Analysis of Selected Methods of Computer-Aided Design for Stage Structures

Abstract

1. Problem Description

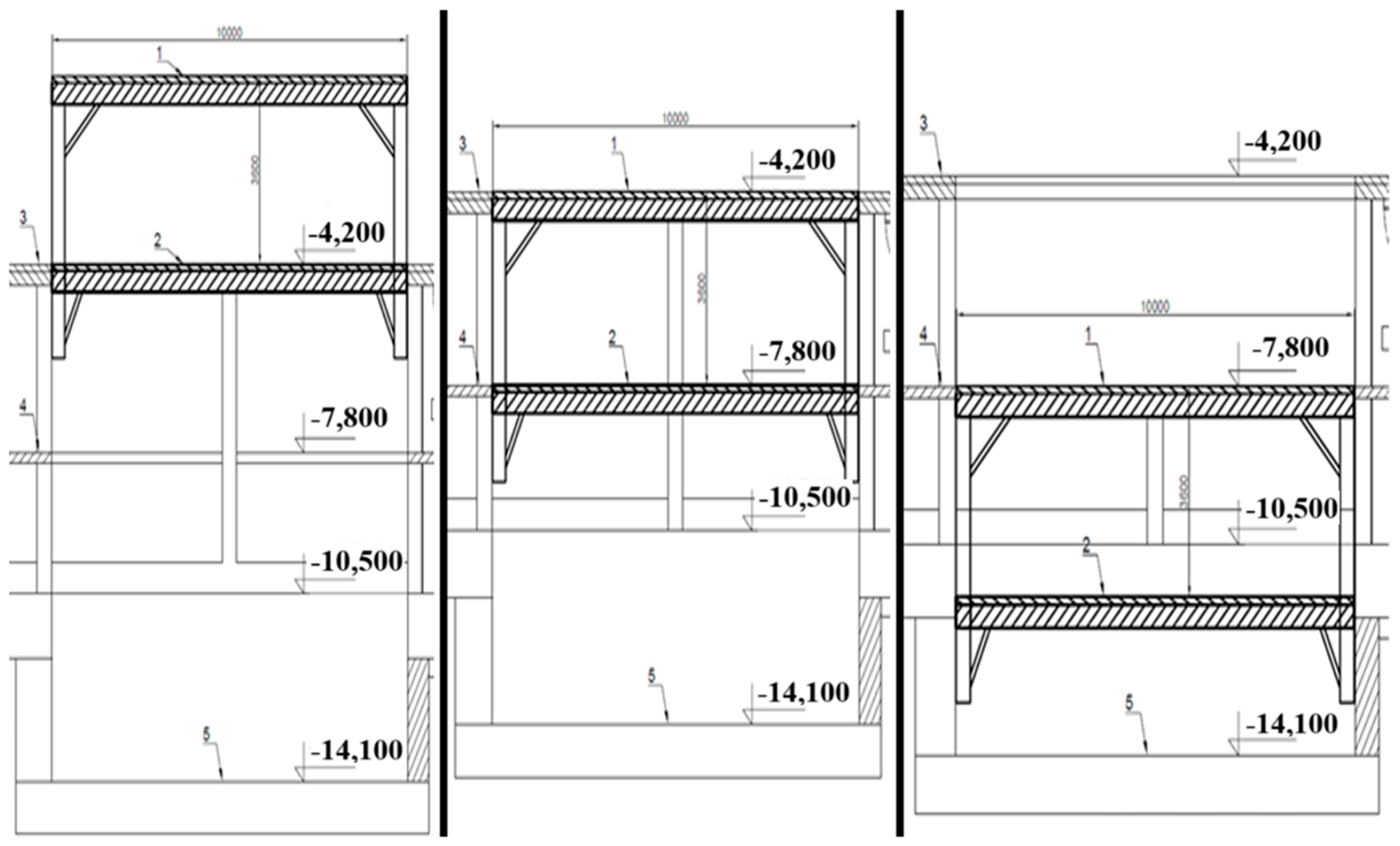

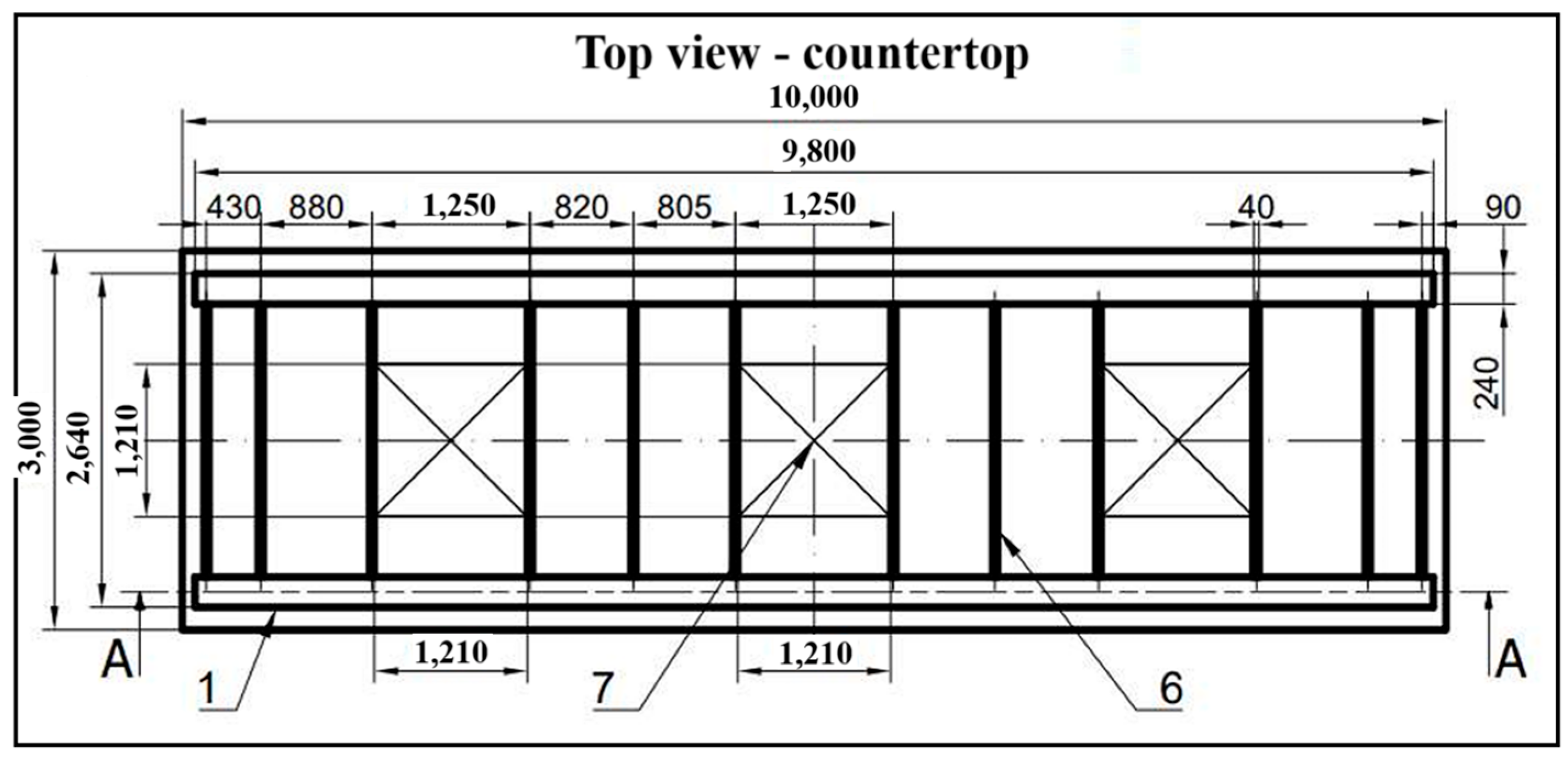

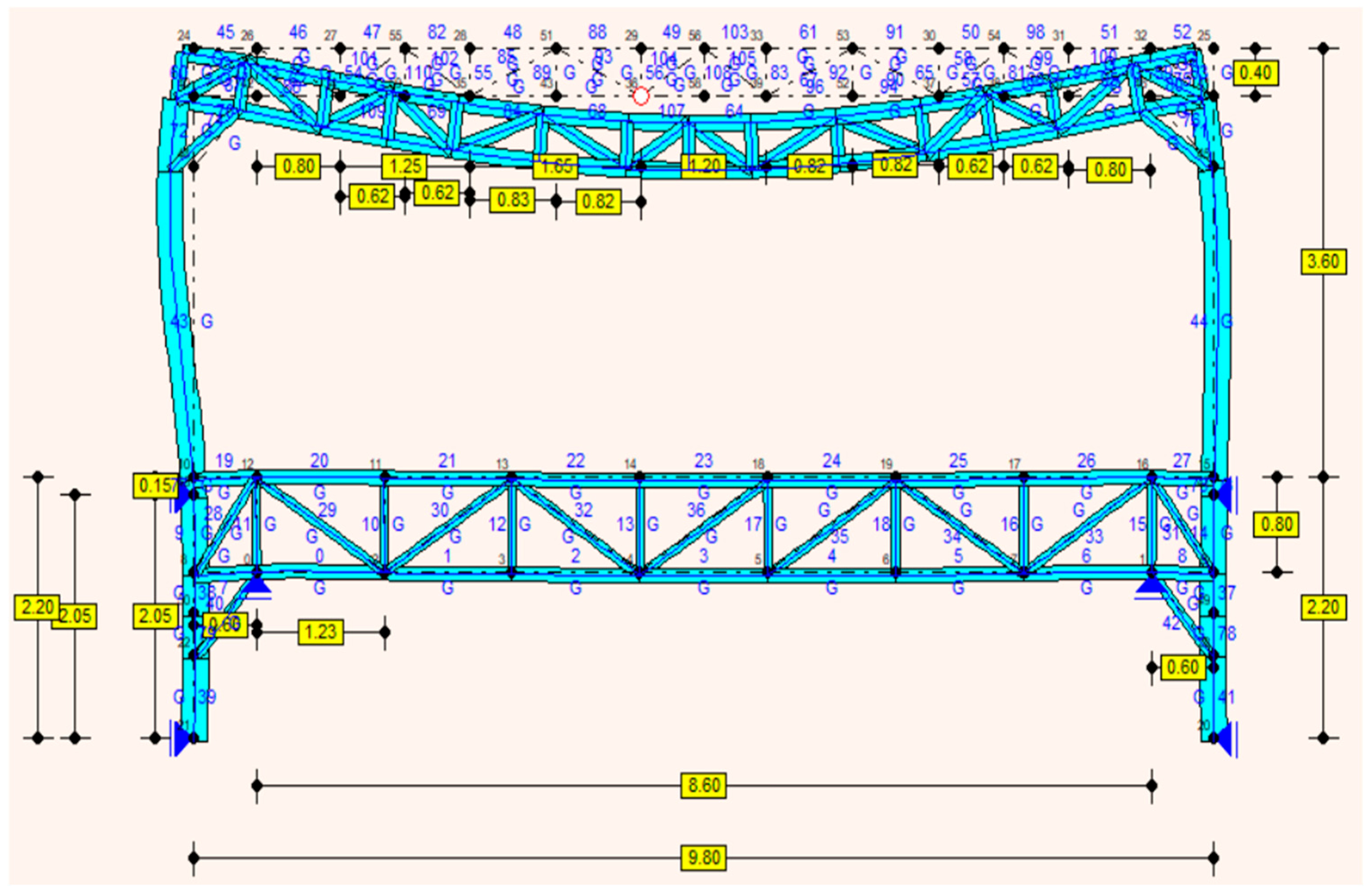

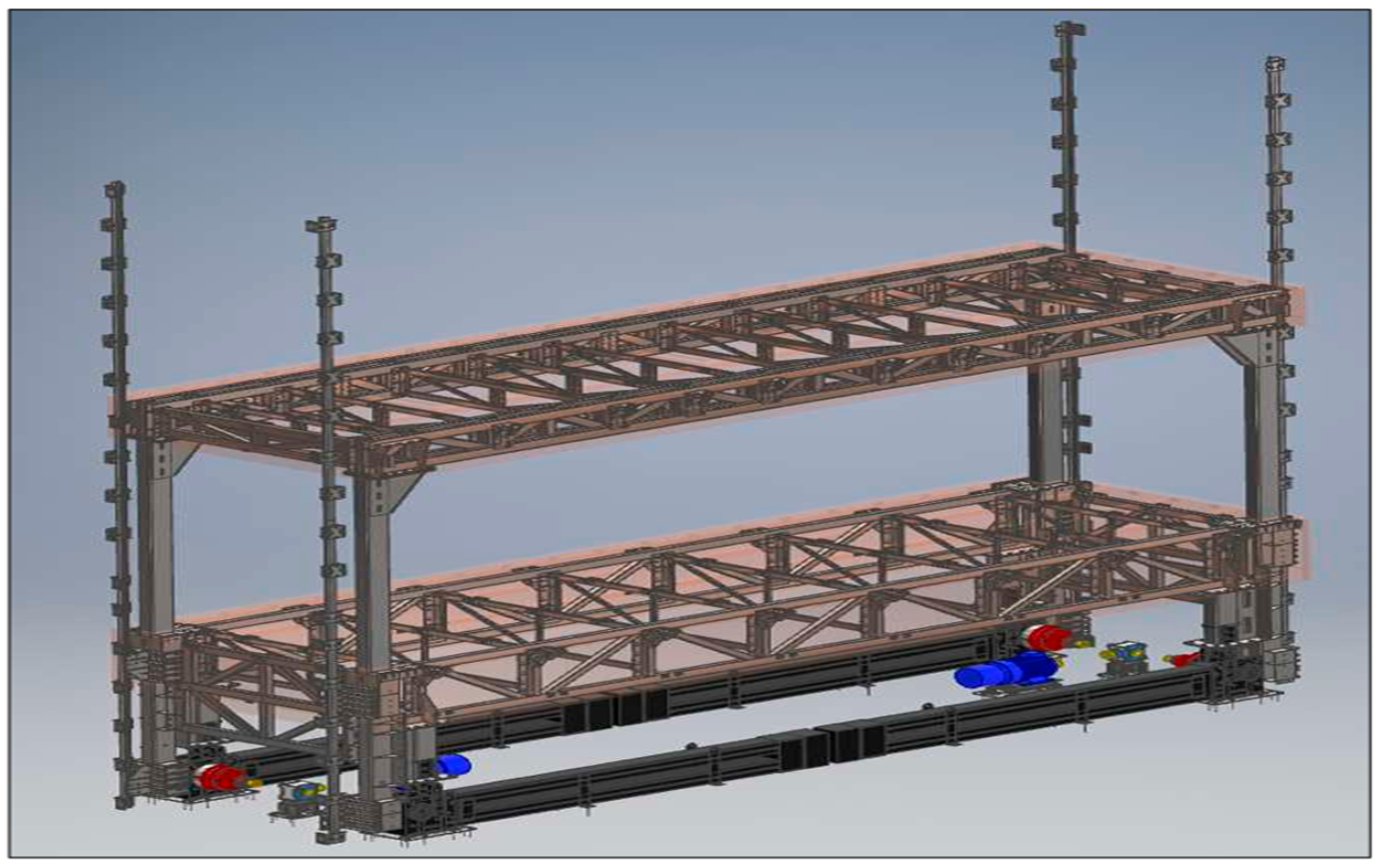

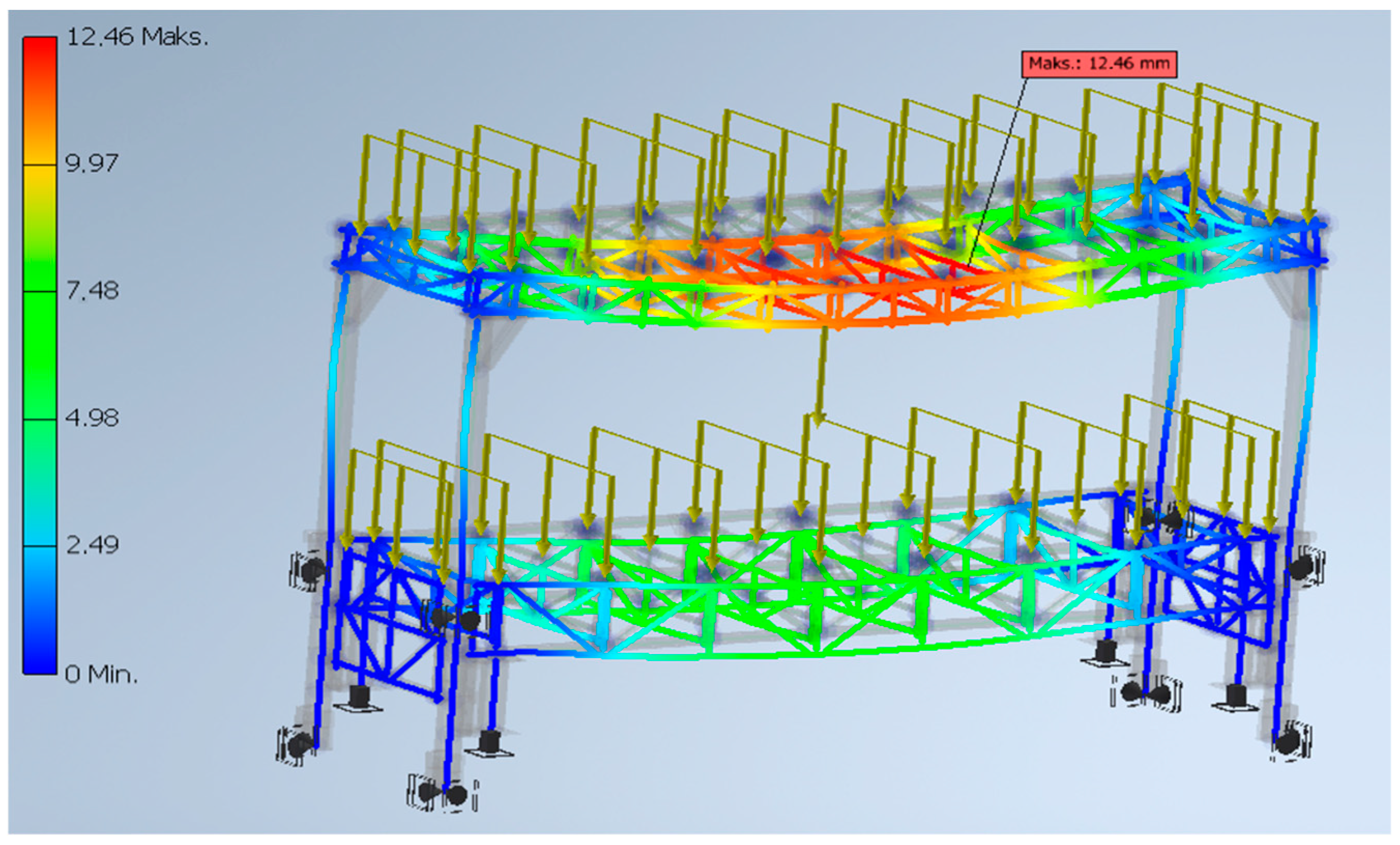

2. Construction Project

- (a)

- platform dimensions: 3.0 × 10.0 m (two-level construction adjusted to the opening in the scene),

- (b)

- distance between platforms: 3.6 m,

- (c)

- load capacity of the platform: 500 kg/m2,

- (d)

- load-bearing capacity: 250 kg/m2,

- (e)

- support: crane rails,

- (f)

- lifting height: 7.2 m.

- (g)

- number and size of personnel trapdoors: 3 pcs., 1210 × 1210 mm,

- (h)

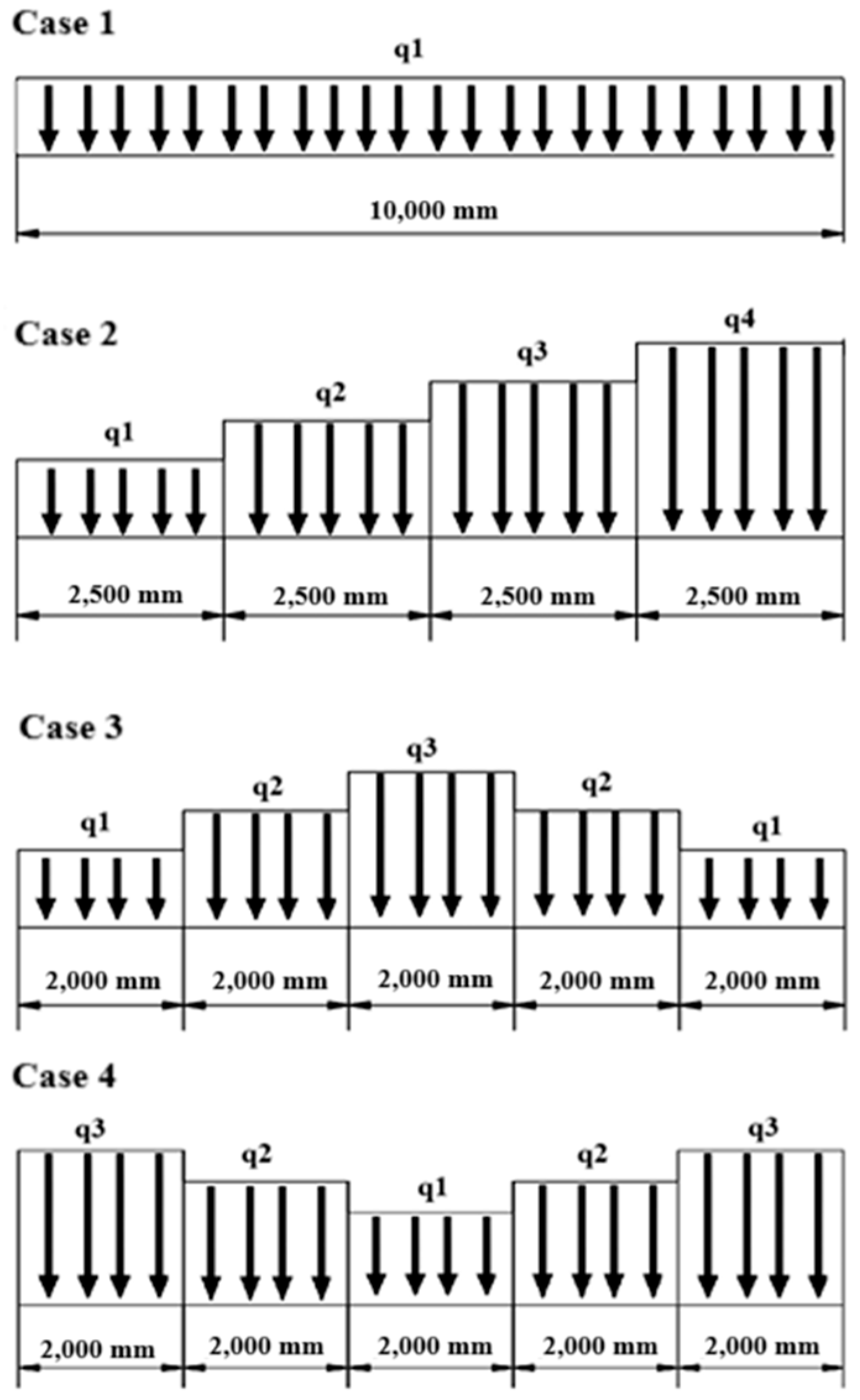

3. Testing and Analysis of the Load-Bearing Structure of a Scenic Trapdoor

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- McComb, C.; Cagan, J.; Kotovsky, K. Lifting the Veil: Drawing insights about design teams from a cognitively-inspired computational model. Des. Stud. 2015, 40, 119–142. [Google Scholar] [CrossRef]

