Strain Rate Effect on Artificially Cemented Clay with Fully Developed and Developing Structure

Abstract

1. Introduction

2. Materials and Methods

3. Results

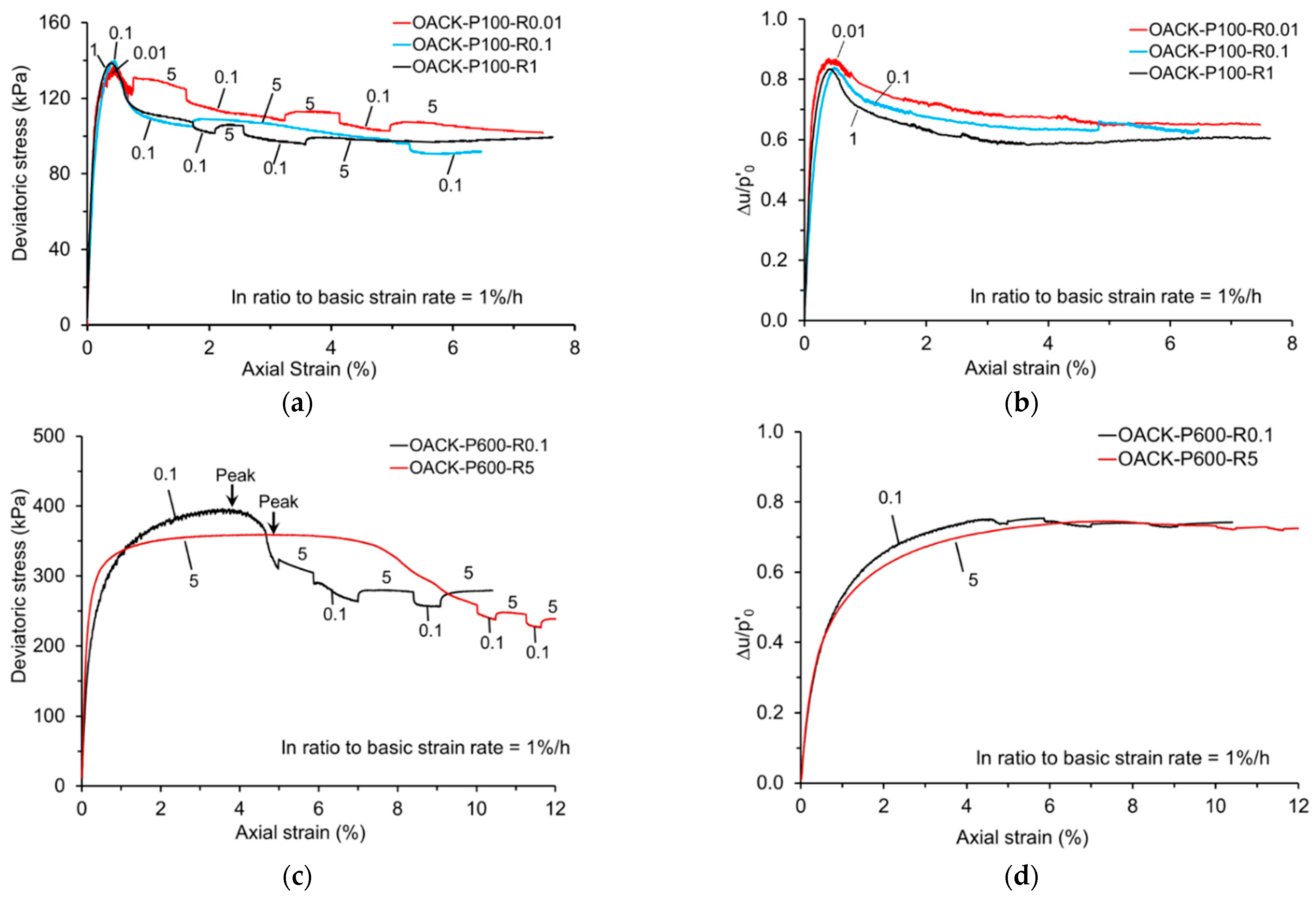

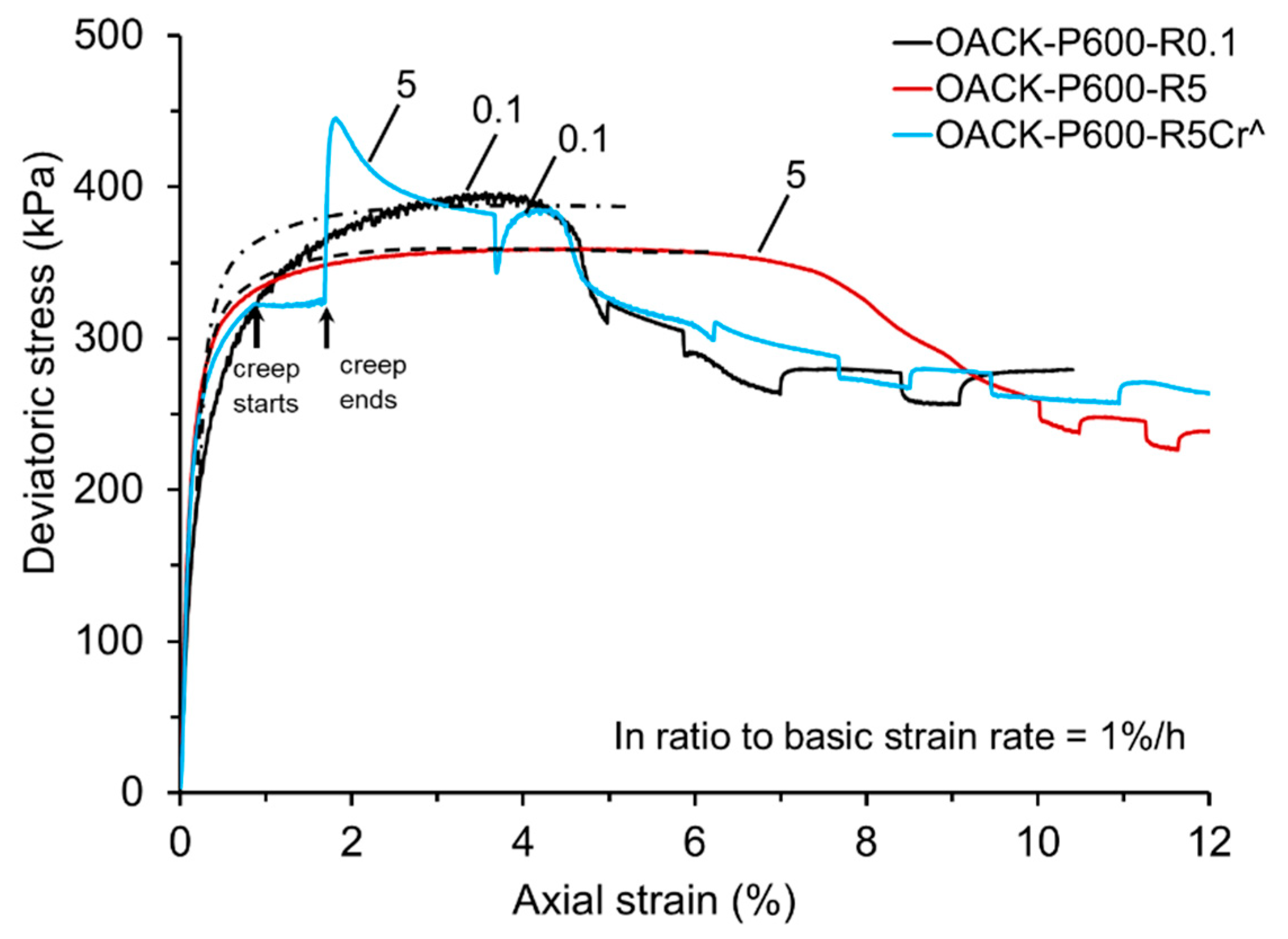

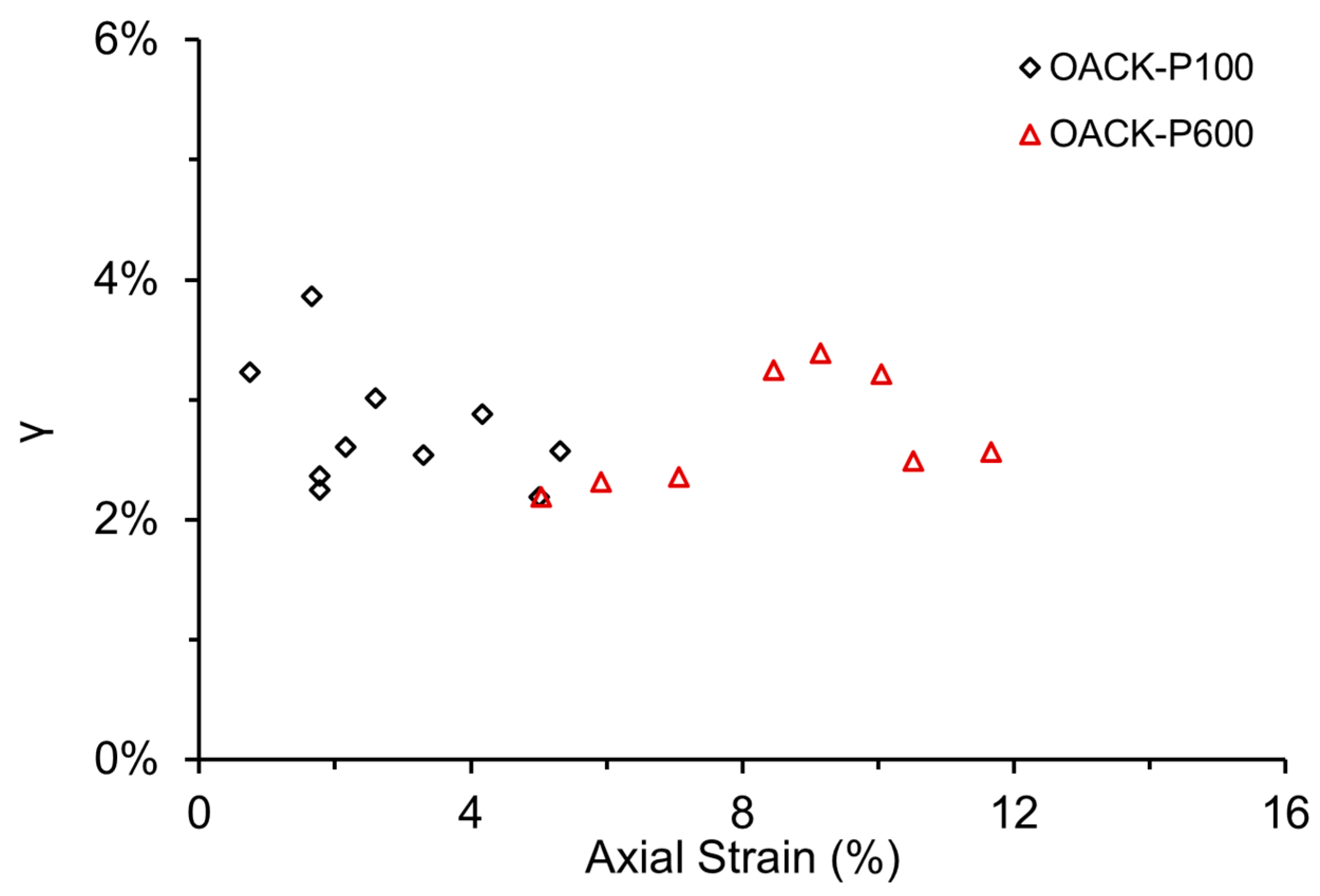

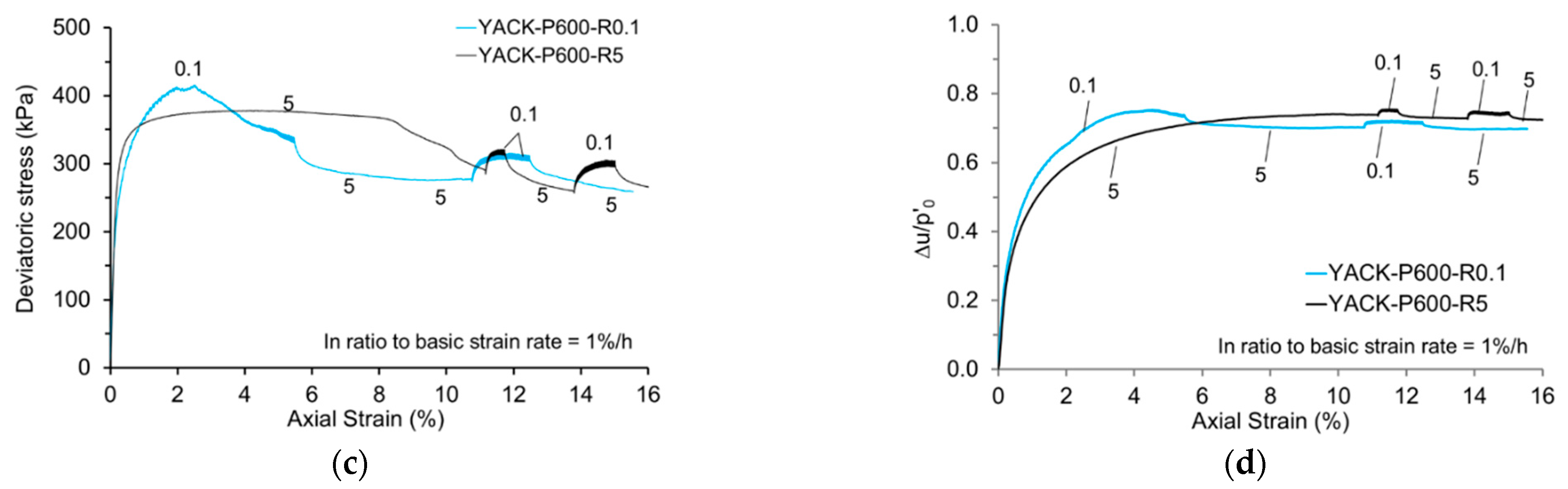

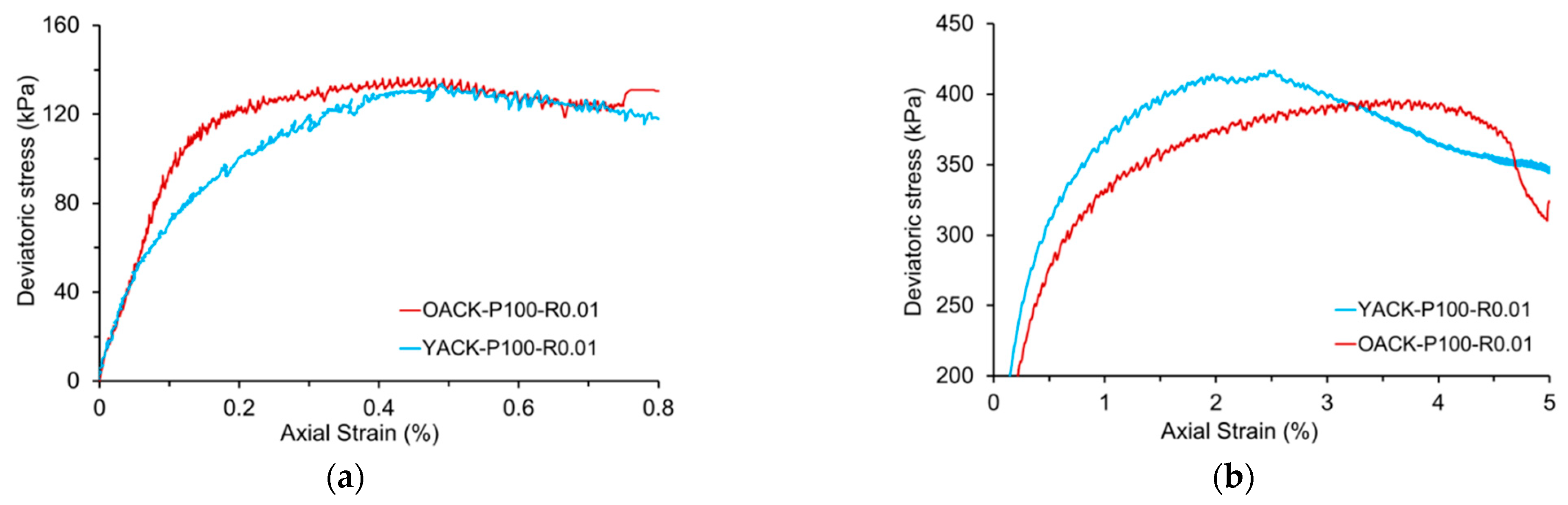

3.1. Rate Effect on Developed Structured Clay

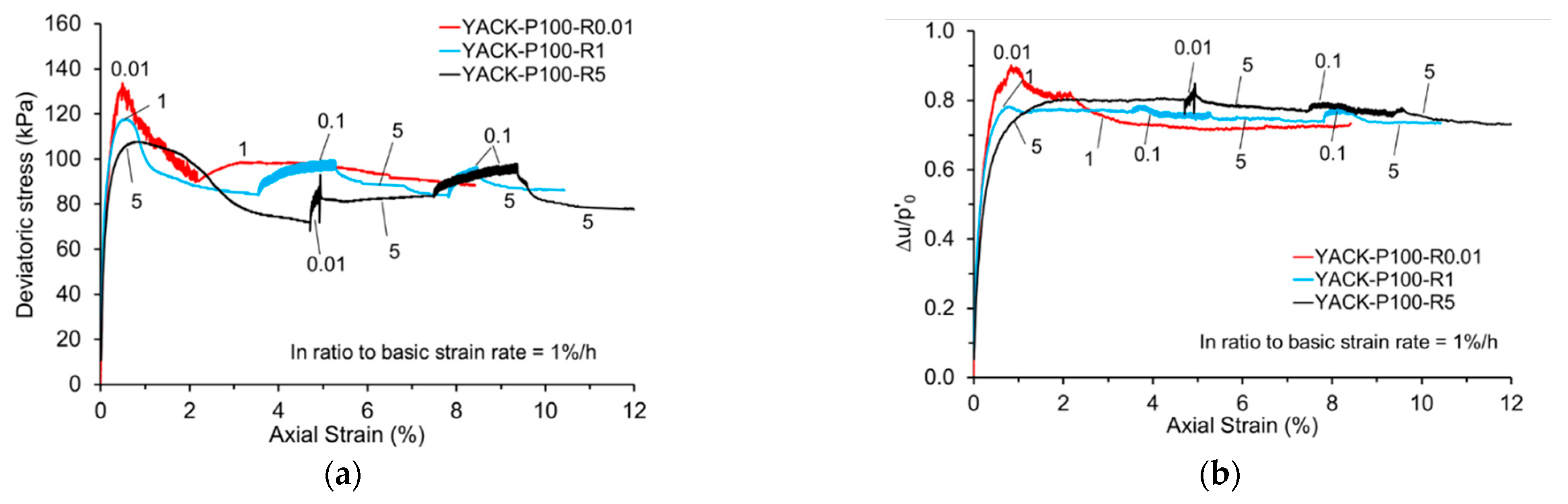

3.2. Rate Effect on Developing Structured Clay

4. Discussion

5. Conclusions

- (1)

- The fully developed ACK exhibited a shearing behaviour primarily governed by the proportion of intact bonds under low confining