I-BIM Applied in Railway Geometric Inspection Activity: Diagnostic and Alert

Abstract

1. Introduction

2. Materials and Methods

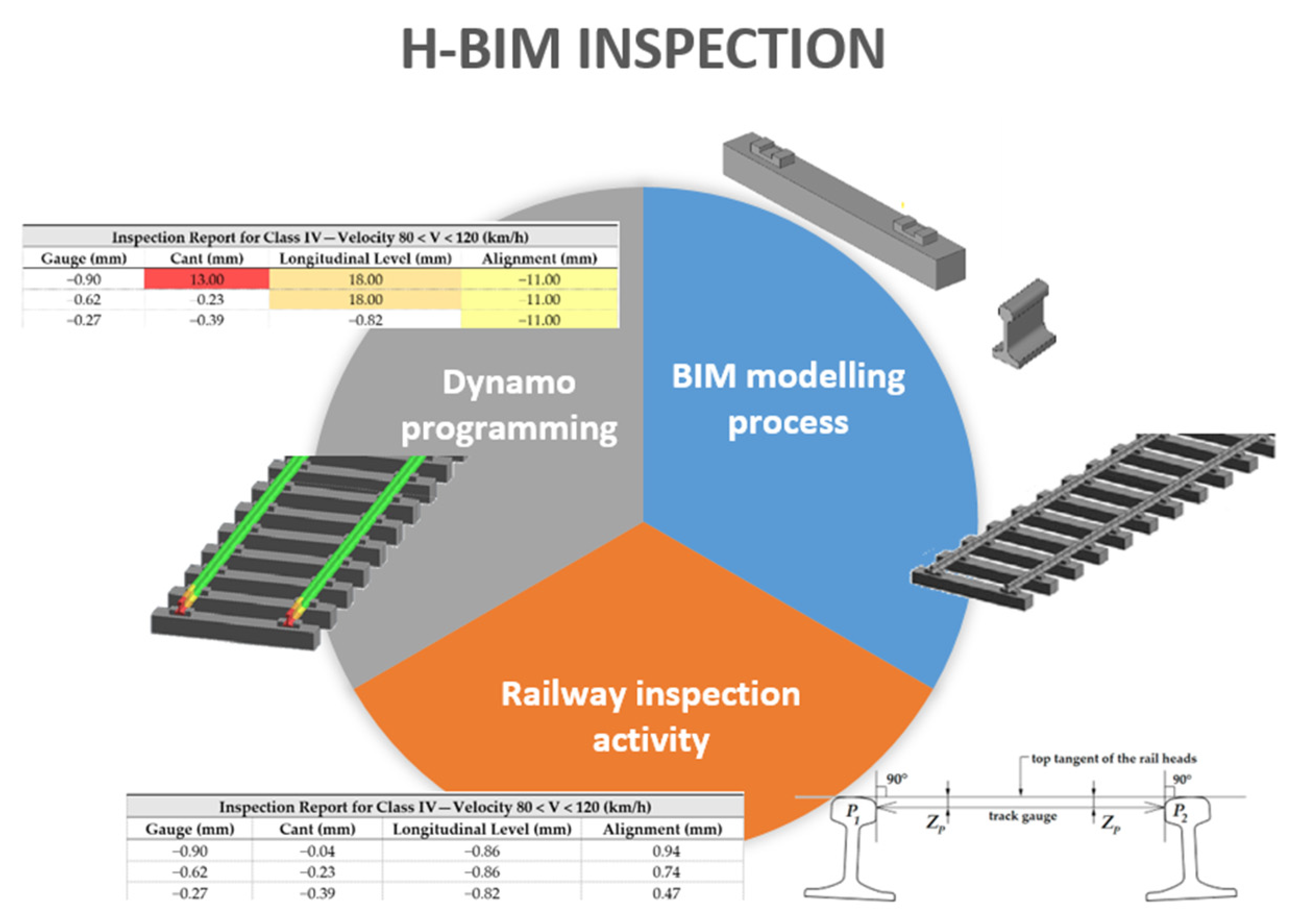

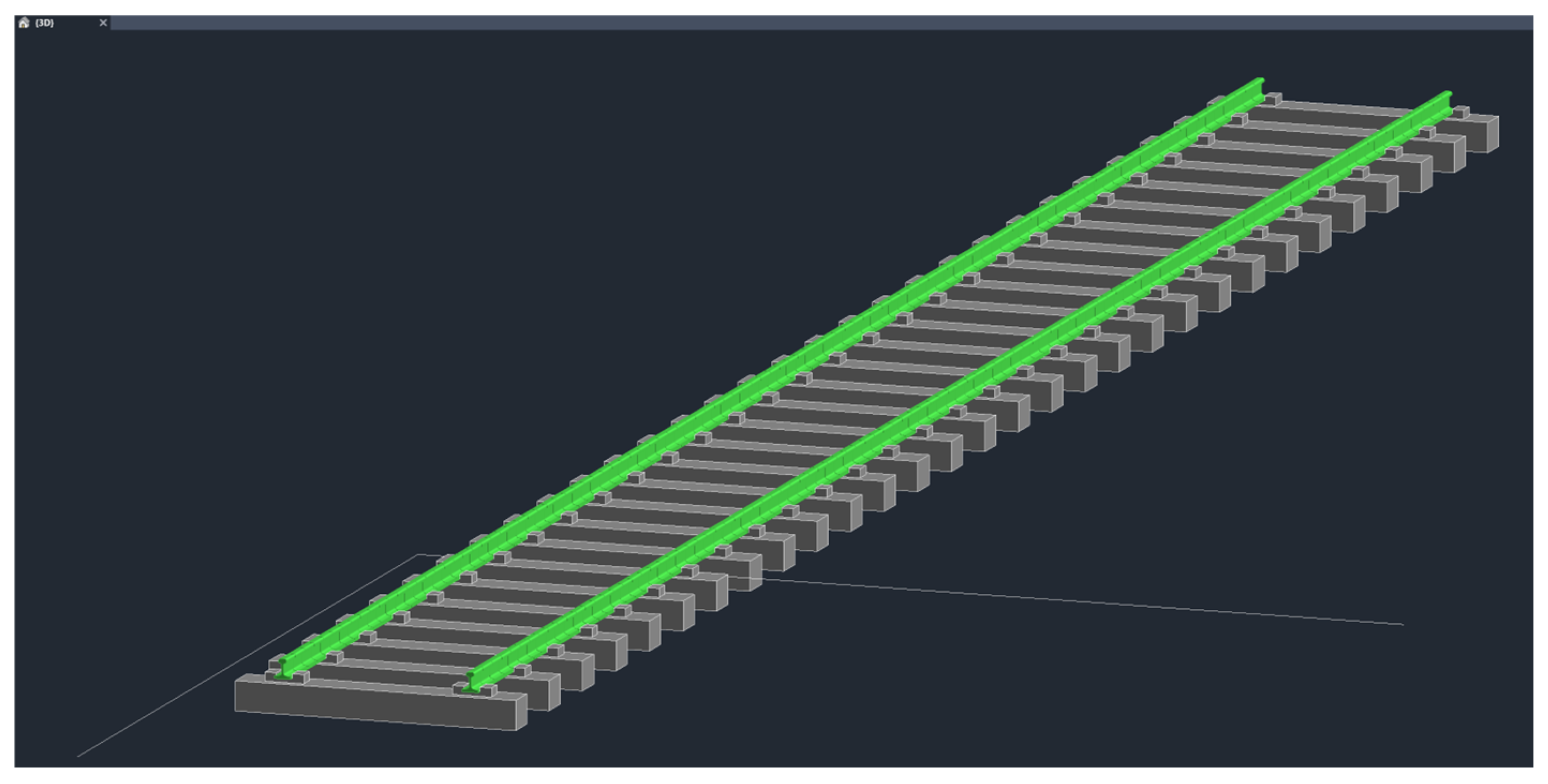

- BIM modeling process: The first stage refers to the BIM modeling process in order to conceive of an accurate representation of the infrastructure it analyzed. A BIM model is a comprehensive 3D digital representation of the infrastructure, imposing a high demand on geometric and semantic data. The railway track components were mainly related to rails, fastenings, sleepers and layers of ballast. The available BIM modeling software did not contain libraries of parametric objects related to the railway infrastructure. As such, the geometry, the material and the related position of the components were carefully analyzed, based on the literature. This bibliographic access supported the generation of the required new parametric objects, accurate geometry and physical proprieties of the associated materials. Although the advanced modeling systems lead to advantages well highlighted by practice, in the case of transportation infrastructure, a time-consuming effort was required in this step. A new set of parametric objects were then generated, allowing the creation of BIM models of railway infrastructure.

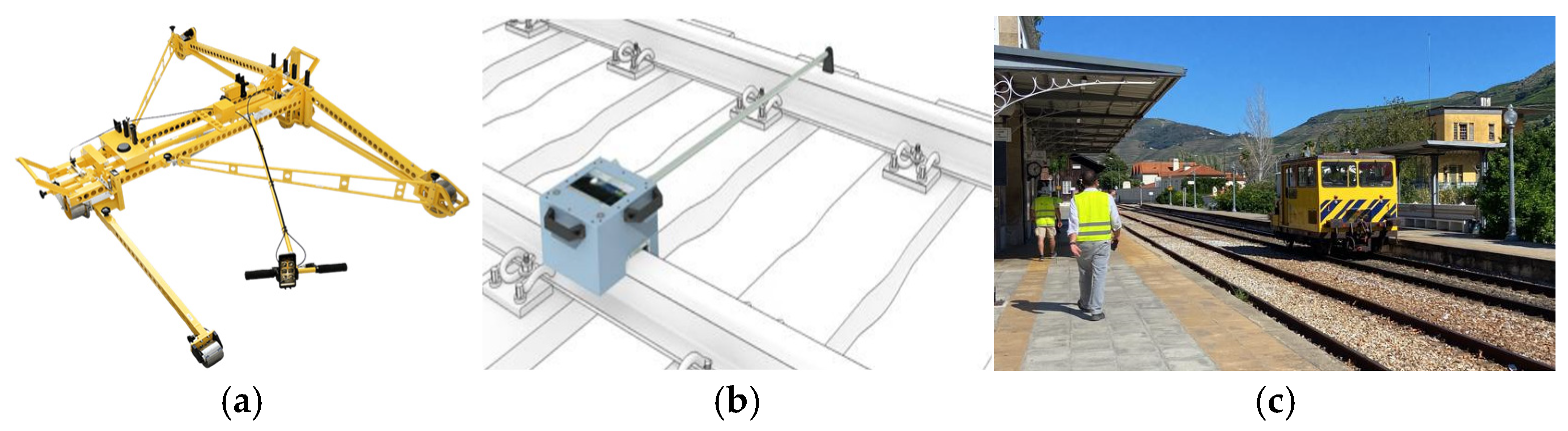

- Railway inspection activity: Next, the railway inspection activity was deeply studied, referring to the identification of the most frequent geometric irregularities and to the traditional inspection practices, considering mechanical, manual and semi-automatic processes. The railway track elements are susceptible to degradation caused by vehicle circulation characteristics (frequency of use, vehicle speed and volume of transported cargo), environmental aspects, infrastructure stability and the fact that the track is supported on a ballast layer subject to displacements in horizontal and vertical directions [24]. Infrequent or inadequate rail inspection plans can provoke negative consequences, and as such, a careful planning schedule of periodic inspections must be well defined and applied. During the inspection process, information about track conditions is collected, recorded and analyzed, and then recommendations can be made, and maintenance actions can be completed. Some of the parameters generally measured in a railway inspection include position, curvature, alignment of the track, smoothness and the cross level of the two rails. Through the utilization of track evaluation equipment, it is possible to determine the values of these parameters and compare them to the safety standards. In this way, it is possible to verify the presence and identification of anomalies, determine their causes and perform the needed repairs. As a case study, an illustrative segment of a real railway track was considered, supporting not just the modelling process, but also the collection of data inspection and the evaluation of the Dynamo script efficiency.

