Design, Characteristic Analysis and Modeling of a Tailored Soft Robot for Phosphorite Grabbing

Abstract

1. Introduction

2. Structural Design and Manufacturing of TSRPG

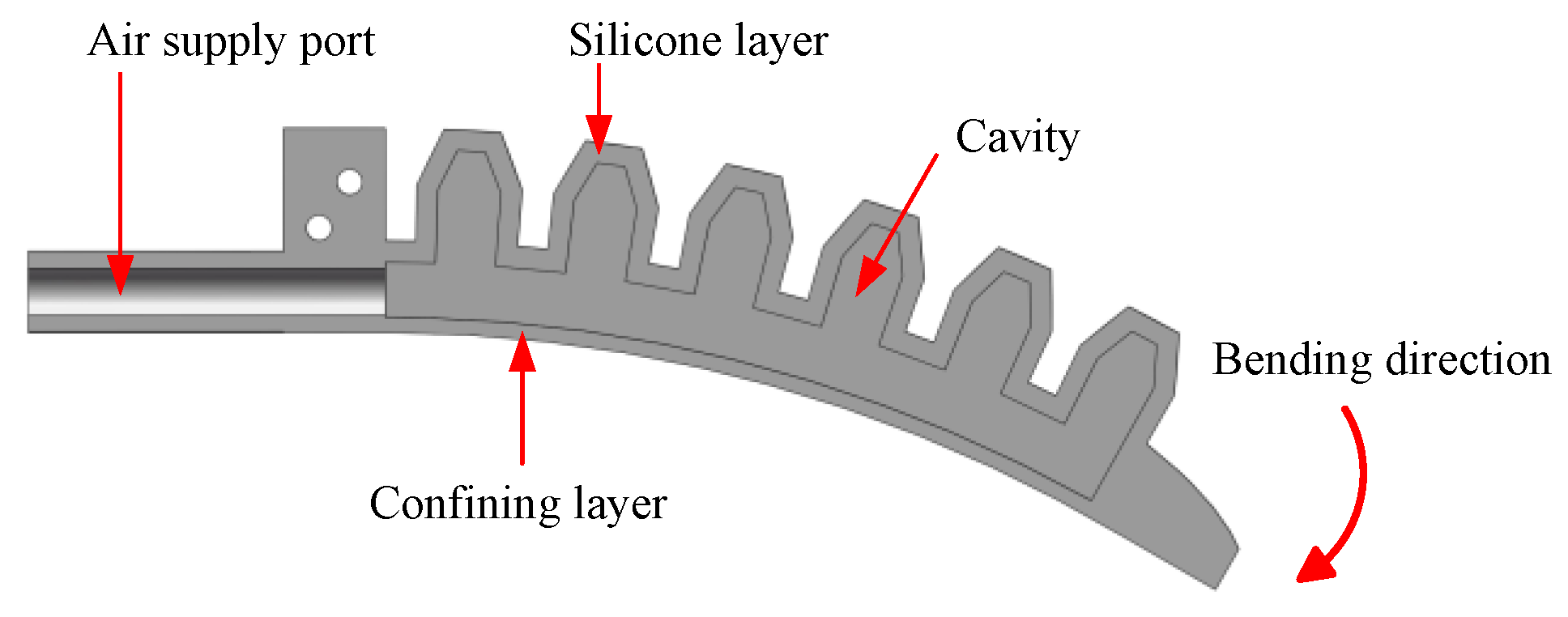

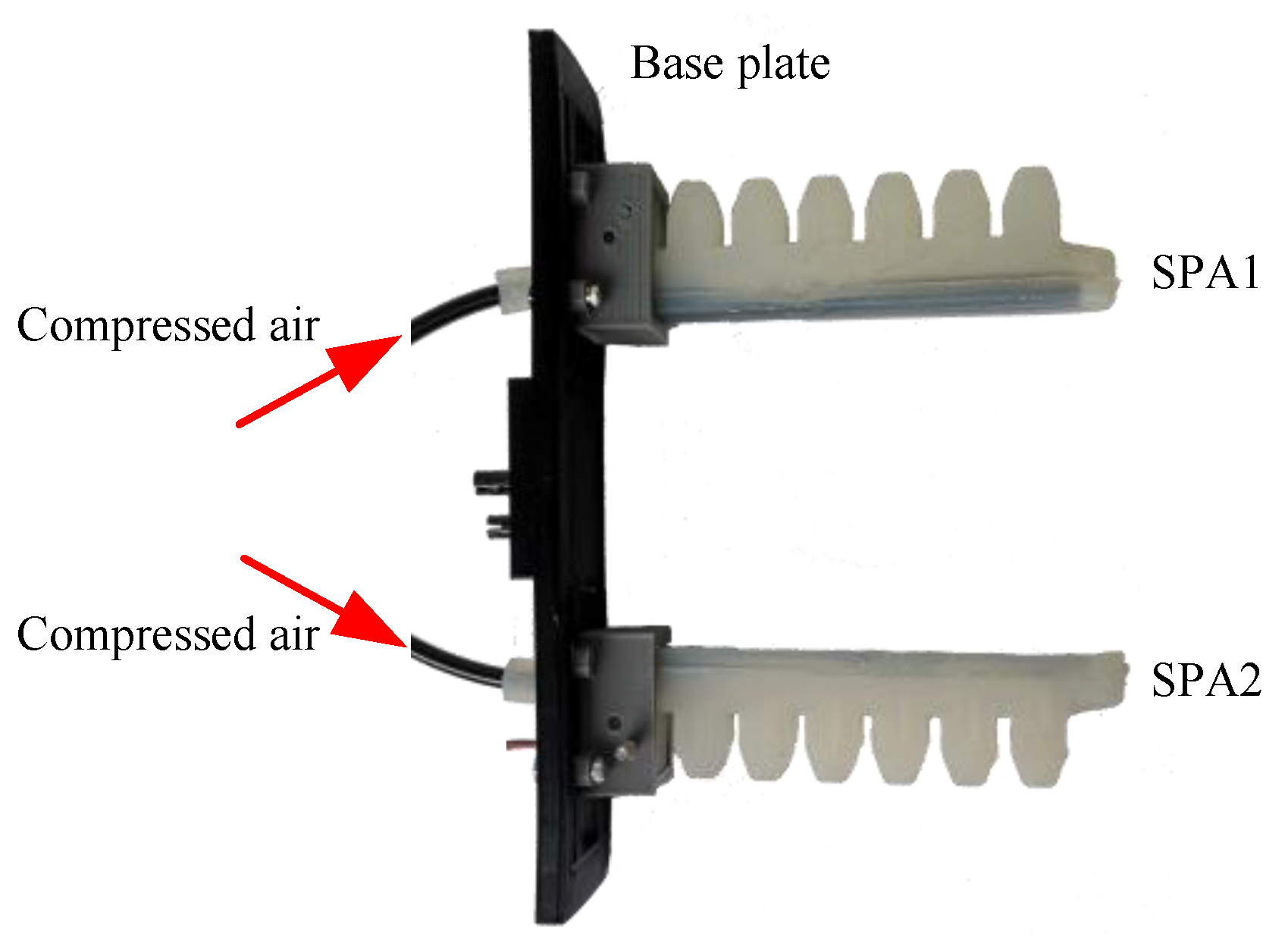

2.1. Design of SPA

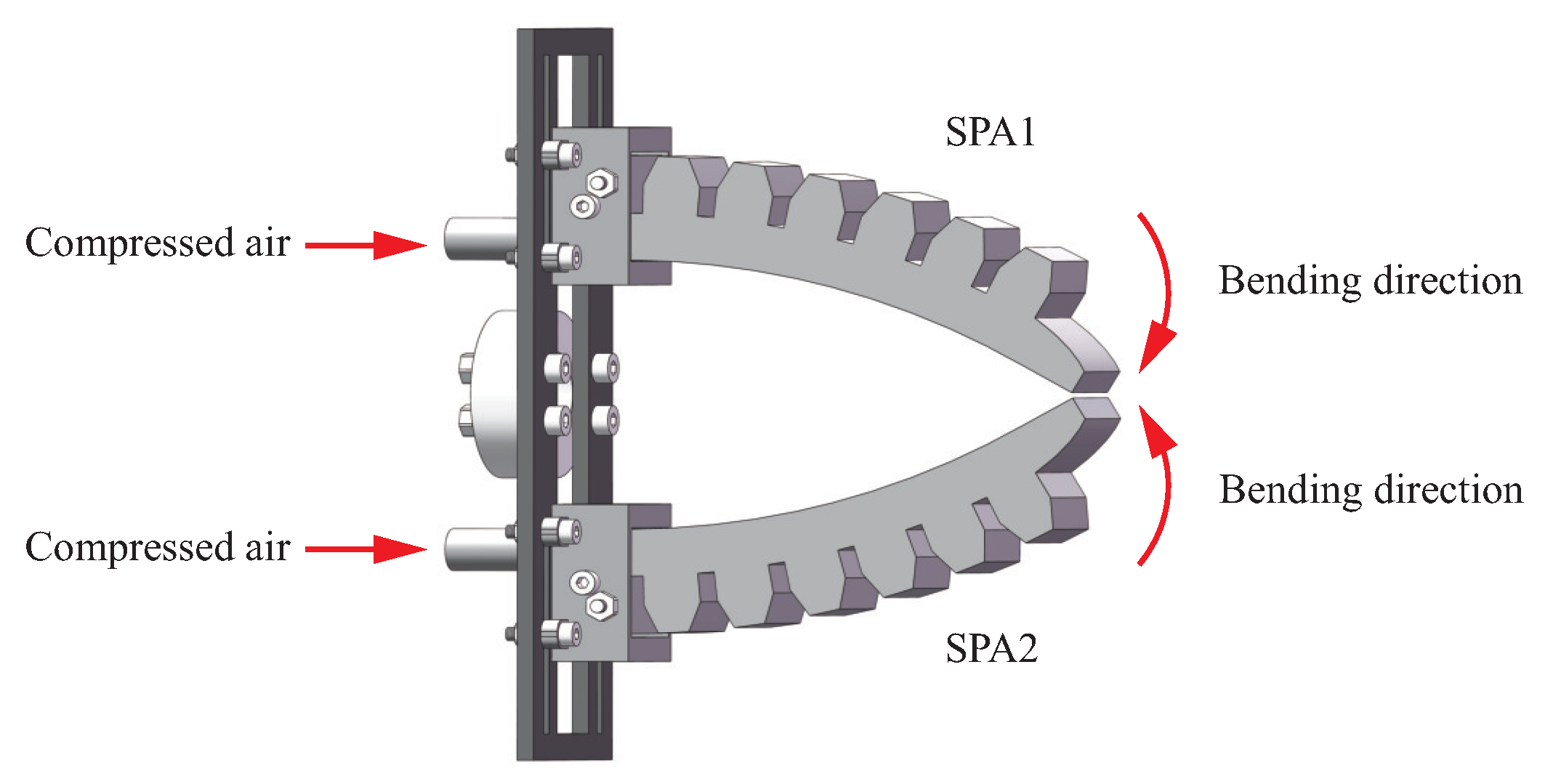

2.2. Design of TSRPG

2.3. Manufacturing of SPA

- •

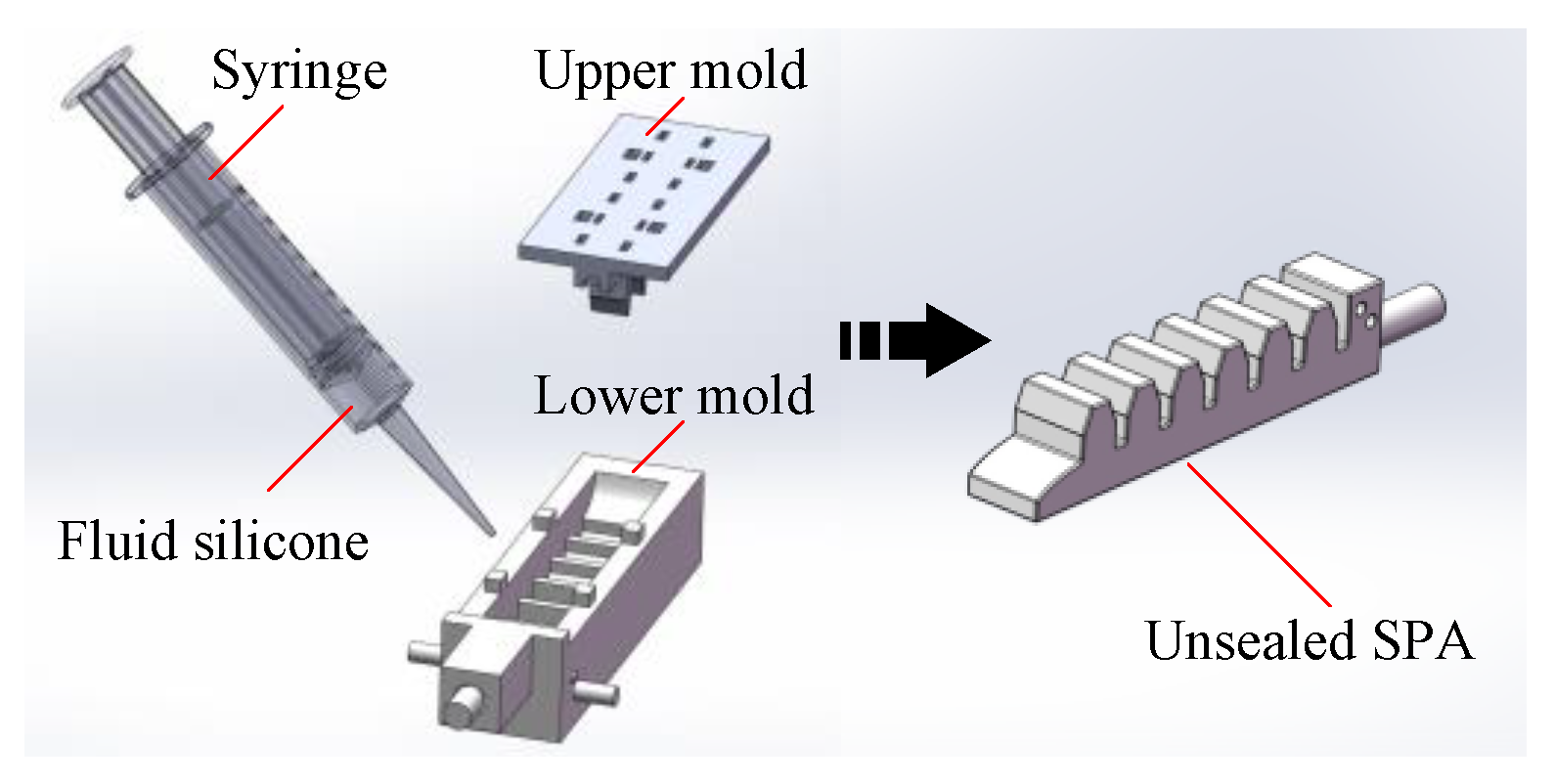

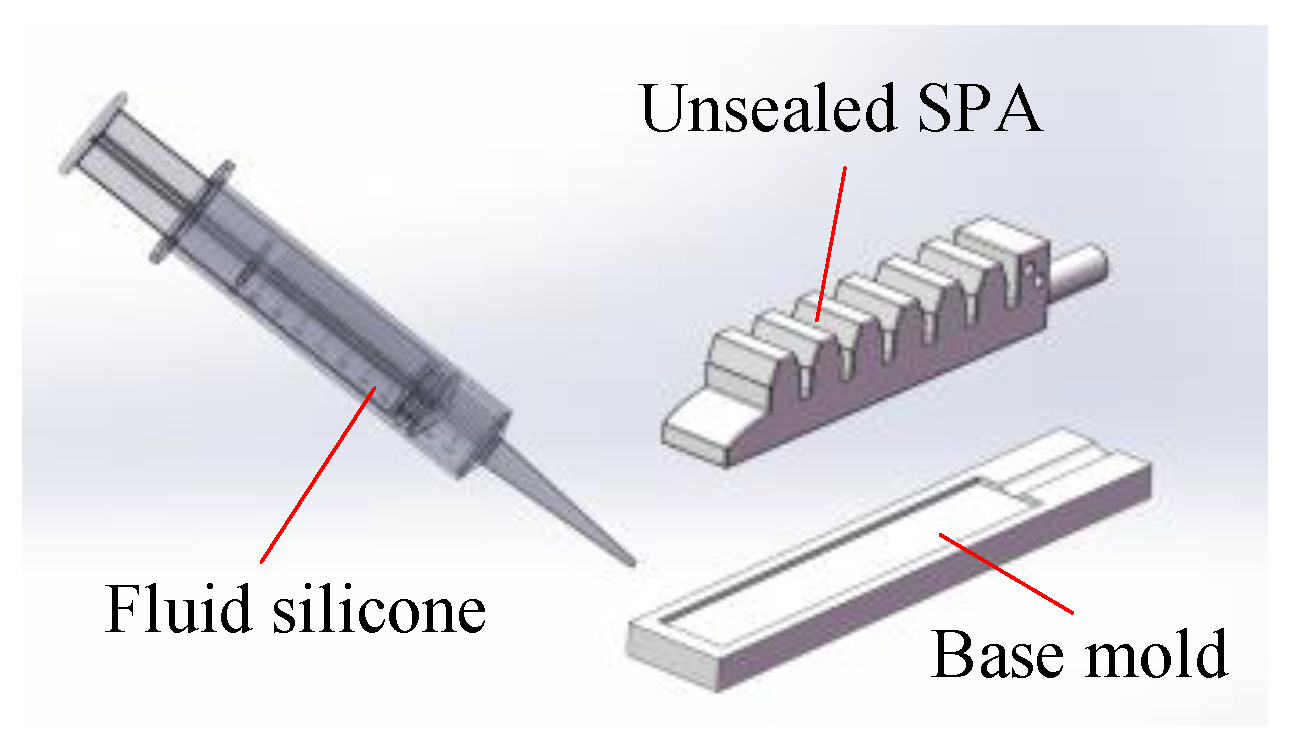

- Step 1: Design and manufacture moldsTo manufacture the SPA, the design and manufacturing of molds should be conducted first. The mold includes the lower mold and the upper mold. According to the structures and dimensions of the SPA (see Figure 1 and Figure 2), the lower mold and upper mold are designed, whose 3D drawings are shown in Figure 4. Then, the lower mold and upper mold can be manufactured by 3D printing equipment or computer numerical control (CNC) engraving machines.