stresses, making it insensitive to strain rate. In contrast, under a large confining stress, the cementing bonds are significantly destroyed during isotropic compression, and a negative rate effect is observed due to local drainage at a slow rate of shearing. During the post-peak stage, the shear behaviour of the fully developed ACK switched to a pure isotach with a well-formed shear plane owing to its inherent viscosity.

- (2)

- The ACK with a developing structure shows a slight negative effect during the pre-peak stage under both low and high confining stresses, resulting from the combined effect of curing time and local drainage. In the post-peak stage, the presence of an intense stick-slip shear pattern and increased bond breakage at a well-formed shear plane results in an increase in shear resistance, i.e., a negative rate effect.

- (3)

- Two types of stick-slip shear patterns were observed during the undrained shearing of ACK with a developing structure. Both types of stick-slip only occurred with a critical threshold strain rate associated with the confining stress. The stick-slip effect at the post-peak stage could be manifested by the normal force on the sliding shear plane, and a linear relationship was found

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ACK | Artificially Cemented Kaolin |

| YACK | Young Artificially Cemented Kaolin |

| OACK | Old Artificially Cemented Kaolin |

| CRS | Constant Rate of Strain |

| SRS | Stepwise change Rate of Strain |

| PWP | Pore Water Pressure |

| OC | Overcosolidated |

| NC | Normal Consolidated |

| CF | Clay Fraction |

| Recon. | Reconstituted Soil |

| SEM | Scanning Electron Microscope |

References

- Indraratna, B.; Korkitsuntornsan, W.; Nguyen, T.T. Influence of kaolin content on the cyclic loading response of railway subgrade. Transp. Geotech. 2020, 22, 100319. [Google Scholar] [CrossRef]

- Jiang, S.; Xu, N.; Li, Z.C. Satellite derived coastal reclamation expansion in China since the 21st century. Glob. Ecol. Conserv. 2021, 30, e01797. [Google Scholar] [CrossRef]

- Yapage, N.N.S.; Liyanapathirana, D.S.; Kelly, R.B. Numerical modeling of an embankment over soft ground improved with deep cement mixed columns: Case history. J. Geotech. Geoenviron. Eng. 2014, 140, 04014062. [Google Scholar] [CrossRef]

- Yin, J.H.; Fang, Z. Physical modeling of a footing on soft soil ground with deep cement mixed soil columns under vertical loading. Mar. Georesour. Geotec. 2010, 28, 173–188. [Google Scholar] [CrossRef]

- Yin, K.S.; Zhang, L.M.; Zou, H.F. Key factors for deep cement mixing construction for undredged offshore land reclamation. J. Geotech. Geoenviron. Eng. 2022, 148, 04022063. [Google Scholar] [CrossRef]