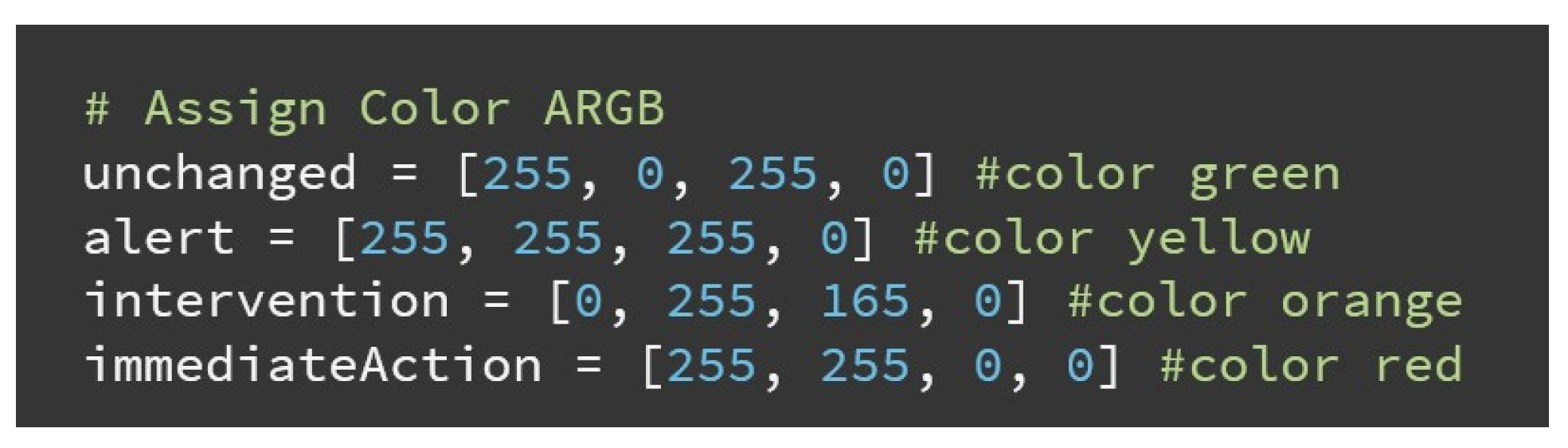

- Dynamo script development: With the aim of introducing BIM as an innovative contribution to railway infrastructure, and in order to contribute to improving the general digital transformation of the construction industry, a new approach was considered based on Dynamo programming. A Dynamo script was developed allowing users to insert the collected inspection data into the 3D BIM model, and to handle the database supporting the geometric incurrences evaluation and the emission of alerts regarding the level of severity of the detected anomalies. The script allowed for the analysis of the geometric railway inspections’ data, its application over the real case study and the emission of an alert visualized over the model components. Several aspects were considered, namely, the process of inserting data into the BIM model, the association of a new inspection parameter with the objects, the classification of the detected degradation level and the identification of the degree of alert associated with a color code, allowing users to be aware of the state of conservation of the infrastructure in the analyses.

3. BIM Modeling Process

3.1. Main Railway Track Components

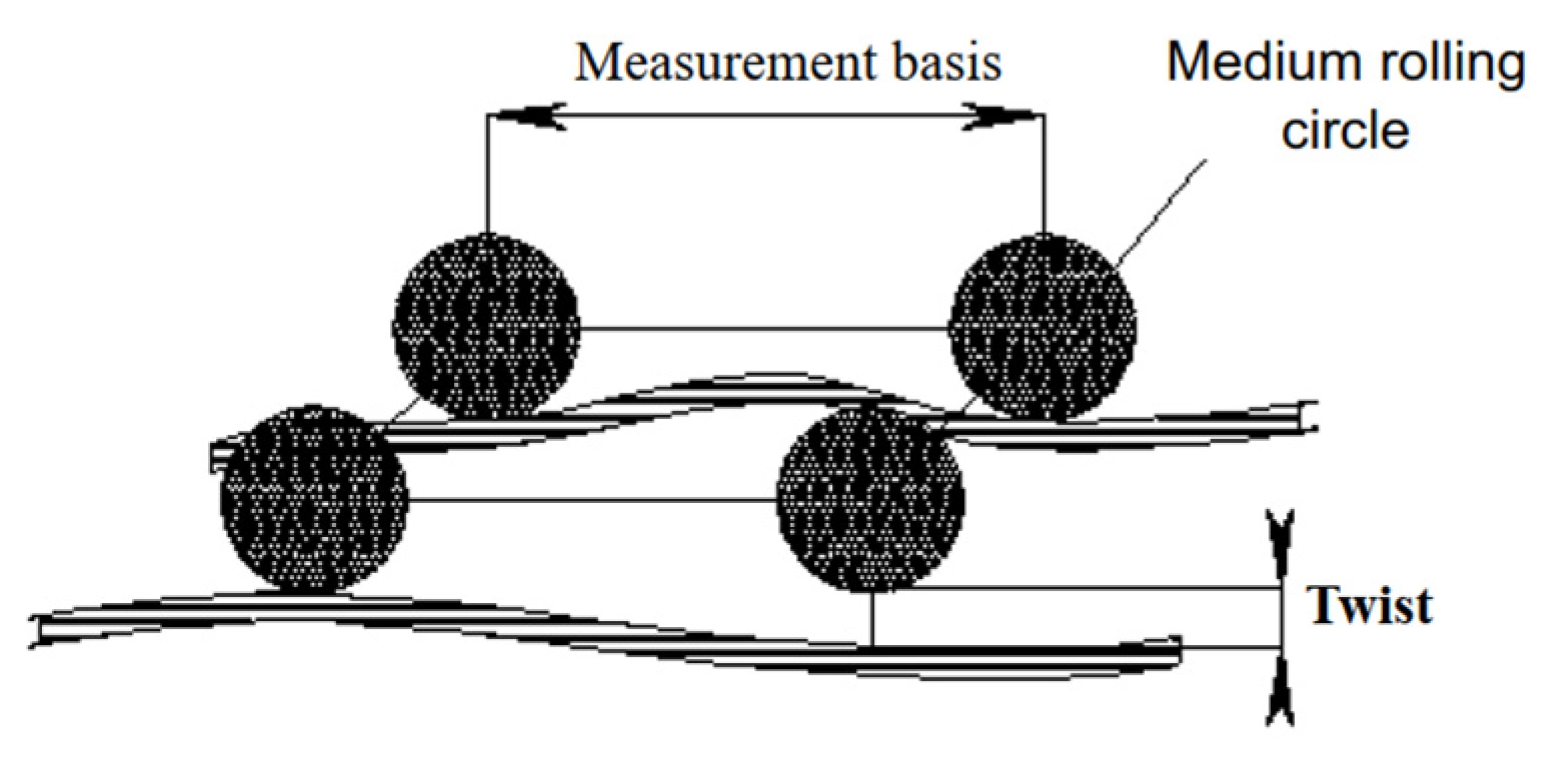

- Rail track geometry components: a set of parameters considered in the description of the geometrical characteristics of the rail elements, namely, track gauge, longitudinal level, alignment, cross level and twist.

- Track geometry quality: the valuation of the geometric deviation impact, in elevation and cross direction, considering the standard geometrical characteristics of each geometric parameter relevant to supporting the necessary safety concerning the drive quality.

- Gauge: the measurement made between the inside faces of the ride rail track head.

- Running table: the top surface of the rail.

- Running surface: the bent surface identified by the longitudinal displacement of a straight rail segment orthogonal to the middle line of the rail track and the peripheral running sides.

