Abstract

Recent advances in visual programming tools for algorithmic modelling have significantly expanded the possibilities for designing industrial products. This study analyses the capacity and adaptability of Grasshopper, a graphical algorithm editor integrated with Rhinoceros 3D, as a parametric design tool in the development of product platforms. Three case studies were conducted to evaluate the impact of parameter configuration in product families: perfume bottles, outdoor furniture, and desk organisers. The analysis provided insight into the ability of Grasshopper to (1) automate the generation of product variants within platforms; (2) enable the flexible creation of scalable, customised design alternatives; and (3) improve efficiency in the platform design process in terms of time and technical resources. The results show that Grasshopper provides strong capabilities for customising geometric parameters compared to traditional modelling in Rhinoceros 3D. However, its adaptability is more limited when customisation involves interdependent parameters, such as those related to ergonomics or usability, due to the difficulty of translating these requirements into algorithmic structures. In addition, the initial definition of parameters and constraints may restrict modifications in later design phases. These findings underline the need for algorithm models that support iterative adjustments and flexible reconfiguration throughout all phases of the design process.

1. Introduction

Industrial progress has been marked by the incorporation of technologies that have transformed societies and production processes [1]. In the field of industrial design, these advances have generated the need for more agile methodologies. These methodologies allow an efficient response to current market demands, characterised by high variability and a growing demand for customisation. Among these, artificial intelligence, advanced automation, and intelligent manufacturing stand out for their ability to drive adaptation to a constantly changing market [2,3,4,5,6,7,8,9].

Industrial product design is characterised by a high demand for customisation and scalability based on user segments and profiles. In response, companies and manufacturers frequently employ product platform strategies. These platforms make it possible to generate product variants that adapt to the market in a more efficient and structured way. This is achieved through a combination of standardisation and customisation in design and manufacture. On the one hand, the standardisation of components, modules, or manufacturing processes facilitates mass production and promotes economies of scale. This approach contributes to reducing costs and reducing development times. On the other hand, these platforms offer flexibility to introduce customisable elements that adapt to specific user demands, satisfying more individualised market segment needs. This balance between standardisation and customisation makes product platforms a useful strategy to optimise the use of technical, human, and economic resources. Additionally, it improves competitiveness in an increasingly dynamic market. However, although they offer the advantages mentioned above, the platform design process is highly complex. This is particularly evident in the generation and management of product variants, as well as in the adaptation of solutions to specific user requirements. These requirements are linked to multiple contexts of use, variants of products, and configurations. This situation increases workload and makes design activities more difficult. Generally, such projects require engineering teams to plan extensively to achieve a proper integration between standardised and customisable components. This level of complexity is usually addressed through the application of specific design methodologies. The implementation of these methodologies requires a significant investment in technical, human, and temporal resources, particularly during the early stages of conceptualisation [10,11].

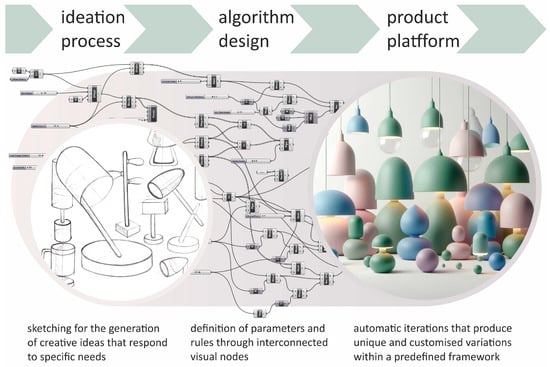

Within this framework, computational design, in its different parametric, algorithmic, or generative scopes, is a solution to address these limitations. This happens because of the possibility of automating repetitive tasks generating multiple design variants and configurations according to predefined criteria. These tools simplify the process and expand creative and technical possibilities by providing agile working environments. Traditionally, computational design resources for product platforms required advanced programming knowledge and specialised technical software. The utilisation of software such as Catia (Dassault Systèmes, Vélizy-Villacoublay, France), Ansys (Ansys Inc., Canonsburg, PA, USA), and Matlab, (MathWorks Inc., Natick, MA, USA) in conjunction with specific programming environments such as Java, Python, or C++, necessitates the possession of advanced coding and programming abilities. Consequently, these tools are predominantly used by multidisciplinary teams. However, recent developments in visual programming tools, such as Grasshopper (an integrated component in Rhinoceros 3D (Robert McNeel & Associates, Seattle, WA, USA) [12], Fusion 360 Generative Design (Autodesk Inc., San Francisco, CA, USA) [13] or Altair HyperWorks (Altair Engineering Inc., Troy, MI, USA) [14], are streamlining design processes through visual interfaces based on node manipulation and graphical flows. In this context, non-programming engineering and design teams can carry out both algorithmic and generative design (Figure 1).

Figure 1.

Algorithmic modelling process applied to product platforms.

Grasshopper (GH) (McNeel Europe, Barcelona, Spain) is a visual parametric programming plug-in for Rhinoceros 3D (RH), used in architecture, engineering and computational design. It facilitates the generation and manipulation of complex geometries using graphical algorithms without the need for textual coding. Its competence in structure algorithmic modelling processes makes it a fundamental tool in structural optimisation, advanced modelling and digital fabrication. Numerous studies have analysed GH in the scientific literature [15,16,17,18,19,20,21]. Publications show how these resources are useful for the generation of complex forms, mass customisation, and design automation based on specific parameters [17,22,23]. Furthermore, GH has also been combined with optimisation strategies, including gradient-based methods, multi-objective optimisation [24,25] and metaheuristic algorithms (e.g., genetic algorithm, neural, or swarm networks) [26,27], to reach the best design solutions. Other sectors that have taken advantage of these tools are architecture [28], textile design [29,30,31,32], jewellery design [33,34], and corporate identity [35,36]. However, no results have been found to evaluate the application of this type of resource in the design of product platforms.

The novelty of this study lies in the application of algorithmic modelling with Grasshopper to product families and platform-based design. While previous studies have assessed product platforms developed through conventional parametric modelling [37,38,39,40], no publications have identified that apply this approach using Grasshopper. In addition, there is a lack of comparative research addressing platform-based products with different functionalities under a unified methodological framework. This study introduces functional diversity across case studies, enabling broader conclusions that may be applicable to various areas of industrial design. Moreover, the research spans multiple phases of the product design process, including conceptual, embodiment, and detailed design stages [41,42], supported by the definition of parameters covering geometric, material, functional, ergonomic, and usability aspects.

To evaluate the use of GH in the development of product platforms, three case studies were selected. The chosen products (perfume bottles, outdoor furniture, and desk organisers) come from different sectors of industrial design to evaluate the applicability of the methodology in various product typologies. The selected case studies represent the typologies of platforms [10,11]: (1) a scale-based platform with variation of four variables (colour, dimensions, materials, and rounding), resulting in a family of perfume bottles; (2) a scale-based platform with variation of several variables (dimensions, proportions, colour, rounding, pattern and materials), resulting in a family of outdoor furniture; and (3) a modular design platform with variation of multiple variables (dimensions, proportions, colour, shape, form, rounding, materials, and pattern), resulting in a family of desk organiser. The variables analysed were only those that affected the customisation of the product. The analysis provided insight into the effectiveness of GH to (1) automate the generation of product variants within the platforms, (2) have the flexibility to generate customised and scalable design alternatives to the target user group, and have (3) the efficiency in the product platform design process, in terms of time and technical resource usage.

This article is structured as follows: Section 2 provides the necessary background to understand the research; Section 3 describes the methodology used in this study; Section 4 builds the case studies of the three product platforms developed with GH; Section 5 shows the results of the evaluation of the ability of the tool to adapt and customise the design of a product platform; and Section 6 discusses the results, setting out the main conclusions of this study in Section 7.

2. Background

Computational design uses algorithms, computer programming, and parametric modelling to generate, analyse, and optimise design solutions. Usually, this approach requires specific programming and coding skills. However, recent advances have enabled the creation of algorithms through intuitive ‘drag-and-drop’ interfaces, simplifying the process. Consequently, digital tools that incorporate visual programming expand the possibilities for design and development.

