Featured Application

This study can be applied to the PV rooftop design of semi-outdoor substations, aiming to achieve better natural ventilation and power generation.

Abstract

In the context of global decarbonization goals and increasing urban electricity demand, the green transformation of power industry buildings to enhance the utilization of renewable energy represents a significant contribution to sustainable social development. Rooftop photovoltaic (PV) systems can reduce unnecessary radiative heat gain and generate clean electricity to support this transition; however, they also alter the rooftop wind environment. Deploying rooftop PV systems requires well-planned design strategies to optimize renewable energy production while ensuring adequate natural ventilation, particularly for semi-outdoor main transformer rooms where ventilation and heat dissipation are crucial for safe substation operations. This concept was tested at a 220 kV substation in Guangzhou, China, using Computational Fluid Dynamics (CFD) and PVSYST to assess the impact of different rooftop PV systems on natural ventilation and power generation. The analysis showed that while the horizontal PV system achieved the highest energy output, it also resulted in a wind speed reduction of 13.2% or 11.8%. In contrast, the 10° symmetrical PV system offers the most balanced solution, with only a 0.6% decrease in ventilation performance but at the cost of a 13.87% reduction in PV output. The unilateral pitched PV system results in ventilation losses of less than 4%, and the power generation loss is also kept below 4%. However, this configuration may lead to increased wind loads. This approach can be developed into a practical design tool to further support the integration of PV systems in substation green retrofitting projects.

1. Introduction

A critical priority in achieving sustainable development involves tackling climate change through greenhouse gas emission mitigation [1,2]. Globally, building energy consumption exceeds 40% of the total usage in developed nations, while this share continues to climb across developing countries [3]. In 2022, the total energy consumption of China’s building and construction sector reached 2.42 billion tons of standard coal equivalent (tce), accounting for 44.8% of the country’s total energy consumption [4]. Following the Paris Agreement, China subsequently set targets to peak carbon emissions by 2030 and achieve nationwide carbon neutrality by 2060 [5]. The construction industry, particularly industrial buildings, plays a crucial role in achieving this decarbonization goal [6,7].

In the context of the United Nations’ Sustainable Development Goals and China’s dual carbon goal, industrial buildings are facing a wide range of green transformation needs [8,9]. The power industry is one of the major contributors to global carbon emissions, making its development a key area of focus. Substations are a crucial part of the power industry, playing a key role in the reception and distribution of electricity. Their operation inevitably generates a significant amount of carbon emissions, making the construction of low-carbon substations a major development trend for the future [10]. The spacious flat roofs of industrial buildings are highly suitable for the installation of rooftop-distributed PV systems. This topic has attracted extensive research attention and has been widely implemented in practice [11]. The installation of PV systems on the roofs of urban substations is one of the approaches to promoting green, low-carbon development and enhancing energy conservation and emission reduction. This practice has already been implemented in China [12]. Urban substations are essential power infrastructure for cities. As urban development progresses, the number of substations continues to increase [13]. Therefore, in the future, more urban substations will require green retrofitting, and rooftop PV systems will be a key topic worthy of focus and discussion [14]. When PV systems are integrated into the building envelope, they expand the surface area available for power generation, reduce the need for additional land, and mitigate the environmental impact [15].

However, it is important to note that the PV system may obstruct the open space above the semi-indoor substation originally intended for natural ventilation, which could negatively impact the safe operation of the substation. The unique structural characteristics of semi-indoor substations, such as partially enclosed walls and rooftop exposure, create a complex thermal environment that necessitates advanced thermal management strategies [16]. Insufficient heat dissipation can lead to elevated temperatures, negatively impacting operational efficiency and the lifespan of equipment. Additionally, excessive heat accumulation increases the risk of safety incidents, posing a threat to the stability and reliability of the power supply network [17]. When the PV system is installed in this type of substation, it is necessary to discuss the impact of the PV system on the wind environment.

Natural ventilation is the process of introducing fresh air into indoor spaces using natural forces (such as wind and/or thermal buoyancy) rather than mechanical energy. These natural forces typically influence the efficiency of natural ventilation; they may act independently, oppose each other, reinforce one another, or sometimes work in synergy [18]. Rooftop natural ventilation and cooling are well-established methods for optimizing indoor environmental quality in buildings [19]. Through numerical studies, the impact of various influencing factors on the thermal performance of naturally ventilated roofs has been analyzed, leading to the identification of optimal design parameters and their adaptability [20].

To study the interaction between PV systems and their surrounding environment, CFD simulation methods have been widely applied [21,22]. With the continuous advancement of numerical algorithms and computational power, CFD has become a reliable and widely used research method across various fields, including PV system analysis. And the airflow above/around photovoltaic (PV) panels and the air gap between PV panels and the building envelope are key topics of discussion in this field [23]. At the same time, enhancing the natural ventilation of rooftop PV systems can improve PV panel cooling. The authors of [24] employed the standard k-ε turbulence model to describe turbulent natural convection. Through numerical studies, they explored the impact of natural convection air cooling on the performance of a novel hybrid photovoltaic/thermal (PV/T) collector. The findings indicated that increasing the tilt angle of the PV/T system can enhance airflow velocity, thereby improving cooling efficiency.

CFD simulation is also widely used in the natural ventilation design of substations [10]. Through numerical modeling and CFD simulation research, the air inlet design of an indoor substation can be optimized to enhance natural ventilation and reduce the dependence on mechanical ventilation, thus reducing the carbon emission of the substation [25]. Natural ventilation can improve heat dissipation in high-temperature, high-load indoor substations, but improper design may interfere with the main air intake of the exhaust fans, leading to low cooling efficiency [26]. The feasibility of natural ventilation in substation control buildings located in cold regions during summer and transitional seasons has been demonstrated using CFD methods [27]. Using CFD simulations, the ventilation and heat dissipation of a semi-indoor substation main transformer room are analyzed and optimized. Reference [17] evaluates the impact of air inlet angles on the velocity distribution, temperature distribution, and airflow rate. The impact of PV system installations on the wind environment of substations is relatively underexplored. However, semi-outdoor substations are highly sensitive to natural ventilation, making it essential to use CFD simulations to assess how PV systems affect such substations.

