Effects of Fiber Length and Content on the Enhancement of Spray-Applied Substrate in Soil Spray Seeding

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.1.1. Fiber Material

2.1.2. Test Soil

2.1.3. Organic Fertilizer

2.1.4. Adhesive

2.2. Experimental Design

2.3. Indicators and Methods

2.3.1. Physical Properties Experiment

- -

- K: Saturated hydraulic conductivity (permeability coefficient), mm/min.

- -

- Qn: Water outflow during the n-th measurement, mL (or cm3).

- -

- L: Soil layer thickness, cm.

- -

- tn: Time interval for each permeability measurement, min.

- -

- S: Cross-sectional area of the permeameter, cm2.

- -

- h: Water layer thickness, cm.

- -

- V: Permeation velocity, mm/min.

2.3.2. Triaxial Test

Sample Preparation

Test Equipment and Methods

- Rσ: Root-containing (reinforcement) effect coefficient.

- (σ1–σ3)fr: Deviatoric stress at failure for fiber-reinforced or root-containing soil.

- (σ1–σ3)fs: Deviatoric stress at failure for unreinforced soil.

2.3.3. Soil Cracking Test

2.4. Data Processing and Analysis

3. Results

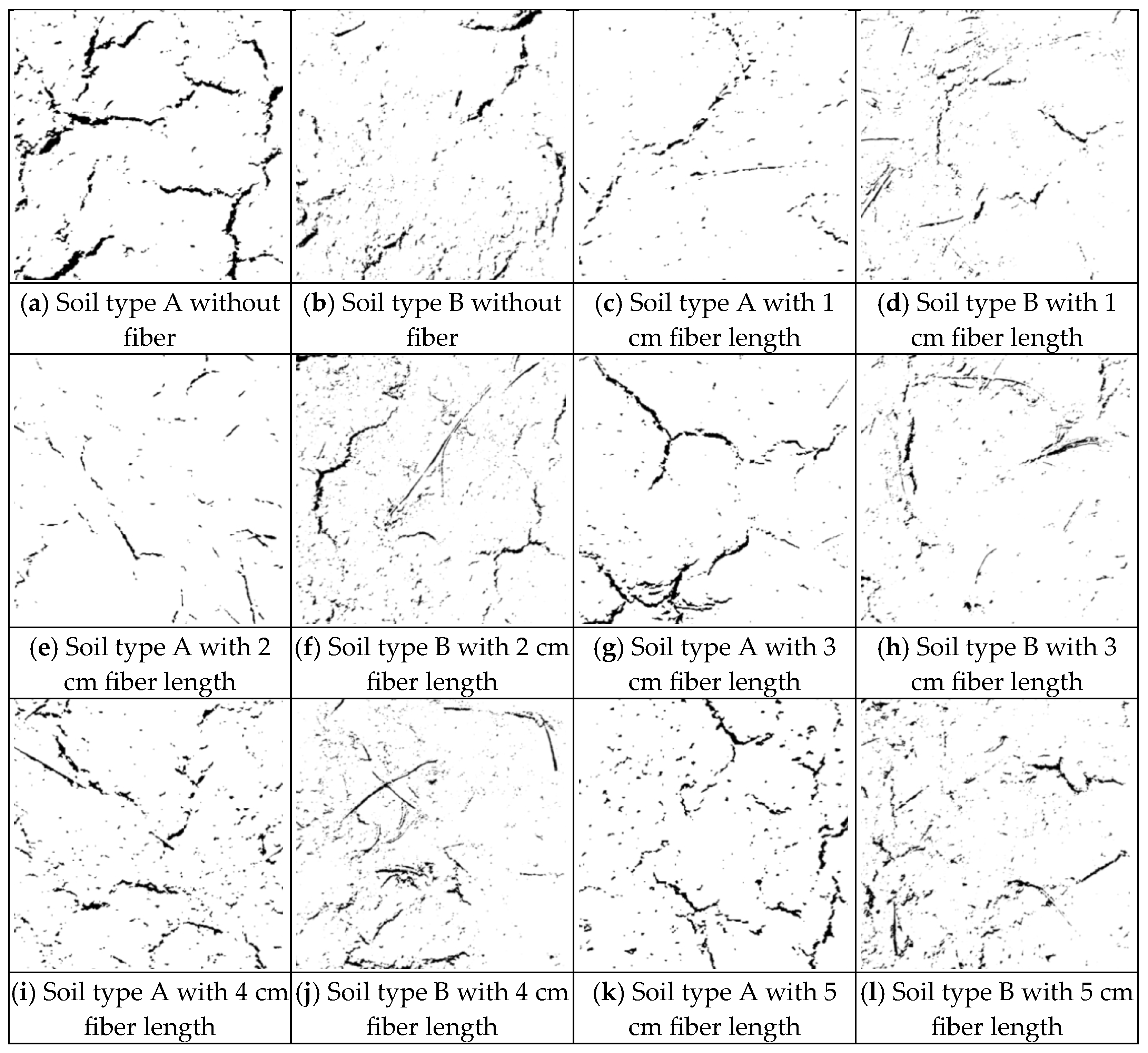

3.1. Effects of Fiber Length and Content on Soil Properties Under Two Soil Conditions

3.1.1. Physical Properties

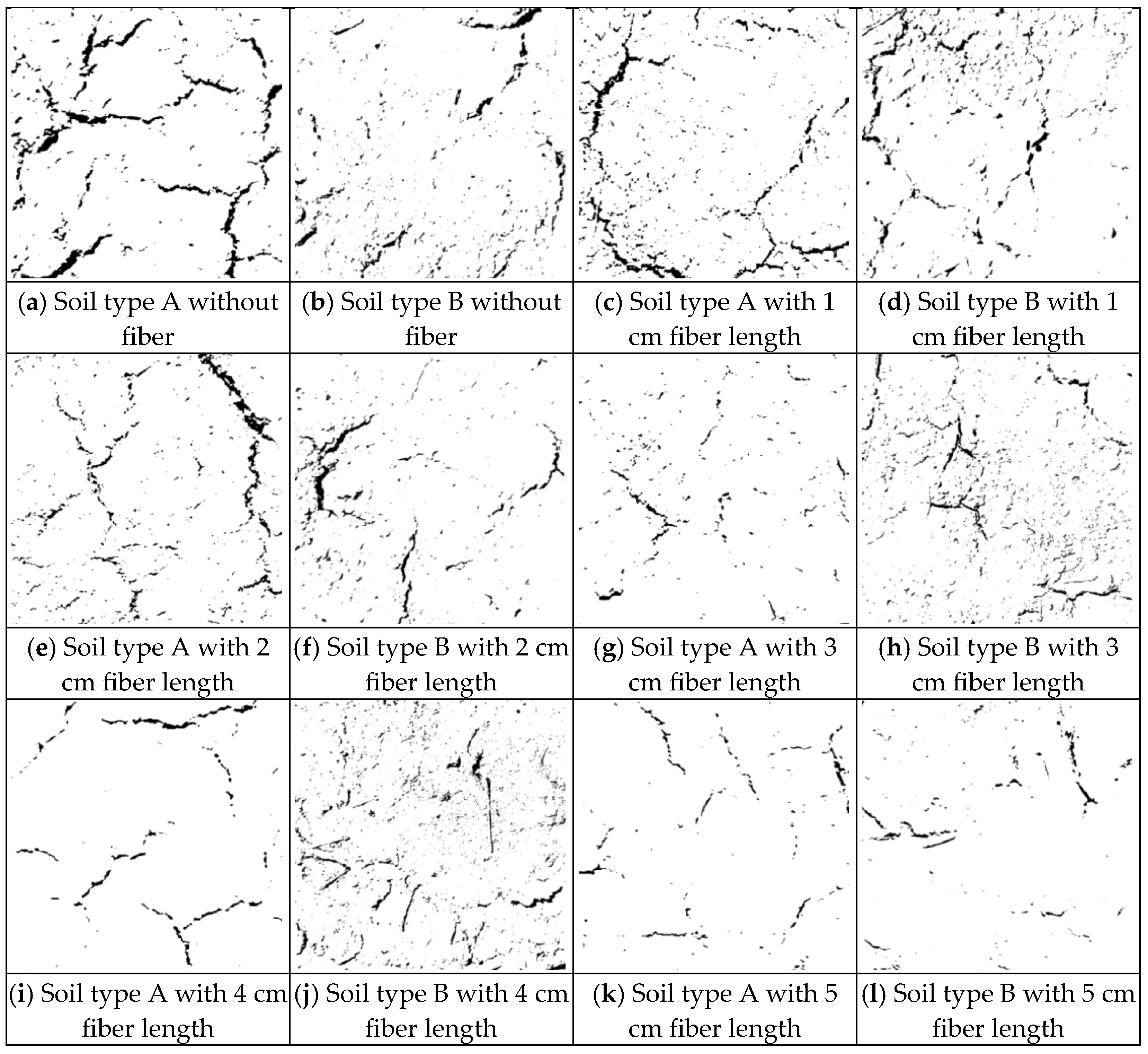

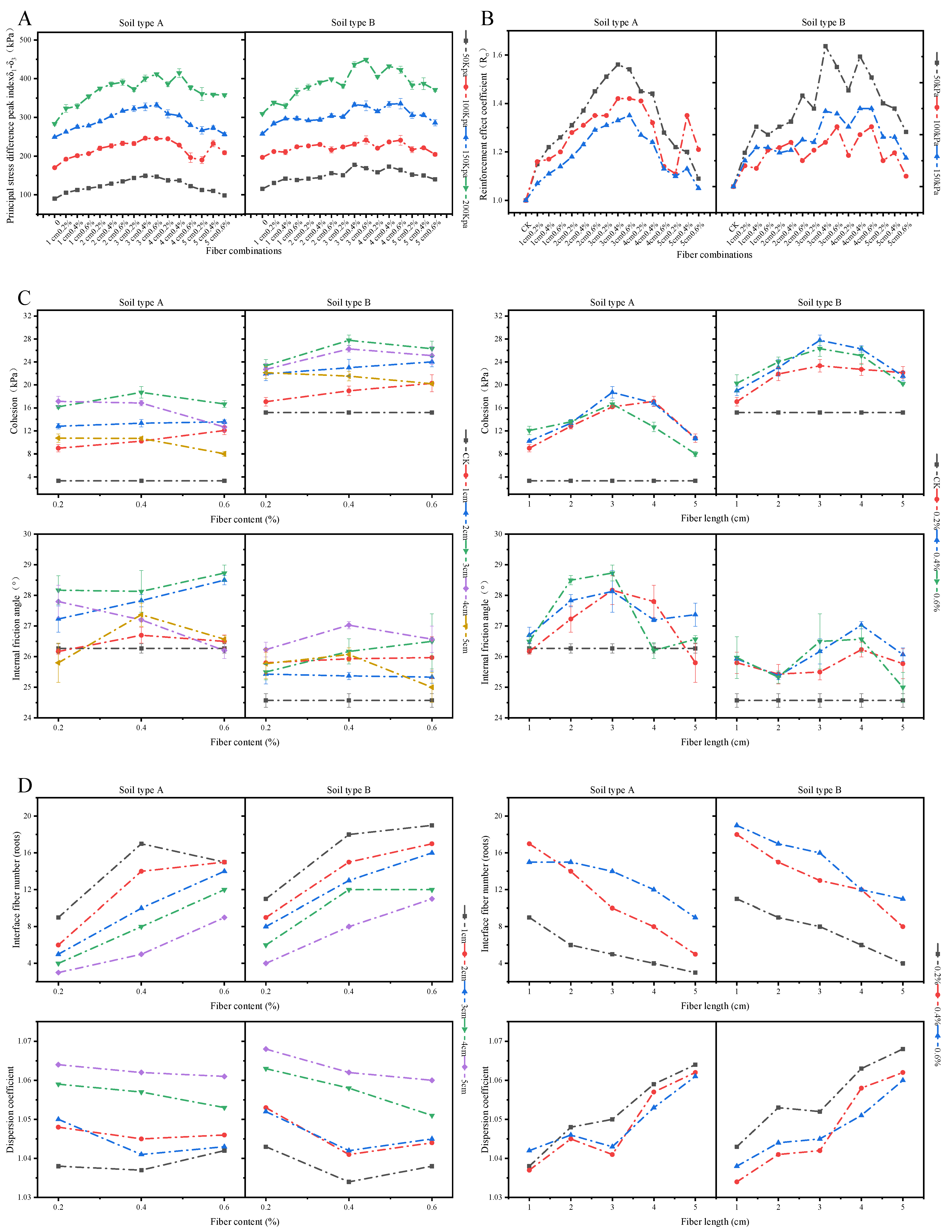

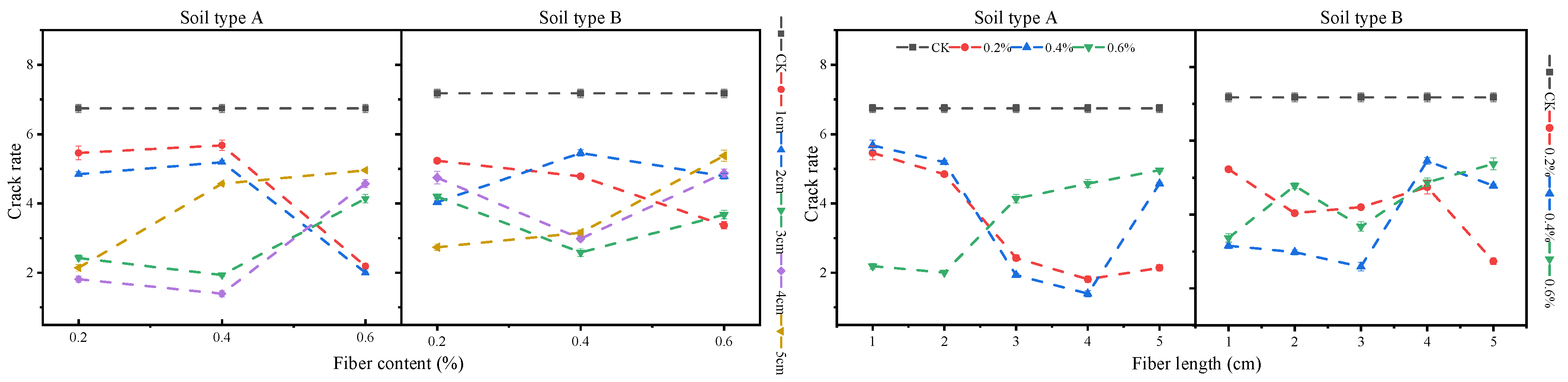

3.1.2. Crack Resistance

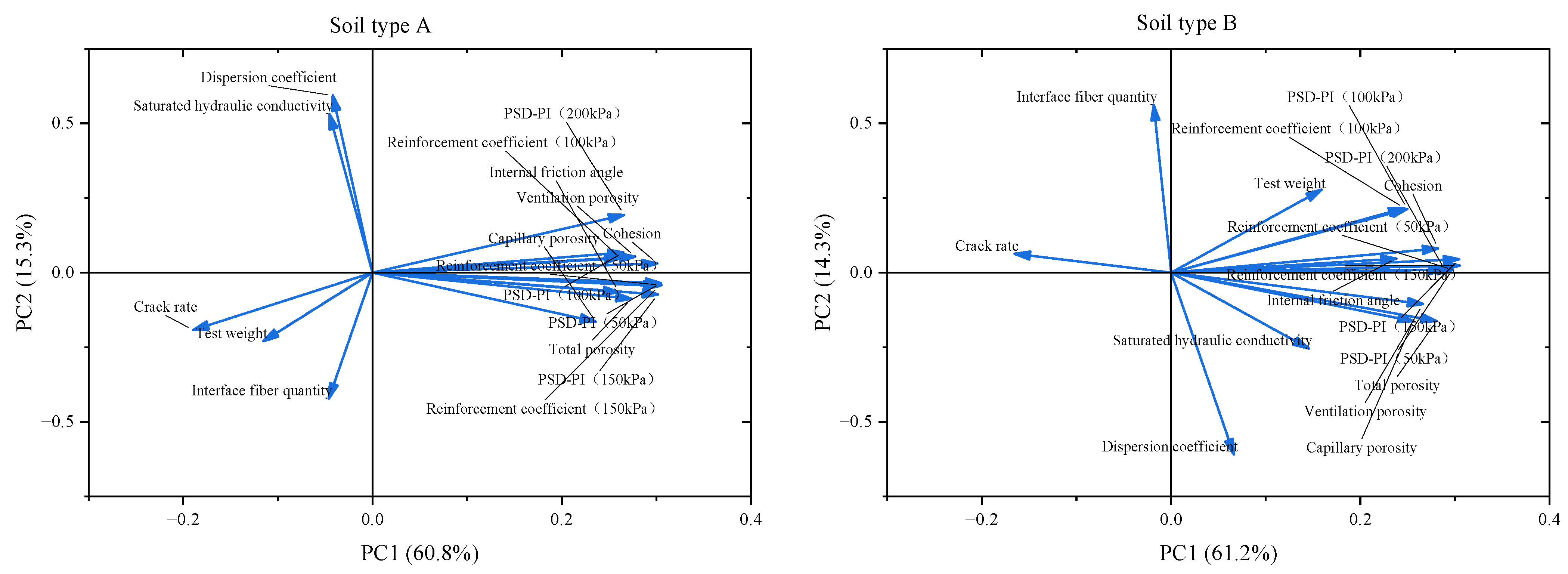

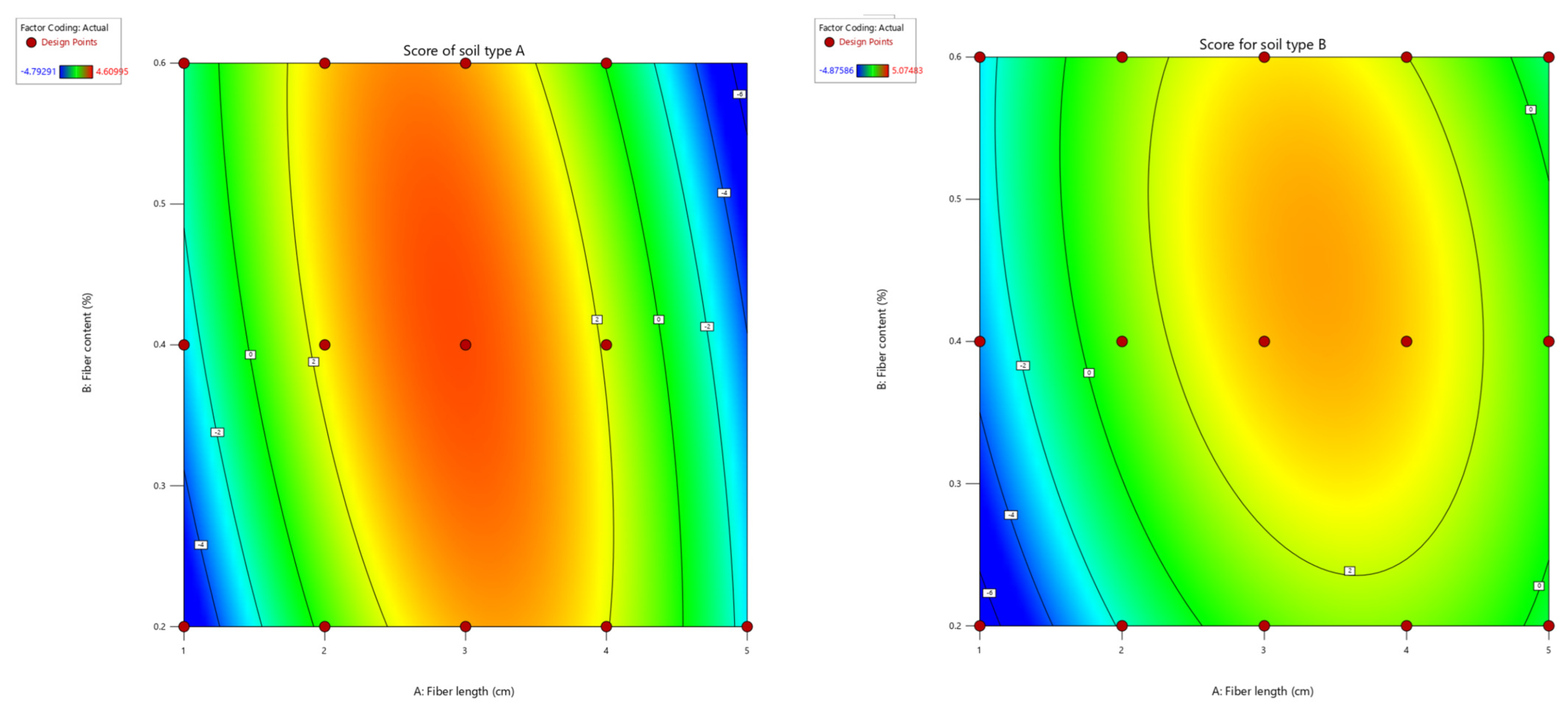

3.2. Optimal Fiber Length and Content Combination Under Two Soil Conditions

