Evaluating the Capture Efficiency of Microchannel Plates Through Photoelectron Detection

Abstract

1. Introduction

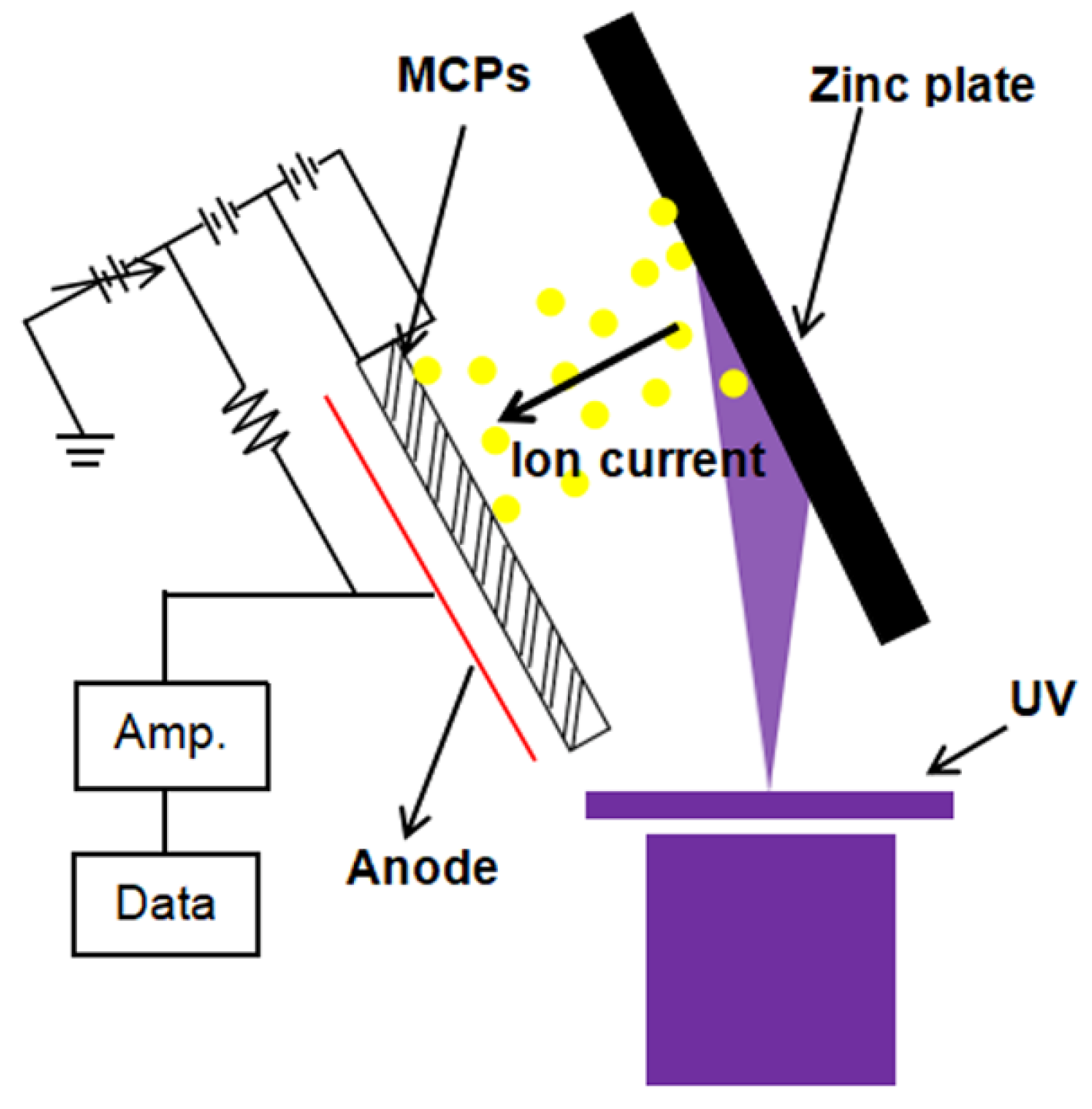

2. Materials and Methods

3. Results

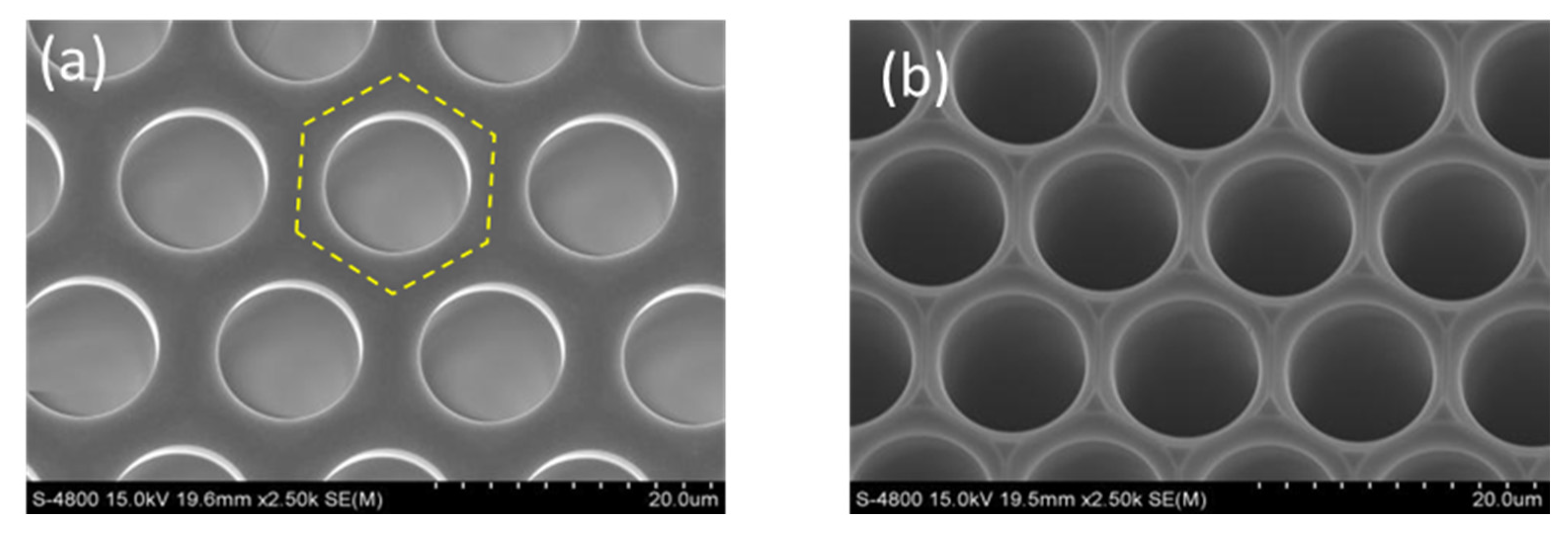

3.1. Fabrication of MCPs with Different OARs