The design of the PV system above the semi-outdoor main transformer room is of critical importance, requiring a balance between ventilation efficiency, energy consumption, and maintenance convenience. Considering local climatic factors, such as wind direction, wind speed, and rainfall, is essential to ensure that the PV system does not negatively impact the ventilation of the main transformer room while maximizing the utilization of these natural factors to enhance both ventilation efficiency and PV power generation. Accurately assessing the impact of PV panel arrangements on airflow is crucial, given the specific operational requirements and internal spatial structure of the main transformer room. Traditional rooftop PV designs typically focus only on factors affecting power generation, such as building orientation, local latitude, and solar resources, while overlooking the impact of PV systems on rooftop wind environments and indoor natural ventilation. Existing substation construction guidelines provide ambiguous instructions regarding PV panel placement, and research in this area is significantly lacking. Therefore, this study introduces an optimized rooftop PV system strategy aimed at maximizing PV generation capacity without compromising the natural ventilation of the main transformer room. This study evaluates the effects of the orientation, tilt angle, and arrangement of PV panels on natural ventilation airflow within the main transformer room and PV power output. The objective is to determine the most effective PV panel layout to enhance both rooftop PV system performance and natural ventilation efficiency within the main transformer room.

2. Materials and Methods

2.1. Research Object

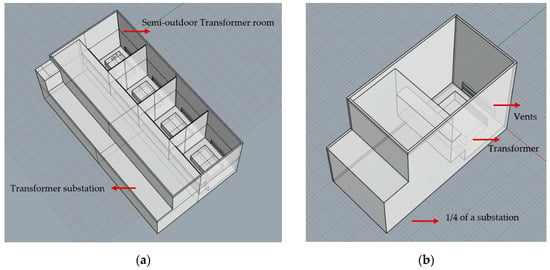

The 220 kV semi-outdoor substation examined in this study is a standard design used in the China Southern Power Grid, as shown in Figure 1a. For the selected 220 kV semi-outdoor substation in this study, the main transformer rooms requiring natural ventilation are concentrated on one side of the building’s long axis, while the office spaces are located on the opposite side. In practical engineering applications, office spaces requiring natural lighting are typically oriented southward, while main transformer rooms that demand ventilation and heat dissipation are positioned on the north side. This study is based on the climatic parameters and architectural characteristics of China’s hot-summer and warm-winter regions, making the findings more applicable to the specific requirements of substations in these areas.

Figure 1.

Geometric model: (a) the 220kV transformer substation; (b) the simplified model.

PV power generation is highly sensitive to factors such as orientation, shading, and ventilation for heat dissipation. Both the main transformer rooms and the PV system require effective ventilation for thermal management. However, the installation of PV panels on the roof can influence the natural ventilation of the main transformer rooms. This study explores the effects of different PV layout configurations on the roof of a substation where the main transformer rooms face north. The analysis focuses on the impact of these layouts on natural ventilation within the main transformer rooms and the power generation performance of the PV system during the summer season.

2.2. CFD Numerical Simulation

2.2.1. Modeling and Computational Domain

This study conducts CFD simulations using the Fluent software [Ansys Fluent|Fluid Simulation Software Available online: https://www.ansys.com/products/fluids/ansys-fluent (accessed on 20 May 2025)].The main transformer room is characterized as a semi-outdoor type that lacks a rooftop cover, which facilitates a spacious area with natural ventilation. The primary objective of this study is to examine the impact of PV arrangement on the wind environment inside the main transformer room. Therefore, the influence of ambient wind and heat sources (transformers) on wind pressure is not considered. The model configuration is delineated in Table 1.

Table 1.

Geometric model of the computational domain.

The substation building in this study consists of four main transformer rooms, each with identical scale and structure. Additionally, the substation exhibits uniform geometric characteristics along the airflow inlet and outlet directions. Therefore, the research model is simplified by retaining only a single main transformer room for CFD simulation, as shown in Figure 1b. The shape of a building typically influences the airflow distribution in its surroundings. When simulating the outdoor wind environment of a building, the three-dimensional model should accurately represent the building’s dimensions and intricate details within the height boundary. However, in practical applications, simplifying the computational model of the actual building is often necessary to reduce computational time and accelerate convergence [28]. This simplification involves minimizing the complexity of protrusions and recesses while ensuring that the modifications do not significantly affect the airflow distribution around the building [29].

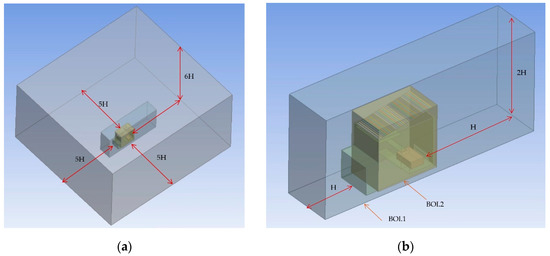

In the computational domain, H (height) represents the height of the tallest building within the considered area. The distance between the inlet and the building is set to at least 5H, a constraint that also applies to the outlet boundary and the lateral boundaries of the building. The height of the computational domain is defined as 6H. The external computational domain measures 316.1 m × 339.2 m × 177.6 m, with the substation positioned at its center, with dimensions of 20.1 m × 43.2 m × 29.6 m. The substation is located 5H away from the horizontal boundaries and 6H from the top boundary, ensuring compliance with the requirements for computational domain boundaries and the blockage ratio [30].

2.2.2. Computational Meshing

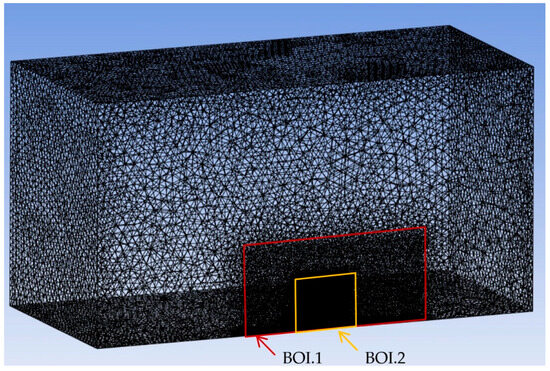

In numerical simulations, an appropriate mesh is crucial for obtaining accurate computational results. Generally, increasing the mesh resolution enhances accuracy; however, excessively refined meshing significantly raises computational costs [19]. In this study, a polyhedral mesh was generated using a partitioned meshing approach, as shown in Figure 2. The external domain was uniformly divided into volume meshes, while mesh refinement was applied to the walls, PV panels, and the space inside the main transformer room. To achieve more precise calculations of ventilation airflow within the main transformer room and to better capture the details of the internal flow field, two body of influence (BOI) regions were defined to enclose the target area, as shown in Figure 3. BOI.1 employed a finer mesh to improve the accuracy of wind field calculations on the windward side of the building and in recirculation zones. BOI.2 utilized the finest mesh to ensure high-accuracy wind field calculations inside the main transformer room. After conducting a mesh independence test and analyzing the trends in pressure and velocity distribution, a grid system with 3.4 million cells was selected for this study, considering both computational accuracy and cost.