- Kazhnabieva, B.A.; Karzhaubayeva, S.K.; Janguzhinova, M.E.; Karamoldaeva, D.O. KEY ISSUES OF TECHNICAL MODERNIZATION OF THE KAZAKHSTAN THEATRE STAGE AND TECHNICAL EQUIPMENT, QazBSQA Bulletin; Architecture and Design: Tokyo, Japan, 2023; Volume 87, pp. 35–45. [Google Scholar]

- Avendaño, J.I.; Zlatanova, S.; Domingo, A.; Pérez, P.; Correa, C. Utilization of BIM in Steel Building Projects: A Systematic Literature Review. Buildings 2022, 12, 713. [Google Scholar] [CrossRef]

- Gutowski, T.; Cooper, D.; Sahni, S. Why We Use More Materials. Philos. Trans. A Math. Phys. Eng. Sci. 2017, 375, 20160368. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.F.; Luo, S.S.; Wang, H. Research on a Complete Set of Technologies for Assembled Residential Buildings with Steel-Structure Based on House Type Modularization and Component Standardization. IOP Conf. Ser. Earth Environ. Sci. 2021, 719, 022063. [Google Scholar] [CrossRef]

- Navaratnam, S.; Ngo, T.; Gunawardena, T.; Henderson, D. Performance Review of Prefabricated Building Systems and Future Research in Australia. Buildings 2019, 9, 38. [Google Scholar] [CrossRef]

- Kwon, J. Assessment of fire protection systems in proscenium theaters. Case Stud. Fire Saf. 2014, 2, 9–15. [Google Scholar] [CrossRef]