- •

- Step 2: Prepare fluid siliconeThis step involves preparing the fluid silicone that will be used for injection molding. Silicone is a flexible and soft material that is suitable for creating soft and compliant parts or components. To employ the integrated injection molding technology to manufacture the SPA, the silicone is prepared in a fluid state. In addition, the fluid silicone is usually mixed with a curing agent or catalyst to promote the curing process.

- •

- Step 3: Inject moldIn this step, the prepared fluid silicone is injected into the cavity of the lower mold by using a syringe (Figure 4). The injection is carefully controlled to ensure that the entire cavity is filled with the fluid silicone without any air bubbles or voids.

- •

- Step 4: Mount upper moldOnce the lower mold is filled with the fluid silicone, the upper mold is mounted onto it. The upper mold is designed to fit precisely onto the lower mold, forming a complete enclosure around the injected fluid silicone.

- •

- Step 5: CureAfter the lower mold and upper mold are clamped, the curing process will be started. Curing is a chemical process. During the curing process, the fluid silicone undergoes polymerization and solidifies into the shape of the unsealed SPA. To accelerate the curing process, the molds are usually placed in oven equipment.

- •

- Step 6: Split moldAfter the curing process is complete, the upper and lower molds are split. Through the split mold process, the unsealed SPA can be obtained.

- •

- Step 7: InspectIn this last step, the manufactured unsealed SPA is carefully inspected. Any excess material or flash around the edges of the unsealed SPA may be trimmed or removed. Moreover, the dimensions and shapes of the manufactured unsealed SPA are carefully inspected to ensure its good quality.