- Yin, Z.Y.; Zhu, Q.Y.; Zhang, D.M. Comparison of two creep degradation modeling approaches for soft structured soils. Acta Geotech. 2017, 12, 1395–1413. [Google Scholar] [CrossRef]

- Burland, J.B. On the compressibility and shear strength of natural clays. Géotechnique 1990, 40, 329–378. [Google Scholar] [CrossRef]

- Graham, J.; Crooks, J.H.A.; Bell, A.L. Time effects on the stress-strain behavior of natural soft clays. Géotechnique 1983, 33, 327–340. [Google Scholar] [CrossRef]

- Soga, K.; Mitchell, J.K. Rate-dependent deformation of structured natural clays. In Measuring and Modeling Time Dependent Soil Behavior; ASCE Geotechnical Special Publication: Reston, VA, USA, 1996; Volume 61. [Google Scholar]

- Sadeghi-Chahardeh, A.; Mollaabbasi, R.; Picard, D.; Taghavi, S.M.; Alamdari, H. Discrete Element Method Modeling for the Failure Analysis of Dry Mono-Size Coke Aggregates. Materials 2021, 14, 2174. [Google Scholar] [CrossRef]

- Sadeghi-Chahardeh, A.; Mollaabbasi, R.; Picard, D.; Taghavi, S.M.; Alamdari, H. Effect of Particle Size Distributions and Shapes on the Failure Behavior of Dry Coke Aggregates. Materials 2021, 14, 5558. [Google Scholar] [CrossRef]

- Li, P.Q.; Baudet, B.A. Strain rate dependence of the critical state line of reconstituted clays. Géotech. Lett. 2016, 6, 66–71. [Google Scholar] [CrossRef]

- Li, X.M.; Jia, Y.L.; Wang, Z.L. Step-changed strain rate effect on the mechanical properties of undisturbed expansive clay. Eur. J. Environ. Civ. Eng. 2024, 28, 38–52. [Google Scholar] [CrossRef]

- Sorensen, K.K.; Baudet, B.A.; Simpson, B. Influence of structure on the time-dependent behaviour of a stiff sedimentary clay. Géotechnique 2007, 57, 113–124. [Google Scholar] [CrossRef]

- Torisu, S.S.; Pereira, J.M.; De Gennaro, V. Strain-rate effects in deep marine clays from the Gulf of Guinea. Géotechnique 2012, 62, 767–775. [Google Scholar] [CrossRef]

- Asaoka, A.; Nakano, M.; Noda, T. Delayed compression/consolidation of natural clay due to degradation of soil structure. Soils Found. 2000, 40, 75–85. [Google Scholar] [CrossRef]

- Oka, F.; Kodaka, T.; Kimoto, S. Step-changed strain rate effect on the stress-strain relations of clay and a constitutive modeling. Soils Found. 2003, 43, 189–202. [Google Scholar] [CrossRef]

- Han, J.; Yin, Z.Y.; Dano, C. Effect of strain rate on the adhesive bond shearing resistance of stiff clay. Transp. Geotech. 2021, 27, 100479. [Google Scholar] [CrossRef]

- Li, Y.R.; Wen, B.P.; Aydin, A. Ring shear tests on slip zone soils of three giant landslides in the Three Gorges Project area. Eng. Geol. 2013, 154, 106–115. [Google Scholar] [CrossRef]

- Sassa, K.; Wang, G.; Fukuoka, H. Landslide risk evaluation and hazard zoning for rapid and long-travel landslides in urban development areas. Landslides 2004, 1, 221–235. [Google Scholar] [CrossRef]

- Wang, L.; Han, J.; Liu, S. Variation in shearing rate effect on residual strength of slip zone soils due to test conditions. Geotech. Geol. Eng. 2020, 38, 2773–2785. [Google Scholar] [CrossRef]

- Tika, T.E.; Vaughan, P.R.; Lemos, L.J.L. Fast shearing of pre-existing shear zones in soils. Géotechnique 1996, 46, 197–233. [Google Scholar] [CrossRef]

- Bhat, D.R. Effect of shearing rate on residual strength of kaolin clay. Electron. J. Geotech. Eng. 2013, 18, 1387–1396. [Google Scholar]

- Li, D.; Yin, K.; Glade, T. Effect of over-consolidation and shear rate on the residual strength of soils of silty sand in the Three Gorges Reservoir. Sci. Rep. 2017, 7, 5503. [Google Scholar] [CrossRef]

- Stark, T.D.; Hussain, M. Shear strength in preexisting landslides. J. Geotech. Geoenviron. Eng. 2010, 136, 957–962. [Google Scholar] [CrossRef]