- Wibawa, L.A.N. DESAIN DAN ANALISIS TEGANGAN STRUKTUR CRANE KAPASITAS 10 TON MENGGUNAKAN METODE ELEMEN HINGGA. J. Muara Sains Teknol. Kedokt. Dan Ilmu Kesehatan 2020, 4, 201–210. [Google Scholar] [CrossRef]

- Grösel, B. Bühnentechnik: Mechanische Einrichtungen; Vulkan-Verlag GmbH: Essen, Germany, 2007. [Google Scholar]

- Rusiński, E.; Czmochowski, J.; Smolnicki, T. Zaawansowana Metoda Elementów Skończonych w Konstrukcjach Nośnych; Oficyna Wydawnicza Politechniki Wrocławskiej: Wrocław, Poland, 2000. [Google Scholar]

- Zienkiewicz, O.C. Metoda Elementów Skończonych; Arkady: Warsaw, Poland, 1972. [Google Scholar]

- Gerdemeli, I.; Kurt, S. Design and finite element analysis of gantry crane. Key Eng. Mater. 2014, 572, 517–520. [Google Scholar] [CrossRef]

- Chan, J.; Dow, S.P.; Schunn, C.H.D. Do the best design ideas (really) come from conceptually distant sources of inspiration? Des. Stud. 2015, 36, 31–58. [Google Scholar] [CrossRef]

- Sung, J.; Jin, S.H.; Saxena, A. Robobarista: Object Part Based Transfer of Manipulation Trajectories From Crowd-Sourcing in 3D Pointclouds. arXiv 2015, arXiv:1504.03071. [Google Scholar]

- PN-EN 10027-1:2007; Stainless Steel in Building Structures—Advantages and Examples of Application. Available online: https://bibliotekanauki.pl/articles/402159 (accessed on 16 May 2025).