2.4. Manufacturing of the TSRPG

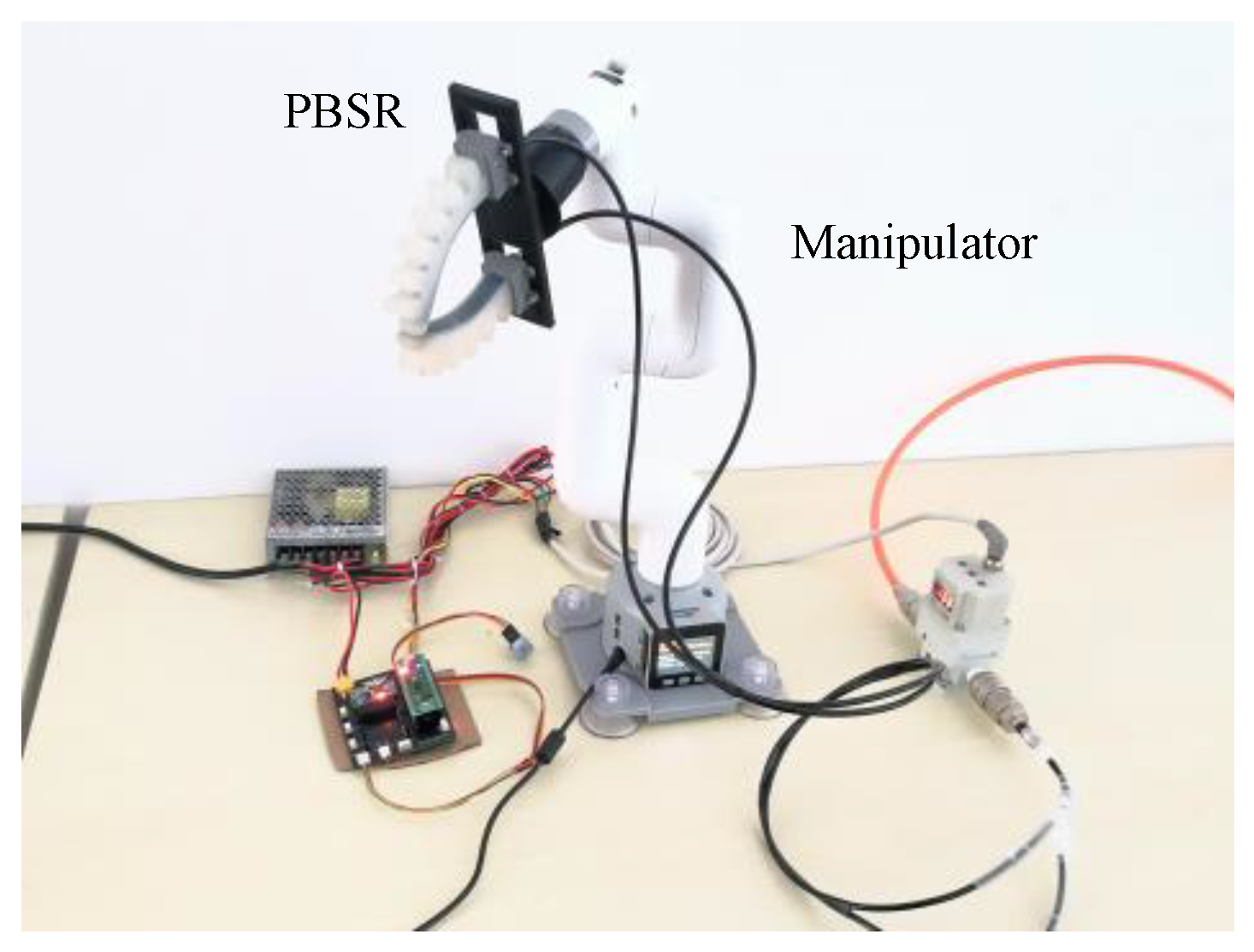

3. Experimental Testbench

3.1. Experimental Testbench A

3.2. Experimental Testbench B

4. Grabbing Experiments and Characteristic Analysis of TSRPG

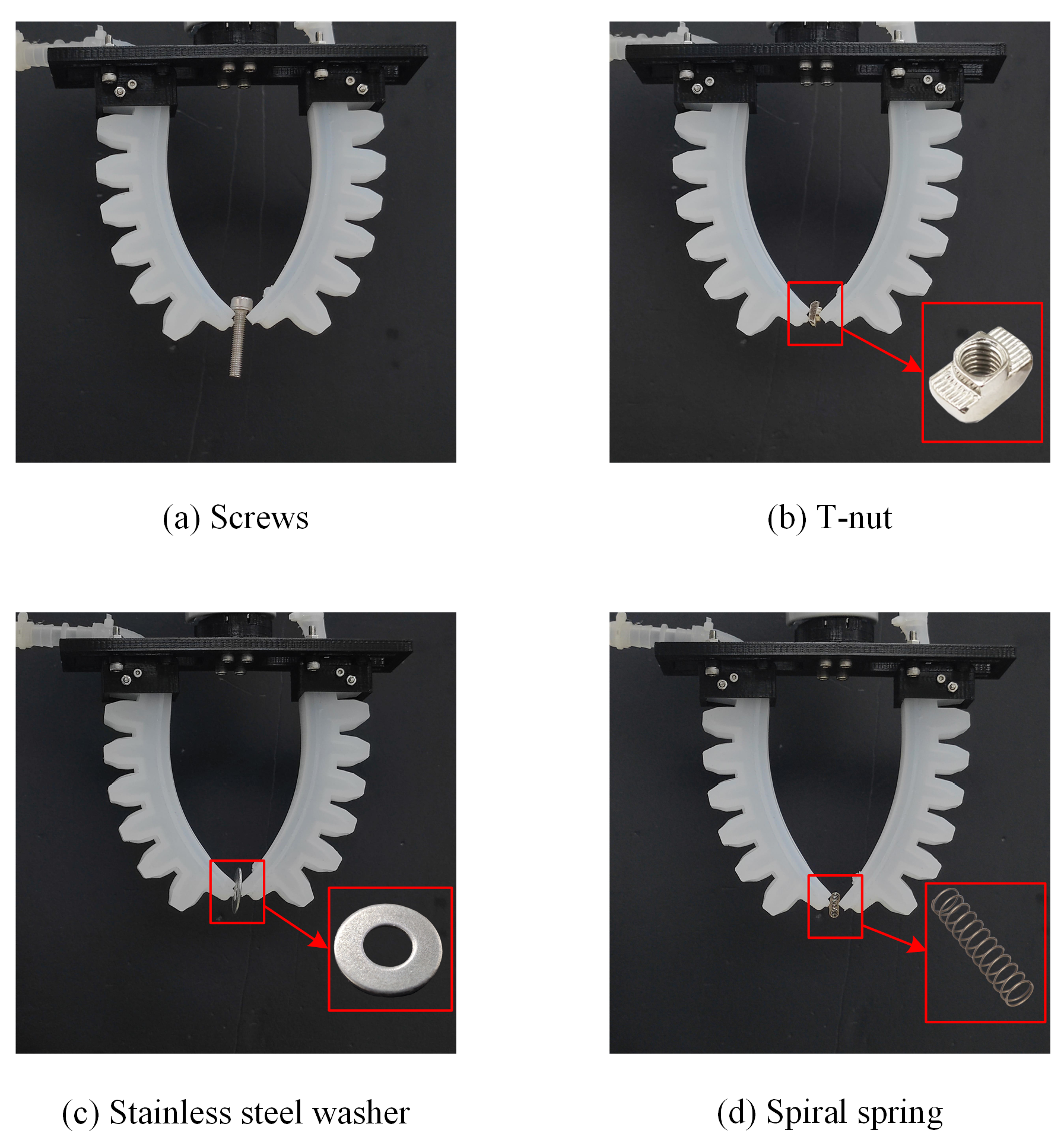

4.1. Grabbing Experiments of TSRPG

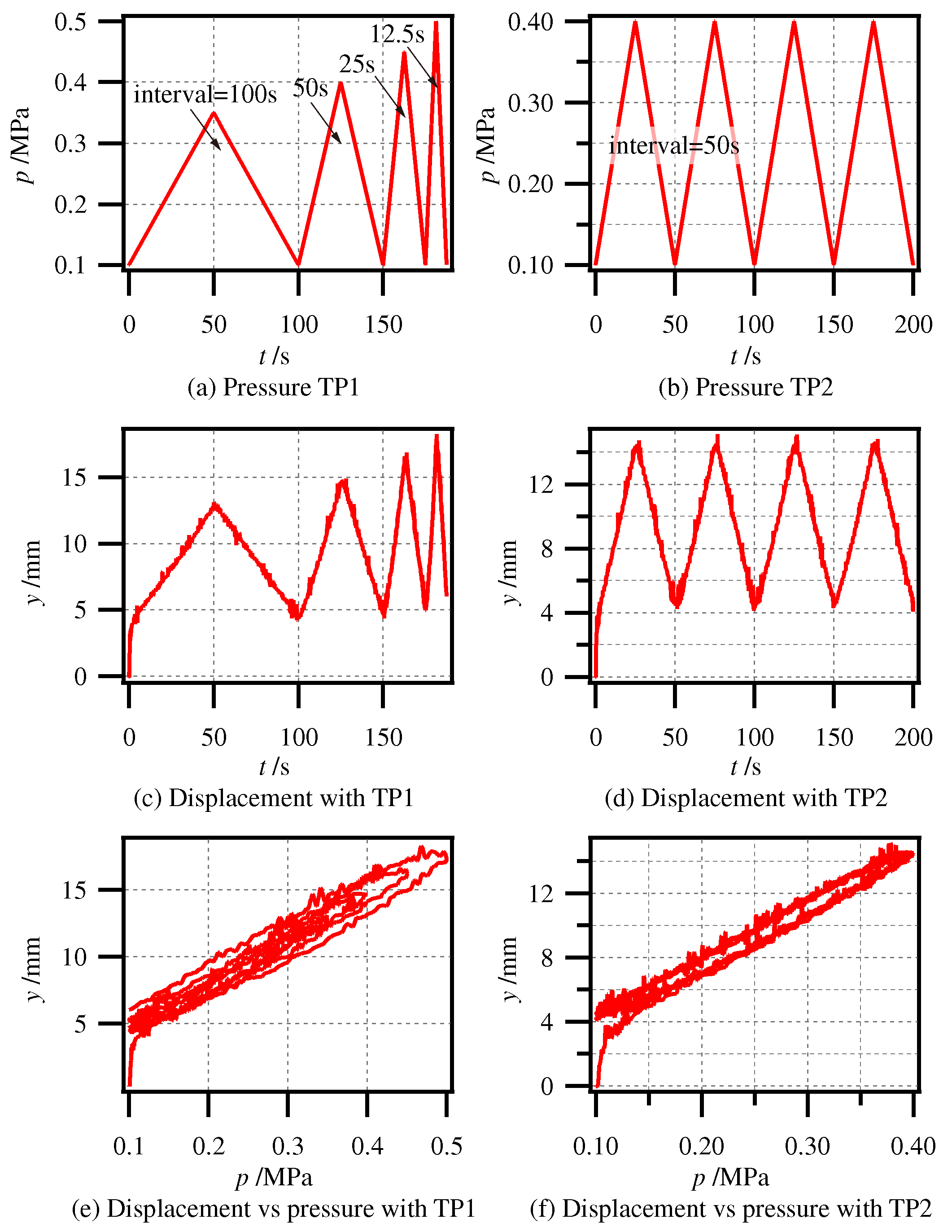

4.2. Characteristic Analysis of TSRPG

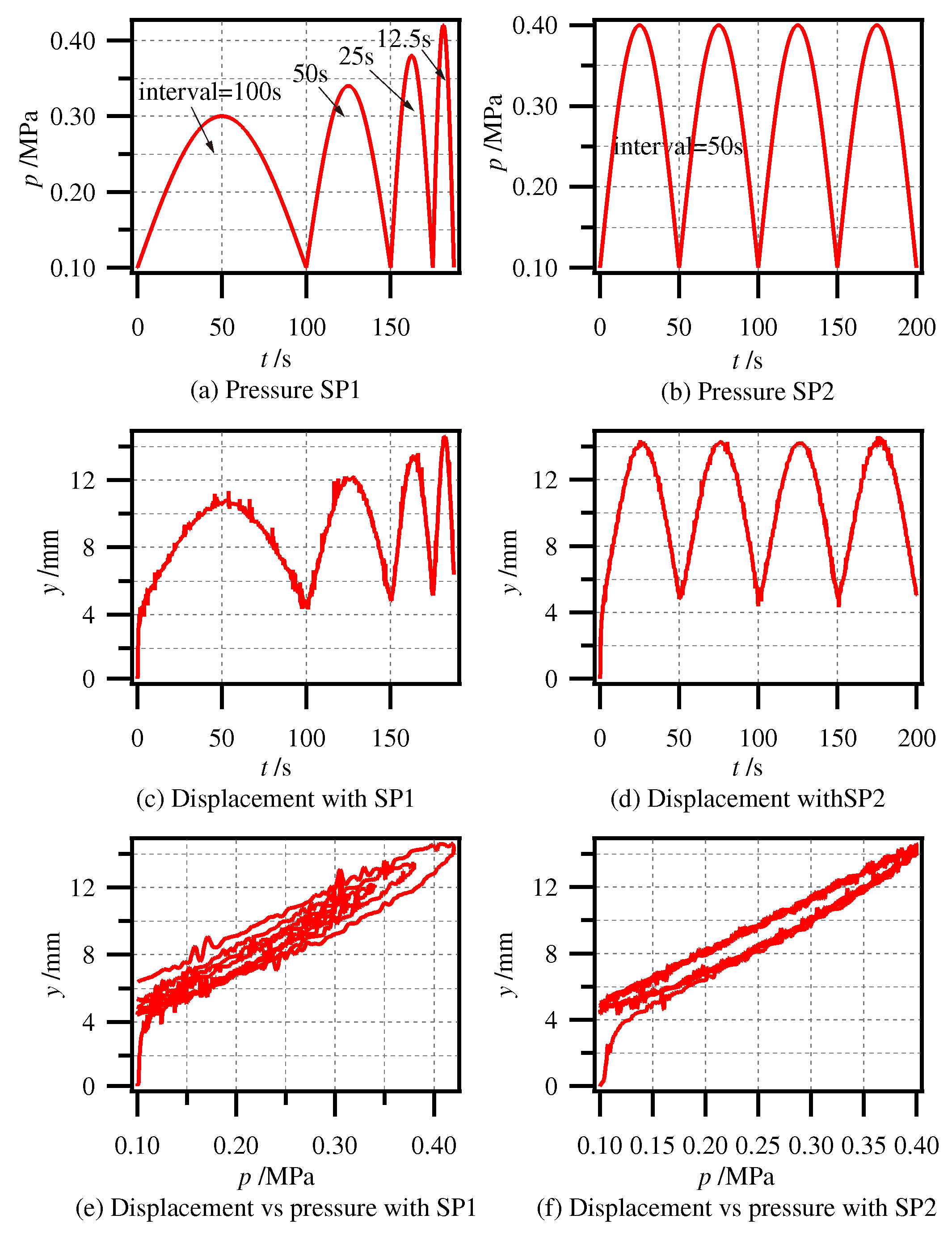

5. Modeling of SPA

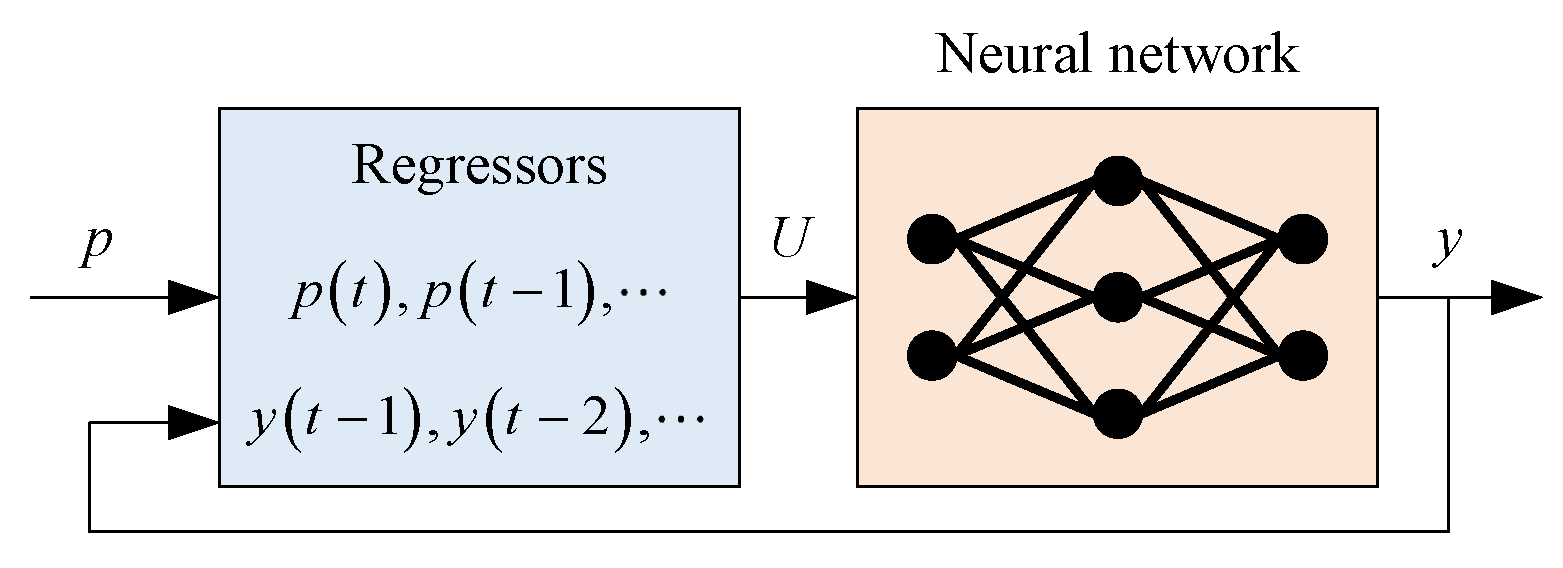

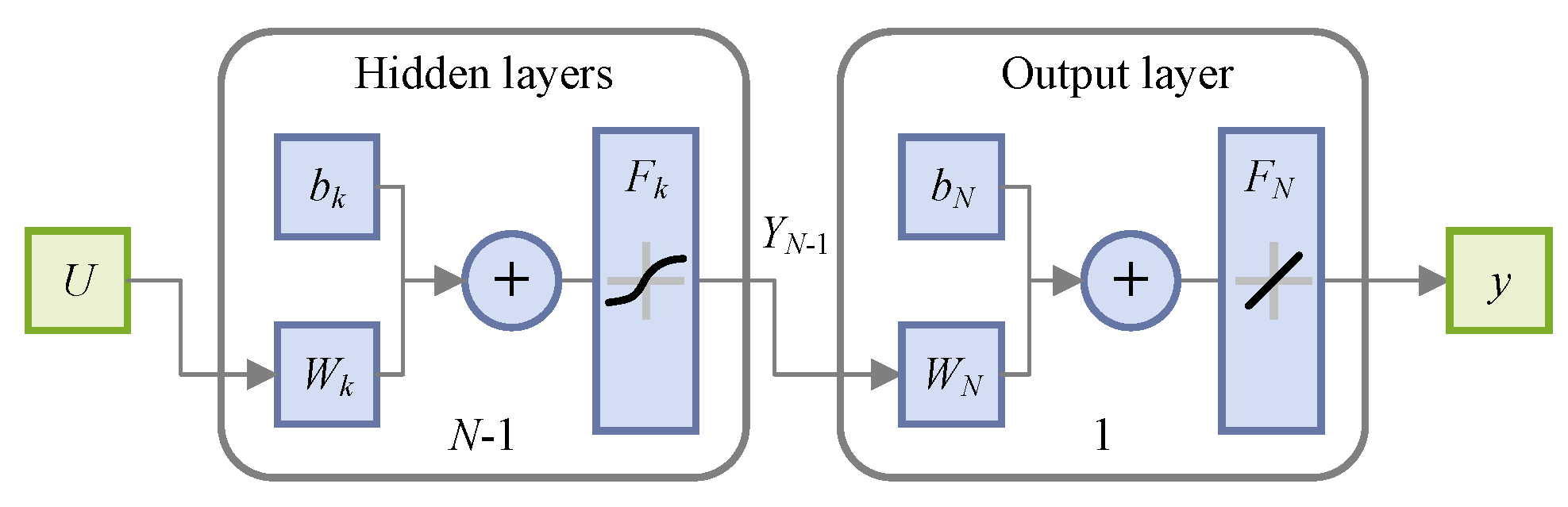

5.1. SPA Modeling Based on Nonlinear ARX Model

5.2. Model Identification

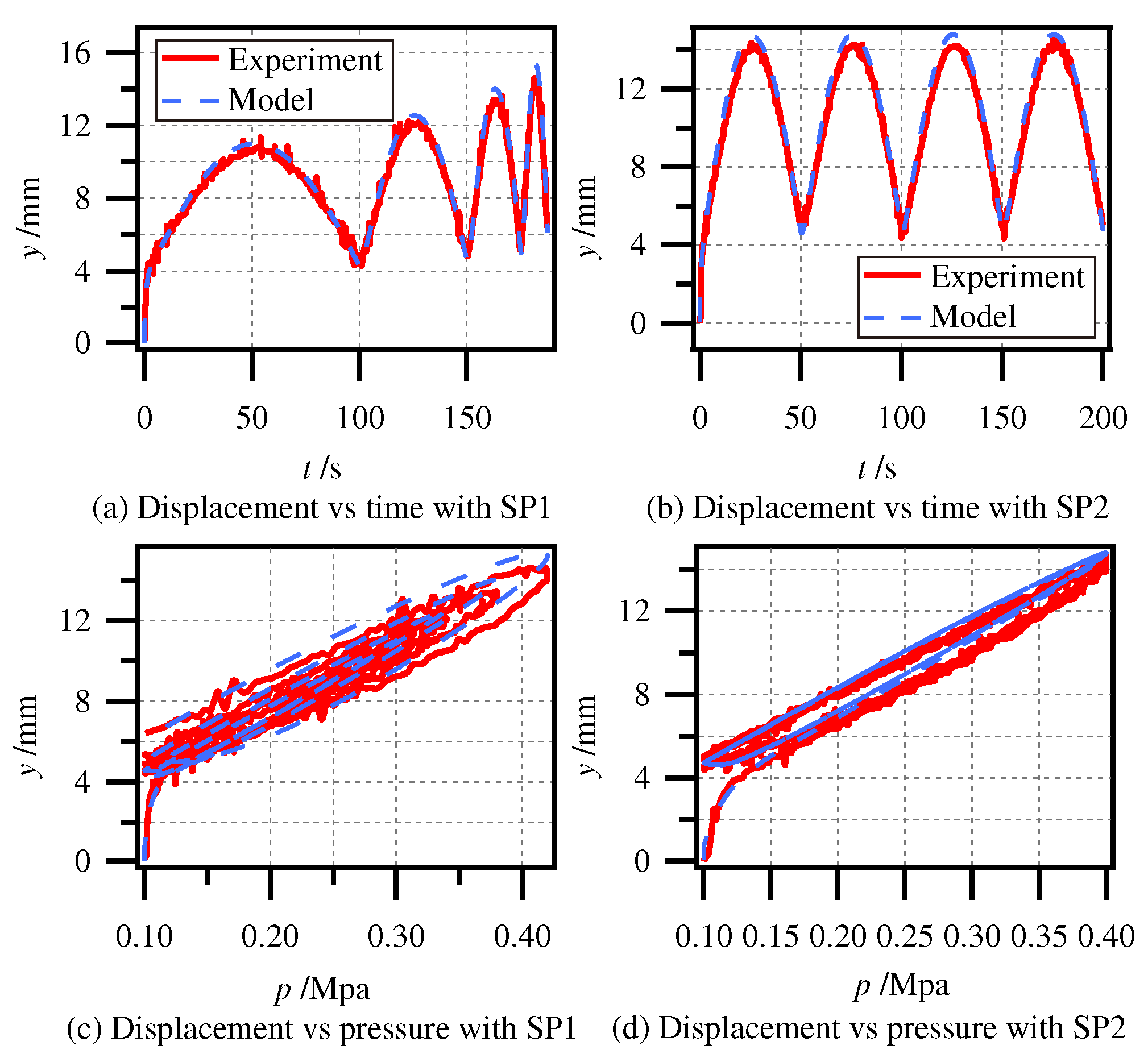

