Annealing Effect After RF (Radio Frequency) Sintering of Dental Zirconia Block with Dramatically Reduced Sintering Time: Experimental Study

Abstract

1. Introduction

2. Materials and Methods

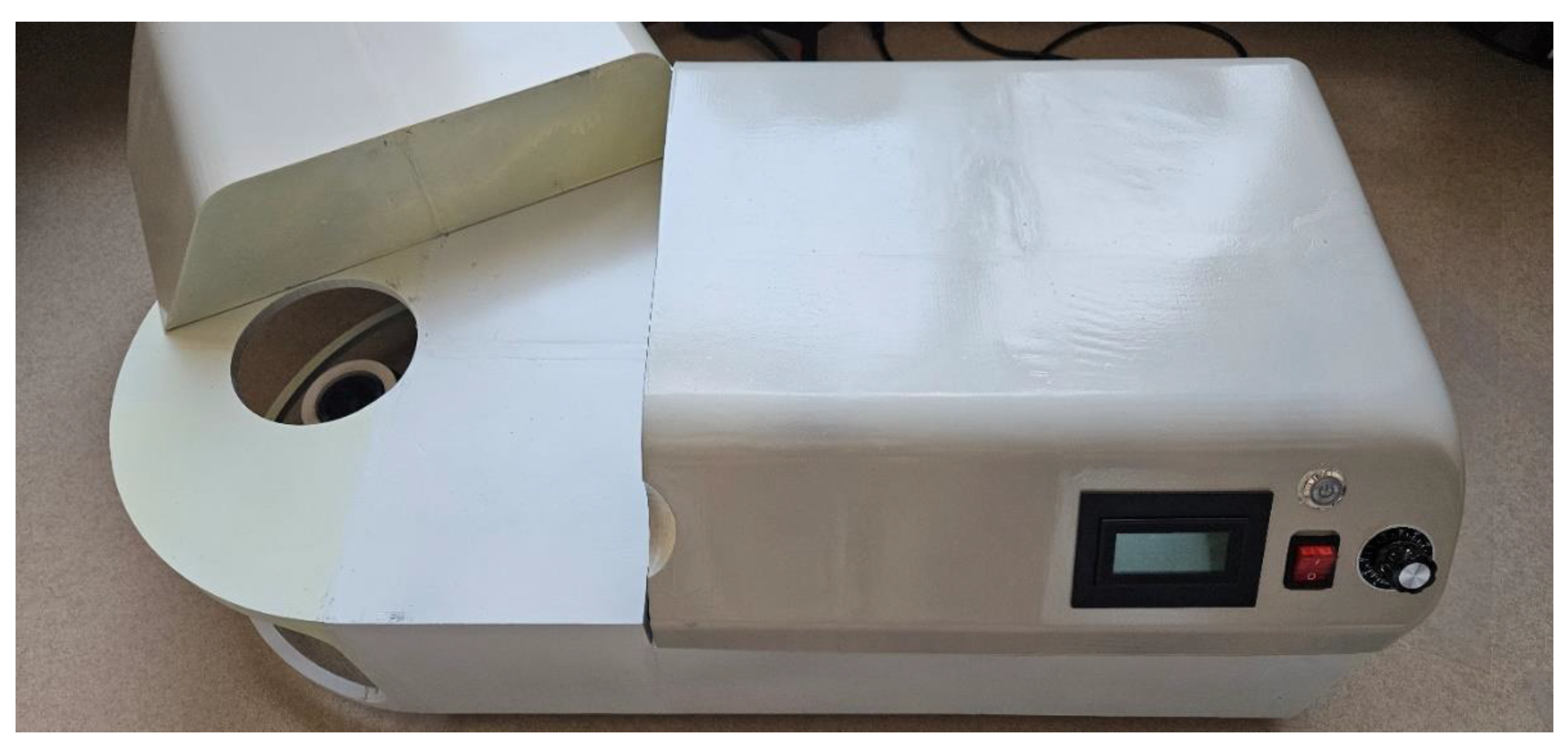

2.1. Experimental Setup and Characterization

- f0 is the frequency generated by the inverter in Hertz (Hz).

- L is the inductance of the RF coil in Henrys (H).

- C is the value of the capacitor connected in parallel with the RF coil in Farads (F).

- ε is the induced voltage.

- Φ is the induced magnetic flux inside the zirconia.

- I is the induced current (eddy current) inside the zirconia.

- R is the electrical resistance of the zirconia.

- P is the heat generated inside the zirconia by the eddy current.

- is the power loss per unit volume.

- B is the magnetic flux density.

- d is the thickness of the material.

- f is the frequency of the AC.

- ρ is the electrical resistivity of the material.

- Control: 1440 °C for 20 min ⟶ 1220 °C for 20 min.

- RF20/20: 1350 °C for 20 min ⟶ 1220 °C for 20 min.

- RF10/20: 1350 °C for 10 min ⟶ 1220 °C for 20 min.