3.2. Validation of the Generation and Detection of Photoelectrons

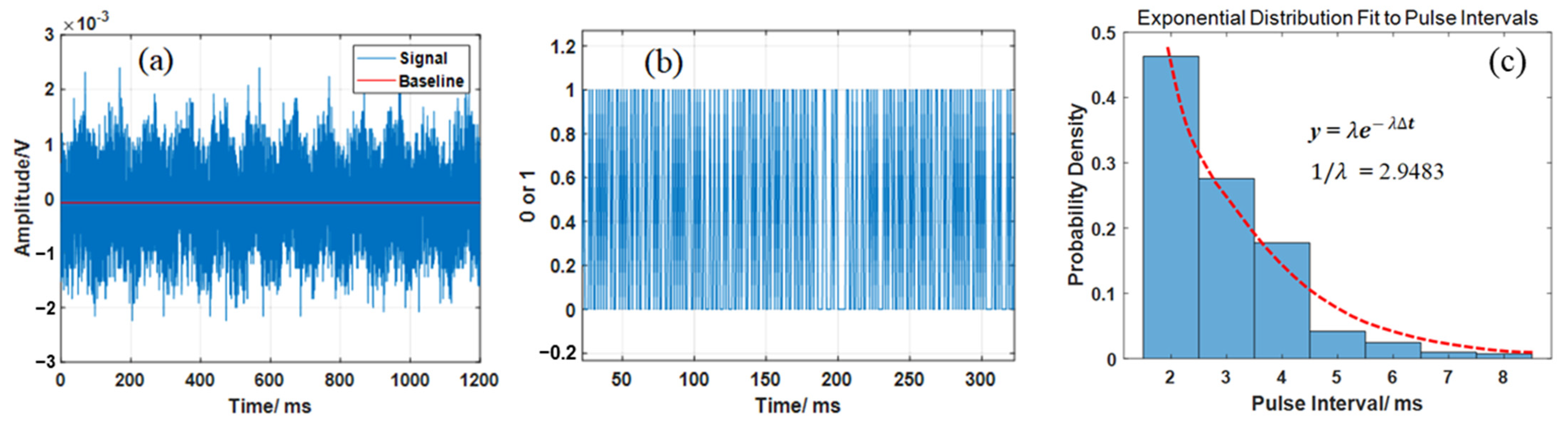

3.3. Data Processing

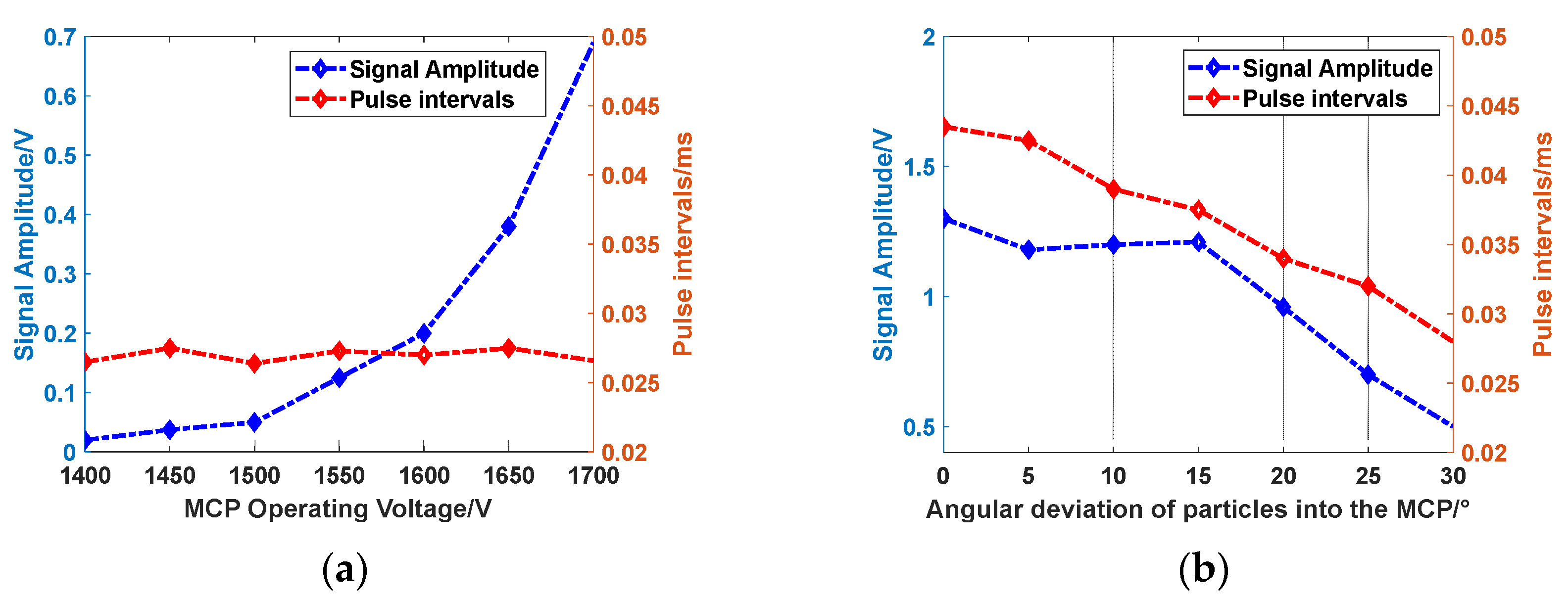

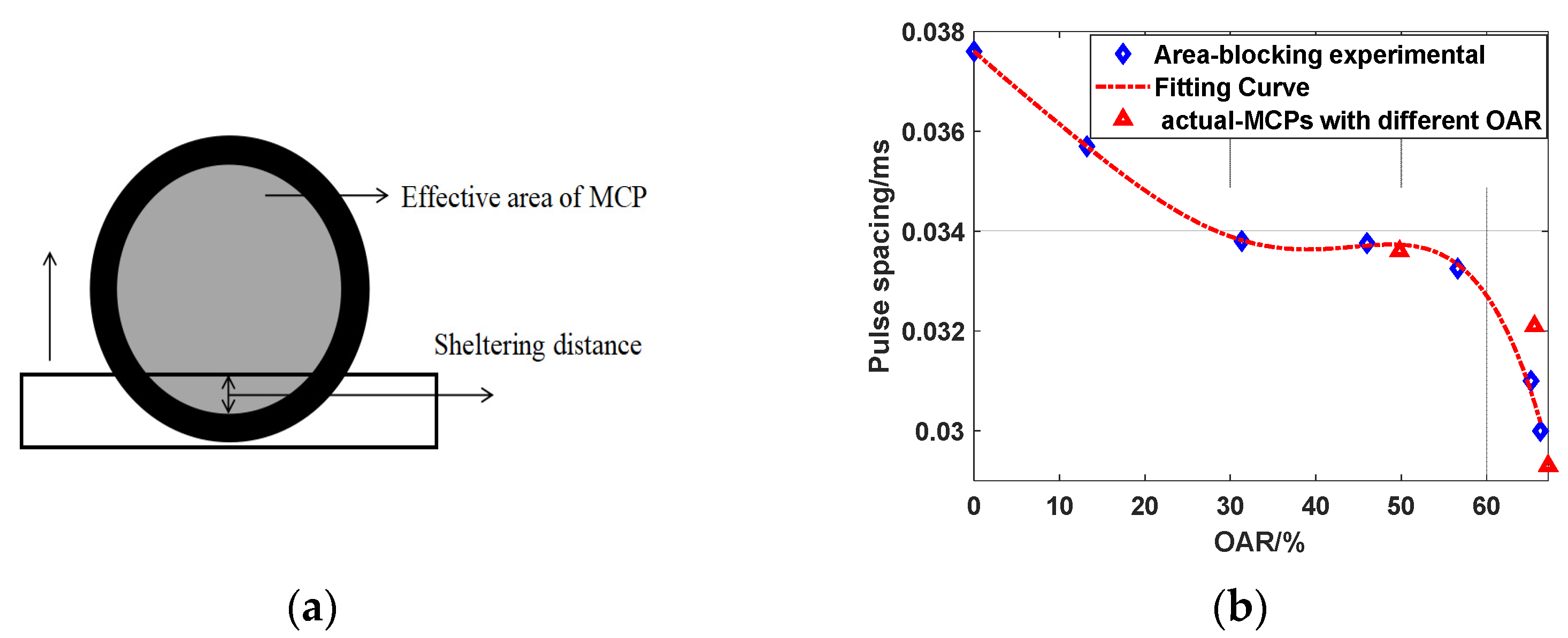

3.4. Factors Affecting the Pulse Intervals

3.5. Testing of Different MCPs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MCP | Microchannel plates |

| CE | Capture efficiency |

| OAR | Open area ratio |

| UV | Ultraviolet light |

References

- Ladislas Wiza, J. Microchannel plate detectors. Nucl. Instrum. Methods 1979, 162, 587–601. [Google Scholar] [CrossRef]

- Zhang, X.; Ouyang, X.; Zhang, J.; Weng, X.; Tan, X.; He, J.; Zhang, X.; Wei, K. The study of neutron sensitivity of the MCP based on recoil proton detection. AIP Adv. 2020, 10, 085310. [Google Scholar] [CrossRef]

