Study on Elastoplastic Damage and Crack Propagation Mechanisms in Rock Based on the Phase Field Method

Abstract

1. Introduction

2. Formulation and Theoretical Derivation of the Elastoplastic Phase Field Fracture Model

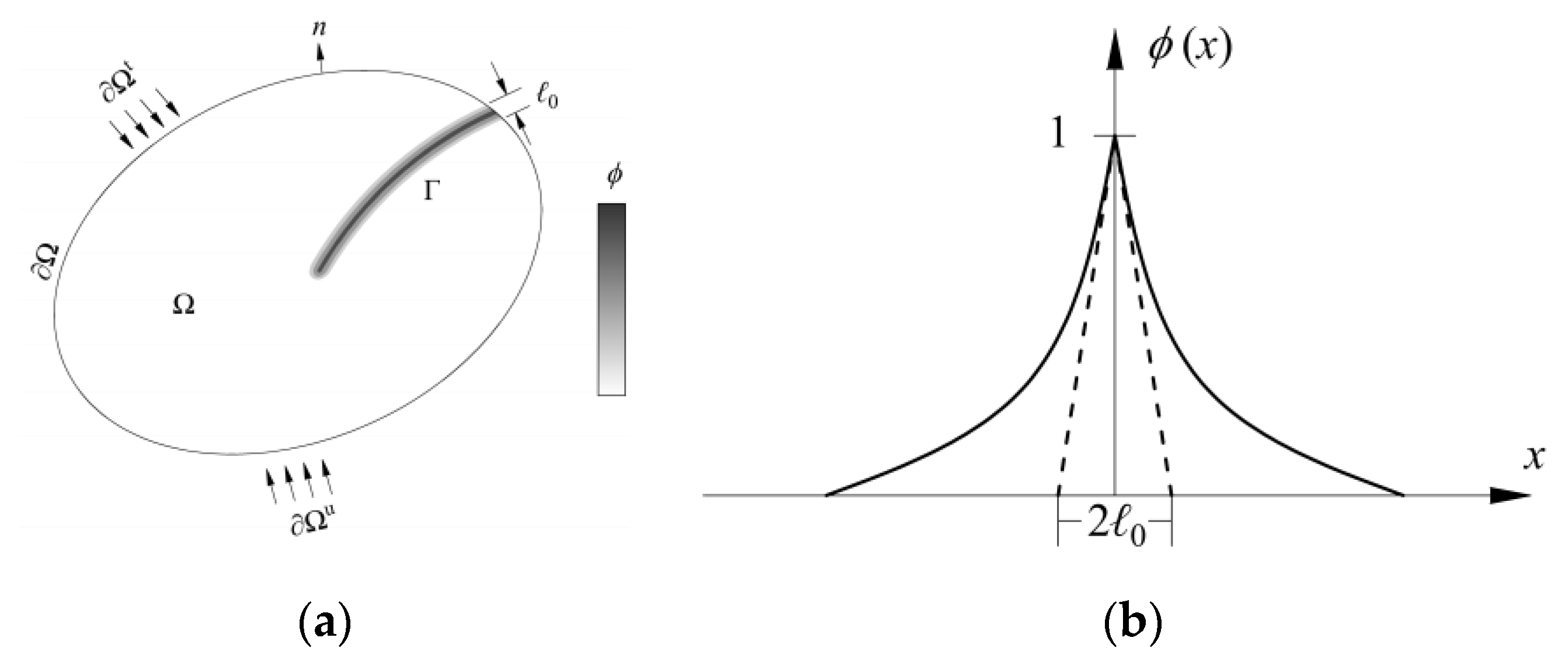

2.1. Crack Surface Energy

2.2. Elastic Strain Energy

2.3. Plastic Damage Strain Energy

2.4. Derivation of Phase Field Governing Equations and Equilibrium Equations

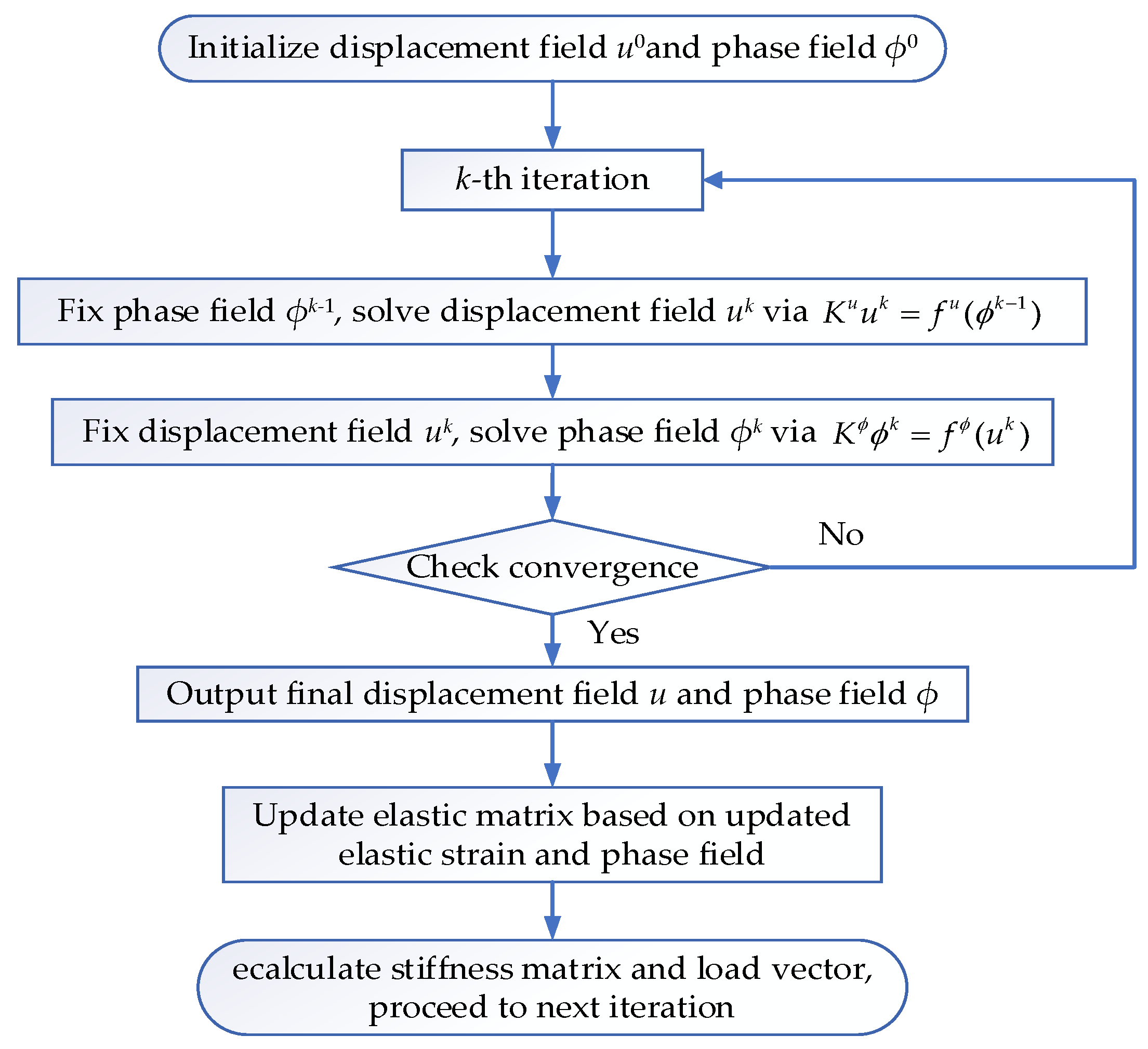

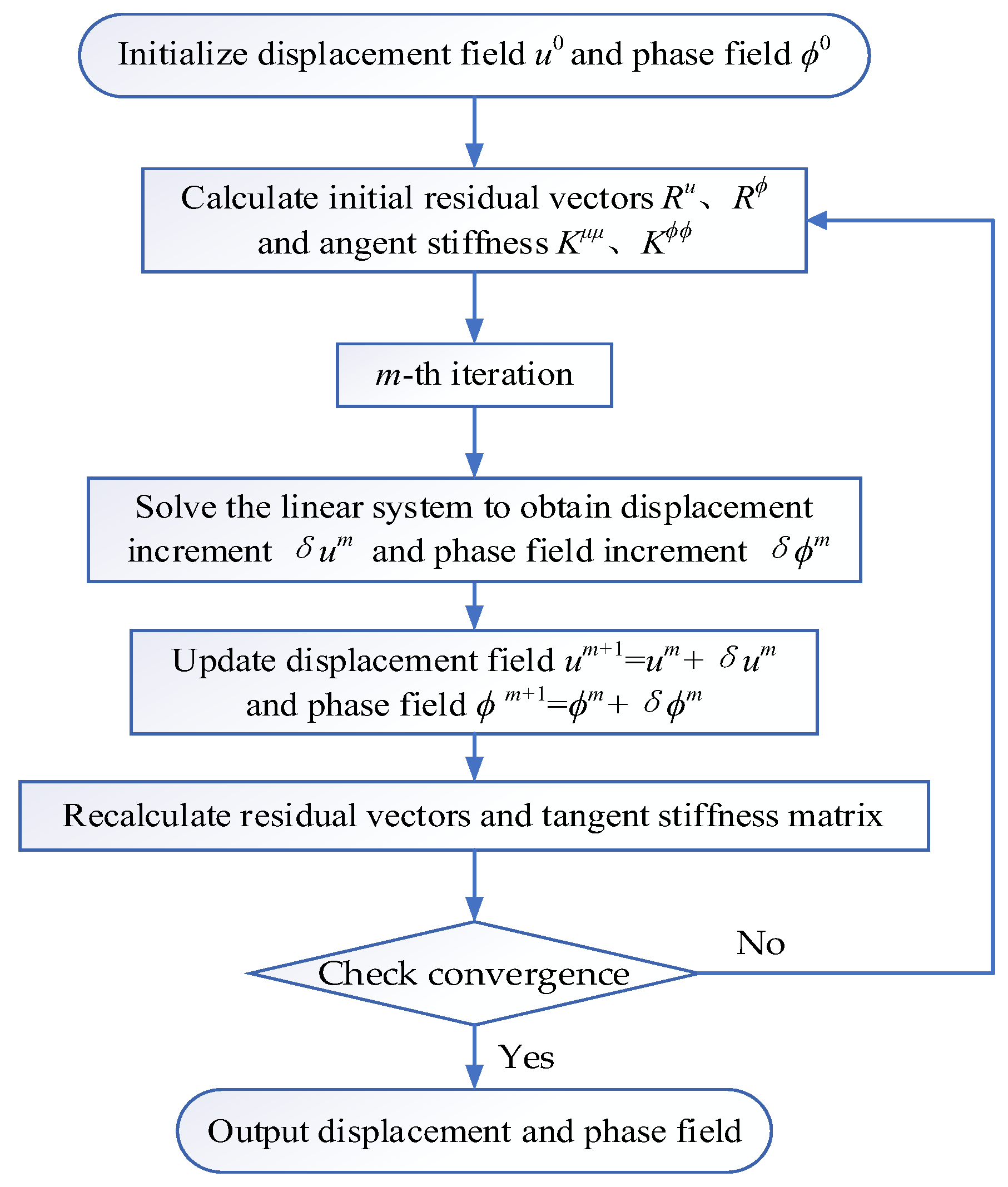

3. Numerical Implementation of Phase Field Fracture Model Based on Finite Elements

3.1. Finite Element Discretization

3.2. Numerical Implementation Process

4. Numerical Examples

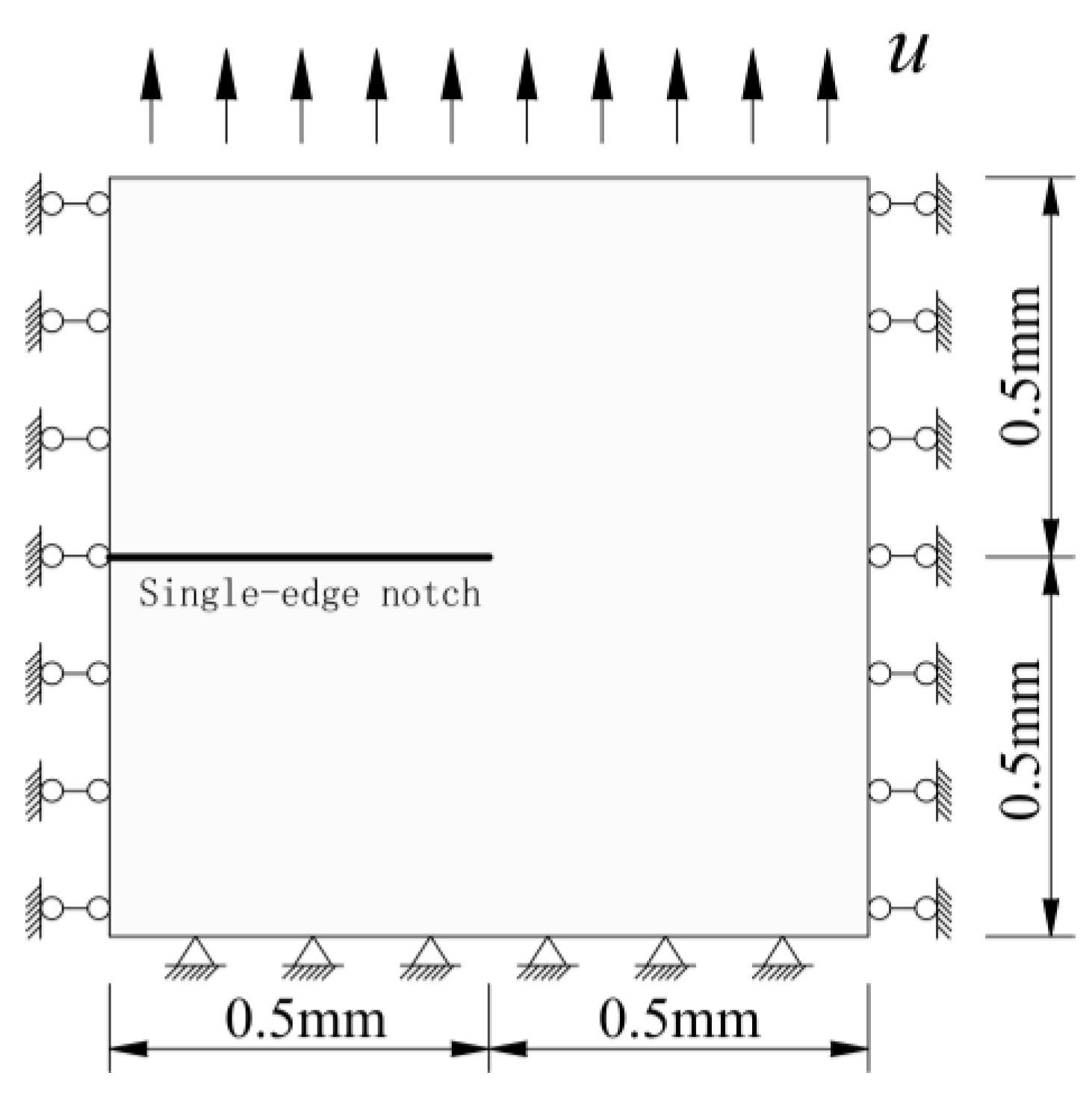

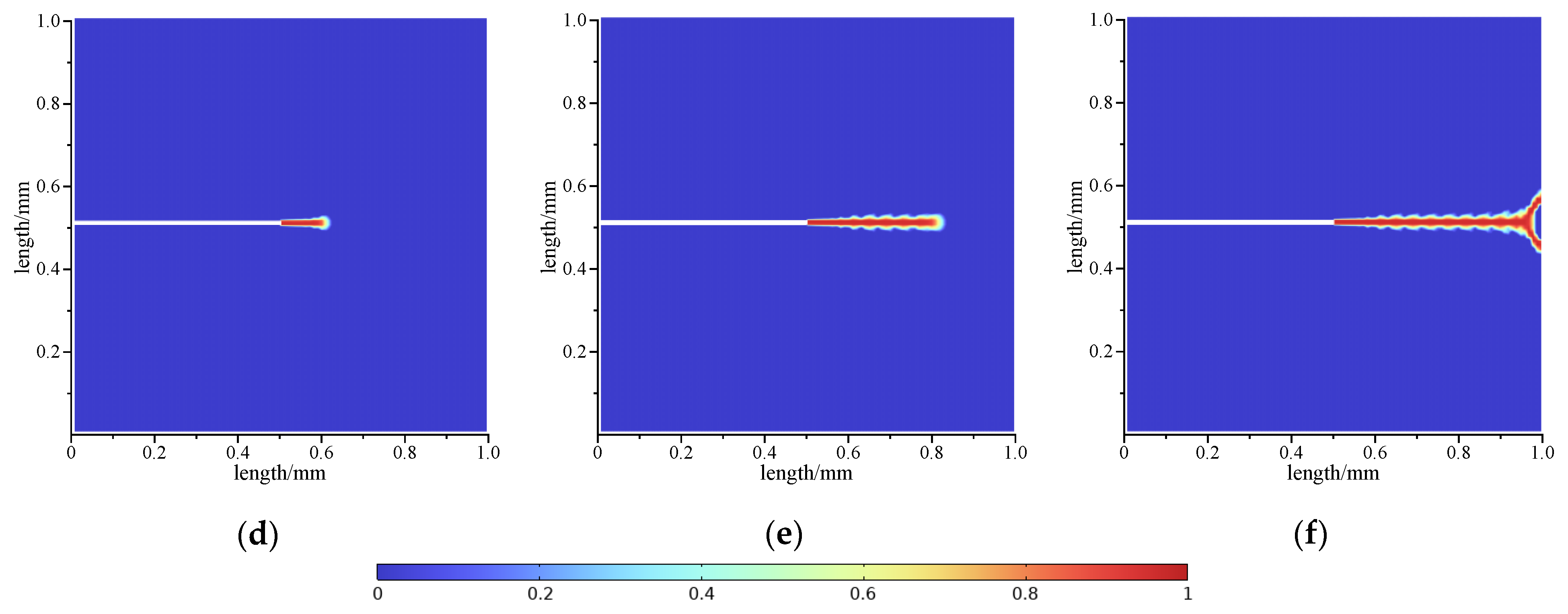

4.1. Single-Edge Notched Tensile Test

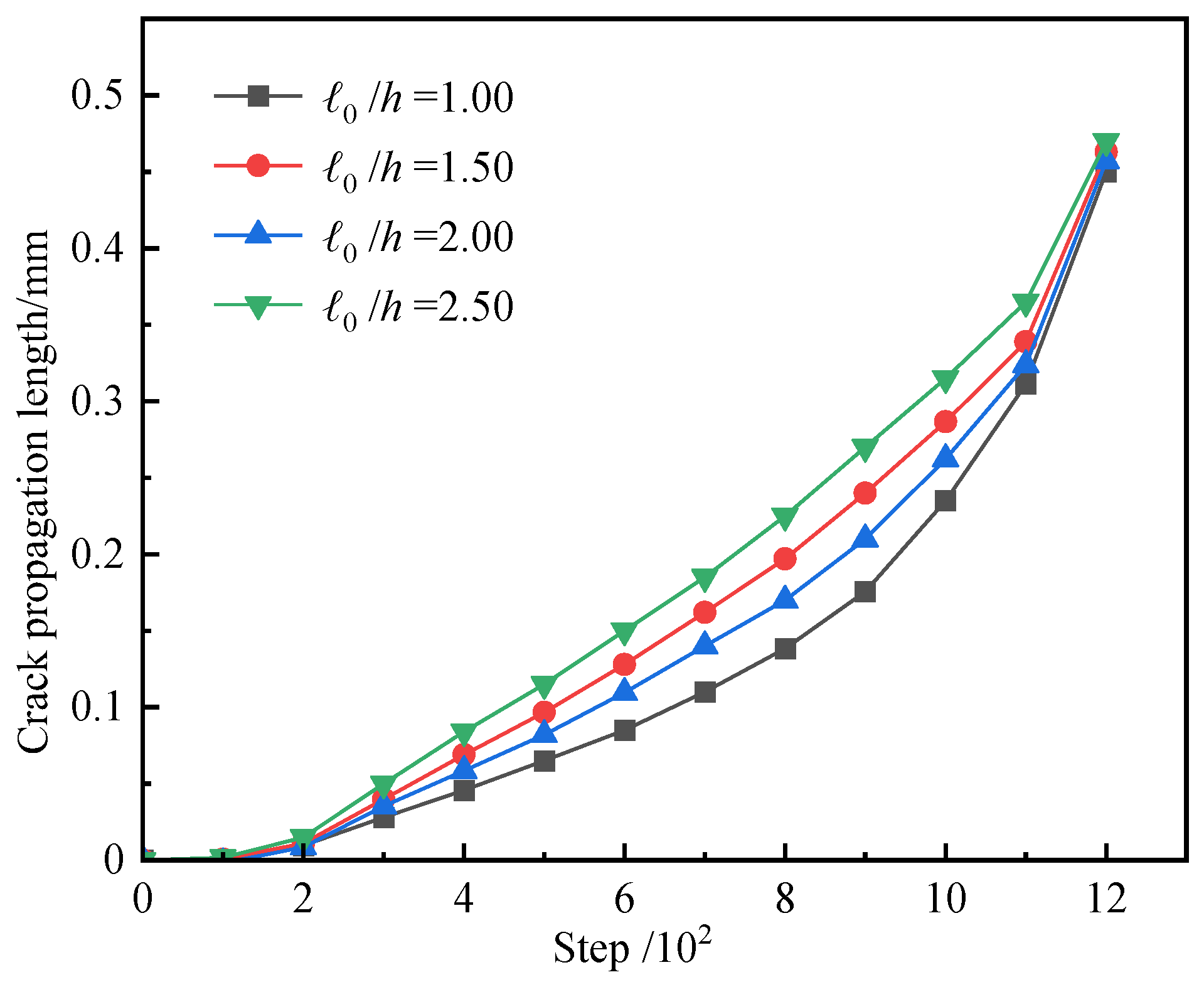

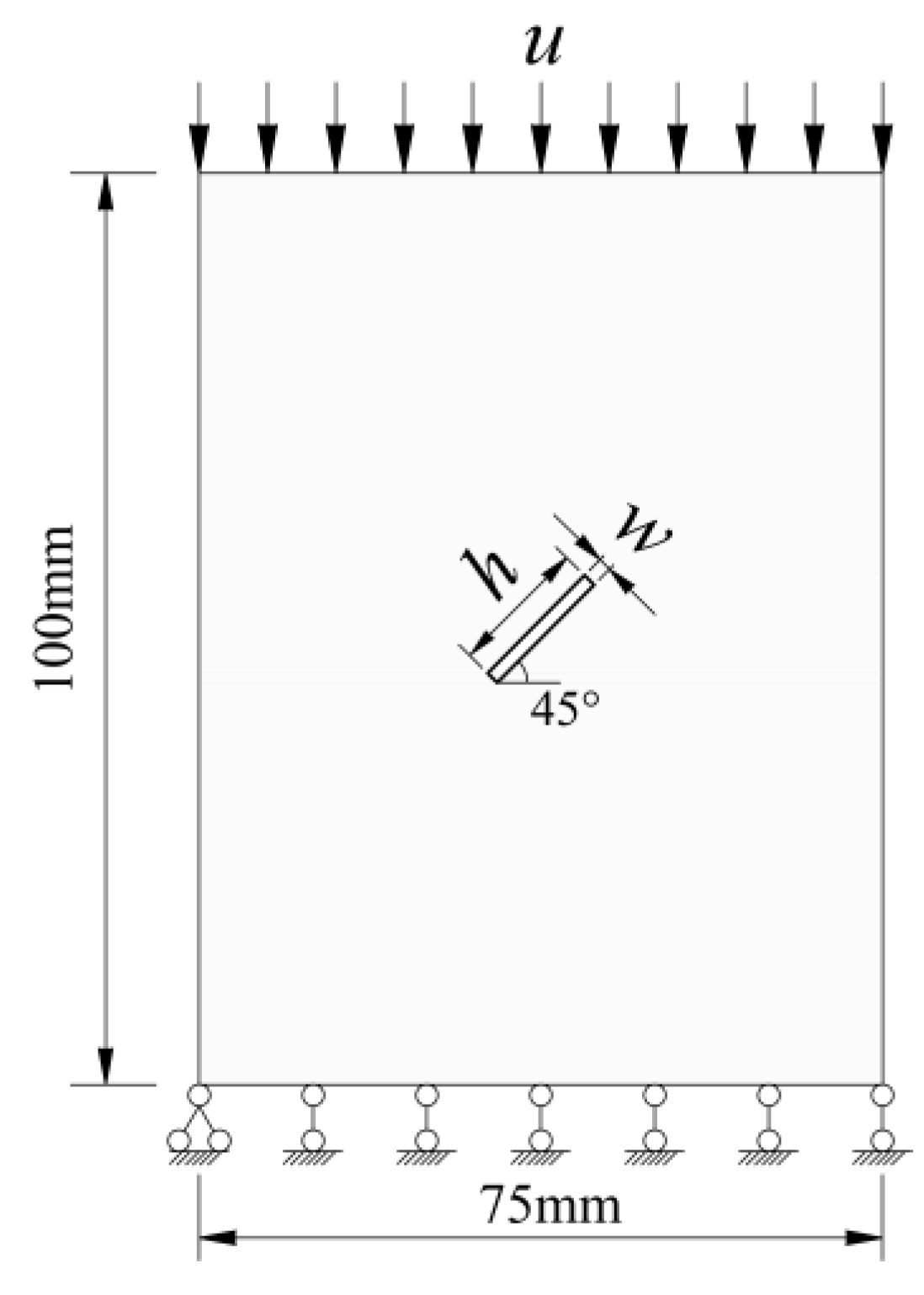

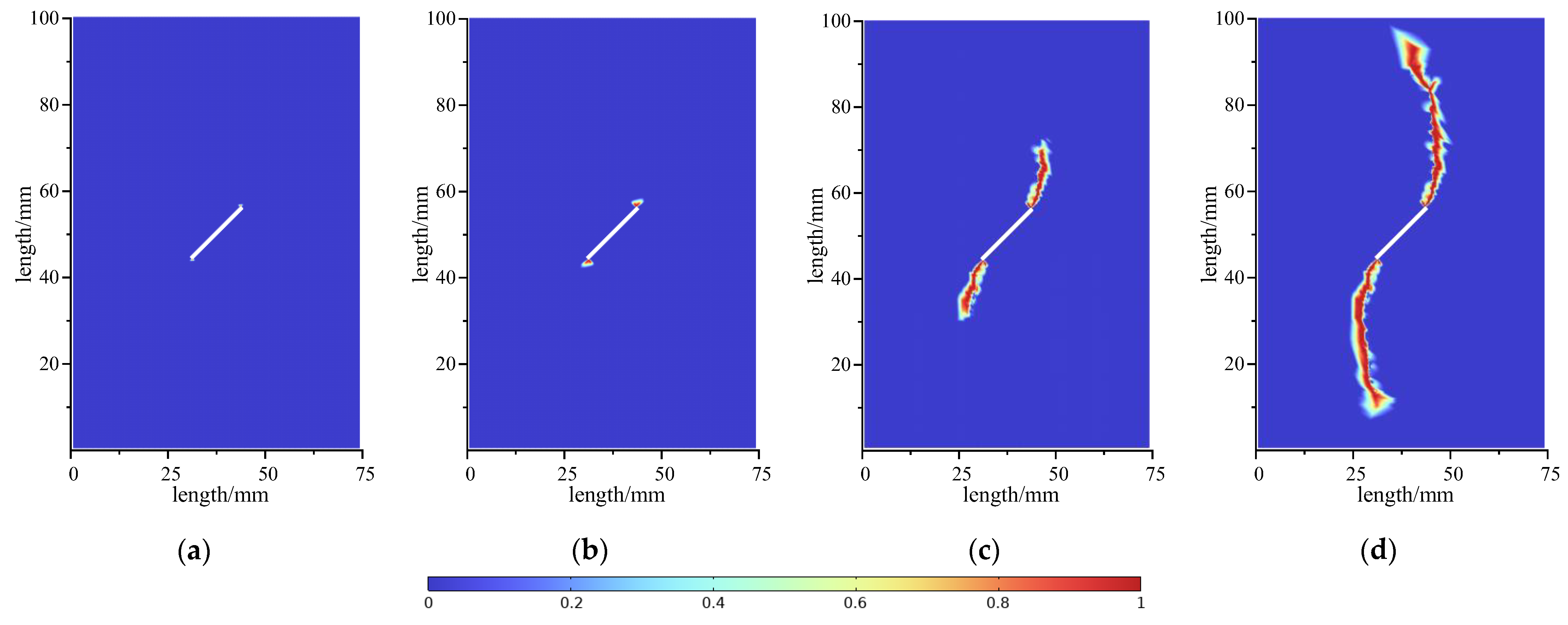

4.2. Uniaxial Compression Test on Rock with a Prefabricated Crack

5. Discussion

- (1)

