1. Introduction

Data centers, serving as the core infrastructure of the digital industry, constitute a critical foundation for digital economic development [

1]. With the accelerated advancement of emerging technology sectors, including 5G networks, cloud computing, and big data, data center scales continue to expand significantly. Projections indicate that by the end of 2025, China’s data center rack inventory will grow to 14 million racks, accompanied by an electricity consumption reaching 120 billion kWh [

2].

The safe and continuous operation of data centers relies on cooling systems to remove heat from server rooms. Studies indicate that cooling systems account for up to 40% of a data center’s total energy consumption [

3]. In recent years, new technologies like liquid cooling and natural cooling have been increasingly adopted to address the high energy consumption of cooling systems, owing to their significant energy-saving potential [

4,

5,

6]. However, traditional air cooling methods remain dominant in existing data center facilities. The fundamental requirement for a 24/7 uninterrupted operation imposes stringent reliability demands on cooling systems. Furthermore, the implementation of new technologies is constrained by local environmental conditions and substantial initial investment costs for large-scale retrofits. Consequently, energy efficiency improvements in existing data centers continue to focus primarily on optimizing current airflow management systems [

7]. These advanced cooling technologies are currently more suitable for newly constructed large-scale data center projects.

The extended cooling path in air-cooled systems often leads to airflow distribution issues, including uneven air supply, imbalance between cooling supply and demand, and cooling air loss, all of which reduce the energy efficiency of air conditioning systems [

8,

9]. Furthermore, as power density per rack continues to rise, the mixed deployment of various high-power IT equipment results in uneven heat load distribution both between and within racks. Under conventional air supply methods, insufficient cooling in high heat flux areas leads to elevated ambient temperatures, jeopardizing data center operational safety [

10].

Operations personnel typically address local hotspots by either lowering supply air temperatures or increasing airflow rates, which further escalates cooling system energy consumption [

11]. Therefore, optimizing airflow distribution to maximize cooling effectiveness is of paramount importance for ensuring both energy efficiency and operational safety in data centers [

12].

Research on data center airflow optimization has primarily focused on three key aspects: improving airflow distribution uniformity, balancing airflow supply and demand, and reducing airflow losses [

13]. To enhance airflow distribution uniformity, researchers have commonly employed strategies such as optimizing air conditioning unit layouts [

14] and adjusting plenum geometric parameters [

15,

16,

17]. Numerical simulations conducted by Nada S A demonstrated that arranging air conditioning units perpendicular to server rows significantly improves airflow uniformity through perforated floors while reducing hot air recirculation at the end racks and cold air bypassing at the middle racks [

18]. Zhang M’s research further identified optimal plenum height ranges for different configurations: 1.0–1.2 m for open cold aisle designs, 0.6–0.8 m for cold aisle containment systems, and 0.4–0.6 m for hot aisle containment systems [

19]. Some studies have proposed installing baffles in plenums to address insufficient airflow near air conditioning units [

20], though these solutions introduce spatial constraints, increased airflow resistance, and potential maintenance challenges that limit their practical application.

In addressing the airflow supply–demand balance, Mohsenian G developed variable airflow panels installed beneath perforated floors that utilize pressure differentials between hot and cold aisles to regulate cooling delivery to different zones [

21]. Wan J advanced this approach by creating active perforated floors with auxiliary fans that adjust airflow through variable fan speeds, enabling precise cooling distribution that improves server inlet temperature uniformity [

22]. However, subsequent research has shown that the additional energy consumption from these active systems may outweigh the energy savings from chillers, while potentially creating vortices in upper rack regions that exacerbate hotspot formation [

23].

Containment solutions, including cold aisle enclosure [

24], rack airflow guides, and blanking panels [

25], have proven effective in reducing airflow losses and optimizing temperature distribution. Sundaralingam V’s comprehensive testing demonstrated that side containment provides superior temperature uniformity under adequate airflow conditions, though partial containment performs worse than open configurations during airflow shortages [

26]. Yuan X’s investigation of adjustable flexible baffles installed on rack doors and server exhaust areas confirmed their effectiveness in improving airflow distribution and reducing hotspot temperatures [

27,

28]. However, the implementation of airflow guides often compromises data center aesthetics and occupies valuable rack space needed for cabling, making blanking panels in unoccupied rack spaces the more widely adopted solution in practice [

11].

