Fracture Behavior and Cracking Mechanism of Rock Materials Containing Fissure-Holes Under Brazilian Splitting Tests

Abstract

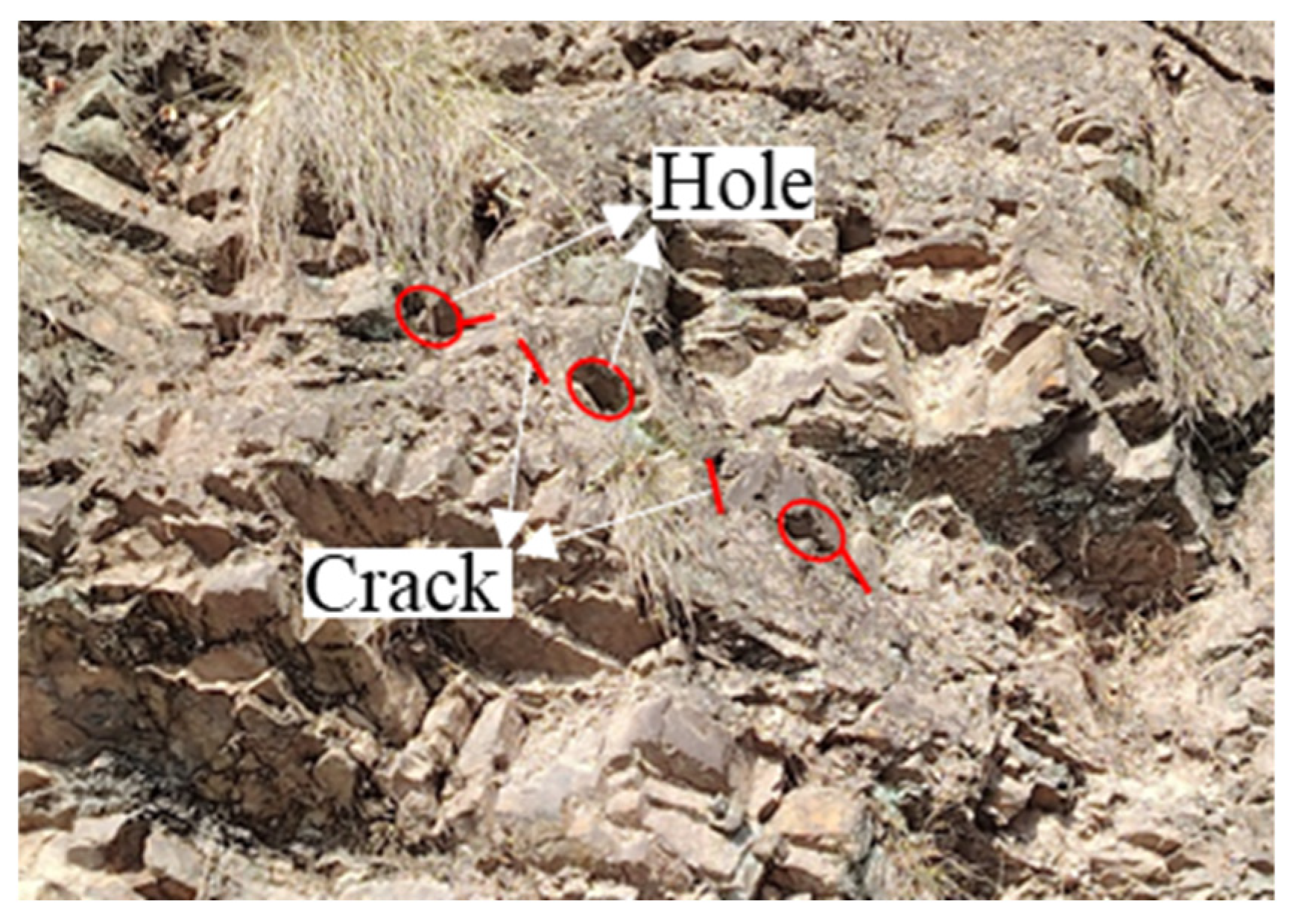

1. Introduction

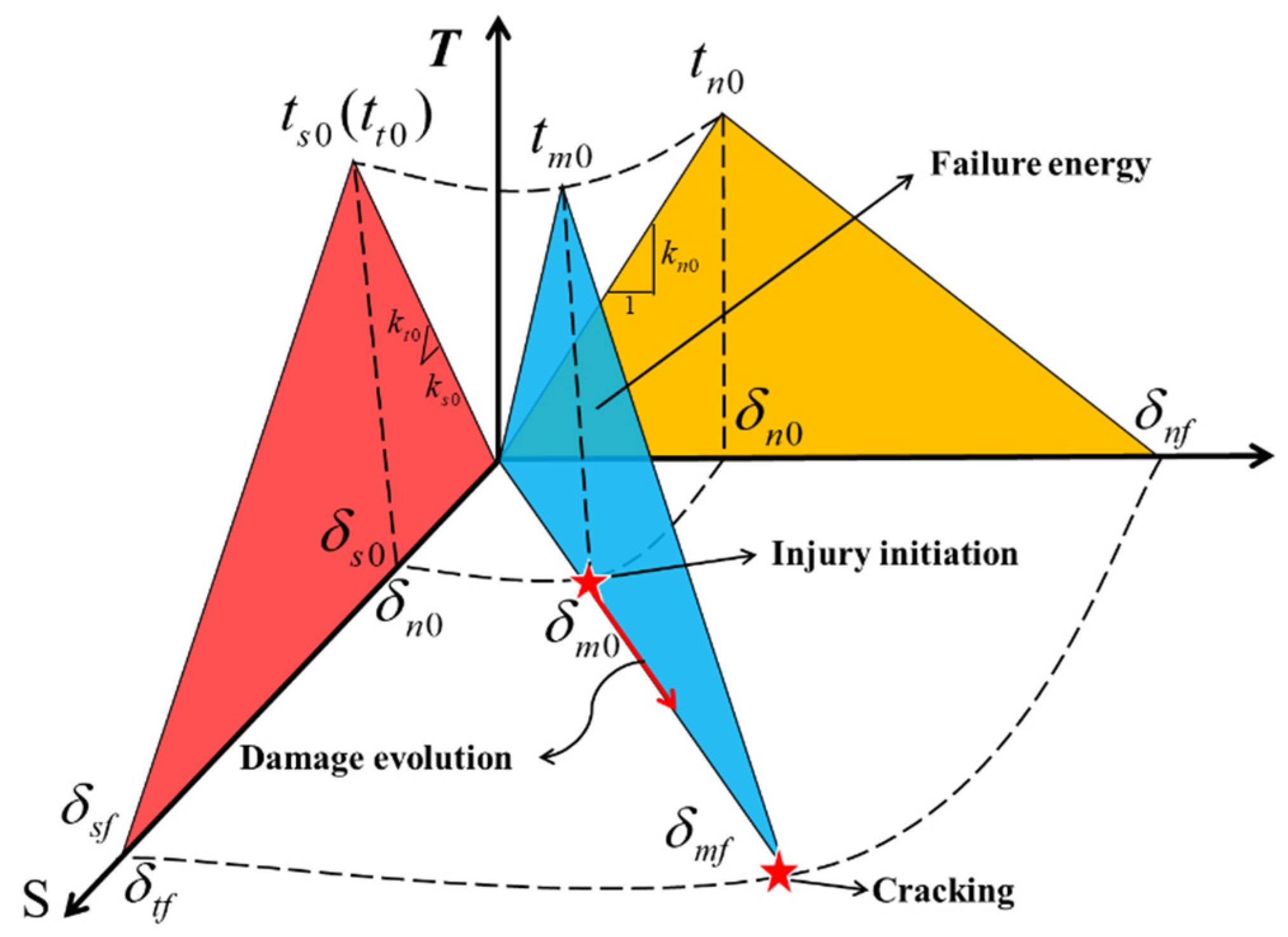