Unlike traditional design, which follows a linear sequence of sketching, CAD modelling and prototyping, computational design uses algorithms. These algorithms generate multiple solutions simultaneously. This enables greater speed and flexibility in exploring variations in product design [43]. Computational design is often classified into three categories: design for customisation, design for digital fabrication, and generative design and creative exploration [44]. The focus of parametric design is the definition of parameters or variables that govern the characteristics of a design. This enables automatic modification of elements based on input values. In this approach, adjustments occur through interdependent relationships between elements. These are governed by the formulation of rules and algorithms that enable the generation of complex structures. On the other hand, generative design allows the automatic generation and evaluation of multiple design solutions based on specific objectives [45]. This is an example of the functionality of GH and other RH software plug-ins, which facilitate the management of highly complex designs through the use of specific parameters. Its primary utility lies in the generation of shapes that facilitate expansive creative possibilities through fluid, flexible, adaptable, rapid, and visual modifications. This software helps define precise instructions for developing products with geometries that maintain the initial design concept. Simultaneously, it allows flexibility in making iterations and necessary adaptations to meet user needs [46].

GH fosters greater creativity compared to traditional design methods that do not rely on algorithms [47]. It influences the creative process of designers. It encourages divergent thinking and the exploration of solutions, although its impact varies according to user experience [48]. It allows rapid iterations, hybrid forms, and the exploration of innovative ideas, although with the challenge of requiring advanced technical skills [18,49].

Product customisation has generated significant interest in the professional and research fields. The aim is to achieve a high capacity to modify the characteristics of the product. There are case studies where automation is focused on products where real-time adaptation to the user is important. For example, mass customisation of glasses, allowing real-time adjustment of 3D models according to user dimensions and preferences of the user [50]; integrating 3D facial data obtained with photogrammetry [51]; performing 3D scanning of the face, improving functionality [52]; and designing glasses frames through a parametric algorithm adapted to user-specific anatomical data [53]. Another recurrent type of product is footwear. This analysis is carried out to evaluate the precision and adaptability of the product, a capability enabled by the integration of individualised user data on the foot. Some studies focus on the design of patterns for the base of the shoe that lasts [54,55,56], while others focus on automatic fitting according to specific data of the user’s foot, optimising costs and time [57]. An additional sector represented in this type of study is furniture. This field involves the creation of interfaces that enable users to directly adjust parameters, thereby facilitating the real-time visualisation of designed furniture. GH is used for the adjustment of dimensions, materials, and aesthetics, as well as for the creation of assembly instructions and files for 3D manufacturing purposes [58,59].

The growing demand for customised solutions has driven the use of algorithmic modelling tools such as GH. These tools make it possible to create products tailored to the individual needs of users, optimising aesthetics and functionality by automating parameters.

In the scientific literature, GH has been used specifically to customise origami-inspired structures [60]. It has also been used to design surfboard and paddleboard fins that optimise performance and suit surfers’ personal preferences [61]. Other uses include generating revolving mesh shapes from customised revolution profiles based on material density and mesh patterns [62], performing isogeometric analysis (IGA) in engineering by optimising the design and analysis cycle [43], and creating product designs with Voronoi patterns inspired by nature and traditional Chinese culture [63]. GH has also been used to optimise the creative and production process in furniture design with greater flexibility and responsiveness to market demands [59], create complex and customised patterns in textile design by improving efficiency and adaptability in the textile industry [64], and design bottles that adapt their shape and texture according to user tactile preferences, combining Kansei engineering and design [65]. Furthermore, GH has been used to design ornamental patterns based on traditional cultural motifs [66] and to design ergonomic seating by integrating anthropometric and ergonomic data to optimise product shape, functionality, and customisation [67].

Although numerous applications of GH have been explored in other areas of design, the current literature on its use in platform design is limited. Product platforms are currently the strategies followed by the industry to manage their product portfolios in the marketplace [10,11]. They offer significant advantages, such as reducing development time and costs through component reuse and increasing product variety without adding excessive production complexity. Moreover, they facilitate mass customisation to address diverse consumer needs. However, product platform design also presents important challenges. These include the complexity of managing interdependent components, the need for efficient modularisation strategies, and the difficulty of balancing standardisation with customisation. In this sense, GH could streamline the product platform design process by automating the generation of multiple customised product variants through a single algorithm. By integrating parametric modelling, GH enables designers to define rules and constraints that ensure consistency across platform variants. It also facilitates real-time visualisation of design alternatives while allowing adjustments to parameters such as dimensions, materials, and functional characteristics.

Finally, it is interesting to consider the relationship between design parameters and manufacturing criteria from the early stages of the process. Decisions taken during parametric modelling condition the technical and economic feasibility of the product. Certain combinations of geometries, materials, or configurations may be complex or unfeasible to manufacture with conventional technologies. Therefore, incorporating manufacturing criteria into algorithmic models allows the constraints of the production process to be considered in the conceptual design phase.

3. Methodology

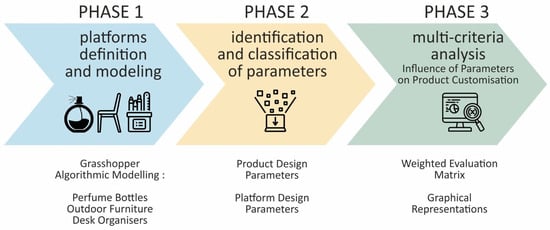

This study adopts a multiple case study method with an exploratory, comparative approach [68] to evaluate the feasibility and effectiveness of algorithmic modelling using GH in the design of product platforms. Three representative cases from different areas of industrial design were selected to cover a variety of functional and use-related contexts. The methodology was structured into the three phases shown in Figure 2: (1) definition and modelling of each platform using GH; (2) identification and classification of design parameters, distinguishing those related to the product and the platform; and (3) multi-criteria analysis to quantify the influence of each parameter on platform customisation.

Figure 2.

Research methodology.

In the first phase, three product platforms were selected, each representative of different areas of industrial design (packaging, furniture, and office organisation), with the aim of covering a range of functional, aesthetic, and contextual requirements. The selected cases encompass all platform typologies described in the literature and commonly used in industry [10,11]: (1) scale-based platforms, which allow resizing or adapting a base design to offer products with different capabilities or performance levels, and (2) module-based platforms, which rely on the combination and interchangeability of standardised modules with a shared architecture and defined interfaces. Parametric models were developed by constructing algorithms in Grasshopper 1.0 and Rhinoceros 8.0, allowing for flexible configuration of each platform through automatic modification of design parameters (dimensions, proportions, colour, shape, rounding, materials, and pattern). This process enables the customisation of the derived products, adapting them to specific user needs and use contexts.

The second phase identified the analysis variables required to assess the feasibility and effectiveness of GH algorithmic modelling in the design of the product platforms. These variables were structured into two groups: Group 1 with product design parameters and Group 2 with platform design parameters. In this context, design parameters are understood as configurable attributes in GH that define the functionality, appearance, or user adaptation of a product (Group 1) or a platform (Group 2).

Table 1 presents both sets of parameters and defines their scope in terms of customisation of product design customisation. Group 1 (PRi) includes the attributes and properties of the product that allow evaluation of its level of customisation (or user adaptation): dimensions, proportions, colour, shape, rounding, materials, and pattern. These parameters can be configured directly within the parametric model. The selection was based on its ability to control the visual and aesthetic aspects of the product; in addition, only those parameters whose manipulation is technically feasible in GH without the use of external resources were included. Group 2 (PLj) includes parameters to evaluate the product platform from a market perspective: scalability, modularity, usability, ergonomics and context of use. An appropriate combination of these properties allows manufacturers to develop a diversified product offering tailored to user groups with highly differentiated needs. The selection was based on their relevance as essential requirements that a platform must meet to effectively adapt to a specific market segment and ensure its economic viability.

Table 1.

Parameters for multi-criteria analysis.

In phase 3, the level of customisation offered by each parametric model developed in GH was evaluated. A systematic observation process was carried out to document the behaviour of the model when modifying the parameters listed in Table 1. The results were used to analyse the feasibility and effectiveness of algorithmic modelling with GH in the design of product platforms.