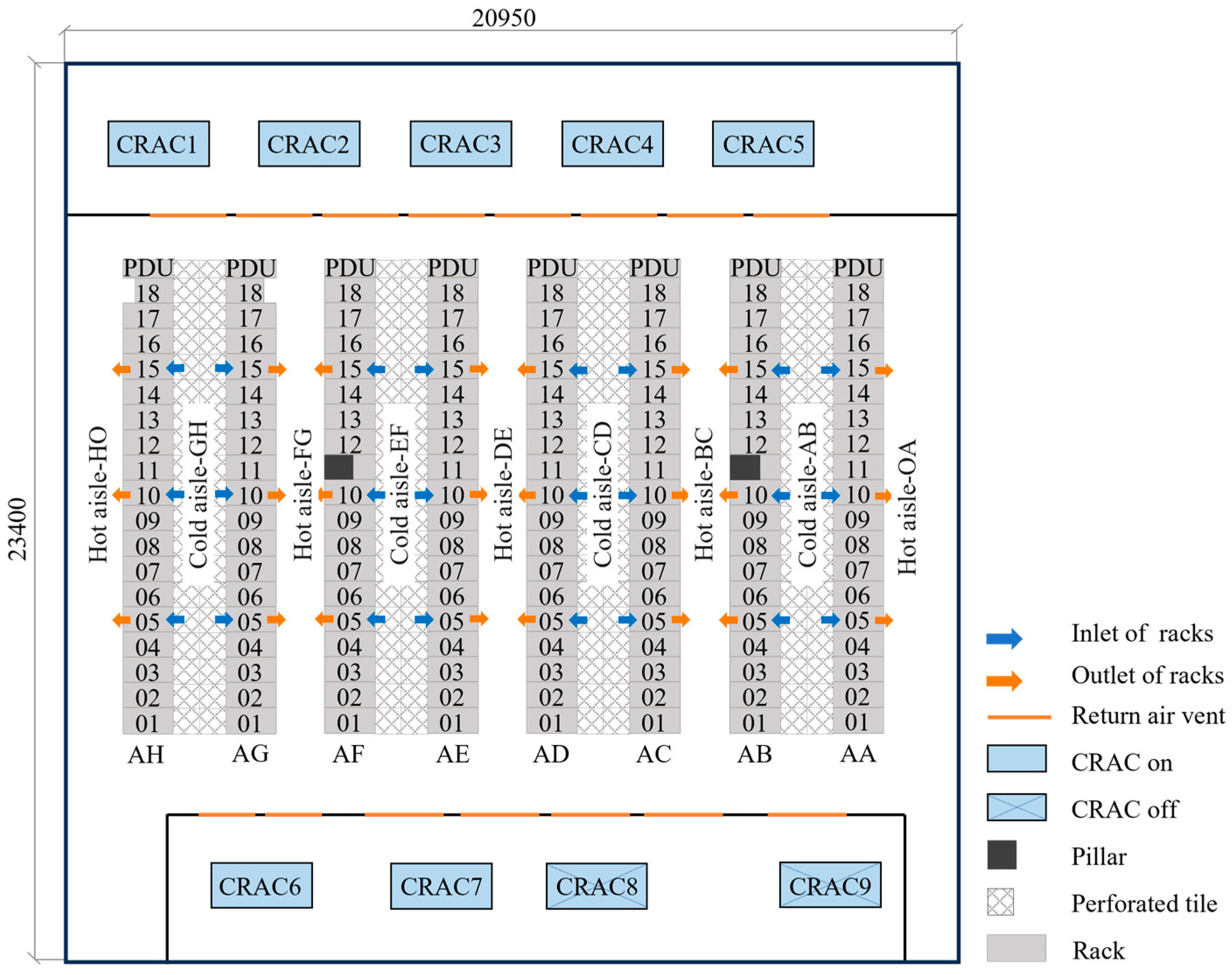

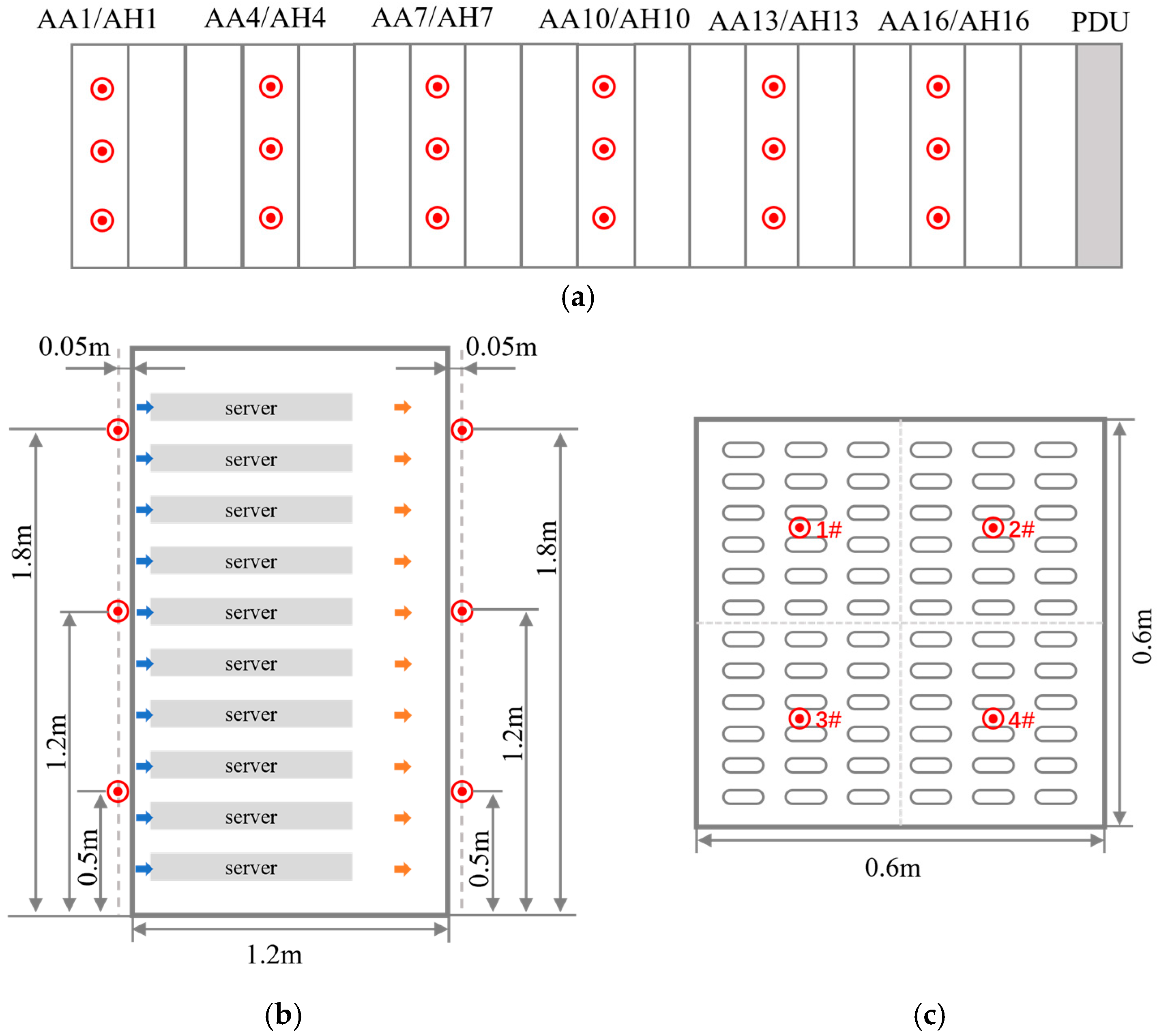

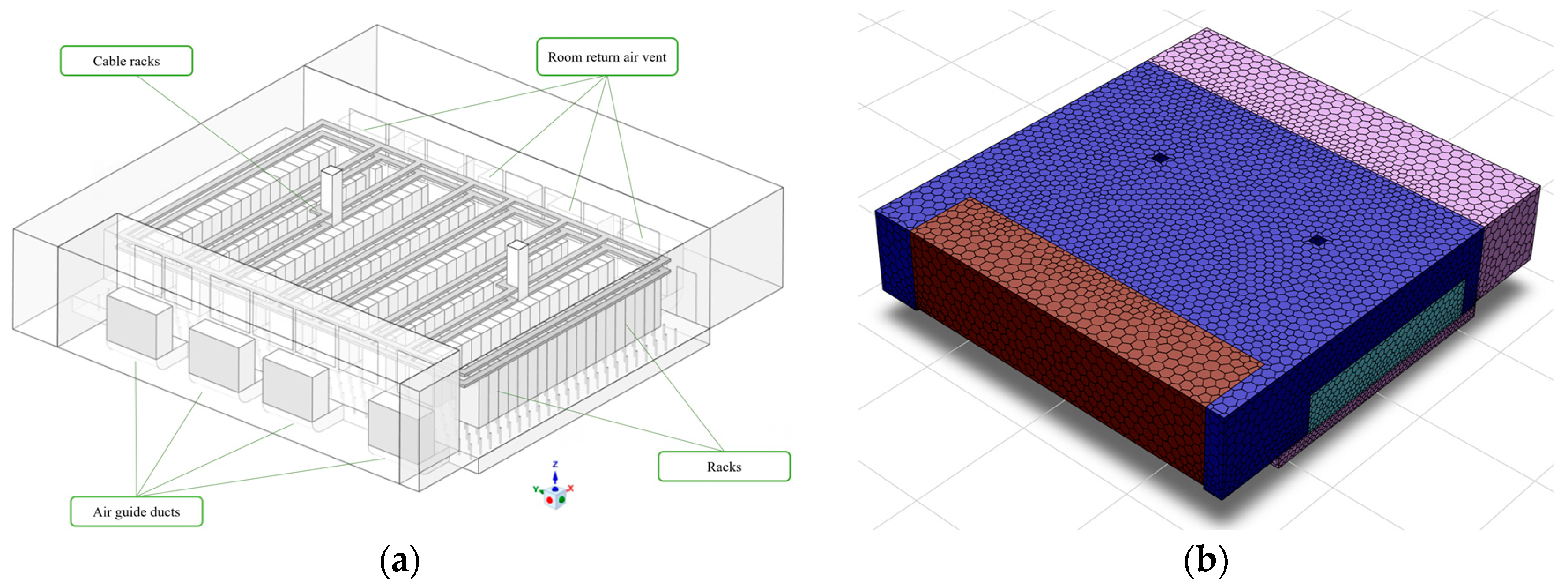

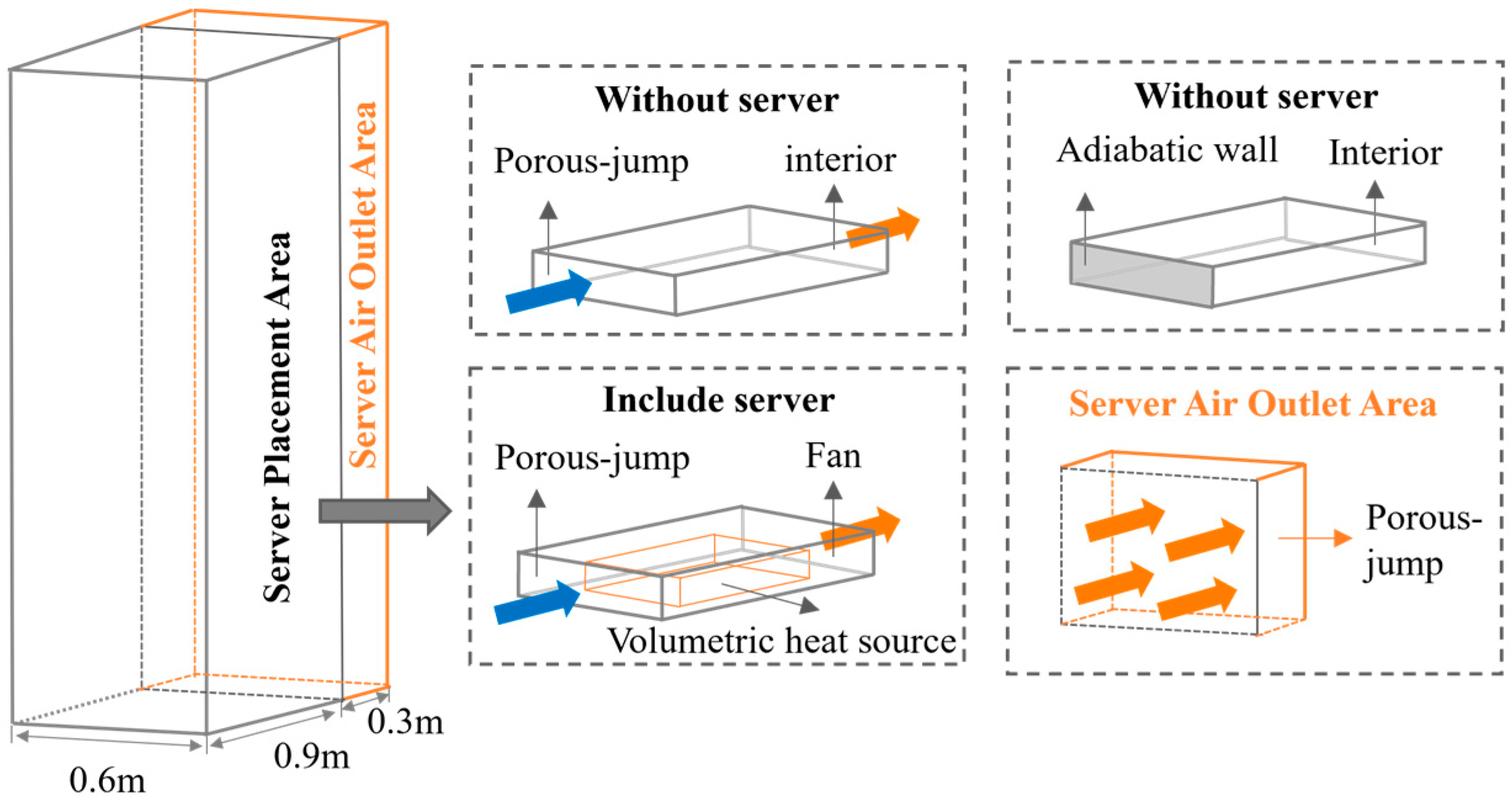

Numerous studies have been conducted to optimize data center airflow and improve thermal environments through experimental testing and numerical simulations. However, most research has focused on single optimization strategies, while combined approaches have received less attention. In operational scenarios, the thermal environment is influenced by multiple factors, including room layout, air conditioning air-flow patterns, server distribution, and heat density. To maintain continuous and stable operation, certain optimization methods prove difficult to implement, such as cooling system modifications or air conditioner layout adjustments. Therefore, ongoing research is still required for thermal environment optimization in existing data centers. A bidirectional airflow server room located in a hot-summer/warm-winter climate zone was selected for investigation in this study. CFD numerical simulations were combined with field measurements to establish a computational model based on actual heat load distributions. The thermal effects of rack blanking panels and cold aisle containment were systematically examined, including both individual implementations and combined strategies. This analysis was conducted to mitigate potential hotspot formation that could compromise equipment reliability. The obtained results provide operational optimization references for energy efficiency improvements in existing data center facilities.

This paper is organized as follows. In