- Gratchev, I.B.; Sassa, K. Shear strength of clay at different shear rates. J. Geotech. Geoenviron. Eng. 2015, 141, 06015002. [Google Scholar] [CrossRef]

- Duong, N.T.; Suzuki, M.; Van Hai, N. Rate and acceleration effects on residual strength of kaolin and kaolin–bentonite mixtures in ring shearing. Soils Found. 2018, 58, 1153–1172. [Google Scholar] [CrossRef]

- Delage, P. A microstructure approach to the sensitivity and compressibility of some eastern Canada sensitive clays. Géotechnique 2010, 60, 353–368. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Miura, N.; Nagaraj, T.S. Assessment of strength development in cement-admixed high-water content clays with Abrams’ law as a basis. Géotechnique 2003, 53, 439–444. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, D.; Di, S. On the compression behavior of remolded cement-admixed soft clay. Mar. Georesour. Geotec. 2017, 36, 323–330. [Google Scholar] [CrossRef]

- Wu, J.; Liu, S.Y.; Deng, Y.F. Microscopic phase identification of cement-stabilized clay by nanoindentation and statistical analytics. Appl. Clay Sci. 2022, 224, 106531. [Google Scholar] [CrossRef]

- Suzuki, M.; Hai, N.V.; Yamamoto, T. Ring shear characteristics of discontinuous plane. Soils Found. 2017, 57, 1–22. [Google Scholar] [CrossRef]

- Berthoud, P.; Baumberger, I. Physical analysis of the state-and rate-dependent friction law: Static friction. Phys. Rev. B 1999, 59, 14313–14327. [Google Scholar] [CrossRef]

- Zhu, J.G.; Yin, J.H. Strain-rate-dependent stress–strain behavior of overconsolidated Hong Kong marine clay. Can. Geotech. J. 2000, 37, 1272–1282. [Google Scholar] [CrossRef]

- Cheng, C.M.; Yin, J.H. Strain-Rate Dependent Stress-Strain Behavior of Undisturbed Hong Kong Marine Deposits under Oedometric and Triaxial Stress States. Mar. Georesour. Geot. 2005, 23, 61–92. [Google Scholar] [CrossRef]

- Scaringi, G.; Di Maio, C. Influence of displacement rate on residual shear strength of clays. Procedia Earth Planet. Sci. 2016, 16, 137–145. [Google Scholar] [CrossRef]

| Test Name | Curing & Consolidation Stress (kPa) | Curing Time (Days) | p’0 | Pre-Peak Strain Rate (%/h) | Post-Peak Strain Rate (%/h) |

|---|---|---|---|---|---|

| OACK-P100-R0.01 | 100 | 30 | 100 | 0.01 | 0.1/5 |

| OACK-P100-R0.1 | 0.1 | 0.1/5 | |||

| OACK-P100-R1 | 1 | 0.1/5 | |||

| OACK-P600-R0.1 | 600 | 0.1 | 0.1/5 | ||

| OACK-P600-R5 | 5 | 0.1/5 | |||

| OACK-P600-R5Cr ^ | 5 + creep | 0.1/5 | |||

| YACK-P100-R0.01 | 100 | 2 | 100 | 0.01 | 0.1/5 |

| YACK-P100-R1 | 1 | 0.1/5 | |||

| YACK-P100-R5 | 5 | 0.1/5 | |||

| YACK-P600-R0.1 | 600 | 0.1 | 0.1/5 | ||

| YACK-P600-R5 | 5 | 0.1/5 |

| Type of Soil | Soil Structure Status | Shearing Procedure | Shear Rate (%/h) | Rate Effect | Mechanism | Reference | |

|---|---|---|---|---|---|---|---|

| Pre-Peak/Small Strain | Post-Peak /Large Strain | ||||||

| Belfast clay | OC Undisturbed | Triaxial SRS | 0.05-0.5-5 | Positive | Positive | Shear viscosity | Graham et al. [8] |

| Hong Kong Marine clay | NC + OC Recon. | Triaxial CRS | 0.15-1.5-15 | Positive | Positive | Shear viscosity | Zhu & Yin [34] |

| OC Undisturbed | Triaxial SRS | 0.2-2-20 | Positive | Positive | Shear viscosity and smaller excess PWP at a higher rate | Cheng & Yin [35] | |

| London clay | NC + OC Recon. | Triaxial SRS | 0.007-0.05-0.5 | Positive | Insensitive | Shear viscosity and decaying isotach at large strain | Sorensen et al. [14] |

