Abstract

This study investigates how small and medium-sized enterprises (SMEs) can successfully transform into high-tech, high-value-added companies within the aviation industry, considering the latest manufacturing, certification, and quality technologies. We identified critical factors through a comprehensive literature review and expert interviews, then analyzed the relationships between these factors using two complementary methodologies: grey DEMATEL (Decision Making and Trial Evaluation Laboratory) and ISM (Interpretive Structural Modeling). Our approach employed grey numbers to address individual uncertainty and utilized the Aczel–Alsina function to integrate expert opinions while accounting for inter-expert disagreements. The research focused on traditional machinery manufacturers in Taiwan transitioning to aviation manufacturing, the findings being applicable to enterprises in other countries with similar environments where small and medium-sized enterprises are the main players. The results revealed three critical factors determining successful transformation: organizational culture and workforce quality, aviation certification protocols, and original equipment manufacturer (OEM) outsourcing policies and requirements. Based on these findings, the study provides strategic recommendations for government policymakers and business executives to facilitate the successful entry of traditional industrial enterprises into the aviation manufacturing sector.

1. Introduction

In today’s global landscape, traditional industries face multiple challenges: rapid technological advancement, market evolution, unexpected disruptions (such as epidemics and regional conflicts), and intensifying international competition. These challenges necessitate transformation toward high-value-added industries to ensure sustainable development and growth [1]. Success in this transformation requires deep understanding of technological upgrade requirements, industrial chain restructuring, and sustainable development practices. The aviation industry, recognized as a high-value-added sector, represents a strategic development priority for many nations [2]. It serves as both a measure of national technological capability and an attractive target for businesses seeking transformation opportunities. The industry’s impact extends beyond its immediate sphere—it catalyzes technological innovations across related sectors, creating a positive feedback loop of advancement while significantly contributing to economic growth [3]. Moreover, the aviation sector’s demand for highly skilled professionals drives the development of specialized talent, fostering expertise in cutting-edge scientific and technological capabilities through hands-on project experience.

However, transitioning from a traditional industrial enterprise into the aviation industry is not an easy task [4]. It involves changes covering a wide range of aspects, such as governmental regulations, manufacturing capabilities, and technology, all of which need to be developed simultaneously, and those who are interested in entering the civil aviation manufacturing industry may not be familiar with or understand its characteristics. In addition to the strict aviation regulations and quality system requirements, the technological threshold of the industry and the relationship between the upstream and downstream supply chains are also important factors in evaluating whether to make the investment required for transitioning into the industry [5]. The aviation industry is a highly complex sector that typically involves numerous international suppliers. Besides having extremely high technical barriers, its logistics systems are also very complex. Therefore, the aviation industry referred to in this study does not mean manufacturers with complete aircraft production capabilities but rather refers to the challenges and transformation directions for traditional small and medium-sized enterprises (SMEs) looking to enter the aviation industry. Thus, the main subjects are all component suppliers and even aviation material suppliers. This study aims to accomplish two key goals. First, to identify the critical factors that enable traditional industrial enterprises to successfully transform into aviation manufacturing firms. Second, to analyze the interrelationships between these factors, providing a comprehensive understanding of how they influence the transformation process.

Previous studies have explored various aspects of industrial transformation using different analytical methods. Lee et al. [6] combined AHP (Analytic Hierarchy Process) and DEMATEL (Decision-Making Trial and Evaluation Laboratory) to identify design and innovation as crucial factors for traditional industry sustainability. Sheng et al. [7] employed a hybrid fuzzy DEMATEL-ISM methodology to examine supply chain sustainability risk management within China’s steel industry. Similarly, Primadasa et al. [8] combined DEMATEL-ISM-MICMAC approaches to develop an interconnected framework of halal-sustainable supply chain management (HSSCM) indicators specifically designed for small and medium-sized enterprises. Wu and Wang [9] examined how industrial transformation could reduce fossil fuel dependence through correlation analysis. Li and Guan [10] used data envelopment analysis (DEA) to study state-owned enterprises’ role in industrial restructuring across Chinese provinces. In technology and innovation studies, Zou [11] developed the LASIS model to analyze how technological innovation drives industrial upgrading, while Wang and Su [12] employed panel models to assess marine technology’s impact on industry development. Jiang and Wang [13] demonstrated the positive effects of digital transformation on supply chain stability and industrial structure through statistical analysis. In aviation-specific research, Poudeh [14] utilized Analytic Network Process (ANP) and DEMATEL methods to evaluate make-or-buy decisions for aviation products. Additional studies focused on manufacturing transformation include Yang and Xiang’s [15] grounded theory approach, Gu and Xu’s [16] Bayesian analysis of innovation paths, and Feng and Wu’s [17] sensitivity analysis of aviation industry management strategies. Liangrokapart and Sittiwatethanasiri [18] combined SWOT analysis with AHP to develop strategic improvements for aviation maintenance operations.

While the existing literature has extensively covered transformation strategies for traditional industries, there is a notable gap in research specifically addressing transitions into the aviation sector. Moreover, the combined application of DEMATEL and Interpretive Structural Modeling (ISM) methodologies remains underutilized in transformation studies. In particular, there has been no comprehensive research examining how traditional industrial enterprises can successfully transform into high-value-added firms within the aviation industry. Our study addresses these knowledge gaps through an integrated methodological approach, combining grey DEMATEL and ISM analysis to identify and examine the critical factors that enable successful entry into the aviation sector.

DEMATEL serves as a graphical analysis tool widely used to study critical factors, distinguishing between cause-and-effect relationships [19,20,21]. Complementing this, ISM provides a hierarchical analysis of factors, revealing their upstream and downstream relationships. The integration of DEMATEL and ISM methodologies can provide a comprehensive analytical framework, revealing both the causal relationships and hierarchical structures among factors essential for traditional businesses seeking to enter the aviation industry. Furthermore, previous studies have mostly used crisp values for analysis, without considering the uncertainty that may arise from incomplete information available to decision-makers, as well as the inconsistencies that may occur due to differences in individual decision-makers’ experiences. To address the inherent limitations of DEMATEL and ISM analyses, which heavily rely on expert judgment, this study employs two specialized methods. The grey number approach [22] helps manage uncertainty stemming from incomplete information, while the Aczel–Alsina function [23] provides a more sophisticated alternative to traditional averaging methods for synthesizing expert opinions. Unlike simple averaging, which can be skewed by extreme values and ignores expert credentials, the Aczel–Alsina function effectively accounts for varying levels of expertise and experience among decision-makers, resulting in more accurate weightings of expert judgments. The specific contributions of this paper include the following:

- Provides information on the factors critical to the transformation of traditional industries into aviation manufacturing;

- Analyzes the interrelationships between factors using research modeling to determine which factors serve as drivers (causes) and which serve as outcomes (effects);

- Uses DEMATEL combined with ISM to reduce the number of pairwise comparisons;

- Combines the grey number and Aczel–Alsina function to effectively improve the uncertainty and inconsistency of data collection;

- Proposes strategies for upgrading traditional industries into the aviation industries, which can be used as a reference for government and industry.