4. Discussion

5. Conclusions

- The incorporation of coir fiber significantly increased soil porosity and aeration, with the most pronounced improvement observed at fiber lengths in the range of 3–4 cm and content in the range of 0.4–0.6%, leading to enhanced water permeability and aeration performance.

- Fiber reinforcement notably improved soil cohesion and shear strength, with the optimal combinations being 3 cm fiber length and 0.4% content for Soil-type A, and 4 cm fiber length and 0.4% content for Soil-type B.

- Fiber length and content had a significant effect on crack resistance, with 3–4 cm fibers at 0.4% content exhibiting the best performance.

- Correlation analysis revealed a strong positive relationship between soil porosity and shear strength, confirming that fiber reinforcement not only improves pore structure but also enhances overall mechanical performance. Additionally, the crack ratio showed a negative correlation with shear strength and reinforcement coefficient, indicating that fiber incorporation effectively mitigates the adverse impact of cracks on soil stability.

- Response surface analysis identified the optimal fiber combinations for Soil-type A as a 3.051 cm fiber length and 4.07% content, and for Soil-type B as a 3.376 cm fiber length and 0.456% content.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Zhang, M.; Qiu, J.; Yan, D. Application of Hydroseeding in Slope Ecological Restoration and Protection. Chin. Soil Water Conserv. Sci. 2004, 2, 3. [Google Scholar]

- Tian, X. Experimental Study on the Formulation of Sprayed Wood Fiber Substrate Materials. Master’s Thesis, Beijing Forestry University, Beijing, China, 2021. [Google Scholar]

- Harianto, T.; Hayashi, S.; Du, Y.J.; Suetsugu, D. Effects of Fiber Additives on the Desiccation Crack Behavior of the Compacted Akaboku Soil as A Material for Landfill Cover Barrier. Water Air Soil Pollut. 2008, 194, 141–149. [Google Scholar] [CrossRef]

- Sharma, V.; Vinayak, H.K.; Marwaha, B.M. Enhancing compressive strength of soil using natural fibers. Constr. Build. Mater. 2015, 93, 943–949. [Google Scholar] [CrossRef]

- Bao, C.; Ding, J. Research and Engineering Applications of Fiber-Reinforced Soil. J. Geotech. Eng. 2012, 26, 4. [Google Scholar]