The evaluation process was based on a multi-criteria analysis to quantify the relationship between the parameters of group 1 (PRi, product design) and group 2 (PLj, platform design). Each relationship was numerically assessed using a three-level scale (low, medium, and high), indicating the degree of influence of each parameter on product customisation. Each level was determined by a combination of three criteria: (i) the number of configurable parameters in the GH environment, (ii) the scope of customisation (aesthetic, functional, or structural), and (iii) the time required to configure the parameter within the parametric model in GH. Table 2 shows the thresholds used. All three criteria are structured incrementally, reflecting increasing degrees of complexity or design intervention. Specifically, in criterion (ii), the scope of customisation progresses from aesthetic (related to perceptual attributes) to functional (modifications affecting the use and operational features of products) and finally to structural (involving the physical configuration and interrelation of components). Each level represents a deeper degree of transformation and builds upon the previous one. The thresholds were defined based on observed values and comparative analysis across the three case studies, with the aim of consistently distinguishing parameter complexity and platform responsiveness using expert-based criteria.

Table 2.

Criteria for classification levels.

For the quantitative analysis, the classification by levels in Table 2 was transformed into discrete numerical values, assigning 1 to the low level, 2 to the medium level, and 3 to the high level. A double-entry matrix was constructed to relate each product design parameter or PRi (Group 1, Table 1) with each platform design parameter or PLj (Group 2, Table 1). Each matrix cell contains the score assigned to the relationship between a pair of parameters. The total score of each product design parameter was calculated using Equation (1); where is the total score of the product design parameter PRi and is the value assigned to the relationship between the product parameter PRi and the platform parameter PLj:

To express the relative influence of each relationship, the values were normalised using Equation (2) against a fixed maximum total score, defined as the hypothetical case in which a product design parameter receives the maximum score (3) in all five platform parameters; where is the normalised value or relative degree of customisation of parameter PRi with respect to the theoretical maximum (MAX):

The goal was to represent the relative distribution of the influence of each product parameter (Group 1) on the platform parameters (Group 2). The results were visualised using stacked bar charts; each bar represents a product design parameter (dimensions, proportions, colour, shape, rounding, materials, and pattern), and its segmentation reflects its impact on the platform (scalability, modularity, usability, ergonomics, and context of use) based on the relative weight of each pairwise score as defined by Equation (3); where represents the relative contribution of the platform parameter PLj to the total score of the product parameter PRi:

4. Case Studies

4.1. Case Study 1: Perfume Bottle Platform

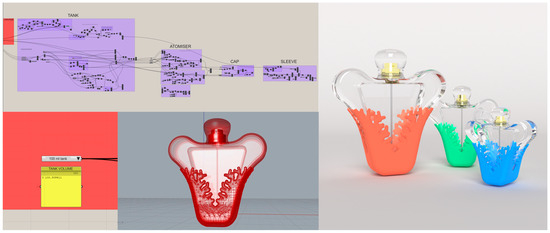

The first platform is based on scales. All containers share the primary function of storing perfume. However, the products differ in their performance level, with different capacities of 30 mL, 50 mL, and 100 mL. This example combines algorithmic modelling tools with traditional design processes [77].

The objective of the project was to develop a family of perfume bottles inspired by marine themes. The proposal focused on creating a single algorithm capable of generating the main design. This design was defined during the early stages of product design and development, along with its variants in different sizes. Although all containers feature the same materials, three different colour ranges are offered.

Conceptual development began with concept sketches, which were evaluated to select the most appropriate solution. Subsequently, the detailed design was developed using visual programming in Grasshopper v01 and Rhinoceros v08.

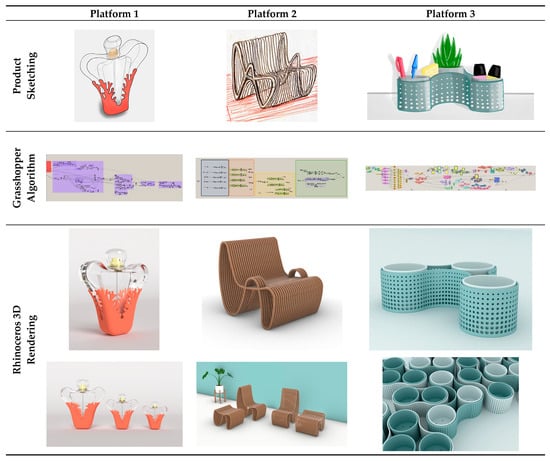

The development of the algorithm (Figure 3) to design a container focused on generating parametric geometries from a specified volume. This was carried out while maintaining the aesthetic design that had been established previously. GH does not allow volume to be used directly as an input parameter. Therefore, a tank with trapezoidal geometry was designed, adjustable through a scaling factor that modifies the width and height, while keeping the depth fixed. This factor was calibrated to obtain specific volumes and integrated as a discrete parameter in the algorithm. The outer geometry of the container was created from an offset of the tank, generating a guide surface that defined the contour and was adjusted proportionally. The algorithm also included the design of a coral-like sleeve using the ‘Dendro’ plug-in, generating a quarter of the initial design and replicating it symmetrically. The sleeve was adapted to all variations of the container by scaling, transforming it into ‘SubD’ geometry for an organic appearance. Finally, the algorithm made it possible to preview all parts and configurations of the product. The full script of the case study can be consulted (see Data Availability Statement).

Figure 3.

Grasshopper algorithm of Case Study 1.

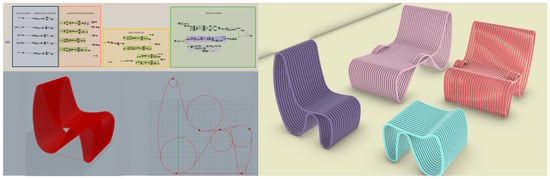

4.2. Case Study 2: Outdoor Furniture Platform

The second case corresponds to the design of a family of outdoor furniture. It is developed as a scale-based platform whose main function is to provide seating with different characteristics. The particularity of this platform lies in the diversity of positions of use, which gives rise to variations in shapes. On this platform, algorithmic modelling plays a key role, allowing adjustments to be made to the dimensions of the product. Through the modification of the roundings, dimensions, and repetition of serial planes, products are created that offer different body support configurations. Backrests, armrests, and leg supports can be customised, generating a diversified product range that forms the family within the platform. In addition, the diversity of design solutions, as well as materials and colours, can be adapted to different contexts of use [78].

During the conceptual design phase, a series of sketches were created to explore the geometric possibilities of the seating profiles. To address the transitions between circular elements, certain points and rounding were modified, along with repetitions of serial planes. These transitions were mathematically controlled using smooth interpolation curves, ensuring continuous and aesthetically pleasing connections between the elements. Therefore, the algorithm can generate all products that form part of the platform.

The GH design process involved rigorous study and experimentation to develop a detailed algorithm (Figure 4), divided into four functional blocks. First, the base points and associated curves, blue block, were created and linked with the technically generated arcs, orange block. Subsequently, additional points were added for details such as armrests and yellow blocks, and all curves were joined together to form complete seat profiles. By repetitions, the serial planes were created, green block. The curves were generated proportionally using an initial radius based on the golden ratio. Structural points were defined on an XZ plane with measurements in centimetres. Tangent arcs connected the curves and were adjusted using shatter blocks to eliminate excess. The profile was obtained by joining the curves and duplicating them to add thickness, creating the surfaces that make up the seat. Finally, the profiles were extruded in repeated serial planes in the Y direction and assembled into a single ‘Brep’. This three-dimensional model was exported to RH and prepared for final presentation. It demonstrated how a single algorithm can generate a functional and aesthetic design in the parametric environment of GH. The full script of the case study can be consulted (see Data Availability Statement).

Figure 4.

Grasshopper algorithm of Case Study 2.

With respect to the selection of variables in Table 1 (see Section 2), Group 1 includes only those parameters that have a direct impact on product customisation: dimensions, proportions, colour, rounding, pattern, and materials. As in the previous case, all Group 2 parameters were included for evaluation.

4.3. Case Study 3: Desk Organiser Platform

The third and final case study addressed the design of a highly customisable modular desk organiser. This strategy aimed to adapt the product to a wide range of specific requirements by modifying predefined parameters [79].