- RF20/10: 1350 °C for 20 min ⟶ 1220 °C for 10 min.

2.2. Statistical Analysis

3. Results

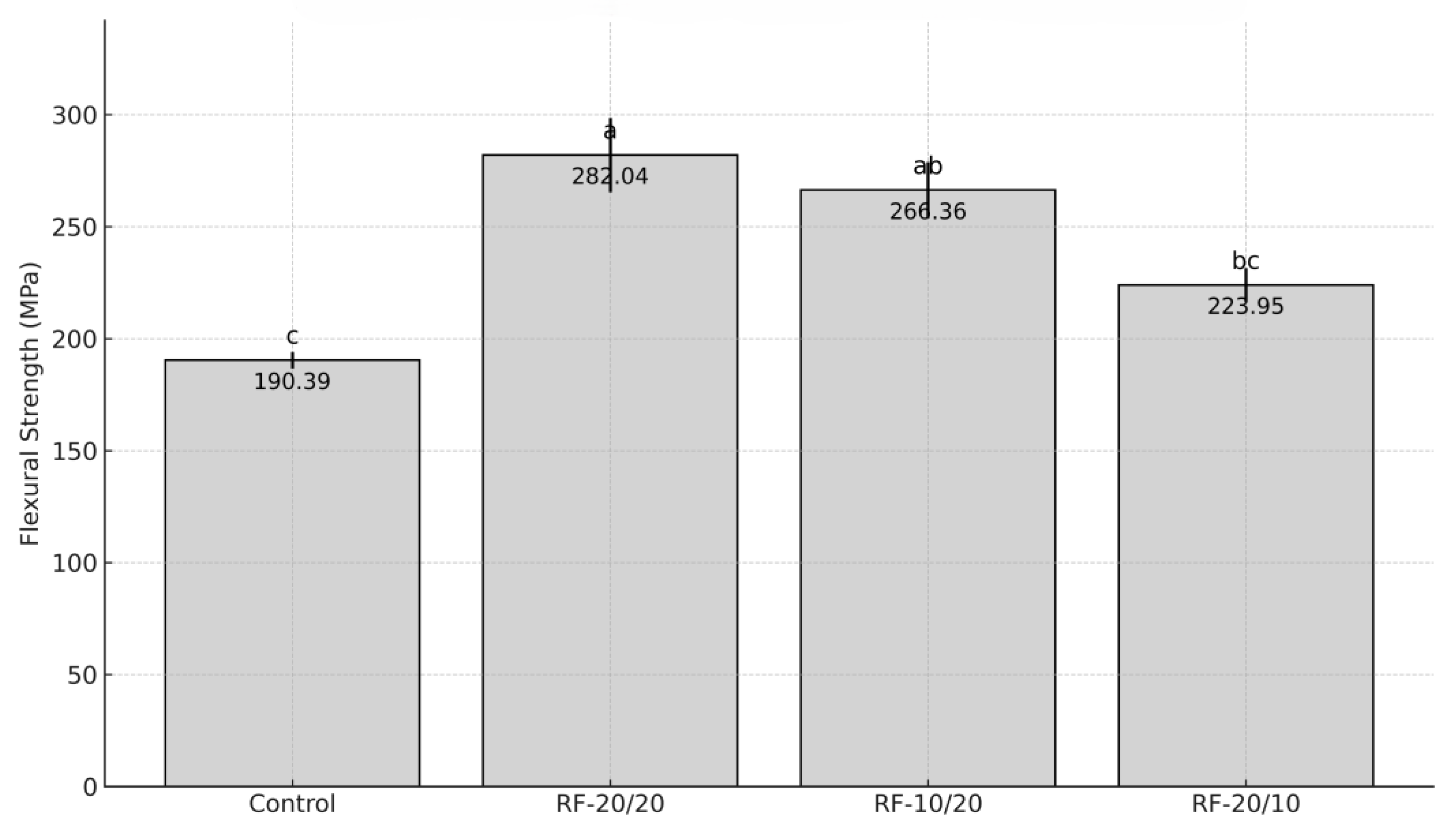

3.1. Flexural Strength Test

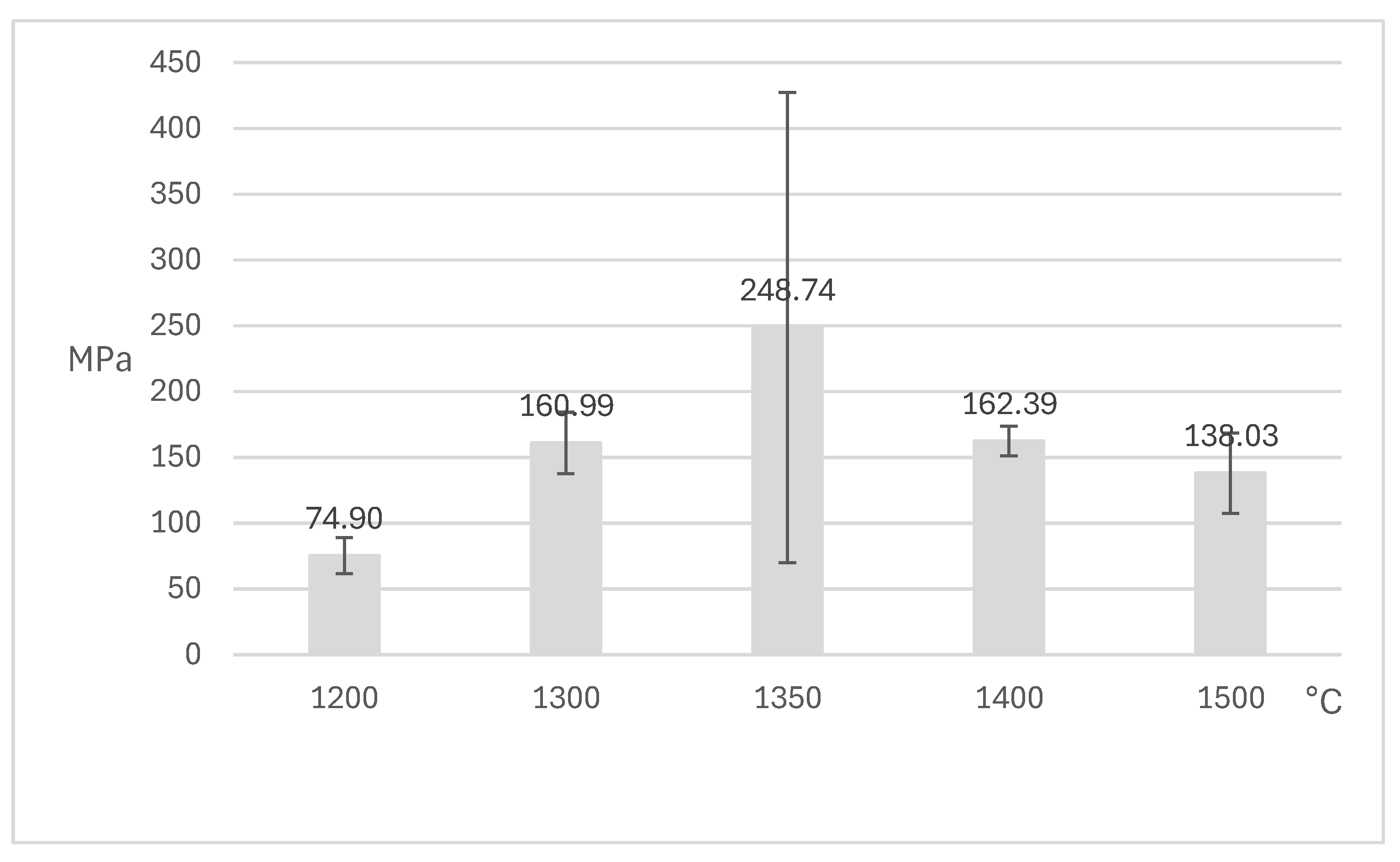

3.1.1. Results Graph for Preliminary Study