- Hu, X.; Hong, L.; Xu, G.; Yang, X.; Jiang, G. Study on the Effect of Fiber Content and Length on the Strength of Fiber-Reinforced Soil. Saf. Environ. Eng. 2015, 22, 139–143. [Google Scholar]

- Wang, W.; Wang, Z.; Zeng, Y.; Pu, Q. Experimental Study on Crack Resistance and Reinforcement Characteristics of Polypropylene Fiber Composite Soil. Rock Soil Mech. 2011, 32, 6. [Google Scholar]

- Li, L.; Ma, W.; Cao, B. Study on the Mechanical Properties of Red Clay Reinforced with Natural Coir Fiber. J. Hainan Univ. (Nat. Sci. Ed.) 2020, 38, 304–308. [Google Scholar]

- Tang, C.; Shi, B.; Gu, K. Microscopic Study on the Interaction at the Reinforcement/Soil Interface in Fiber-Reinforced Soil. J. Eng. Geol. 2011, 19, 610–614. [Google Scholar]

- Divya, P.V.; Viswanadham, B.; Gourc, J.P. Evaluation of tensile strength-strain characteristics of fiber-reinforced soil through laboratory tests. J. Mater. Civ. Eng. 2014, 26, 14–23. [Google Scholar] [CrossRef]

- Miller, C.J.; Rifai, S. Fiber reinforcement for waste containment soil liners. J. Environ. Eng. 2004, 130, 891–895. [Google Scholar] [CrossRef]

- Huang, X.; Jiang, B. Microstructure Study of Coconut Fiber Reinforced Cement-Based Composites. Shanxi Archit. 2021, 47, 97–99. [Google Scholar]

- Yin, Q. Experimental Study on the Tensile Properties of Fiber-Reinforced Soil. Master’s Thesis, Northwest A&F University, Shaanxi, China, 2019. [Google Scholar]

- Lei, S. Triaxial Test Study on Reinforced Loess. J. Xian Highw. Transp. Univ. 2000, 20, 5. [Google Scholar]

- Wang, P.; Tang, C.; Wang, D.; Du, Y.; Wang, H. Experimental Study on Drying Evaporation and Cracking Characteristics of Fiber-Reinforced Municipal Sludge. J. Southeast Univ. (Nat. Sci. Ed.) 2016, 46, 88–93. [Google Scholar]

- Lin, D.Y. Soil Science Experimental Manual; China Forestry Publishing House: Beijing, China, 2004. [Google Scholar]

- Mantel, S.; Dondeyne, S.; Deckers, S. World reference base for soil resources (WRB). Encycl. Soils Environ. 2023, 4, 206–217. [Google Scholar]

- HJ/T 166-2004; Technical Specification for Soil Environmental Monitoring. China Environmental Science Press: Beijing, China, 2004.

- Chen, Y. Study on the Mechanical Mechanism of Fiber’s Effect on the Root Zone of Football Field Turf and Its Impact on Turf Quality. Ph.D. Thesis, Beijing Forestry University, Beijing, China, 2021. [Google Scholar]

- GB/T 50123-2019; Standard for Soil Test Method. China Planning Press: Beijing, China, 2019.

- SL237-1999; Specification of Soil Test. China Water Conservancy and Hydropower Press: Beijing, China, 1999.

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Wang, D.; Tang, C.; Li, J.; Liu, B.; Tang, W.; Zhu, K. Shear Strength Characteristics of Fiber-Reinforced Unsaturated Cohesive Soil. Chin. J. Geotech. Eng. 2013, 35, 8. [Google Scholar]

- Chang, Z.; Pei, X.; Wu, M.; Yang, Q. Experimental Study on Compressive Strength and Permeability of Plant Fiber Reinforced Stabilized Soil. J. Eng. Geol. 2017, 25, 8. [Google Scholar]

- Deng, Y.; Zheng, Y.; Wang, Q.; Li, P.; Feng, A.; Chen, G.; Zhang, M. Properties of Fiber-Reinforced Cement-Modified Loess under Freeze-Thaw Cycles. J. Hunan Univ. Sci. Technol. Nat. Sci. Ed. 2023, 38, 26–33. [Google Scholar]

- Lv, Y.; Nie, L.; Xu, Y.; Liu, F.; Zhang, M. Mechanism Analysis of the Influence of Organic Matter on the Physical and Mechanical Properties of Peat Soil. Chin. J. Geotech. Eng. 2011, 33, 655–660. [Google Scholar]

- Lemos, L.; Correia, A.A.; Oliveira, P.V. Comportamento de solos estabilizados quimicamente e reforçados com fibras sob ações monotónicas e cíclicas. Geotecnia 2021, 152, 509–529. [Google Scholar] [CrossRef]