The use of a modular platform ensured that each component could be modified, added, or replaced without affecting the integrity of the overall design. This approach is especially relevant in contexts where the diversity of user needs is high. It is also of high interest for its adaptation to various typologies of workspaces, whether shared or personal. It also enhanced the interconnectivity between various components of the system, improving efficiency and functionality.

The following describes the process of creating the algorithm in GH (Figure 5) to design this platform based on a six-cell grid. First, the grid was created using the ‘Square’ command, which assigned binary values to the cells to indicate the placement of a lobe in the cells. Using the ‘Dispatch’ command, active cells can be selected and circles placed at their centres. They can then be related by tangent arcs with the command ‘Tangent Arcs’. These relations allow a geometric pattern to be generated based on combinations of cells. The ‘Loft’ command was then used to generate surfaces between tangent arcs, and these were merged with the ‘Merge’ tool to create a single set of geometries. To generate a volume, the extrusion operation was applied, and a hollow inside the module was created by a smaller-scale solid using move and offset operations. Finally, a Boolean operation was performed to obtain the basic geometry, and the edges were rounded with the ‘Fillet Edge’. The process also included the application of gradient perforations by separating surfaces and selecting the appropriate ones to apply the texture. The full script of the case study can be consulted (see Data Availability Statement).

Figure 5.

Grasshopper algorithm of Case Study 3.

5. Results

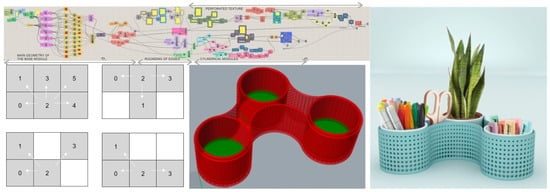

This study revealed that platforms designed using algorithms created with GH offer great opportunities for customisation. Figure 6 shows the design results for each platform. In all case studies, it was necessary to start the ideation process by sketching. The conceptual exploration culminated in the selection of the alternative that best satisfied the predefined design requirements. The next step was the design of the algorithm, which had as its first objective the creation of products that met the characteristics of each family. Finally, various product solutions were generated to test the correct functioning of the algorithm. In this way, satisfactory results were obtained in all cases.

Figure 6.

Results of the sketching, algorithm, and rendering of each platform.

5.1. Platform 1: Perfume Bottles

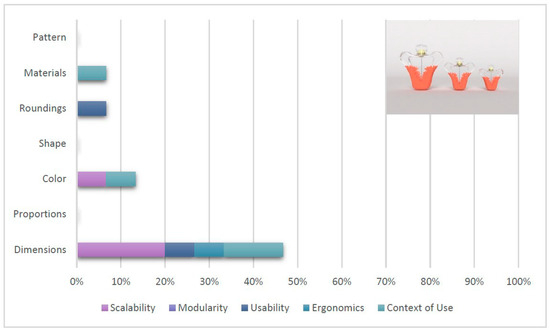

The degree of customisation of each parameter of the perfume bottle family is shown in Table 3. The values were obtained with the thresholds in Table 2 (see Section 3). The product parameters with the greatest capacity for influence are dimensions and colour. In particular, adjustment of the basic dimensions of the bottle, which directly affects the storage volume and the overall size, allows scalability of the product and adaptation to the context of use. To a lesser extent, this platform supports the adaptation of usability and the improvement of ergonomics through the adjustment of product parameters.

Table 3.

Platform 1 evaluation matrix.

Figure 7 shows the influence of the adjustment of product parameters in relation to the adaptation to platform parameters. The results were calculated using expressions (1)–(3) (see Section 3). Specifically, the modification of the dimensions is perceived to affect the scalability of the platform products to a higher degree. Usability, ergonomics, and context of use are also influenced. In any case, compared to 100%, less than half of the possibility of adapting the platform parameters is reached. As far as colour is concerned, the variations allowed by the algorithm generate very limited options in terms of the suitability of the product. These variations also affect its adaptation to different contexts of use. In general, it can be stated that this algorithm is quite limited in terms of generating a diversity of platform products.

Figure 7.

Influence of product parameters on Platform 1.

5.2. Platform 2: Outdoor Furniture

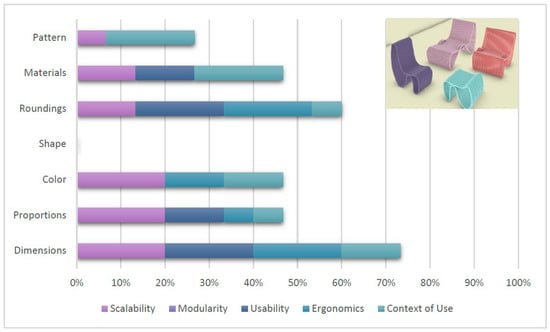

The second case study, as can be seen in Table 4, shows a greater impact of the adjustment of the product parameters on the platform parameters. The values were obtained with the thresholds in Table 2 (see Section 3). The algorithm of this platform makes it possible to adjust dimensions, proportions, colour, rounding, and materials to a greater extent. The aforementioned characteristics facilitate the achievement of high levels of product scalability, usability, ergonomic adaptation, and contextual adaptation. In particular, and in contrast to the previous case, the modification of proportions makes it possible to create products of different sizes. It also allows for the creation of backrests of different heights and seats of different lengths. Therefore, the variety of possible products is greater than in the perfume bottle family, where only the dimensions can be modified while maintaining the proportions. It should be noted that this platform has an excellent capacity to adapt to the context of use. This is achieved through adjustment not only of dimensions and proportions but also of colour, rounding, materials, and patterns. A distinctive attribute of this platform is the capacity to increase the number of serialised planes, thereby enabling a single seat type to be tailored to disparate spatial configurations. This can make the furniture family viable for smaller-scale domestic environments, as well as for hotel or commercial environments, for example.

Table 4.

Platform 2 evaluation matrix.

The results of the versatility of Platform 2 are shown in Figure 8. The results were calculated using expressions (1)–(3) (see Section 3). It is not possible to achieve the highest degree of customisation of the platform through any single product parameter. However, it is observed that most of the product parameters have a high degree of scalability, usability, ergonomics, and adaptation to the context of use. Only the shape parameter is impossible to modify as the algorithm is not prepared to switch between geometric and organic shapes.

Figure 8.

Influence of product parameters on Platform 2.

It is worth noting the importance of the rounding adjustment in this platform. In this case, it allows for large transformations that generate very different solutions. It is a parameter that allows for a high degree of customisation in almost all platform parameters. The wide versatility of colour and material adjustment is also relevant. In this case, it is highly adaptable to various contexts of use. It also makes it possible to fit the design to users with special needs who may be affected, for example, by the degree of colour saturation of the product. Finally, due to the adjustment of the dimensions, all the platform parameters benefit to a great extent. While there are parameters that achieve very positive results, this one achieves more than 70% platform customisation capability.

5.3. Platform 3: Desk Organiser

The third case study is the one that demonstrates the highest degree of customisation overall. This platform was already expected to offer great flexibility. This was evident from a simple comparison of the algorithmic complexity and the number of components involved. However, through the evaluation matrix, it is possible to analyse the case in detail.

As shown in Table 5, this platform has multiple product parameters that allow versatile results to be obtained for each platform parameter. The values were obtained with the thresholds in Table 2 (see Section 3). Most of these parameters exhibit a high level of correlation. Unlike the two previous cases, this algorithm generates ample possibilities for platform modularity through the adjustment of almost all parameters. In particular, the parameters of dimensions, proportions, colour, and materials produce the best results. In contrast, the rounding parameter has the least influence on the customisation possibilities of the platform.

Table 5.

Platform 3 evaluation matrix.

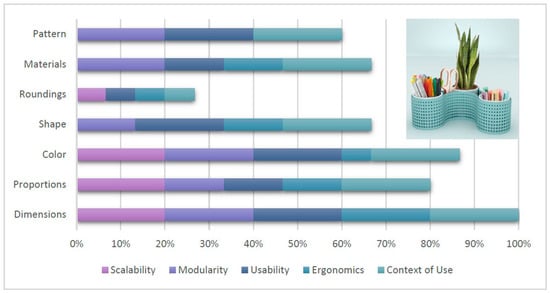

Figure 9 reveals that this platform is the one that achieves the highest levels of customisation. The results were calculated using expressions (1)–(3) (see Section 3). In essence, the results demonstrate that, for most of the product parameters, the percentage of customisation possibilities exceeds 60%. For the parameters of dimensions, proportions, and colour, the best results are obtained, with a total of at least 80%. The greatest impact on the modularity of the platform is also obtained. The rounding parameter has the worst impact.