3.1.2. Results Table for Main Test

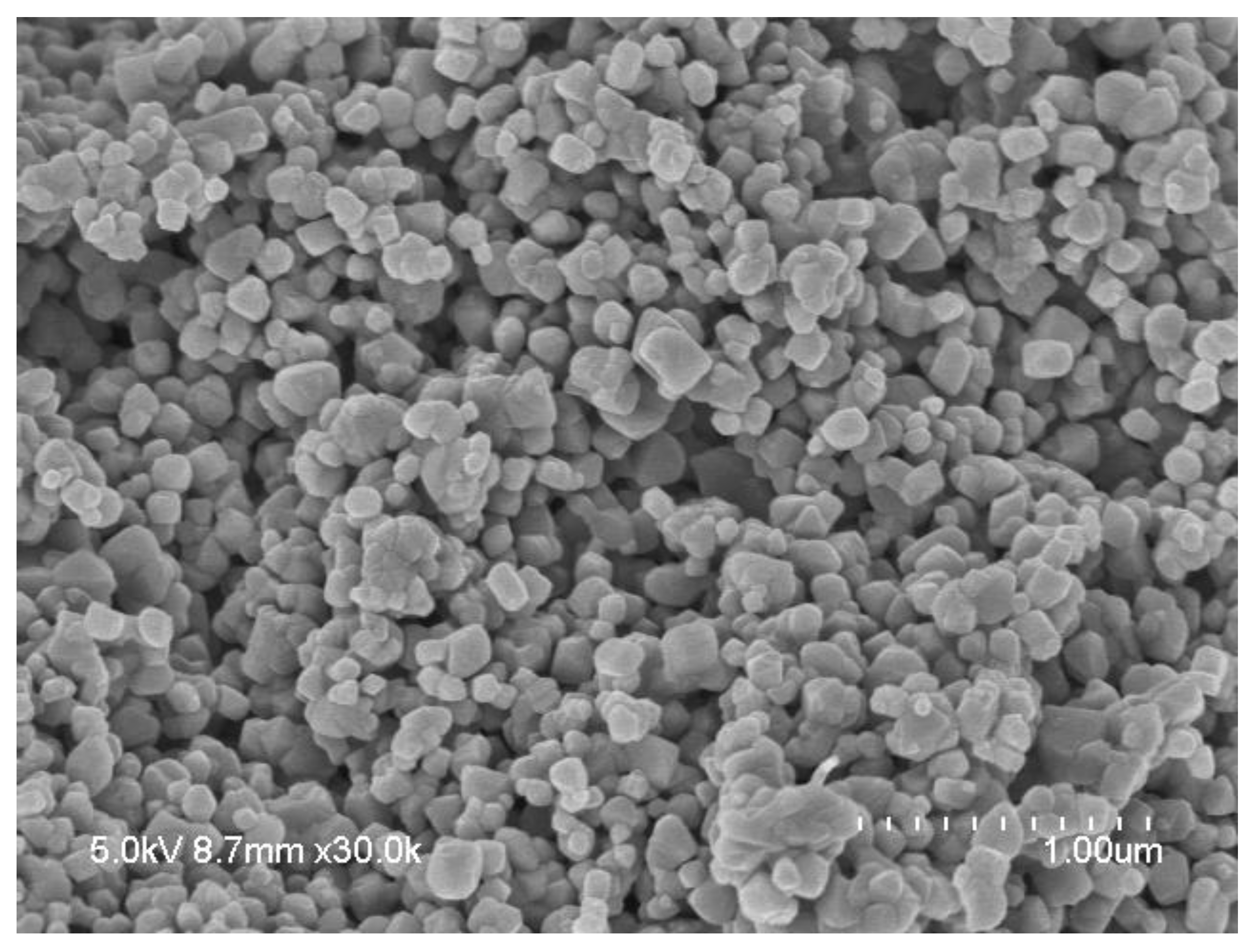

3.2. Scanning Electron Microscope Images

Main Test Results

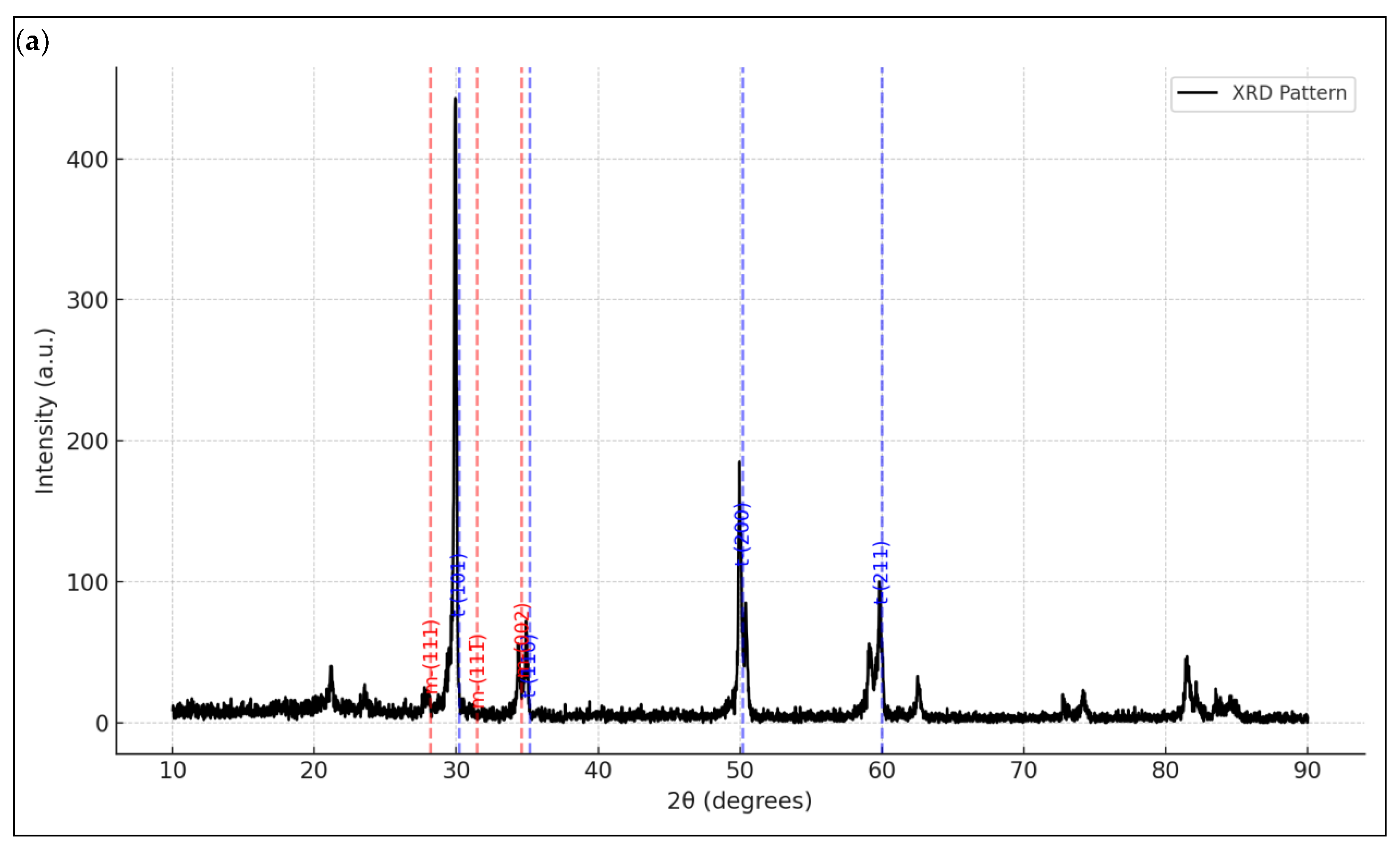

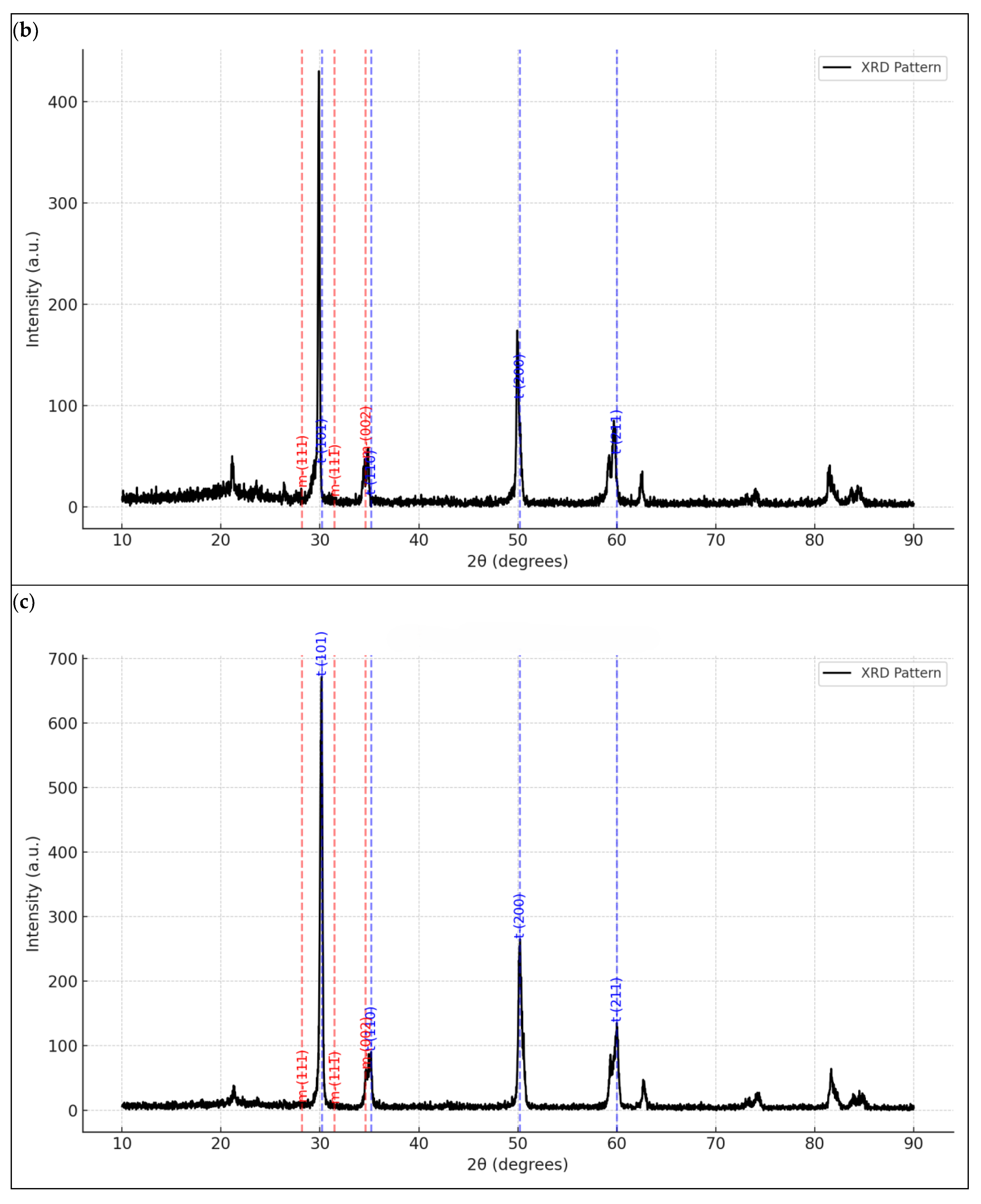