Figure 2.

Diagram of meshing (sectional view).

Figure 3.

Computational domain: (a) computational domain; (b) body of the influence (BOI) region.

2.2.3. Governing Equations

When using CFD tools to address ventilation problems, two-equation models such as the standard k-ε model, the RNG k-ε model, and the Realizable k-ε model are widely used in engineering applications [19]. A study by [31] compared various engineering applications and theoretical models, concluding that the Realizable k-ε model provides the most accurate simulation results for industrial workshops under high-temperature buoyancy effects. Therefore, this study adopts the Realizable k-ε model to simulate the natural ventilation of the transformer.

2.2.4. Calculation Boundary Condition Setting

Since wind direction, ambient temperature, and solar radiation exhibit significant seasonal variations, summer is characterized by the highest temperatures, leading to the greatest demand for natural ventilation. Additionally, it is the period with the highest PV energy yields. Therefore, the operating conditions in this study are set for the summer season.

Based on the meteorological conditions [32] of Guangzhou and the CFD experimental settings from the previous study [33], this study assumes a wind environment condition of a southerly wind in summer with a wind speed of 2.0 m/s. The fixed walls were mainly the indoor ground, walls, and roof, which were set as non-slip walls.

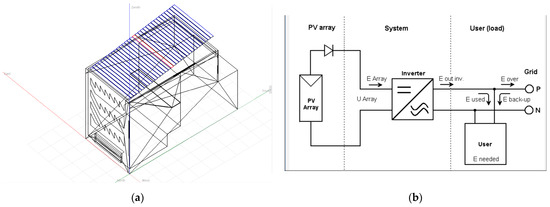

2.3. Photovoltaic Capacity Simulation

PVsyst is used to evaluate the performance of various photovoltaic technologies in accordance with the IEC 61724 standard [34]. Known for its advanced weather data processing, energy yield simulation, and shading analysis, PVsyst enables the accurate comparison of PV technologies under different climatic conditions. This level of detailed analysis is essential for validating system performance [35]. In PVsyst, the modeling process involves defining the site location and setting up meteorological data. Subsequently, the PV system components, including modules, inverters, and the layout, are configured. The system is then simulated to evaluate performance and optimize the design.

- The first step is to select the geographical location of the PV system based on its latitude and longitude. This ensures that the system design is tailored to the specific solar irradiance and climatic conditions of the selected region. In PVsyst, selecting the predefined Guangzhou site (Guangzhou_Baiyun_MN80) from the software’s database provides access to local climate data, such as solar irradiance, temperature, humidity, as well as time zone and altitude information.

- We then specify the electrical parameters of the PV system, including equipment specifications such as PV modules and the inverter. A 400 W PV module from the software’s predefined database is selected, as described in Table 2. The inverter is chosen based on the installed capacity using the predefined 100 kW model SUN2000-100KTL-H1. The PVsyst software package [PVsyst|Photovoltaic Software, Design and Simulate Photovoltaic Systems. Available online: https://www.pvsyst.com (accessed on 20 May 2025)] includes predefined detailed technical specifications for these electrical components, so no additional input from the user is required during the simulation process.

Table 2. Electrical specifications of the PV panels in PVsyst.

Table 2. Electrical specifications of the PV panels in PVsyst. - Finally, based on the PV system configurations in each case (as shown in Table 3), the specific position of each row of PV panels is defined in PVsyst, thus allowing for the construction of a complete PV system model, as illustrated in Figure 4. PVsyst incorporates both the electrical equipment specifications and the 3D layout of the PV modules to account for factors affecting power generation, such as detailed electrical losses and near shading, and provides comprehensive simulation data.

Table 3. Cases of various roof PV types and roof directions.

Table 3. Cases of various roof PV types and roof directions. Figure 4. PVsyst simulation: (a) PV system layout (The blue part represents PV panels.); (b) electrical schematic diagram.

Figure 4. PVsyst simulation: (a) PV system layout (The blue part represents PV panels.); (b) electrical schematic diagram.

3. Simulation of Operating Conditions

3.1. Case Study

When the same number of PV panels is installed, different layout configurations of the PV panels can influence the wind environment within the building cavity and affect the natural ventilation performance. However, the position and arrangement of the PV panels may cause self-shading, reducing the PV output. This study first aims to verify whether different PV panel positions and configurations impact the wind environment of the main transformer room and whether these effects remain within an acceptable range.

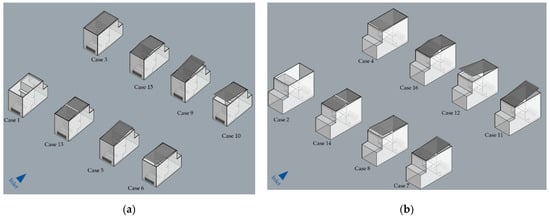

Figure 5 and Table 3 present the details of the substation cases, including different PV panel installation methods on the roof and variations in roof structures, such as flat roofs, symmetrical pitched roofs, and single-slope roofs.

Figure 5.

Different types of roof PV: (a) The main transformer room is oriented north. (b) The main transformer room is oriented south.

3.2. Model Setup

The material settings for the industrial workshop natural ventilation simulation model are shown in Table 4. The main structure of the substation is made of concrete, while the roof is equipped with monocrystalline silicon PV modules, with detailed parameters listed in Table 2.

Table 4.

Material setting.

In both the CFD simulation and the PV performance simulation, the opening areas of all roof vents and the boundary conditions, as well as the number of PV panels and their spacing in the horizontal direction, are kept consistent throughout the analysis.

