algorithm

The improved multi-objective adaptive human learning optimization (IMOAHLO) algorithm is adopted to solve the optimization problem described in Section 3, which is derived from the fundamental HLO algorithm and primarily includes the following components.

4.1. Individual Encoding and Initialization

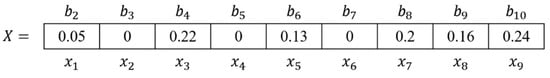

In the optimization problem described in Section 3, the proportions of internal blending bins require optimization, resulting in a total of nine optimization variables, represented as to and encoded using floating-point numbers. Therefore, each individual in the IMOAHLO algorithm is a 9-dimensional row vector, as shown in Equation (12). Figure 2 gives a coding example for an individual.

Figure 2.

An individual coding example.

to are optimization variables corresponding to bins 2 to 10 () and numbers in the box represent the current blending ratio of each raw material.

During initialization, 90% of the individuals in the population are randomly generated and normalized to satisfy Equation (2). Meanwhile, considering that the original proportions have certain reference values and that there is a practical preference for minimizing fluctuations in operating conditions, the remaining individuals are set according to Equation (13):

where and are stochastic numbers between 0 and 1, and is the original proportions.

4.2. Random Learning Operator (RLO)

Throughout the entire learning process of the IMOAHLO algorithm, random learning is consistently applied. Especially during the initial stage, due to the lack of prior knowledge, extensive random searches are required to explore potential solutions. In the middle and later stages of the algorithm, random learning is employed to maintain the diversity of solutions. Equation (14) simulates the random exploration behavior of humans:

where and represent the upper and lower bounds in the constraint conditions, while and are stochastic numbers between 0 and 1. To explore formulation schemes with deactivated bins, the optimization variables have a 50% probability of being updated to zero. In this way, the random learning operator is improved to effectively explore the entire solution space. An illustrative example of the implemented random learning operator is shown in Figure 3. For an individual undergoing random learning, any variable marked in green is set to either 0 or a random value within the allowed range, based on the random number .

Figure 3.

An example for performing RLO.

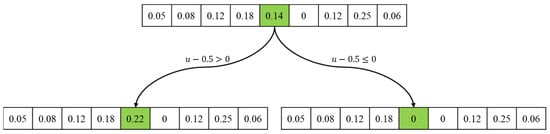

4.3. Individual Learning Operator (ILO)

Individual learning is a spontaneous learning behavior of humans, which generates solutions that meet the requirements according to the existing knowledge and experience of individuals. Self-learning and self-inspection can effectively enhance problem-solving abilities. To simulate this self-learning behavior, the IMOAHLO algorithm enhances its search capabilities through the individual learning operator. The individual knowledge database (IKD) is used to implement the memory function of individuals. The IKD is defined as follows:

where is the IKD of the -th individual, is the value of the -th variable of the -th solution in the -th individual’s IKD, and , , and are the population size, the size of the individual knowledge database, and the solution dimension, respectively. When executing the individual learning operator, an individual generates a new solution as Equation (17):

where is a stochastic number between 0 and 1, and is a solution from the IKD corresponding to the -th individual. and are the individuals before and after the operator execution, respectively. When the algorithm performs individual learning, it explores potential optimal solutions by combining the current solution with the solution from the knowledge database based on random numbers. Figure 4 presents an example of an individual undergoing self-learning when the random number is 0.2. Each variable in updated via individual learning is recalculated using Equation (17), based on the corresponding IKD value and the random number , thereby forming the new individual .

Figure 4.

An example for performing ILO.

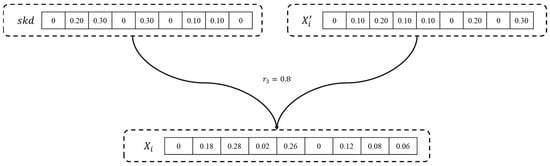

4.4. Social Learning Operator (SLO)

Humans can independently solve some problems. However, when the problems become complex, the efficiency of individual learning might be insufficient to handle them. Social learning plays a crucial role in human learning, as it significantly improves learning efficiency through knowledge sharing. By imitating excellent examples, useful information can be accumulated. The social learning operator is used to mimic human social learning behavior. The social knowledge database (SKD) is defined as Equation (18):

where represents the -th solution in the SKD, and is the size of the SKD. When executing the social learning operator, an individual generates a new solution as Equation (19):

where is a stochastic number between 0 and 1, and is a solution from the SKD. Similar to the individual learning operator, during the social learning process, the algorithm explores potential optimal solutions by combining the current solution with the solution from the knowledge database based on random numbers. Figure 5 illustrates an example of an individual performing social learning when the random number is 0.8. Each variable in updated via social learning is recalculated using Equation (19), based on the corresponding SKD value and the random number , thereby forming the new individual .

Figure 5.

An example for performing SLO.