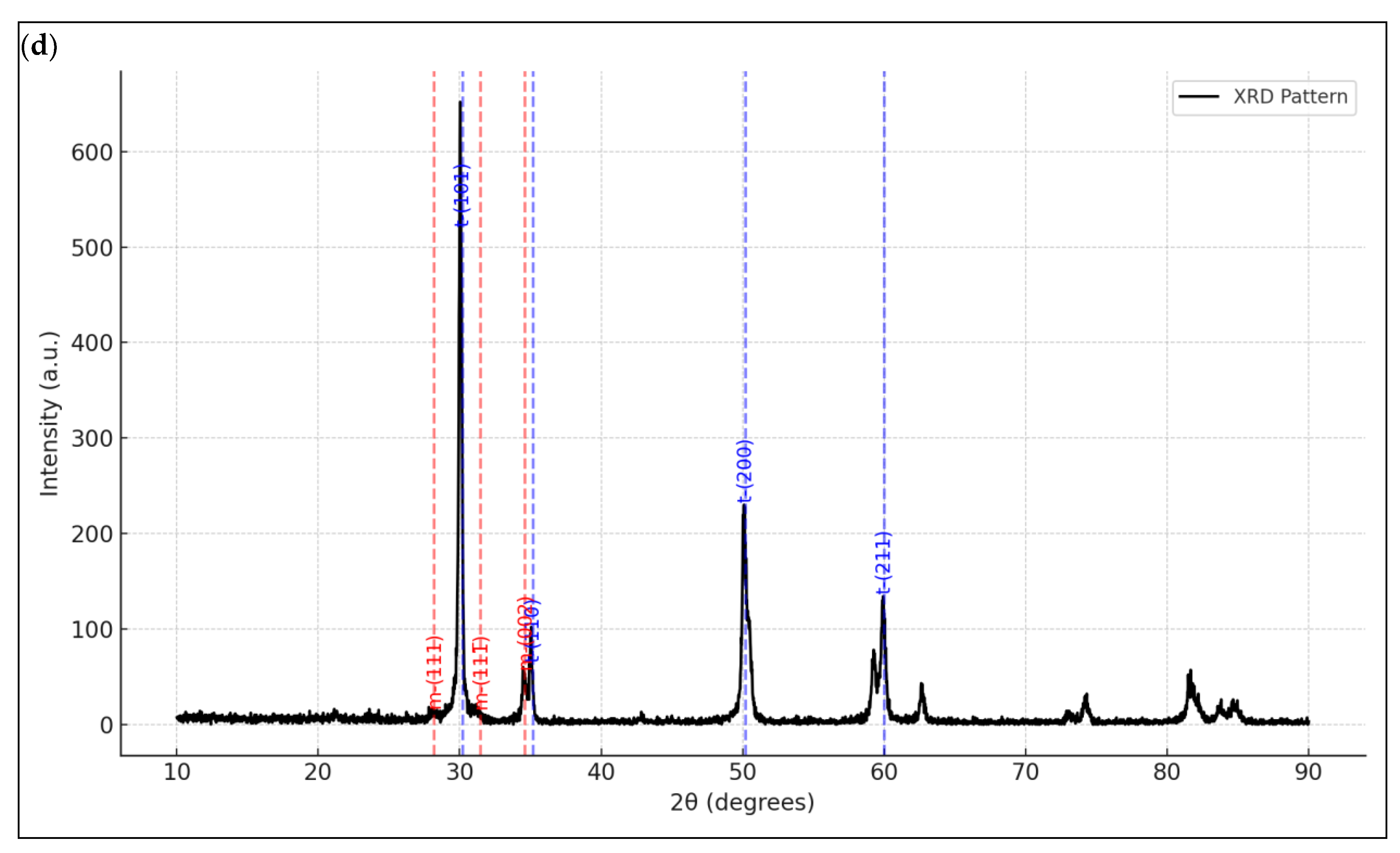

3.3. X-Ray Diffraction Results

3.4. Statistical Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grech, J.; Antunes, E. Zirconia in dental prosthetics: A literature review. J. Mater. Res. Technol. 2019, 8, 4956–4964. [Google Scholar] [CrossRef]

- Kim, H.K.; Kim, S.H. Comparison of the optical properties of pre-colored dental monolithic zirconia ceramics sintered in a conventional furnace versus a microwave oven. J. Adv. Prosthodont. 2017, 9, 394. [Google Scholar] [CrossRef] [PubMed]

- Bencharit, S.; Clark, W.A.; Stoner, L.O.; Chiang, G.; Sulaiman, T.A. Recent Advancements in CAD/CAM Same-Day Dentistry in Practice and Education. Preprints 2021, 2021110490. [Google Scholar]