4. Results and Discussion

4.1. Effect of Roof PV Forms on Natural Ventilation

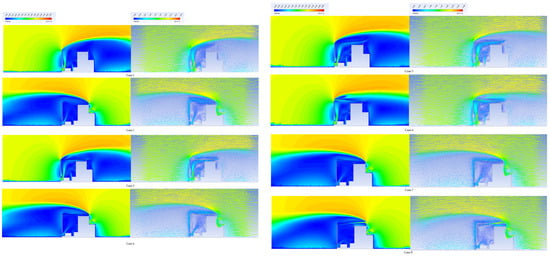

Figure 6 illustrates the wind velocity contours and vector diagrams of the substation under various scenarios. When the incoming wind faces the building, Case 1—with no PV system—is taken as the baseline. Particular attention is given to the main transformer room located on the windward side, including the airflow at its ventilation openings, within its interior, and across the rooftop space. The ventilation openings remain critical to facilitating natural ventilation in the main transformer room. Compared to the leeward-facing Case 2, the airflow velocity at the inlets is higher in the windward-facing Case 1, and the airflow has a broader influence within the interior space. However, after entering the main transformer room, a significant portion of the airflow tends to converge along the walls with the overhead airflow within the building. When the PV system is installed horizontally (Case 3), the airflow at the ventilation openings shifts toward the center of the main transformer room, which is more favorable for internal ventilation. Simultaneously, the PV panels guide the airflow along the underside of the panels, aiding in the heat dissipation of the PV back surface. When the PV system is installed facing the wind (Cases 5 and 9), the inlet airflow also shifts toward the center of the transformer room. Case 9, which features an offset angle, performs better than Case 5, further demonstrating the influence of panel angle on ventilation. Additionally, the PV panels help channel the airflow beneath them, and the slope more effectively directs the air out. When the PV system is symmetrically installed (symmetrical pitched roof, Cases 13 and 15), the indoor stagnant zones are reduced, resulting in improved ventilation performance. In this configuration, the PV panels also achieve ventilation effects similar to those seen in windward-facing PV systems. In the case of leeward PV installations (Cases 6 and 10), the PV panels interact with airflow separation at the building’s rooftop edge, guiding a portion of the high-speed airflow beneath the panels. However, this airflow does not enter the interior space. While this high-speed flow benefits the cooling of the PV back surface, it also increases the wind load on the panels, necessitating more robust structural support. The airflow at the ventilation openings remains largely unaffected, but a reduction in indoor stagnant zones is observed.

Figure 6.

Contours and vector diagrams for different cases.

When the incoming wind blows toward the building, Case 2—without a PV system—is taken as the reference. Particular attention is given to the leeward-side main transformer room, including its ventilation inlets, internal airflow, and rooftop space. On the windward side, airflow separates at the roof edge of the building, leading to wind speed-up. On the leeward side, a large wind shadow zone forms near the main transformer room, where wind speeds decrease and vortices occur. Most of the vortex airflow ascends along the exterior wall of the main transformer room toward the rooftop, while a smaller portion enters the room through the ventilation openings and merges with the vortex wake above the room. The wind velocity from the ventilation openings toward the transformer is appreciable; however, much of the interior space remains in a stagnant airflow zone. When the PV system is horizontally installed (Case 4), the PV panels disrupt the interaction between the vortex wake and the airflow entering through the ventilation openings, thus weakening the natural ventilation effect. Additionally, airflow beneath the PV panels is limited, which is also detrimental to the ventilation cooling of the PV back surface. When the PV system is installed in a windward orientation (Case 7 and Case 11) or symmetrically (Case 14 and Case 16), it does not cause significant disruption to the indoor airflow. The rooftop airflow is split by the PV panels and flows along their surfaces, which facilitates cooling of the PV backsheet. Among these, the airflow on the backside of the PV panels in Case 11 is better than in Case 7, and in Case 16, it is better than in Case 14, further highlighting the influence of installation angle on PV system ventilation performance. When the PV system is installed in a leeward configuration (Case 8 and Case 12), the PV panels contribute to the airflow separation occurring at the building’s rooftop edge and direct part of the high-speed airflow into the main transformer room. However, this high-speed airflow conflicts with the natural airflow entering through the ventilation openings, thereby weakening the room’s ventilation effectiveness and expanding stagnant airflow zones. Although this redirected airflow benefits PV backsheet cooling, it also increases the wind load on the PV panels, imposing stricter structural requirements for panel mounting. In particular, the wind speed-up effect in Case 11 is more pronounced than in Case 7, indicating that when PV panels are installed leeward with a tilt, the angle significantly affects the wind environment above the building.

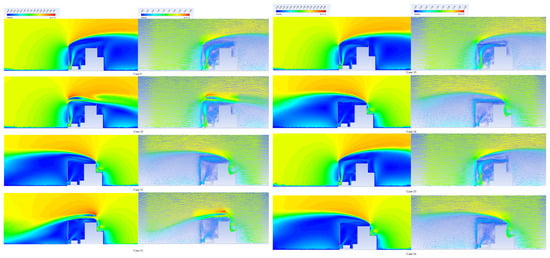

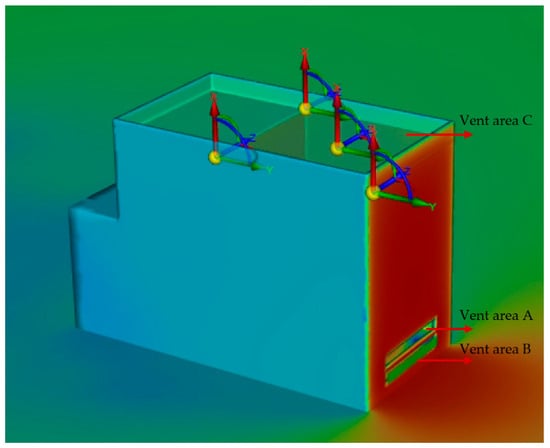

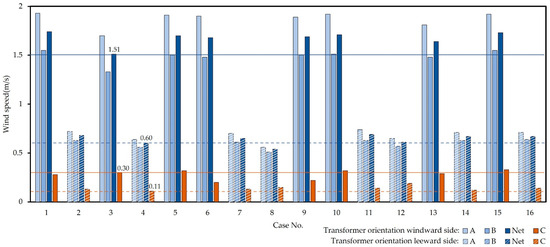

To further quantify the impact of different PV system configurations on ventilation in the main transformer room, three vent area (vent areas A, B, and C, as shown in Figure 7) were defined at critical locations where the room exchanges air with the external environment—specifically at the rooftop and bottom space. In the post-processing stage, the area-weighted average method was used to calculate the velocity. Since areas A and B are identical in size and share the same ventilation conditions, their values were combined to obtain a net value representing the bottom ventilation performance. Figure 8 shows detailed data for all cases. The ventilation performance of Case 1 (transformer orientation: windward side) and Case 2 (transformer orientation: leeward side) is used to evaluate the baseline heat dissipation level of the main transformer room without PV systems. This serves as the reference for comparing the impact of various PV installation strategies on thermal performance. The model adopted in this study is based on a standard construction scheme that has been in practical use for nearly two decades, and its effectiveness in meeting heat dissipation requirements under typical wind conditions has been well validated. Using this as a benchmark, other cases are compared to assess whether the proposed PV installation methods meet the heat dissipation demands of the electrical system. Case 3 and Case 4 are used as reference cases. Both use horizontally mounted PV systems. These are used to compare and assess the impact of PV installation on ventilation performance. Detailed data can be found in Appendix B.