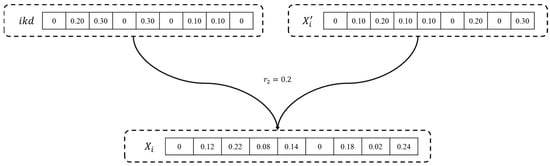

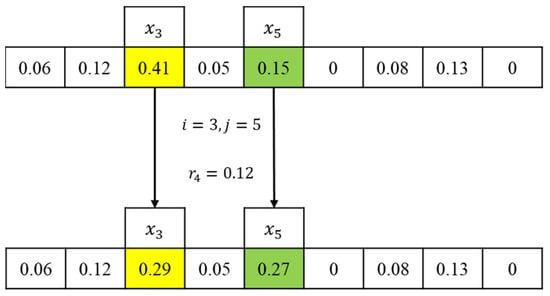

4.5. Neighborhood Search Operator (NSO)

When solving optimization problems, it can be observed that humans often adopt a strategy of making small random adjustments to the original solution in search of potential better solutions. For example, in order to optimize a relatively good formulation scheme, one might slightly reduce the proportion of a certain material and adjust the other proportions to meet the constraints. By summarizing this behavior, a new neighborhood search operator is developed to perform searches in IMOAHLO, thereby enhancing its local search capabilities. This helps the algorithm to refine the solution after discovering a better one, improving the quality of the solution and the precision of the algorithm. The neighborhood search operator is typically used to explore potential better solutions in the vicinity of the current solution, making it particularly useful for local optimization. When executing the neighborhood search operator, individuals are updated according to Equation (20):

where and are two randomly selected indices of non-zero elements in , and is a stochastic number between 0 and . This operator simulates the common practice of engineers when dealing with such problems, which involves conducting further local searches around relatively optimal solutions, thereby enhancing the algorithm’s local search capability and ensuring that the obtained solutions meet practical engineering requirements. Figure 6 illustrates an example of an individual performing neighborhood search on two nonzero variables, and , when the random number is 0.12. An individual performing neighborhood search randomly selects two non-zero variables, and , and then updates them using the random number . The resulting new values are and .

Figure 6.

An example for performing NSO.

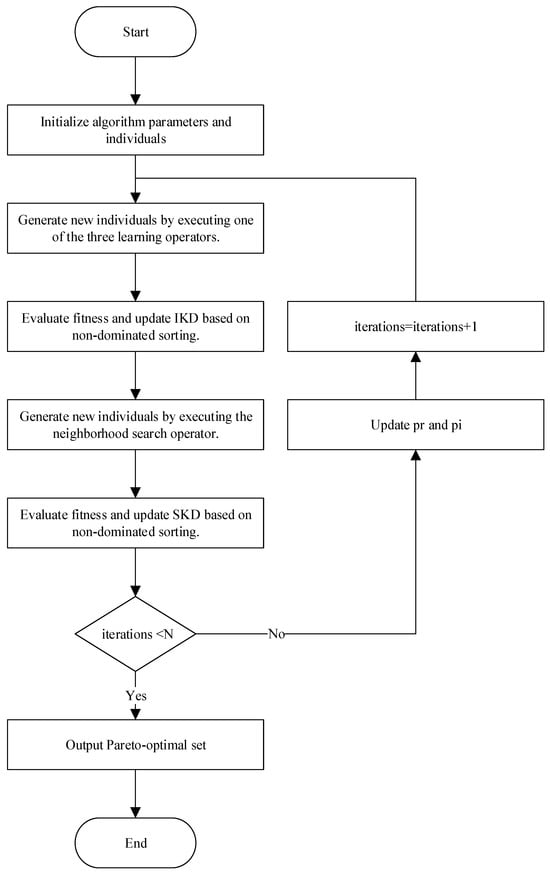

4.6. Algorithm Implementation

During the algorithm’s iterative process, each individual executes only one of the three operators—RLO, ILO, or SLO. Additionally, after each iteration, individuals with a better performance will execute the NSO to seek better solutions. The individual generates a new solution using one of the three learning operators as described in Equation (21):

where is a stochastic number between 0 and 1, and and represent the random learning probability and individual learning probability, respectively. Together, they determine the probability of everyone selecting different learning operators. Obviously, and affect the algorithm’s search performance. Improper settings can lead to insufficient solution diversity or difficulty in convergence. An adaptive mechanism is employed in the IMOAHLO algorithm to dynamically adjust and , defined as follows:

where and are the control parameters for the decay rates of and , and and represent the current iteration number and the total number of iterations, respectively. As the algorithm runs, individuals transition from a preference for random learning to a preference for social learning, which helps ensure solution diversity while promoting the convergence of the algorithm. Figure 7 illustrates the implementation flowchart of the IMOAHLO algorithm.

Figure 7.

A flowchart of the IMOAHLO algorithm.