3.2. Railway Track BIM Model

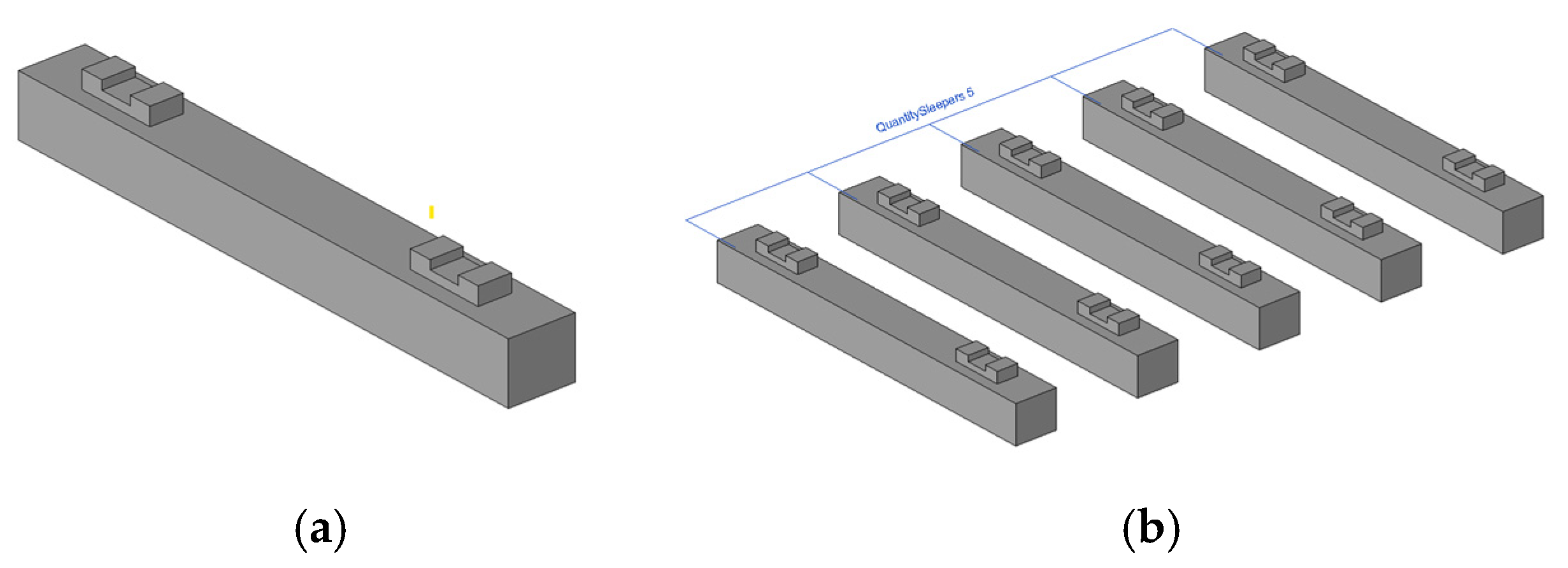

3.2.1. Sleepers and Fastening Families

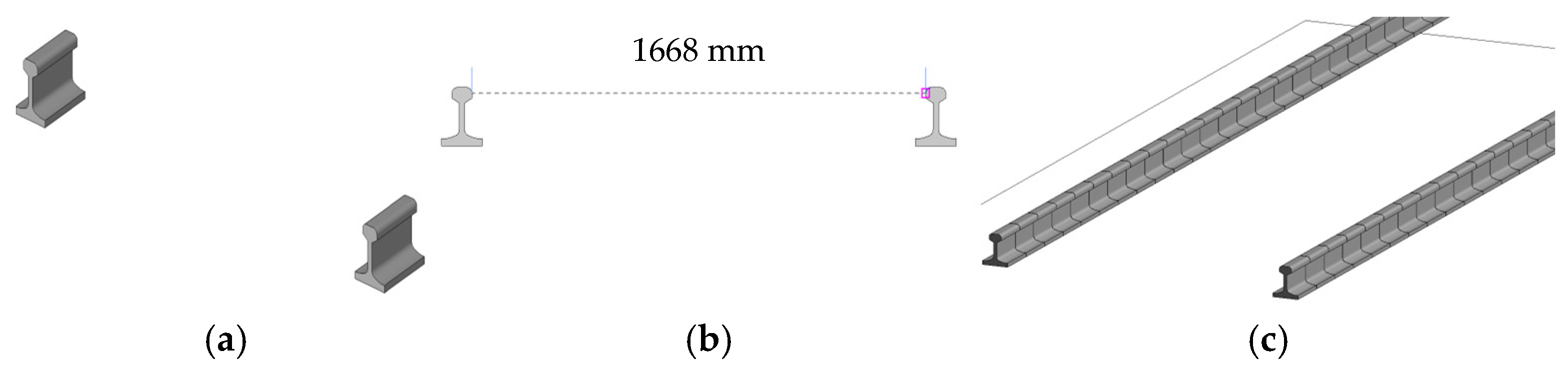

3.2.2. Rail Track Family

3.2.3. Composed Model

4. Railway Inspection Activity

4.1. Degradation of Railway Track Components

4.1.1. Track Gauge and Cant

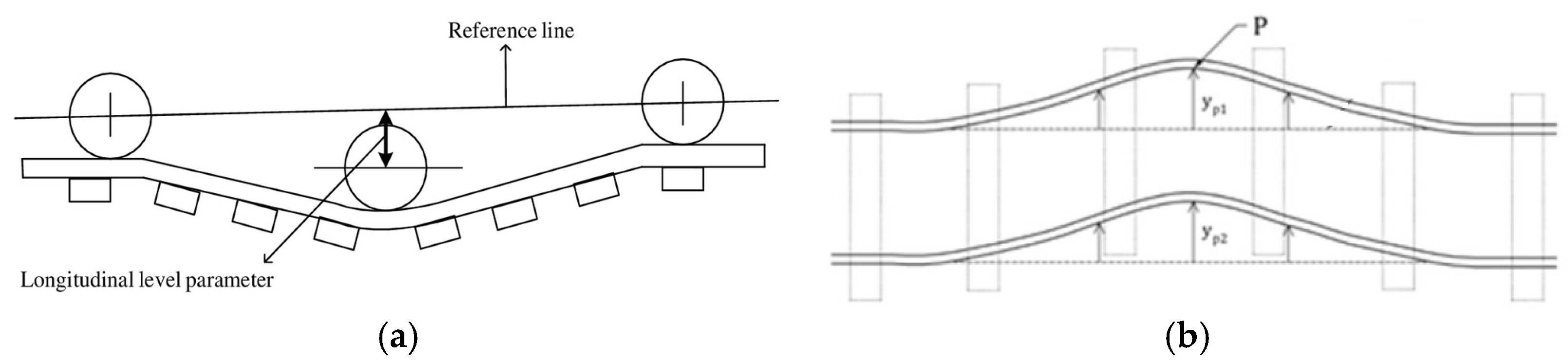

4.1.2. Longitudinal Level and Alignment

4.1.3. Twist

4.2. Rail Inspection Metodologies

4.2.1. EM 120 Inspection Vehicle

4.2.2. Data Evaluation and Diagnostic

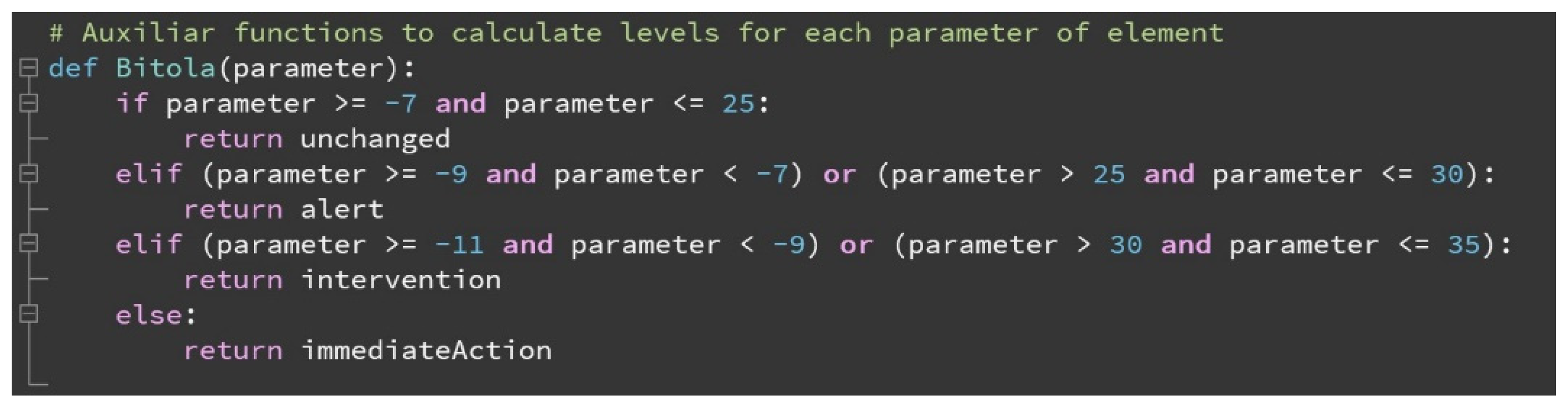

- The alert level refers to a parameter value that did not exceed the tolerance;

- The intervention level indicates that a value did not reach the tolerance;

- The immediate action alert is considered when a value exceeds the tolerance.

5. Dynamo Visual Programming

5.1. Development of the Dynamo Script

- As the available inspection data were organized in an Excel format, the Python node used to import the listed values into the model was the “Data.Import.Excel”;

- Next, the selection of the railway elements was realized, using the node “Family Types” related to the rail components included in the model;