Section 2, the data center configuration and experimental methodology are described, with the numerical modeling approach being presented in detail. In

Section 3, the numerical model is validated through field measurements, with the existing thermal conditions being completely characterized. In

Section 4, optimization strategies are developed, and thermal performance improvements for each design scenario are systematically analyzed. The main research conclusions are summarized in

Section 5.

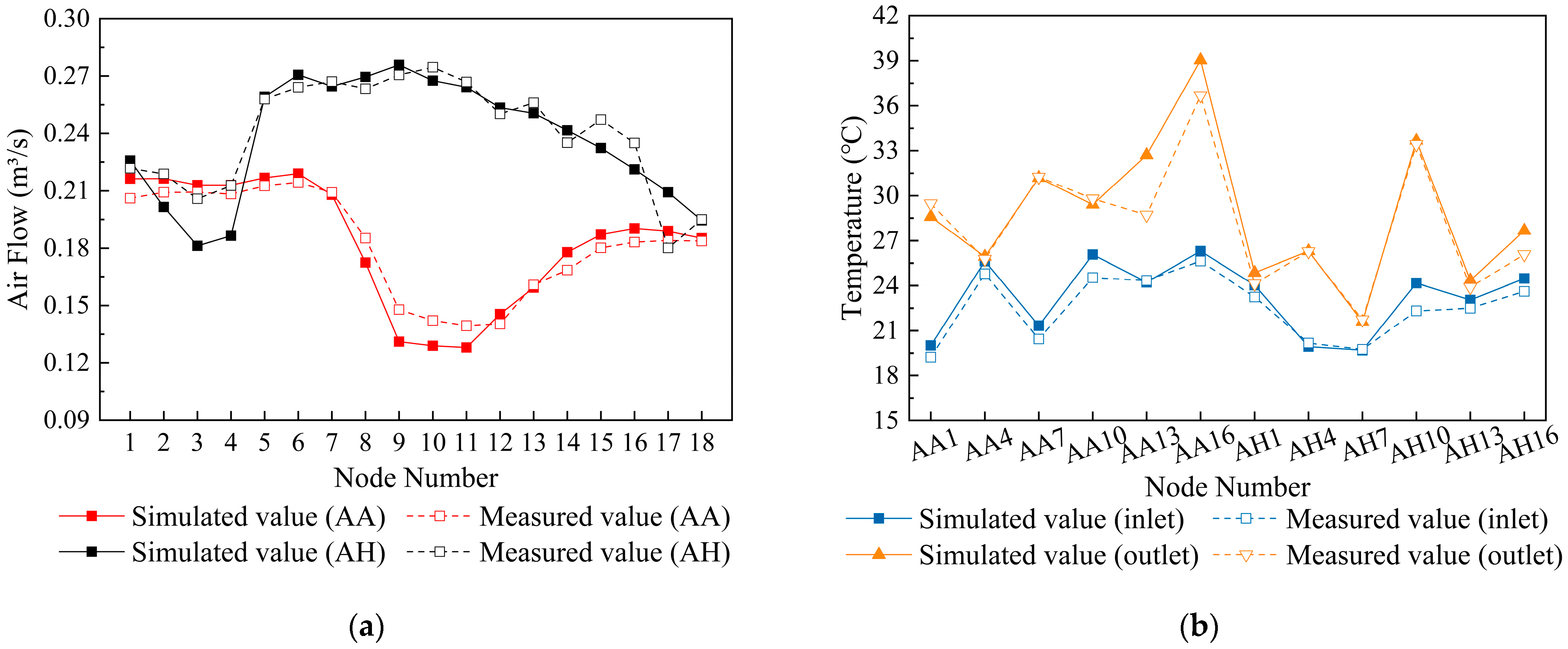

4. Airflow Organization Optimization

4.1. Airflow Optimization Strategies

An analysis of the numerical simulation results in

Section 3 reveals that the original data center exhibits non-uniform air supply, leading to severe thermal recirculation and cold air bypassing within server racks and cold aisles. These issues result in uneven temperature distribution at the rack inlets and the formation of numerous hotspots throughout the facility.

From a practical application perspective, this study proposes the airflow optimization strategies presented in

Table 4. In this data center, servers vary in type, specification, and physical dimensions. To standardize server arrangement, operational personnel position all servers close to the intake-side rails during installation, creating varying distances between server rear panels and exhaust-side rack doors. Consequently, when implementing the blanking panel strategy for unoccupied rack spaces, only the intake-side openings are sealed. All boundary conditions, including the air supply parameters of CRAC units and heat source configurations, remain consistent with the original model to ensure comparability.