The rest of this paper is organized as follows: Section 2 provides a comprehensive literature review examining both theoretical underpinnings and practical considerations in civil aviation manufacturing. Section 3 details the research methodology. Section 4 presents and discusses the research findings. The concluding section addresses study limitations and provides key recommendations for future evaluation and development.

2. Literature Review

The literature review comprises two main subsections. The first examines the challenges confronting traditional industries and outlines the distinctive characteristics of the aviation sector. The second subsection introduces the concept of multi-criteria decision modeling in terms of the key factors to be explored.

2.1. Challenges Faced by Traditional Industries

In the context of rapid global economic change and the accelerated pace of scientific and technological advancement, traditional industries are confronted with a multitude of challenges. These challenges include intensified market competition, product homogeneity, rising labor costs, increasingly stringent environmental regulations, and changing consumer demands. These factors have resulted in a narrowing of profit margins for traditional industries and an intensification of operational pressure, compelling companies to contemplate the necessity of transformation and modernization. Against this background, traditional industries must undergo a process of transformation and upgrading in order to enhance their competitiveness and achieve sustainable development. The direction of transformation and upgrading includes technological innovation, product upgrades, industrial chain extension, and changes in service models [24]. Such measures can not only enhance a company’s production efficiency and product added value, they can also facilitate the company’s ability to adapt to market changes and identify new avenues for development.

Previous studies have shown that the transformation and upgrading of traditional industries are crucial to the long-term development of enterprises. For example, Zhou and Wang [25] pointed out that through the introduction of advanced manufacturing technologies and automated equipment, enterprises can significantly improve production efficiency, reduce costs, and thus place themselves in a favorable position to succeed in the face of fierce market competition. In addition, by strengthening R&D investment and developing high-value-added products, enterprises can also realize the transformation from low-end manufacturing to high-end manufacturing. Using statistical analysis and case studies, Porter [26] scrutinized the impact of technological innovation, which is the core driver to enhance the competitiveness of a country and its enterprises. Based on the results, they concluded that technological innovation can significantly improve the efficiency of the production of added value products, as well as help enterprises to take advantage of market competition. Prahalad and Hamel [27] investigated how enterprises can improve their competitiveness through the development of core competencies and product upgrading. They concluded that enterprises can realize the transformation from low-end manufacturing to high-end manufacturing by strengthening R&D investment and developing high-value-added products. Gereffi et al. [28] explored the governance structure of the global value chain and its impact on the competitiveness of enterprises. They maintained that firms can form a complete industrial chain by expanding into upstream and downstream industries, which can enhance their overall competitiveness and resilience to risk. The methods used in these studies include case studies, statistical analysis of data, questionnaire surveys, and experimental studies.

In terms of the traditional manufacturing process, in the process of technological innovation, product upgrading, and extension of the industrial chain [29], as the market becomes more and more competitive, the industry has evolved from single-product original equipment manufacturing (OEM) to the mass production of a wide range of products [30]. However, due to the rise of OEM in China and the development of emerging economies in Southeast Asia [31], labor costs have risen, which has eroded the profits of traditional industrial enterprises, forcing their transformation into the milieu of high-value-added technology industry, moving from large-scale mass production to small-batch production [32]. In high-value-added industries [33], customers’ product expectations are more diverse, more varied, and of higher quality, with a demand for customization which has become a challenge that companies must face.

The aviation industry is characterized by a strong reliance on technological innovation and R&D investment, a high technological threshold, and the need for substantial capital investment [34]. Whether it is R&D, production, or market development, all require sufficient capital support. This is a high-risk and high-reward industry. The aviation industry is characterized by high risk due to the high technological requirements and long R&D cycles [35], but the rewards for success are quite generous. Internationalization, meaning a global vision and the ability to enter international markets [36], is another basic requirement for enterprises in the aviation industry. In short, the upgrading of traditional industries to enter the aviation industry necessitates not only improvement at the technological level and market competitiveness [37], but it also drives the development of related industries, stimulating the transformation and upgrading of the whole economy [38]. Therefore, the aviation industry is often regarded as one of the best choices for the upgrading of traditional industrial enterprises, mainly because it involves such a large number of high-tech developments in various fields [39], including material science, electronic engineering, mechanical design, etc., which can drive the technological progress of related industries [40]. At the same time, aviation products are high-value-added products and have a stable market demand [41], which can bring substantial returns to enterprises. In addition, the aviation industry has a strong industry-driven effect [42], which can promote the synergistic development of upstream and downstream industries and form a complete industrial chain.

2.2. Exploring Factor-Related Methods

Multi-criteria decision-making methods, particularly DEMATEL and ISM, have emerged as effective tools for analyzing relationships between factors across various industries. ISM has been successfully applied in several contexts: examining sustainable supply chain management factors in the oil and gas industry [43], analyzing barriers to 6 Sigma certification in SMEs through integration with structural equation modeling [44], investigating obstacles to information modeling in construction [45], and exploring Industry 4.0 implementation challenges when combined with the Analytic Network Process [46]. Similarly, DEMATEL has demonstrated versatility in different applications. It has been used to assess smart city development factors and, in its grey variant, to explore key factors in green business failure [47]. The method has also been integrated with other analytical tools: it has been combined with Best Worst Method (BWM) and Bayesian networks for security management decisions [48] and adapted into fuzzy DEMATEL to analyze human resource challenges in start-ups [49]. Yazdi et al. [50] enhanced safety management decision-making by combining DEMATEL with multi-criteria decision-making tools and Bayesian networks. Khalilzadeh et al. [51] used DEMATEL-ISM method to analyze the key factors affecting risk tolerance in project-oriented firms. This widespread application of DEMATEL and ISM across diverse fields demonstrates their effectiveness as analytical tools for identifying and understanding key factors and their relationships. However, past research has mostly used crisp numbers, but this approach often fails to accurately represent cognitive results with a single value due to insufficient information being available to decision-makers. Additionally, when the members of a decision-making team come from different units or backgrounds, they may have different perspectives due to variations in their experiences or positions. Previous research has mostly adopted averaging methods for analysis, but this approach can easily lead to data loss and fails to reflect the importance of individual decision-makers. Therefore, the use of grey numbers combined with the Aczel–Alsina function proposed in this research can effectively improve upon these shortcomings.

DEMATEL has the following advantages [20]: (1) Structural analysis: It can help to analyze the relationship among factors in a complex system. (2) Influence assessment: It can assess the degree of influence of each factor on the system and help decision-makers prioritize the factors that have a greater influence on the system. (3) Causality analysis: It can reveal the causal relationship among factors and help determine which factors are dominant so as to formulate an effective decision-making plan. (4) Graphical presentation: Graphical presentation of the results makes complex analysis results more intuitive and easier to understand. (5) Decision support: It provides tools for a comprehensive analysis of the system, which can provide decision-makers with objective data support and help them make informed decisions.