- The imported data were then correctly associated with the respective parameter of each selected element, through the application of the “Element.SetParameterByName” and “List.GetItemAtIndex” nodes, allowing data to be connected by index;

- An important function required for the script was the inspection of the value evaluation requiring the analyses of the parametric values, confronted by the tolerance standard values, and the attribution of a category concerning the alert level. Figure 10 shows the routine program related to the value evaluation of a parameter and the identification of the respective alert level (unchanged, alert and intervention).

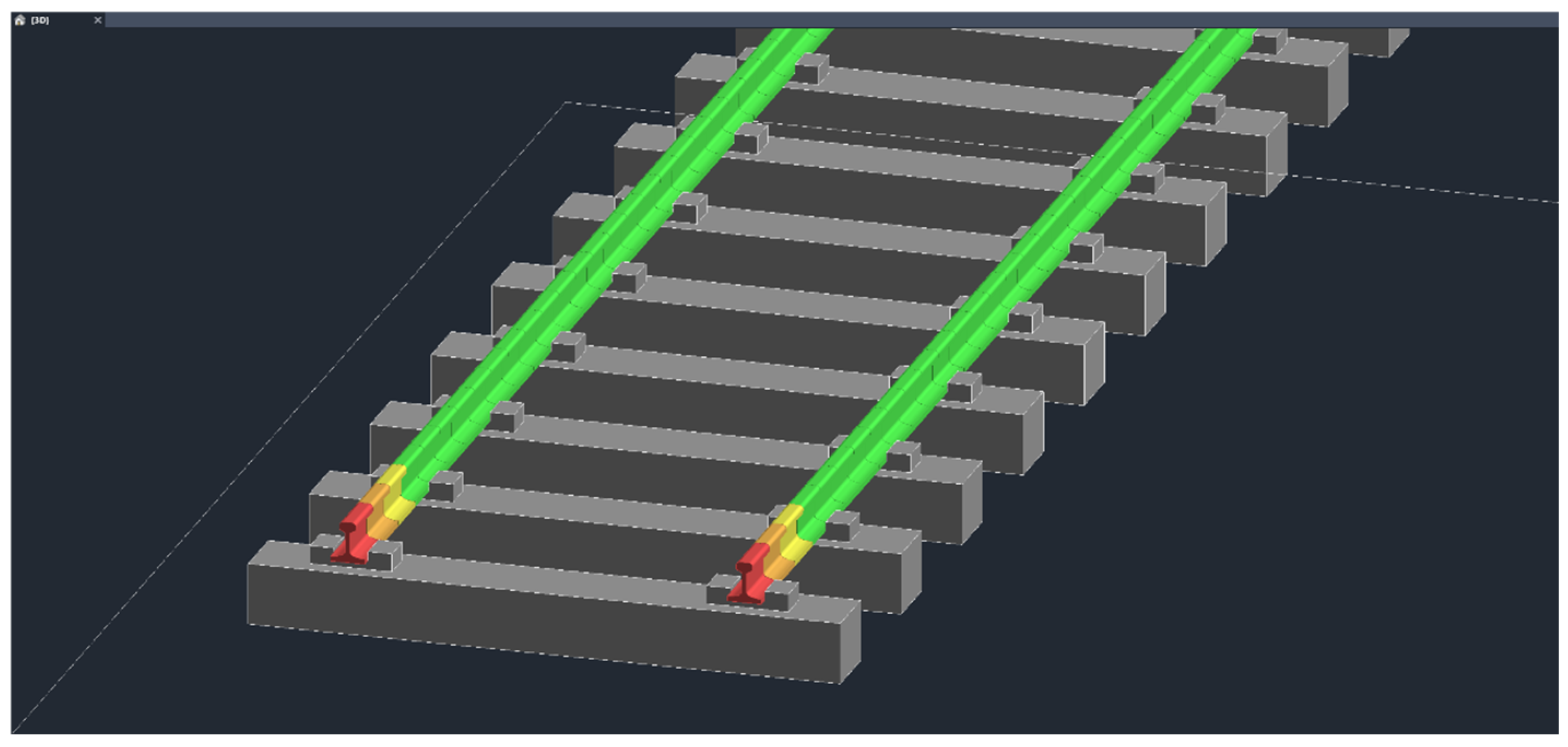

- The final step concerned the association of a color to each alert level, allowing users to visualize it over the rail I-BIM model. In Dynamo, the colors were assigned using Alpha, Red, Green and Blue (ARGB) inputs, where Alpha represented the color transparency and the others the basic colors. In the routine listed in Figure 11, each color was assigned to its respective alert level. The green color denoted no action required, yellow was the alert level, orange was the intervention level and red was an immediate action level.