- ASTM A36; Standard Specification for Carbon Structural Steel. Available online: https://store.astm.org/a0036_a0036m-19.html (accessed on 16 May 2025).

- Blicharski, M. Inżynieria Materiałowa: Stal, Warszawa; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2010. [Google Scholar]

- Ciurej, H. Analiza Wrażliwości Konstrukcji Prętowych w Liniowej Statyce; Wydawnictwo Politechniki Krakowskiej: Kraków, Poland, 2015. [Google Scholar]

- Falkowski, J. Wytrzymałość Materiałów; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2006. [Google Scholar]

- Gabryszewski, Z. Teoria Sprężystości i Plastyczności; Poznań University of Technology: Poznań, Poland, 2001. [Google Scholar]

- Jaskulski, A. Autodesk Inventor Professional 2021 PL/2021+/Fusion 360 Metodyka Projektowania; Helion: Everett, WA, USA, 2020. [Google Scholar]

- DIN 56950-1:2012-05; Entertainment Technology—Machinery Installations—Part 1: Safety Requirements and Inspections. Available online: https://webstore.ansi.org/standards/din/din569502012?srsltid=AfmBOoqNEy6AycafG9mZJftavqoIBKcdIan6kPyffhESePTrvDxIrcPD (accessed on 16 May 2025).

- Zamorowski, J. Modelowanie i Analiza Stalowych Konstrukcji Prętowych; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2022. [Google Scholar]

- Żmuda, J. Projektowanie Konstrukcji Stalowych cz.1: Dźwigary Kratownicowe, Słupy, Ramownice; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2016. [Google Scholar]

- Żmuda, J. Projektowanie Konstrukcji Stalowych cz.2: Belki, Płatwie, Węzły i Połączenia, Ramy, Łożyska; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2016. [Google Scholar]