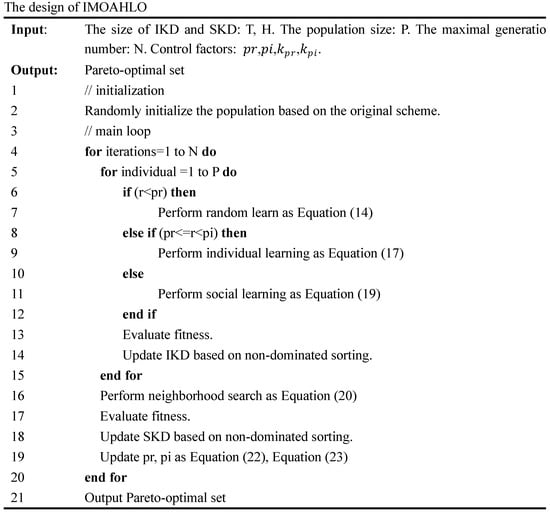

Based on the design described above, the details of the IMOAHLO algorithm are outlined in Figure 8.

Figure 8.

The design of IMOAHLO.

5. Experimental Results and Cases Analysis

Section 3 developed a multi-objective mathematical model for raw material blending based on production requirements and assumptions, while Section 4 proposed the improved IMOAHLO algorithm to solve this model. Building on these foundations, this section integrates the model input variables and constraints defined in Section 3 with the algorithmic workflow presented in Section 4 to perform a comparative analysis of optimization algorithm performance on real-production data, thereby evaluating IMOAHLO’s performance with three multi-objective algorithms: the Non-Dominated Sorting Genetic Algorithm II (NSGA-II) [14], Multi-Objective Human Learning Optimization Algorithm (MOHLO) [8], and Speed-Constrained Multi-Objective Particle Swarm Optimization Algorithm (SMPSO) [15].

These four multi-objective optimization algorithms are deployed on the RHF production line computers and run in parallel with the manual schemes in the blending system. The optimization algorithms update the recommend formulation schemes on a fixed schedule and display the results on the human–machine interface. Field operators review the current RHF operating conditions and the fitness values from each algorithm’s formulation scheme to decide whether to update the active blending plan. All computed blending proposals are stored in a historical database for future reference. Due to the huge amount of data, 100 on-site proposals of formulation schemes under different conditions were selected from the historical database during November to December 2024, along with the corresponding chemical composition and raw material inventory levels.

To ensure the optimality of the results, all algorithms used the same calibration parameter method. Apart from the solving process, all algorithms employed identical encoding, decoding, and other operations to ensure a fair evaluation of their performance. The termination condition for all algorithms was set to stop after the same number of iterations with the same population size. The implementation and execution were carried out on the line computer running the Windows 10 operating system with MATLAB R2023b. The computer is equipped with an Intel Core i7-7700HQ CPU @ 2.80 GHz processor with 8 GB of RAM.

5.1. Analysis of the Algorithm Parameters

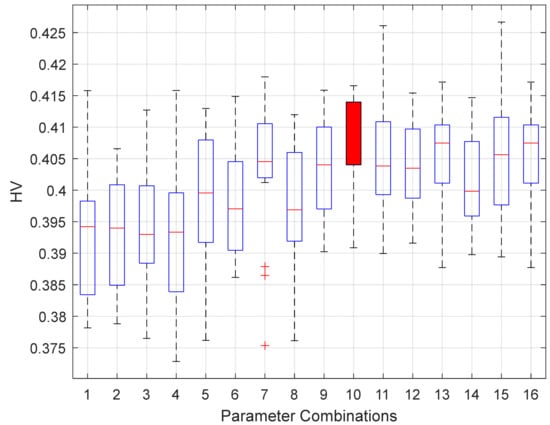

Given the paramount influence of parameters on algorithm performance, it is necessary to calibrate the parameters for each algorithm. For the proposed IMOAHLO algorithm, the parameters to be calibrated are the random learning probability (), the probability of individual learning (), the random learning decay rate (), and the individual learning decay rate . The four parameters have the following levels: (0.4, 0.6, 0.8, 1.0), (0.8, 1.0), (0.6, 0.8, 1.0), and (0.4, 0.6, 0.8). Orthogonal experiments were conducted to select the optimal parameter combination. Table 1 presents the orthogonal experiment parameter groups and the results.

Table 1.

Orthogonal arrays and mean HV.

To determine the optimal parameter combination, experiments were conducted using hypervolume (HV) as the evaluation metric. HV represents the volume of the obtained Pareto front. The calculation formula is shown in Equation (24):

where represents the hypervolume formed by the -th solution in the given solution set and the reference point. The larger the HV value, the better the overall performance of the algorithm. Due to the difficulty of calculating HV, this paper approximates the volume of the Pareto front obtained by the algorithm through Monte Carlo simulation. Each set of parameters is run 20 times under 20 cases. The test results for different parameter groups are shown in Figure 9.

Figure 9.