- Advantages and Contributions: The model’s primary strength lies in its ability to overcome the limitations of purely elastic phase field approaches. Traditional models often neglect plastic deformation mechanisms such as shear band localization and residual strength, leading to overly brittle predictions. By integrating plastic strain energy and non-associated flow rules, this work quantifies the reduction in crack propagation resistance caused by plastic slip, enabling a seamless transition from elastic loading to plastic damage accumulation and unstable fracture. Numerical validation through single-edge notch tension and uniaxial compression tests confirms the model’s accuracy, with load–displacement curves exhibiting less than 5% error in elastic stiffness and a 1.2% deviation in peak load compared to experimental benchmarks. These results highlight its potential for predicting residual strength in underground engineering structures, where stress redistribution and long-term stability are paramount.

- (2)

- However, the model’s reliance on small-deformation theory and isotropic hardening assumptions introduces constraints. Scenarios involving large rotations, such as shear band widening or rockbursts, may require extensions to finite-deformation frameworks to account for geometric nonlinearity. Additionally, the omission of crack interaction mechanisms—such as coalescence or branching—limits its applicability to multi-fracture systems. Furthermore, while key parameters (e.g., critical energy release rates, regularization length scale, and residual strength coefficient) are calibrated through benchmark tests, their sensitivity to crack propagation behavior and energy dissipation remains to be systematically quantified. A comprehensive parametric sensitivity analysis would refine calibration protocols for heterogeneous rock masses, though such an exploration is deferred to future work to maintain focus on the foundational coupling framework proposed here.

- (3)

- Comparison with Existing Studies: When compared to existing studies, the proposed model distinguishes itself through its explicit integration of plasticity and fracture mechanics. Prior hydromechanical phase field