5.2. Dynamo Script Application

5.3. Evaluation of the Dynamo Script Performance

6. Results and Discussion

- The present study demonstrates that the script application can identify alert levels, visualized over the model based in a coloring perception, supporting maintenance engineer work as it allows for the easy detection of the sections or rail segments with anomalies. From the analyses of the parametric values related to the irregular points, the inspection value or values that exceed the tolerance are then easily identified in the inspection report list. The access to the particular data responsible for the alert emission is also easily detected, by observing the data contained in the Excel file, related to each irregular rail section or segment. The engineer must then carry out the corresponding maintenance action, according to the geometry type and the detected level of gravity.

- The script can be used over other I-BIM models referring to the same type of rail components considered in the present case. For that, the modeling process of other rail projects should use the BIM parametric objects generated in the study. The type of elements and shape, defined as new parametric objects related to rail track geometry, should then be applied in the generation of a new rail project. In addition, as these new rail components present an accurate geometry and are associated with the parameters required in an inspection activity, the new I-BIM model can support the script application. To proceed with the generation of other railway models, the parametric objects representing the sleepers, the fastenings and the rail track segments of 25 cm long must first be inserted as new families in the new Revit project. This I-BIM model is then composed of all rail objects associated with the necessary inspection parameters needed to perform the script application. As such, the same type of results can be easily achieved in other railway projects.

- In addition, the script can be adjusted to other standards’ gauges, used in other countries, or to different components concerning fasteners or sleepers. The script was elaborated following the inspection data process mentioned in the national standard EN 13848:2022 [26] and tolerance guidelines of GR.IT.VIA.018 [49]. Both standard manuscripts were used to support the script application in national railway infrastructures. Other new families of parametric objects can be used to represent a national railway segment, supporting not just the generation of the respective I-BIM model but also the rail inspection activity. The script attends only to the national gauge standards. For other uses of the script, in a distinct gauge, the script must be adjusted for conformity.

7. Conclusions

7.1. BIM Benefits in Railways

- Using the Revit BIM modeling parametric system, an I-BIM railway track model was created, focused on the essential components required for the geometric quality assessment. New parametric families were defined for sleepers, fastenings and rails, considering not just an accurate geometry but also the addition of new parameters related to the inspection work;

- A Dynamo script was developed allowing users to transfer the collected inspection data into the railway model; to associate the data to the respective parameter of the objects, used in the modeling process; and to perform color coding according to the alert level standards;

- The application of the new script, as an innovative approach, allows engineers to enhance optimized inspection planning, with adequate and accurate maintenance prevention, efficient streamlining workflow and a global time-saving measure.

7.2. Study Limtations and Future Directions

- An adequate computing skill by the user is required. This capacity becomes increasingly important for civil engineers because learning visual programming in Dynamo and text-based syntax in Python is essential for tackling complex scenarios;

- The modeled objects and data collected only refer to a selected set of geometric elements and irregularities. The layers of ballast and sub-ballast are not considered. Similar research work can be made following the present procedure, allowing users to conduct a larger inspection over other rail components;

- Future development areas include expanding the analysis to include curved alignments, integrating maintenance planning with all necessary parameters to design more complete manner quality control inspection tests and developing new parametric families tailored to railway infrastructures in order to facilitate the modeling process of more comprehensive and realistic infrastructure projects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, T.; Chen, H.-M. Integration of building information modeling and project management in construction project life cycle. Autom. Constr. 2023, 150, 104832. [Google Scholar] [CrossRef]

- Omrany, H.; Ghaffarianhoseini, A.; Chang, R.; Ghaffarianhoseini, A.; Rahimian, F.P. Applications of Building information modelling in the early design stage of high-rise buildings. Autom. Constr. 2023, 152, 104934. [Google Scholar] [CrossRef]

- Zhang, A.; Zhou, X.; Wang, F.; Yang, J. A multi-objective optimization and display framework for time-cost-carbon emissions in building materialization phase based on nD BIM concept. J. Build. Eng. 2025, 103, 111993. [Google Scholar] [CrossRef]

- Khorchi, A.; Boton, C. An OpenBIM-based 4D approach to support coordination meetings in virtual reality environments. J. Build. Eng. 2024, 85, 108647. [Google Scholar] [CrossRef]

- Sampaio, A.Z.; Domingos, I.M.; Gomes, A.M. The 7D BIM model used in the maintenance of buildings. In Advances in Sustainability Science and Technology; Semião, J.F.L.C., Sousa, N.M.S., Cruz, R.M.S., Prates, G.N.D., Eds.; INCREaSE 2023; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Alzara, M.; Yosri, A.; Alruwaili, A.; Cuce, E.; Eldin, S.; Ehab, A. Dynamo script and a BIM-based process for measuring embodied carbon in buildings during the design phase. Int. J. Low-Carbon Technol. 2023, 18, 943–955. [Google Scholar] [CrossRef]

- Rocha, G.; Mateus, L. Using Dynamo for automatic reconstruction of BIM elements from point clouds. Appl. Sci. 2024, 14, 4078. [Google Scholar] [CrossRef]

- Sampaio, A.Z.; Domingos, I.M.; Gomes, A.M. BIM teaching and programming in dynamo applied in the maintenance of buildings. In Proceedings of the International Conference on Computer Graphics, Visualization, Computer Vision and Image Processing, Lisbon, Portugal, 20–22 July 2022. [Google Scholar]

- Moreira, N. Application of BIM Methodology to Railway Monitoring. Master’s Thesis, University of Lisbon, Lisbon, Portugal, 2024. Available online: https://fenix.tecnico.ulisboa.pt/cursos/mec21/dissertacao/1128253548923753 (accessed on 1 May 2025).

- Sampaio, A.Z.; Figueiras, J.; Gomes, A.M. The BIM methodology applied to the design of box-section viaducts (in Portuguese). In Proceedings of the National Meeting Structural Concrete, Porto, Portugal, 13–15 November 2024; Available online: https://www.fe.up.pt/be2024/sobre-o-be2024/ (accessed on 1 May 2025).