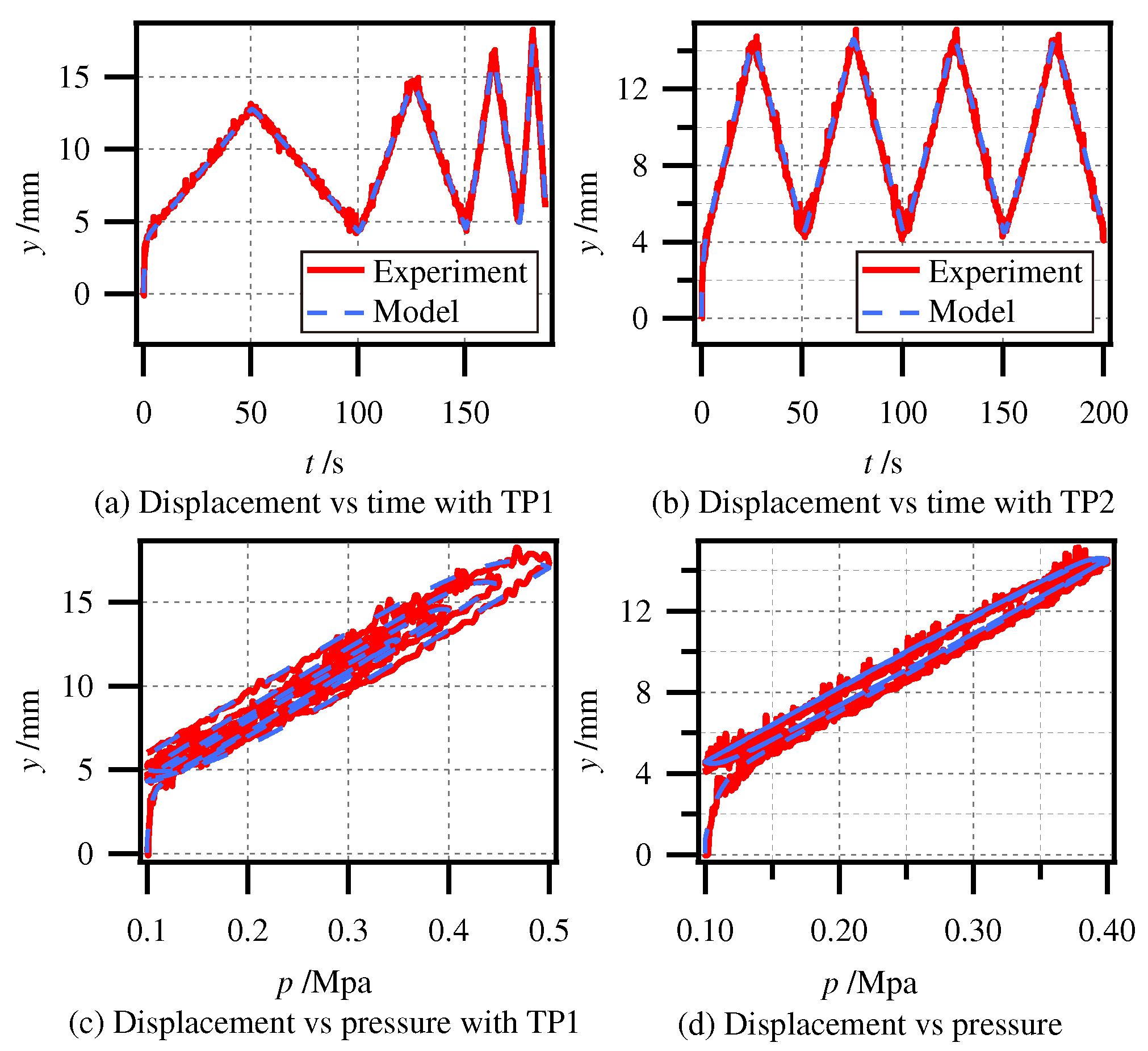

5.3. Model Validation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jordens, A.; Cheng, Y.P.; Waters, K.E. A review of the beneficiation of rare earth element bearing minerals. Miner. Eng. 2013, 41, 97–114. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, J.; Huang, Z.; Feng, B. Modeling and hysteresis inverse compensation control of soft pneumatic gripper for gripping phosphorites. Actuators 2025, 14, 193. [Google Scholar] [CrossRef]

- Yang, X. Beneficiation studies of tungsten ores–A review. Miner. Eng. 2018, 125, 111–119. [Google Scholar] [CrossRef]