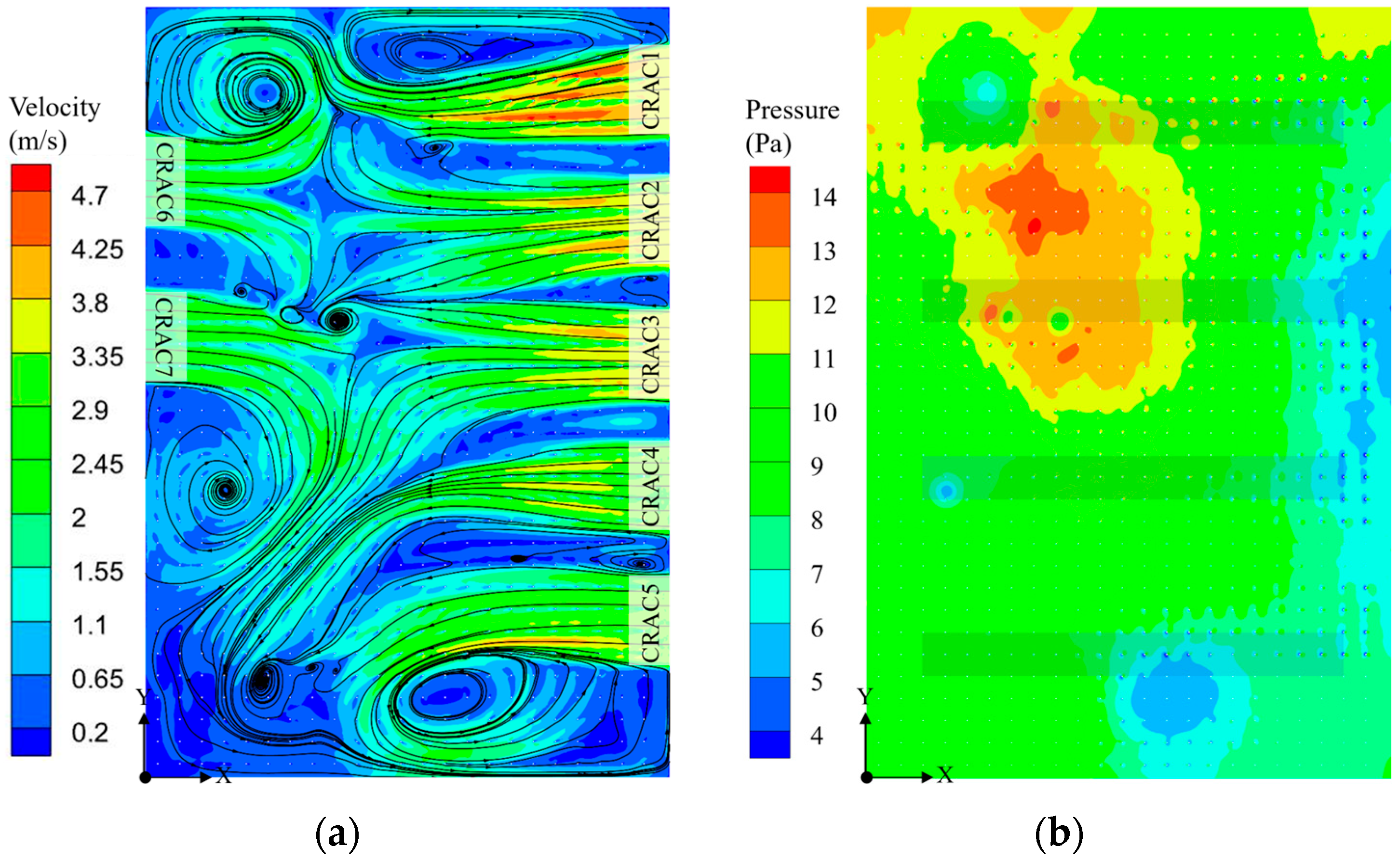

4.2. Analysis of the Optimized Data Center Flow Field

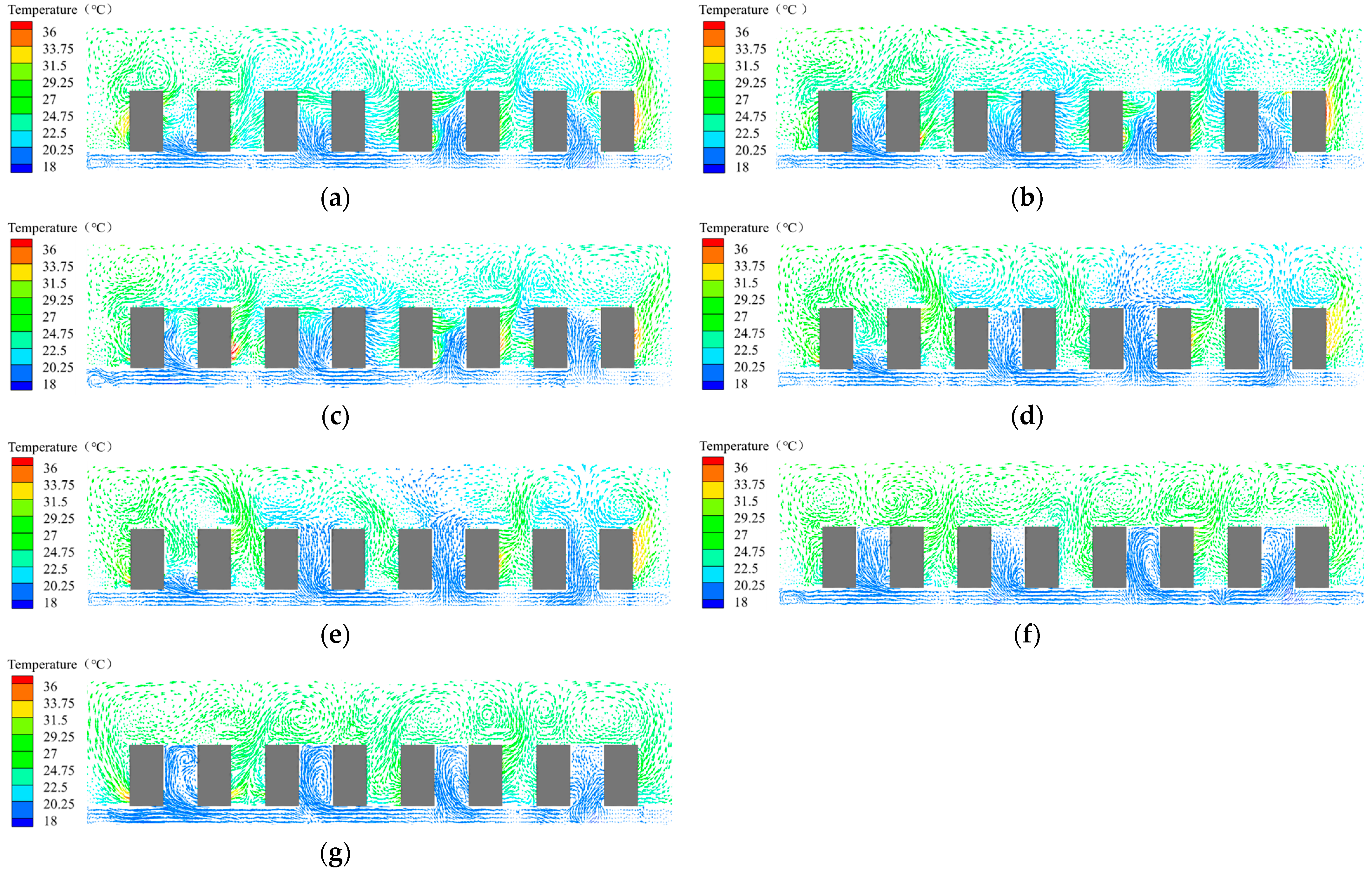

Figure 10 presents the velocity distributions at the mid-section (x = 5.7 m) of the rack rows under different optimization strategies compared with the baseline model.

Case1 demonstrates negligible influence on the airflow patterns in the central zone of the computer room.

Case2 effectively isolates the hot air recirculation from the aisle top while confining the rack-induced hot air reflux within the cold aisles. Concurrently, the cold airflow increases in both cold side aisles AB and GH at this cross-section, while excessive cold airflow in cold aisle CD bypasses into adjacent hot aisles through rack gaps.

Case3, when compared to Case2, shows no improvement in addressing the reflux issue through unoccupied rack spaces, with severe cold–hot air mixing persisting.