Figure 7.

Schematic diagram of the designated ventilation areas.

Figure 8.

Airflow velocity in the vent area. The solid and dashed legends indicate the relationship between the main transformer room and wind direction. Case 3 (Net: 1.51 m/s, C: 0.30 m/s) and Case 4 (Net: 0.60 m/s, C: 0.11 m/s), both with horizontally mounted PV systems, are used as reference cases for comparison.

First, the impact of PV system installation on ventilation in the main transformer room is evaluated. Compared to the initial condition without PV systems, the comparison between Case 1 and Case 3, as well as between Case 2 and Case 4, shows that horizontal PV installation reduces airflow velocity in the ventilation zones. Specifically, in the windward scenario, the wind speed at the bottom ventilation area is reduced by 13.2%, while in the leeward scenario, it is reduced by 11.8%. The ventilation speed in the overhead space remains low in both conditions and is largely unaffected. This indicates that the commonly used horizontal PV installation method has a negative impact on substation ventilation.

Next, this study evaluates whether the proposed PV installation methods can mitigate the ventilation rate losses caused by PV system placement. Under the windward condition of the main transformer room, the PV layout strategies proposed in this study (Case 5, Case 6, Case 9, Case 10, Case 13, and Case 15) all show significant improvements in ventilation performance compared to Case 3. The increases are 12.6%, 11.3%, 11.9%, 13.2%, 8.6%, and 14.6%, respectively. Compared to Case 1, all of these layout strategies demonstrate good ventilation performance. In comparison to the condition without PV panels, the ventilation speed losses caused by the PV systems in these cases are 2.3%, 3.4%, 2.9%, 1.7%, 5.7%, and 0.6%, respectively.

Among these, the unilateral pitched roof configurations demonstrate consistent improvement, while the symmetrical pitched roof cases exhibit greater variation in performance. Under the leeward condition of the main transformer room, the proposed layout configurations in this study (Case 7, Case 8, Case 11, Case 12, Case 14, and Case 16) exhibit relatively small fluctuations. Among them, Case 8 performs less favorably than Case 4, while the other configurations show improvements. In the unilateral pitched structure, smaller angles are more advantageous. The symmetrical pitched structures consistently demonstrate improved performance, nearly equivalent to that of Case 2, which represents the condition without the PV system.

Finally, taking into account ventilation performance (wind velocity contours, vector diagrams, and velocity), PV back surface cooling, and structural risks due to wind loads, the most balanced configuration is the 10° symmetrical PV system (Case 15/16). This configuration achieves the best ventilation performance among all PV-installed cases, with only a 0.6% reduction compared to the no-PV baseline and a 14.6% improvement over the horizontal PV setup. It also features minimal indoor stagnant zones and smooth airflow beneath the PV panels for effective cooling. Additionally, it avoids high wind pressure loads, offering greater structural safety. Horizontal configurations (Case 3/4) are not recommended due to their significant reduction in ventilation performance. The use of single-pitched structures should be approached with caution, especially at larger slopes, as they may introduce increased wind loads.

4.2. Influence of PV System Forms on Power Generation Output

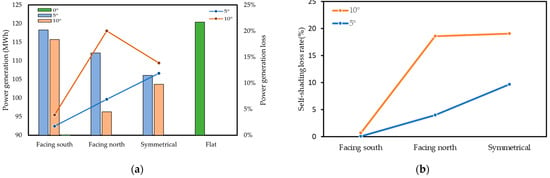

This section investigates the power generation, generation loss, and self-shading ratio of rooftop PV systems under three tilt angles (0°, 5°, and 10°) and two orientations (south-facing and north-facing). The analysis is based on simulation results from the PVsyst software, with detailed outputs provided in Appendix A.

As shown in Figure 9a, the horizontally mounted system, which is free from inter-panel self-shading, achieves the highest power output of 120.4 MWh and is used as the reference for evaluating generation losses in other configurations. For south-facing single-slope systems with 5° and 10° tilt angles, the power outputs are 118.3 MWh and 115.7 MWh, corresponding to generation losses of 1.74% and 3.90%, respectively. These systems outperform the south-facing symmetrical pitched roof configurations, which generate power outputs of 106.1 MWh and 103.7 MWh, with respective losses of 11.88% and 13.87%.

Figure 9.

Power generation: (a) photovoltaic system power generation and power generation loss; (b) photovoltaic self-shading loss.

For north-facing single-slope systems with 5° and 10° tilt angles, the influence of tilt on self-shading becomes particularly significant. At a 10° tilt, severe shading leads to the lowest power output of 96.3 MWh and a loss rate of 20.02%, making it the least favorable option for PV generation.

As shown in Figure 9b, symmetrical pitched roofs exhibit the highest self-shading ratio. However, within this roof type, the tilt angle has a limited impact on power output; the 10° configuration generates 2.26% less electricity than the 5° configuration.

4.3. Lessons Learned for PV Layouts in Semi-Outdoor Substations

This section discussed the impact of different PV system configurations on indoor ventilation and now provides a deeper comparison with other related studies to highlight the specific application context of this research. The focus here is on how the PV panel layout affects the wind environment of the building. This study evaluates the influence of PV system installation on ventilation and cooling in the main transformer room to ensure that power generation performance is achieved without significantly compromising natural ventilation.

The existing literature has begun to recognize the importance of jointly optimizing ventilation openings and PV layouts in industrial buildings to satisfy natural ventilation requirements. One study, which focused on adjusting rooftop vents and PV layouts in industrial workshops, showed that for naturally ventilated buildings, the form and position of rooftop vents had no significant effect on the indoor thermal environment, provided that the total exhaust area was maintained. Ventilation volume dropped slightly by approximately 5% [19], but adjusting the roof structure and vent layout allowed for increased PV coverage. This is consistent with the findings in the present study, which observed that a horizontal PV layout led to a ventilation reduction of around 10%, while a well-designed system (e.g., 10° symmetrical layout) reduced the impact to just 0.6%. However, the mentioned study was conducted on enclosed industrial buildings with roofs and focused on repositioning ventilation openings rather than modifying the PV layout itself. In contrast, ventilation studies on substations have primarily focused on fully indoor substations. For example, the study titled An Investigation of the Ventilation Systems of Whole-Indoor Urban Substations developed a combined natural and mechanical ventilation strategy to address high indoor temperatures. It concluded that improving ventilation—whether by reducing outdoor temperatures or increasing airflow—can effectively lower indoor temperatures [36]. Like the present study, it emphasized the importance of natural ventilation for cooling in substations. Another study using CFD to optimize the air inlet design of an indoor substation (110 kV) under natural ventilation found that a dual-inlet configuration improved cooling uniformity and avoided airflow decay. Compared to a single-inlet design, the dual-inlet layout reduced the maximum transformer temperature by 1.3 °C and improved energy utilization by 9.1% [26]. This aligns with the findings in this study, where symmetrical PV configurations function effectively as ventilation openings, offering the most balanced performance.

