Evaluation of Manufacturing Accuracy in Merlon Fracture Models Fabricated by Vat Photopolymerization 3D-Printing Technologies

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Devices

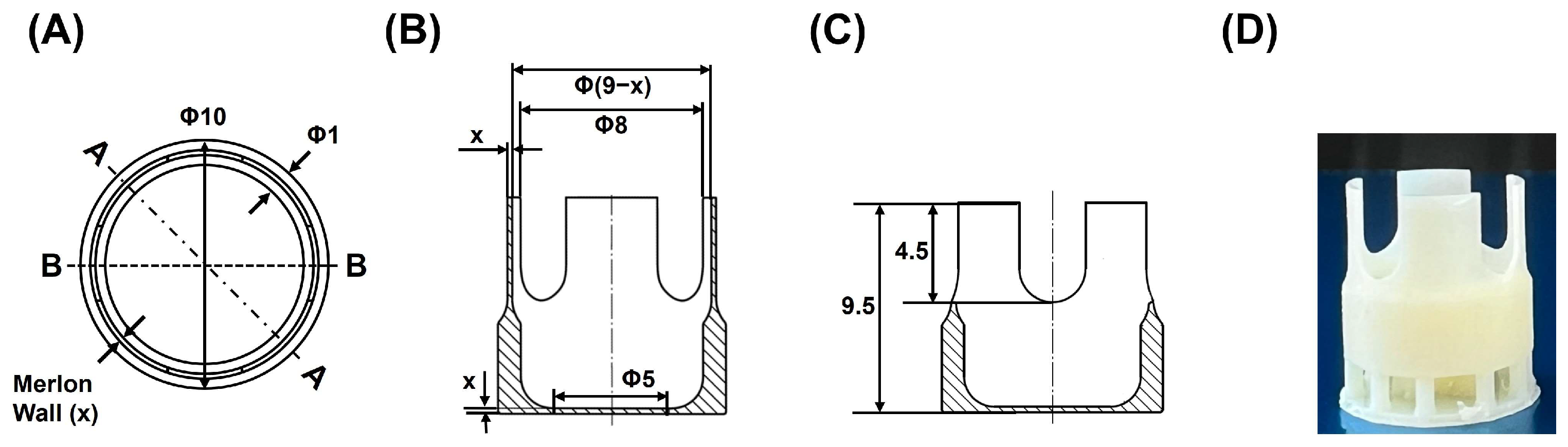

2.2. CAD Reference-Data Design

2.3. Sample Preparation

2.4. Manufacturing Accuracy Test

2.5. Thickness Measurement of Wall and Bottom Part

2.6. FE-SEM Observation

2.7. Statistical Analysis

3. Results

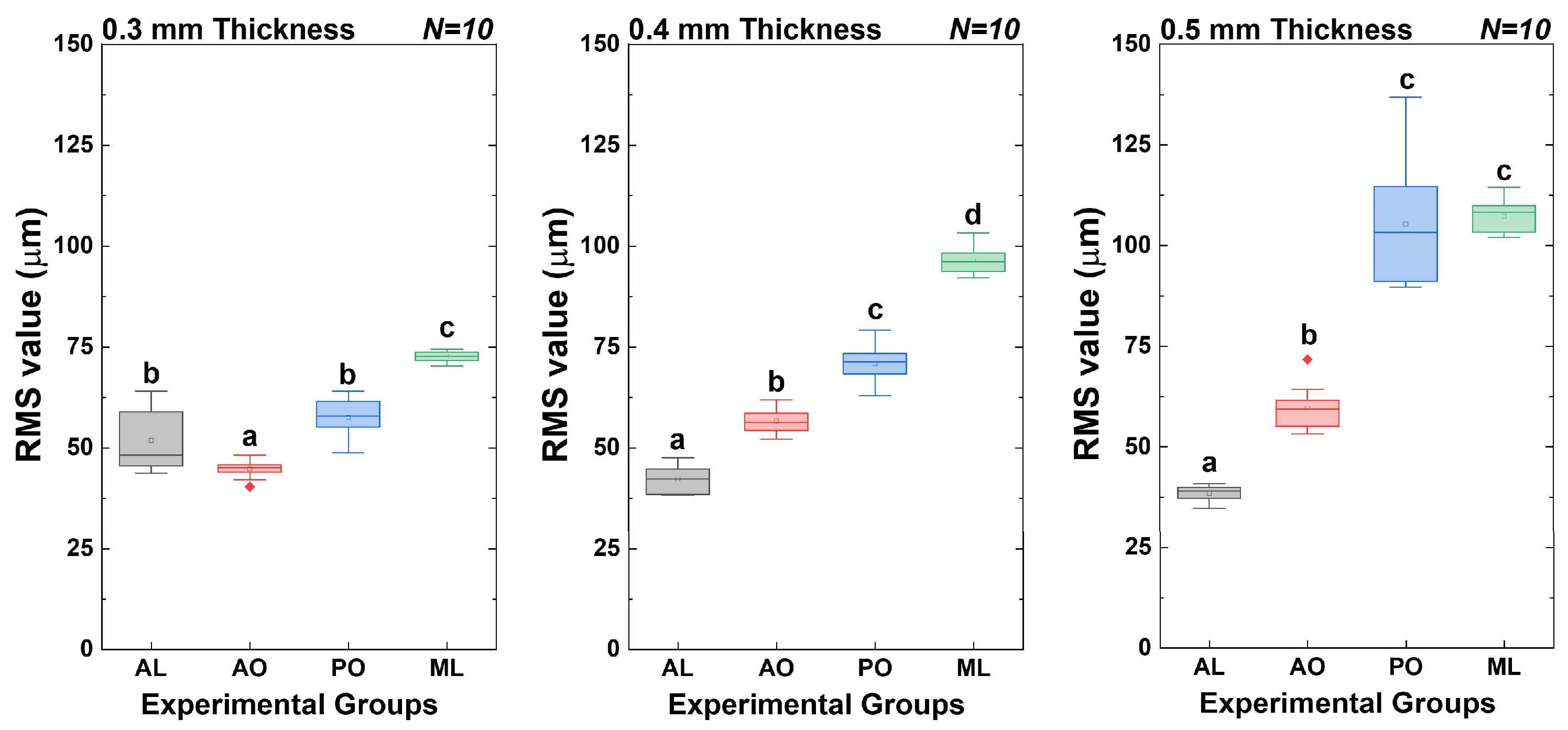

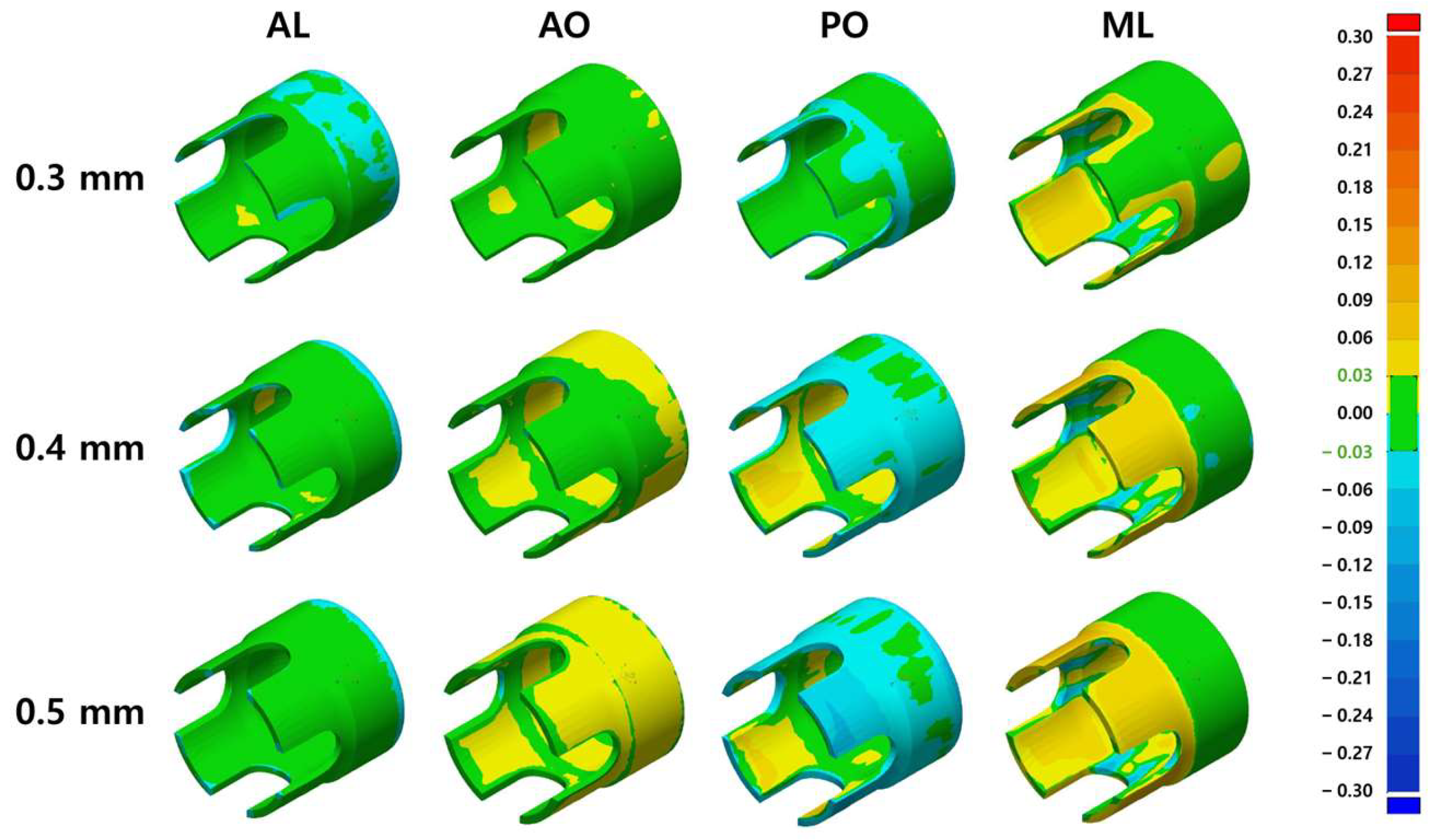

3.1. Manufacturing Accuracy Test