Case4 demonstrates that the underfloor air supply in cold aisles CD and EF is no longer obstructed by rack exhaust flows, enabling effective delivery to the aisle tops without significant temperature rise. However, excessive cold air escaping from the cold aisles mixes with hot air in the upper space, resulting in cooling capacity loss. Furthermore, cold aisle AB shows insufficient cold air supply, failing to effectively mitigate the hot air recirculation phenomenon in its upper section. In cold aisle GH, the vertical travel distance of perforated tile airflow increases, partially alleviating upper-level hot air recirculation and consequently improving cooling efficiency for upper rack servers. The blanking panel installation prevents localized recirculation of rack exhaust through rack gaps. Instead, the heated air rises to the ceiling under buoyancy effects, forming intense vortex fields when obstructed by the overhead structure.

In the combined optimization strategies, all configurations incorporate the blanking panel installation at rack intake sides, which effectively segregates the internal airflow paths between cold and hot streams within the server racks. This implementation results in more distinct airflow streamline distributions throughout the aisles.

Compared with Case4, Case5 demonstrates no significant improvement in airflow organization patterns, showing persistent hot air recirculation at the top of the racks in both cold aisle AB and cold aisle GH without observable mitigation.

Case6 effectively isolates the recirculated hot airflow from the upper sections of cold aisles AB and GH, enabling the unobstructed delivery of cold airflow to the mid–upper portions of the aisles, thereby achieving efficient server cooling. Furthermore, this solution addresses the cold airflow bypass issues at the tops of cold aisles CD and EF. The analysis reveals a reduction in floor-supplied airflow volume in cold aisle CD at this cross-section, while the excess cold air in cold aisle EF deflects upon reaching the aisle top and redistributes to other regions of the cold aisle.

Case7 achieves complete isolation between cold and hot air streams in the computer room. The pressure drop in the cold aisle increases, optimizing pressure distribution in the plenum. This enhancement improves cold airflow redistribution within the plenum, producing more uniform air supply distribution across aisles. As shown in

Figure 10g, reduced airflow rates are measured at the floor vents in cold aisles EF and GH (bidirectional zone), while increased rates are recorded at vents in cold aisles AB and CD of the unidirectional airflow zone.