ISM was proposed by Warfield [52] and has the following advantages: (1) Hierarchical structure: ISM uses a hierarchical structure to represent the interrelationships among factors, which helps users to clearly understand the hierarchical structure among the factors and thus better understand the problem. (2) Expert participation: It encourages experts to participate in the modeling process, to make full use of their knowledge and experience to improve the accuracy and credibility of the modeling. (3) Causality analysis: ISM can help analyze the causality among factors, reveal the mechanism of interaction among factors, and help identify the main factors and key influencing factors. (4) Decision support: ISM provides a systematic approach to analyzing problems and making decisions, which can provide an objective reference for decision-makers and assist them in making wiser decisions.

This study develops an integrated grey DEMATEL-ISM model, combining the strengths of both methodologies to provide decision-makers with more comprehensive insights. The model reveals both causal relationships between key factors and their hierarchical structure. To address the challenge of varying expert judgments, the study implements two complementary approaches: grey numbers to handle uncertainty in expert assessments and the Aczel–Alsina function to calculate weighted averages that effectively resolve inconsistencies in group decision-making. Together, these methods provide an optimal approach for synthesizing diverse expert opinions while maintaining accuracy and reliability.

3. Research Methodology

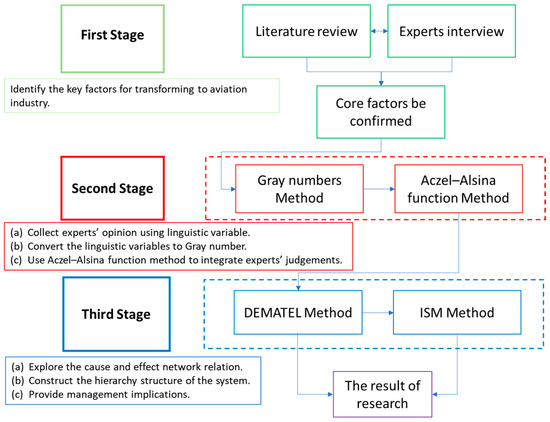

The research methodology followed a three-stage process. Stage one involved identifying key factors through a literature review and expert interviews. Stage two focused on data collection and integration: experts evaluated factor relationships using linguistic variables, which were then converted into grey numbers. The Aczel–Alsina function was applied to synthesize these evaluations while addressing expert uncertainty and inconsistency. In stage three, the DEMATEL and ISM methods were employed to analyze the relationships between factors. Figure 1 illustrates this research process in a flow chart, and the notations used are illustrated in the Abbreviations Section.

Figure 1.

Research flow chart.

3.1. Aggregation of Expert Opinions Using the Aczel–Alsina Function

The criteria for expert selection included the following: (1) participation in aerospace certification programs (AS9100/NADCAP) [53,54], (2) familiarity with both local and international aerospace supply chains, and (3) direct involvement in SME upgrading projects. This study enhanced the original Aczel–Alsina method [55] to create a grey multi-criteria decision-making matrix. By using interval numbers rather than simple averages, the combined grey number and Aczel–Alsina approach effectively integrates expert opinions while managing the uncertainty and inconsistency inherent in group decision-making processes.

For example, when expert k provides an assessment of how factor i influences factor j, their evaluation is represented by an interval value, , consisting of a lower and upper bound, i.e., , where is the lower bound and is the upper bound. These bounds are processed separately using the Aczel–Alsina nonlinear function to aggregate the expert opinions. The processing of these lower and upper bounds is detailed in the following section.

The aggregated values are determined by calculating the lower and upper bounds using Equations (1) and (2), respectively [56]:

where is defined as follows:

and .

The weight (wk) in Equations (1) and (2) is determined by the expert’s academic credentials (ak) and years of professional experience (pk).

Finally, the aggregated impact of expert k on factor i and factor j through the Aczel–Alsina weighted averaging strategy is represented as an interval, as shown in Equation (6):

3.2. Using the DEMATEL Method for Relationship Evaluation

The DEMATEL method helps analyze and make decisions in complex systems by generating an Influence Network Relations Map (INRM), which reveals causal relationships between system factors. The following section details the equations and analytical process of the DEMATEL methodology.

- Step 1. Obtain the normalized direct influence relationship matrix.

The direct influence matrix is constructed by integrating expert judgments using grey numbers and the Aczel–Alsina nonlinear function, which capture the influence degree, expert weights, inconsistency, and uncertainty of factor i with respect to factor j. The normalized direct influence matrix is then calculated using Equations (7) and (8), where the elements of the matrix are divided by the maximum sum of rows and columns.

and n is the number of factors.

- Step 2. Establish the total influence relationship matrix.

The total influence relation matrix is derived through repeated influence relation iterations using the Markov chain convergence principle, as shown in Equation (9):

- Step 3. Derive the influence relationships of the criteria.

In the total influence relationship matrix, the row sum (hi) represents the total influence that factor i exerts on all other factors (Equation (10)). Conversely, the column sum (li) indicates the total influence received by factor i from all other factors (Equation (11)).

When the difference is positive, factor i has greater influence on other factors than it receives, identifying it as a causal factor. Conversely, a negative value indicates that factor i is more influenced by others, making it an effect factor. The sum represents the total involvement of factor i in the system—both its influence on others and the influence it receives. A higher sum indicates the greater overall importance of the factor in the system.

- Step 4. Create the INRM.

The Influence Network Relations Map (INRM) is constructed by plotting each factor’s coordinates, where the x-coordinate represents the factor’s total influence, , and the y-coordinate represents its net influence, . This visualization reveals the relationship network among all factors.

3.3. Using the CFCS Method for the Transformation of Crisp Values

The DEMATEL method produces a total influence relationship matrix expressed as grey number intervals. To determine clear causal relationships between factors, these intervals must be converted into crisp values. The following section details the CFCS (Converting Fuzzy Data into Crisp Scores) aggregation method formulas and steps, as developed by Xia et al. [57].

- Step 1. Normalization of the grey number.

Grey numbers are normalized to establish uniform scaling across all values. The normalization process is applied separately to both the lower and upper bounds of each grey number, following Equations (12) and (13):

where

- Step 2. Calculate the total normalized crisp value.

Equation (15) is applied to calculate the total normalized crisp value (Nij):

- Step 3. Derive the crisp value.

Equation (16) is applied to obtain the final crisp value for the matrix:

Each matrix element is converted from a grey number range to a single crisp value by combining the normalized value (Nij) with the range boundaries.

3.4. Delineating the Hierarchical Structures and Relationships Using the ISM Approach

The ISM method simplifies complex problems by creating clear, understandable frameworks. It uses a multi-level structural model to illustrate both the relationships between factors and their hierarchical order in complex socio-economic systems. When applied to the total influence matrix, ISM generates a hierarchical structure showing how factors are organized and interconnected. The following section outlines the step-by-step process for implementing the ISM method:

- Step 1. Derive the overall influence matrix.