The algorithm HV indicator under different parameters.

It can be seen that the optimal parameter combination for the proposed algorithm is group 10 ( = 0.8, = 1.0, = 0.6, and = 0.8). Under these parameters, the algorithm’s performance is the best, with an average HV value of 0.407305. The same experimental method was used to determine the parameters of the other three algorithms. Table 2 summarizes the optimal parameters after calibration for all algorithms.

Table 2.

A summary of the algorithm parameters.

5.2. Evaluation and Comparison

This section endeavors to provide a comparative analysis of the proposed IMOAHLO algorithm alongside other widely utilized multi-objective optimization algorithms, specifically the fast Non-Dominated Sorting Genetic Algorithm (NSGA-II), the Multi-Objective Human Learning Optimization Algorithm (MOHLO) and the Speed-Constrained Multi-Objective Particle Swarm Optimization Algorithm (SMPSO). To compare the performance of the aforementioned multi-objective algorithms, Hypervolume (HV), Inverted Generational Distance (IGD), and Generational Distance (GD) are employed as evaluation metrics. The calculation method of HV is shown in Section 5.1. The detailed introductions of IGD and GD are as follows.

IGD is a metric for the diversity and convergence of the solution set generated by the algorithm. Its calculation formula is as Equation (25):

GD is a metric for the convergence of the solution set generated by the algorithm. Its calculation formula is as Equation (26):

where is the Euclidean distance, is the number of solutions in the reference set and is the number of solutions in the obtained solution set. The smaller the IGD and GD values, the better the performance of the algorithm.

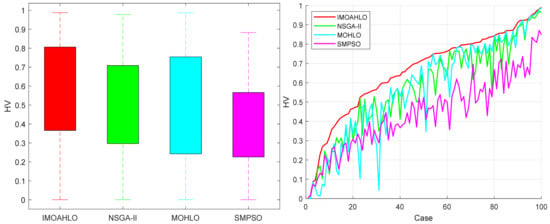

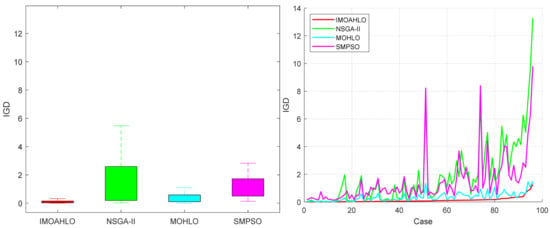

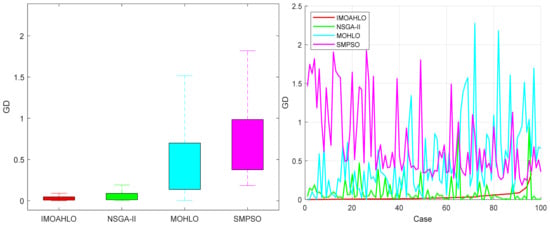

All algorithms were independently run 30 times with a population size of 100 and 100 iterations. The solution sets obtained by all algorithms were subjected to non-dominated sorting, and the non-dominated solution set were taken as the true Pareto front. The computational results are presented in Figure 10, Figure 11 and Figure 12 and Table 3.

Figure 10.

Comparative results of the four algorithms on the HV metric.

Figure 11.

Comparative results of the four algorithms on the IGD metric.

Figure 12.

Comparative results of the four algorithms on the GD metric.

Table 3.

Test results of four algorithms.

Figure 10 shows the block plots and line charts of the average HV metric for 30 independent runs of four multi-objective optimization algorithms under 100 test cases. For clarity, the 100 cases are sorted according to the metric results of the IMOAHLO algorithm. It is observed that the IMOAHLO algorithm outperformed other algorithms, achieving better results than NSGA-II and MOHLO, and significantly better than SMPSO, which indicates that IMOAHLO has better performance in multi-objective optimization problems. Figure 11 and Figure 12 show the IGD and GD metrics in the same way, respectively, clearly illustrating the differences among the four algorithms. The smaller the IGD and GD values, the closer the solution set generated by the algorithm is to the true Pareto front, indicating the better the performance of the algorithm. In terms of IGD and GD metrics, IMOAHLO surpasses the other three algorithms significantly. This success is attributed to the algorithm’s diverse search strategy and its adaptive mechanism, which continuously adjusts individual search strategies throughout the entire iteration process.