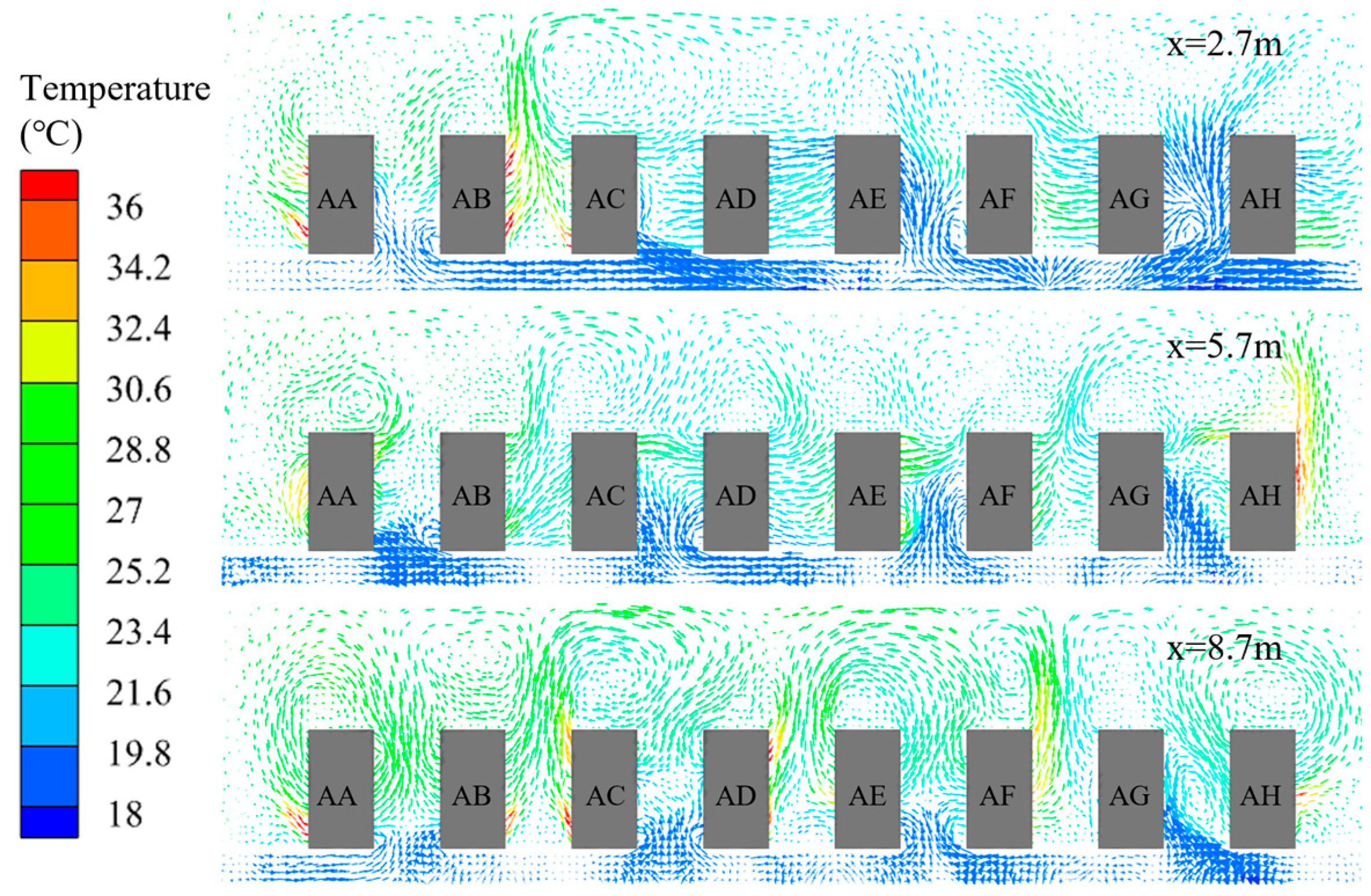

4.3. Analysis of the Optimized Data Center Temperature Distribution

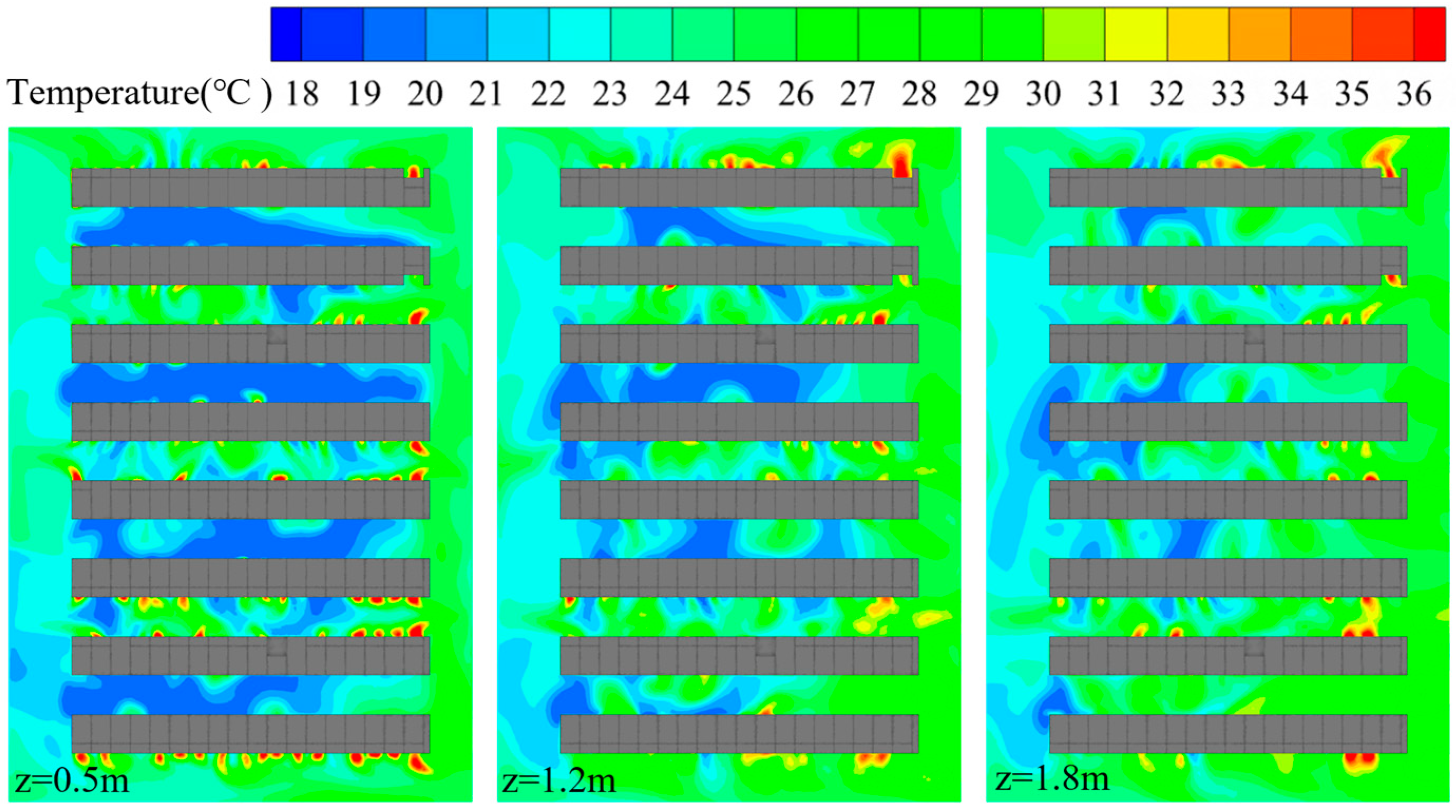

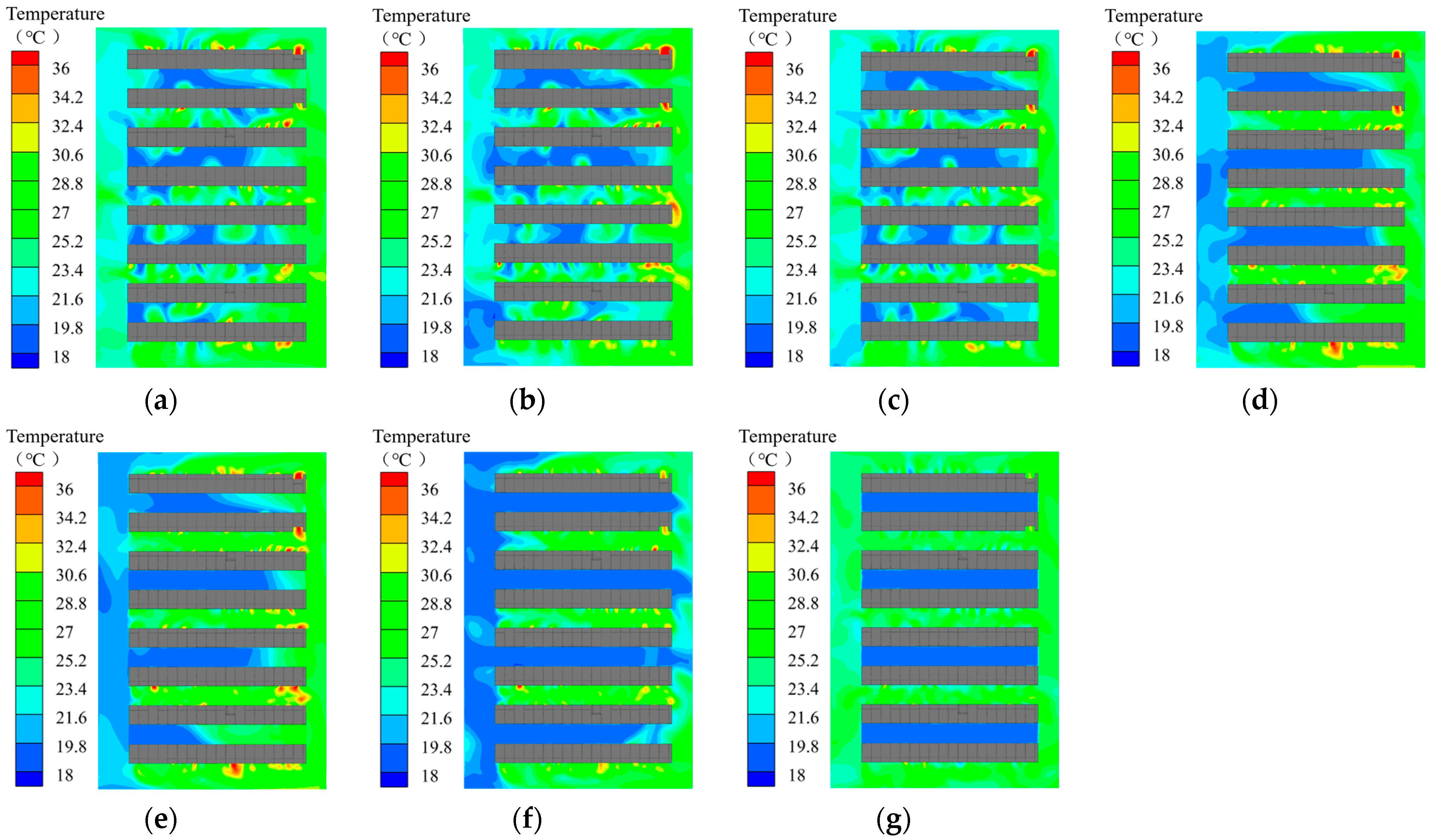

Figure 11 presents the temperature contour plots at the cross-section (z = 1.2 m) under different optimization strategies, while

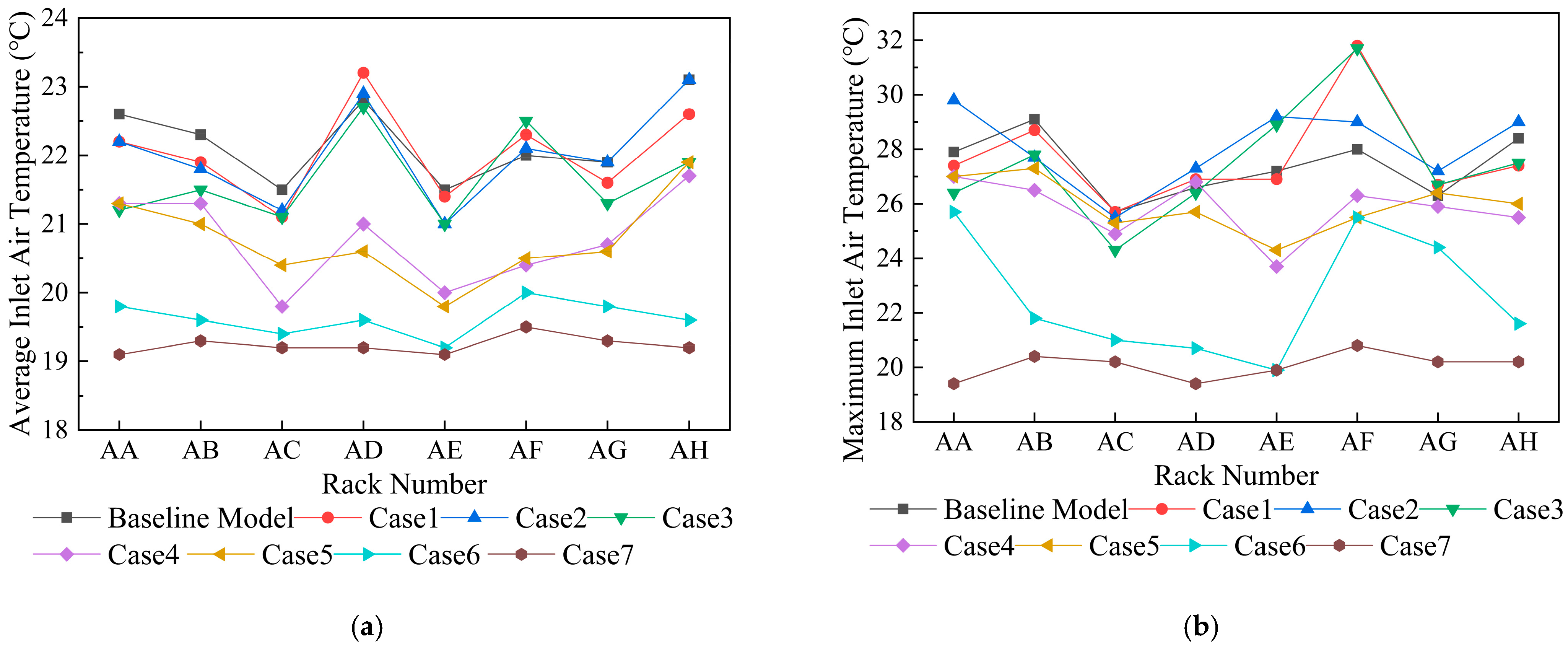

Figure 12 shows the average and maximum inlet air temperatures for each server rack row in both the baseline model and the optimized model.