models, such as those by Wang et al. [15] and Liu et al. [16], omitted plastic energy dissipation, while cohesive zone approaches employed by Liu et al. [14] relied on predefined crack paths. In contrast, this work eliminates such constraints, enabling autonomous crack initiation and propagation through a unified energy functional. This theoretical innovation not only enhances computational flexibility but also provides a more holistic representation of rock behavior under compressive-shear loading, as evidenced by its alignment with classical experimental observations.

- (4)

- Future Directions: Future research should focus on expanding the model’s scope to address multifield coupling and dynamic loading scenarios. Incorporating thermo-hydro-mechanical (THM) interactions would improve predictions for saturated or thermally altered rock masses, where pore pressure and temperature gradients significantly influence fracture behavior. Extending the framework to dynamic regimes, such as blasting or seismic loading, could unravel crack propagation mechanisms under rapid stress changes. Preliminary studies on cyclic loading and crack branching already show promise, with results correlating well with experimental acoustic emission data. Furthermore, integrating machine learning techniques could streamline parameter inversion processes, particularly for heterogeneous formations where empirical calibration is impractical. These advancements would transform the model into a versatile tool for both academic research and industrial applications, ultimately advancing the safety and efficiency of rock engineering projects.

6. Conclusions and Prospects

- (1)

- This study develops an elastoplastic phase field fracture model, incorporating plastic deformation mechanisms and overcoming the limitations of conventional elastic models under compressive-shear conditions. By integrating plastic strain energy and non-associated flow rules, the framework couples plasticity with phase field damage evolution, explicitly quantifying how plastic slip and shear band formation regulate crack driving forces and propagation paths. The model successfully simulates complete energy evolution processes—from elastic loading to plastic damage accumulation and unstable fracture—providing a novel theoretical tool for analyzing mesoscale rock failure mechanisms under compressive-shear stresses.

- (2)

- The numerical implementation leverages finite element discretization and nonlinear solvers, validating the model’s capability to simulate complex crack propagation. The coupled interpolation of displacement and phase fields, staggered algorithms, and Newton–Raphson iterations address elastoplastic coupling nonlinearities. Benchmark tests—including single-edge notched tension and prefabricated-crack compression—demonstrate the accurate capture of crack initiation dynamics, wing crack propagation, and through-going failure. Specifically, in the elastic deformation stage, the load–displacement curve exhibits a slope error < 5% and a correlation coefficient R2 > 0.99. At the peak load, the relative error between this model and data from the literature is only 1.2%. These quantitative results further validate the reliability of this model.