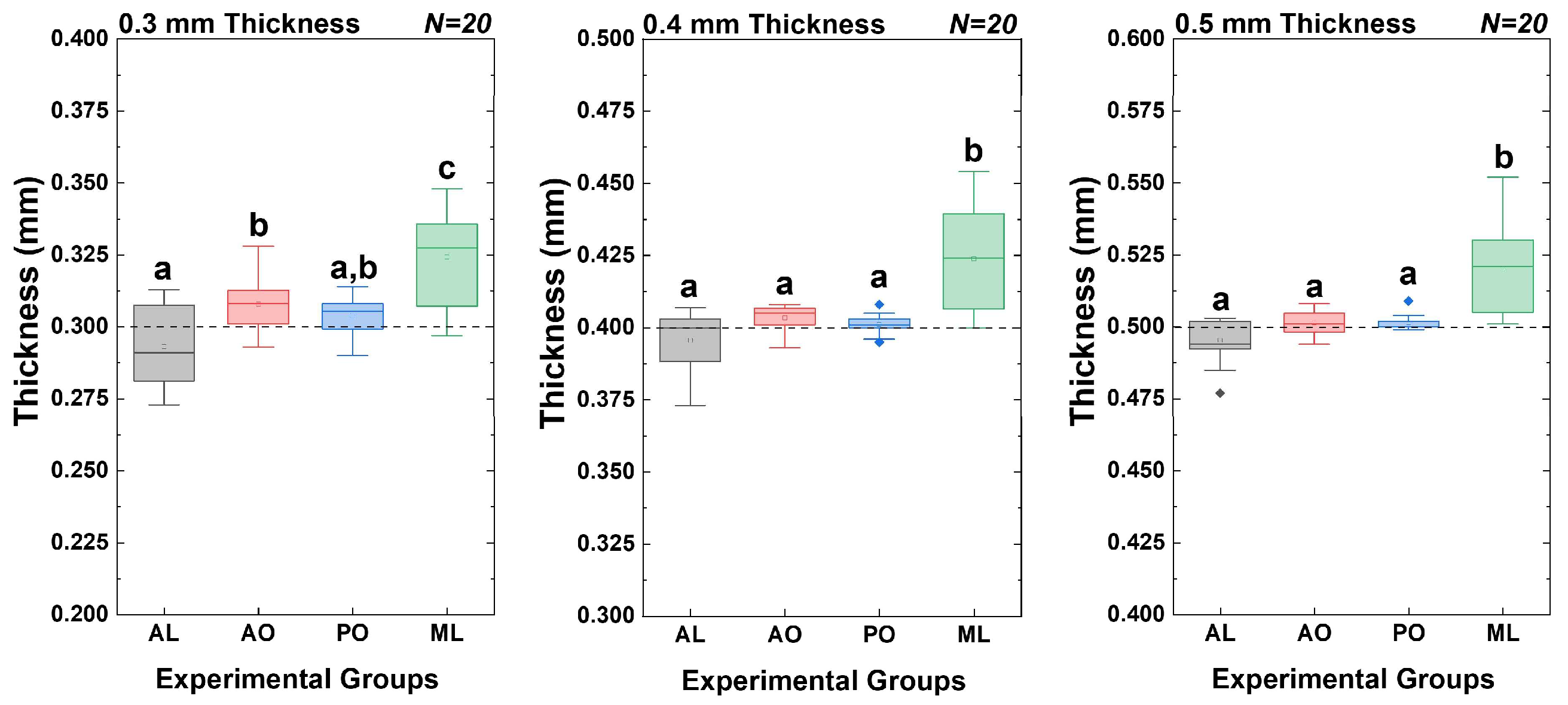

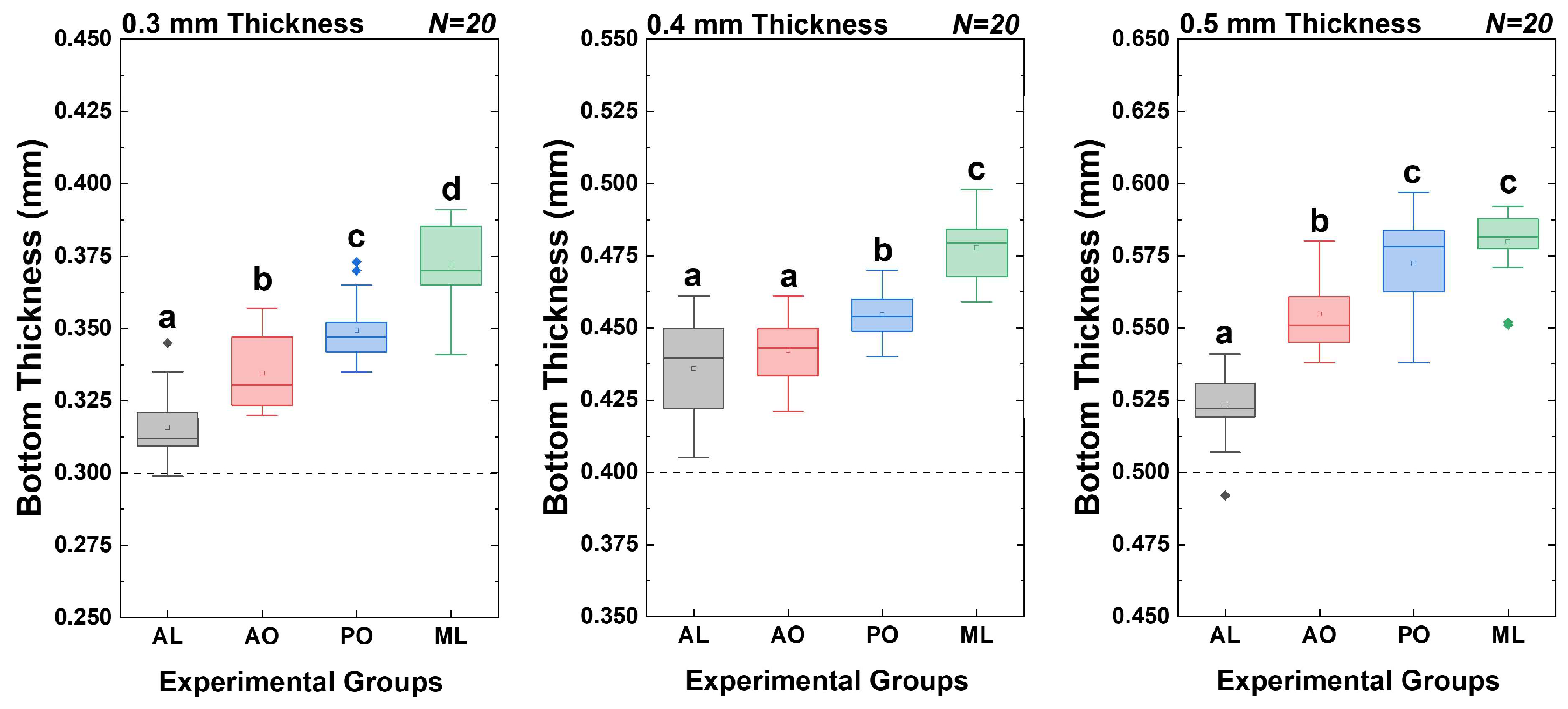

3.2. Thickness Measurement of Wall and Bottom Part

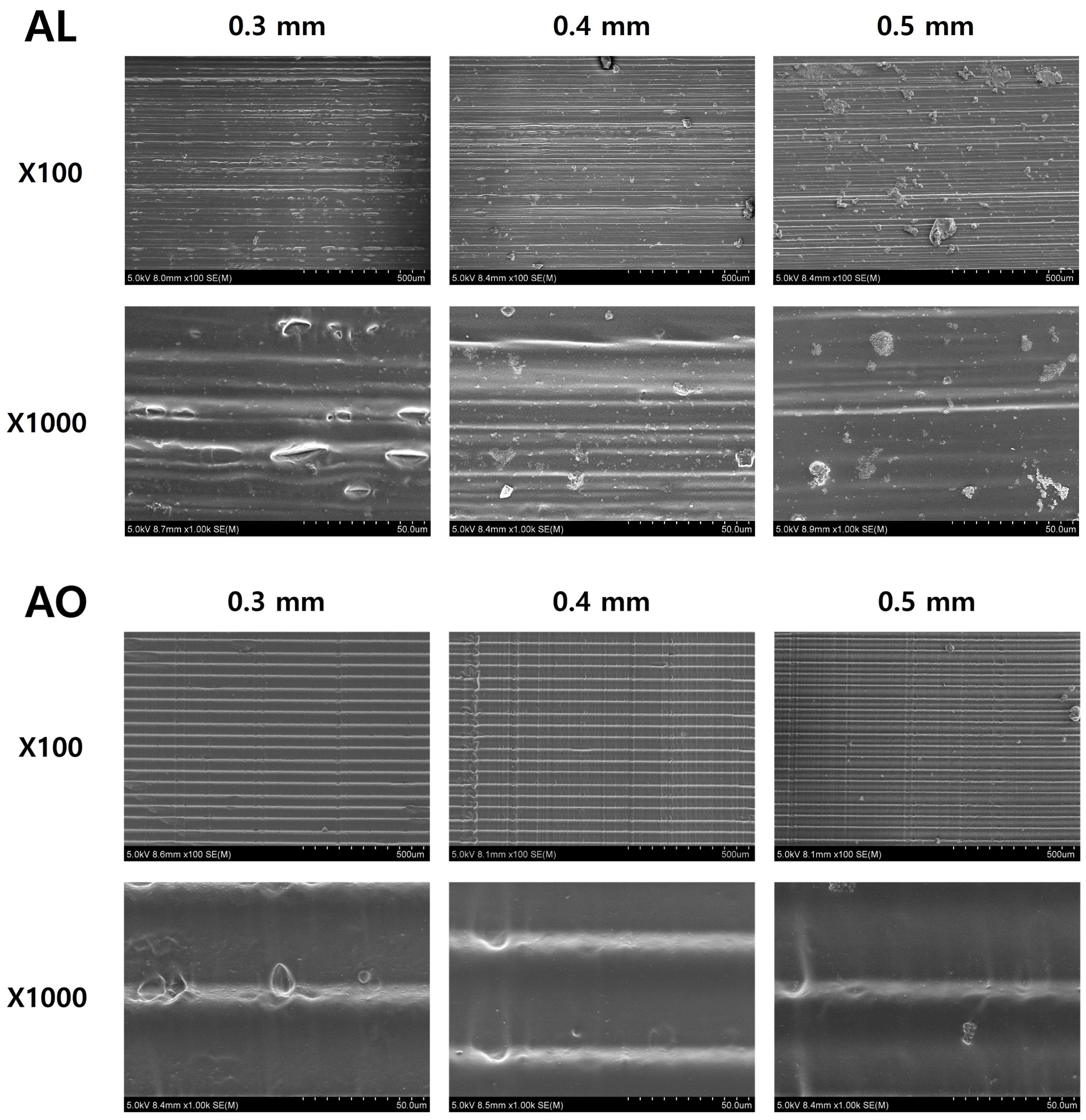

3.3. FE-SEM Obsevation

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nulty, A. A literature review on prosthetically designed guided implant placement and the factors influencing dental implant success. Br. Dent. J. 2024, 236, 169–180. [Google Scholar] [CrossRef]

- Brenes, C.; Bencharit, S.; Fox, T. Evaluation of Prosthetic Outcomes and Patient Satisfaction with 