Figure 9.

Influence of product parameters on Platform 3.

This platform is the only one that reaches a percentage of 100% in one of the product parameters, namely, the dimension parameter. In this case, the adjustment of length, height, and depth allows for a high degree of flexibility in the modification. This modification positively affects scalability, modularity, usability, ergonomics, and context of use. Similarly, the colour parameter, both in tone and in value and saturation, has a high influence on almost all platform parameters. It should be noted that, for this type of product, the influence of colour on the adaptation of the platform to various contexts of use is very important. Therefore, the context of use is one of the platform parameters that most benefit from the algorithm design in this case study.

5.4. Comparative Analysis of Case Studies

The comparative analysis (Table 6) reveals significant differences in the capacity of each platform to generate customised variants through the parametric configuration of models in GH.

Table 6.

Synthesis of results.

The three case studies allow for the assessment of how effectively the algorithmic model has been structured to enable product customisation while preserving the integrity of the base architecture used in the platform.

The platform for desk organisers (Case 3) stands out as the most robust in terms of parametric design. The algorithm that was developed makes it possible to generate variants by modifying both geometric and functional aspects, while maintaining a coherent shared structure. This is the only case that incorporates explicit modularity into the architecture of the product, which significantly increases the potential for adaptation to different user needs and contexts of use.

The platform for outdoor furniture (Case 2) also supports a high level of customisation, especially in formal attributes such as dimensions and proportions. However, it is based on scaling a single product typology without altering its structure. As a result, it does not incorporate a modular approach or enable reorganisation of components. This limitation reflects a design strategy that emphasises scalability over component reconfiguration.

In the case of perfume bottles (Case 1), although the model allows some variation through adjustments in colour, volume, and finish, the overall capacity for customisation remains limited.

Among the analysed parameters, dimension appears as the most commonly configurable aspect in all three cases, confirming its relevance as a key variable in parametric modelling. In contrast, decorative pattern has limited presence, possibly because it is not associated with structural or functional differentiation, but rather with purely aesthetic variation.

In conclusion, the desk organiser platform (Case 3) achieved the highest degree of product variety, supported by a modular architecture that enables both geometric and functional differentiation. The outdoor furniture platform (Case 2) was oriented towards scalability through dimensional variation of a fixed product type. In contrast, the perfume bottle platform (Case 1) exhibited the lowest level of configurability, limited primarily to aesthetic modifications. These findings highlight the importance of early architectural decisions in enhancing platform robustness and enabling the reuse of core design elements across multiple variants.

6. Discussion

This research aligns with a broad consensus that algorithmic modelling effectively supports real-time updates and iterative modifications in design. This is affirmed by studies on customisation for product design, such as, for example, those of Manavis, Madrigal, and Bai [19,50,58]. In terms of mass customisation, some studies have included interfaces where users can adjust parameters and obtain immediate visualisations [24,53,80]. Furthermore, this approach encourages collaboration with clients or end-users in the field of industrial design while simultaneously facilitating design flexibility in the final outcome. These are advantages in product customisation that can also be applicable to platforms, although they have not been the specific object of study.

In the context of product platforms, it is worth mentioning a systematic review published in 2019 [81]. This study establishes the foundations for future research on platform design under uncertainty. Specifically, a reference is made to algorithmic modelling, in its generative aspect, as an opportunity for multi-objective product optimisation. However, there is currently no research whose results can be compared with the work presented here. In any case, it is important to note that some publications yield some interesting conclusions that could be useful for the generative design of product families. Among them, the articles published by Krish and Barbieri [16,18] are worth noting. Although the focus is not on platforms, the results obtained are of great interest in this area. In the exploration of generated solutions, it can be observed that generative design methodology can contribute to the design of platforms. In this sense, it would not be complicated to modify the objective of exploring design alternatives to the generation of products with similar characteristics within the product platform framework. An MP3 player, using Solidworks Genoform software, and a stool, using Autodesk Fusion 360 software, are used as case studies. In both cases, a multitude of iterations is obtained. If these are well-focused and restrict the limits of the algorithm, they have the potential to serve as a basis for the development of families. In this sense, the generation of product platforms through generative design would be an interesting line of future research.

In addition, references to research on shape grammar have been valuable for the developed study. Authors such as Dy, Costa, Refalian, Kielarova, Madrigal, and Alcaide-Marzal have agreed on the importance of the control of grammar rules to correctly encode algorithms [15,19,24,82,83,84]. We agree with their view that determining design parameters based on formal grammar provides flexible and accurate solutions. This approach includes features such as shapes, dimensions, colour, proportional relationships, and other parameterisable attributes. In all cases, the benefit becomes evident in the design outcomes. Parametric logic enables automatic adaptation of outputs in response to changes in inputs. If this procedure is properly controlled, design processes could be simplified. The main goal is to generate multiple solutions and preserve their common characteristics within the definition of a product platform.

Based on the results obtained, algorithmic modelling provides a viable solution to improve the product platform design process in relation to customisation. It is worth mentioning that it was expected that there would be a noticeable difference between the three platforms studied. However, the large gap between the case studies in terms of their customisation possibilities has been surprising. Furthermore, it was found that the preliminary design strategy used during the algorithm development process played an important role. This strategy was key to achieving an optimal degree of versatility. It also emphasises the need for a change in the design paradigm to ensure accurate adaptation and use of the algorithmic method.

The application of GH has several limitations in industrial contexts. One of the most relevant is that it does not include the necessary complements for the detailed design phase of product platforms. This includes simulation tools (mechanical behaviour, ergonomics, etc.), cost estimation or technical documentation resources for automatically generating manufacturing plans, bills of materials, or assembly instructions. This limitation can be partially overcome by integrating GH with external software or plug-ins, although this results in a fragmented workflow. In the context of product design, ergonomic analysis can be approximated by exporting geometry to tools such as AnyBody (AnyBody Technology A/S, Aalborg, Denmark) or Autodesk Fusion. Plug-ins like Karamba3D (structural analysis) (Karamba3D GmbH, Vienna, Austria), Wallacei (multi-objective optimisation) (Wallacei Ltd., London, United Kingdom), Crystallon (internal structures for additive manufacturing) (FATHOM, Oakland, CA, USA), and Millipede (topology optimisation and basic structural simulation) (Digital Structures, Massachusetts Institute of Technology, Cambridge, MA, USA) allow for the integration of performance criteria from early design stages, significantly expanding the capabilities of the parametric environment. Another limitation lies in the reduced capacity to address complex multidimensional parameters (such as those related to ergonomics or usability), which cannot always be easily translated into algorithmic rules or simulations.

In addition, GH is mainly based on visual programming. Through its system of nodes and graphical connections, it is possible to define parametric relationships between components, generate and modify geometries, and automate the design of product variants. This approach facilitates the creation of algorithms without the need for advanced programming skills. However, in complex product platform projects, such as those involving families with different product ranges, a large number of variants or modular designs, visual programming is not sufficient. The design process demands a range of challenging tasks, including the conditional use of geometries and the verification of compatibility between modules or combinations of properties within the platform architecture. Additionally, it does not support the direct implementation of optimisation methods. In these cases, it is necessary to complement the visual flows with scripting using languages such as Python or C# integrated in GH. This makes it possible to create more sophisticated CAD models using structures such as conditionals (for example, to generate one geometry or another depending on the type of user or the context of use) or loops (which make it possible to automate the generation of multiple iterations of the same part with different configurations). Through scripting, it is also possible to access external data to automatically adapt the design according to technical, economic, or contextual criteria. This includes the use of material databases, standardised component catalogues, or cost information. It is also possible to implement dynamic filtering, such as automatically selecting variants that meet restrictions on mass, maximum dimensions, costs, or mechanical properties. This process involves the elimination of configurations that are not feasible.