To date, there has been limited research on how PV installation affects the wind environment in semi-outdoor substations. However, because semi-outdoor substations are highly sensitive to natural ventilation, using CFD simulations to assess the impact of PV systems is especially important. This research contributes new insights into the application of PV systems in semi-outdoor substation settings, filling an important gap in the existing literature.

5. Conclusions

This study proposes an optimization strategy for installing PV systems above the main transformer room of semi-outdoor substations, aiming to enhance natural ventilation for both the main transformer room and the PV panels while also comparing the power generation performance of various PV configurations. Through in-depth analysis, this study evaluates the effects of adjusting roof form, slope angle, and windward orientation on improving both the natural ventilation performance of the main transformer room and the power generation capacity of the rooftop PV system.

The horizontally arranged PV system yields the best photovoltaic performance and has minimal impact on the wind environment inside the main transformer room. However, the installation of horizontal PV systems reduces airflow velocity in ventilation zones, particularly in the windward bottom area, where the ventilation speed is decreased by 13.2% and by 11.8% in the leeward condition. Additionally, under leeward conditions, horizontal PV systems have a negative effect on heat dissipation in the main transformer room and offer poor ventilation conditions for cooling the rear surface of the PV modules.

For unilateral pitched PV systems, since Guangzhou is located in the Northern Hemisphere, south-facing installations are more favorable for power generation. Compared to horizontal PV systems, the energy losses are smaller: at tilt angles of 5° and 10°, the south-facing single-slope configurations generate power outputs of 118.3 MWh (1.74% loss) and 115.7 MWh (3.90% loss), respectively. However, for north-facing systems with the same tilt angles, the effect of self-shading becomes particularly significant; at 10°, the loss rate reaches 20.02%, making it the least favorable option for PV generation. Therefore, north-facing configurations are not recommended. In terms of natural ventilation, when the PV system is oriented windward, it can improve the airflow inside the main transformer room, reduce stagnant zones, and guide the inlet airflow toward the center of the room. Compared to horizontal PV systems, the proposed PV layouts in this study significantly improve ventilation performance, with increases of 12.6% (Case 5), 11.3% (Case 6), 11.9% (Case 9), and 13.2% (Case 10). Compared to the no-PV baseline (Case 1), these configurations also demonstrate good ventilation, with minor airflow losses of 2.3%, 3.4%, 2.9%, and 1.7%, respectively, ensuring adequate ventilation for the transformer room. Additionally, these layouts offer better airflow beneath the PV panels, aiding module cooling. Larger tilt angles (10°) have a more pronounced effect on indoor airflow than smaller angles (5°), but they also result in higher power losses, especially for north-facing installations. In leeward configurations, PV systems can negatively impact ventilation in the transformer room and are subjected to higher wind loads; the steeper the angle, the greater the wind pressure, which increases structural requirements for mounting the PV system. Therefore, careful consideration is needed when choosing a single-slope orientation, particularly in controlling the overall tilt angle.

For symmetrical pitched PV systems, good ventilation conditions are maintained under both windward and leeward conditions. Compared to horizontal PV systems, symmetrical layouts significantly improve ventilation by 8.6% (5°) and 14.6% (10°). Ventilation performance improves with increasing tilt angle, with the 10° symmetrical layout achieving the best ventilation performance among all PV-equipped cases—only a 0.6% reduction compared to the no-PV baseline. However, due to self-shading, power generation is reduced by 11.88% (5°) and 13.87% (10°), with losses increasing at steeper angles. When the transformer room is on the windward side, the PV system improves indoor airflow; on the leeward side, the impact is minimal. Furthermore, no wind speed-up is observed near the PV modules, which supports safe system operation.

From the perspective of thermal safety for electrical equipment, the 10° symmetrical PV system offers the most balanced solution in terms of ventilation velocity, airflow distribution in the transformer room, PV back surface cooling, and structural wind load risks. It provides the best ventilation performance among all PV-equipped cases (only a 0.6% reduction compared to the no-PV baseline and a 14.6% improvement over the horizontal PV system), the least indoor stagnation, smooth PV backflow ventilation, and no excessive structural burden from wind pressure, ensuring high operational safety.

The conclusions are as follows:

- (1)

- The 10° symmetrical PV system offers the most balanced solution. Although the symmetrical pitched roof installation has relatively lower power output, it provides the most stable and reliable ventilation performance without introducing additional wind load risks. The 10° symmetrical PV system offers the most balanced solution in terms of ventilation velocity, airflow distribution in the transformer room, PV back surface cooling, and structural wind load risks, showing only a 0.6% reduction compared to the no-PV baseline and a 14.6% improvement over the horizontal PV system. While the symmetrical roof installation results in lower power generation, it provides the most reliable ventilation effect and eliminates concerns about the additional wind load.

- (2)

- The traditional horizontal PV installation method presents certain drawbacks for both natural ventilation in the main transformer room and heat dissipation from the rear side of the PV modules. In the windward condition, airflow velocity at the bottom ventilation zone is reduced by 13.2% and by 11.8% in the leeward condition. Therefore, when applying PV systems in semi-outdoor substations, it is essential to integrate wind environment assessments into the design process. However, this installation method is not affected in terms of power generation performance.

- (3)

- The unilateral pitched installation method requires a comprehensive evaluation of multiple factors. It is most suitable for environments with a consistent prevailing wind direction, where a windward layout can achieve dual optimization of power generation and natural ventilation. Compared to the horizontal PV system, ventilation performance improves by more than 10%, and the ventilation loss relative to the no-PV condition remains below 4%. For south-facing orientations, the power generation loss remains under 4%. However, this layout can lead to higher wind loads, increasing installation costs, and may also hinder the airflow entering the ventilation openings in windward configurations.

6. Patents

The PV system design method for rooftop ventilation and heat dissipation proposed in this study has been submitted as a patent. It addresses the technical issue of low ventilation and cooling efficiency in semi-indoor substations where PV panels are horizontally installed with intervals on the rooftop.