2. FEM-CZM Method

2.1. Separation-Traction Criteria

2.2. The Formation Process of Zero Thickness Cohesive Force Unit

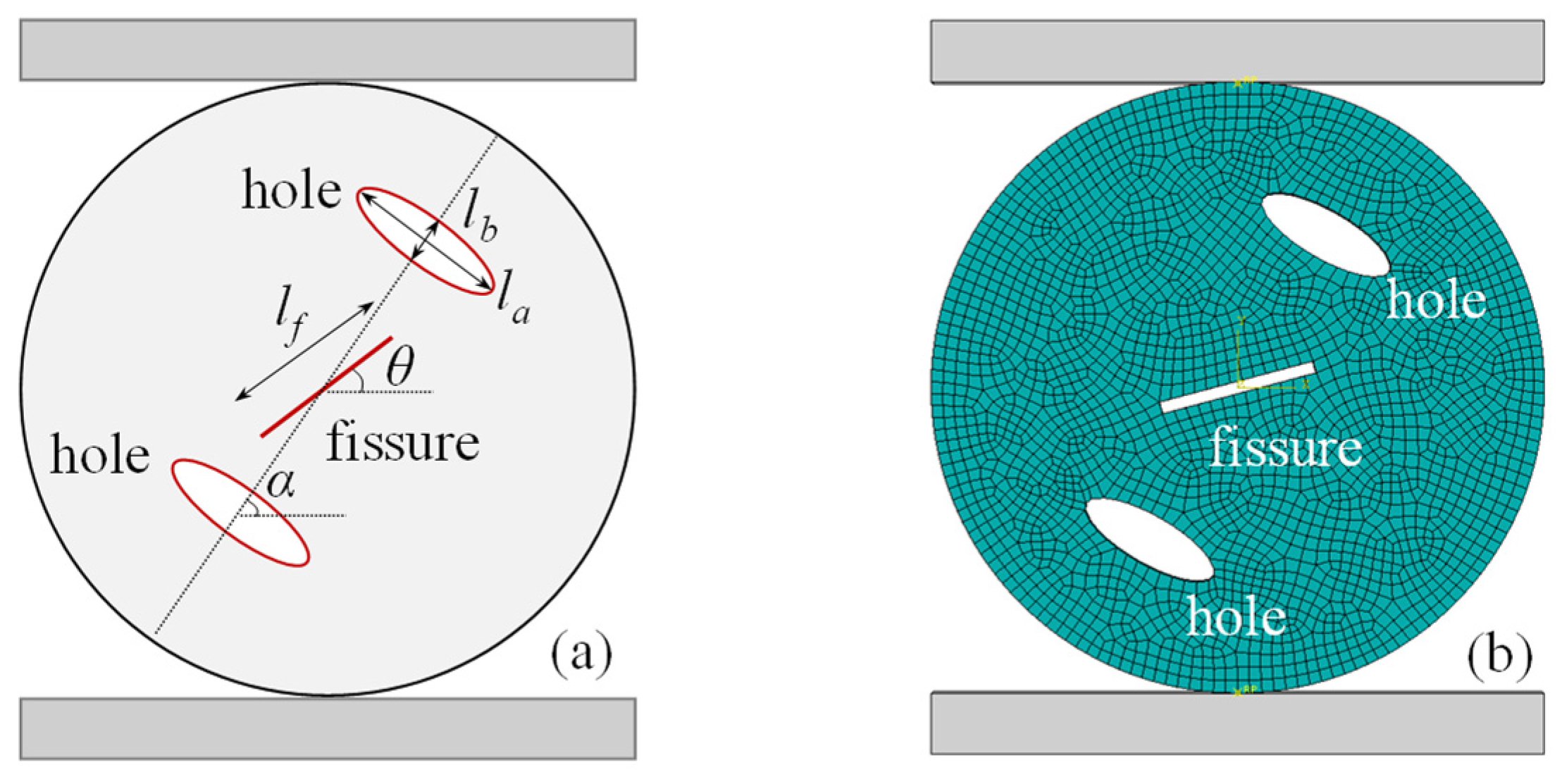

3. Model Establishment

- (1)