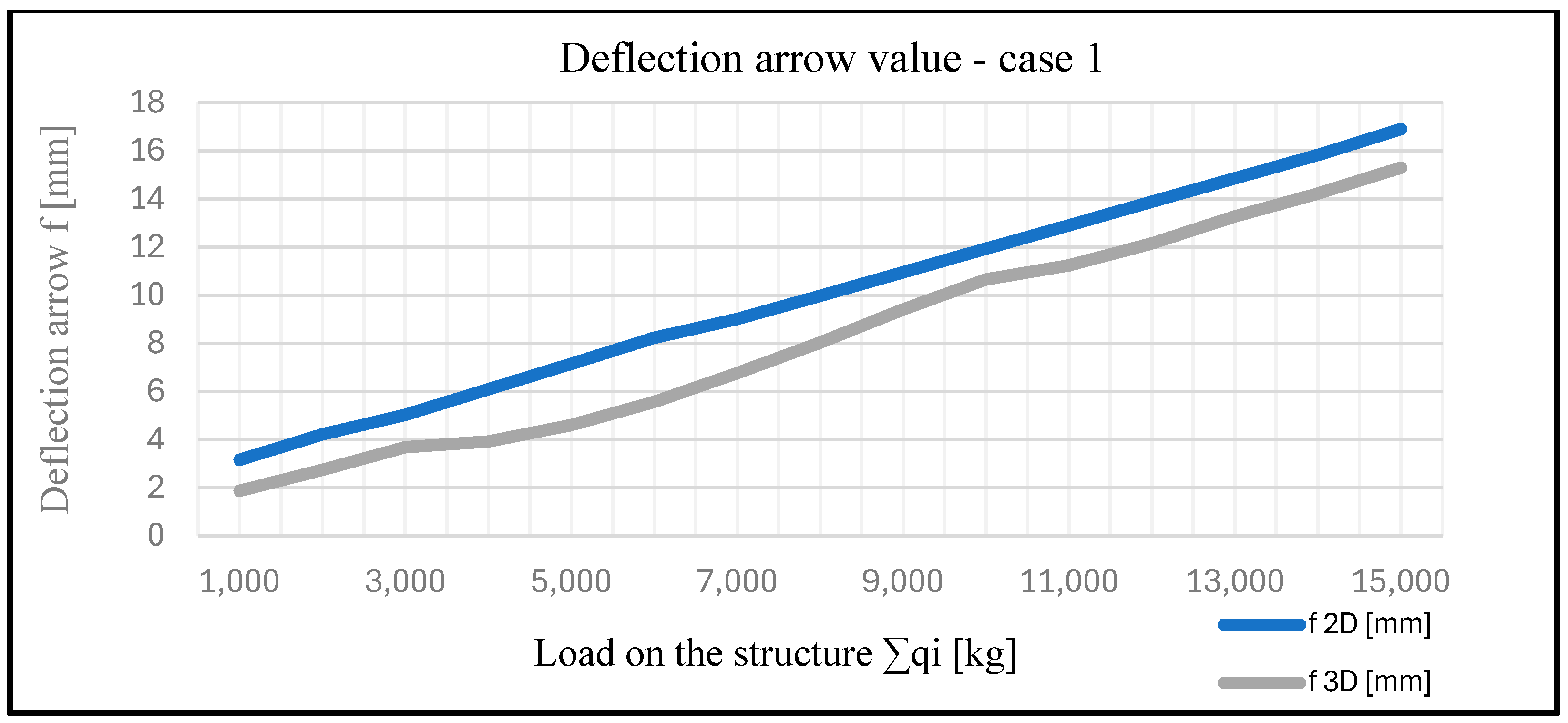

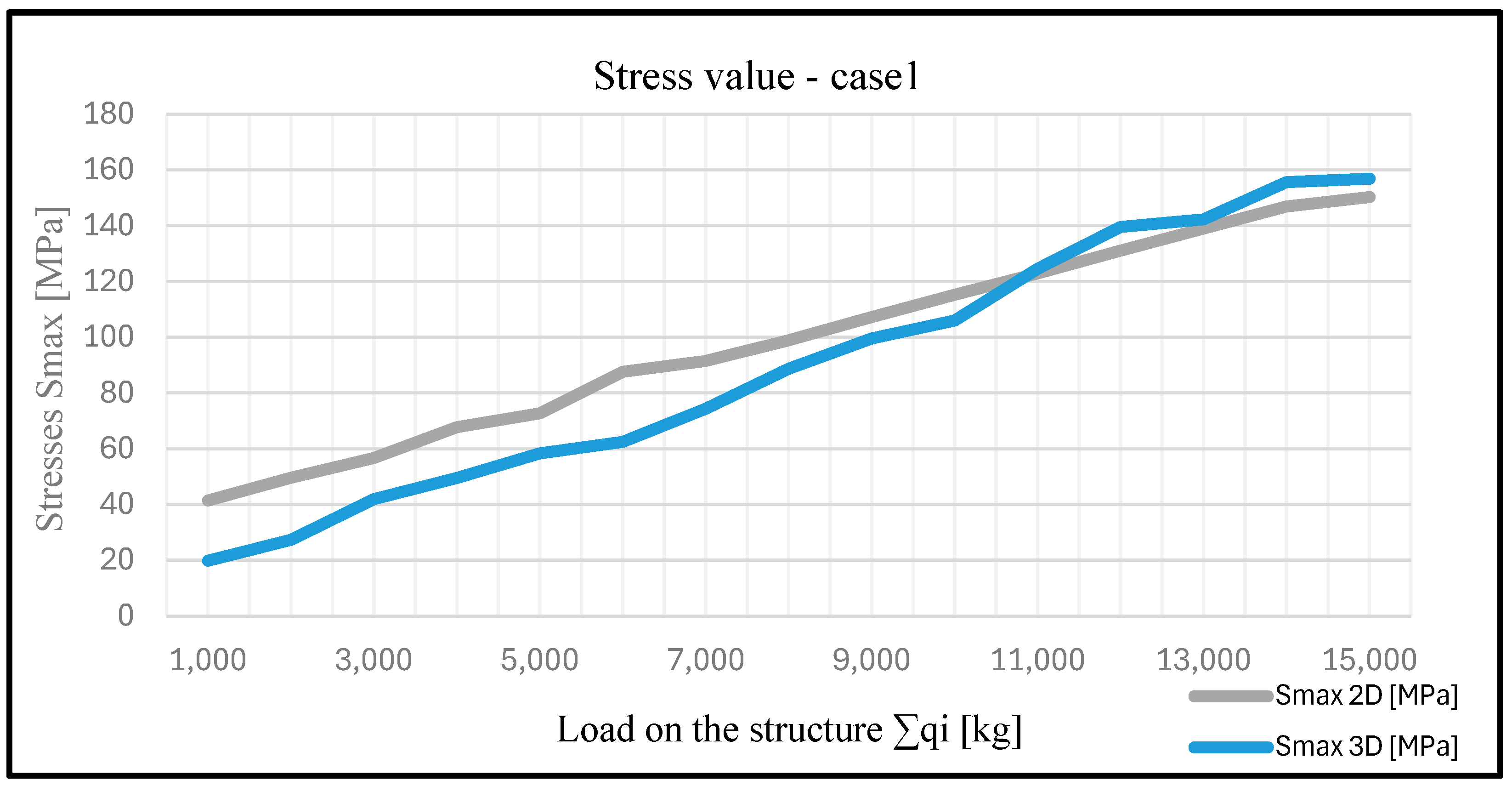

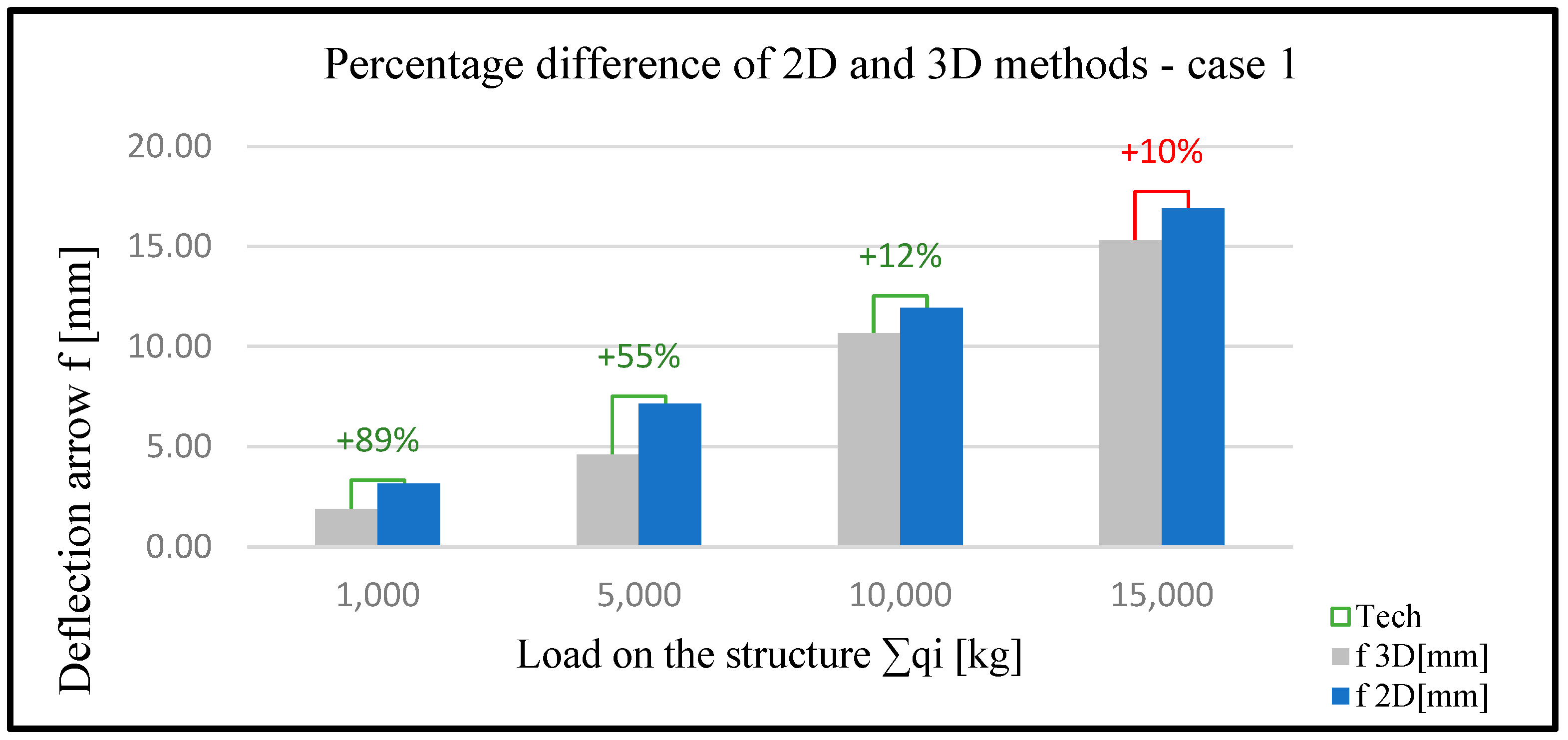

| Load Results | |||||

|---|---|---|---|---|---|

| Case 1 | |||||

| q1 [kg] | ∑qi [kg] | f 2D [mm] | f 3D [mm] | Smax 2D [MPa] | Smax 3D [MPa] |

| 1000 | 1000 | 3.16 | 1.88 | 41.49 | 19.88 |

| 2000 | 2000 | 4.22 | 2.74 | 49.61 | 27.34 |

| 3000 | 3000 | 5.03 | 3.68 | 56.7 | 41.98 |

| 4000 | 4000 | 6.09 | 3.92 | 67.7 | 49.5 |

| 5000 | 5000 | 7.15 | 4.6 | 72.65 | 58.36 |

| 6000 | 6000 | 8.23 | 5.56 | 87.63 | 62.45 |

| 7000 | 7000 | 9.01 | 6.764 | 91.46 | 74.37 |

| 8000 | 8000 | 9.97 | 8.03 | 98.9 | 88.71 |