- Jesus, J.D.F.; Souza, M.J.F.; Cota, L.P. A hybrid metaheuristic algorithm for scheduling iron ore reclaiming in ports. Eng. Optim. 2024, 1–18. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef]

- Ning, L.; Limpabandhu, C.; Tse, Z.T.H. Engineering magnetic soft and reconfigurable robots. Soft Robot. 2024, 11, 2–20. [Google Scholar] [CrossRef]

- Wang, X.; Bo, Z.; Guo, C.; Wu, J.; Liu, Y.; Sun, W. A magnetic soft robot with rolling and grasping capabilities. Proc. Inst. Mech. Eng. Part C-J. Mech. Eng. Sci. 2023, 237, 1741–1754. [Google Scholar] [CrossRef]

- Han, W.B.; Ko, G.J.; Lee, K.G.; Kim, D.; Lee, J.H.; Yang, S.M.; Kim, D.J.; Shin, J.W.; Jang, T.M.; Han, S.; et al. Ultra-stretchable and biodegradable elastomers for soft, transient electronics. Nat. Commun. 2023, 14, 2263. [Google Scholar] [CrossRef]

- Li, G.R.; Chen, X.P.; Zhou, F.H.; Liang, Y.M.; Xiao, Y.H.; Cao, X.N.; Zhang, Z.; Zhang, M.Q.; Wu, B.S.; Yin, S.Y.; et al. Self-powered soft robot in the Mariana Trench. Nature 2021, 591, 66–71. [Google Scholar] [CrossRef]

- Chen, Y.F.; Zhao, H.C.; Mao, J.; Chirarattananon, P.; Helbling, E.F.; Hyun, N.s.P.; Clarke, D.R.; Wood, R.J. Controlled flight of a microrobot powered by soft artificial muscles. Nature 2019, 575, 324–329. [Google Scholar] [CrossRef]