- Padrós, R.; Giner, L.; Herrero-Climent, M.; Falcao-Costa, C.; Ríos-Santos, J.V.; Gil, F.J. Influence of the CAD-CAM systems on the marginal accuracy and mechanical properties of dental restorations. Int. J. Environ. Res. Public Health 2020, 17, 4276. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Inokoshi, M.; Nozaki, K.; Shimizubata, M.; Nakai, H.; Too, T.D.; Minakuchi, S. Influence of high-speed sintering protocols on translucency, mechanical properties, microstructure, crystallography, and low-temperature degradation of highly translucent zirconia. Dent. Mater. 2022, 38, 451–468. [Google Scholar] [CrossRef] [PubMed]

- Kauling, A.E.; Güth, J.F.; Erdelt, K.; Edelhoff, D.; Keul, C. Influence of speed sintering on the fit and fracture strength of 3-unit monolithic zirconia fixed partial dentures. J. Prosthet. Dent. 2020, 124, 380–386. [Google Scholar] [CrossRef] [PubMed]

- Ersoy, N.M.; Aydoğdu, H.M.; Değirmenci, B.Ü.; Çökük, N.; Sevimay, M. The effects of sintering temperature and duration on the flexural strength and grain size of zirconia. Acta Biomater. Odontol. Scand. 2015, 1, 43–50. [Google Scholar] [CrossRef] [PubMed]

- Almazdi, A.A.; Khajah, H.M.; Monaco, E.A., Jr.; Kim, H. Applying microwave technology to sintering dental zirconia. J. Prosthet. Dent. 2012, 108, 304–309. [Google Scholar] [CrossRef] [PubMed]

- Sakuma, T.; Yoshizawa, Y.I.; Suto, H. The microstructure and mechanical properties of yttria-stabilized zirconia prepared by arc-melting. J. Mater. Sci. 1985, 20, 2399–2407. [Google Scholar] [CrossRef]

- Khasanov, O.; Reichel, U.; Dvilis, E.; Khasanov, A. Lower sintering temperature of nanostructured dense ceramics compacted from dry nanopowders using powerful ultrasonic action. IOP Conf. Ser. Mater. Sci. Eng. 2011, 18, 082004. [Google Scholar] [CrossRef]

- Oghbaei, M.; Mirzaee, O. Microwave versus conventional sintering: A review of fundamentals, advantages and applications. J. Alloys Compd. 2010, 494, 175–189. [Google Scholar] [CrossRef]

- Choi, E.S. Zirconia Sintering Apparatus and Method Using High-Frequency Induction Heating. KR Patent 10-2024-0023578, 19 February 2024. [Google Scholar]

- ISO 9693-2:2016; Dentistry—Compatibility Testing—Part 2: Ceramic-ceramic Systems. International Organization for Standardization: Geneva, Switzerland, 2016.

- Faul, F.; Erdfelder, E.; Buchner, A.; Lang, A.-G. Statistical power analyses using G*Power 3.1: Tests for correlation and regression analyses. Behav. Res. Methods 2009, 41, 1149–1160. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.C. Effects of Zirconia Sintering Condition on Flexural Strength and Grain Size. Master’s Thesis, Korea University, Seoul, Republic of Korea, 2014. [Google Scholar]

- Matsui, K.; Yoshida, H.; Ikuhara, Y. Isothermal sintering effects on phase separation and grain growth in yttria-stabilized tetragonal zirconia polycrystal. J. Am. Ceram. Soc. 2009, 92, 467–475. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Özcan, M.; Hallmann, L.; Ender, A.; Mehl, A.; Hämmerlet, C.H. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin. Oral Investig. 2013, 17, 269–274. [Google Scholar] [CrossRef] [PubMed]

- Nightingale, S.A.; Dunne, D.P.; Worner, H.K. Sintering and grain growth of 3 mol% yttria zirconia in a microwave field. J. Mater. Sci. 1996, 31, 5039–5043. [Google Scholar] [CrossRef]

- Casellas, D.; Alcala, J.; Llanes, L.; Anglada, M. Fracture variability and R-curve behavior in yttria-stabilized zirconia ceramics. J. Mater. Sci. 2001, 36, 3011–3025. [Google Scholar] [CrossRef]