| 9000 | 9000 | 10.95 | 9.4 | 107.23 | 99.6 |

| 10,000 | 10,000 | 11.93 | 10.65 | 115.21 | 106 |

| 11,000 | 11,000 | 12.9 | 11.24 | 122.88 | 124.5 |

| 12,000 | 12,000 | 13.88 | 12.15 | 131.04 | 139.51 |

| 13,000 | 13,000 | 14.85 | 13.26 | 138.96 | 142.3 |

| 14,000 | 14,000 | 15.82 | 14.21 | 146.88 | 155.6 |

| 15,000 | 15,000 | 16.9 | 15.3 | 150.27 | 156.9 |

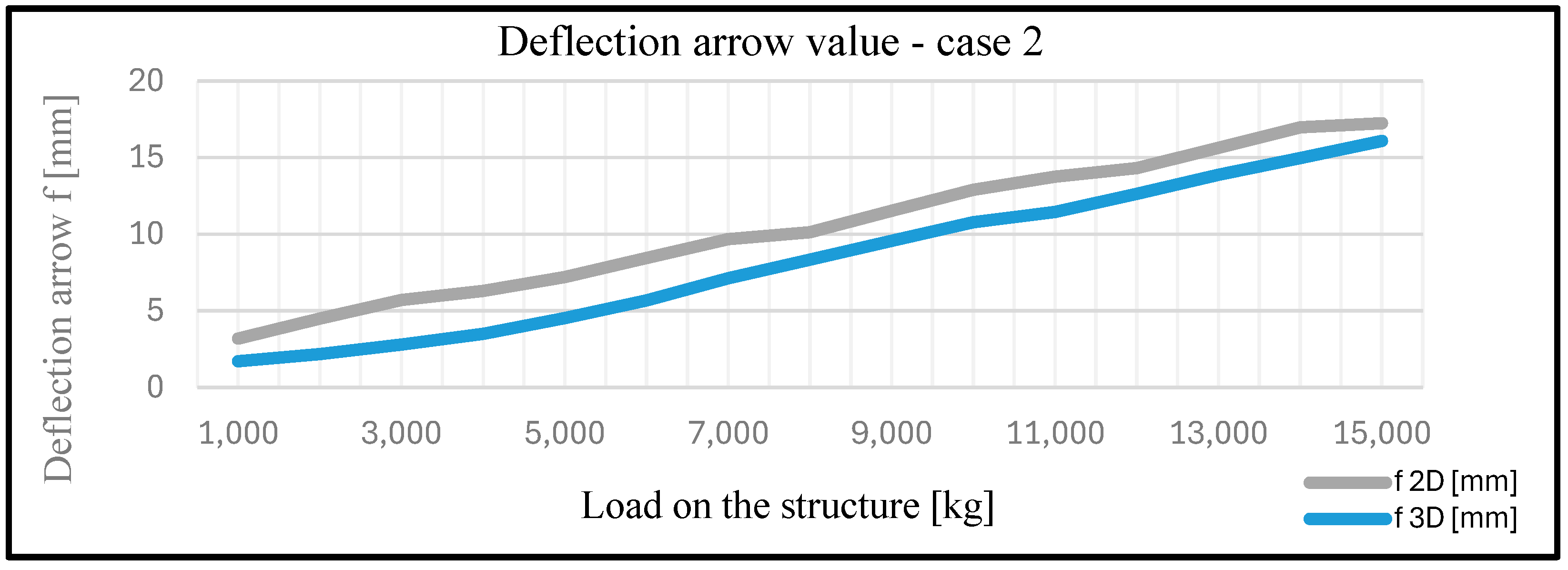

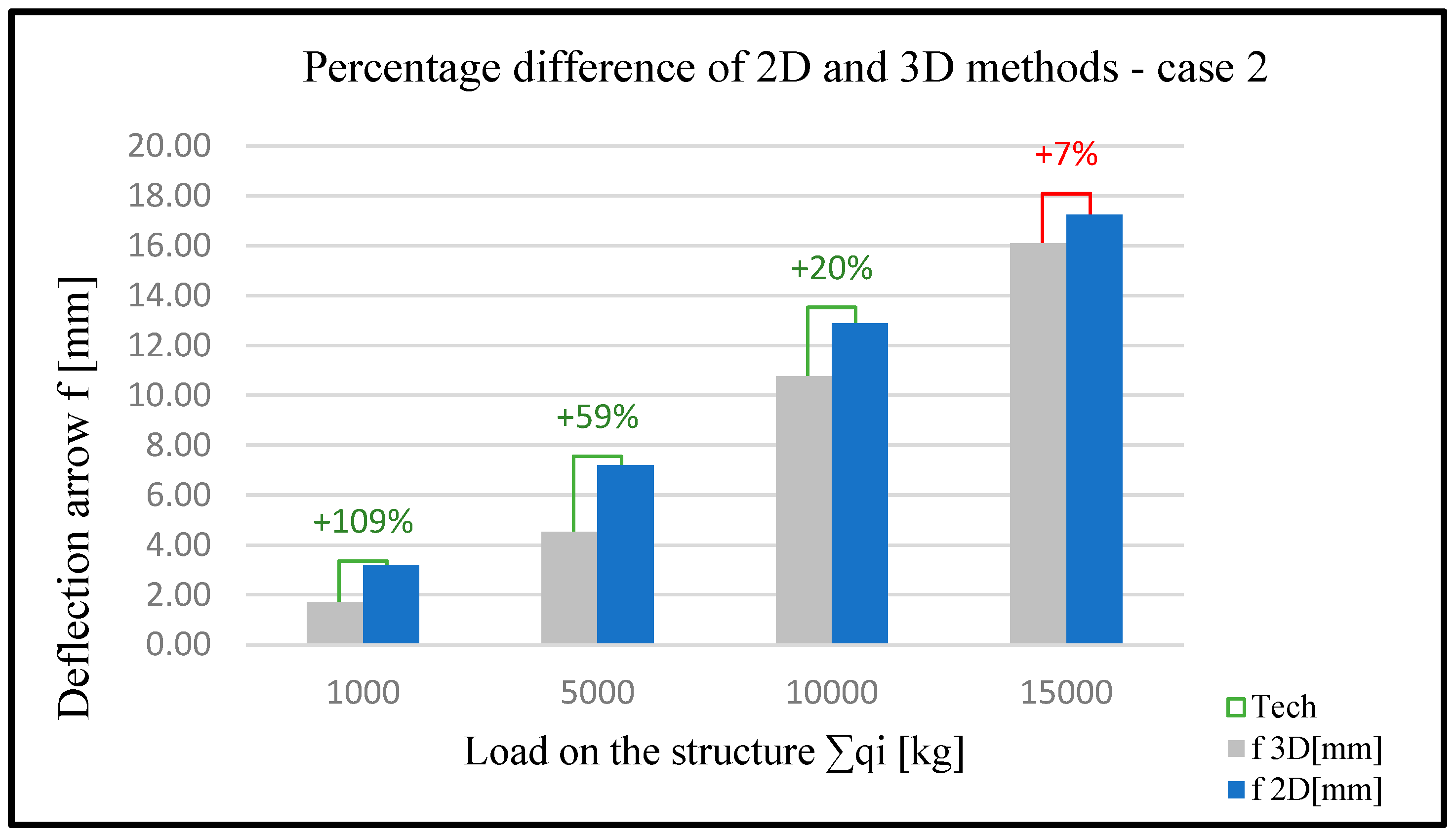

| Load Results | ||||||||

|---|---|---|---|---|---|---|---|---|

| Case 2 | ||||||||

| q1 [kg] | q2 [kg] | q3 [kg] | q4 [kg] | ∑qi [kg] | f 2D [mm] | f 3D [mm] | Smax 2D [MPa] | Smax 3D [MPa] |