- Changing the crack Angle θ (0°, 15°, 60°, 90°, 150°), lf = 13 mm, α = 60°, la = 12 mm, lb = 4 mm;

- (2)

- Changing the fracture length lf (20 mm, 28 mm, 40 mm), θ = 15°, α = 60°, la = 12 mm, lb = 4 mm.

4. Test Result

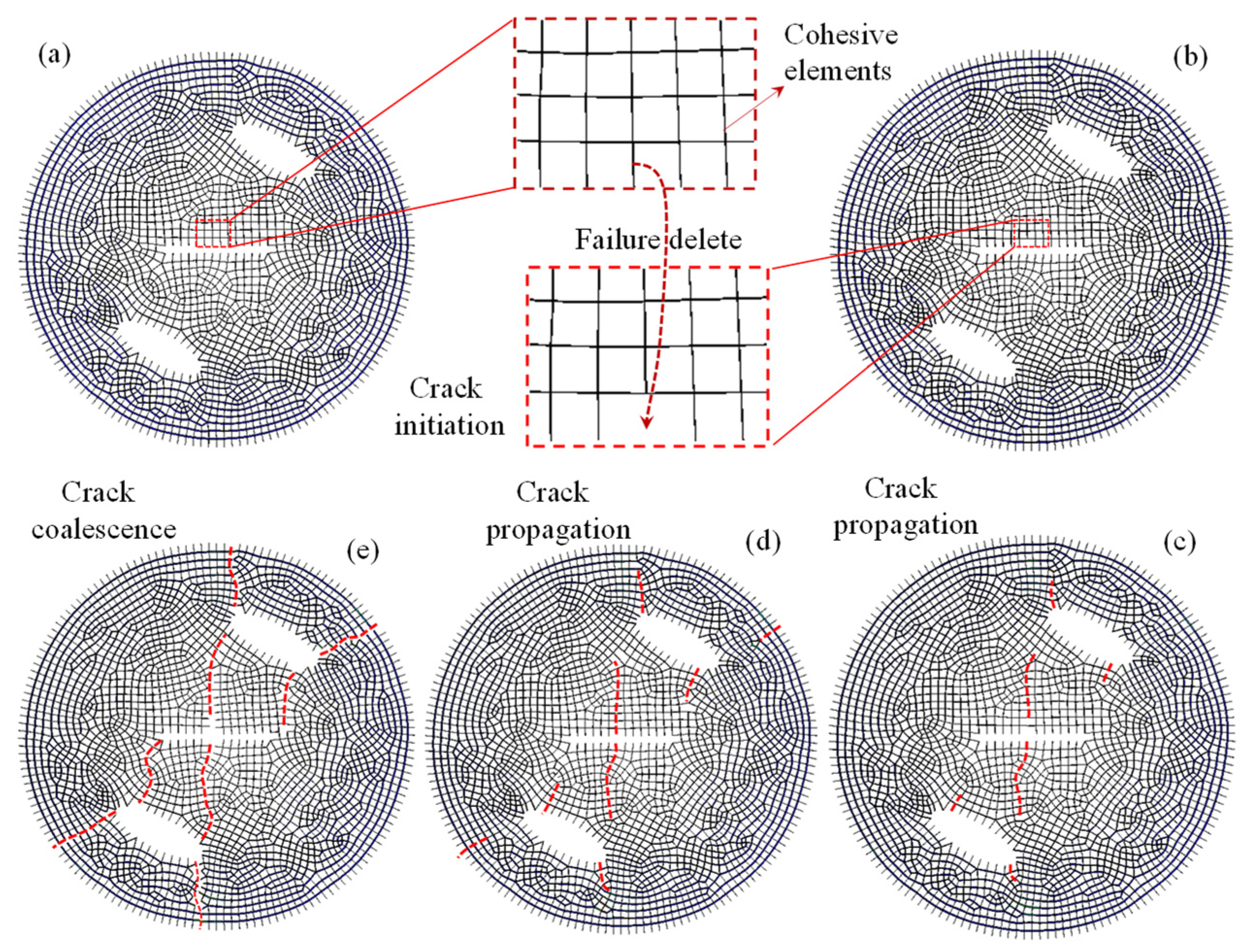

4.1. Principle of Crack Generation

4.2. Mechanical Characteristic Analysis

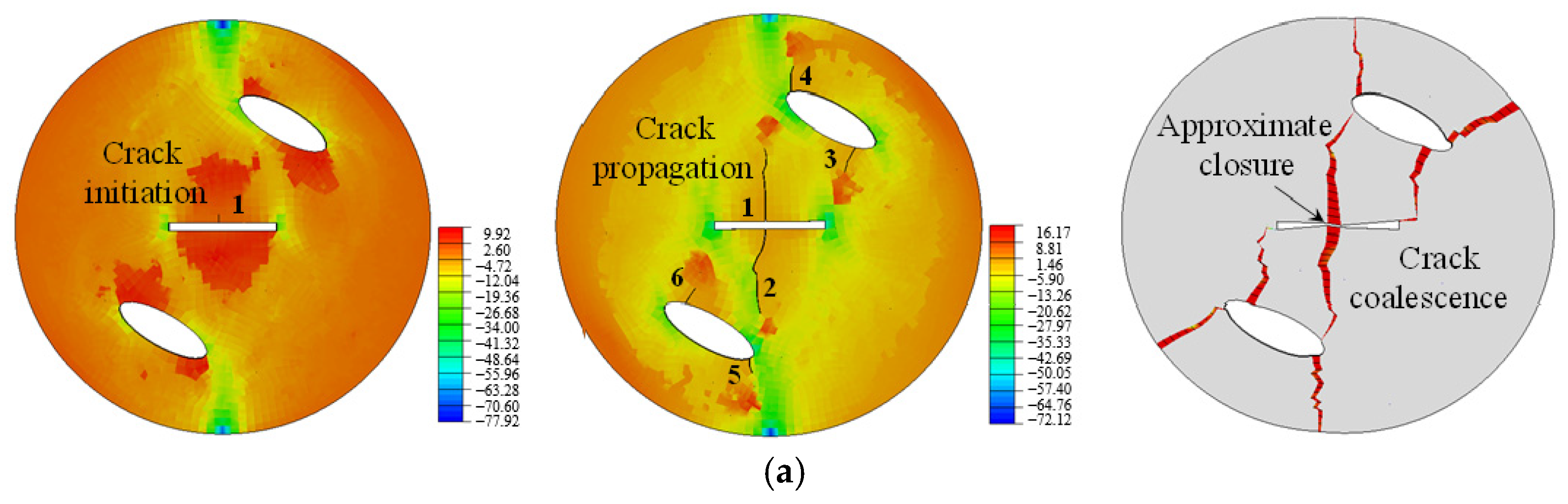

4.2.1. Influence of Crack Angle on Cracking Characteristics