The scope of this study is limited to the use of Grasshopper as the only algorithmic modelling environment under analysis. While this allowed for an in-depth evaluation of its capabilities, the results cannot be directly compared with those from other parametric or visual programming tools. These limitations open opportunities to expand the research, including the integration of external simulation tools such as Karamba3D for structural analysis, AnyBody for ergonomic evaluation, or Ladybug Tools for environmental performance (Ladybug Tools LLC, Washington, DC, USA). Also, future work could study the application of this methodology in sectors where product platforms are widely used, such as automotive, consumer electronics, medical devices, or modular construction, thereby assessing its adaptability in more technically demanding design contexts.

7. Conclusions

This study demonstrates that the use of Grasshopper for the development of parametric design algorithms improves the efficiency and control of the product platform design process. Algorithmic modelling supports the management and adjustment of design parameters, supporting a high degree of customisation while maintaining the structural coherence of the platform. Grasshopper also facilitates the automation of repetitive tasks and the systematic generation of product variants, reorganisation of the inherently complex process of platform-based design, and improvement of its adaptability and scalability across diverse scenarios.

The results underscore the importance of establishing a precise and well-structured algorithmic strategy from the early stages of the design process, as the initial configuration of parameters significantly affects the flexibility and responsiveness of the resulting platform. Grasshopper has proven to be an effective environment for this purpose, allowing for rapid iteration, adaptation to different use contexts, and integration of user-centred aspects such as usability and ergonomics.

Overall, this study confirms the relevance of algorithmic modelling as a strategic approach for developing adaptable and customisable product platforms. At the same time, it reveals important limitations and opens avenues for future research, including the integration of external simulation tools and the evaluation of more complex, multidimensional design parameters.

Author Contributions

Conceptualization, A.M.-M. and E.P.; Methodology, A.M.-M.; Software, J.F.F.-R. and A.P.; Validation, J.F.F.-R. and A.P.; Formal Analysis, A.M.-M.; Investigation, A.M.-M., E.P., J.F.F.-R., and A.P.; Resources, E.P.; Data Curation, A.M.-M.; Writing—Original Draft Preparation, A.M.-M. and E.P.; Writing—Review and Editing, A.P. and J.F.F.-R.; Visualization, A.M.-M.; Supervision, E.P.; Funding Acquisition, E.P. All authors have read and agreed to the published version of the manuscript.

Funding

This publication is part of the R&D&I project/Grant PID2023-149083OA-I00 funded by MICIU/AEI/10.13039/501100011033 and by FEDER EU.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are only available upon request from the corresponding author due to privacy reasons.

Conflicts of Interest

The authors declare no conflicts of interest.

Correction Statement

This article has been republished with a minor correction to the Funding statement. This change does not affect the scientific content of the article.

References

- Singh, R.; Tyagi, A.K.; Arumugam, S.K. Imagining the Sustainable Future with Industry 6.0: A Smarter Pathway for Modern Society and Manufacturing Industries. In Machine Learning Algorithms Using Scikit and TensorFlow Environments; IGI Global: Hershey, PA, USA, 2024; pp. 318–331. ISBN 9781668485330. [Google Scholar]

- Jevons, H.S. The Second Industrial Revolution. Econ. J. 1931, 41, 1–18. [Google Scholar] [CrossRef]

- Mokyr, J.; Strotz, R.H. The Second Industrial Revolution, 1870–1914; Northwestern University: Evanston, IL, USA, 2000. [Google Scholar]

- Castells, M. The Rise of the Network Society: With a New Preface, Volume I: Second Edition with a New Preface; Wiley-Blackwell: Hoboken, NJ, USA, 2010; ISBN 9781405196864. [Google Scholar]

- Schwab, K. The Fourth Industrial Revolution; Portfolio Penguin: New York, NY, USA, 2017; ISBN 9780241300756. [Google Scholar]

- Coelho, P.; Bessa, C.; Landeck, J.; Silva, C. Industry 5.0: The Arising of a Concept. Procedia Comput. Sci. 2023, 217, 1137–1144. [Google Scholar] [CrossRef]

- Hassan, M.A.; Zardari, S.; Farooq, M.U.; Alansari, M.M.; Nagro, S.A. Systematic Analysis of Risks in Industry 5.0 Architecture. Appl. Sci. 2024, 14, 1466. [Google Scholar] [CrossRef]

- Industry 5.0—European Commission. Available online: https://research-and-innovation.ec.europa.eu/research-area/industrial-research-and-innovation/industry-50_en (accessed on 21 November 2024).

- Subbiah, P.; Tyagi, A.K.; Mazumdar, B.D. The Future of Manufacturing and Artificial Intelligence Industry 6.0 and Beyond. In Industry 4.0, Smart Manufacturing, and Industrial Engineering; CRC Press: Boca Raton, FL, USA, 2024; pp. 347–362. ISBN 9781040116906. [Google Scholar]

- Simpson, T.W.; Siddique, Z.; Jiao, J. Product Platform and Product Family Design: Methods and Applications; Springer: New York, NY, USA, 2006; ISBN 0387257217. [Google Scholar]

- Simpson, T.W.; Jiao, J.R.; Siddique, Z.; Hölttä-Otto, K. Advances in Product Family and Product Platform Design: Methods & Applications; Springer: New York, NY, USA, 2014; ISBN 9781461479376. [Google Scholar]

- Rhino in Architecture, Engineering, and Construction. Available online: https://www.rhino3d.com/en/for/architecture/ (accessed on 3 December 2024).

- Fusion 360 Introduction to Generative Design. Available online: https://www.autodesk.com/autodesk-university/article/Fusion-360-Introduction-Generative-Design (accessed on 3 December 2024).

- Altair Hyperworks 2024. Available online: https://altair.com/hyperworks-2024 (accessed on 3 December 2024).

- Alcaide-Marzal, J.; Diego-Mas, J.A.; Acosta-Zazueta, G. A 3D Shape Generative Method for Aesthetic Product Design. Des. Stud. 2020, 66, 144–176. [Google Scholar] [CrossRef]

- Krish, S. A Practical Generative Design Method. Comput.-Aided Des. 2011, 43, 88–100. [Google Scholar] [CrossRef]

- Dean, L.; Loy, J. Generative Product Design Futures. Des. J. 2020, 23, 331–349. [Google Scholar] [CrossRef]

- Barbieri, L.; Muzzupappa, M. Form Innovation: Investigating the Use of Generative Design Tools to Encourage Creativity in Product Design. Int. J. Des. Creat. Innov. 2024, 12, 163–182. [Google Scholar] [CrossRef]

- Madrigal, J.; Jeong, S. Personalization Process of 3D Printed Products Using Parametric Design. Arch. Des. Res. 2022, 35, 31–46. [Google Scholar] [CrossRef]

- Mountstephens, J.; Teo, J. Progress and Challenges in Generative Product Design: A Review of Systems. Computers 2020, 9, 80. [Google Scholar] [CrossRef]

- Urquhart, L.; Wodehouse, A.; Loudon, B.; Fingland, C. The Application of Generative Algorithms in Human-Centered Product Development. Appl. Sci. 2022, 12, 3682. [Google Scholar] [CrossRef]

- Lobos, A. Applying Generative Systems to Product Design. In Proceedings of the XXII Generative Art Conference, Rome, Italy, 19–20 December 2019; Soddu, C., Colabella, E., Eds.; Generative Art Conference: Rome, Italy, 2019; pp. 1–11. [Google Scholar]

- Gürel, A.; Şenyapılı Ozcan, B. Cognitive Comparison of Design Methods in the Conceptual Phase. Int. J. Archit. Comput. 2023, 21, 581–601. [Google Scholar] [CrossRef]

- Kielarova, S.W.; Pradujphongphet, P. New Design Algorithm: Interactive-Generative Product Design for Shape Generation and Optimization. In Proceedings of the Advances in Swarm Intelligence, Konstanz, Germany, 9–11 October 2024; Tan, Y., Shi, Y., Eds.; Springer: Singapore, 2024; Volume 14789 LNCS, pp. 353–362. [Google Scholar]

- García-Dominguez, A.; Claver, J.; Sebastián, M.A. Optimization Methodology for Additive Manufacturing of Customized Parts by Fused Deposition Modeling (FDM). Application to a Shoe Heel. Polymers 2020, 12, 2119. [Google Scholar] [CrossRef] [PubMed]