Table 3 summarizes the performance comparison of four multi-objective optimization algorithms—IMOAHLO, NSGA-II, MOHLO, and SMPSO—using three commonly accepted metrics. Each entry in the table reports the mean value ± standard deviation over 30 independent runs. HV measures the volume of objective space dominated by the obtained Pareto front relative to a reference point, with larger values indicating a better convergence and diversity. In Table 3, IMOAHLO achieves an average HV of 0.5636 ± 0.2892, which is higher than NSGA-II (0.5040 ± 0.2676), MOHLO (0.4913 ± 0.3023), and SMPSO (0.3870 ± 0.2193). This result demonstrates that IMOAHLO consistently finds Pareto-front solutions that cover a larger portion of the desirable objective space with a greater spread. IGD quantifies the average distance from points on the true Pareto front to the approximated front; lower IGD values indicate that the algorithm’s solutions closely approximate the true Pareto front. IMOAHLO’s IGD is 0.1271 ± 0.1948, which is substantially lower than MOHLO (0.3477 ± 0.3263), SMPSO (1.4313 ± 1.7409), and NSGA-II (1.8104 ± 2.2911). The much smaller mean and tighter standard deviation for IMOAHLO imply a more accurate and stable convergence toward the reference front across repeated runs. GD measures the average distance from the approximated Pareto front to the true front. Again, smaller values are preferable. In this metric, IMOAHLO obtains 0.0320 ± 0.0492, outperforming NSGA-II (0.0952 ± 0.1586), MOHLO (0.4678 ± 0.4749), and SMPSO (0.7442 ± 0.4936). The low GD mean and small deviation of IMOAHLO indicate that its solutions lie consistently close to the true Pareto set, confirming its superior convergence ability.

Compared to the other three algorithms, IMOAHLO’s average HV is 11.8% higher, while its average IGD and GD values are only 36.6% and 33.6% of those of the other methods, respectively. Taken together, the results in Table 3 clearly demonstrate that IMOAHLO outperforms the other algorithms across three evaluation metrics. Its higher HV, coupled with a significantly lower IGD and GD, confirms that IMOAHLO not only finds a wider, more diverse set of Pareto-optimal solutions but also converges more precisely to the true optimal front. These quantitative improvements substantiate IMOAHLO’s enhanced search capability and robustness in RHF-blending scenarios.

5.3. Cases Analysis

This section conducts a detailed analysis on two representative cases from 100 test cases in Section 5.2, evaluating algorithmic performance under typical real-world production conditions. Such analysis is particularly crucial for evaluating the performance of different optimization algorithms in practical applications, as it helps identify which algorithms can more effectively adapt to changes in raw materials, thereby maintaining the continuity and efficiency of the production process. In both of the two cases, the total raw material flow is 18t/h, and the proportion ranges for each bin as well as the elemental composition limits of the blended pellets specified by the production plan are shown in Table 4.

Table 4.

Proportion limitations and element content limitations.

In Table 5, Case I presents a resource-constrained scenario in which a specific raw material is approaching depletion, necessitating the formulation of a reasonable scheme. Among the multi-objective optimization solution sets provided by the four optimization algorithms, the final solution for each algorithm is chosen based on the weighted sum and normalized fitness values. This approach allows for the selection of a solution that comprehensively considers multiple objectives, with the goal balancing different performance metrics such as cost, efficiency, and quality.

Table 5.

Optimization results of different algorithms in Case I.

Facing the urgent scenario where the remaining materials in bin 6 and bin 8 were nearly exhausted, the IMOAHLO algorithm demonstrated a high degree of adaptability and intelligent decision-making by proactively deactivating bin 6, which contained an extremely low remaining material volume. The NSGA-II and MOHLO algorithms made similar decisions. The remaining material weight in bin 8 is relatively low, but since the current proportion is set at 0.4, the material in bin 8 will be quickly depleted if this proportion remains unchanged. The IMOAHLO algorithm preemptively adjusted the proportion from 0.4 to 0.07, effectively increasing the operation time of the formulation scheme from the original 1.28 h to 7.32 h, thereby providing sufficient time for subsequent material replenishment.

Table 6 presents the fitness function results of the four optimization algorithms and the manual formulation scheme. The IMOAHLO algorithm exhibited the best performance. An element content value of 0 indicates that the elemental composition of the blended pellets met the required specifications. The similarity difference between the new scheme and the original one was 1.1. The operation time is −7.32 where the negative sign indicates that the system can continue to operate for 7.32 h under the current conditions. A start–stop switching value of 2 means that two bins were either deactivated or activated. In the table, the manual formulation scheme failed to consider the maximum operation time, which would lead to rapid material depletion and frequent updates of the formulation scheme. The MOHLO and SMPSO algorithms generated similar fitness function values and did not significantly extend the operation time. The IMOAHLO algorithm adjusted the proportion in bin 8 from the original scheme’s 0.4 to 0.07 and triggered only two start–stop operations, achieving a longer operation time with minimal adjustments. Benefiting from the neighborhood search operator’s fine-tuning of local solutions and an adaptive mechanism that prioritizes the social learning operator in later iterations to accelerate convergence, the IMOAHLO algorithm can rapidly adjust its strategy to devise a reasonable formulation scheme in a resource-constrained production environment.

Table 6.

The objective function results of different algorithms in Case I.