| 100 | 200 | 300 | 400 | 1000 | 3.2 | 1.71 | 40.47 | 18.31 |

| 200 | 400 | 600 | 800 | 2000 | 4.5 | 2.18 | 50.16 | 29.6 |

| 300 | 600 | 900 | 1200 | 3000 | 5.7 | 2.8 | 61 | 36.2 |

| 400 | 800 | 1200 | 1600 | 4000 | 6.3 | 3.49 | 67.51 | 40.02 |

| 500 | 1000 | 1500 | 2000 | 5000 | 7.2 | 4.52 | 74.81 | 47.71 |

| 600 | 1200 | 1800 | 2400 | 6000 | 8.45 | 5.67 | 83.15 | 60.45 |

| 700 | 1400 | 2100 | 2800 | 7000 | 9.67 | 7.12 | 88.64 | 75.12 |

| 800 | 1600 | 2400 | 3200 | 8000 | 10.12 | 8.34 | 95.2 | 90.36 |

| 900 | 1800 | 2700 | 3600 | 9000 | 11.53 | 9.56 | 100.38 | 105.67 |

| 1000 | 2000 | 3000 | 4000 | 10,000 | 12.89 | 10.78 | 106.7 | 120.89 |

| 1100 | 2200 | 3300 | 4400 | 11,000 | 13.76 | 11.45 | 110.68 | 134.9 |

| 1200 | 2400 | 3600 | 4800 | 12,000 | 14.31 | 12.63 | 120.94 | 145.37 |

| 1300 | 2600 | 3900 | 5200 | 13,000 | 15.64 | 13.87 | 135.57 | 155 |

| 1400 | 2800 | 4200 | 5600 | 14,000 | 16.98 | 14.96 | 145.83 | 160.11 |

| 1500 | 3000 | 4500 | 6000 | 15,000 | 17.24 | 16.1 | 152.33 | 166.8 |

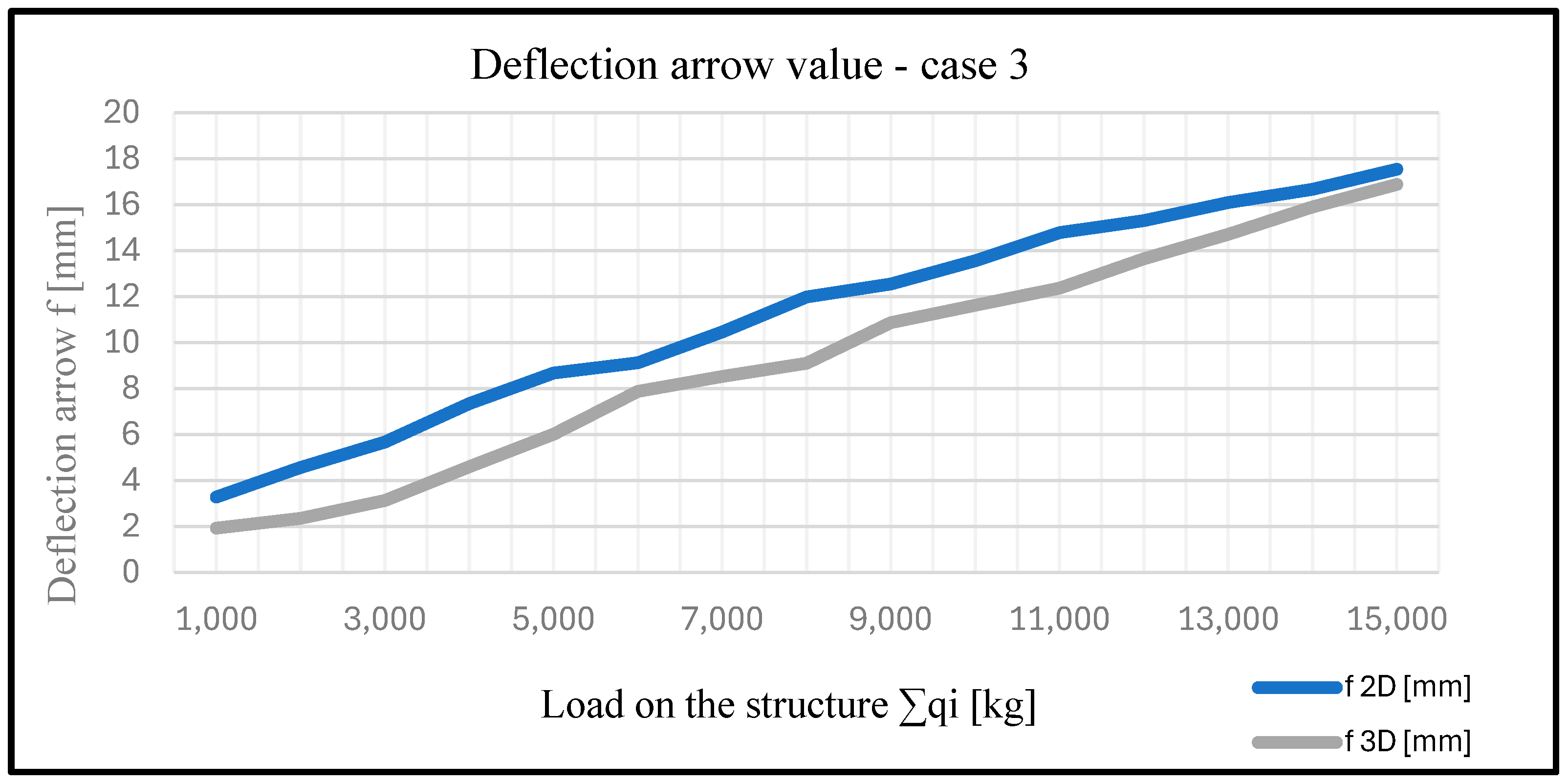

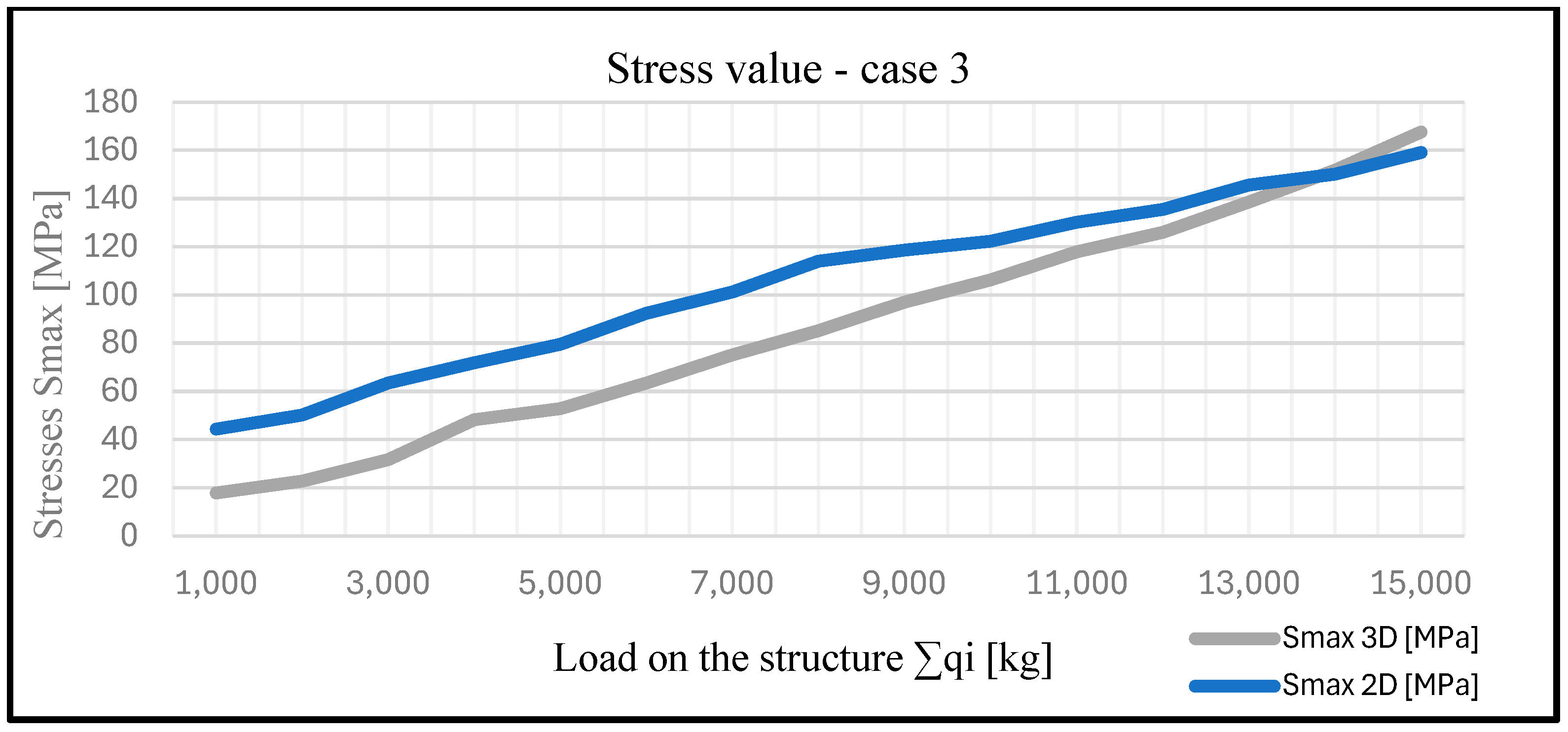

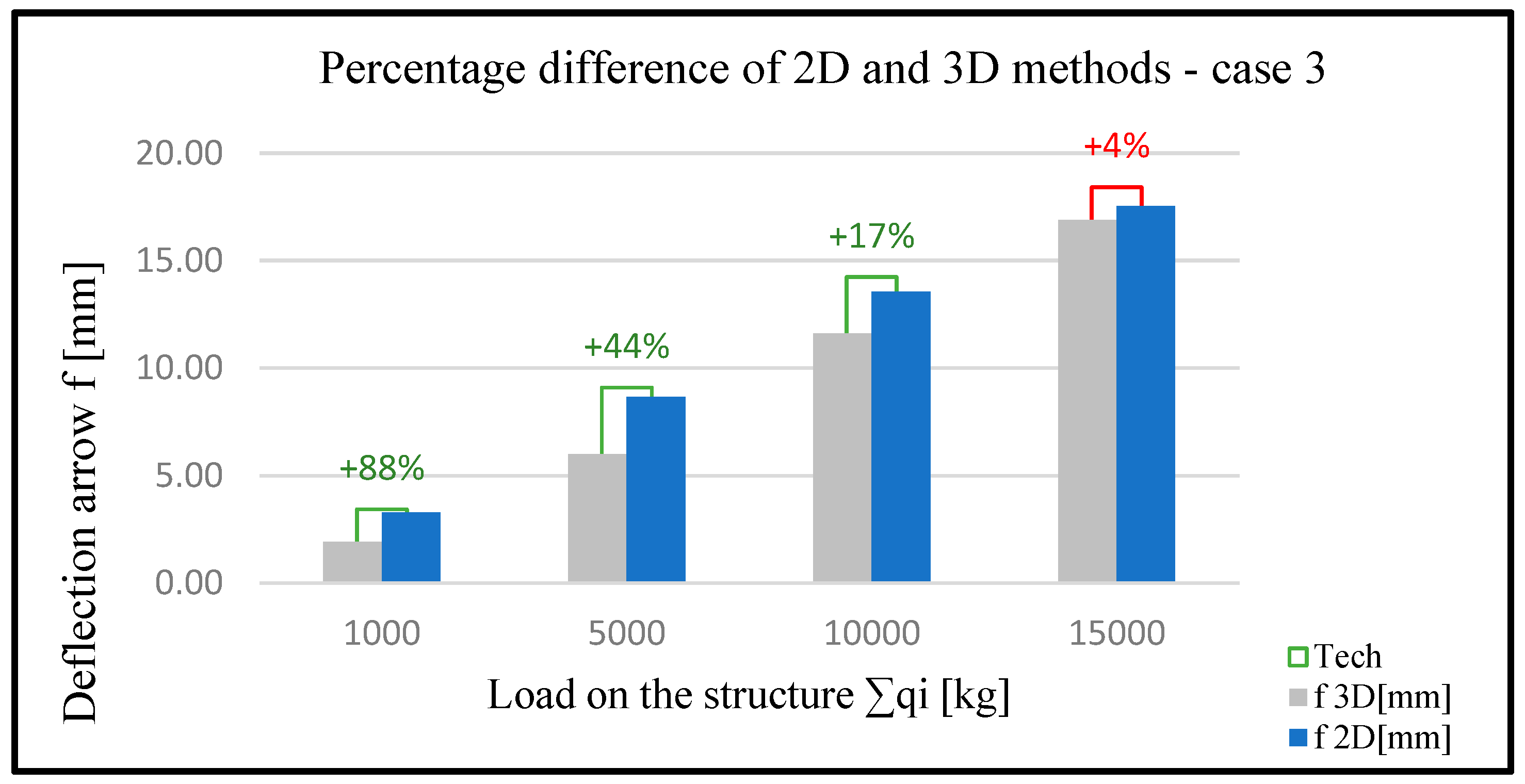

| Load Results | |||||||

|---|---|---|---|---|---|---|---|

| Case 3 | |||||||

| q1 [kg] | q2 [kg] | q3 [kg] | ∑qi [kg] | f 2D [mm] | f 3D [mm] | Smax 2D [MPa] | Smax 3D [MPa] |