A comparative analysis of

Figure 11 and

Figure 12 reveals that among the individual optimization strategies, Case1, Case2, and Case3 exhibit non-uniform temperature distributions and significant cold–hot air mixing.

Specifically, Case1 demonstrates a distinct temperature boundary on the left side of the cold aisle. Compared to the baseline model, this strategy achieves a 0.35 °C reduction in average server inlet temperatures for all rack rows except AD and AF. However, the high-temperature area expands at the left end of cold aisle EF, with the maximum inlet temperature reaching 32 °C for AF rack servers, indicating intensified hot air recirculation in localized zones.

In Case2, the bidirectional supply zone shows expanded blue low-temperature areas at this cross-section. However, compared with Scheme A, the average inlet air temperature of servers in this zone increases by 0.15 °C, indicating that the cold aisle top containment actually reduces the effective cooling capacity available for server cooling. In the unidirectional supply zone, the left side of cold aisle AB is almost entirely covered by high-temperature regions, with the maximum inlet air temperature of servers in row AA reaching 30 °C. This occurs because the underfloor-supplied cold air bypasses the servers and directly escapes from the cold aisle, causing the temperature in the return air zone to drop to approximately 20 °C.

In Case3, an overall expansion of the low-temperature zones within the cold aisles is observed, accompanied by a 0.6 °C reduction in the average server inlet temperature compared to the baseline configuration. However, intensified local thermal recirculation is identified in cold aisle EF, resulting in elevated maximum inlet temperatures for servers in row AE. Furthermore, both the average and peak inlet temperatures for servers in row AF are found to increase, with the maximum temperature reaching 32 °C, demonstrating comparable performance to Case1.

In Case4, the temperature field shows a distinct left—low/right—high non-uniform distribution pattern. Specifically, the return air temperature on the left side decreases to 21 °C, reducing the supply–return temperature differential to 2 °C. The cold air bypass-induced low-temperature zones in hot aisles are completely eliminated, leading to a significant reduction in average server inlet temperatures. However, localized high-temperature regions persist near the air conditioning units on the right side of rack rows, with maximum inlet temperatures exceeding 26 °C observed for servers in rows AA, AB, AD, and AF, suggesting potential hotspot risks.

In the combined optimization strategies, Case5 demonstrates no significant improvement in aisle temperature distribution, with large uncooled areas persisting at the right end of cold aisle AB in the unidirectional supply zone and cold aisle GH in the bidirectional supply zone.

In Case6, the return air temperature on the left side is further reduced, with cold aisles predominantly covered by blue zones, indicating significantly improved temperature uniformity. The average server inlet temperature decreases to 19.6 °C, although maximum inlet temperatures approaching 24 °C are still observed for servers in rows AA and AF. A significant reduction in exhaust air temperatures from high-power racks is achieved, indicating improved server cooling efficiency.

Case7 achieves complete physical segregation between cold and hot air streams, resulting in clearly defined thermal zones across the server room cross-section. Measurement data indicate that the average rack intake temperature remains consistently near the supply air temperature of 19 °C, with maximum intake temperatures staying at approximately 20 °C, maintaining a 7 °C safety margin below ASHRAE’s recommended upper limit of 27 °C. Under these conditions, the air conditioning setpoint temperature can be safely elevated to reduce cooling energy consumption while maintaining equipment cooling reliability.

4.4. Analysis of Thermal Environment Evaluation Metrics

Three thermal performance metrics—the Return Temperature Index (RTI), Supply Heat Index (SHI), and Rack Cooling Index (RCI)—are commonly employed to evaluate bypass airflow recirculation and mixing characteristics in data centers [

7,

31]. Notably, SHI can be applied for both room-level and row-level assessments [

32].

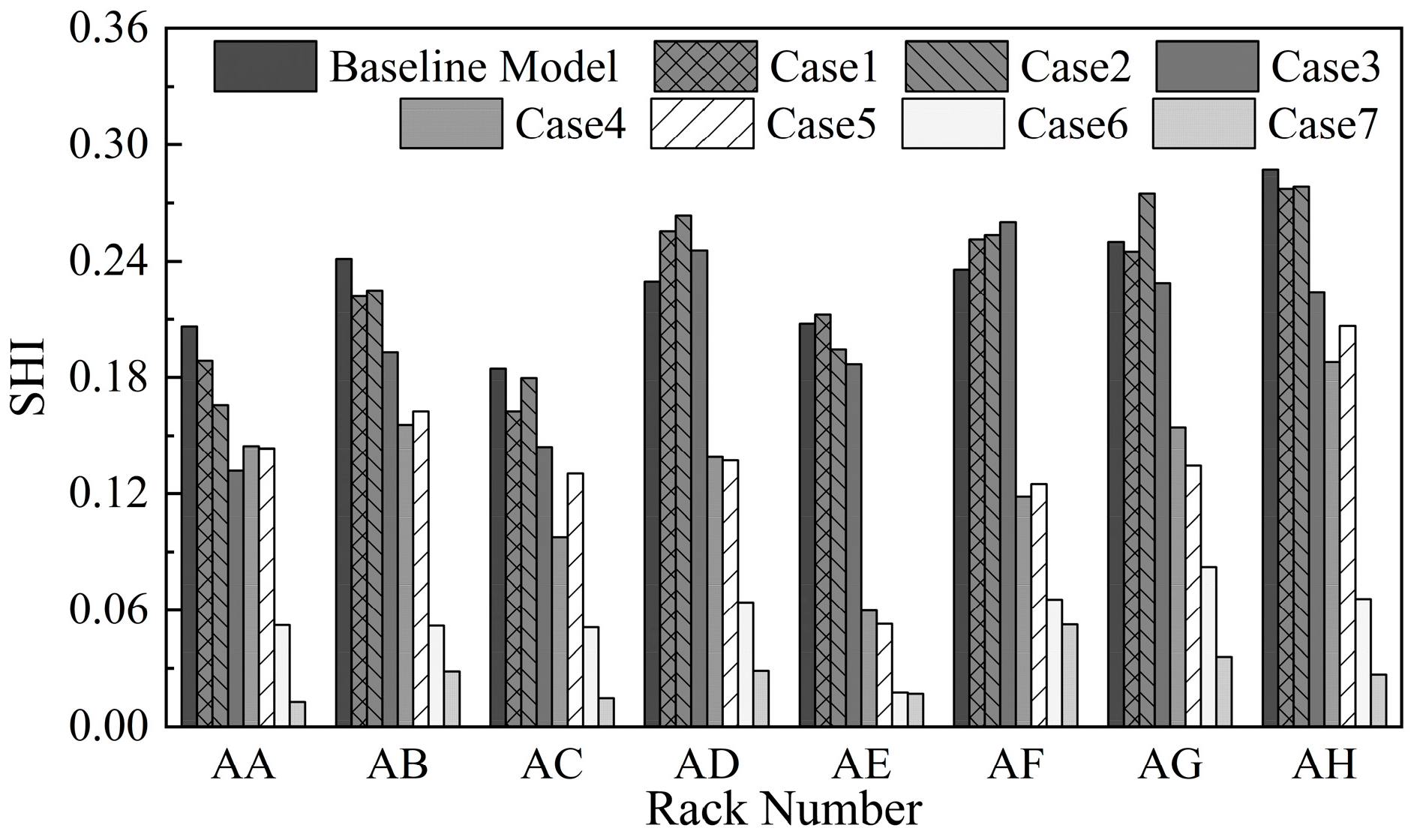

Figure 13 presents comparative SHI values for each rack row in the baseline and optimized configurations. The baseline model exhibits SHI values exceeding 0.2 for all rows except AC, indicating poor thermal conditions, with average SHI values of 0.215 and 0.245 for unidirectional and bidirectional supply zones, respectively.