3D-Printed Implant-Supported Fixed Prosthesis. Cureus 2023, 15, e42537. [Google Scholar] [CrossRef]

- Suganna, M.; Kausher, H.; Tarek Ahmed, S.; Sultan Alharbi, H.; Faraj Alsubaie, B.; Ds, A.; Haleem, S.; Meer Rownaq Ali, A.B. Contemporary Evidence of CAD-CAM in Dentistry: A Systematic Review. Cureus 2022, 14, e31687. [Google Scholar] [CrossRef] [PubMed]

- Alhallak, K.; Hagi-Pavli, E.; Nankali, A. A review on clinical use of CAD/CAM and 3D printed dentures. Br. Dent. J. 2023. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.Y.; Chen, C.X.; Xu, X.T.; Wang, J.Y.; Hou, X.Y.; Li, K.L.; Lu, X.Y.; Shi, H.Y.; Lee, E.S.; Jiang, H.B. A Review of 3D Printing in Dentistry: Technologies, Affecting Factors, and Applications. Scanning 2021, 2021, 9950131. [Google Scholar] [CrossRef]

- Mobarak, M.H.; Islam, M.A.; Hossain, N.; Al Mahmud, M.Z.; Rayhan, M.T.; Nishi, N.J.; Chowdhury, M.A. Recent advances of additive manufacturing in implant fabrication—A review. Appl. Surf. Sci. Adv. 2023, 18, 100462. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, L.; Rajan, S.S.; Damade, Y.; Zhang, X.; Mishra, K.; Qu, L.; Dubey, N. Recent