Case II illustrates another multi-objective conflict scenario that demands a superior formulation scheme. Although the original scheme can achieve long-term operation, the C element content in the blended pellets reached 11.23%, exceeding the standard by 1.23%. This indicated that there was still room for optimization in terms of element composition. Table 7 shows the optimization results of the various algorithms. From the optimization results, it is evident that each algorithm conducted its search within the constraints based on the originally set values. Table 8 summarizes the fitness function results obtained by each algorithm under this case.

Table 7.

Optimization results of different algorithms in Case II.

Table 8.

The objective function results of different algorithms in Case II.

Although the manually implemented formulation scheme significantly optimized the elemental content limits after adjustments, there remains room for improvement because it is challenging for humans to fully consider all factors. In contrast, the IMOAHLO algorithm, by leveraging its broader solution search space, successfully identified a solution that completely meets the elemental content requirements. Compared with the NSGA-II and MOHLO algorithms, which also satisfy the element ratio requirements, the IMOAHLO algorithm extended the operation time to a maximum of 10.30 h, thereby reducing workload and enhancing system stability. Moreover, the scheme similarity provided by the IMOAHLO algorithm is significantly lower than that of the SMPSO and MOHLO algorithms. These results indicate that the IMOAHLO algorithm can better balance solution diversity and convergence while satisfying the constraints. By dynamically balancing exploration and exploitation, it effectively uncovers high-potential solutions from the non-dominated solution set, thereby offering a more stable and reliable formulation scheme for practical production.

In summary, compared with manual formulation schemes and other multi-objective optimization algorithms, the advantages of the IMOAHLO algorithm in solving the RHF formulation optimization problem lie not only in its ability to adapt to different production conditions and resource constraints but also in its capacity to achieve a superior multi-objective balance at a lower adjustment cost, especially in maintaining solution diversity when handling multiple conflicting objectives. The outstanding flexibility and remarkable performance of the IMOAHLO algorithm validate the design concept of synergistic enhancement through neighborhood search and adaptive mechanisms, providing a solution that balances stability and flexibility for complex industrial optimization problems.

6. Conclusions and Future Work

In addressing the practical engineering problem of RHF raw material blending, this paper constructs a multi-objective optimization mathematical model with two constraints and four objective functions, and proposes an IMOAHLO algorithm. Unlike prior studies’ conventional focusing on singular objectives of economic cost minimization or metallurgical grade maximization, the mathematical model developed in Section 3 systematically incorporates the following multidimensional constraints. Elemental content constraints ensure the blended green pellets meet strict compositional requirements. Scheme similarity constraints limit the degree of change between successive formulation schemes to reduce operational disruptions. Continuous operation constraints and start–stop penalties reflect the real cost of opening or closing the valve. This model therefore fills a critical research gap by incorporating the full spectrum of practical engineering considerations encountered by operators in real-world scenarios. Building on the classical HLO framework, a novel mechanism was introduced in Section 4: a neighborhood search operator that intensifies local exploration around promising solutions, thereby improving the precision of fine-tuning each formulation scheme. IMOAHLO’s hybrid search strategy is specifically tailored to the high-dimensional, continuous characteristics of RHF formulation schemes, achieving significantly superior Pareto-front coverage and convergence compared to other well-known algorithms. One hundred real production datasets collected from a steel-plant RHF line demonstrate that the proposed algorithm achieves a clear performance improvement: the average HV increases by 11.8%, while the average IGD and GD are only 36.6% and 33.6% of those of the other algorithms, respectively. Additionally, two typical case studies further demonstrate that the IMOAHLO algorithm can improve system stability, reduce operational fluctuations, and optimize the elemental composition of blended materials in scenarios with resource constraints and dynamic conflicts, proving its remarkable performance and decision robustness in practical applications.

However, this study has some limitations that need further improvement. Firstly, the primary purpose of the RHF is to recover and reuse waste streams generated by other production units. The proposed scheme optimization model focuses on how to incorporate those external waste fractions in a stable, continuous manner to ensure the long-term unattended operation of the blending line. In evaluating the model’s performance, this paper primarily examined relevant algorithmic performance metrics. However, different schemes significantly impact the drying and combustion processes in the rotary hearth furnace, ultimately impacting key production indicators such as fuel consumption rate, pelletizing yield, and metallization rate. Therefore, subsequent research will focus on using these industrial KPIs as evaluation benchmarks to conduct comprehensive and systematic assessments of formulation scheme performance, thereby establishing a more precise-process optimization model. Secondly, due to resource and time constraints, this study did not perform a full thermodynamic or detailed process simulation to validate the optimized formulation schemes. Without comprehensive process modeling, optimizing only the formulation schemes leaves uncertainties regarding practical performance. Therefore, future research will focus on coupling the scheme optimization model with drying and reduction process simulations to achieve whole-chain optimization, ensuring that the optimization model yields the desired results under actual operating conditions. Finally, since this study mainly focuses on the raw material blending problem for the RHF production line, future work could extend the algorithm to multi-objective optimization problems in fields such as chemicals and energy, further validating its generality and applicability, and assisting industrial systems in transforming toward more intelligent and sustainable operations.