- Tamassoki, S.; Daud, N.N.N.; Nejabi, M.N.; Roshan, M.J. Fibre-Reinforced Soil Mixed Lime/Cement Additives: A Review. Pertanika J. Sci. Technol. 2023, 31, 217–235. [Google Scholar] [CrossRef]

| Average Fineness (μm) | Density (kg/m3) | Elastic Modulus (GPa) | Tensile Strength (Mpa) | Ultimate Elongation (%) | Moisture Absorption (%) |

|---|---|---|---|---|---|

| 100–450 | 1390–1520 | 3–6 | 100–225 | 12–51.4 | 130–180 |

| Particle Size Range (mm) | 1–0.05 | 0.05–0.01 | <0.01 | 0.01–0.001 | <0.001 | |

|---|---|---|---|---|---|---|

| Soil Type | ||||||

| Soil-type A | 51.8% | 28.2% | 20% | 14% | 6% | |

| Soil-type B | 40.8% | 42.4% | 16.8% | 13.8% | 3% | |

| pH | EC (kg/m3) | Total Phosphorus (GPa) | Total Potassium (MPa) | Organic Matter (%) |

|---|---|---|---|---|

| 7.74 | 8331 | 3.883 | 2.32 | 53.8 |

| Fiber Content | Fiber Length | Total Porosity (%) | Aeration Porosity (%) | Capillary Porosity (%) | Bulk Density (g/cm3) | Hydraulic Conductivity (mm/min) |

|---|---|---|---|---|---|---|

| CK | 38.63 ± 1.11 c | 10.97 ± 1.14 c | 27.66 ± 0.33 a | 1.4347 + 0.022 a | 0.69 ± 0.01 b | |

| 0.2% | 1 cm | 41.8 ± 0.74 b | 16.91 ± 0.17 b | 24.89 ± 0.6 bc | 1.2987 + 0.003 b | 0.74 ± 0.01 a |

| 2 cm | 42.83 ± 0.49 b | 17.43 ± 0.11 ab | 25.41 ± 0.41 bc | 1.2907 + 0.004 b | 0.75 ± 0.02 a | |

| 3 cm | 44.57 ± 0.49 ab | 17.75 ± 0.12 ab | 26.82 ± 0.42 ab | 1.2773 + 0.010 b | 0.76 ± 0.01 a | |

| 4 cm | 44.07 ± 0.28 ab | 18.03 ± 0.34 ab | 26.04 ± 0.54 b | 1.1637 + 0.033 c | 0.76 ± 0.01 a | |

| 5 cm | 42.63 ± 0.2 b | 17.23 ± 0.04 ab | 25.4 ± 0.23 bc | 1.2873 + 0.004 b | 0.77 ± 0.02 a | |

| 0.4% | 1 cm | 42.83 ± 0.49 b | 17.43 ± 0.11 ab | 25.41 ± 0.41 bc | 1.2907 + 0.004 b | 0.75 ± 0.02 a |

| 2 cm | 44.1 ± 0.12 ab | 17.66 ± 0.09 ab | 26.44 ± 0.19 ab | 1.2803 + 0.005 b | 0.75 ± 0.01 a | |

| 3 cm | 44.87 ± 0.22 a | 18.1 ± 0.08 ab | 26.77 ± 0.22 ab | 1.2423 + 0.009 b | 0.75 ± 0.02 a | |

| 4 cm | 44.77 ± 0.37 ab | 18.43 ± 0.28 a | 26.34 ± 0.13 ab | 1.1483 + 0.067 c | 0.76 ± 0.01 a | |

| 5 cm | 42.7 ± 0.32 b | 17.23 ± 0.03 ab | 25.47 ± 0.29 bc | 1.2853 + 0.004 b | 0.77 ± 0.02 a | |

| 0.6% | 1 cm | 44.57 ± 0.3 ab | 17.65 ± 0.07 ab | 26.92 ± 0.24 ab | 1.2883 + 0.005 b | 0.75 ± 0.01 a |

| 2 cm | 44.07 ± 0.3 ab | 17.93 ± 0.11 ab | 26.14 ± 0.24 b | 1.2693 + 0.002 b | 0.76 ± 0.01 a | |

| 3 cm | 44.23 ± 0.28 ab | 18.33 ± 0.34 ab | 25.9 ± 0.27 b | 1.2740 + 0.003 b | 0.76 ± 0.02 a | |

| 4 cm | 44 ± 0.44 ab | 17.85 ± 0.11 ab | 26.15 ± 0.34 b | 1.1010 + 0.026 c | 0.77 ± 0.01 a | |

| 5 cm | 41.4 ± 0.31 b | 17.15 ± 0.07 ab | 24.25 ± 0.24 c | 1.3040 + 0.007 b | 0.78 ± 0.02 a |