| OC Undisturbed | Triaxial SRS | 0.05-0.2-0.8 | Positive | Positive | Rate dependence of post-sedimentation structure | ||

| Merville stiff clay | NC + OC Recon. | Triaxial CRS | 0.26-2.6-26.0 | Positive | Positive | Shear viscosity | Han et al. [18] |

| OC Undisturbed | Triaxial CRS | 0.26-2.6-26.0 | Positive | Insensitive | Rate dependence of interparticle debonding | ||

| Pure Kaolin clay | NC + OC Recon. | Triaxial SRS | 0.1-0.5-2-10 | Positive | Positive | Shear viscosity | Li & Baudet [12] |

| Artificial cemented Kaolin clay | OACK at low p’ | Triaxial CRS + SRS | 0.01-0.1-1-5 | Insensitive | Positive | Stiff bonds at pre-peak; shear mode change at post-peak | This study |

| OACK at high p’ | Triaxial CRS + SRS | 0.1-5 | Negative | Positive | Bonds broken and local drainage near shear plane; | ||

| YACK at low p’ | Triaxial CRS + SRS | 0.01-1-5 | Negative | Negative | Combined curing effect and stick-slip | ||

| YACK at high p’ | Triaxial CRS + SRS | 0.1-5 | Negative | Negative | Combined curing effect and stick-slip | ||

| Type of Soil | Soil Structure Status | Shearing Procedure | Shear Rate (mm/min) | Rate Effect on Residual Strength | Mechanism | Reference |

|---|---|---|---|---|---|---|

| Kaolin clay | Recon. CF = 74% | Ring shear | 0.013-0.13-1.12-9.9-90.8-230 | Positive | Shear viscosity; sliding to turbulent shear with a higher rate | Tika et al. [22] |

| Claystone | Recon. CF = 52% | Ring shear | 0.05-0.92-10-100-400-6000 | Negative | Soils with transitional shear | |

| Amber clay | Recon. CF = 66% | Ring shear | 12-60-120-300 | Negative | Healing, broken bonds restoration at a lower rate | Gratchev & Sassa [26] |

| Brown clay | Recon. CF = 19% | Ring shear | 12-60-120-300 | Negative | Healing, broken bonds restoration at a lower rate | |

| Kaolin clay | Recon. CF = 100% | Direct shear | 3.6-36-360 | Negative | Larger excess PWP with a higher rate | Li et al. [19] |

| Kaolin clay | Recon. CF = 74% | Ring shear | 0.09-0.6-1-11.1 | Positive | Shear viscosity; Only significant v > 0.5 mm/min | Scaringi & Di Maio [36] |

| Kualiangzi landslide | Recon. CF = 74% | Ring shear | 0.002-0.6-1-120 | Positive | Shear viscosity; only positive v > 3 mm/min | |

| Kaolin clay | Recon. CF = 74% | Ring shear | 0.02-0.1-0.2-1-10 | Positive | Shear viscosity; Only significant v > 0.1 mm/min | Suzuki et al. [32] |

| 4% Cemented Kaolin clay | Recon. | Ring shear | 0.02-0.1-0.2-1-10 | Insensitive | undulating shear behaviour | |

| Kaolin clay | Recon. CF = 46% | Ring shear | 0.02-0.2-2-20 | Positive | Shear viscosity; sliding to turbulent shear; | Duong et al. [27] |

| Kaolin + Bentonite clay | Recon. CF = 50.8% | Ring shear | 0.02-0.2-2-20 | Negative | Larger excess PWP and finer particles at the shear zone with a higher rate |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Baudet, B.A.; Zhang, X. Strain Rate Effect on Artificially Cemented Clay with Fully Developed and Developing Structure. Appl. Sci. 2025, 15, 5839. https://doi.org/10.3390/app15115839

Li Q, Baudet BA, Zhang X. Strain Rate Effect on Artificially Cemented Clay with Fully Developed and Developing Structure. Applied Sciences. 2025; 15(11):5839. https://doi.org/10.3390/app15115839

Chicago/Turabian StyleLi, Qiang, Beatrice Anne Baudet, and Xiaoyan Zhang. 2025. "Strain Rate Effect on Artificially Cemented Clay with Fully Developed and Developing Structure" Applied Sciences 15, no. 11: 5839. https://doi.org/10.3390/app15115839

APA StyleLi, Q., Baudet, B. A., & Zhang, X. (2025). Strain Rate Effect on Artificially Cemented Clay with Fully Developed and Developing Structure. Applied Sciences, 15(11), 5839. https://doi.org/10.3390/app15115839