- Sampaio, A.Z.; Tomé, J.; Gomes, A.M. Heritage Building Information Modelling Implementation First Steps Applied in a Castle Building: Historic Evolution Identity, Data Collection and Stratigraphic Modelling. Heritage 2023, 6, 338. [Google Scholar] [CrossRef]

- Sampaio, A.Z. BIM multitask project manager: Responsibility, organization and interoperability. Procedia Comput. Sci. 2024, 239, 58–65. [Google Scholar] [CrossRef]

- Pasetto, M.; Giordano, A.; Borin, P.; Giacomello, G. Integrated railway design using Infrastructure-Building Information Modeling. The case study of the port of Venice. Transp. Res. Procedia 2020, 45, 850–857. [Google Scholar] [CrossRef]

- Rempelos, G.; Ognibene, G.; Le Pen, L.; Blainey, S.; Preston, J.; Powrie, W. Railway track deterioration models: A review of the state of the art. Transp. Geotech. 2024, 49, 101377. [Google Scholar] [CrossRef]

- Vilutienė, T.; Šarkiene, E.; Šarka, V.; Kiaulakis, A. BIM application in infrastructure projects. Balt. J. Road Bridge Eng. 2020, 15, 74–92. [Google Scholar] [CrossRef]

- Melo, A.L.; Kaewunruen, S.; Papaelias, M.; Bernucci, L.L.B.; Motta, R. Methods to monitor and evaluate the deterioration of track and its components in a railway in-service: A systemic review. Front. Built. Environ. 2020, 6, 118. [Google Scholar] [CrossRef]

- Soleimanmeigouni, I.; Ahmadi, A.; Kumar, U. Track geometry degradation and maintenance modelling: A review. Proc. Inst. Mech. Eng. Part F 2016, 232, 73–102. [Google Scholar] [CrossRef]

- Wu, J.; Peng, L.; Sheng, W.; Changxin, C.; Wang, J.S. Track gauge measurement based on model matching using UAV image. Autom. Constr. 2023, 155, 105070. [Google Scholar] [CrossRef]

- Ferreno, D.; Sainz-Aja, J.A.; Carrascal, I.A.; Cuartas, M.J.; Pombo, J.A.; Casado, S.D. Prediction of mechanical properties of rail pads under in-service conditions through machine. learning algorithms. Adv. Eng. Softw 2021, 151, 102927. [Google Scholar] [CrossRef]

- Chellaswamy, C.; Krishnasamy, M.; Balaji, L.; Dhanalakshmi, A.; Ramesh, R. Optimized railway track health monitoring system based on dynamic differential evolution algorithm. Measurement 2020, 152, 107332. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, K.; Wang, Y.; Shen, Y.; Hu, H. Rail crack detection using acoustic emission technique by joint optimization noise clustering and time window feature detection. Appl. Acoust. 2020, 160, 107141–107153. [Google Scholar] [CrossRef]

- Chakraborty, T.; Nurain, N.; Tairin, S.; Khan, T.A.; Noor, J.; Islam, M.R.; Al Islam, A.B.M.A. A new network paradigm for low-cost and lightweight real-time communication between train and rail track to detect missing and faulty rail blocks. J. Netw. Comput. Appl. 2019, 131, 40–54. [Google Scholar] [CrossRef]

- Neves, J.; Sampaio, A.Z.; Vilela, M. Analysis of BIM Implementation on Railway Infrastructures through an application to rail track rehabilitation and inspection. In Advances in Transportation Geotechnics IV; Tutumluer, E., Nazarian, S., Al-Qadi, I., Qamhia, I.I., Eds.; Serie: Lecture Notes in Civil, Engineering; Springer Nature Switzerland AG: Berlin/Heidelberg, Germany, 2022; Volume 166, pp. 665–675. [Google Scholar] [CrossRef]

- Tomas, L. Railway infrastructure maintenance: A survey of planning problems and conducted research. Transp. Res. Procedia 2015, 10, 574–583. [Google Scholar] [CrossRef]

- National Organization of Transport Infrastructures of Portugal. 2025. Available online: https://www.infraestruturasdeportugal.pt/en (accessed on 1 May 2025).

- EN 13848:2022; Railway Applications–Track–Track Geometry quality–Part 1: Characterization of Track Geometry. ISO: Geneva, Switzerland, 2022. Available online: https://www.en-standard.eu/une-en-13848-1-2020-railway-applications-track-track-geometry-quality-part-1-characterization-of-track-geometry/?srsltid=AfmBOopKyVom0HoTiiXBomhpPROOeQ8Nja8o5nexOUioDA21wFI6GeD5 (accessed on 1 May 2025).

- Revit Autodesk. 2025. Available online: https://www.autodesk.com/products/revit/overview (accessed on 1 May 2025).

- Han, L.; Liao, Y.; Wang, H.; Zhang, H. Analysis and prediction of railway track longitudinal level using multiple machine learning methods. Meas. Sci. Technol. 2024, 35, 024001. Available online: https://iopscience.iop.org/article/10.1088/1361-6501/ad060a (accessed on 1 May 2025). [CrossRef]

- Elkhoury, N.; Hitihamillage, L.; Moridpour, S.; Robert, D. Degradation prediction of rail tracks: A review of the existing literature. Open Transp. J. 2018, 12, 88–104. [Google Scholar] [CrossRef]

- Loidolt, M.; Weilguny, R.; Marschnig, S. Impact of rail irregularities on longitudinal level deterioration based on deconvoluted data. Civ. Eng. Infrastruct. J. 2024, 9, 162. [Google Scholar] [CrossRef]

- Li, Q.; Zhong, Z.; Liang, Z.; Liang, Y. Rail inspection meets big data: Methods and trends. In Proceedings of the International Conference on Network-Based Information Systems, Taipei, Taiwan, 2–4 September 2015; pp. 302–308. [Google Scholar] [CrossRef]

- Fischer, S.; Németh, D.; Horváth, H. Investigation of the track gauge in curved sections, considering hungarian railway lines. Infras. 2023, 8, 69. [Google Scholar] [CrossRef]

- Tepedino, T.; Ribeiro, M.; Tressia, G. Effect of rail cant on stress distribution. World J. Adv. Eng. Technol. Sci. 2023, 9, 372–386. [Google Scholar] [CrossRef]

- Valehrach, J.; Riha, T.; Dušek, E. Cant excess and cant deficiency evaluation in relation to train speed. Acta Polytech. CTU Proc. 2017, 11, 80–85. Available online: https://ojs.cvut.cz/ojs/index.php/APP/article/view/4460/4335 (accessed on 1 May 2025). [CrossRef][Green Version]