| Fiber Content | Fiber Length | Total Porosity (%) | Aeration Porosity (%) | Capillary Porosity (%) | Bulk Density (g/cm3) | Hydraulic Conductivity (mm/min) |

|---|---|---|---|---|---|---|

| CK | 44.4 ± 0.45 c | 5.13 ± 0.05 d | 39.27 ± 0.41 a | 1.3137 + 0.00769 a | 0.6 ± 0.01 b | |

| 0.2% | 1 cm | 46.27 ± 0.55 bc | 10.87 ± 0.06 c | 35.39 ± 0.62 b | 1.1687 + 0.01943 b | 0.65 ± 0.01 a |

| 2 cm | 46.5 ± 0.74 bc | 11.16 ± 0.12 bc | 35.34 ± 0.82 b | 1.1907 + 0.0111 b | 0.65 ± 0.01 a | |

| 3 cm | 47.67 ± 0.61 b | 11.72 ± 0.07 ab | 35.95 ± 0.54 b | 1.052 + 0.03424 c | 0.67 ± 0.01 a | |

| 4 cm | 49.83 ± 0.47 ab | 11.51 ± 0.11 b | 38.33 ± 0.37 ab | 1.1393 + 0.02043 b | 0.67 ± 0.01 a | |

| 5 cm | 48.87 ± 0.26 ab | 11.87 ± 0.19 ab | 36.99 ± 0.44 ab | 1.0673 + 0.01517 c | 0.67 ± 0.02 a | |

| 0.4% | 1 cm | 46.4 ± 0.72 bc | 11.11 ± 0.09 bc | 35.29 ± 0.65 b | 1.1267 + 0.01559 b | 0.66 ± 0.02 a |

| 2 cm | 47.3 ± 0.38 b | 11.31 ± 0.09 b | 35.99 ± 0.29 b | 1.1503 + 0.02305 b | 0.66 ± 0.01 a | |

| 3 cm | 48.93 ± 0.7 ab | 12.01 ± 0.21 a | 36.93 ± 0.8 ab | 1.1483 + 0.06645 b | 0.67 ± 0.01 a | |

| 4 cm | 50.7 ± 0.59 a | 12.06 ± 0.06 a | 38.64 ± 0.62 ab | 1.0857 + 0.02422 c | 0.67 ± 0.02 a | |

| 5 cm | 47.9 ± 0.15 b | 11.73 ± 0.09 ab | 36.17 ± 0.16 b | 1.112 + 0.03291 b | 0.68 ± 0.01 a | |

| 0.6% | 1 cm | 46.83 ± 1.17 bc | 11.42 ± 0.07 b | 35.41 ± 1.11 b | 1.101 + 0.04219 b | 0.65 ± 0.02 a |

| 2 cm | 47.67 ± 0.61 b | 11.72 ± 0.07 ab | 35.95 ± 0.54 b | 1.052 + 0.03424 c | 0.67 ± 0.01 a | |

| 3 cm | 48.57 ± 0.37 ab | 12.14 ± 0.14 a | 36.43 ± 0.27 b | 1.101 + 0.02608 b | 0.68 ± 0.01 a | |

| 4 cm | 50.37 ± 0.47 ab | 11.99 ± 0.09 a | 38.37 ± 0.41 ab | 1.0773 + 0.02422 c | 0.68 ± 0.01 a | |

| 5 cm | 46.27 ± 0.48 bc | 11.71 ± 0.08 ab | 34.56 ± 0.41 b | 1.0467 + 0.0227 c | 0.69 ± 0.02 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, Y.; Wang, P.; Zhao, W.; Wang, L.; Liu, Y.; Yang, G.; Song, G. Effects of Fiber Length and Content on the Enhancement of Spray-Applied Substrate in Soil Spray Seeding. Appl. Sci. 2025, 15, 6075. https://doi.org/10.3390/app15116075

Qu Y, Wang P, Zhao W, Wang L, Liu Y, Yang G, Song G. Effects of Fiber Length and Content on the Enhancement of Spray-Applied Substrate in Soil Spray Seeding. Applied Sciences. 2025; 15(11):6075. https://doi.org/10.3390/app15116075

Chicago/Turabian StyleQu, Yifei, Pengfei Wang, Wenhao Zhao, Long Wang, Yifan Liu, Gang Yang, and Guilong Song. 2025. "Effects of Fiber Length and Content on the Enhancement of Spray-Applied Substrate in Soil Spray Seeding" Applied Sciences 15, no. 11: 6075. https://doi.org/10.3390/app15116075

APA StyleQu, Y., Wang, P., Zhao, W., Wang, L., Liu, Y., Yang, G., & Song, G. (2025). Effects of Fiber Length and Content on the Enhancement of Spray-Applied Substrate in Soil Spray Seeding. Applied Sciences, 15(11), 6075. https://doi.org/10.3390/app15116075