Author Contributions

Conceptualization, X.W. and Z.C.; methodology, X.W. and Y.W.; software, Z.C.; validation, X.W., Y.W. and P.S.; formal analysis, Z.C. and X.W.; investigation, X.W., Y.W. and P.S.; resources, X.W., Y.W. and P.S.; data curation, X.W., Y.W. and P.S.; writing—original draft preparation, X.W., Y.W. and Z.C.; writing—review and editing, X.W. and P.S.; visualization, Z.C.; supervision, X.W. and P.S. project administration, X.W. and P.S.; funding acquisition, X.W. and Y.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Science and Technology Project of China Southern Power Grid Co., Ltd. (GDKJXM20230406).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Xiaohui Wu and Yanfeng Wang were employed by the company Power Grid Planning Research Center of Guangdong Power Grid Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

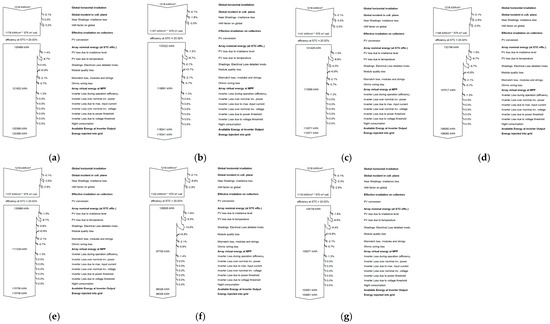

Appendix A

Loss Diagram of Cases in the Study for the Whole Year by PVsyst 7.2

Figure A1.

(a) Annual power generation of the horizontal PV system. (b) Annual power generation of the 5° south-facing PV system. (c) Annual power generation of the 5° north-facing PV system. (d) Annual power generation of the 5° symmetrical PV system. (e) Annual power generation of the 10° south-facing PV system. (f) Annual power generation of the 10° north-facing PV system. (g) Annual power generation of the 10° symmetrical PV system.

Appendix B

| Case No. | Transformer Orientation | Vent Area A (m/s) | Vent Area B (m/s) | Net of A and B (m/s) | Vent Area C (m/s) |

| 1 | Windward side | 1.93 | 1.55 | 1.74 | 0.28 |

| 2 | Leeward side | 0.72 | 0.63 | 0.68 | 0.13 |

| 3 | Windward side | 1.70 | 1.33 | 1.51 | 0.11 |

| 4 | Leeward side | 0.64 | 0.56 | 0.60 | 0.11 |

| 5 | Windward side | 1.91 | 1.50 | 1.70 | 0.32 |

| 6 | Windward side | 1.90 | 1.48 | 1.68 | 0.2 |

| 7 | Leeward side | 0.70 | 0.61 | 0.65 | 0.13 |

| 8 | Leeward side | 0.56 | 0.51 | 0.54 | 0.15 |

| 9 | Windward side | 1.89 | 1.50 | 1.69 | 0.22 |

| 10 | Windward side | 1.92 | 1.51 | 1.71 | 0.32 |

| 11 | Leeward side | 0.74 | 0.63 | 0.69 | 0.14 |

| 12 | Leeward side | 0.65 | 0.57 | 0.61 | 0.19 |

| 13 | Windward side | 1.81 | 1.48 | 1.64 | 0.29 |

| 14 | Leeward side | 0.71 | 0.63 | 0.67 | 0.12 |

| 15 | Windward side | 1.92 | 1.55 | 1.73 | 0.33 |

| 16 | Leeward side | 0.71 | 0.64 | 0.67 | 0.14 |

References

- United States Joint Economic Committee. Energy Efficiency Is a Bright Idea. Available online: https://www.jec.senate.gov/public/index.cfm/democrats/2007/6/energy-efficiency-is-a-bright-idea-_395 (accessed on 30 March 2025).

- Del Borghi, A.; Spiegelhalter, T.; Moreschi, L.; Gallo, M. Carbon-Neutral-Campus Building: Design Versus Retrofitting of Two University Zero Energy Buildings in Europe and in the United States. Sustainability 2021, 13, 9023. [Google Scholar] [CrossRef]

- Santamouris, M.; Vasilakopoulou, K. Present and future energy consumption of buildings: Challenges and opportunities towards decarbonisation. e-Prime—Adv. Electr. Eng. Electron. Energy 2021, 1, 100002. [Google Scholar] [CrossRef]

- The China Association of Building Energy Efficiency. Research Report on Carbon Emissions in the Urban and Rural Construction Sector. 2024. Available online: https://www.cabee.org/site/content/25289.html (accessed on 30 March 2025).

- Xinhua News Agency: China’s Policies and Actions for Addressing Climate Change. Available online: https://www.gov.cn/zhengce/2021-10/27/content_5646697.htm (accessed on 30 March 2025).

- Korra, C.; Sadhana V., A. Green Warehouses: The Benefits, Challenges and Strategies of Industrial Building Decarbonization. Int. J. Innov. Sci. Res. Technol. (IJISRT) 2024, 9, 1454–1462. [Google Scholar] [CrossRef]

- Reis, D.C.; De Domenico, A.T.; Lopes, L.; Almeida, M. Strategies and Actions for Achieving Carbon Neutrality in Portuguese Residential Buildings by 2050. Sustainability 2023, 15, 15626. [Google Scholar] [CrossRef]

- Solar Energy: Applications, Trends Analysis, Bibliometric Analysis and Research Contribution to Sustainable Development Goals (SDGs). Available online: https://www.mdpi.com/2071-1050/15/2/1418 (accessed on 30 March 2025).

- Notice of the General Office of the State Council. Work Plan for Accelerating Energy Conservation and Carbon Reduction in the Building Sector; National Development and Reform Commission and the Ministry of Housing and Urban-Rural Development: Beijing, China, 2024. [Google Scholar]

- Che, W.; Wang, Y.; Zhu, W.; Hong, L.; Fang, C.; Wu, H.; Liu, J. A Review of Carbon Emission Reduction During the Operation Stage of Substations. Sustainability 2024, 16, 10017. [Google Scholar] [CrossRef]

- Byrne, J.; Taminiau, J.; Kurdgelashvili, L.; Kim, K.N. A Review of the Solar City Concept and Methods to Assess Rooftop Solar Electric Potential, with an Illustrative Application to the City of Seoul. Renew. Sustain. Energy Rev. 2015, 41, 830–844. [Google Scholar] [CrossRef]

- Sha, Y.; Xu, J. Construction Plan for Rooftop Distributed PV Systems in Urban 110 kV Indoor Substations. Electr. Power Energy 2022, 43, 524–528. [Google Scholar]

- Shenzhen Power Grid Construction Accelerates Across the Board: Number of New Substations and Main Transformer Capacity in 2023 Both Reach Highest Levels in a Decade—Shenzhen News Network. Available online: https://www.sznews.com/news/content/2024-01/19/content_30707543.htm (accessed on 30 March 2025).