Author Contributions

Conceptualization, J.Y.; methodology, L.W.; software, S.Z.; data curation, S.Z.; writing—original draft preparation, S.Z.; writing—review and editing, J.Y.; funding acquisition, X.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 62073210.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| RHF | Rotary hearth furnace |

| IMOAHLO | Improved multi-objective adaptive human learning optimization |

| HLO | Human Learning Optimization |

| PSO | Particle Swarm Optimization |

| RLO | Individual learning operator |

| IKD | Individual knowledge database |

| SLO | Social learning operator |

| SKD | Social knowledge database |

| NSO | Neighborhood search operator |

| NSGA-II | Non-Dominated Sorting Genetic Algorithm II |

| MOHLO | Multi-Objective Human Learning Optimization |

| SMPSO | Speed-Constrained Multi-Objective Particle Swarm Optimization |

| HV | Hypervolume |

| IGD | Inverted Generational Distance |

| GD | Generational Distance |

References

- Zhao, Z.; Kong, F.; Tong, L.; Yin, S.; Xie, Y.; Wang, L. Analysis of Carbon Dioxide Emission Reduction Path and Potential in China’s Steel Industry Based on the “3060” Target. Steel 2022, 57, 162–174. [Google Scholar] [CrossRef]

- Chen, J. Research on Industrial Metabolic Regulation of Steel Manufacturing System Towards Low-Carbon Goals. Ph.D. Thesis, Wuhan University of Science and Technology, Wuhan, China, 2024. [Google Scholar]

- Shi, L.; Chen, R.; Wang, R. The current status and development direction of resource utilization of zinc containing dust and sludge in the steel industry. China Resour. Recycl. 2009, 27, 19–22. [Google Scholar]

- Qu, H. Research on hot charging and hot delivery technology of metalized pellets in rotary hearth furnace. Shanxi Metall. 2023, 46, 154–155+158. [Google Scholar] [CrossRef]

- Zhu, R.; Ren, J.; Liu, G.; Wan, T.; Xu, M. Development and Practice of Rotary Bottom Furnace Technology. J. Beijing Univ. Sci. Technol. 2007, 171–174. [Google Scholar]

- Sakallı, Ü.S.; Baykoç, Ö.F. Strong Guidance on Mitigating the Effects of Uncertainties in the Brass Casting Blending Problem: A Hybrid Optimization Approach. J. Oper. Res. Soc. 2013, 64, 562–576. [Google Scholar] [CrossRef]

- Wang, L.; Ni, H.; Yang, R.; Fei, M.; Ye, W. A Simple Human Learning Optimization Algorithm. In Computational Intelligence, Networked Systems and Their Applications: International Conference on Life System Modeling and Simulation, LSMS 2014 and International Conference on Intelligent Computing for Sustainable Energy and Environment, ICSEE 2014, Shanghai, China, 20–23 September 2014; Fei, M., Peng, C., Su, Z., Song, Y., Han, Q., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 56–65. [Google Scholar]

- Cao, J.; Yan, Z.; He, G. Application of Multi-Objective Human Learning Optimization Method to Solve AC/DC Multi-Objective Optimal Power Flow Problem. Int. J. Emerg. Electr. Power Syst. 2016, 17, 327–337. [Google Scholar] [CrossRef]

- Yang, Y.; dela Rosa, L.; Chow, T.Y.M. Non-Convex Chance-Constrained Optimization for Blending Recipe Design under Uncertainties. Comput. Chem. Eng. 2020, 139, 106868. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Y.; Sun, B.; Li, Y.; Zhu, H.; Chen, Z. A Chance-Constrained Programming Approach for a Zinc Hydrometallurgy Blending Problem under Uncertainty. Comput. Chem. Eng. 2020, 140, 106893. [Google Scholar] [CrossRef]

- Long, J.; Jiang, S.; He, R.; Zhao, L. Diesel Blending under Property Uncertainty: A Data-Driven Robust Optimization Approach. Fuel 2021, 306, 121647. [Google Scholar] [CrossRef]

- Amini, S.H.; Vass, C.; Shahabi, M.; Noble, A. Optimization of Coal Blending Operations under Uncertainty—Robust Optimization Approach. Int. J. Coal Prep. Util. 2022, 42, 30–50. [Google Scholar] [CrossRef]

- Huang, Z.; Huang, J.; Luo, J.; Hu, D.; Yin, Z. Performance Enhancement and Emission Reduction of a Diesel Engine Fueled with Different Biodiesel-Diesel Blending Fuel Based on the Multi-Parameter Optimization Theory. Fuel 2022, 314, 122753. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A Fast and Elitist Multiobjective Genetic Algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, X.; Cheng, R.; Qiu, J.; Jin, Y. A Competitive Mechanism Based Multi-Objective Particle Swarm Optimizer with Fast Convergence. Inf. Sci. 2018, 427, 63–76. [Google Scholar] [CrossRef]