- Grossoni, I.; Powrie, W.; Zervos, A.; Bezin, Y.; Le Pen, L. Modelling railway ballasted track settlement in vehicle-track interaction analysis. Transp. Geotech. 2021, 26, 100433. [Google Scholar] [CrossRef]

- Varandas, J.; Silva, R.; Silva, M.; Lopes, N.; Holscher, P. The impact of rail corrugation on the degradation of the ballast. In Proceedings of the International Conference on Railway Technology: Research, Development and Maintenance, Las Palmas de Gran Canaria, Spain, 18–20 April 2012. [Google Scholar] [CrossRef]

- Weston, P.; Roberts, C.; Yeo, G.; Stewart, E. Perspectives on railway track geometry condition monitoring from in-service railway vehicles’. Veh. Syst. Dyn. 2015, 53, 1063–1091. [Google Scholar] [CrossRef]

- Alqatawna, A.; Sánchez-Cambronero, S.; Gallego, I.; López-Morales, J.M. A graphical method for designing the horizontal alignment and the cant in high-speed railway lines aimed at mixed-speed traffic. Sustainability 2022, 14, 8377. [Google Scholar] [CrossRef]

- Mohammadzadeh, S.; Heydari, H.; Karimi, M.; Mosleh, A. Correlation analysis of railway track alignment and ballast stiffness: Comparing frequency-based and machine learning algorithms. Algorithms 2024, 17, 372. [Google Scholar] [CrossRef]

- Gong, W.; Akbar, M.F.; Jawad, G.N.; Mohamed, M.F.P.; Wahab, M.N.A. Nondestructive testing technologies for rail inspection: A review. Coatings 2022, 12, 1790. [Google Scholar] [CrossRef]

- Trolley KRAB. Available online: https://kzv.cz/wp-content/uploads/2021/10/NCI-EN.pdf (accessed on 1 May 2025).

- Laser Rail Inspection System. Available online: https://www.pavemetrics.com/applications/rail-inspection/laser-rail-inspection-system/ (accessed on 1 May 2025).

- Iris 320 Railway Inspection Vehicle. Available online: https://youngtransportpro.com/wp-content/uploads/2021/08/20_iris320.pdf (accessed on 1 May 2025).

- Wang, H.; Berkers, J.; Hurk, N.; Layegh, N.F. Study of loaded versus unloaded measurements in railway track inspection. Measurement 2021, 169, 108556. [Google Scholar] [CrossRef]

- Ye, Y.; Li, H.; Wang, Q.; Li, F.; Yi, C.; Peng, X.; Huang, C.; Zeng, J. Fault diagnosis of railway wheelsets: A review. Measurement 2025, 242 Pt E, 116169. [Google Scholar] [CrossRef]

- Rahmat Rabi, R.; Monti, G. Genetic Algorithm-Based Model Updating in a Real-Time Digital Twin for Steel Bridge Monitoring. Appl. Sci. 2025, 15, 4074. [Google Scholar] [CrossRef]

- Rabi, R.R.; Vailati, M.; Monti, G. Effectiveness of Vibration-Based Techniques for Damage Localization and Lifetime Prediction in Structural Health Monitoring of Bridges: A Comprehensive Review. Buildings 2024, 14, 1183. [Google Scholar] [CrossRef]

- Mei, G.; Chen, G. Slip of wheels on rails: The root cause for rail undulant wear. Wear 2023, 523, 204727. [Google Scholar] [CrossRef]

- GR.IT.VIA.018 Tolerance Geometric Track Parameters (in Portuguese). Available online: https://www.infraestruturasdeportugal.pt/sites/default/files/inline-files/NormativosInternos.pdf (accessed on 1 May 2025).

- Dynamo Version for Revit. Available online: https://dynamobim.org/ (accessed on 1 May 2025).

| Class IV—Velocity 80 < V < 120 (km/h) | |||

|---|---|---|---|

| Gauge (mm) | Cant (mm) | Longitudinal Level (mm) | Alignment (mm) |

| −7/+25 | −12/+12 | −13/+13 | −10/+10 |

| Inspection Report for Class IV—Velocity 80 < V < 120 (km/h) | |||

|---|---|---|---|

| Gauge (mm) | Cant (mm) | Longitudinal Level (mm) | Alignment (mm) |

| −0.90 | −0.04 | −0.86 | 0.94 |

| −0.62 | −0.23 | −0.86 | 0.74 |

| −0.27 | −0.39 | −0.82 | 0.47 |

| −0.23 | −0.39 | −0.70 | 0.12 |

| 0.00 | −0.43 | −0.62 | −0.31 |

| 0.08 | −0.43 | −0.51 | −0.86 |

| −0.27 | −0.39 | −0.39 | −1.29 |

| −0.66 | −0.20 | −0.23 | −0.52 |

| −1.02 | −0.04 | −0.08 | −0.56 |

| −1.21 | −0.27 | 0.04 | −0.52 |

| Inspection Report for Class IV—Velocity 80 < V < 120 (km/h) | |||

|---|---|---|---|

| Gauge (mm) | Cant (mm) | Longitudinal Level (mm) | Alignment (mm) |

| −0.90 | 13.00 | 18.00 | −11.00 |

| −0.62 | −0.23 | 18.00 | −11.00 |

| −0.27 | −0.39 | −0.82 | −11.00 |

| −0.23 | −0.39 | −0.70 | 0.12 |

| 0.00 | −0.43 | −0.62 | −0.31 |

| 0.08 | −0.43 | −0.51 | −0.86 |

| −0.27 | −0.39 | −0.39 | −1.29 |

| −0.66 | −0.20 | −0.23 | −0.52 |

| −1.02 | −0.04 | −0.08 | −0.56 |

| −1.21 | −0.27 | 0.04 | −0.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sampaio, Z.; Moreira, N.; Neves, J. I-BIM Applied in Railway Geometric Inspection Activity: Diagnostic and Alert. Appl. Sci. 2025, 15, 5733. https://doi.org/10.3390/app15105733

Sampaio Z, Moreira N, Neves J. I-BIM Applied in Railway Geometric Inspection Activity: Diagnostic and Alert. Applied Sciences. 2025; 15(10):5733. https://doi.org/10.3390/app15105733

Chicago/Turabian StyleSampaio, Zita, Nuno Moreira, and José Neves. 2025. "I-BIM Applied in Railway Geometric Inspection Activity: Diagnostic and Alert" Applied Sciences 15, no. 10: 5733. https://doi.org/10.3390/app15105733

APA StyleSampaio, Z., Moreira, N., & Neves, J. (2025). I-BIM Applied in Railway Geometric Inspection Activity: Diagnostic and Alert. Applied Sciences, 15(10), 5733. https://doi.org/10.3390/app15105733