- (3)

- The findings offer practical engineering relevance for hydraulic fracturing and underground energy storage applications. By quantifying plastic deformation’s impact on crack driving forces, the model enables reliable residual strength predictions, reducing dependency on costly physical tests for the long-term stability assessments of underground structures. Additionally, full-process energy evolution simulations support parameter inversion in real-time monitoring systems, enhancing safety and cost-efficiency in rock engineering projects.

- (4)

- Future research should focus on multifield coupling extensions and parameter optimization under dynamic loads. Integrating thermal, hydraulic, and mechanical (THM) couplings into phase field frameworks will advance the modeling of complex geological conditions. Developing data-driven parameter inversion methods and incorporating non-local plasticity theory to refine shear band width simulations are critical directions for advancing rock fracture mechanics research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, B.; Barboza, B.R.; Sun, Y.; Bai, J.; Thomas, H.R.; Dutko, M.; Cottrell, M.; Li, C. A review of hydraulic fracturing simulation. Arch. Comput. Methods Eng. 2022, 29, 1–58. [Google Scholar] [CrossRef]

- Ismail, A.; Azadbakht, S. A comprehensive review of numerical simulation methods for hydraulic fracturing. Int. J. Numer. Anal. Methods Geomech. 2024, 48, 1433–1459. [Google Scholar] [CrossRef]

- Liu, X.; Hao, Z.; Liu, S.; Zhang, P.; Pan, Y. Study of fracture behavior in three-dimensional Brazilian disk based on phase field method. J. Dalian Univ. Technol. 2025, 65, 181–190. [Google Scholar]

- Ying, Y.; Huang, W.; Ma, Y.; Peng, F. Fracture behavior of periodic porous structures by phase field method. Chin. J. Theor. Appl. Mech. 2022, 54, 3430–3443. [Google Scholar]

- Xu, Q.; Wang, S.; Chen, J.; Wang, M.; Liu, J. Polygon finite element simulation based on unified phase field theory. Yangtze River 2025, 56, 216–223+239. [Google Scholar]

- Khisamitov, I.; Meschke, G. Variational interface element model for 2d and 3d hydraulic fracturing simulations. Comput. Methods Appl. Mech. Eng. 2021, 373, 113450. [Google Scholar] [CrossRef]

- Yoshioka, K.; Naumov, D.; Kolditz, O. On crack opening computation in variational phase-field models for fracture. Comput. Methods Appl. Mech. Eng. 2020, 369, 113210. [Google Scholar] [CrossRef]

- Long, X.; Zhu, J.; Su, Y.; Jiang, X.; Jin, P. Analysis of crack evolution and mechanical properties degradation of polymer bonded explosives based on phase-field fracture. Chin. J. Comput. Mech. 2024, 41, 682–688. [Google Scholar]

- Francfort, G.A.; Marigo, J.-J. Revisiting brittle fracture as an energy minimization problem. J. Mech. Phys. Solids 1998, 46, 1319–1342. [Google Scholar] [CrossRef]

- Wu, J. On the unified phase-field theory for damage and failure in solids and structures: Theoretical and numerical aspects. Chin. J. Theor. Appl. Mech. 2021, 53, 301–329. [Google Scholar]

- Zhang, W.; Shen, Z.; Xu, L.; Zhang, H.; Gan, L.; Li, G. A phase-field fracture model for brittle materials based on COMSOL. Chin. J. Comput. Mech. 2023, 40, 273–280. [Google Scholar]

- Xiang, F.; Zhao, C.; Xing, J. Research on crack propagation and damage evolution of rock based on the unified phase-field theory. Chin. J. Rock Mech. Eng. 2023, 42 (Suppl. S1), 3519–3528. [Google Scholar]

- Sun, G.; Yi, Q.; Yao, Y.; Shang, H.; Ji, W. Study on the potential instability patterns of tunnel type underground cavernsfor compressed air energy storage. Chin. J. Rock Mech. Eng. 2024, 43, 41–49. [Google Scholar]

- Liu, S.; Wang, W.; Cao, Y.; Zhu, Q.; Shao, J. Study on the elastoplastic damage model for rock based on the phase-fieldmethod and its numerical implementation. Chin. J. Rock Mech. Eng. 2023, 42, 896–905. [Google Scholar]

- Wang, Y.; Wang, Y.; Liu, S.; Kou, M. Phase field modelling of the hydro-mechanical coupling failure mechanisms of fissured rock masses. J. Civ. Environ. Eng. 2024, 46, 211–220. [Google Scholar]

- Liu, J.; Xue, Y.; Gao, F.; Teng, T.; Liang, X. Propagation of hydraulic fractures in bedded shale based on phase-field method. Chin. J. Geotech. Eng. 2022, 44, 464–473. [Google Scholar]

- Yi, L.; Li, X.; Yang, Z.; Yang, C. Phase field modeling of hydraulic fracturing in porous media formation with natural fracture. Eng. Fract. Mech. 2020, 236, 107206. [Google Scholar] [CrossRef]

- Yousef, H. A review on phase-field modeling of hydraulic fracturing. Eng. Fract. Mech. 2021, 253, 107881. [Google Scholar]

- Zhou, S.; Zhuang, X.; Rabczuk, T. Phase field method for quasi-static hydro-fracture in porous media under stress boundary condition considering the effect of initial stress field. Theor. Appl. Fract. Mech. 2020, 107, 102523. [Google Scholar] [CrossRef]