- Gershman, D.J.; Avanov, L.A.; Chornay, D.J.; Rager, A.C.; Pollock, C.J.; Grubbs, G.; Mackler, D.A.; Tucker, C.J.; Paschalidis, N.P. Extending the dynamic range of microchannel plate detectors using charge-integration-based counting. Rev. Sci. Instrum. 2018, 89, 073301. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.; Pang, Y.; Yuan, Y.; Hu, W.; Bu, R.; Fan, H. Numerical simulation of outgassing characteristics of microchannel plate glass. AIP Adv. 2021, 11, 075015. [Google Scholar] [CrossRef]

- Funsten, H.O.; Harper, R.W.; Dors, E.E.; Janzen, P.A.; Larsen, B.A.; MacDonald, E.A.; Poston, D.I.; Ritzau, S.M.; Skoug, R.M.; Zurbuchen, T.H. Comparative Response of Microchannel Plate and Channel Electron Multiplier Detectors to Penetrating Radiation in Space. IEEE Trans. Nucl. Sci. 2015, 62, 2283–2293. [Google Scholar] [CrossRef]

- Ge, Z. Overview of High-Performance Timing and Position-Sensitive MCP Detectors Utilizing Secondary Electron Emission for Mass Measurements of Exotic Nuclei at Nuclear Physics Facilities. Sensors 2024, 24, 7261. [Google Scholar] [CrossRef]

- Barnes, J.H.; Hieftje, G.M. Recent advances in detector-array technology for mass spectrometry. Int. J. Mass Spectrom. 2004, 238, 33–46. [Google Scholar] [CrossRef]

- Jiang, Z.; Ni, Q. Design and Performance of Photon Imaging Detector Based on Cross-Strip Anode with Charge Induction. Appl. Sci. 2022, 12, 8471. [Google Scholar] [CrossRef]

- Fehre, K.; Trojanowskaja, D.; Gatzke, J.; Kunitski, M.; Trinter, F.; Zeller, S.; Schmidt, L.P.H.; Stohner, J.; Berger, R.; Czasch, A.; et al. Absolute ion detection efficiencies of microchannel plates and funnel microchannel plates for multi-coincidence detection. Rev. Sci. Instrum. 2018, 89, 045112. [Google Scholar] [CrossRef]

- Matoba, S.; Takahashi, R.; Io, C.; Koizumi, T.; Shiromaru, H. Absolute Detection Efficiency of a High-Sensitivity Microchannel Plate with Tapered Pores. Jpn. J. Appl. Phys. 2011, 50, 112201. [Google Scholar] [CrossRef]

- Deconihout, B.; Gerard, P.; Bouet, M.; Bostel, A. Improvement of the detection efficiency of channel plate electron multiplier for atom probe application. Appl. Surf. Sci. 1996, 94–95, 422–427. [Google Scholar] [CrossRef]

- Deconihout, B.; Vurpillot, F.; Bouet, M.; Renaud, L. Improved ion detection efficiency of microchannel plate detectors. Rev. Sci. Instrum. 2002, 73, 1734–1740. [Google Scholar] [CrossRef]

- Fraser, G.W. The ion detection efficiency of microchannel plates (MCPs). Int. J. Mass Spectrom. 2002, 215, 13–30. [Google Scholar] [CrossRef]

- Krauss, S.; Böhm, M.; Gumbert, K.; Lehmann, A.; Miehling, D.; Belias, A.; Dzhygadlo, R.; Gerhardt, A.; Lehmann, D.; Peters, K.; et al. Performance of the most recent Microchannel-Plate PMTs for the PANDA DIRC detectors at FAIR. Nucl. Instrum. Methods Phys. Res. Sect. A 2023, 1057, 168659. [Google Scholar] [CrossRef]

- Frey, S.; Antognini, L.; Beygi, M.; Ballif, C.; Wyrsch, N. New Developments in Amorphous Silicon-Based Microchannel Plates. IEEE Trans. Nucl. Sci. 2023, 70, 2226–2233. [Google Scholar] [CrossRef]