Referring to the computational process studied by Liang et al. [58], the initial reachability matrix, M, is obtained by utilizing matrix S after defuzzification of the total influence matrix in Equation (16).

- Step 2. Obtain the structural interaction matrix (SIM).

The total influence matrix, S, is used to generate the structural interaction matrix, Q, and the threshold, , is applied as the filtering parameter in the subsequent hierarchy. In this study, is the average value of all elements of the total influence matrix, S. The main purpose in applying the threshold is to exclude less influential factors and gradually simplify the parameters that constitute the hierarchical structure. When the total influence of factor i on j is lower than , its influence can be ignored, and when the total influence of factor i on j is higher than , it is considered to have influence.

- Step 3. Identify the reachability sets.

We transformed the SIM matrix (Q) into the reachability matrix (M) by incorporating transitivity effects according to Equation (18). From this reachability matrix, we derived both the reachability set (R) and the antecedent set (A) using Equations (19)–(21).

- Step 4. Build the ISM hierarchy.

If an element of set F produced by Equation (22) is the same as an element of set R produced by Equation (19), then that element is removed from the matrix, M, and is also assigned to the first level. The steps in Equations (19)–(21) are repeated to generate the elements of each level until all elements are assigned to different levels, after which the upper- and lower-level structures of all the elements can be generated.

4. Empirical Study

This study discusses how SMEs, faced with the pressure to transform their business, should consider moving into high-value-added technology-based industries, specifically the aviation industry. This study proposed an analytical model, starting with the collection of the opinions of experts with experience in aviation manufacturing and analysis of the current situation in the industry, and we then identified the most critical factors for entering the industry.

4.1. Constructing the Key Factors for Enterprise Transformation into the Aviation Industry

Our expert panel consisted of six senior industry leaders: five CEOs and one general manager, each bringing over 30 years of experience in the field. As mentioned above, the research sample is representative of the information obtained from the participating experts. Through interviews and questionnaires, the experts first proposed 23 key factors for the upgrading of traditional industrial enterprises into the aviation industry, based on their own experience and professional knowledge. Then, in the second expert meeting, they made comments on each of the key factors, such as whether they should be retained or deleted. If more than four experts considered factors important, they were retained, and if less than four experts considered them important, they were deleted. After a consensus discussion among the experts, 12 key factors were retained for the next stage of analysis. The 12 key factors and their definitions are listed in Table 1.

Table 1.

Extracted key factors for transforming to the aviation industry.

4.2. Using the Aczel–Alsina Function to Integrate Expert Assessments

The grey DEMATEL-ISM method is applied to explore the influence relationship among the factors. The experts had different views about the definition of quantification. Therefore, the linguistic variables and grey number correspondence shown in Table 2 were used for quantitative analysis. The Aczel–Alsina function was applied to effectively integrate the experts’ opinions in order to capture inconsistency generated by each individual in the assessment process.

Table 2.

Linguistic variables for influence assessment using grey numbers.

Based on the linguistic variables in Table 2, the linguistic variable matrix was converted into a grey number matrix, and the experts were asked to compare the key factors pairwise, with each expert rating the influence degree between the key factors. Take the evaluation by expert 1 as an example (shown in Table 3). The expert evaluated the influence degree of C1 on C2 as “High Influence (HI)”, which was transformed by the linguistic variables in Table 2 into the grey number [2.5, 3.5]. He rated the degree of influence of C1 on C3 as “Very Strong Influence (VHI)”, with the corresponding grey number [3.5, 4]. Other pairwise influences can be generated in the same way, as shown in Table 4.

Table 3.

Direct influence degrees rated by expert 1.

Table 4.

The grey number matrix converted from the linguistic variable matrix of expert 1.

Six experts evaluated the mutual influences using identical methods, with partial results presented in Table 5. To convert these linguistic assessments into grey numbers, we applied the Aczel–Alsina function through Equations (1)–(4). For demonstration, we show the calculation process of integrating the six experts’ evaluations into a grey number for the relationship between C1 and C2 as follows:

Table 5.

Direct influence degrees rated by the six experts.

The expert weights in the above equations were obtained using Equation (5), based on the experts’ educational backgrounds and relevant work experience. The other influence relationships could be calculated in the same way to obtain the direct influence matrix of all experts, as shown in Table 6.

Table 6.

Integrated initial direct influence matrix of all experts.

4.3. Exploring the Causal Relationships Using DEMATEL

The causal relationships between key barrier factors were analyzed using grey DEMATEL. Following standard procedures, we constructed the initial influence matrix (Table 6) and applied Equations (7)–(9) to generate the total influence relationship matrix (Table 7). Using the CFCS method through Equations (12)–(16), we converted the grey matrix into a crisp matrix (Table 8). We then calculated the total influence (h + l) and net influence (h − l) for each factor using Equations (10) and (11), as shown in Table 9 and Table 10. The results indicate that the most important factors by total influence are “C11 (OEM outsourcing policies and regulations)”, “C12 (aviation certification regulations)”, “C9 (degree of internationalization)”, and “C8 (management strategy and enterprise learning capability)”.

Table 7.

Total influence matrix obtained by grey DEMATEL.

Table 8.

Total influence matrix obtained using CFCS method.

Table 9.

Grey numbers of total and net influence.

Table 10.

The total influence and net influence calculated using CFCS.

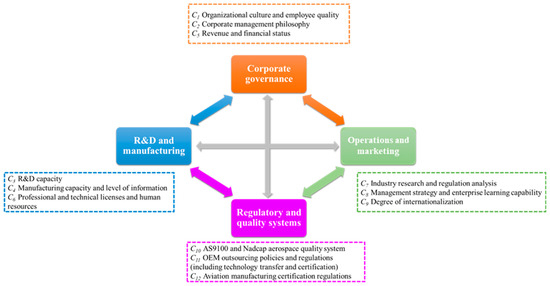

Using the data in Table 8, we plotted the INRM. For clearer visualization, we organized the twelve factors into four categories: corporate governance (C1, C2, and C5), R&D and manufacturing (C3, C4, and C6), operations and marketing (C7, C8, and C9), and regulatory and quality systems (C10, C11, and C12). The complete INRM showing these critical transformation factors is illustrated in Figure 2.

Figure 2.

INRM of the key factors.

4.4. Establishing a Hierarchical Structure of Key Factors Through ISM

We generated matrix Q (Table 11) from matrix S (Table 8) using Equation (16). Based on ISM principles, we established factor relationships by comparing values to the average influence values exceeding the average indicated relationships, while lower values indicate no relationships [20]. The final reachability matrix, M (Table 12), obtained by applying transitivity through Equation (18), displays the comprehensive factor relationships.

Table 11.

Structural interaction matrix.

Table 12.

Reachability matrix.