advances in additive manufacturing for tooth restorations. Appl. Mater. Today 2024, 39, 102275. [Google Scholar] [CrossRef]

- Yüceer, Ö.M.; Kaynak Öztürk, E.; Çiçek, E.S.; Aktaş, N.; Bankoğlu Güngör, M. Three-Dimensional-Printed Photopolymer Resin Materials: A Narrative Review on Their Production Techniques and Applications in Dentistry. Polymers 2025, 17, 316. [Google Scholar] [CrossRef]

- Subedi, S.; Liu, S.; Wang, W.; Naser Shovon, S.M.A.; Chen, X.; Ware, H.O.T. Multi-material vat photopolymerization 3D printing: A review of mechanisms and applications. NPJ Adv. Manuf. 2024, 1, 9. [Google Scholar] [CrossRef]

- Shah, M.; Ullah, A.; Azher, K.; Rehman, A.U.; Juan, W.; Aktürk, N.; Tüfekci, C.S.; Salamci, M.U. Vat photopolymerization-based 3D printing of polymer nanocomposites: Current trends and applications. RSC Adv. 2023, 13, 1456–1496. [Google Scholar] [CrossRef]

- Chekkaramkodi, D.; Jacob, L.; Shebeeb, C.M.; Umer, R.; Butt, H. Review of vat photopolymerization 3D printing of photonic devices. Addit. Manuf. 2024, 86, 104189. [Google Scholar] [CrossRef]