- Kar, S.; Chaudhuri, A.; Singh, A.; Pal, S. Phase field method to model hydraulic fracturing in saturated porous reservoir with natural fractures. Eng. Fract. Mech. 2023, 286, 109289. [Google Scholar] [CrossRef]

- Lü, M.; Zhu, Z.; Zhou, L.; Ge, X. Numerical simulation of hydraulic fracture propagation in rock masses with pre-existing double fractures using the phase field method. Rock Soil Mech. 2024, 45, 1850–1862. [Google Scholar] [CrossRef]

- Lü, Z.; Wu, M.; Duan, J.; Huang, Y. Phase-field modeling of frost propagation of cracks for rock mass under frost action. Chin. J. Geotech. Eng. 2023, 45, 2258–2267. [Google Scholar]

- Bourdin, B.; Francfort, G.A.; Marigo, J.J. Numerical experiments in revisited brittle fracture. J. Mech. Phys. Solids 2000, 48, 797–826. [Google Scholar] [CrossRef]

- Wang, S.; Yang, S.; Tian, W.; Huang, Y. Research on phase-field simulation method of crack propagation of rockwith pre-existing fissures. Chin. J. Rock Mech. Eng. 2023, 42, 365–377. [Google Scholar]

- Wang, F. Unified fracture phase-field method and determination of crack width for brittle materials. Eng. Mech. 2024, 41, 1–8. [Google Scholar] [CrossRef]

- Lu, Q.; Zhang, H.; Guo, J.; Ren, Y.; He, L.; Yuan, C. Status and prospect of hydraulic fracture propagation simulation based on phase field method. Nat. Gas Ind. 2023, 43, 59–68. [Google Scholar]

- Cao, Y.; Sun, K.; Zhu, S.; Huang, J.; Ma, L. Elastoplastic fracture simulation of plate with hole based on phase field method. Ordnance Mater. Sci. Eng. 2021, 44, 39–44. [Google Scholar]

- Zhao, C.; Rao, Q.; Yi, W.; Luo, S. A study on multiple-crack propagation of brittle rock based onmixed-mode phase field model. J. Railw. Sci. Eng. 2023, 20, 565–575. [Google Scholar]

- Qiu, S.; Duan, Q.; Shao, Y.; Yao, W. Consistent element-free Galerkin method for phase-field model of brittle fracture in elasto-plastic solids. Chin. J. Comput. Mech. 2023, 40, 60–65. [Google Scholar]

- Wang, H.; Wu, G. Study on mechanical properties of steel fiber reinforced concrete interface transition zone based on unified phase-field theory and cohesive zone model. J. Hebei Univ. Sci. Technol. 2023, 44, 112–122. [Google Scholar]

- Yuan, J.; Chen, C. Brittle Fracture Analysis of One-dimensional Pull Rod Based on Phase-field Model. J. Hunan Univ. Nat. Sci. 2021, 48, 53–58. [Google Scholar]

- Zhang, W.; Zhuang, M.; Zhu, X.; Shen, W.; Chen, M. A Novel Degradation Function of the Phase Field Method for Quasi-brittle Fracture. China Rural. Water Hydropower 2022, 2022, 201–207. [Google Scholar]

- Liu, G.; Li, Q.; Zuo, Z. Implementation of a staggered algorithm for a phase field model in ABAQUS. Chin. J. Rock Mech. Eng. 2016, 35, 1019–1030. [Google Scholar]

- Li, M.; Li, S.; Zuo, J.; Wang, Z.; Peng, L.; Xue, X. Numerical simulation of three-point bending failure behavior of basalt based on phase field method. Sci. Technol. Eng. 2022, 22, 13441–13449. [Google Scholar]

- Liu, G.; Li, Q.; Liang, G. A phase-field description of dynamic hydraulic fracturing. Chin. J. Rock Mech. Eng. 2017, 36, 1400–1412. [Google Scholar]

- Zhang, Z.; Hao, L. Application of X-FEM in a phase-field model for crack propagation. Acta Aeronaut. Astronaut. Sin. 2022, 43, 475–485. [Google Scholar]

| Symbol of Material Parameter | Name of Material Parameter | Values | Unit |

|---|---|---|---|

| elastic modulus | |||

| Poisson’s ratio | |||

| angle of internal friction | |||

| cohesion | |||

| critical energy release rate for tensile fracture | |||

| critical energy release rate for tension–shear fracture | |||

| critical energy release rate for compression–shear fracture | |||

| critical energy release rate for plastic damage | |||

| plastic bulk modulus | |||

| plastic shear modulus | |||

| material parameter | |||

| hardening parameter | |||

| scale parameter |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Qin, G.; Wang, B. Study on Elastoplastic Damage and Crack Propagation Mechanisms in Rock Based on the Phase Field Method. Appl. Sci. 2025, 15, 6206. https://doi.org/10.3390/app15116206

Zhang J, Qin G, Wang B. Study on Elastoplastic Damage and Crack Propagation Mechanisms in Rock Based on the Phase Field Method. Applied Sciences. 2025; 15(11):6206. https://doi.org/10.3390/app15116206

Chicago/Turabian StyleZhang, Jie, Guang Qin, and Bin Wang. 2025. "Study on Elastoplastic Damage and Crack Propagation Mechanisms in Rock Based on the Phase Field Method" Applied Sciences 15, no. 11: 6206. https://doi.org/10.3390/app15116206

APA StyleZhang, J., Qin, G., & Wang, B. (2025). Study on Elastoplastic Damage and Crack Propagation Mechanisms in Rock Based on the Phase Field Method. Applied Sciences, 15(11), 6206. https://doi.org/10.3390/app15116206