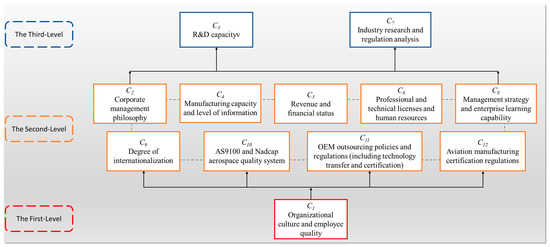

Using Equations (19)–(21), we derived the first-level reachability set (R), the antecedent set (A), and their intersection (C) from the reachability matrix, M (Table 13). Factors C3 and C7 were identified as first-level factors, as their reachability sets (R) matched their intersection sets (C). After eliminating these factors’ corresponding rows and columns, we iterated the process to construct the complete hierarchical structure, as shown in Figure 3.

Table 13.

Level portioning iterations.

Figure 3.

Hierarchical framework of key influence factors.

5. Discussion

In this section, the managerial significance of industrial transformation and upgrading expressed in this study is introduced, and the theoretical significance of this study is presented and explained based on the results of the analytical process described in Section 4.

5.1. Management Implications

This study investigated pathways for traditional manufacturers to enter the aviation manufacturing sector, a high-value-added technology industry. Our methodology consisted of three main steps: identifying 12 key factors from 23 expert-suggested factors, integrating expert opinions using grey numbers and the Aczel–Alsina function, and employing DEMATEL-ISM to analyze factor interactions and hierarchical structure. The results are shown in Table 10 and Figure 2 and Figure 3. According to Table 8, the most important factors by total influence are (C11) OEM outsourcing policies and regulations and (C12) aviation manufacturing certification regulations. This reflects the aviation industry’s extremely high technological barriers, where traditional manufacturers typically require technology transfer or OEM support for market entry. Since aviation prioritizes safety, countries establish civil aviation regulations requiring sound certification to verify technological and manufacturing capabilities for consumer acceptance.

Aviation manufacturing certification regulations issued by authorities (FAA and EASA) define required certifications for each product/component, establishing qualifications, procedures, and standards. Applicants must define test methods and demonstrate regulatory compliance. These high regulatory thresholds make it difficult for newcomers to complete manufacturing and achieve compliant product functions without OEM-provided information on materials, designs, and test methods. The results indicate that meeting aviation certification requirements is the most critical decision-making factor for new entrants. We recommend that governments establish appropriate verification regulations and organizations while developing aviation industries, providing clear manufacturer guidelines. Companies should enhance technological capabilities and obtain OEM certification to become suppliers. The INRM (Figure 2) demonstrates that C11 and C12 serve as foundational industry entry requirements, substantially influencing all other key factors. These findings align with our expert interview results.

To demonstrate the reliability and robustness of our findings, we employed a dual validation approach. First, we conducted an empirical case study of a mid-sized precision machining company located in Taichung. This firm underwent a strategic transformation from traditional mechanical manufacturing to aerospace supply chain integration by securing AS9100 certification, enhancing CNC machining technologies, and implementing comprehensive organizational restructuring. By analyzing the company’s transformation pathway through the lens of our identified critical success factors—particularly C11 (OEM policies) and C12 (certification mechanisms)—we validated the practical relevance and real-world applicability of our theoretical model. Second, to ensure the stability of our analytical framework, we performed a comprehensive sensitivity analysis by introducing ±10% perturbations to the grey number intervals established by our expert panel. The analysis revealed that the hierarchical ranking of pivotal factors, including C11, C12, and C9, remained consistent across all perturbation scenarios. This stability demonstrates that our model maintains its predictive accuracy and reliability even when accounting for reasonable variations in expert judgment, thereby reinforcing confidence in the validity of our research outcomes.

Table 10 shows that (C1) organizational culture and employee quality has the strongest net influence. A company cannot transform without changing its culture. Traditional industries must first change their organizational cultures to succeed. This change requires developing talent and bringing in new people with fresh ideas. Senior management must fully support these changes. These steps are essential for entering high-value industries. A strong organizational culture helps solve other challenges naturally. It guides the company in a positive direction. The ISM results confirm this by showing C1 at the first level, affecting all other factors. According to Table 10, when examining both total and net influence, (C2) corporate management philosophy emerges as a key factor. Since management philosophy determines how leadership guides initiatives and shapes operational principles, top executives must maintain a clear vision for the company’s future. This clarity ensures efficient transformation without wasting resources. Senior management should either continually enhance their understanding of technological and market trends or engage external consultants for specific reform strategies. From the ISM results (Figure 3), (C3) R&D capacity and (C7) industry research and regulation analysis sit at the top level. This means that when a company improves its other factors, its R&D and market analysis abilities grow stronger. These two improved abilities show that a company has become more competitive. These results show that despite the technological advancement and innovation of traditional industries, it is still not easy to make the transition into the aviation industry. Companies must first transform their organizational culture and focus on talent recruitment and development. In addition to establishing sound verification regulations, the government should also use various trade negotiation opportunities to help companies obtain original manufacturer technology licenses or certifications. Therefore, the results of this study are expected to enable enterprises in the industry to understand the ecology of the aviation manufacturing system and, at the same time, to grasp the key factors to become a part of the supply chain.

5.2. Theoretical Contribution

In group decision-making processes, different perspectives often arise due to individual decision-makers’ varying knowledge, experience, and departmental backgrounds. Each decision-maker may also reach different conclusions due to incomplete information reception and personal uncertainties in interpreting linguistic variables. This study first used grey numbers to capture the uncertainty in individual expert judgments. In the past, group opinions were mostly aggregated using averages, but averages are easily affected by extreme values and may lead to information loss. This study adopted the Aczel–Alsina function to integrate different expert opinions. This approach not only considers expert weights but is also less likely to cause information loss. Additionally, it works well with grey numbers and fuzzy logic, can process imprecise or uncertain expert assessments, and maintains the integrity of uncertainties throughout calculations [21,50].

The DEMATEL and ISM methods rely on expert opinions rather than large-scale statistical surveys, typically employing alternative means to enhance reliability, such as fuzzy, rough, or grey numbers, to capture uncertainty in expert opinions. Our proposed model uses grey numbers and the Aczel–Alsina function to aggregate input data, representing an integrated approach that constitutes this study’s improvement. For validation, we asked a decision-making team to confirm the findings, and experts indicated results that aligned with their practical experience, suggesting credible outcomes. The DEMATEL and ISM analysis data derived from expert surveys regarding pairwise influence comparisons between factors. This survey method differs from other MCDM approaches, making it impossible to use identical survey data for analysis and comparison with other models. Currently, most MCDM models (AHP, ANP, TOPSIS, and VIKOR) focus primarily on calculating factor weights or ranking alternatives, with no similar methods available for investigating influential relationships between factors. This limitation reinforces the uniqueness and necessity of our approach in examining inter-factor relationships rather than simple weighting or ranking.