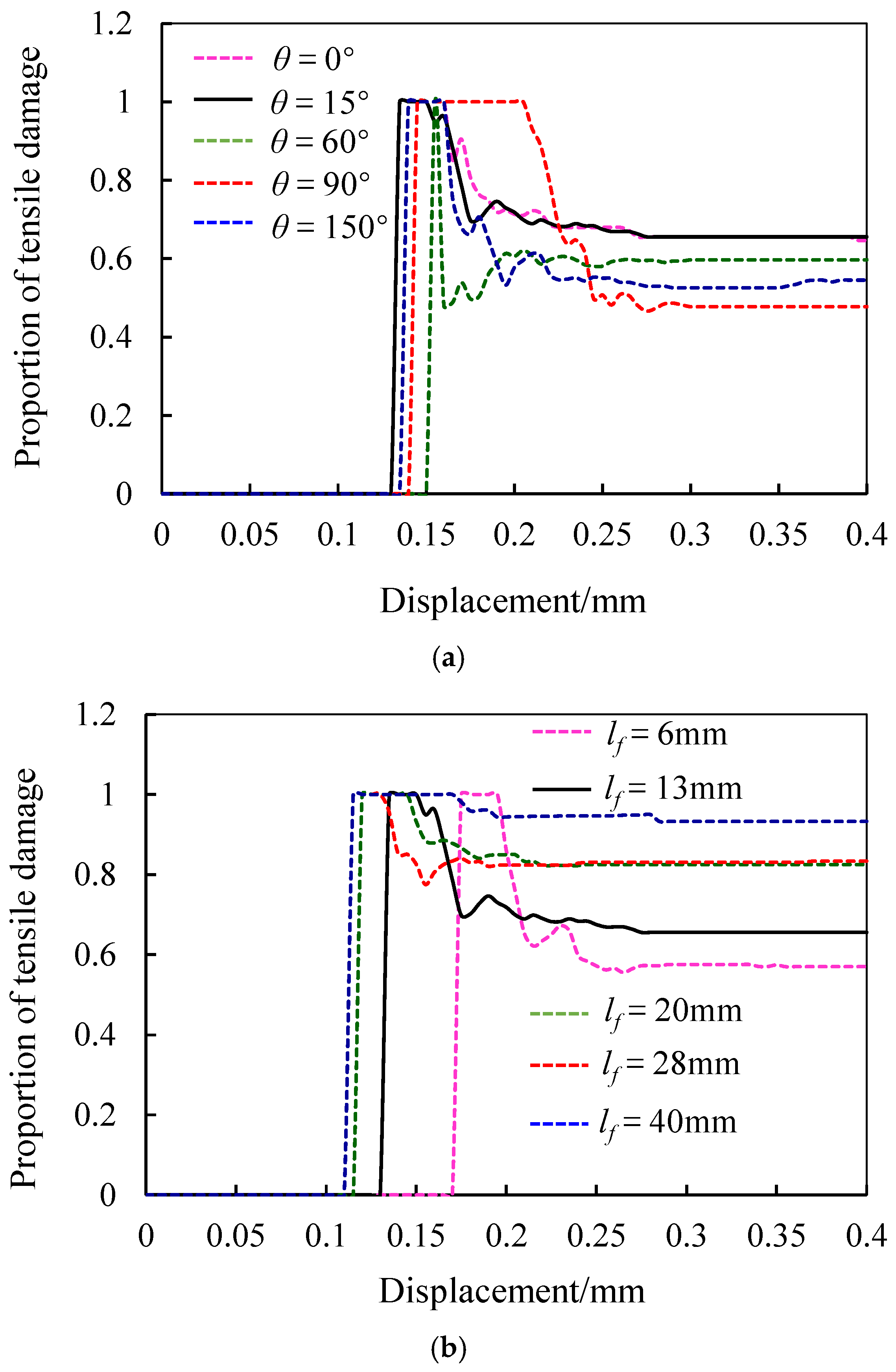

4.2.2. Influence of Crack Length on Cracking Characteristics

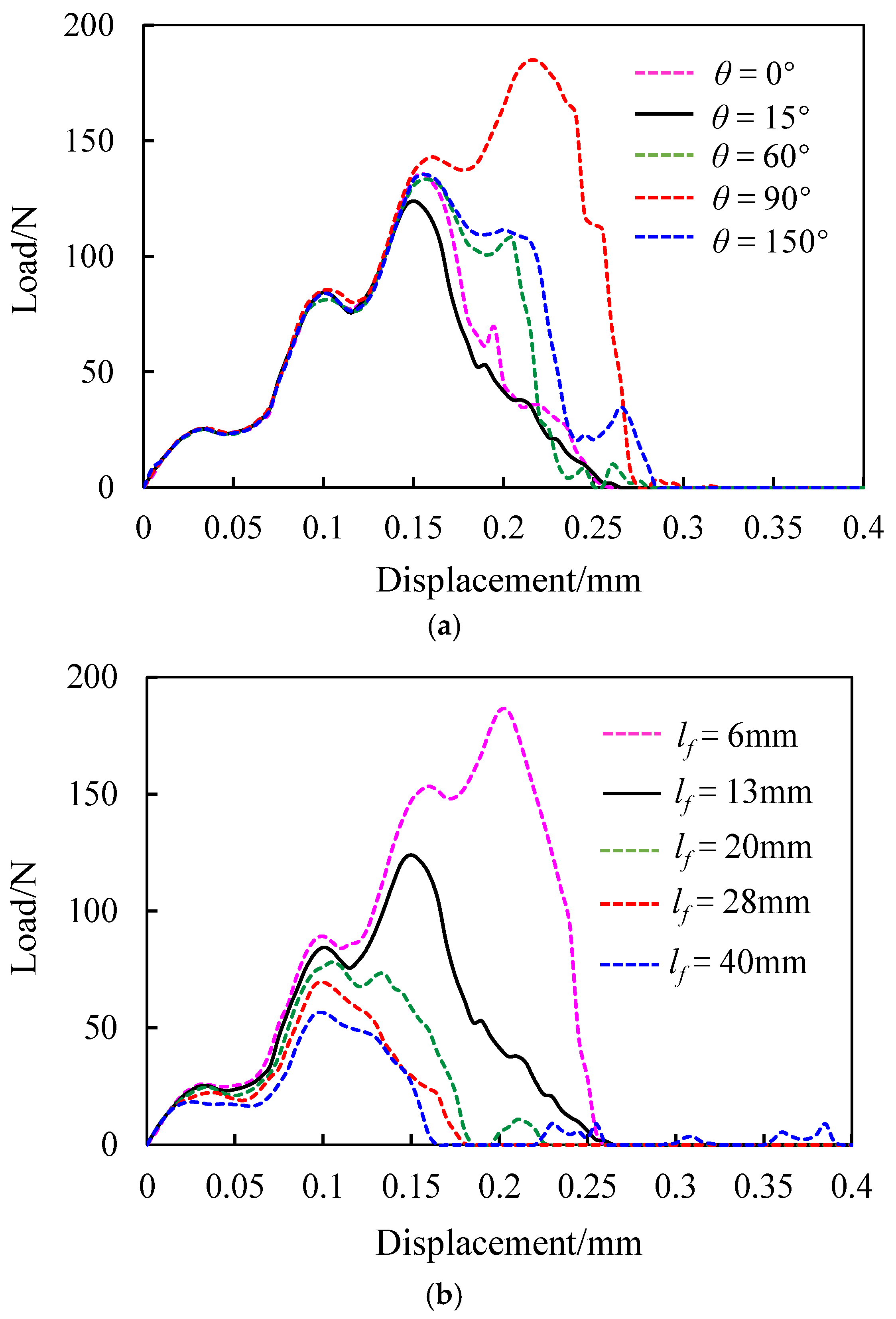

4.3. Crack Cracking Mechanism