- Kumano, A.; Yoshinari, Y.; Yamaguchi, O.; Miyazawa, T. An Optimization for Ore Blending Schedules Using Mathematical Programming Methods. Tetsu-Hagane 2020, 106, 611–620. [Google Scholar] [CrossRef]

- Zi, J.; Jin, F.; Zhao, J.; Wang, W.; Liu, Q. A Multi-Objective Simulated Annealing Algorithm-Based Coal Blending Optimization Approach in Coking Process. In Proceedings of the 2020 IEEE Intl Conf on Dependable, Autonomic and Secure Computing, Intl Conf on Pervasive Intelligence and Computing, Intl Conf on Cloud and Big Data Computing, Intl Conf on Cyber Science and Technology Congress (DASC/PiCom/CBDCom/CyberSciTech), Calgary, AB, Canada, 17–22 August 2020; pp. 103–109. [Google Scholar]

- Hu, T.; Mao, D.; Cheng, P.; Chen, S. Research on a Multi-Objective Optimization Coal Blending Method Based on Coal Quality Prediction. J. Eng. Therm. Energy Power/Reneng Dongli Gongcheng 2021, 36, 151–156. [Google Scholar]

- Wu, J.; Huang, L.; He, B.; Li, Z.; Chen, G.; Chen, G.; Li, X. Research on Multi-Objective Ore Blending Optimization Based on Non-Equilibrium Grade Polymetallic Mine of Shizhuyuan. Minerals 2022, 12, 1358. [Google Scholar] [CrossRef]

- Chen, Y.; Jin, W.; Zheng, L.; Xiu, X.; Huang, Y.; Qiu, W.; Li, Y. Closed-Loop Dynamic Blending Optimization Based on Variational Bayesian and Its Application in Industry. IEEE Access 2023, 11, 494–505. [Google Scholar] [CrossRef]

- Wang, G.; Zhou, S.; Li, B.; Wei, Y. Copper Concentrate Blending and Melting Prediction Based on Particle Swarm Optimization Algorithm. JOM 2023, 75, 4350–4360. [Google Scholar] [CrossRef]

- Chen, L.; Gu, Q.; Wang, R.; Feng, Z.; Zhang, C. Comprehensive Utilization of Mineral Resources: Optimal Blending of Polymetallic Ore Using an Improved NSGA-III Algorithm. Sustainability 2022, 14, 10766. [Google Scholar] [CrossRef]

- Li, J.; Yi, F.; Ma, Y.; Wang, Y. Coal Blending Optimization in Thermal Power Plants Based on Multi-Strategy Fusion Multi-Objective Particle Swarm Optimization. Int. J. Coal Prep. Util. 2024, 44, 1679–1709. [Google Scholar] [CrossRef]

- Wang, L.; Yang, R.; Ni, H.; Ye, W.; Fei, M.; Pardalos, P.M. A Human Learning Optimization Algorithm and Its Application to Multi-Dimensional Knapsack Problems. Appl. Soft Comput. 2015, 34, 736–743. [Google Scholar] [CrossRef]

- Ding, H.; Gu, X. Hybrid of Human Learning Optimization Algorithm and Particle Swarm Optimization Algorithm with Scheduling Strategies for the Flexible Job-Shop Scheduling Problem. Neurocomputing 2020, 414, 313–332. [Google Scholar] [CrossRef]

- Zhang, A.; Zhang, W.; Tong, X.; Wang, X. Research on Variable Domain Fuzzy PID Control Based on the Human Learning Optimization Algorithm. Ind. Control. Comput. 2017, 30, 45–47. [Google Scholar]

- Zhang, P.; Fei, M.; Wang, L.; Wu, X.; Peng, C.; Chen, K. A Novel Segmentation Method for Furnace Flame Using Adaptive Color Model and Hybrid-Coded HLO. Complexity 2021, 2021, 3027126. [Google Scholar] [CrossRef]

- Zhang, P.; Jiang, Y.; Wang, M.; Fei, M.; Wang, L.; Rakić, A. Furnace Temperature Prediction Using Optimized Kernel Extreme Learning Machine. In Proceedings of the 2021 40th Chinese Control Conference (CCC), Shanghai, China, 26–28 July 2021; pp. 2711–2715. [Google Scholar]

- Huang, J.; Xue, J. Optimization of SVR Functions for Flyrock Evaluation in Mine Blasting Operations. Environ. Earth Sci. 2022, 81, 434. [Google Scholar] [CrossRef]

- Cheng, C.; Peng, C.; Rong, M. A Composite Weighted Human Learning Network and Its Application for Modeling of the Intermediate Point Temperature in USC. Appl. Soft Comput. 2023, 144, 110488. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).