Integrating DEMATEL and ISM methodologies offers two key advantages: it eliminates the need for additional surveys and enables direct transitivity analysis using the DEMATEL-derived influence matrix through ISM concepts. This integration creates stronger consistency between the factor hierarchy and DEMATEL’s network relationships. By combining the ISM hierarchical structure with the INRM network diagram, decision-makers can better understand factor relationships, distinguish between causes and effects, and establish improvement priorities under resource constraints. This provides manufacturers with a more efficient transformation strategy.

6. Conclusions

Small and medium-sized enterprises in developing countries face competition from multinational corporations and must undergo transformation to achieve sustainable development. What are the key success factors for traditional industries transforming into the high-value-added aviation industry? Additionally, it is also important to consider the interrelationships among these factors. In this study, many transformation factors were analyzed, including enterprises’ own capabilities, technological capacities, internationalization, and regulatory constraints. This study first identified the key factors for enterprises in traditional industries to transform into the aviation industry through a literature review and in-depth interviews with experts. Then, the DEMATEL-ISM method was used to explore the causal and hierarchical relationships among these factors. To address the uncertainty and inconsistency in expert decisions, the data were integrated using grey theory combined with the Aczel–Alsina function. This study identified three paramount factors for aviation sector entry: organizational culture and employee quality, aviation certification regulations, and OEM outsourcing policies. While our analysis centered on Taiwan’s traditional industries, these findings offer valuable insights for developing nations whose industries seek to transition into aviation manufacturing.

Despite its valuable findings, this study has certain limitations. For example, it is still necessary to consider the MRO issues in the later stages of aviation manufacturing by deepening FAA or EASA’s MRO requirements, strengthening operational risk and safety management, and promoting long-term quality assurance and regulatory compliance through a third-party audit mechanism to ensure quality and regulatory compliance. Further, any business transformation involves dynamic adjustments to strategy and also varies according to the circumstances of individual companies. Therefore, this paper serves as preliminary research that attempts to use experts’ past successful transformation experiences to provide strategic direction for SME transformations. Future researchers may discuss its dynamic strategy. While our expert panel brought extensive experience from Taiwan’s industry, the research scope primarily focused on the aviation machinery manufacturing sector’s perspective. In the future, it would be beneficial to include perspectives from other industries or government officers, such as the avionics industry or certification professionals, to explore the transformation issues and compare the results with those of this study. Additionally, this study used grey numbers combined with the Aczel–Alsina function to integrate the expert opinions; in the future, other fuzzy number or data aggregation methods could be used for data consolidation.

Author Contributions

C.-W.C.: Data collection, analysis, and draft writing. J.-H.L.: Concept, correction, and revised draft. S.-W.H.: re-calculation and results check. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Abbreviation

| Notation | Explanation |

| ] | The integrated direct influence matrix; influence degree from factor i to j through the Aczel–Alsina function |

| The normalized direct influence matrix | |

| The total influence matrix | |

| Q | The structural interaction matrix for factor i to j |

| M | The reachability matrix |

| wk | The weight of expert k |

| The kth expert considers the influence degree from factor i to factor j | |

| ak | The years of education for expert k |

| pk | The years of relative experience for expert k |

| The total influence degree from factor i to other factors | |

| The total influence degree obtained from other factors to factor i | |

| The lower bound of the total influence matrix | |

| The upper bound of the total influence matrix | |

| Nij | The total normalized crisp value |

| Xij | The final crisp value for the total influence matrix |

| R | The reachability set |

| A | The antecedent set |

| F | The intersection set of R and A |

References

- Lee, Y.H.; Kao, L.L.; Liu, W.H.; Pai, J.T. A Study on the Economic Resilience of Industrial Parks. Sustainability. 2023, 15, 2462. [Google Scholar] [CrossRef]

- Yim, J.; Mah, J.S. The Role of the Government in the Development of the Aircraft Manufacturing Industry in Korea: Implications for Developing Countries. J. Aerosp. Technol. Manag. 2024, 16, 1335. [Google Scholar] [CrossRef]

- Chu, B.; Zhang, H.; Jin, F. Identification and comparison of aircraft industry clusters in China and United States. Int. J. Supply Chain Manag. 2010, 20, 471–480. [Google Scholar] [CrossRef]

- Yin, Y.C.; Yang, B.; Wang, S.; Li, S.; Fu, G. Cloud service composition of collaborative manufacturing in main manufacturer-suppliers mode for aviation equipment. Robot. Comput. Integr. Manuf. 2023, 84, 102603. [Google Scholar] [CrossRef]

- Makarova, E.L.; Pavlov, P.V. Supplier Management Improvement in Aviation Industry: A Case Study of Beriev Aircraft Company. Int. J. Supply Chain Manag. 2017, 6, 41–54. [Google Scholar]

- Lee, Z.Y.; Chu, M.T.; Chen, S.S.; Tsai, C.H. Identifying Comprehensive Key Criteria of Sustainable Development for Traditional Manufacturing in Taiwan. Sustainability 2018, 10, 103275. [Google Scholar] [CrossRef]

- Sheng, Y.P.; Lou, L.; Cho, H.J.; Cho, K. Supply chain sustainability risk management in China‘s iron and steel industry: A hybrid fuzzy DEMATEL-ISM approach. Asia Pac. Bus. Rev. 2025, 1–26. [Google Scholar] [CrossRef]

- Primadasa, R.; Kusrini, E.; Mansur, A.; Masudin, I. Integrating DEMATEL-ISM-MICMAC: An interconnected model of halal-sustainable supply chain management (HSSCM) indicatorsfor SMEs. J. Islam. Mark. 2025. [Google Scholar] [CrossRef]

- Wu, B.; Wang, Z.; Tian, Y.; Zheng, S. The impact of industrial transformation and upgrading on fossil energy elasticity in China. J. Clean. Prod. 2024, 434, 140287. [Google Scholar] [CrossRef]

- Li, M.; Shu, G.S. China’s state-owned sector lead industrial transformation and upgrading? J. Clean. Prod. 2022, 338, 130412. [Google Scholar] [CrossRef]

- Zou, T. Technological innovation promotes industrial upgrading: An analytical framework. Struct. Chang. Econ. Dyn. 2024, 70, 150–167. [Google Scholar] [CrossRef]

- Wang, L.; Su, M.; Kong, H.; Ma, Y. The impact of marine technological innovation on the upgrade of China’s marine industrial structure. Ocean. Coast. Manag. 2021, 211, 105792. [Google Scholar] [CrossRef]

- Jiang, W.; Wang, X. Enterprise digital transformation empowers supply Chain stability. Financ. Res. Lett. 2024, 66, 105693. [Google Scholar] [CrossRef]

- Poudeh, H.D.; Cheshmberah, M.; Torabi, H.; Gavareshki, M.H.K.; Hosnavi, R. Determining and prioritizing the factors influencing the outsourcing of Complex Product Systems R&D projects employing ANP and grey-DEMATEL method (case study: Aviation Industries Organization, Iran). Technol. Soc. 2019, 56, 57–68. [Google Scholar] [CrossRef]