- Juneja, M.; Thakur, N.; Kumar, D.; Gupta, A.; Bajwa, B.; Jindal, P. Accuracy in dental surgical guide fabrication using different 3-D printing techniques. Addit. Manuf. 2018, 22, 243–255. [Google Scholar] [CrossRef]

- Deng, K.; Chen, H.; Wei, W.; Wang, X.; Sun, Y. Accuracy of tooth positioning in 3D-printing aided manufactured complete dentures: An in vitro study. J. Dent. 2023, 131, 104459. [Google Scholar] [CrossRef]

- ISO 18675; Dentistry—Machinable Ceramic Blanks. ISO: Geneva, Switzerland, 2022.

- ISO 12836; Dentistry—Digitizing Devices for CAD/CAM Systems for Indirect Dental Restorations—Test Methods for Assessing Accuracy. ISO: Geneva, Switzerland, 2015.

- ISO 23298; Dentistry—Test Methods for Machining Accuracy of Computer-Aided Milling Machines. ISO: Geneva, Switzerland, 2023.

- Alyami, M.H. The Applications of 3D-Printing Technology in Prosthodontics: A Review of the Current Literature. Cureus 2024, 16, e68501. [Google Scholar] [CrossRef]

- Su, G.; Zhang, Y.; Jin, C.; Zhang, Q.; Lu, J.; Liu, Z.; Wang, Q.; Zhang, X.; Ma, J. 3D printed zirconia used as dental materials: A critical review. J. Biol. Eng. 2023, 17, 78. [Google Scholar] [CrossRef] [PubMed]

- Dawood, A.; Marti, B.M.; Sauret-Jackson, V.; Darwood, A. 3D printing in dentistry. Br. Dent. J. 2015, 219, 521–529. [Google Scholar] [CrossRef]

- Revilla-Leon, M.; Ozcan, M. Additive Manufacturing Technologies Used for Processing Polymers: Current Status and Potential Application in Prosthetic Dentistry. J. Prosthodont. 2019, 28, 146–158. [Google Scholar] [CrossRef]

- Young, J.C.; Brinckmann, S.A.; Fertig Iii, R.S.; Lynch, S.P.; Frick, C.P. Influence of layer thickness and exposure on mechanical properties of additively manufactured polymer-derived SiOC ceramics. Open Ceram. 2024, 19, 100652. [Google Scholar] [CrossRef]

- Alharbi, N.; Osman, R.B.; Wismeijer, D. Factors Influencing the Dimensional Accuracy of 3D-Printed Full-Coverage Dental Restorations Using Stereolithography Technology. Int. J. Prosthodont. 2016, 29, 503–510. [Google Scholar] [CrossRef]

- Sahrir, C.D.; Ruslin, M.; Lee, S.Y.; Lin, W.C. Effect of various post-curing light intensities, times, and energy levels on the color of 3D-printed resin crowns. J. Dent. Sci. 2024, 19, 357–363. [Google Scholar] [CrossRef]

- Liu, Y.; Jin, G.; Lim, J.-H.; Kim, J.-E. Effects of washing agents on the mechanical and biocompatibility properties of water-washable 3D printing crown and bridge resin. Sci. Rep. 2024, 14, 9909. [Google Scholar] [CrossRef] [PubMed]

- Katheng, A.; Prawatvatchara, W.; Tonprasong, W.; Namano, S.; Kongkon, P. Effect of Postrinsing Times and Methods on Surface Roughness, Hardness, and Polymerization of 3D-Printed Photopolymer Resin. Eur. J. Dent. 2025, 19, 154–164. [Google Scholar] [CrossRef] [PubMed]