| 100 | 200 | 400 | 1000 | 3.28 | 1.93 | 44.39 | 17.85 |

| 200 | 400 | 800 | 2000 | 4.56 | 2.35 | 50.12 | 22.68 |

| 300 | 600 | 1200 | 3000 | 5.67 | 3.13 | 63.45 | 31.6 |

| 400 | 800 | 1600 | 4000 | 7.34 | 4.6 | 71.8 | 48.19 |

| 500 | 1000 | 2000 | 5000 | 8.67 | 6.01 | 79.48 | 52.83 |

| 600 | 1200 | 2400 | 6000 | 9.12 | 7.87 | 92.39 | 63.46 |

| 800 | 1200 | 3000 | 7000 | 10.46 | 8.52 | 101.23 | 75.08 |

| 1000 | 1500 | 3000 | 8000 | 11.98 | 9.1 | 114 | 85.14 |

| 1000 | 2000 | 3000 | 9000 | 12.55 | 10.86 | 118.64 | 97.03 |

| 1000 | 2000 | 4000 | 10,000 | 13.56 | 11.62 | 122.25 | 106.2 |

| 1100 | 2200 | 4400 | 11,000 | 14.78 | 12.37 | 130.11 | 117.84 |

| 1200 | 2400 | 4800 | 12,000 | 15.3 | 13.64 | 135.45 | 125.96 |

| 1300 | 2600 | 5200 | 13,000 | 16.09 | 14.71 | 145.62 | 138.5 |

| 1400 | 2800 | 5600 | 14,000 | 16.67 | 15.9 | 150.12 | 151.71 |

| 2000 | 3000 | 5000 | 15,000 | 17.54 | 16.88 | 159.2 | 167.67 |

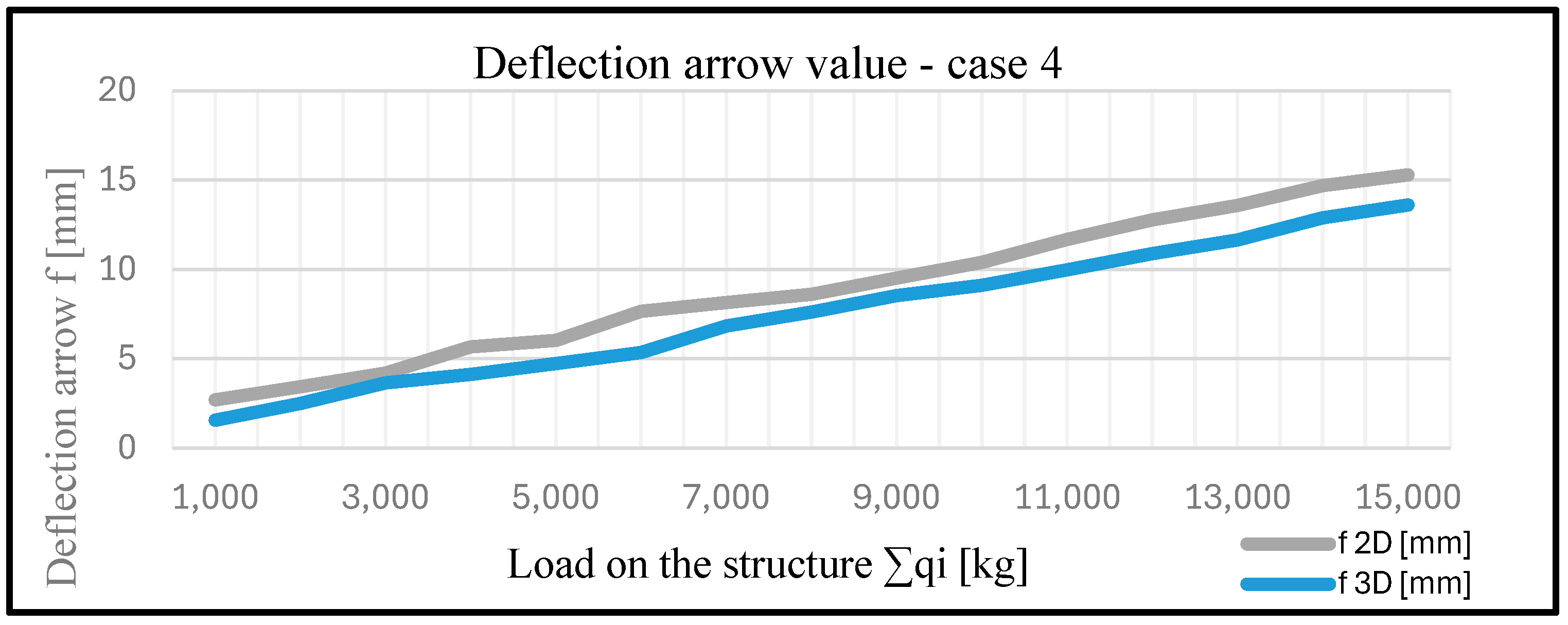

| Load Results | |||||||

|---|---|---|---|---|---|---|---|

| Case 4 | |||||||

| q1 [kg] | q2 [kg] | q3 [kg] | ∑qi [kg] | f 2D [mm] | f 3D [mm] | Smax 2D [MPa] | Smax 3D [MPa] |

| 100 | 200 | 250 | 1000 | 2.7 | 1.56 | 35.64 | 15.24 |

| 200 | 400 | 500 | 2000 | 3.43 | 2.5 | 43.05 | 19.7 |

| 300 | 600 | 750 | 3000 | 4.19 | 3.65 | 50.86 | 24.65 |

| 400 | 800 | 1000 | 4000 | 5.66 | 4.12 | 58.04 | 30.15 |

| 500 | 1000 | 1250 | 5000 | 6.02 | 4.72 | 65.38 | 48.64 |

| 600 | 1200 | 1500 | 6000 | 7.65 | 5.34 | 70.2 | 55.12 |

| 800 | 1400 | 1700 | 7000 | 8.14 | 6.82 | 76.9 | 64.63 |

| 1000 | 1600 | 1900 | 8000 | 8.6 | 7.61 | 82.5 | 77.5 |

| 1100 | 1800 | 2150 | 9000 | 9.5 | 8.53 | 90.65 | 88.67 |

| 1200 | 1900 | 2500 | 10,000 | 10.38 | 9.1 | 98.6 | 103.5 |

| 1300 | 2250 | 2600 | 11,000 | 11.67 | 9.97 | 108.6 | 112.58 |

| 1400 | 2400 | 2900 | 12,000 | 12.76 | 10.87 | 111.48 | 120.65 |

| 1500 | 2500 | 3250 | 13,000 | 13.57 | 11.64 | 119.34 | 131.49 |

| 1600 | 2600 | 3600 | 14,000 | 14.68 | 12.88 | 127.98 | 137.27 |

| 2000 | 2750 | 3750 | 15,000 | 15.28 | 13.6 | 138.65 | 144.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wyrąbkiewicz, S.; Zastempowski, M.; Burczyński, J.; Gajewski, M. Analysis of Selected Methods of Computer-Aided Design for Stage Structures. Appl. Sci. 2025, 15, 6146. https://doi.org/10.3390/app15116146

Wyrąbkiewicz S, Zastempowski M, Burczyński J, Gajewski M. Analysis of Selected Methods of Computer-Aided Design for Stage Structures. Applied Sciences. 2025; 15(11):6146. https://doi.org/10.3390/app15116146

Chicago/Turabian StyleWyrąbkiewicz, Szymon, Marcin Zastempowski, Jurand Burczyński, and Maciej Gajewski. 2025. "Analysis of Selected Methods of Computer-Aided Design for Stage Structures" Applied Sciences 15, no. 11: 6146. https://doi.org/10.3390/app15116146

APA StyleWyrąbkiewicz, S., Zastempowski, M., Burczyński, J., & Gajewski, M. (2025). Analysis of Selected Methods of Computer-Aided Design for Stage Structures. Applied Sciences, 15(11), 6146. https://doi.org/10.3390/app15116146