- Yang, S.; Xiang, L.; Yi, Y. Research on the Influencing Factors of Manufacturing Transformation and Upgrading Based on Grounded Theory. In Proceedings of the 6th International Conference on Electronic Technology and Information Science (ICETIS 2021), Harbin, China, 22–24 January 2021; pp. 8–10. [Google Scholar] [CrossRef]

- Gu, G.; Xu, B. Innovation Path of Manufacturing Enterprises and Strategies for Transformation and Upgrading in China. J. Adv. Comput. Intell. 2017, 21, 1048–1055. [Google Scholar] [CrossRef]

- Feng, K.; Wu, Y. Transformation path and promotion countermeasures of aerospace enterprise management strategy based on industrial chain integration. Hyliyon 2024, 10, E3199. [Google Scholar] [CrossRef]

- Liangrokapart, J.; Sittiwatethanasiri, T. Strategic direction for aviation maintenance, repair, and overhaul hub after crisis recovery. Asia Pac. Manag. Rev. 2023, 28, 81–89. [Google Scholar] [CrossRef]

- Deliktas, D.; Gunhan, B. Part-time student selection problem with a novel hybrid approach based on DEMATEL-modified ANP and MULTIMOORA methods. J. Eng. Res. 2022, 10, 347–361. [Google Scholar] [CrossRef]

- Si, S.-L.; You, X.-Y.; Liu, H.-C.; Zhang, P. DEMATEL technique: A systematic review of the state-of-the-art literature on methodologies and applications. Math. Probl. Eng. 2018, 2018, 3696457. [Google Scholar] [CrossRef]

- Chen, C.Y.; Huang, J.J. A Novel DEMATEL Approach by Considering Normalization and Invertibility. Symmetry 2022, 14, 1109. [Google Scholar] [CrossRef]

- Santos, S.T.; Silva, M.M.; Santos, S.M. A hybrid Grey-DEMATEL approach to identify barriers to the implementation of an end-of-life vehicle management system in Brazil. J. Clean. Prod. 2023, 386, 135791. [Google Scholar] [CrossRef]

- Asif, M.; Zeb, A.; Ishtiaq, U.; Ahmad, W.; Hou, M. Aczel-Alsina aggregation operators for linear diophantine fuzzy set and their application to multiple-attribute decision making problems. Exp. Sys. Appl. 2025, 271, 126552. [Google Scholar] [CrossRef]

- Zhang, M.; Song, G.; Ma, N. A mechanism for upgrading the global value chain of China’s wood industries based on sustainable green growth. J. Clean. Prod. 2024, 449, 141717. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, F. Edge computing and machinery automation application for intelligent manufacturing equipment. Microprocess. Microsystems 2021, 87, 104389. [Google Scholar] [CrossRef]

- Porter, M.E. The competitive advantage of nations. Organ. Dyn. 1990, 19, 76–77. [Google Scholar]

- Prahalad, C.K.; Hamel, G. The Core Competence of the Corporation. In Strategic Learning in a Knowledge Economy; Routledge: Oxfordshire, UK, 2000; pp. 3–22. [Google Scholar]

- Gereffi, G.; Humphrey, J.; Sturgeon, T. The Governance of Global Value Chains. Rev. Int. Polit. Econ. 2006, 12, 78–104. [Google Scholar] [CrossRef]

- Rothwell, R. Towards the fifth-generation innovation process. Int. Mark. Rev. 1994, 11, 7–31. [Google Scholar] [CrossRef]

- Mark, M.W.; Bras, B. Determining the Value of Remanufacture in an Integrated Manufacturing-Remanufacturing Organization. In ASME 1998 Design Engineering Technical Conferences, Atlanta, GA, USA, 13–16 September 1998; ASME: New York, NY, USA, 2021; p. DETC98/DFM-5750:V004T04A037. [Google Scholar] [CrossRef]

- Felker, G.B. Southeast Asian industrialisation and the changing global production system. Third World Q. 2010, 24, 255–282. [Google Scholar] [CrossRef]

- Pack, H.; Westphal, L.E. Industrial strategy and technological change: Theory versus reality. J. Dev. Econ. 1986, 22, 87–128. [Google Scholar] [CrossRef]

- Gui, S.P.; Niu, B.Z.; Zhang, X.; Lu, A.H. Analysis of Current Status and Countermeasure Study on High Value-added Industries in Pearl River Delta. In Proceedings of the 2006 International Conference on Management Science and Engineering, Lille, France, 5–7 October 2006. [Google Scholar] [CrossRef]

- Frenken, K. A complexity approach to innovation networks. The case of the aircraft industry (1909–1997). Res. Policy. 2000, 29, 257–272. [Google Scholar] [CrossRef]

- Kivits, R.; Charles, M.B.; Ryan, N. A post-carbon aviation future: Airports and the transition to a cleaner aviation sector. Futures 2010, 42, 199–211. [Google Scholar] [CrossRef]

- Welch, L.S.; Luostarinen, R. Internationalization: Evolution of a Concept. J. Gen. Manag. 1988, 14, 34–55. [Google Scholar] [CrossRef]

- Inui, T.; Kawakami, A.; Miyagawa, T. Market competition, differences in technology, and productivity improvement: An empirical analysis based on Japanese manufacturing firm data. Jpn. World. Econ. 2012, 24, 197–206. [Google Scholar] [CrossRef]

- Su, J.; Su, K.; Wang, S. Does the Digital Economy Promote Industrial Structural Upgrading ?—A Test of Mediating Effects Based on Heterogeneous Technological Innovation. Sustainability 2021, 13, 10105. [Google Scholar] [CrossRef]

- Esposito, E.; Raffa, L. Global reorganisation in a high-technology industry: The aircraft industry. Int. J. Glob. Small Bus. 2007, 2, 166–184. [Google Scholar] [CrossRef]

- Gupta, A.; Mau, R.R.; Marion, J.W. Supply chain risk management in aviation and aerospace manufacturing industry—An empirical study. Int. J. Supply Chain Oper. Resil. 2015, 1, 300–317. [Google Scholar] [CrossRef]

- Fung, K.Y.; Law, J.S.; Ng, W.K. Economic Contribution to Hong Kong of the Aviation Sector: A Value-Added Approach. Chia. Econ. Rev. 2006, 39, 19–38. [Google Scholar] [CrossRef]

- Floor, R. The political economy of aerospace industries. A key driver of growth and international competitiveness. Prometheus 2015, 33, 86–88. [Google Scholar] [CrossRef]

- Gardas, B.B.; Raut, R.D. Determinants of sustainable supply chain management: A case study from the oil and gas supply chain Sustain. Prod. Consum. 2019, 17, 241–253. [Google Scholar] [CrossRef]

- Singh, M.; Rathi, R. Investigation and modeling of lean six sigma barriers in small and medium-sized industries using hybrid ISM-SEM approach. Int. J. Lean Six Sigma 2021, 12, 1115–1145. [Google Scholar] [CrossRef]