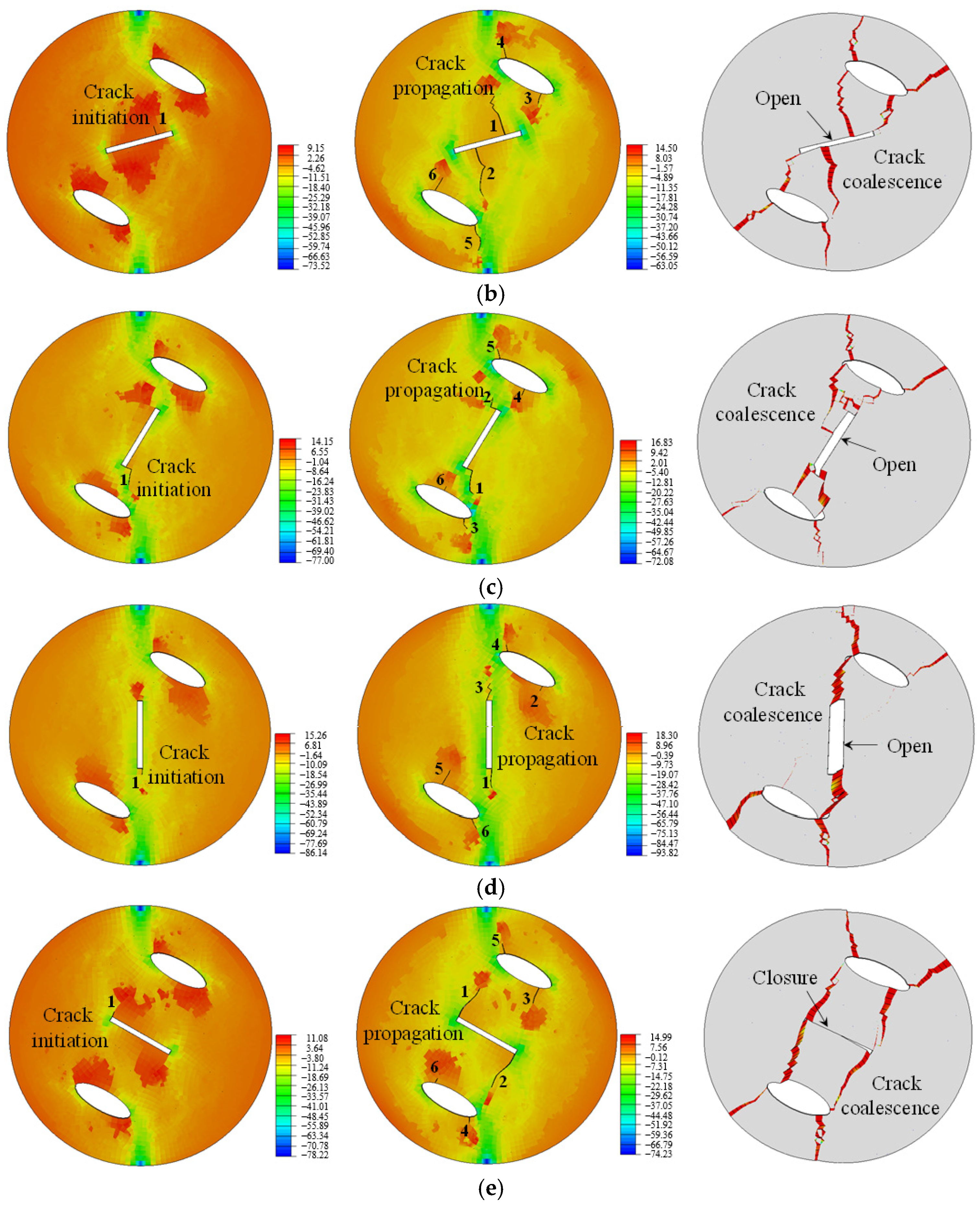

4.4. Load Displacement Curve Change Trend

4.5. Sample Failure Mode

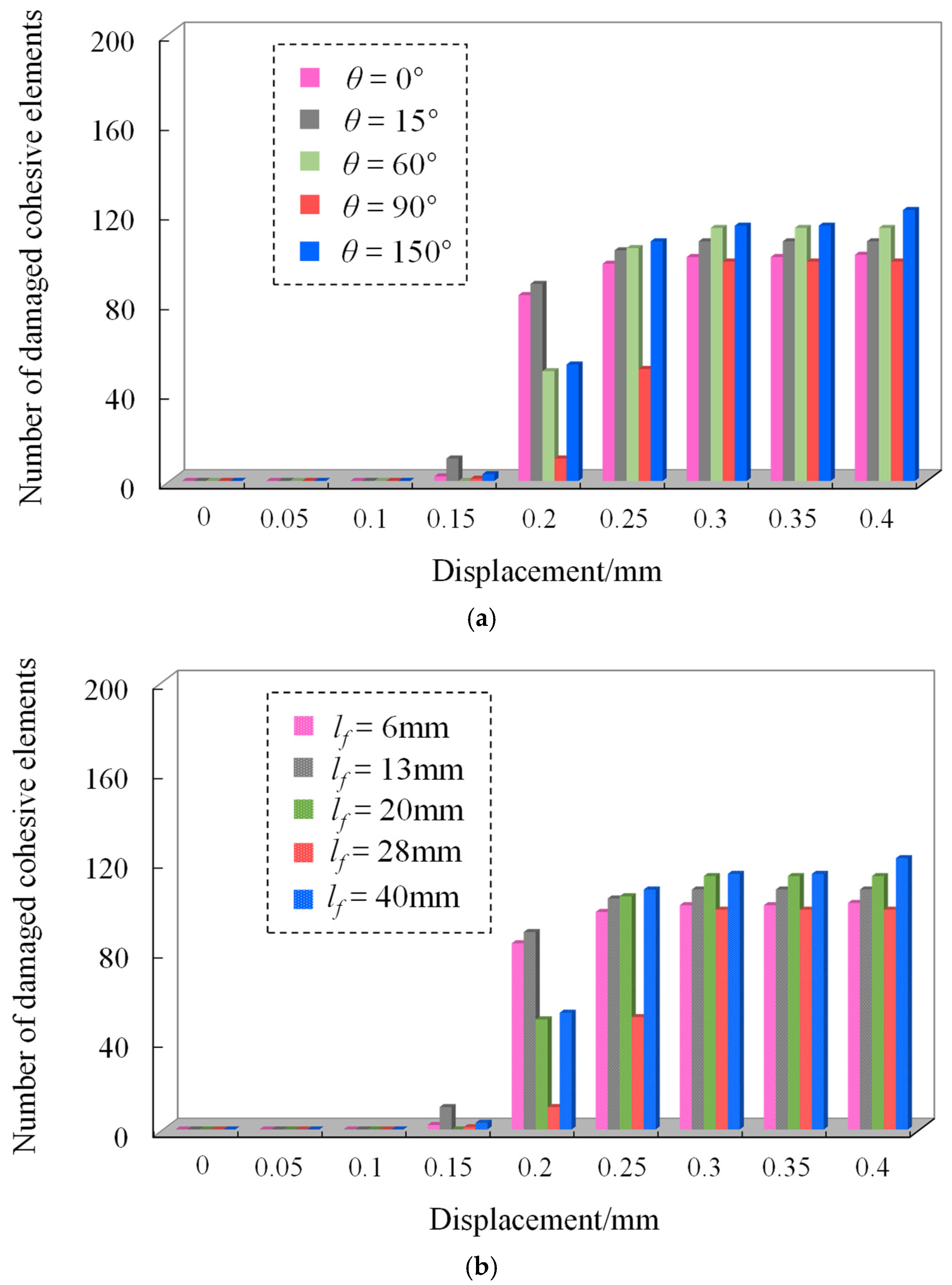

4.6. The Number of Cohesiveness Unit Damage

5. Conclusions

- (1)