- Qin, T. Research on the Application of Photovoltaic Power Generation Technology in Green and Energy-Efficient Renovation Projects of Substations. Hydropower Tech. Superv. 2024, 10, 251–254. [Google Scholar]

- Corti, P.; Bonomo, P.; Frontini, F. Paper Review of External Integrated Systems as Photovoltaic Shading Devices. Energies 2023, 16, 5542. [Google Scholar] [CrossRef]

- Tang, B.; Zhang, L.; Liu, S.; Bai, X.; Chen, G.; Shang, Z. Calculation of Noise Field in Main Transformer Room of Indoor Substation Based on Thermal-Acoustic Coupling. Energy 2024, 297, 131046. [Google Scholar] [CrossRef]

- Chen, Y.; Shao, Y.; Li, Y.; Deng, L.; Che, D. Numerical Simulation and Optimization of Ventilation and Heat Dissipation in Main Transformer Room of Semi-Indoor Substations. Appl. Therm. Eng. 2025, 269, 126105. [Google Scholar] [CrossRef]

- Chen, C.-M.; Lin, Y.-P.; Chung, S.-C.; Lai, C.-M. Effects of the Design Parameters of Ridge Vents on Induced Buoyancy-Driven Ventilation. Buildings 2022, 12, 112. [Google Scholar] [CrossRef]

- Cao, Z.; Liu, Y.; Bai, Y.; Wang, Y.; Ye, S.; Cao, H. Study on the Optimal Layout of Roof Vents and Rooftop Photovoltaic of the Industrial Workshop. Build. Environ. 2024, 260, 111624. [Google Scholar] [CrossRef]

- Wang, H.; Wei, J.; Guo, C.; Yang, L.; Wang, Z. Numerical Investigation of the Effects of Different Influencing Factors on Thermal Performance of Naturally Ventilated Roof. Energy 2024, 289, 130039. [Google Scholar] [CrossRef]

- Roeleveld, D.; Hailu, G.; Fung, A.; Naylor, D.; Yang, T.; Athienitis, A. Validation of Computational Fluid Dynamics (CFD) Model of a Building Integrated Photovoltaic/Thermal (BIPV/T) System. Energy Procedia 2015, 78, 1901–1906. [Google Scholar] [CrossRef]

- Baloch, A.A.B.; Bahaidarah, H.M.S.; Gandhidasan, P.; Al-Sulaiman, F.A. Experimental and Numerical Performance Analysis of a Converging Channel Heat Exchanger for PV Cooling. Energy Convers. Manag. 2015, 103, 14–27. [Google Scholar] [CrossRef]

- Zhou, Q.; Dong, P.; Li, M.; Wang, Z. Analyzing the interactions between photovoltaic system and its ambient environment using CFD techniques: A review. Energy Build. 2023, 296, 113394. [Google Scholar] [CrossRef]

- Lebbi, M.; Boutina, L.; Hassani, S.; Touafek, K.; Khelifa, A.; Kherrour, S.; Benchatti, A. Improvement of the Photovoltaic Panel Cooling by Natural Air Ventilation. Environ. Prog. Sustain. Energy 2024, 43, e14304. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Yang, P.; Liu, Y.; Zhu, C.; Wang, L.; Zhong, H. Optimizing air inlet designs for enhanced natural ventilation in indoor substations: A numerical modelling and CFD simulation study. Case Stud. Therm. Eng. 2024, 59, 104408. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, H.-M.; Wu, S.-Y.; Liu, Y.-W.; Zhong, H. Numerical simulation and optimisation design for ventilation and heat dissipation in high-temperature and high-load indoor substations. Case Stud. Therm. Eng. 2024, 59, 104502. [Google Scholar] [CrossRef]

- Wang, Y.; Jin, X.; Zhang, J.; Zeng, C.; Gao, X.; Zhao, L.; Sha, S. Scheme Design and Energy-Saving Optimization of Cold and Heat Energy Supply System for Substation Main Control Building in Cold Area. Appl. Sci. 2024, 14, 1562. [Google Scholar] [CrossRef]

- Ricci, A.; Kalkman, I.; Blocken, B.; Burlando, M.; Freda, A.; Repetto, M. Local-Scale Forcing Effects on Wind Flows in an Urban Environment: Impact of Geometrical Simplifications. J. Wind. Eng. Ind. Aerodyn. 2017, 170, 238–255. [Google Scholar] [CrossRef]

- Muhsin, F.; Yusoff, W.F.M.; Mohamed, M.F.; Sapian, A.R. CFD Modeling of Natural Ventilation in a Void Connected to the Living Units of Multi-Storey Housing for Thermal Comfort. Energy Build. 2017, 144, 1–16. [Google Scholar] [CrossRef]

- Tominaga, Y.; Mochida, A.; Yoshie, R.; Kataoka, H.; Nozu, T.; Yoshikawa, M.; Shirasawa, T. AIJ Guidelines for Practical Applications of CFD to Pedestrian Wind Environment around Buildings. J. Wind. Eng. Ind. Aerodyn. 2008, 96, 1749–1761. [Google Scholar] [CrossRef]

- Serra, N. Revisiting RANS Turbulence Modelling Used in Built-Environment CFD Simulations. Build. Environ. 2023, 237, 110333. [Google Scholar] [CrossRef]

- Guangzhou Weather. Available online: http://www.tqyb.com.cn/gz/climaticprediction/bulletin/ (accessed on 31 March 2025).

- Wu, Y. Research on Urban Block Ventilation Optimization Method Based on Surrogate Models—Taking Guangzhou as an Example. Ph.D. Thesis, Wuhan University, Wuhan, China, 2023. [Google Scholar]

- IEC 61724; Photovoltaic System Performance Monitoring—Guidelines for Measurement, Data Exchange and Analysis. International Electrotechnical Commission: Geneva, Switzerland, 2021.

- Serat, Z.; Chen, X.; Zuo, H.; Li, J. Design Strategies for Building Rooftop Photovoltaic Systems: Efficiency and Grid Integration. J. Build. Eng. 2025, 100, 111693. [Google Scholar] [CrossRef]

- Xu, D.; Zhang, L.; Wang, H.; Wang, K.; Zhang, W. An Investigation of the Ventilation Systems of Whole-Indoor Urban Substations. Buildings 2024, 14, 3749. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).