- Harding, J.E.; Shepherd, P. Meta-Parametric Design. Des. Stud. 2017, 52, 73–95. [Google Scholar] [CrossRef]

- Harding, J.; Brandt-Olsen, C. Biomorpher: Interactive Evolution for Parametric Design. Int. J. Archit. Comput. 2018, 16, 144–163. [Google Scholar] [CrossRef]

- Tünger, Ç.; Pektaş, Ş.T. A Comparison of the Cognitive Actions of Designers in Geometry-Based and Parametric Design Environments. Open House Int. 2020, 45, 87–101. [Google Scholar] [CrossRef]

- Novak, J.I. A Boolean Method to Model Knit Geometries with Conditional Logic for Additive Manufacturing. Comput. Aided Des. Appl. 2020, 17, 659–673. [Google Scholar] [CrossRef]

- Zou, Y.; Wang, Y.; Luh, D.B. Application and Parametric Design of Line Visual Illusion Graphics in Clothing. Fibres Text. East. Eur. 2023, 31, 65–74. [Google Scholar] [CrossRef]

- Lee, K.S.; Song, H.K. Automation of 3D Average Human Body Shape Modeling Using Rhino and Grasshopper Algorithm. Fash. Text. 2021, 8, 23. [Google Scholar] [CrossRef]

- Kielarova, S.W.; Pradujphongphet, P. Collaborative Product Design for Product Customization: An Industrial Case of Fashion Product. In Proceedings of the Cooperative Design, Visualization, and Engineering, Bangkok, Thailand, 25–28 October 2020; Luo, Y., Ed.; Springer: Cham, Switzerland, 2020; Volume 12341 LNCS, pp. 37–46. [Google Scholar]

- Kielarova, S.W.; Pradujphongphet, P. Genetic Algorithm for Product Design Optimization: An Industrial Case Study of Halo Setting for Jewelry Design. In Proceedings of the Advances in Swarm Intelligence, Shenzhen, China, 14–18 July 2023; Yin, T., Shi, Y., Luo, W., Eds.; Springer: Cham, Switzerland, 2023; Volume 13968 LNCS, pp. 219–228. [Google Scholar]

- Wang, X.; Wang, Y.; Bai, X. Research on Interactive Jewelry Customization Design Driven by Intelligent Technology. In Proceedings of the 2nd International Conference on Intelligent Design and Innovative Technology, Chengdu, China, 4–6 August 2023; Appleby, R., Imparato, M., Feng, Y., Wheeb, A.H., Eds.; Atlantis Press: Dordrecht, The Netherlands, 2023; pp. 172–182. [Google Scholar]

- Manavis, A.; Kyratsis, P. A Computational Study on Product Shape Generation to Support Brand Identity. Int. J. Mod. Manuf. Technol. 2021, 13, 115–122. [Google Scholar]

- Manavis, A.; Tzotzis, A.; Tsagaris, A.; Kyratsis, P. A Novel Computational-Based Visual Brand Identity (CbVBI) Product Design Methodology. Machines 2022, 10, 1065. [Google Scholar] [CrossRef]

- Johannesson, H.; Claesson, A. Systematic Product Platform Design: A Combined Function-Means and Parametric Modeling Approach. J. Eng. Des. 2005, 16, 25–43. [Google Scholar] [CrossRef]

- Yu, Y.Y.; Chen, M.; Lin, Y.; Ji, Z.S. A New Method for Platform Design Based on Parametric Technology. Ocean. Eng. 2010, 37, 473–482. [Google Scholar] [CrossRef]

- Simpson, T.W. Product Platform Design and Optimization: Status and Promise. Proc. ASME Des. Eng. Tech. Conf. 2008, 2A, 131–142. [Google Scholar] [CrossRef]

- Zheng, P.; Xu, X.; Yu, S.; Liu, C. Personalized Product Configuration Framework in an Adaptable Open Architecture Product Platform. J. Manuf. Syst. 2017, 43, 422–435. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.H. Engineering Design: A Systematic Approach; Springer: London, UK, 2007; ISBN 1846283183. [Google Scholar]

- Ulrich, K.T.; Eppinger, S.D. Product Design and Development; McGraw-Hill: New York, NY, USA, 1995; ISBN 0-07-065811-0. [Google Scholar]

- Hsu, M.C.; Wang, C.; Herrema, A.J.; Schillinger, D.; Ghoshal, A.; Bazilevs, Y. An Interactive Geometry Modeling and Parametric Design Platform for Isogeometric Analysis. Comput. Math. Appl. 2015, 70, 1481–1500. [Google Scholar] [CrossRef]

- Lopes, R.A.P. Computational Strategies Applied to Product Design. Ph.D. Thesis, Universidade do Lisboa, Lisbon, Portugal, 2018. [Google Scholar]

- Caetano, I.; Santos, L.; Leitão, A. Computational Design in Architecture: Defining Parametric, Generative, and Algorithmic Design. Front. Archit. Res. 2020, 9, 287–300. [Google Scholar] [CrossRef]

- Davis Edge, A. Guidelines for Practical Algorithmic Design for Industrial Designers. Master’s Thesis, Auburn University, Auburn, AL, USA, 2019. [Google Scholar]

- Lee, J.H.; Gu, N.; Williams, A.P. Exploring Design Strategy in Parametric Design to Support Creativity. In Proceedings of the 18th International Conference on Computer-Aided Architectural Design Research in Asia, Wellington, New Zealand, 15–18 April 2019; Rudi Stouffs, P., Janssen, S., Roudacski, B.T., Eds.; National University of Singapore: Singapore, 2013; pp. 489–498. [Google Scholar]

- Chien, S.-F.; Yeh, Y.-T. On Creativity and Parametric Design: A Preliminary Study of Designer’s Behaviour When Employing Parametric Design Tools. In Physical Digitality, Proceedings of the 30th International Conference on Education and research in Computer Aided Architectural Design in Europe, Prague, Czech Republic, 12–14 September 2012; Valencia, Spain, 7–9 March 2016, Achten, H., Pavliček, J., Hulín, J., Matějovská, D., Eds.; Brussels: Education in Computer Aided Architectural Design in Europe; České Vysoké Učení Technické v Praze: Prague, Czech Republic, 2012; Volume 2, pp. 245–253. [Google Scholar]

- Yusof, F.M.; Hashim, A.M.; Azizan, H.A.; Wongtanasuporn, P. Exploring Idea Generation of Parametric Concept on Industrial Product Design. Environ.-Behav. Proc. J. 2025, 10 (Suppl. 29), 35–43. [Google Scholar] [CrossRef]

- Bai, X.; Huerta, O.; Unver, E.; Allen, J.; Clayton, J.E. A Parametric Product Design Framework for the Development of Mass Customized Head/Face (Eyewear) Products. Appl. Sci. 2021, 11, 5382. [Google Scholar] [CrossRef]

- Rodrigo Corbaton, C.; Fernández-Vicente, M.; Conejero, A. Design and 3D Printing of Custom-Fit Products with Free Online Software and Low Cost Technologies. A Study of Viability for Product Design Student Projects. In Proceedings of the 10th International Technology, Education and Development Conference, Valencia, Spain, 7–9 March 2016; Chova, L.G., López Martínez, A., Candel Torres, I., Eds.; International Association of Technology, Education and Development: Valencia, Spain, 2016; Volume 1, pp. 3906–3910. [Google Scholar]

- Tian, Y.; Ball, R. Parametric Design for Custom-Fit Eyewear Frames. Heliyon 2023, 9, e19946. [Google Scholar] [CrossRef]

- Jiao, Y.; Jung, H.; Lozano Robledo, A.; O’Kane, B. UX Design Approach to Guide Parametric Product Customization: A Case for Eyeglass Frame Design. In Proceedings of the International Association of Societies of Design Research Congress 2023: Life-Changing Design, Milan, Italy, 9–13 October 2023; De Sainz Molestina, D., Galluzzo, L., Rizzo, F., Spallazzo, D., Eds.; Design Research Society: London, UK, 2023; pp. 1–13. [Google Scholar]