- When the crack angle is small, the crack typically initiates at a specific distance from the initial crack. As the external load increases, the crack propagates and intersects along the radial direction, potentially leading to specimen failure. The crack propagation mode exhibits local closure. With an increase in the crack inclination angle, the initiation location shifts, becoming more pronounced as the angle further increases. As crack length increases, the initiation location may shift to other parts of the crack or near the hole. Shorter cracks tend to penetrate more easily but do not necessarily exhibit closure, whereas longer cracks may show local closure with a more complex penetration pattern.

- (2)

- The load–displacement curves for samples with different fracture angles coincide during the tensile and stability failure stages but diverge in the shear failure stage due to varying fracture angles. The fracture angle has a negligible effect on the overall trend of the load–displacement curve. Similarly, the load–displacement curves for samples with different crack lengths exhibit characteristics of an initial straight rise, followed by three gradual declines, a rapid rise to the peak, a rapid decline, and eventual stabilization. While the fracture length significantly influences the peak value of the load–displacement curve, it has minimal impact on the overall trend.

- (3)

- As displacement increases, the proportion of tensile failure undergoes a process of rapid decline, slow rise, another rapid decline, and finally stabilizes. Specimens with crack inclinations of 0° and 15° have the highest tensile failure ratio at stability, while those with a 90° inclination have the lowest. Crack inclination significantly affects the tensile failure ratio. Although fracture length influences the specific value of the tensile failure ratio, it does not affect the overall change trend.

- (4)

- As the crack angle and crack length increase, the damage quantity of cohesive force units also increases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fakhimi, A.; Labuzb, J.F. A simple apparatus for tensile testing of rock. Int. J. Rock Mech. Min. Sci. 2022, 158, 105208. [Google Scholar] [CrossRef]

- Asem, P.; Wang, X.; Hu, C.; Labuz, J.F. On tensile fracture of a brittle rock. Int. J. Rock Mech. Min. Sci. 2021, 144, 104823. [Google Scholar] [CrossRef]

- Wu, C.; Chen, X.; Hong, Y.; Xu, R.; Yu, D. Experimental Investigation of the Tensile Behavior of Rock with Fully Grouted Bolts by the Direct Tensile Test. Rock Mech. Rock Eng. 2018, 51, 351–357. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, J.; Guo, J.; Lü, Q.; Deng, J. A Method for Evaluating the Maximum Bending Degree of Flexural Toppling Rock Masses Based on the Rock Tensile Strain-Softening Model. J. Earth Sci. 2024, 35, 1243–1253. [Google Scholar] [CrossRef]

- Hu, X.; Su, G.; Li, Z.; Xu, C.; Yan, X.; Liu, Y.; Yan, L. Suppressing rock burst by increasing the tensile strength of rock surface: An experimental study. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2021, 107, 103645. [Google Scholar] [CrossRef]

- Liu, S.; Xu, J.; Fang, X. Study on the Splitting Tensile Mechanical Behavior and Failure Characteristics of Thermally-Damaged Rock. Géotechnique Lett. 2021, 11, 1–26. [Google Scholar]

- Ghasem, S.; Patrice, R.; Omid, M. Observation of fracture process zone and produced fracture surface roughness in granite Under Brazilian splitting tests. Theor. Appl. Fract. Mech. 2023, 125, 103680. [Google Scholar]

- Komurlu, E.; Kesimal, A. Evaluation of Indirect Tensile Strength of Rocks Using Different Types of Jaws. Rock Mech. Rock Eng. 2015, 48, 1723–1730. [Google Scholar] [CrossRef]

- Gutierrez, M.; Youn, D. Effects of fracture distribution and length scale on the equivalent continuum elastic compliance of fractured rock masses. J. Rock Mech. Geotech. Eng. 2015, 7, 626–637. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, P.; Teng, S.; Tian, W.; Huang, Y. Experimental study of tensile strength crack evolution characteristics of the Brazilian disc containing three pre-existing fissures. J. China Univ. Min. Technol. 2021, 50, 90–98. [Google Scholar] [CrossRef]

- Zhang, M.; Yao, H.; Jiang, H.; Liu, W.; Wang, X.; Zhu, Y. Experimental Study on Brazilian Splitting Fracture Characteristics of Prefabricated Fissured Sandtone. Met. Mine 2024, 4, 20–27. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.; Cao, S.; Pan, R.; Yang, H.; Zhang, K.; Liu, Y. Brazilian splitting test study on crack propagation process and macroscopic failure mode of pre-cracked black shale. Chin. J. Rock Mech. Eng. 2020, 39, 912–926. [Google Scholar]

- Janeiro, P.R.; Einstein, H.H. Experimental study of the cracking behavior of specimens containing inclusions (Under uniaxial compression). Int. J. Fract. 2010, 164, 83–102. [Google Scholar] [CrossRef]