Among individual optimization strategies, Case1, Case2, and Case3 demonstrate limited improvement in cooling utilization efficiency through partial or full aisle containment, while inadvertently increasing cooling loss during airflow delivery to servers in rows AD and AF, resulting in elevated SHI values. Case4 achieves significant reductions after implementing intake-side blanking panels on unoccupied rack spaces, with all row SHI values decreasing below 0.2—representing 46.9% and 37.7% reductions in bidirectional and unidirectional zones, respectively, compared to the baseline, establishing favorable thermal conditions.

For combined optimization strategies, Case5 shows regressed performance, with some rows (particularly AH at 0.206) exceeding Case4’s values. Both Case6 and Case7 achieve SHI values below 0.1 across all rows, indicating minimal air mixing and optimized cooling utilization efficiency.

Table 5 presents a comparative analysis of the overall thermal performance metrics between the baseline data center model and various optimization strategies. RTI < 1 across all configurations, indicating predominant cold air bypass with excessive air conditioning supply. Compared to the baseline model, strategies A and B demonstrate slight reductions in RTI, while Case3 exhibits a 1.78% RTI increase.

Following intake-side blanking panel implementation on unoccupied rack spaces, Case4, Case5, and Case6 demonstrate RTI reductions of 5.85%, 6.74%, and 3.94%, respectively, effectively mitigating hot air recirculation. Case7 achieves complete thermal separation (RTI = 1) with matched air conditioning and equipment temperature differentials.

All optimized strategies improve cooling utilization efficiency, with SHI reductions of 1.30% (Case1), 0.43% (Case2), 12.17% (Case3), 42.61% (Case4), 40.43% (Case4), 75.65% (Case6), and 88.26% (Case7) relative to the baseline. Prior to the implementation of rack blanking panels, the efficiency hierarchy becomes fully contained cold aisle containment > cold aisle door-only containment > cold aisle top-only containment. Following the implementation of rack blanking panels, the efficiency hierarchy becomes fully contained cold aisle containment > cold aisle top-only containment > cold aisle door-only containment. Under current operating conditions, Case4, Case5, Case6, and Case7 maintain RTI = 1, confirming compliance with ASHRAE thermal guidelines (inlet temperatures below recommended maximums) without localized hotspot risks.

5. Conclusions

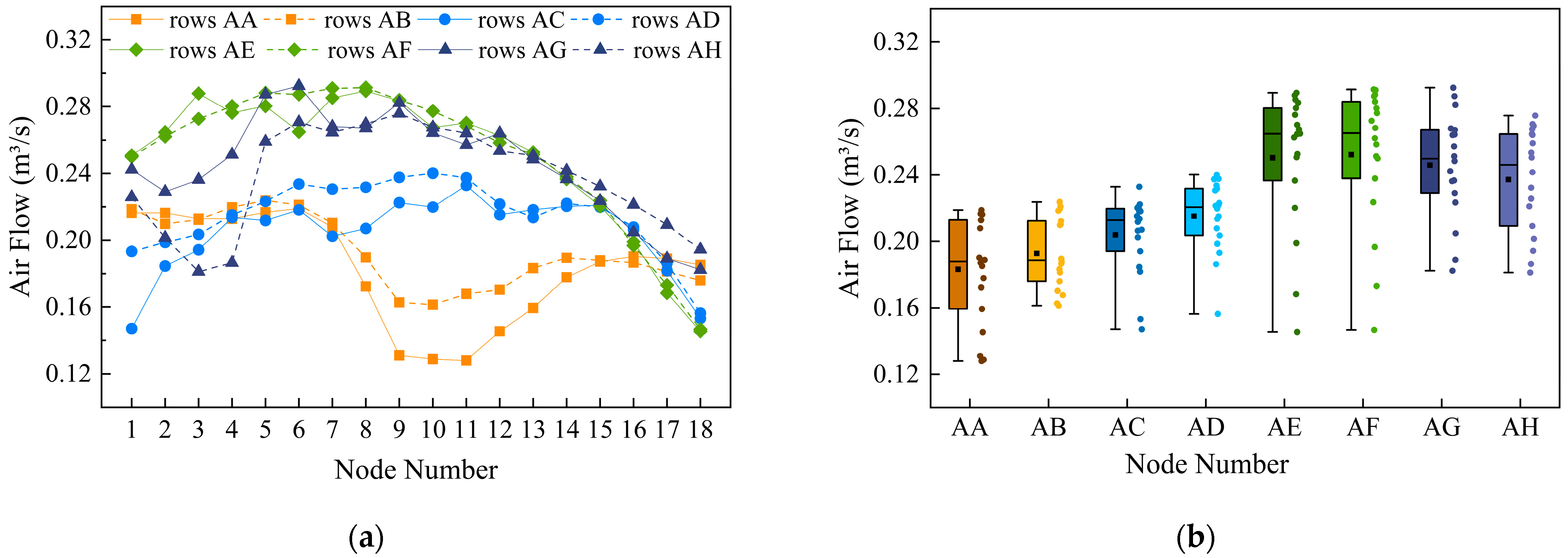

This study investigates a bidirectional data center located in a hot-summer and warm-winter region, employing CFD numerical simulations combined with field measurements to analyze airflow characteristics and thermal environment features. Multiple practical retrofit solutions are proposed, with comparative evaluations conducted on their respective airflow patterns and cooling performance. The main research findings are summarized as follows:

(1) Under the current bidirectional air supply mode of the air conditioning system, the airflow distribution through perforated tiles exhibits distinct patterns characterized by either lower–middle/higher-end or higher–middle/lower-end configurations. The data center demonstrates excessive air supply from the cooling system, with cold air bypass dominating the overall airflow organization. However, severe mixing between cold and hot airflows is observed, resulting in imbalanced cooling capacity distribution and low cooling utilization efficiency.

(2) Among the individual optimization strategies, the rack blanking panel strategy demonstrates the most significant thermal environment improvement. Compared to the baseline model, it achieves 46.9% and 37.7% reductions in SHI values for racks in bidirectional and unidirectional supply zones, respectively, significantly enhancing cooling utilization efficiency. In contrast, cold aisle door-only containment, cold aisle top-only containment, and fully contained cold aisle containment show limited performance improvements with SHI reductions of 1.30%, 0.43%, and 12.17%, respectively, exhibiting minimal effects on cooling efficiency enhancement while increased SHI values are recorded in certain rack rows for these configurations.

(3) Among combined optimization strategies, the RCIHI is maintained at 1.0 across the computer room, indicating complete elimination of local hotspot risks. Rack blanking panels with fully contained cold aisle containment demonstrate superior thermal performance improvement compared to rack blanking panels with cold aisle top-only containment, which in turn outperforms rack blanking panels with cold aisle door-only containment. The implementation of rack blanking panels with full cold aisle containment achieves an SHI reduction to 0.027, corresponding to an 88.26% enhancement in cooling utilization efficiency.

(4) Among all optimization configurations, rack blanking panels with fully contained cold aisle containment demonstrate optimal performance improvement. However, full containment may potentially create negative pressure or fire safety concerns. The implementation of additional fire protection measures would further increase retrofit costs. Under budget constraints, rack blanking panels with cold aisle top-only containment represents the primary alternative, followed by rack blanking panels with cold aisle door-only containment as the secondary option.

This study validates the effectiveness of airflow optimization schemes in improving data center thermal environments, though certain limitations remain. Future work will focus on comprehensive lifecycle cost–benefit analysis, where an economic model incorporating initial investment, operational costs, and energy savings will be developed. Additionally, scalability analysis will be conducted to further validate the scheme’s applicability and return-on-investment period across different geographical locations and facility scales.