- Tian, Y.; Miao, Y.; Yu, Y.; Zhang, Z. Parametric Design of Grasshopper Based on Moulding Characteristics of Longitudinal Profile of Shoe Last. J. Phys. Conf. Ser. 2019, 1267, 012045. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, H.; Lu, G.; Liu, Z. Rapid parametric design methods for shoe-last customization. Int. J. Adv. Manuf. Technol. 2011, 54, 173–186. [Google Scholar] [CrossRef]

- Verbiscer, A.J.; Helfenstein, P.; Zhang, Y.; Wei, H.; Lv, Y.; Tian, Y.; Miao, Y.; Yu, Y.; Zhang, Z. Parametric Design Method Based on Grasshopper and Shoe Last Bottom Pattern Moulding Characteristics. IOP Conf. Ser. Mater. Sci. Eng. 2019, 520, 012017. [Google Scholar] [CrossRef]

- Firtikiadis, L.; Manavis, A.; Kyratsis, P.; Efkolidis, N. Product Design Trends within the Footwear Industry: A Review. Designs 2024, 8, 49. [Google Scholar] [CrossRef]

- Manavis, A.; Minaoglou, P.; Efkolidis, N.; Kyratsis, P. Digital Customization for Product Design and Manufacturing: A Case Study within the Furniture Industry. Electronics 2024, 13, 2483. [Google Scholar] [CrossRef]

- Felek, S.Ö. Parametric Modelling in Furniture Design A Case Study: Two Door Wardrope. Eur. J. Res. Dev. 2022, 2, 62–74. [Google Scholar] [CrossRef]

- Higa, P.; Jia, Y.; Mitani, J. 3D Printing of Flat-Folded Bistable Origami-Like Structures-All Databases. J. Geom. Graph. 2024, 28, 103–116. [Google Scholar]

- Novak, J.I. A Parametric Method to Customize Surfboard and Stand up Paddle Board Fins for Additive Manufacturing. Comput. Aided Des. Appl. 2021, 18, 297–308. [Google Scholar] [CrossRef]

- Tsuchiya, S. A Study of a Design Support Method for Generating Revolved Mesh Shapes Using Grasshopper. In Proceedings of the 21st International Conference on Geometry and Graphics, Fukuoka, Japan, 5–9 August 2024; Takenouchi, K., Ed.; Springer: Cham, Switzerland, 2024; pp. 311–320. [Google Scholar]

- Chang, H.-C.; Chang, H.-C. Parametric Design Techniques Applied to Creative Hollow out Product Design with 3D Voronoi Patterns. J. Comput. Commun. 2021, 9, 32–47. [Google Scholar] [CrossRef]

- Li, W.; Abidin, S.Z.; Mokhtar, S. Parametric Technology is Used for the Design of Weaving Products. In Proceedings of the Second International Conference on Digital Society and Intelligent Systems, Chendgu, China, 2–4 December 2022; Hu, J., Yang, X., Eds.; SPIE: Bellingham, WA, USA, 2023; Volume 12599, pp. 295–302. [Google Scholar]

- Huang, Y. A Generative Bottle Design System Based on Users’ Touch Feelings. In Proceedings of the 26th HCI International Conference: Human Interface and the Management of Information, Washington, DC, USA, 29 June–4 July 2024; Mori, H., Asahi, Y., Eds.; Springer: Cham, Switzerland, 2024; Volume 14689 LNCS, pp. 142–161. [Google Scholar]

- Jiang, Y.; Zhou, M.; Liu, Q.; Xia, B. Parametric Design Experiment of Cultural and Creative Patterns Based on Grasshopper Plug-In. In Proceedings of the Seventh International Conference on Mechatronics and Intelligent Robotics, Kunming, China, 19–21 May 2023; Patnaik, S., Shen, T., Eds.; SPIE: Bellingham, WA, USA, 2023; Volume 12779, p. 127792K. [Google Scholar]

- Zeng, S.; Qiu, S. Parametric Design for Industrial Products—Taking Ergonomic Seat Design as an Example. In Proceedings of the 26th International Conference of the Association for Computer-Aided Architectural Design Research in Asia, Hong Kong, China, 29 March–1 April 2021; Globa, A., Van Ameijide, L., Fingrut, A., Kim, N., Sky Lo, T., Eds.; CAADRIA: Bunkyo-ku, Japan, 2021; Volume 1, pp. 121–130. [Google Scholar]

- Yin, R.K. Case Study Research and Applications: Design and Methods; SAGE Publications: Thousand Oaks, CA, USA, 2017. [Google Scholar]

- ISO 9241-11:2018; Ergonomics of Human-System Interaction—Part 11: Usability: Definitions and Concepts. ISO: Geneva, Switzerland, 2018.

- CEN TC 122 EN 1005-1:2001+A1:2008; Safety of Machinery—Human Physical Performance—Part 1: Terms and Definitions. CEN: Brussels, Belgium, 2001.

- CEN TC 122 EN 1005-2:2003+A1:2008; Safety of Machinery—Human Physical Performance—Part 2: Manual Handling of Machinery and Component Parts of Machinery. CEN: Brussels, Belgium, 2003.

- CEN TC 122 EN 1005-3:2002+A1:2008; Safety of Machinery—Human Physical Performance—Part 3: Recommended Force Limits for Machinery Operation. CEN: Brussels, Belgium, 2002.

- CEN TC 122 EN 1005-4:2005+A1:2008; Safety of Machinery—Human Physical Performance—Part 4: Evaluation of Working Postures and Movements in Relation to Machinery. CEN: Brussels, Belgium, 2001.

- ISO 15534-2:2000; Ergonomic Design for the Safety of Machinery—Part 2: Principles for Determining the Dimensions Required for Access Openings. ISO: Geneva, Switzerland, 2000.

- ISO 15534-1:2000; Ergonomic Design for the Safety of Machinery—Part 1: Principles for Determining the Dimensions Required for Openings for Whole-Body Access into Machinery. ISO: Geneva, Switzerland, 2000.

- ISO 15534-3:2000; Ergonomic Design for the Safety of Machinery—Part 3: Anthropometric Data. ISO: Geneva, Switzerland, 2000.

- Borrero Comino, S.; Martín-Mariscal, A.; Peralta, E. Algorithmic Design of Perfume Bottle Family. Bachelor’s Thesis, Universidad de Sevilla, Seville, Spain, 2023, unpublished. [Google Scholar]

- Villa-Álvarez de Toledo, C.; Martín-Mariscal, A. Design and Development of a Family of Seats by Algorithmic Design. Bachelor’s Thesis, Universidad de Sevilla, Seville, Spain, 2023, unpublished. [Google Scholar]

- Castillo Pérez, Á.; Martín-Mariscal, A. Algorithmic Design of a Desk Organiser. Bachelor’s Thesis, Universidad de Sevilla, Seville, Spain, 2023, unpublished. [Google Scholar]

- Djokikj, J.; Angeleska, E.; Rizov, T.; Kandikjan, T. Parametric Design as an Approach for Designing Personalized Products. In Proceedings of the 8th International Scientific Conference on Geometry and Graphics, Belgrade, Serbia, 10–12. September 2021; Jeli, Z., Ed.; SUGIG: Belgrade, Serbia, 2021; pp. 19–24. [Google Scholar]

- Han, X.; Li, R.; Wang, J.; Ding, G.; Qin, S. A Systematic Literature Review of Product Platform Design under Uncertainty. J. Eng. Des. 2020, 31, 266–296. [Google Scholar] [CrossRef]

- Dy, B.; Stouffs, R. Combining Geometries and Descriptions A Shape Grammar Plug-in for Grasshopper. In Proceedings of the 36th International Conference on Education and Research in Computer Aided Architectural Design in Europe: Computing for a Better Tomorrow, Lodz, Poland, 19–21 September 2018; Kępczyńska-Walczak, A., Białkowski, S., Eds.; eCAADe: Brussels, Belgium, 2018; Volume 2, pp. 499–508. [Google Scholar]

- Costa, E.C.E.; Jorge, J.; Duarte, J. Comparing Digital Tools for Implementing a Generative System for the Design of Customized Tableware. Comput. Aided Des. Appl. 2019, 16, 803–821. [Google Scholar] [CrossRef]

- Refalian, G.; Coloma, E.; Moya, J.N. Formal Grammar Methodology for Digital Visualization of Islamic Geometric Patterns. Int. J. Archit. Comput. 2022, 20, 297–315. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).