- Kamgue Tiam, F.F.; Danwe, R.; Konaï, N. Experimental study and numerical simulation using ex-tended finite element method (XFEM) combined with cohesive zone model (CZM), of crack growth induced by non-explosive expansive material on two neighboring circular holes of a gneiss rock. Open J. Appl. Sci. 2020, 10, 592–612. [Google Scholar] [CrossRef]

- Qin, H.; Han, Z.; Huang, D. Nonlocal peridynamic modeling for split of notched brazilian disk. Chin. J. Solid Mech. 2017, 38, 483–491. [Google Scholar]

- Wang, M.; Liu, Z.X.; Zhao, Y.L.; Wan, W. Peak strength, coalescence and failure processes of rock-like materials containing preexisting joints and circular holes under uniaxial compression: Experimental and numerical study. Theor. Appl. Fract. Mech. 2023, 125, 103898. [Google Scholar] [CrossRef]

- Han, Z.; Liu, K.; Ma, J.; Li, D. Numerical simulation on the dynamic mechanical response and fracture mechanism of rocks containing a single hole. Int. J. Coal Sci. Technol. 2024, 11, 64. [Google Scholar] [CrossRef]

- Santis, D.F.; Renaud, V.; Gunzburger, Y.; Kinscher, J.; Bernard, P.; Contrucci, I. In situ monitoring and 3D geomechanical numerical modelling to evaluate seismic and aseismic rock deformation in response to deep mining. Int. J. Rock Mech. Min. Sci. 2020, 129, 104273. [Google Scholar] [CrossRef]

- Dugdale, D.S. Yielding of steel sheets containing slits. J. Mech. Phys. Solids 1960, 8, 100–104. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, G.; Jiang, Y.; Wu, X.; Li, G.; He, P.; Yu, J.; Sun, L. Study on Shear Mechanism of Bolted Jointed Rocks: Experiments and CZM-Based FEM Simulations. Appl. Sci. 2019, 10, 62. [Google Scholar] [CrossRef]

- Song, S.H.; Paulino, G.H.; Buttlar, W.G. A bilinear cohesive zone model tailored for fracture of asphalt concrete considering viscoelastic bulk material. Eng. Fract. Mech. 2006, 73, 2829–2848. [Google Scholar] [CrossRef]

- Han, W.; Jiang, Y.; Luan, H.; Liu, J.; Wu, X.; Du, Y. Fracture evolution and failure mechanism of rock-like materials containing cross-flaws under the shearing effect. Theor. Appl. Fract. Mech. 2020, 110, 102815. [Google Scholar] [CrossRef]

- Han, W.; Jiang, Y.; Luan, H.; Du, Y.; Zhu, Y.; Liu, J. Numerical investigation on the shear behavior of rock-like materials containing fissure-holes with FEM-CZM method. Comput. Geotech. 2020, 125, 103670. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, S.-b.; Lian, L.; Zhao, C.; Wang, K.; Zhang, X.D. Macro-micro study on shear failure mechanism of rock joint based on zero-thickness cohesive element. Chin. J. Geotech. Eng. 2019, 41, 2224–2232. [Google Scholar]

- Xie, D.; Waas, A.M. Discrete cohesive zone model for mixed-mode fracture using finite element analysis. Eng. Fract. Mech. 2006, 73, 1783–1796. [Google Scholar] [CrossRef]

- Yao, Y. Linear elastic and cohesive fracture analysis to model hydraulic fracture in brittle and ductile rocks. Rock Mech. Rock Eng. 2012, 45, 375–387. [Google Scholar] [CrossRef]

- Du, Y.; Du, X.; Han, W.; Wang, X.; Huang, B.; Zhang, S. Fracture Behavior of Brazilian Disc Specimens Containing Fissure-Holes Based on the FEM-CZM Method. Geotech. Geol. Eng. 2025, 43, 92. [Google Scholar] [CrossRef]

| Materials | Parameters | Value |

|---|---|---|

| Solid elements | Density/kg·m−3 | 2500 |

| Young’s modulus/GPa | 15 | |

| Poisson’s ratio | 0.3 | |

| Cohesive elements | /GPa·mm−1 | 15 |

| /GPa·mm−1 | 5.28 | |

| /GPa·mm−1 | 5.28 | |

| /MPa | 5.5 | |

| /MPa | 20 | |

| /MPa | 20 | |

| Model-I fracture energy/N/mm | 0.055 | |

| Model-II fracture energy N/mm | 0.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luan, H.; Liu, K.; Ge, D.; Han, W.; Zhou, Y.; Wang, L.; Zhang, S. Fracture Behavior and Cracking Mechanism of Rock Materials Containing Fissure-Holes Under Brazilian Splitting Tests. Appl. Sci. 2025, 15, 5592. https://doi.org/10.3390/app15105592

Luan H, Liu K, Ge D, Han W, Zhou Y, Wang L, Zhang S. Fracture Behavior and Cracking Mechanism of Rock Materials Containing Fissure-Holes Under Brazilian Splitting Tests. Applied Sciences. 2025; 15(10):5592. https://doi.org/10.3390/app15105592

Chicago/Turabian StyleLuan, Hengjie, Kun Liu, Decheng Ge, Wei Han, Yiran Zhou, Lujie Wang, and Sunhao Zhang. 2025. "Fracture Behavior and Cracking Mechanism of Rock Materials Containing Fissure-Holes Under Brazilian Splitting Tests" Applied Sciences 15, no. 10: 5592. https://doi.org/10.3390/app15105592

APA StyleLuan, H., Liu, K., Ge, D., Han, W., Zhou, Y., Wang, L., & Zhang, S. (2025). Fracture Behavior and Cracking Mechanism of Rock Materials Containing Fissure-Holes Under Brazilian Splitting Tests. Applied Sciences, 15(10), 5592. https://doi.org/10.3390/app15105592