- Kim, E.J. Observation of Strength and Color Changes According to Sintering Temperature of Zirconia Material. Master’s Thesis, Catholic University of Pusan, Busan, Republic of Korea, 2024. [Google Scholar]

| Time (minute) | Temperature (°C) |

|---|---|

| 0 | 20 |

| 1 | 703 |

| 2 | 1161 |

| 3 | 1352 |

| 4 | 1371 |

| 5 | 1386 |

| 6 | 1413 |

| 7 | 1440 |

| 8 | 1455 |

| 9 | 1470 |

| 10 | 1486 |

| 11 | 1496 |

| 12 | 1513 |

| 13 | 1520 |

| 20 | 1531 |

| Control | RF20/20 | RF10/20 | RF20/10 | |

|---|---|---|---|---|

| Sintering condition | 1440 °C 20 min 1220 °C 20 min | 1350 °C 20 min 1220 °C 20 min | 1350 °C 10 min 1220 °C 20 min | 1350 °C 20 min 1220 °C 10 min |

| Flexural strength | 190.4 MPa | 282.0 MPa | 266.4 MPa | 224.0 MPa |

| Standard deviation | 11.744 | 52.482 | 39.714 | 24.144 |

| 95% CI | ||||||

|---|---|---|---|---|---|---|

| (I) Group | N | Mean | Std. Deviation | Std. Error. | Lower Bound | Upper Bound |

| control | 10 | 190.3913 | 11.74436 | 3.71389 | 181.9899 | 198.7927 |

| RF20/20 | 10 | 282.0364 | 52.48262 | 16.59646 | 244.4926 | 319.5802 |

| RF10/20 | 10 | 266.3627 | 39.71490 | 12.55896 | 237.9524 | 294.7730 |

| RF20/10 | 10 | 223.9538 | 24.14455 | 7.63518 | 206.6818 | 241.2258 |

| Sum of Squares | df | Mean Square | F | Sig. | |

|---|---|---|---|---|---|

| Between groups | 51,786.719 | 3 | 17,262.240 | 13.666 | <0.000 |

| Within groups | 45,473.293 | 36 | 1263.147 | ||

| Total | 97,260.012 | 39 |

| 95% CI | ||||||

|---|---|---|---|---|---|---|

| (I) Group | (J) Group | Mean Difference (I-J) | Std. Error | Sig. | Lower Bound | Upper Bound |

| control | 2.00 | −91.64510* | 15.89432 | <0.001 | −134.4521 | −48.8381 |

| 3.00 | −75.97140* | 15.89432 | <0.001 | −118.7784 | −33.1644 | |

| 4.00 | −33.56250 | 15.89432 | 0.169 | −76.3695 | 9.2445 | |

| RF20/20 | 1.00 | 91.64510* | 15.89432 | <0.001 | 48.8381 | 134.4521 |

| 3.00 | 15.67370 | 15.89432 | 0.758 | −27.1333 | 58.4807 | |

| 4.00 | 58.08260* | 15.89432 | 0.004 | 15.2756 | 100.8896 | |

| RF10/20 | 1.00 | 75.97140* | 15.89432 | <0.001 | 33.1644 | 118.7784 |

| 2.00 | −15.67370 | 15.89432 | 0.758 | −58.4807 | 27.1333 | |

| 4.00 | 42.40890 | 15.89432 | 0.053 | −0.3981 | 85.2159 | |

| RF20/10 | 1.00 | 33.56250 | 15.89432 | 0.169 | −9.2445 | 76.3695 |

| 2.00 | −58.08260* | 15.89432 | 0.004 | −100.8896 | −15.2756 | |

| 3.00 | −42.40890 | 15.89432 | 0.053 | −85.2159 | 0.3981 | |

| Strength | ||||

|---|---|---|---|---|

| Tukey HSDa | Subset for Significance Level of 0.05 | |||

| Group | N | 1 | 2 | 3 |

| Control | 10 | 190.3913 | ||

| RF20/10 | 10 | 223.9538 | 223.9538 | |

| RF10/20 | 10 | 266.3627 | 266.3627 | |

| RF20/20 | 10 | 282.0364 | ||

| Sig. | 0.169 | 0.053 | 0.758 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, E.-S.; Lee, J.-H.; Park, J.-H.; Kim, J.-H. Annealing Effect After RF (Radio Frequency) Sintering of Dental Zirconia Block with Dramatically Reduced Sintering Time: Experimental Study. Appl. Sci. 2025, 15, 5754. https://doi.org/10.3390/app15105754

Choi E-S, Lee J-H, Park J-H, Kim J-H. Annealing Effect After RF (Radio Frequency) Sintering of Dental Zirconia Block with Dramatically Reduced Sintering Time: Experimental Study. Applied Sciences. 2025; 15(10):5754. https://doi.org/10.3390/app15105754

Chicago/Turabian StyleChoi, Eun-Sung, Je-Hoon Lee, Jung-Hyun Park, and Ji-Hwan Kim. 2025. "Annealing Effect After RF (Radio Frequency) Sintering of Dental Zirconia Block with Dramatically Reduced Sintering Time: Experimental Study" Applied Sciences 15, no. 10: 5754. https://doi.org/10.3390/app15105754

APA StyleChoi, E.-S., Lee, J.-H., Park, J.-H., & Kim, J.-H. (2025). Annealing Effect After RF (Radio Frequency) Sintering of Dental Zirconia Block with Dramatically Reduced Sintering Time: Experimental Study. Applied Sciences, 15(10), 5754. https://doi.org/10.3390/app15105754