- Rana, N.P.; Barnard, D.J.; Baabdullah, A.M.; Rees, D.; Roderick, S. Exploring barriers of m-commerce adoption in SMEs in the UK: Developing a framework using ISM. Int. J. Inf. Manag. 2019, 44, 141–153. [Google Scholar] [CrossRef]

- Raut, R.D.; Kumar, S.; Nayal, K.; Kraus, S.; Yadav, V.S.; Narkhede, B.E. To identify industry 4.0 and circular economy adoption barriers in the agriculture supply chain by using ISM-ANP. J. Clean. Prod. 2021, 293, 126023. [Google Scholar] [CrossRef]

- Li, C.; Chan, H.K.; Zhou, C.Y.; Dai, J.; Lim, J.J. Exploring critical factors of green business failure based on Grey-Decision Making Trial and Evaluation Laboratory (DEMATEL). J. Bus. Res. 2019, 98, 450–461. [Google Scholar] [CrossRef]

- Muhammad, A.H.; Santoso, J.D. Information security investment prioritization using best-worst method for small and medium enterprises. Indones. J. Electr. Eng. Comput. Sci. 2023, 31, 271–280. [Google Scholar] [CrossRef]

- Priyanka, R.; Ravindran, K.; Sankaranarayanan, B.; Ali, S.M. A fuzzy DEMATEL decision modeling framework for identifying key human resources challenges in start-up companies: Implications for sustainable development. Decis. Anal. 2023, 6, 100192. [Google Scholar] [CrossRef]

- Yazdi, M.; Khan, F.; Abbassi, R.; Rusli, R. Improved DEMATEL methodology for effective safety management decision-making. Saf. Sci. 2020, 27, 104705. [Google Scholar] [CrossRef]

- Mohammad, K.; Darko, B.; Puska, A. Analysis of key factors affecting risk tolerance in project-oriented firms using hybrid fuzzy DEMATEL-ISM: An empirical study. Yugosl. J. Oper. Res. 2025, 35, 5. [Google Scholar] [CrossRef]

- Venkatesan, M. An Alternate Approach to Transitive Coupling in ISM. IEEE Trans. Syst. Man. Cybern. 2007, 27, 125–130. [Google Scholar] [CrossRef]

- International Aerospace Quality Group. (2020). AS9100: Quality Management Systems — Requirements for Aviation, Space, and Defense Organizations (Rev. D). International Aerospace Quality Group. Available online: https://www.sae.org/standards/content/as9100d/ (accessed on 27 May 2025).

- Performance Review Institute. (2022). AC7101: Nadcap Audit Criteria for Heat Treating. National Aerospace and De-fense Contractors Accreditation Program. Available online: https://p-r-i.org/nadcap/ (accessed on 27 May 2025).

- Aczel, J.; Alsina, C. Characterizations of some classes of quasilinear functions with applications to triangular norms and to synthesizing judgements. Aequationes Math. 1982, 25, 313–315. [Google Scholar] [CrossRef]

- Hussain, A.; Liu, Y.; Ullah, K.; Rashid, M.; Senapati, T.; Moslem, S. Decision algorithm for picture fuzzy sets and Aczel Alsina aggregation operators based on unknown degree of wights. Heliyon 2024, 10, e27548. [Google Scholar] [CrossRef]

- Xia, X.; Govindan, K.; Zhu, Q. Analyzing internal barriers for automotive parts remanufacturers in China using grey-DEMATEL approach. J. Clean. Prod. 2015, 87, 811–825. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, H.; Zhao, X. Analysis of factors affecting economic operation of electric vehicle charging station based on DEMATEL-ISM. Comput. Ind. Eng. 2022, 163, 107818. [Google Scholar] [CrossRef]

- Yilmaz, C.; Ergun, E. Organizational culture and firm effectiveness: An examination of relative effects of culture traits and the balanced culture hypothesis in an emerging economy. J. World Bus. 2008, 43, 290–306. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive Advantage: Creating and Sustaining Superior Performance; Free Press: Los Angeles, CA, USA, 1985. [Google Scholar]

- Pisano, G.P.; Shih, W.C. Does America Really Need Manufacturing? Harv. Bus. Rev. 2012, 90, 94–102. [Google Scholar]

- Modigliani, F.; Miller, M. The Cost of Capital, Corporation Finance and the Theory of Investment. Am. Econ. Rev. 1958, 48, 261–297. [Google Scholar]

- Lepak, D.P.; Snell, S.A. The Human Resource Architecture: Toward a Theory of Human Capital Allocation and Development. Acad. Manag. Rev. 1999, 24, 31–48. [Google Scholar] [CrossRef]

- Barney, J.B. Firm Resources and Sustained Competitive Advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Kagan, R.A.; Scholz, J.T. The “Criminology of the Corporation” and Regulatory Enforcement Strategies. In Enforcing Regulation; Springer: Dordrecht, The Netherlands, 1984. [Google Scholar]

- Huselid, M.A. The Impact of Human Resource Management Practices on Turnover, Productivity, and Corporate Financial Performance. Acad. Manag. J. 1995, 38, 635–672. [Google Scholar] [CrossRef]

- Calantone, R.J.; Cavusgil, S.T.; Zhao, Y. Learning Orientation, Firm Innovation Capability, and Firm Performance. Ind. Mark. Manag. 2002, 31, 515–524. [Google Scholar] [CrossRef]

- Zahra, S.A.; George, G. Absorptive Capacity: A Review, Reconceptualization, and Extension. Acad. Manag. Rev. 2002, 27, 185–203. [Google Scholar] [CrossRef]

- International Organization for Standardization. (2015). ISO 9001: Quality management systems — Requirements (ISO 9001:2015). International Organization for Standardization. Available online: https://www.iso.org/iso-9001-quality-management.html (accessed on 27 May 2025).

- Bulaeva, V. Quality Management System According to AS9100-C. 2015. Available online: https://urn.fi/URN:NBN:fi:amk-201504104182 (accessed on 27 May 2025).

- Durham, N. Obtaining Nadcap Accreditation: Helping You Pass Your Audit. In Proceedings of the ASM Heat Treating Society 28th Conference and Exposition, Detroit, MI, USA, 20–22 October 2015; ASM International: Materials Park, OH, USA, 2015; pp. 178–185. Available online: https://dl.asminternational.org/heat-treating/proceedings-abstract/HT2015/84123/178/31500 (accessed on 30 May 2025).

- Ellram, L.M.; Tate, W.L.; Billington, C. Understanding and Managing the Services. J. Supply Chain Manag. 2006, 40, 17–32. [Google Scholar] [CrossRef]

- Alice, S.; Jeffrey, S.; Teran-Somohano, A. Mission Quality Assurance Virtual Training and Certification Using the NASA Academy of Aerospace Quality. Available online: https://digitalcommons.usu.edu/cgi/viewcontent.cgi?article=4279&context=smallsat (accessed on 27 May 2025).

- Li, S.; Lu, Y. Study on civil aviation airworthiness management requirements for standard parts. Procedia Eng. 2014, 80, 119–126. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).