- Ashkhotov, O.G.; Ashkhotova, I.B.; Magkoev, T.T. Formation of an Inlet Funnel in the Channels of Microchannel Plates. Glass Ceram. 2024, 81, 306–308. [Google Scholar] [CrossRef]

- Huang, J.; Gong, Y.; Zeng, J.; Li, T.; Wang, Y.; Yang, Q.; Yue, R.; Wu, P.; Chu, Z.; Li, X. Study on the input electrode depth of the funnel microchannel plate. Proc. SPIE 2023, 12617, 126170D. [Google Scholar]

- Gao, R.S.; Gibner, P.S.; Newman, J.H.; Smith, K.A.; Stebbings, R.F. Absolute and angular efficiencies of a microchannel-plate position-sensitive detector. Rev. Sci. Instrum. 1984, 55, 1756–1759. [Google Scholar] [CrossRef]

- Blase, R.C.; Benke, R.R.; Pickens, K. Review of Measured Photon Detection Efficiencies of Microchannel Plates. IEEE Trans. Nucl. Sci. 2018, 65, 2839–2851. [Google Scholar] [CrossRef]

- Meng, S.; Yi, Q.; Zhou, L.; Yan, X.; Yang, J.; Ye, F.; Yang, R.; Jiang, S.; Ning, J.; Huang, Z.; et al. Restoration of saturated outputs from microchannel plate photomultiplier tubes in sub-microsecond single-pulse-current mode. Rev. Sci. Instrum. 2023, 94, 113101. [Google Scholar] [CrossRef]

- Tetsuo, K.; Yuta, C. Absolute detection efficiencies of an ion-counting system with a channel-electron multiplier. J. Phys. Conf. Ser. 2009, 163, 012114. [Google Scholar] [CrossRef]

- Laksman, J.; Dietrich, F.; Maltezopoulos, T.; Liu, J.; Ferreira de Lima, D.E.; Gerasimova, N.; Karpics, I.; Kujala, N.; Schmidt, P.; Karabekyan, S.; et al. Operation of Photo Electron Spectrometers for Non-Invasive Photon Diagnostics at the European X-ray Free Electron Laser. Appl. Sci. 2024, 14, 10152. [Google Scholar] [CrossRef]

- Liu, F.; Sidhik, S.; Hoffbauer, M.A.; Lewis, S.; Neukirch, A.J.; Pavlenko, V.; Tsai, H.; Nie, W.; Even, J.; Tretiak, S.; et al. Highly efficient photoelectric effect in halide perovskites for regenerative electron sources. Nat. Commun. 2021, 12, 673. [Google Scholar] [CrossRef]

- De Ninno, G.; Wätzel, J.; Ribič, P.R.; Allaria, E.; Coreno, M.; Danailov, M.B.; David, C.; Demidovich, A.; Di Fraia, M.; Giannessi, L.; et al. Photoelectric effect with a twist. Nat. Photonics 2020, 14, 554–558. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, M.; Ye, L.; Li, S.; Zhao, X.; Cai, H.; Yu, Q. Evaluating the Capture Efficiency of Microchannel Plates Through Photoelectron Detection. Appl. Sci. 2025, 15, 6301. https://doi.org/10.3390/app15116301

Wu M, Ye L, Li S, Zhao X, Cai H, Yu Q. Evaluating the Capture Efficiency of Microchannel Plates Through Photoelectron Detection. Applied Sciences. 2025; 15(11):6301. https://doi.org/10.3390/app15116301

Chicago/Turabian StyleWu, Mutong, Lingmin Ye, Shangtong Li, Xuan Zhao, Hua Cai, and Quan Yu. 2025. "Evaluating the Capture Efficiency of Microchannel Plates Through Photoelectron Detection" Applied Sciences 15, no. 11: 6301. https://doi.org/10.3390/app15116301

APA StyleWu, M., Ye, L., Li, S., Zhao, X., Cai, H., & Yu, Q. (2025). Evaluating the Capture Efficiency of Microchannel Plates Through Photoelectron Detection. Applied Sciences, 15(11), 6301. https://doi.org/10.3390/app15116301