- Caussin, E.; Moussally, C.; Le Goff, S.; Fasham, T.; Troizier-Cheyne, M.; Tapie, L.; Dursun, E.; Attal, J.P.; Francois, P. Vat Photopolymerization 3D Printing in Dentistry: A Comprehensive Review of Actual Popular Technologies. Materials 2024, 17, 950. [Google Scholar] [CrossRef] [PubMed]

| Group Name | Devices | Materials | |

|---|---|---|---|

| Name | Composition | ||

| AL | Asiga Pro 4K DLP 3D printer 1 | Arum C&B 5.0 hybrid 4 | Titanium dioxide, Trimethylolpropane trimethacrylate, Diphenyl phosphine oxide, Silicon Oxide, Urethane Dimethacrylate, and pigments |

| AO | Asiga Pro 4K DLP 3D printer | ODS C&B Permanent A2 5 | Diurethane dimethacrylate, 2-Propenoic acid, 2-methyl-, (1-methylethylidene) bis (4,1-phenyleneoxy(1-methyl-2,1-ethanediyl)) ester, 2-HEMA, diphenyl (2,4,6- trimethylbenzoyl) phosphine oxide, and additives |

| PO | Phrozen sonic mighty 4K LCD 3D printer 2 | ODS C&B Permanent A2 | Same as the composition of AO group |

| ML | DWX-51D milling machine 3 | Kuwotech PMMA A2 6 | Polymethyl methacrylate |

| Group | Thickness | ||

|---|---|---|---|

| 0.3 mm | 0.4 mm | 0.5 mm | |

| AL | 51.83 ± 7.72 | 42.25 ± 3.27 | 38.50 ± 2.05 |

| AO | 44.78 ± 2.19 | 56.58 ± 3.02 | 59.54 ± 5.41 |

| PO | 57.53 ± 4.49 | 70.86 ± 4.50 | 105.30 ± 15.01 |

| ML | 72.68 ± 1.27 | 96.31 ± 3.31 | 107.29 ± 4.06 |

| Group | Thickness | ||

|---|---|---|---|

| 0.3 mm | 0.4 mm | 0.5 mm | |

| AL | 0.293 ± 0.013 | 0.396 ± 0.010 | 0.495 ± 0.007 |

| AO | 0.303 ± 0.010 | 0.403 ± 0.004 | 0.501 ± 0.004 |

| PO | 0.304 ± 0.006 | 0.401 ± 0.003 | 0.501 ± 0.002 |

| ML | 0.324 ± 0.016 | 0.424 ± 0.018 | 0.520 ± 0.014 |

| Group | Thickness | ||

|---|---|---|---|

| 0.3 mm | 0.4 mm | 0.5 mm | |

| AL | 0.316 ± 0.011 | 0.436 ± 0.018 | 0.523 ± 0.011 |

| AO | 0.335 ± 0.012 | 0.442 ± 0.011 | 0.555 ± 0.013 |

| PO | 0.349 ± 0.010 | 0.455 ± 0.008 | 0.572 ± 0.016 |

| ML | 0.372 ± 0.013 | 0.478 ± 0.012 | 0.580 ± 0.011 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.-j.; Jeong, C.-s.; Moon, J.-m.; Bae, J.-m.; Choi, E.-j.; Oh, S.-h. Evaluation of Manufacturing Accuracy in Merlon Fracture Models Fabricated by Vat Photopolymerization 3D-Printing Technologies. Appl. Sci. 2025, 15, 5595. https://doi.org/10.3390/app15105595

Lee H-j, Jeong C-s, Moon J-m, Bae J-m, Choi E-j, Oh S-h. Evaluation of Manufacturing Accuracy in Merlon Fracture Models Fabricated by Vat Photopolymerization 3D-Printing Technologies. Applied Sciences. 2025; 15(10):5595. https://doi.org/10.3390/app15105595

Chicago/Turabian StyleLee, Hee-jung, Chang-sub Jeong, Joon-mo Moon, Ji-myung Bae, Eun-joo Choi, and Seung-han Oh. 2025. "Evaluation of Manufacturing Accuracy in Merlon Fracture Models Fabricated by Vat Photopolymerization 3D-Printing Technologies" Applied Sciences 15, no. 10: 5595. https://doi.org/10.3390/app15105595

APA StyleLee, H.-j., Jeong, C.-s., Moon, J.-m., Bae, J.-m., Choi, E.-j., & Oh, S.-h. (2025). Evaluation of Manufacturing Accuracy in Merlon Fracture Models Fabricated by Vat Photopolymerization 3D-Printing Technologies. Applied Sciences, 15(10), 5595. https://doi.org/10.3390/app15105595