- Xavier, M.S.; Tawk, C.D.; Zolfagharian, A.; Pinskier, J.; Howard, D.; Young, T.; Lai, J.; Harrison, S.M.; Yong, Y.K.; Bodaghi, M.; et al. Soft pneumatic actuators: A review of design, fabrication, modeling, sensing, control and applications. IEEE Access 2022, 10, 59442–59485. [Google Scholar] [CrossRef]

- Yuk, H.; Lin, S.; Ma, C.; Takaffoli, M.; Fang, N.X.; Zhao, X. Hydraulic hydrogel actuators and robots optically and sonically camouflaged in water. Nat. Commun. 2017, 8, 14230. [Google Scholar] [CrossRef] [PubMed]

- Nocentini, S.; Parmeggiani, C.; Martella, D.; Wiersma, D.S. Optically driven soft micro robotics. Adv. Opt. Mater. 2018, 6, 1800207. [Google Scholar] [CrossRef]

- Lendlein, A. Fabrication of reprogrammable shape-memory polymer actuators for robotics. Sci. Robot. 2018, 3, eaat9090. [Google Scholar] [CrossRef]

- Hu, W.; Lum, G.Z.; Mastrangeli, M.; Sitti, M. Small-scale soft-bodied robot with multimodal locomotion. Nature 2018, 554, 81–85. [Google Scholar] [CrossRef]

- Shen, Z.; Chen, F.; Zhu, X.; Yong, K.T.; Gu, G. Stimuli-responsive functional materials for soft robotics. J. Mater. Chem. B 2020, 8, 8972–8991. [Google Scholar] [CrossRef]

- Suo, Z. Theory of dielectric elastomers. Acta Mech. Solida Sin. 2010, 23, 549–578. [Google Scholar] [CrossRef]

- Kim, D.S.; Lee, Y.J.; Kim, Y.B.; Wang, Y.; Yang, S. Autonomous, untethered gait-like synchronization of lobed loops made from liquid crystal elastomer fibers via spontaneous snap-through. Sci. Adv. 2023, 9, eadh5107. [Google Scholar] [CrossRef]

- Ni, C.; Chen, D.; Yin, Y.; Wen, X.; Chen, X.; Yang, C.; Chen, G.; Sun, Z.; Wen, J.; Jiao, Y.; et al. Shape memory polymer with programmable recovery onset. Nature 2023, 622, 748–753. [Google Scholar] [CrossRef]

- Kim, Y.; Zhao, X. Magnetic soft materials and robots. Chem. Rev. 2022, 122, 5317–5364. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, X. Marching towards flexible intelligent materials. Sci. China-Mater. 2022, 65, 1991–1993. [Google Scholar] [CrossRef]

- Jiang, Q.; Chai, Z.; Zong, Z.; Hu, Z.; Zhang, S.; Wu, Z. Micro/Nano soft film sensors for intelligent plant systems: Materials, fabrications, and applications. Chemosensors 2023, 11, 197. [Google Scholar] [CrossRef]

- Zatopa, A.; Walker, S.; Menguc, Y. Fully soft 3D-printed electroactive fluidic valve for soft hydraulic robots. Soft Robot. 2018, 5, 258–271. [Google Scholar] [CrossRef] [PubMed]

- Navas, E.; Rodriguez-Nieto, D.; Rodriguez-Gonzalez, A.A.; Fernandez, R. Parallel fin ray soft gripper with embedded mechano-optical force sensor. Appl. Sci. 2025, 15, 2576. [Google Scholar] [CrossRef]

- Wang, D.; Wu, X. Grasping performance analysis and comparison of multi-chamber ring-shaped soft grippers. Biomimetics 2023, 8, 337. [Google Scholar] [CrossRef]

- Terrile, S.; Arguelles, M.; Barrientos, A. Comparison of different technologies for soft robotics grippers. Sensors 2021, 21, 3253. [Google Scholar] [CrossRef]

- Jones, T.J.; Jambon-Puillet, E.; Marthelot, J.; Brun, P.T. Bubble casting soft robotics. Nature 2021, 599, 229–233. [Google Scholar] [CrossRef]

- Tang, Y.; Chi, Y.; Sun, J.; Huang, T.H.; Maghsoudi, O.H.; Spence, A.; Zhao, J.; Su, H.; Yin, J. Leveraging elastic instabilities for amplified performance: Spine-inspired high-speed and high-force soft robots. Sci. Adv. 2020, 6, eaaz6912. [Google Scholar] [CrossRef]

- Baines, R.; Patiballa, S.K.; Booth, J.; Ramirez, L.; Sipple, T.; Garcia, A.; Fish, F.; Kramer-Bottiglio, R. Multi-environment robotic transitions through adaptive morphogenesis. Nature 2022, 610, 283–289. [Google Scholar] [CrossRef]

- Gai, L.J.; Huang, J.; Zong, X. Stiffness-Tunable Soft Bellows Actuators by Cross-Fiber Jamming Effect for Robust Grasping. IEEE/ASME Trans. Mechatron. 2023, 28, 2897–2907. [Google Scholar] [CrossRef]

- Terryn, S.; Brancart, J.; Lefeber, D.; Assche, G.V.; Vanderborght, B. Self-healing soft pneumatic robots. Sci. Robot. 2017, 2, eaan4268. [Google Scholar] [CrossRef] [PubMed]

- Moseley, P.; Florez, J.M.; Sonar, H.A.; Agarwal, G.; Curtin, W.; Paik, J. Modeling, design, and development of soft pneumatic actuators with finite element method. Adv. Eng. Mater. 2016, 18, 978–988. [Google Scholar] [CrossRef]

- Shen, X. Nonlinear model-based control of pneumatic artificial muscle servo systems. Control Eng. Pract. 2010, 18, 311–317. [Google Scholar] [CrossRef]

- Dao, Q.T.; Le, H.T.; Nguyen, M.L.; Do, T.H.; Duong, M.D. A Modified Bouc–Wen Model of Pneumatic Artificial Muscles in Antagonistic Configuration. In Proceedings of the 2020 International Conference on Advanced Mechatronic Systems, Hanoi, Vietnam, 10–13 December 2020; pp. 157–161. [Google Scholar]

- Xie, S.; Ren, G.; Wang, B. A modified asymmetric generalized Prandtl–Ishlinskii model for characterizing the irregular asymmetric hysteresis of self-made pneumatic muscle actuators. Mech. Mach. Theory 2020, 149, 103836. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Lu, J.; Huang, Z.; Feng, B. Design, Characteristic Analysis and Modeling of a Tailored Soft Robot for Phosphorite Grabbing. Appl. Sci. 2025, 15, 5615. https://doi.org/10.3390/app15105615

Zhang Y, Lu J, Huang Z, Feng B. Design, Characteristic Analysis and Modeling of a Tailored Soft Robot for Phosphorite Grabbing. Applied Sciences. 2025; 15(10):5615. https://doi.org/10.3390/app15105615

Chicago/Turabian StyleZhang, Yang, Junjie Lu, Zixin Huang, and Bing Feng. 2025. "Design, Characteristic Analysis and Modeling of a Tailored Soft Robot for Phosphorite Grabbing" Applied Sciences 15, no. 10: 5615. https://doi.org/10.3390/app15105615

APA StyleZhang, Y., Lu, J., Huang, Z., & Feng, B. (2025). Design, Characteristic Analysis and Modeling of a Tailored Soft Robot for Phosphorite Grabbing. Applied Sciences, 15(10), 5615. https://doi.org/10.3390/app15105615